pcm voltage JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 454 of 2199

ergize the combination flasher in response to mes-

sage inputs received over the Programmable

Communications Interface (PCI) data bus network.

The BCM can energize the combination flasher when

the VTSS is requested.

Vehicles equipped with the optional Electronic

Vehicle Information Center (EVIC) use turn signal

status messages received from the Electro-Mechani-

cal Instrument Cluster (EMIC) and distance mes-

sages received from the Powertrain Control Module

(PCM) over the PCI data bus to determine when the

Turn Signal On warning should be activated. The

EMIC receives hard wired inputs from the combina-

tion flasher to operate the turn signal indicators,

then sends the proper turn signal status message to

the EVIC. If a turn signal is left on for more than

about 1.6 kilometers (1 mile) of driving distance, the

EVIC will display a visual ªTurn Signal Onº message

and will send a request to the BCM over the PCI

data bus to notify the vehicle operator.

During both the turn signal and the hazard warn-

ing operation, if the exterior lamps are turned Off,

the front park/turn signal lamps and the front side

marker lamps will flash in unison. If the exterior

lamps are turned On, the front park/turn signal

lamps and the front side marker lamps will flash

alternately. Refer to the owner's manual.

DIAGNOSIS AND TESTING - TURN SIGNAL &

HAZARD WARNING SYSTEMS

When diagnosing the turn signal and hazard warn-

ing circuits, remember that high generator output

can burn out bulbs rapidly and repeatedly. If this is a

concern on the vehicle being diagnosed, test the

charging system as required.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the ignition switch to the On position.

Actuate the turn signal switch or the hazard warning

switch. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

check for a turn signal bulb that is not lit or is verydimly lit. Repair the circuits to that lamp or replace

the faulty bulb, as required. If the turn signal indi-

cator(s) fail to light, go to Step 2.

(2) Turn the ignition switch to the Off position.

Check the ignition run fuse and the flasher fuse in

the Junction Block (JB). If OK, go to Step 3. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(3) Check for battery voltage at the flasher fuse in

the JB. If OK, go to Step 4. If not OK, repair the

open fused B(+) circuit between the JB and the

Power Distribution Center (PDC).

(4) Turn the ignition switch to the On position.

Check for battery voltage at the ignition run fuse in

the JB. If OK, go to Step 5. If not OK, repair the

open fused ignition switch output (run) circuit

between the JB and the ignition switch.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the combination flasher from the JB and

replace it with a known good unit. Reconnect the bat-

tery negative cable. Test the operation of the turn

signal and hazard warning systems. If OK, discard

the faulty combination flasher. If not OK, remove the

test flasher and go to Step 6.

(6) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity in the JB for the combina-

tion flasher. If OK, go to Step 7. If not OK, repair the

open fused ignition switch output (run) circuit

between the combination flasher and the ignition run

fuse in the JB.

(7) Turn the ignition switch to the Off position.

Check for battery voltage at the B(+) circuit of the JB

for the combination flasher. If OK, go to Step 8. If

not OK, repair the open B(+) circuit between the

combination flasher and the flasher fuse in the JB.

(8) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the turn signal and hazard warning

switches from the multi-function switch connector.

Check for continuity between the ground circuit of

the instrument panel wire harness connector for the

left multi-function switch and a good ground. There

should be continuity. If OK, go to Step 9. If not OK,

repair the open ground circuit.

(9) Check for continuity between the hazard switch

sense circuit of the instrument panel wire harness

connector for the multi-function switch and a good

ground. There should be no continuity. If OK, go to

Step 10. If not OK, repair the shorted hazard switch

sense circuit between the multi-function switch and

the combination flasher.

(10) Check for continuity between the hazard

switch sense circuit of the JB for the combination

flasher and the instrument panel wire harness con-

WJLAMPS/LIGHTING - EXTERIOR 8L - 3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 583 of 2199

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

Once the speed control has been disengaged,

depressing the RES/ACCEL switch (when speed is

greater than 30 mph) restores the vehicle to the tar-

get speed that was stored in the PCM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the RES/AC-

CEL switch. The new target speed is stored in the

PCM when the RES/ACCEL is released. The PCM

also has a9tap-up9feature in which vehicle speed

increases at a rate of approximately 2 mph for each

momentary switch activation of the RES/ACCEL

switch.

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

OVERSHOOT/UNDERSHOOT

If the vehicle operator repeatedly presses and

releases the SET button with their foot off of the

accelerator (referred to as a ªlift foot setº), the vehicle

may accelerate and exceed the desired set speed by

up to 5 mph (8 km/h). It may also decelerate to less

than the desired set speed, before finally achieving

the desired set speed.

