lamp JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1232 of 2199

(5) Reconnect the right and left body wire harness

bulkhead connectors to the connector receptacles

located near the center of the JB.

(6) Install and tighten the screws that secure the

right and left body wire harness bulkhead connectors

to the connector receptacles located near the center

of the JB. Tighten the screws to 2.2 N´m (20 in. lbs.).

(7) Reconnect the fused B(+) and the IOD wire

harness connectors to the connector receptacles

located near the bottom of the JB.

(8) Reach behind the JB to reconnect the instru-

ment panel wire harness bulkhead connector to the

connector receptacle located near the top of the JB.

(9) Install and tighten the screw that secures the

instrument panel wire harness bulkhead connector to

the connector receptacle located near the top of the

JB. Tighten the screw to 2.2 N´m (20 in. lbs.).

(10)

Reach behind the JB to reconnect the two

instrument panel wire harness connectors to the BCM

connector receptacles located near the bottom of the JB.

(11) Install the steering column opening cover onto

the instrument panel. Refer toSteering Column

Opening Coverin Body for the location of the steer-

ing column opening cover installation procedures.

(12)

Install the fuse cover onto the bottom of the JB.

(13) Reconnect the battery negative cable.

POWER DISTRIBUTION

CENTER

DESCRIPTION

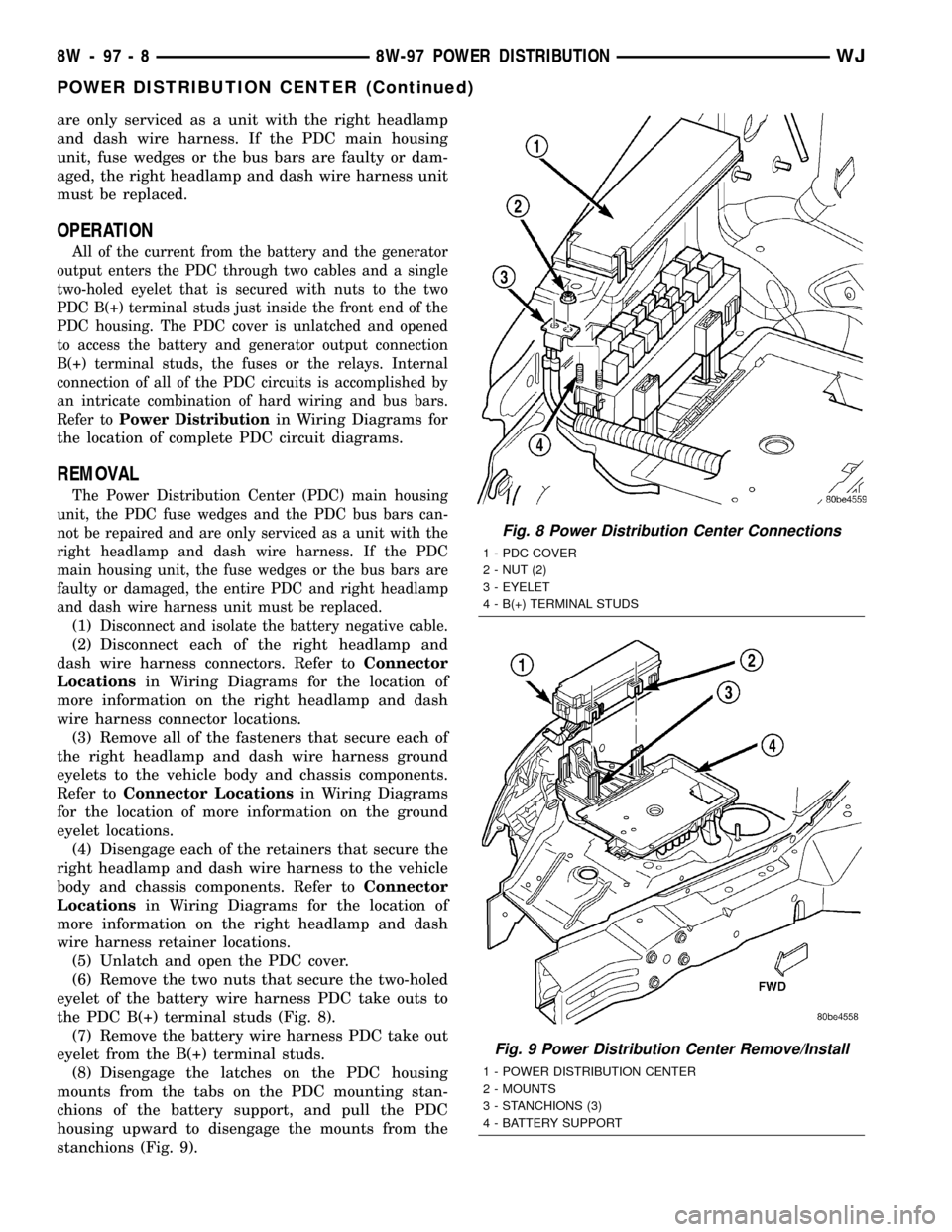

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-ment Power Distribution Center (PDC) (Fig. 7). The

molded plastic PDC housing is located in the right

front corner of the engine compartment, between the

battery and the right front inner fender shield. The

PDC houses up to fifteen maxi-type cartridge fuses,

which replace all in-line fusible links. The PDC also

houses up to thirteen blade-type mini fuses, and up

to ten International Standards Organization (ISO)

relays (two standard-type and eight micro-type).

The PDC housing is secured in the engine compart-

ment at three points. Integral mounts on both sides of

the PDC housing engage and latch to stanchions that

are integral to the molded plastic battery support. The

PDC is integral to the right headlamp and dash wire

harness, which exits from the bottom of the PDC hous-

ing. The PDC housing has a molded plastic cover that

includes two integral latches at the front and pivot

hooks at the back that snap over a hinge pin on the

rear of the PDC housing. The PDC cover is easily

opened or removed for service access and has a conve-

nient fuse and relay layout map integral to the inside

surface of the cover to ensure proper component identi-

fication. A fuse puller is also stored on the inside of the

PDC cover.

The PDC cover, the PDC housing lower cover, the

PDC relay wedges, the PDC relay cassettes and the

PDC B(+) terminal stud module are available for ser-

vice replacement. The PDC main housing unit, the

fuse wedges and the bus bars cannot be repaired and

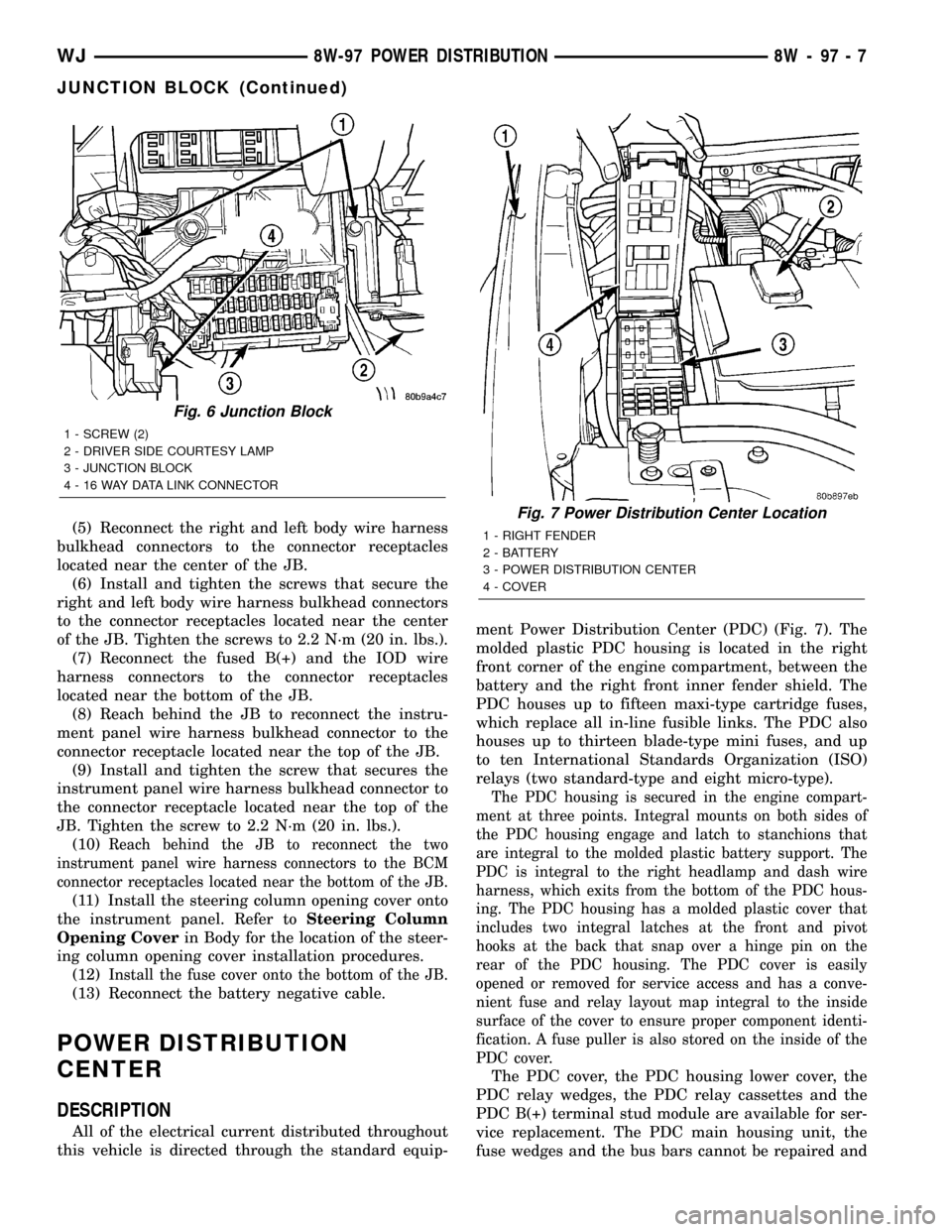

Fig. 6 Junction Block

1 - SCREW (2)