The Speed Control System has an adaptive strat-

egy that compensates for vehicle-to-vehicle variations

in speed control cable lengths. When the speed con-

trol is set with the vehicle operators foot off of the

accelerator pedal, the speed control thinks there is

excessive speed control cable slack and adapts

accordingly. If the ªlift foot setsº are continually used,

a speed control overshoot/undershoot condition will

develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed using

the accelerator pedal (not decelerating or accelerat-

ing), and then turning the cruise control switch to

the OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8J,

Instrument Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo. Corrosion should be removed from

electrical terminals and a light coating of Mopar

MultiPurpose Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment of both ends of the speed con-

trol servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

8P - 2 SPEED CONTROLWJ

SPEED CONTROL (Continued)

Page 588 of 2199

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system. The steering-wheel-

mounted switches use multiplexed circuits to provide

inputs to the PCM for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

OPERATION

When speed control is selected by depressing the

ON, OFF switch, the PCM allows a set speed to be

stored in its RAM for speed control. To store a set

speed, depress the SET switch while the vehicle is

moving at a speed between approximately 35 and 85

mph. In order for the speed control to engage, the

brakes cannot be applied, nor can the gear selector

be indicating the transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal.

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The VSS signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed

The previous disengagement conditions are pro-

grammed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the PCM's RAM.

NOTE: Depressing the OFF switch will erase the set

speed stored in the PCM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the PCM is pro-

grammed for an acceleration feature. With the

ACCEL switch held closed, the vehicle accelerates

slowly to the desired speed. The new target speed is

stored in the PCM's RAM when the ACCEL switch isreleased. The PCM also has a9tap-up9feature in

which vehicle speed increases at a rate of approxi-

mately 2 mph for each momentary switch activation

of the ACCEL switch.

The PCM also provides a means to decelerate with-

out disengaging speed control. To decelerate from an

existing recorded target speed, depress and hold the

COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the PCM's ON, OFF input, and

the battery voltage to the brake switch, which powers

the speed control servo.

Multiplexing

The PCM sends out 5 volts through a fixed resistor

and monitors the voltage change between the fixed

resistor and the switches. If none of the switches are

depressed, the PCM will measure 5 volts at the sen-

sor point (open circuit). If a switch with no resistor is

closed, the PCM will measure 0 volts (grounded cir-

cuit). Now, if a resistor is added to a switch, then the

PCM will measure some voltage proportional to the

size of the resistor. By adding a different resistor to

each switch, the PCM will see a different voltage

depending on which switch is pushed.

Another resistor has been added to the 'at rest cir-

cuit' causing the PCM to never see 5 volts. This was

done for diagnostic purposes. If the switch circuit

should open (bad connection), then the PCM will see

the 5 volts and know the circuit is bad. The PCM will

then set an open circuit fault.

REMOVAL

WARNING: BEFORE BEGINNING ANY AIRBAG SYS-

TEM COMPONENT REMOVAL OR INSTALLATION,

REMOVE AND ISOLATE THE NEGATIVE (-) CABLE

FROM THE BATTERY. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. THEN

WAIT TWO MINUTES FOR SYSTEM CAPACITOR TO

DISCHARGE BEFORE FURTHER SYSTEM SERVICE.

FAILURE TO DO THIS COULD RESULT IN ACCIDEN-

TAL AIRBAG DEPLOYMENT AND POSSIBLE

INJURY.

(1) Disconnect and isolate negative battery cable.

(2) Remove airbag module. Refer to Group 8M,

Passive Restraint Systems.

(3) Remove electrical connector at switch.

(4) Remove switch-to-steering wheel mounting

screw (Fig. 7) .

(5) Remove switch.

INSTALLATION

(1) Install switch and mounting screw.

(2) Tighten screw to 1.5 N´m (15 in. lbs.) torque.

(3) Install electrical connector to switch.

WJSPEED CONTROL 8P - 7

Page 597 of 2199

(2) Check for battery voltage at the fused B(+) fuse

in the JB. If OK, go to Step 3. If not OK, repair the

open B(+) circuit between the JB fuse and the Power

Distribution Center (PDC).

(3) Check the fused ignition switch output (st-run)

fuse in the JB. If OK, go to Step 4. If not OK, repair

the shorted circuit or component and replace the

faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (st-run) fuse in the JB. If OK, go to Step 5. If

not OK, repair the open fused ignition switch output

(st-run) circuit between the JB fuse and the ignition

switch as required.

(5) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the Sentry Key Immobilizer Module

(SKIM) from the SKIM connector. Check for continu-

ity between the ground circuit of the instrument

panel wire harness connector for the SKIM and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit.

(6) Reconnect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

instrument panel wire harness connector for the

SKIM. If OK, go to Step 7. If not OK, repair the open

fused B(+) circuit between the SKIM and the JB

fuse.

(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (st-run) circuit of the instrument panel wire

harness connector for the SKIM. If OK, refer to the

appropriate diagnostic information and use a

DRBIIItscan tool to complete the diagnosis of the

SKIS. If not OK, repair the open fused ignition

switch output (st-run) circuit between the SKIM and

the JB fuse.

SKIS INDICATOR FLASHES OR LIGHTS SOLID FOLLOWING

BULB TEST

A SKIS indicator that flashes following a successful

bulb test indicates that an invalid key has been

detected, or that a key-related fault has been set. A

SKIS indicator that lights solid following a successful

bulb test indicates that the SKIM has detected a sys-

tem malfunction or that the SKIS is inoperative. In

either case, fault information will be stored in the

SKIM memory. For retrieval of this fault information

and further diagnosis of the SKIS, the PCI data bus,

the SKIM message outputs to the instrument cluster,

the SKIM message outputs to the Body Control Mod-

ule (BCM), or the message inputs and outputs

between the SKIM and the Powertrain Control Mod-

ule (PCM), a DRBIIItscan tool and the appropriate

diagnostic information are required. Following are

preliminary troubleshooting guidelines to be followed

during diagnosis using a DRBIIItscan tool:(1) Using the DRBIIItscan tool, read and record

the faults as they exist in the SKIM when you first

begin your diagnosis of the vehicle. It is important to

document these faults because the SKIM does not

differentiate between historical and active faults. If

this problem turns out to be an intermittent condi-

tion, this information may become invaluable to your

diagnosis.

(2) Using the DRBIIItscan tool, erase all of the

faults from the SKIM.

(3) Cycle the ignition switch to the Off position,

then back to the On position.

(4) Using the DRBIIItscan tool, read any faults

that are now present in the SKIM. These are the

active faults.

(5) Using this active fault information, refer to the

proper procedure in the appropriate diagnostic infor-

mation for the additional specific diagnostic steps.

STANDARD PROCEDURE

STANDARD PROCEDURE - SKIS

INITIALIZATION

The Sentry Key Immobilizer System (SKIS) must

be initialized following a Sentry Key Immobilizer

Module (SKIM) replacement. SKIS initialization

requires the use of a DRBIIItscan tool. Initialization

will also require that you have access to the unique

four-digit PIN code that was assigned to the original

SKIM. The PIN codemustbe used to enter the

Secured Access Mode in the SKIM. This PIN number

may be obtained from the vehicle owner, from the

original vehicle invoice, or from the DaimlerChrysler

Customer Center. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES - STANDARD PRO-

CEDURE - PCM/SKIM PROGRAMMING).

NOTE: If a Powertrain Control Module (PCM) is

replaced on a vehicle equipped with the Sentry Key

Immobilizer System (SKIS), the unique Secret Key

data must be transferred from the Sentry Key

Immobilizer Module (SKIM) to the new PCM using

the PCM replacement procedure. This procedure

also requires the use of a DRBIIITscan tool and the

unique four-digit PIN code to enter the Secured

Access Mode in the SKIM. Refer to the appropriate

diagnostic information for the proper PCM replace-

ment procedures.

STANDARD PROCEDURE - SENTRY KEY

TRANSPONDER PROGRAMMING

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Immobi-

lizer System (SKIS) when it is shipped from the

8Q - 6 VEHICLE THEFT SECURITYWJ

VEHICLE THEFT SECURITY (Continued)

Page 614 of 2199

ods may not prove conclusive in the diagnosis of the

Body Control Module (BCM), the Rain Sensor Mod-

ule (RSM), the Powertrain Control Module (PCM) or

the inputs to or outputs from these modules that con-

trol the various front wiper and washer system oper-

ating modes. The most reliable, efficient, and

accurate means to diagnose the BCM, the RSM, the

PCM or the BCM inputs and outputs related to the

various front wiper and washer system operating

modes requires the use of a DRBIIItscan tool. Refer

to the appropriate diagnostic information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

FRONT WASHER SYSTEM

The diagnosis found here addresses an electrically

inoperative washer system. If the washer pump/mo-

tor operates, but no washer fluid is emitted from the

front washer nozzles, be certain to check the fluid

level in the reservoir. Also inspect the front washer

system components as required. (Refer to 8 - ELEC-

TRICAL/FRONT WIPERS/WASHERS - INSPEC-

TION). Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Turn the ignition switch to the On position.

Turn the control knob on the control stalk of the

right (wiper) multi-function switch to the Low or

High wiper position. Check whether the front wiper

system is operating. If OK, go to Step 2. If not OK,

test and repair the front wiper system before con-

tinuing with these tests. Refer to FRONT WIPER

SYSTEM

(2) Turn the control knob on the control stalk of

the right (wiper) multi-function switch to the Off

position. Pull the control stalk of the right (wiper)

multi-function switch toward the steering wheel to

close the front washer switch. The front washer

pump should operate and the front wipers should

operate for about three sweep cycles after the switch

is released before they park. If the front wipers are

OK, but the front washers are not, go to Step 3. If

the front washers are OK, but the front wipers are

not, go to Step 5.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the left headlamp and dash wire harness

connector for the front washer pump/motor from the

pump/motor connector receptacle. Check for continu-

ity between the ground circuit cavity of the left head-

lamp and dash wire harness connector for the front

washer pump/motor and a good ground. There should

be continuity. If OK, go to Step 4. If not OK, repair

the open ground circuit to ground (G106) as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. While pulling the

control stalk of the right (wiper) multi-function

switch toward the steering wheel to close the front

washer switch, check for battery voltage at the

washer pump switch sense circuit cavity of the left

headlamp and dash wire harness connector for the

front washer pump/motor unit. If OK, replace the

faulty front washer pump/motor. If not OK, repair

the open washer pump switch sense circuit between

the right (wiper) multi-function switch and the front

washer pump/motor unit as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the instrument panel wire harness con-

nector (Connector C2) for the Body Control Module

(BCM) from the BCM connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. While pulling the control

stalk of the right (wiper) multi-function switch

toward the steering wheel to close the front washer

WJFRONT WIPERS/WASHERS 8R - 7

FRONT WIPERS/WASHERS (Continued)

Page 1299 of 2199

(9) Lower the engine until it is properly located on

the engine mounts.