2 - DRIVER SIDE COURTESY LAMP

3 - JUNCTION BLOCK

4 - 16 WAY DATA LINK CONNECTOR

Fig. 7 Power Distribution Center Location

1 - RIGHT FENDER

2 - BATTERY

3 - POWER DISTRIBUTION CENTER

4 - COVER

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1233 of 2199

are only serviced as a unit with the right headlamp

and dash wire harness. If the PDC main housing

unit, fuse wedges or the bus bars are faulty or dam-

aged, the right headlamp and dash wire harness unit

must be replaced.

OPERATION

All of the current from the battery and the generator

output enters the PDC through two cables and a single

two-holed eyelet that is secured with nuts to the two

PDC B(+) terminal studs just inside the front end of the

PDC housing. The PDC cover is unlatched and opened

to access the battery and generator output connection

B(+) terminal studs, the fuses or the relays. Internal

connection of all of the PDC circuits is accomplished by

an intricate combination of hard wiring and bus bars.

Refer toPower Distribution

in Wiring Diagrams for

the location of complete PDC circuit diagrams.

REMOVAL

The Power Distribution Center (PDC) main housing

unit, the PDC fuse wedges and the PDC bus bars can-

not be repaired and are only serviced as a unit with the

right headlamp and dash wire harness. If the PDC

main housing unit, the fuse wedges or the bus bars are

faulty or damaged, the entire PDC and right headlamp

and dash wire harness unit must be replaced.

(1)Disconnect and isolate the battery negative cable.

(2) Disconnect each of the right headlamp and

dash wire harness connectors. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness connector locations.

(3) Remove all of the fasteners that secure each of

the right headlamp and dash wire harness ground

eyelets to the vehicle body and chassis components.

Refer toConnector Locationsin Wiring Diagrams

for the location of more information on the ground

eyelet locations.

(4) Disengage each of the retainers that secure the

right headlamp and dash wire harness to the vehicle

body and chassis components. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness retainer locations.

(5) Unlatch and open the PDC cover.