(10) Install the through bolts and tighten the nuts.

(11) Lower the jack stand and remove the piece of

wood.

(12) Install the engine flywheel and transmission

torque converter housing access cover.

(13) Install the engine starter motor. (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(14) Connect the exhaust pipe to the hanger and to

the engine exhaust manifold.

(15) Install transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

attach to the oil pan studs.

(16) Install the oil pan drain plug (Fig. 81).

Tighten the plug to 34 N´m (25 ft. lbs.) torque.

(17) Lower the vehicle.

(18) Connect negative cable to battery.

(19) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(20) Start the engine and inspect for leaks.

ENGINE OIL PRESSURE

SENSOR

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to theinstrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

OIL PUMP

REMOVAL

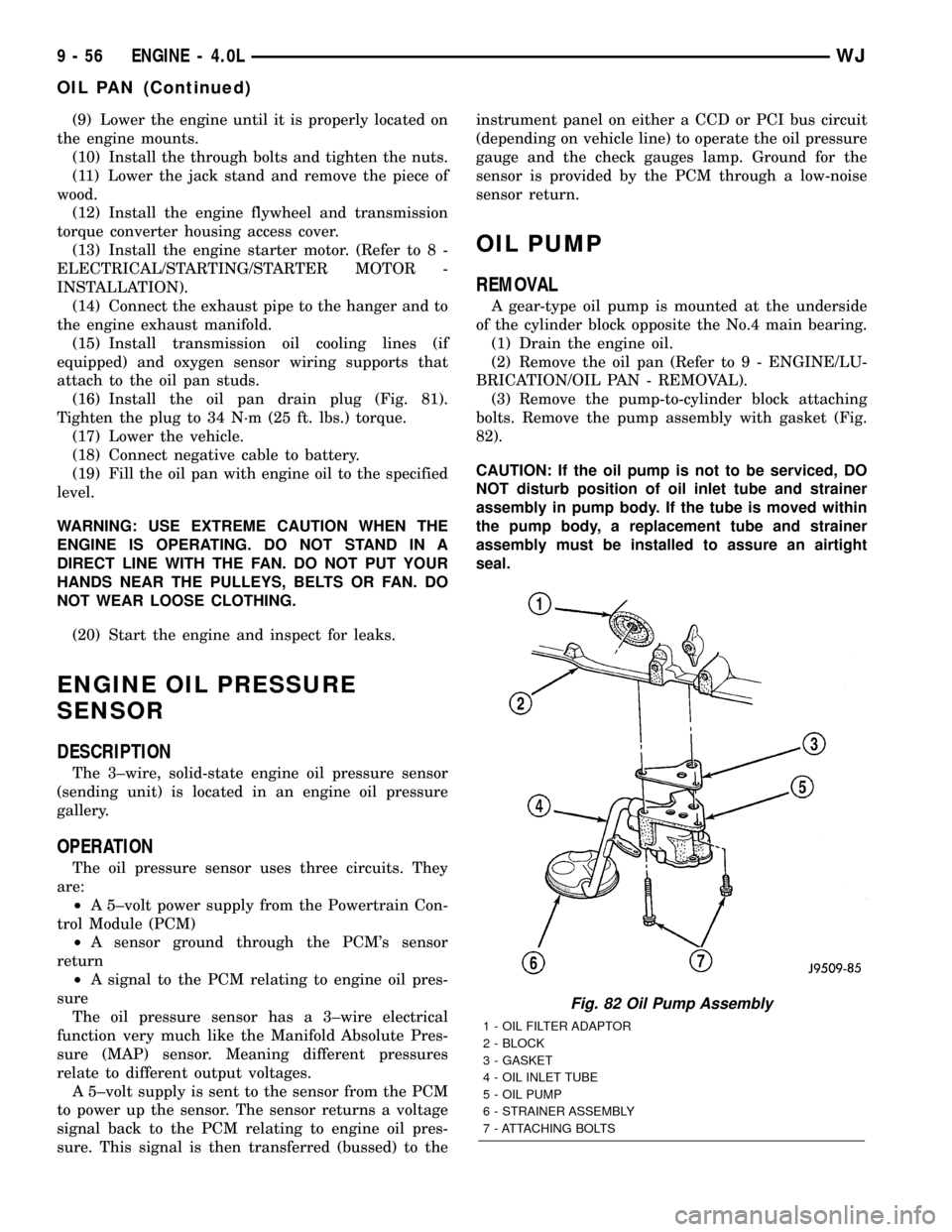

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Drain the engine oil.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

82).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer

assembly must be installed to assure an airtight

seal.