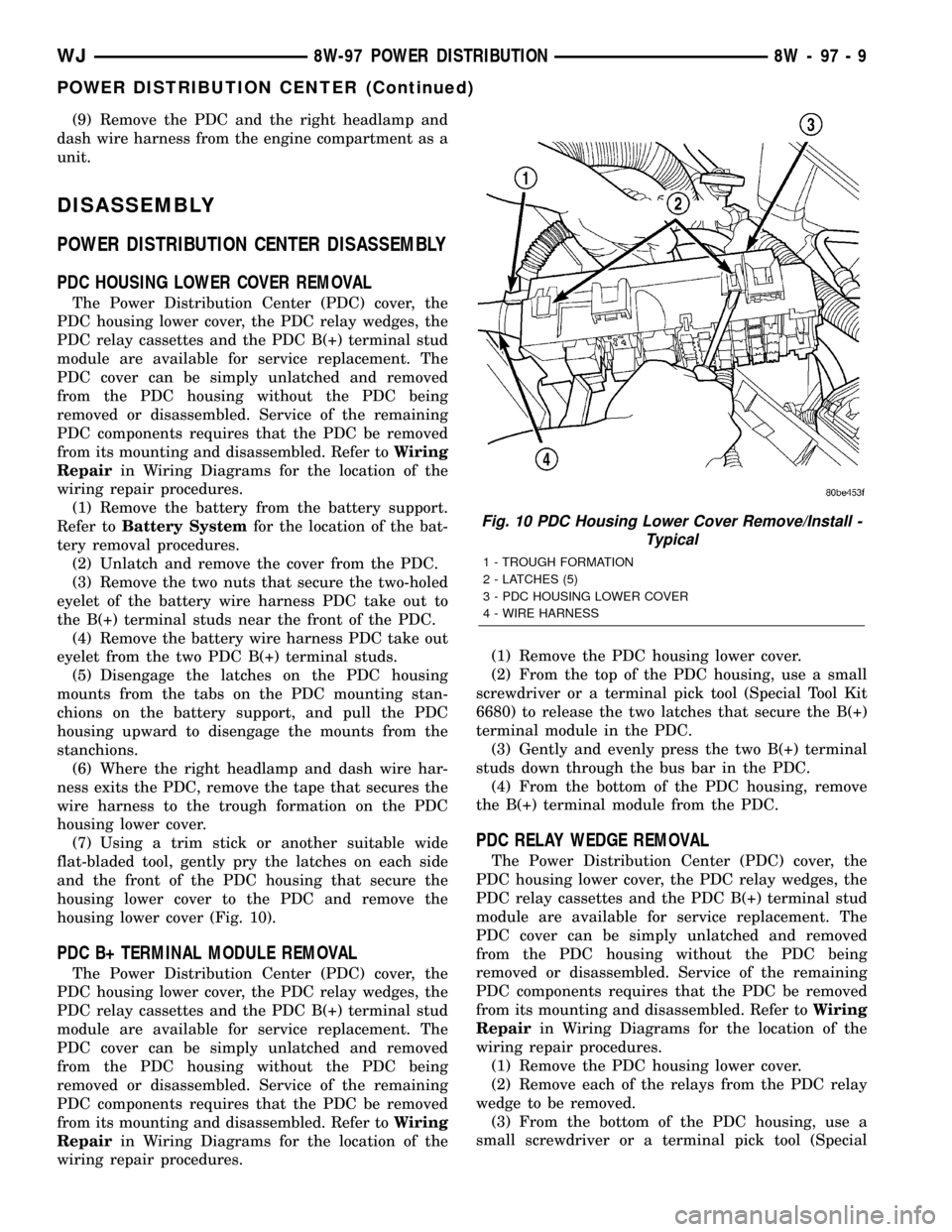

(6) Remove the two nuts that secure the two-holed

eyelet of the battery wire harness PDC take outs to

the PDC B(+) terminal studs (Fig. 8).

(7) Remove the battery wire harness PDC take out

eyelet from the B(+) terminal studs.

(8) Disengage the latches on the PDC housing

mounts from the tabs on the PDC mounting stan-

chions of the battery support, and pull the PDC

housing upward to disengage the mounts from the

stanchions (Fig. 9).

Fig. 8 Power Distribution Center Connections

1 - PDC COVER

2 - NUT (2)

3 - EYELET

4 - B(+) TERMINAL STUDS

Fig. 9 Power Distribution Center Remove/Install

1 - POWER DISTRIBUTION CENTER

2 - MOUNTS

3 - STANCHIONS (3)

4 - BATTERY SUPPORT

8W - 97 - 8 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION CENTER (Continued)

Page 1234 of 2199

(9) Remove the PDC and the right headlamp and

dash wire harness from the engine compartment as a

unit.

DISASSEMBLY

POWER DISTRIBUTION CENTER DISASSEMBLY

PDC HOUSING LOWER COVER REMOVAL

The Power Distribution Center (PDC) cover, the

PDC housing lower cover, the PDC relay wedges, the

PDC relay cassettes and the PDC B(+) terminal stud

module are available for service replacement. The

PDC cover can be simply unlatched and removed

from the PDC housing without the PDC being

removed or disassembled. Service of the remaining

PDC components requires that the PDC be removed

from its mounting and disassembled. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.

(1) Remove the battery from the battery support.

Refer toBattery Systemfor the location of the bat-

tery removal procedures.

(2) Unlatch and remove the cover from the PDC.

(3) Remove the two nuts that secure the two-holed

eyelet of the battery wire harness PDC take out to

the B(+) terminal studs near the front of the PDC.

(4) Remove the battery wire harness PDC take out

eyelet from the two PDC B(+) terminal studs.

(5) Disengage the latches on the PDC housing

mounts from the tabs on the PDC mounting stan-

chions on the battery support, and pull the PDC

housing upward to disengage the mounts from the

stanchions.

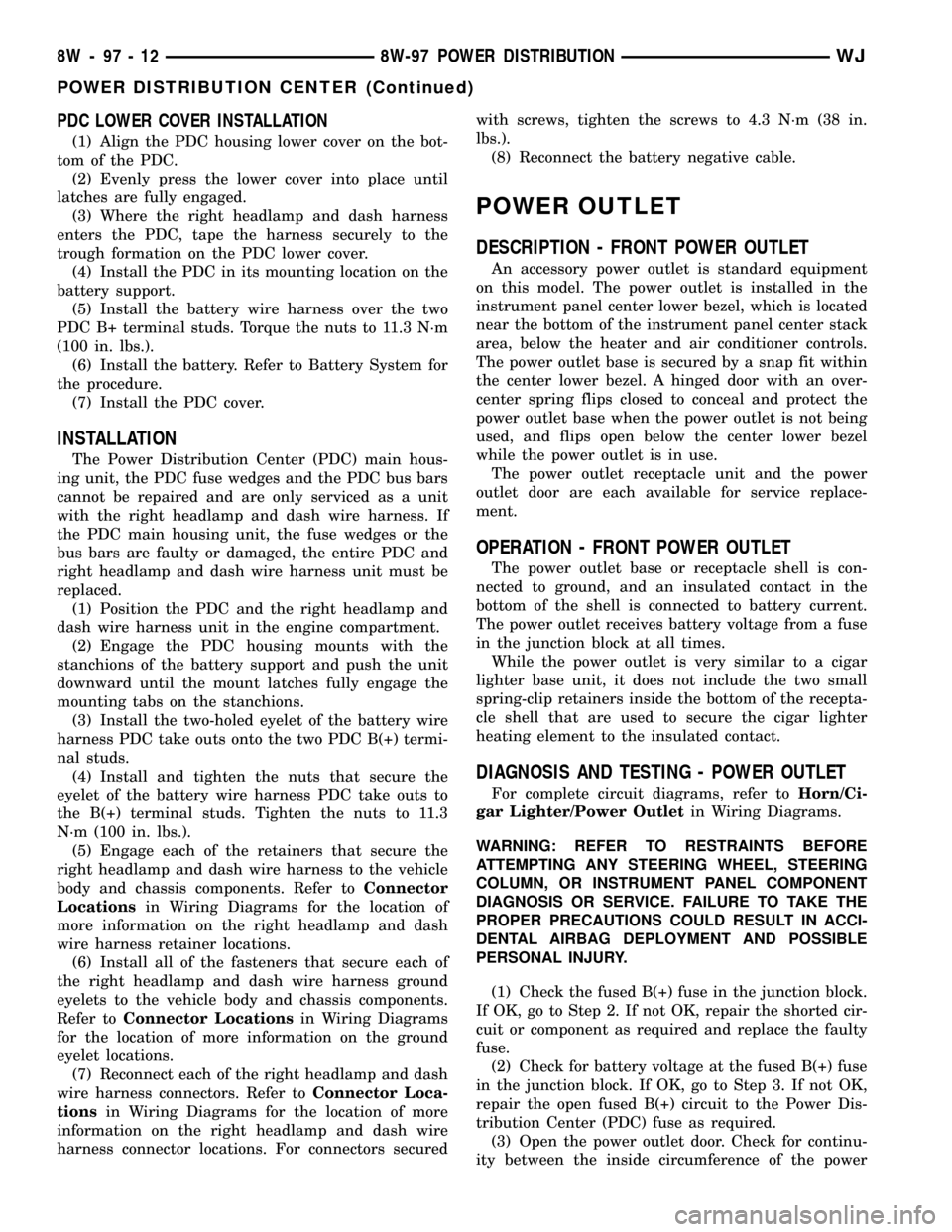

(6) Where the right headlamp and dash wire har-

ness exits the PDC, remove the tape that secures the

wire harness to the trough formation on the PDC

housing lower cover.

(7) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the latches on each side

and the front of the PDC housing that secure the

housing lower cover to the PDC and remove the

housing lower cover (Fig. 10).

PDC B+ TERMINAL MODULE REMOVAL

The Power Distribution Center (PDC) cover, the

PDC housing lower cover, the PDC relay wedges, the

PDC relay cassettes and the PDC B(+) terminal stud

module are available for service replacement. The

PDC cover can be simply unlatched and removed

from the PDC housing without the PDC being

removed or disassembled. Service of the remaining

PDC components requires that the PDC be removed

from its mounting and disassembled. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.(1) Remove the PDC housing lower cover.

(2) From the top of the PDC housing, use a small

screwdriver or a terminal pick tool (Special Tool Kit

6680) to release the two latches that secure the B(+)

terminal module in the PDC.

(3) Gently and evenly press the two B(+) terminal

studs down through the bus bar in the PDC.

(4) From the bottom of the PDC housing, remove

the B(+) terminal module from the PDC.

PDC RELAY WEDGE REMOVAL

The Power Distribution Center (PDC) cover, the

PDC housing lower cover, the PDC relay wedges, the

PDC relay cassettes and the PDC B(+) terminal stud

module are available for service replacement. The

PDC cover can be simply unlatched and removed

from the PDC housing without the PDC being

removed or disassembled. Service of the remaining

PDC components requires that the PDC be removed

from its mounting and disassembled. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.

(1) Remove the PDC housing lower cover.

(2) Remove each of the relays from the PDC relay

wedge to be removed.

(3) From the bottom of the PDC housing, use a

small screwdriver or a terminal pick tool (Special

Fig. 10 PDC Housing Lower Cover Remove/Install -

Typical

1 - TROUGH FORMATION

2 - LATCHES (5)

3 - PDC HOUSING LOWER COVER

4 - WIRE HARNESS

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 9

POWER DISTRIBUTION CENTER (Continued)

Page 1237 of 2199

PDC LOWER COVER INSTALLATION

(1) Align the PDC housing lower cover on the bot-

tom of the PDC.