Fig. 82 Oil Pump Assembly

1 - OIL FILTER ADAPTOR

2 - BLOCK

3 - GASKET

4 - OIL INLET TUBE

5 - OIL PUMP

6 - STRAINER ASSEMBLY

7 - ATTACHING BOLTS

9 - 56 ENGINE - 4.0LWJ

OIL PAN (Continued)

Page 1376 of 2199

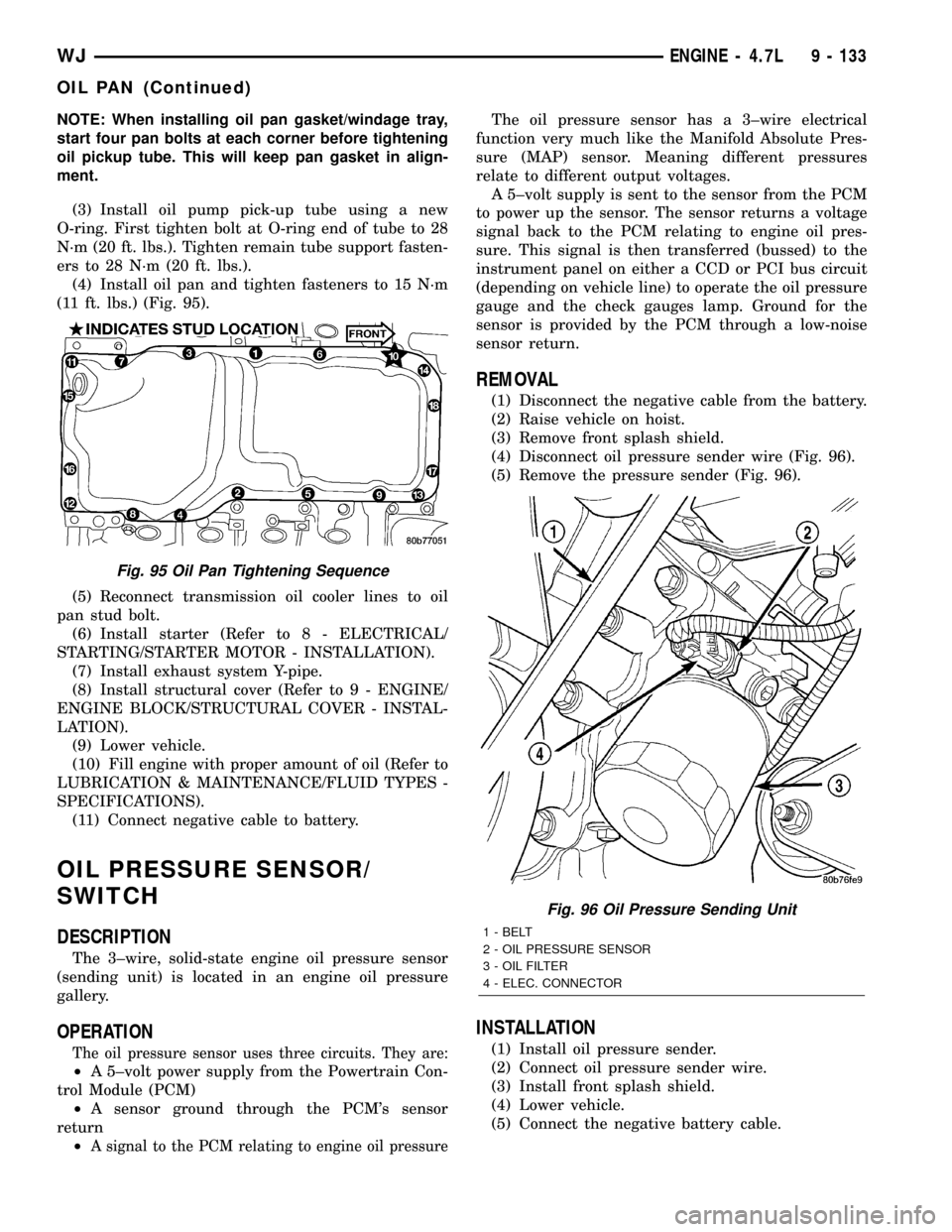

NOTE: When installing oil pan gasket/windage tray,

start four pan bolts at each corner before tightening

oil pickup tube. This will keep pan gasket in align-

ment.

(3) Install oil pump pick-up tube using a new

O-ring. First tighten bolt at O-ring end of tube to 28

N´m (20 ft. lbs.). Tighten remain tube support fasten-

ers to 28 N´m (20 ft. lbs.).

(4) Install oil pan and tighten fasteners to 15 N´m

(11 ft. lbs.) (Fig. 95).

(5) Reconnect transmission oil cooler lines to oil

pan stud bolt.

(6) Install starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

(7) Install exhaust system Y-pipe.

(8) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(9) Lower vehicle.

(10) Fill engine with proper amount of oil (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

(11) Connect negative cable to battery.

OIL PRESSURE SENSOR/

SWITCH

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²

A signal to the PCM relating to engine oil pressure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to the

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

(4) Disconnect oil pressure sender wire (Fig. 96).