(2) Evenly press the lower cover into place until

latches are fully engaged.

(3) Where the right headlamp and dash harness

enters the PDC, tape the harness securely to the

trough formation on the PDC lower cover.

(4) Install the PDC in its mounting location on the

battery support.

(5) Install the battery wire harness over the two

PDC B+ terminal studs. Torque the nuts to 11.3 N´m

(100 in. lbs.).

(6) Install the battery. Refer to Battery System for

the procedure.

(7) Install the PDC cover.

INSTALLATION

The Power Distribution Center (PDC) main hous-

ing unit, the PDC fuse wedges and the PDC bus bars

cannot be repaired and are only serviced as a unit

with the right headlamp and dash wire harness. If

the PDC main housing unit, the fuse wedges or the

bus bars are faulty or damaged, the entire PDC and

right headlamp and dash wire harness unit must be

replaced.

(1) Position the PDC and the right headlamp and

dash wire harness unit in the engine compartment.

(2) Engage the PDC housing mounts with the

stanchions of the battery support and push the unit

downward until the mount latches fully engage the

mounting tabs on the stanchions.

(3) Install the two-holed eyelet of the battery wire

harness PDC take outs onto the two PDC B(+) termi-

nal studs.

(4) Install and tighten the nuts that secure the

eyelet of the battery wire harness PDC take outs to

the B(+) terminal studs. Tighten the nuts to 11.3

N´m (100 in. lbs.).

(5) Engage each of the retainers that secure the

right headlamp and dash wire harness to the vehicle

body and chassis components. Refer toConnector

Locationsin Wiring Diagrams for the location of

more information on the right headlamp and dash

wire harness retainer locations.

(6) Install all of the fasteners that secure each of

the right headlamp and dash wire harness ground

eyelets to the vehicle body and chassis components.

Refer toConnector Locationsin Wiring Diagrams

for the location of more information on the ground

eyelet locations.

(7) Reconnect each of the right headlamp and dash

wire harness connectors. Refer toConnector Loca-

tionsin Wiring Diagrams for the location of more

information on the right headlamp and dash wire

harness connector locations. For connectors securedwith screws, tighten the screws to 4.3 N´m (38 in.

lbs.).

(8) Reconnect the battery negative cable.

POWER OUTLET

DESCRIPTION - FRONT POWER OUTLET

An accessory power outlet is standard equipment

on this model. The power outlet is installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area, below the heater and air conditioner controls.

The power outlet base is secured by a snap fit within

the center lower bezel. A hinged door with an over-

center spring flips closed to conceal and protect the

power outlet base when the power outlet is not being

used, and flips open below the center lower bezel

while the power outlet is in use.

The power outlet receptacle unit and the power

outlet door are each available for service replace-

ment.

OPERATION - FRONT POWER OUTLET

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the junction block at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toHorn/Ci-

gar Lighter/Power Outletin Wiring Diagrams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Dis-

tribution Center (PDC) fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

8W - 97 - 12 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION CENTER (Continued)