(5) Remove the pressure sender (Fig. 96).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

Fig. 95 Oil Pan Tightening Sequence

Fig. 96 Oil Pressure Sending Unit

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

WJENGINE - 4.7L 9 - 133

OIL PAN (Continued)

Page 1426 of 2199

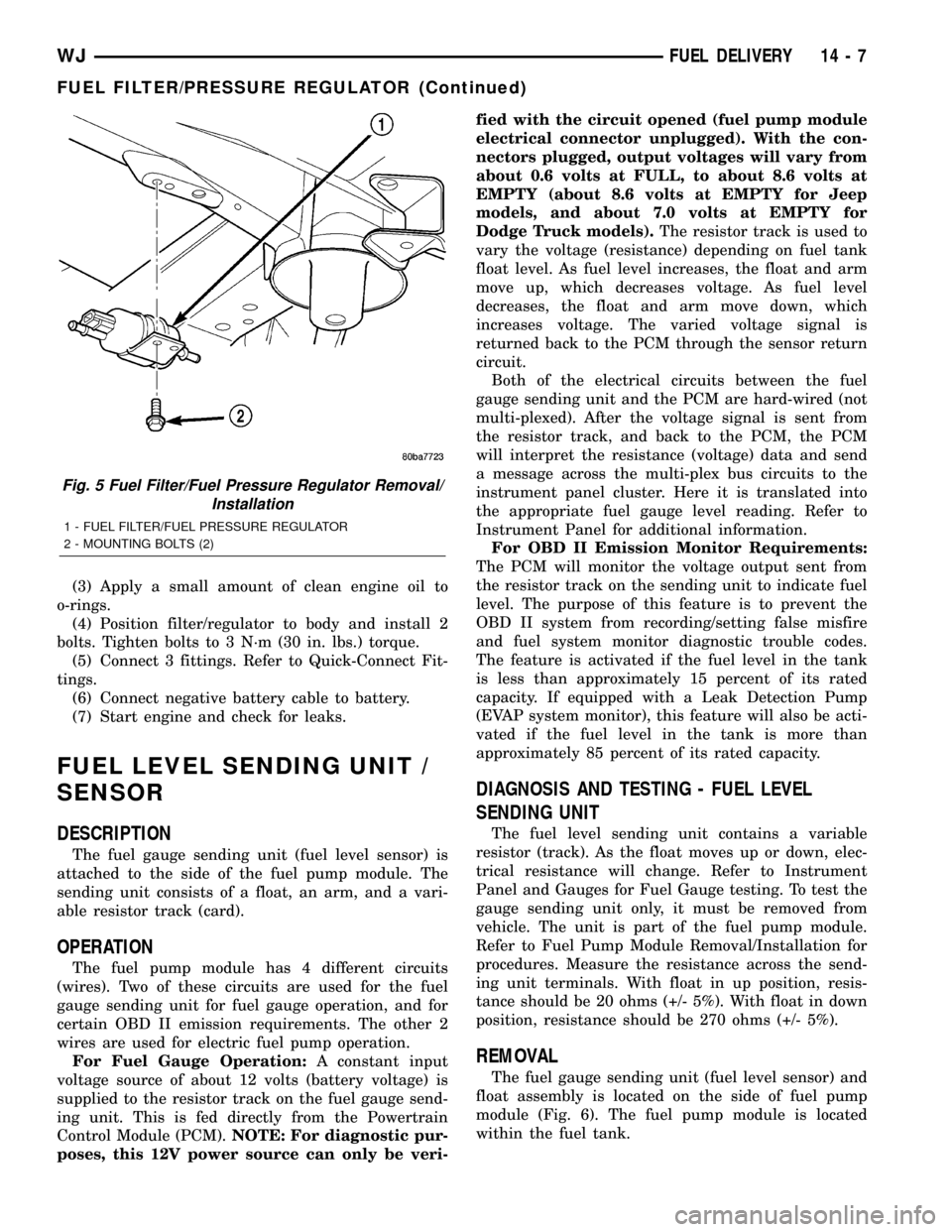

(3) Apply a small amount of clean engine oil to

o-rings.

(4) Position filter/regulator to body and install 2

bolts. Tighten bolts to 3 N´m (30 in. lbs.) torque.

(5) Connect 3 fittings. Refer to Quick-Connect Fit-

tings.

(6) Connect negative battery cable to battery.

(7) Start engine and check for leaks.

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-fied with the circuit opened (fuel pump module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about 0.6 volts at FULL, to about 8.6 volts at

EMPTY (about 8.6 volts at EMPTY for Jeep

models, and about 7.0 volts at EMPTY for

Dodge Truck models).The resistor track is used to

vary the voltage (resistance) depending on fuel tank

float level. As fuel level increases, the float and arm

move up, which decreases voltage. As fuel level

decreases, the float and arm move down, which

increases voltage. The varied voltage signal is

returned back to the PCM through the sensor return

circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

DIAGNOSIS AND TESTING - FUEL LEVEL

SENDING UNIT

The fuel level sending unit contains a variable

resistor (track). As the float moves up or down, elec-

trical resistance will change. Refer to Instrument

Panel and Gauges for Fuel Gauge testing. To test the

gauge sending unit only, it must be removed from

vehicle. The unit is part of the fuel pump module.

Refer to Fuel Pump Module Removal/Installation for

procedures. Measure the resistance across the send-

ing unit terminals. With float in up position, resis-

tance should be 20 ohms (+/- 5%). With float in down

position, resistance should be 270 ohms (+/- 5%).

REMOVAL

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 6). The fuel pump module is located

within the fuel tank.

Fig. 5 Fuel Filter/Fuel Pressure Regulator Removal/

Installation

1 - FUEL FILTER/FUEL PRESSURE REGULATOR

2 - MOUNTING BOLTS (2)

WJFUEL DELIVERY 14 - 7

FUEL FILTER/PRESSURE REGULATOR (Continued)

Page 1462 of 2199

(5) Push sensor against flywheel/drive plate. With

sensor pushed against flywheel/drive plate, tighten

mounting bolt to 7 N´m (60 in. lbs.) torque.

(6) Route sensor wiring harness into wire shield.

(7) Connect sensor pigtail harness electrical con-

nector to main wiring harness.

INSTALLATION - 4.7L

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Install starter motor. Refer to Starter Removal/

Installation.

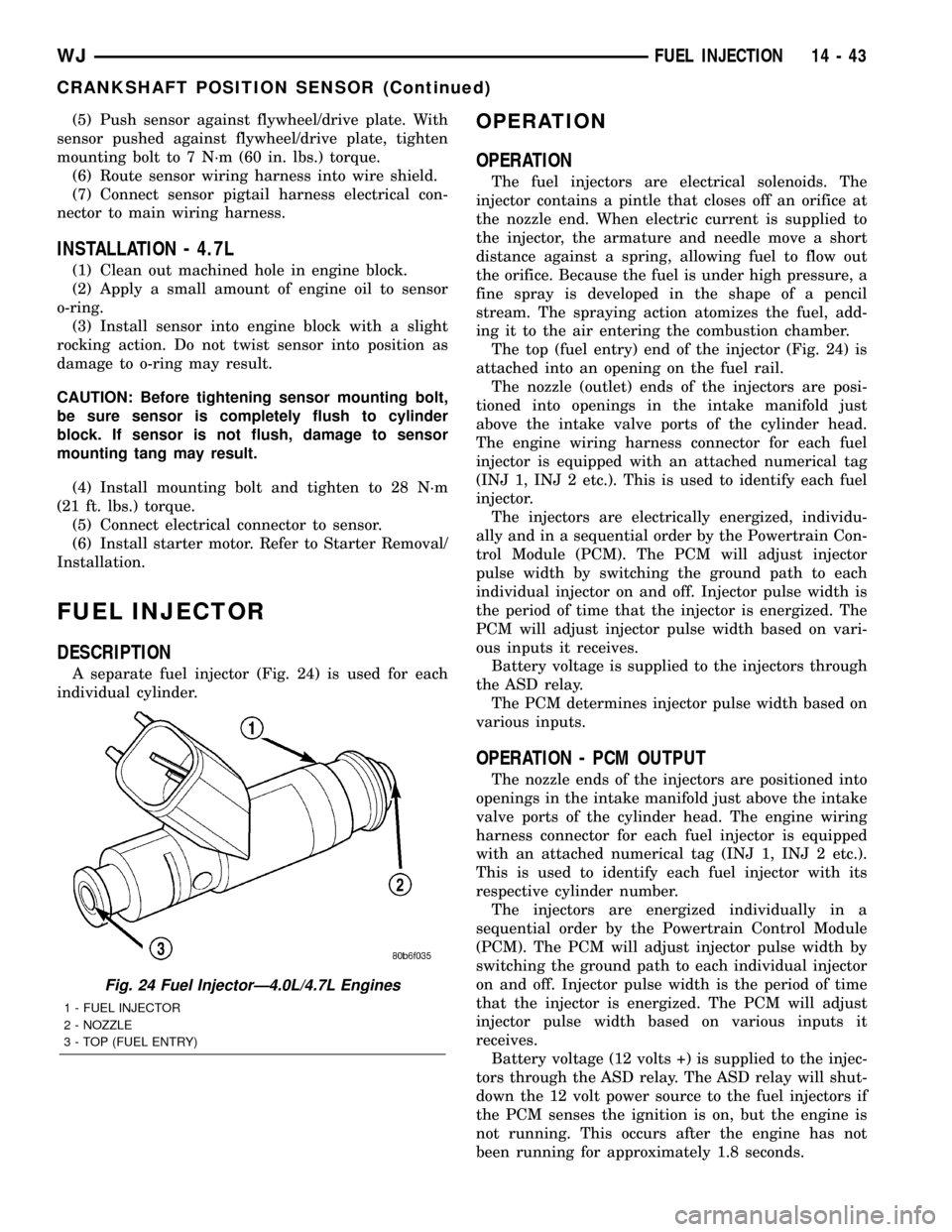

FUEL INJECTOR

DESCRIPTION

A separate fuel injector (Fig. 24) is used for each

individual cylinder.

OPERATION

OPERATION

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The top (fuel entry) end of the injector (Fig. 24) is

attached into an opening on the fuel rail.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are electrically energized, individu-

ally and in a sequential order by the Powertrain Con-

trol Module (PCM). The PCM will adjust injector

pulse width by switching the ground path to each

individual injector on and off. Injector pulse width is

the period of time that the injector is energized. The

PCM will adjust injector pulse width based on vari-

ous inputs it receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

Fig. 24 Fuel InjectorÐ4.0L/4.7L Engines

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

WJFUEL INJECTION 14 - 43

CRANKSHAFT POSITION SENSOR (Continued)

Page 1463 of 2199

The PCM determines injector on-time (pulse width)

based on various inputs.