Page 1254 of 2199

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

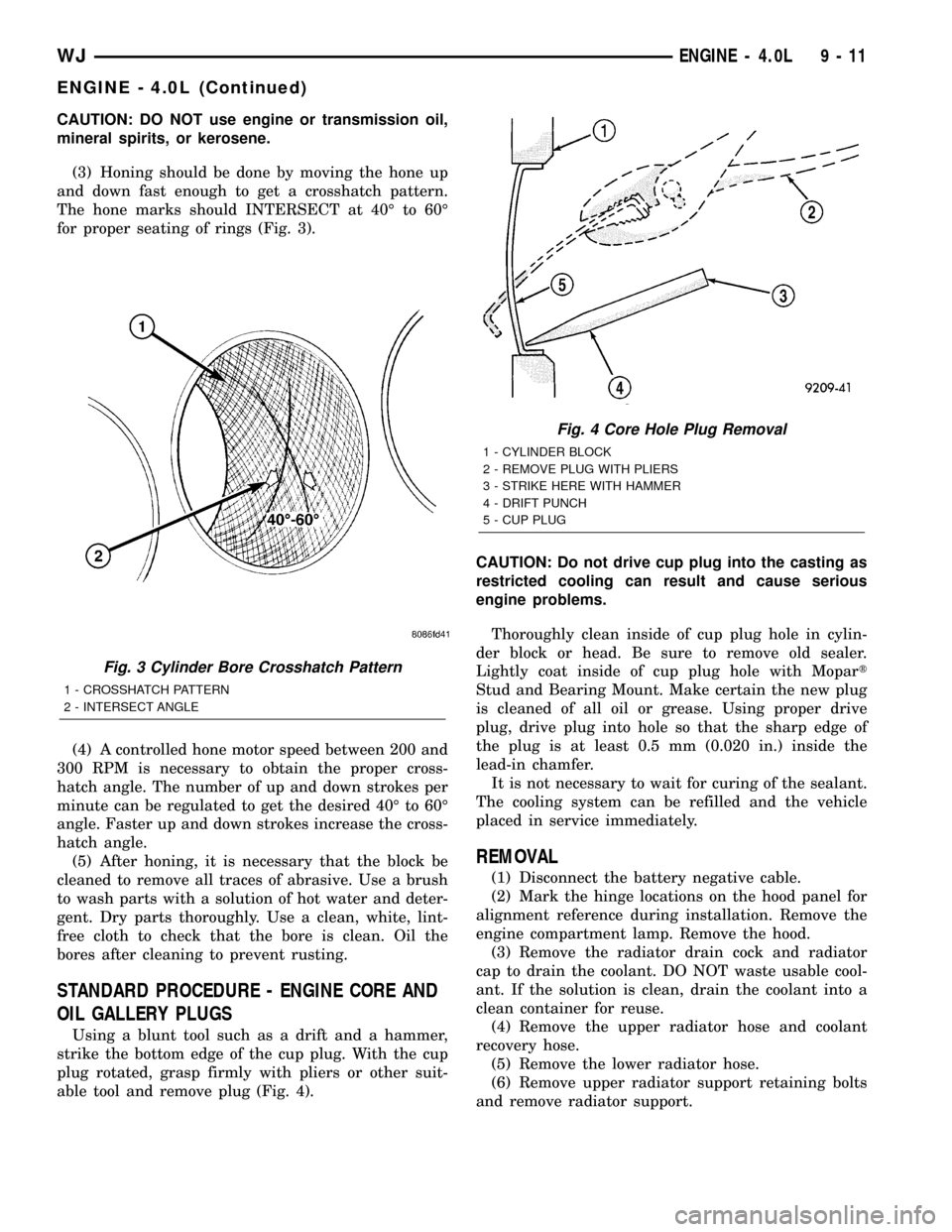

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

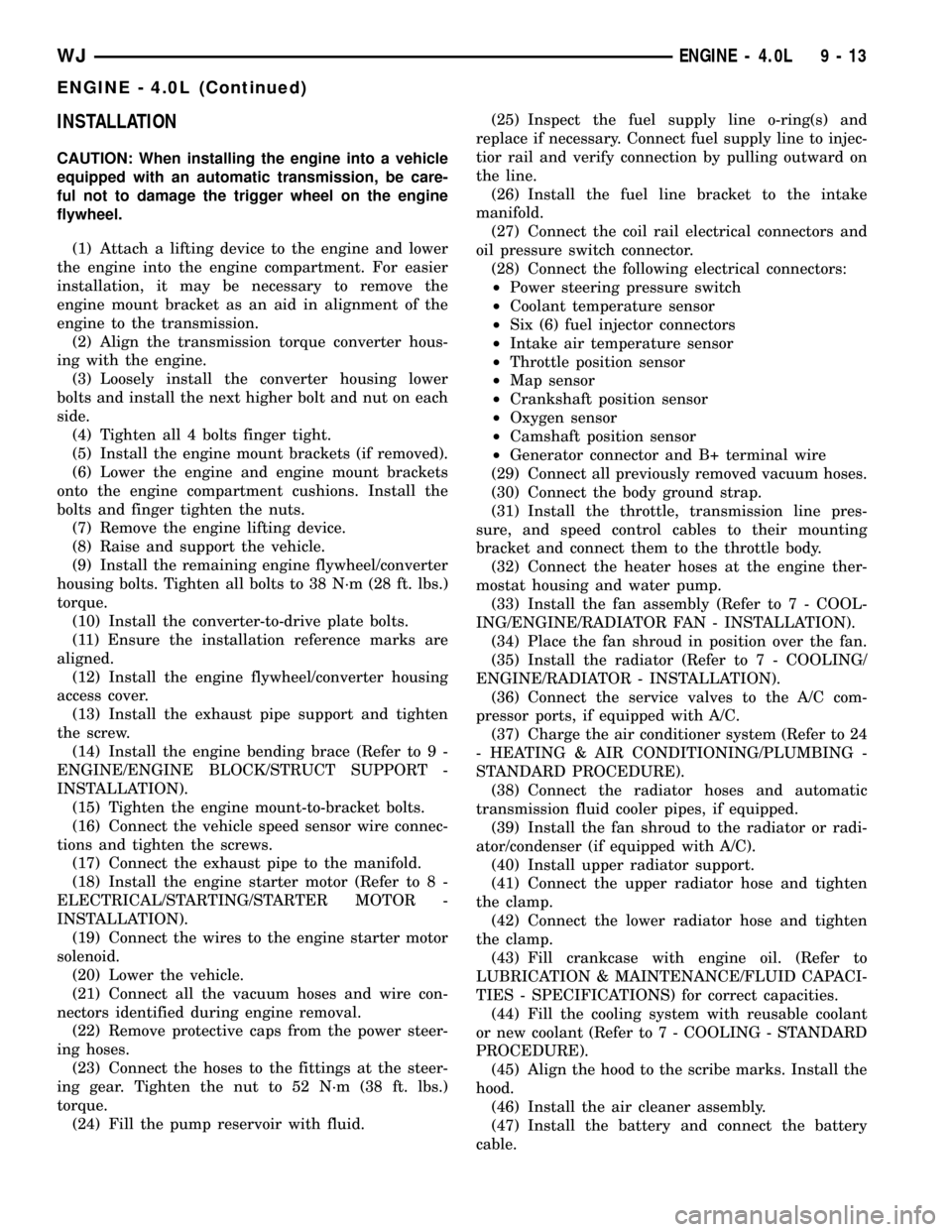

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 4).CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the upper radiator hose and coolant

recovery hose.

(5) Remove the lower radiator hose.

(6) Remove upper radiator support retaining bolts

and remove radiator support.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 4 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.0L 9 - 11

ENGINE - 4.0L (Continued)

Page 1256 of 2199

INSTALLATION

CAUTION: When installing the engine into a vehicle

equipped with an automatic transmission, be care-

ful not to damage the trigger wheel on the engine

flywheel.

(1) Attach a lifting device to the engine and lower

the engine into the engine compartment. For easier

installation, it may be necessary to remove the

engine mount bracket as an aid in alignment of the

engine to the transmission.

(2) Align the transmission torque converter hous-

ing with the engine.

(3) Loosely install the converter housing lower

bolts and install the next higher bolt and nut on each

side.

(4) Tighten all 4 bolts finger tight.

(5) Install the engine mount brackets (if removed).

(6) Lower the engine and engine mount brackets

onto the engine compartment cushions. Install the

bolts and finger tighten the nuts.

(7) Remove the engine lifting device.

(8) Raise and support the vehicle.

(9) Install the remaining engine flywheel/converter

housing bolts. Tighten all bolts to 38 N´m (28 ft. lbs.)

torque.

(10) Install the converter-to-drive plate bolts.

(11) Ensure the installation reference marks are

aligned.

(12) Install the engine flywheel/converter housing

access cover.

(13) Install the exhaust pipe support and tighten

the screw.

(14) Install the engine bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

INSTALLATION).

(15) Tighten the engine mount-to-bracket bolts.

(16) Connect the vehicle speed sensor wire connec-

tions and tighten the screws.

(17) Connect the exhaust pipe to the manifold.

(18) Install the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(19) Connect the wires to the engine starter motor