DIAGNOSIS AND TESTING - FUEL INJECTOR

To perform a complete test of the fuel injectors and

their circuitry, use the DRB scan tool and refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the injector only, refer to the following:

Disconnect the fuel injector wire harness connector

from the injector. The injector is equipped with 2

electrical terminals (pins). Place an ohmmeter across

the terminals. Resistance reading should be approxi-

mately 12 ohms 1.2 ohms at 20ÉC (68ÉF).

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL INJECTOR(S), FUEL

SYSTEM PRESSURE MUST BE RELEASED.

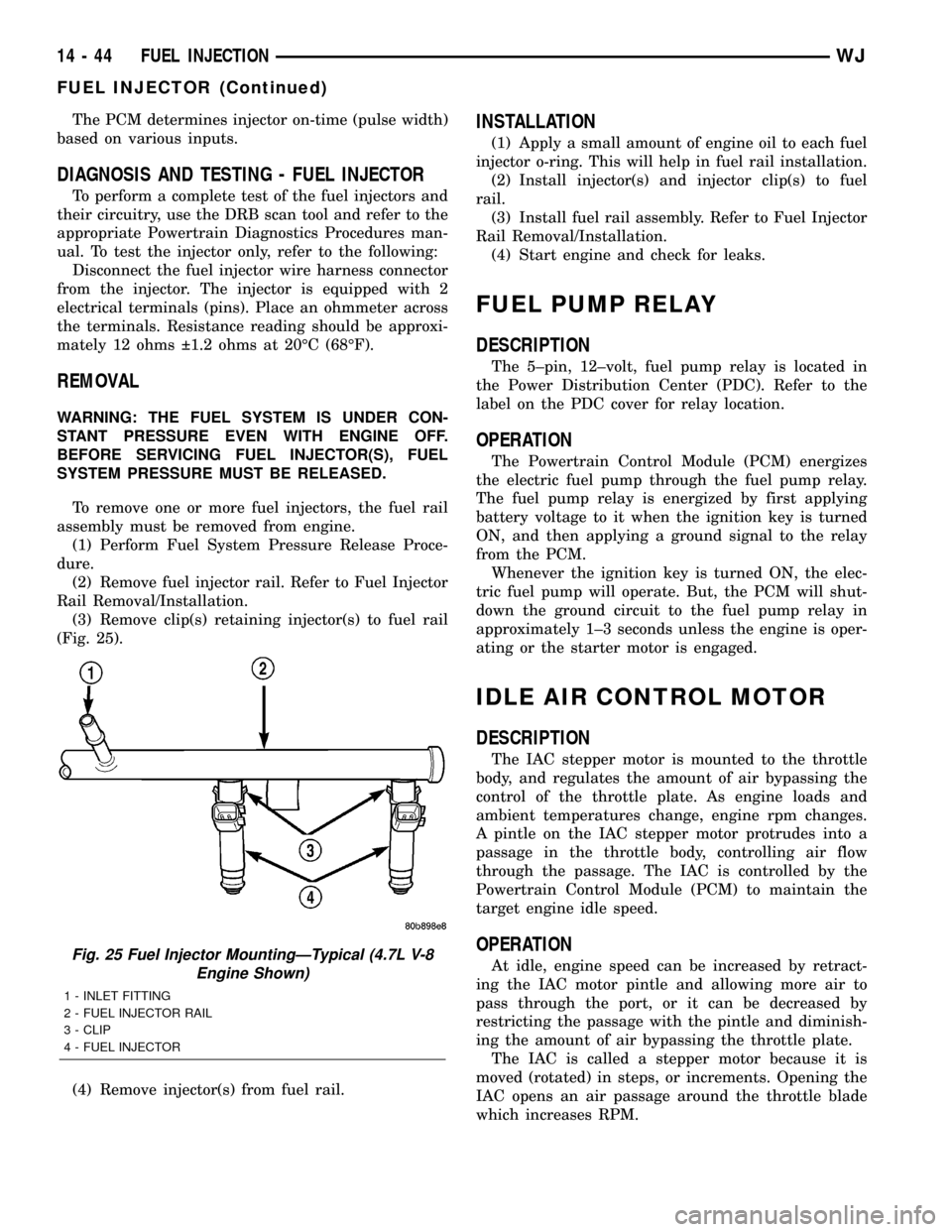

To remove one or more fuel injectors, the fuel rail

assembly must be removed from engine.

(1) Perform Fuel System Pressure Release Proce-

dure.

(2) Remove fuel injector rail. Refer to Fuel Injector

Rail Removal/Installation.

(3) Remove clip(s) retaining injector(s) to fuel rail

(Fig. 25).

(4) Remove injector(s) from fuel rail.

INSTALLATION

(1) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(2) Install injector(s) and injector clip(s) to fuel

rail.

(3) Install fuel rail assembly. Refer to Fuel Injector

Rail Removal/Installation.

(4) Start engine and check for leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

IDLE AIR CONTROL MOTOR

DESCRIPTION

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.Fig. 25 Fuel Injector MountingÐTypical (4.7L V-8

Engine Shown)

1 - INLET FITTING

2 - FUEL INJECTOR RAIL

3 - CLIP

4 - FUEL INJECTOR

14 - 44 FUEL INJECTIONWJ

FUEL INJECTOR (Continued)