solenoid.

(20) Lower the vehicle.

(21) Connect all the vacuum hoses and wire con-

nectors identified during engine removal.

(22) Remove protective caps from the power steer-

ing hoses.

(23) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 N´m (38 ft. lbs.)

torque.

(24) Fill the pump reservoir with fluid.(25) Inspect the fuel supply line o-ring(s) and

replace if necessary. Connect fuel supply line to injec-

tior rail and verify connection by pulling outward on

the line.

(26) Install the fuel line bracket to the intake

manifold.

(27) Connect the coil rail electrical connectors and

oil pressure switch connector.

(28) Connect the following electrical connectors:

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(29) Connect all previously removed vacuum hoses.

(30) Connect the body ground strap.

(31) Install the throttle, transmission line pres-

sure, and speed control cables to their mounting

bracket and connect them to the throttle body.

(32) Connect the heater hoses at the engine ther-

mostat housing and water pump.

(33) Install the fan assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION).

(34) Place the fan shroud in position over the fan.

(35) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(36) Connect the service valves to the A/C com-

pressor ports, if equipped with A/C.

(37) Charge the air conditioner system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(38) Connect the radiator hoses and automatic

transmission fluid cooler pipes, if equipped.

(39) Install the fan shroud to the radiator or radi-

ator/condenser (if equipped with A/C).

(40) Install upper radiator support.

(41) Connect the upper radiator hose and tighten

the clamp.

(42) Connect the lower radiator hose and tighten

the clamp.

(43) Fill crankcase with engine oil. (Refer to

LUBRICATION & MAINTENANCE/FLUID CAPACI-

TIES - SPECIFICATIONS) for correct capacities.

(44) Fill the cooling system with reusable coolant

or new coolant (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(45) Align the hood to the scribe marks. Install the

hood.

(46) Install the air cleaner assembly.

(47) Install the battery and connect the battery

cable.

WJENGINE - 4.0L 9 - 13

ENGINE - 4.0L (Continued)

Page 1260 of 2199

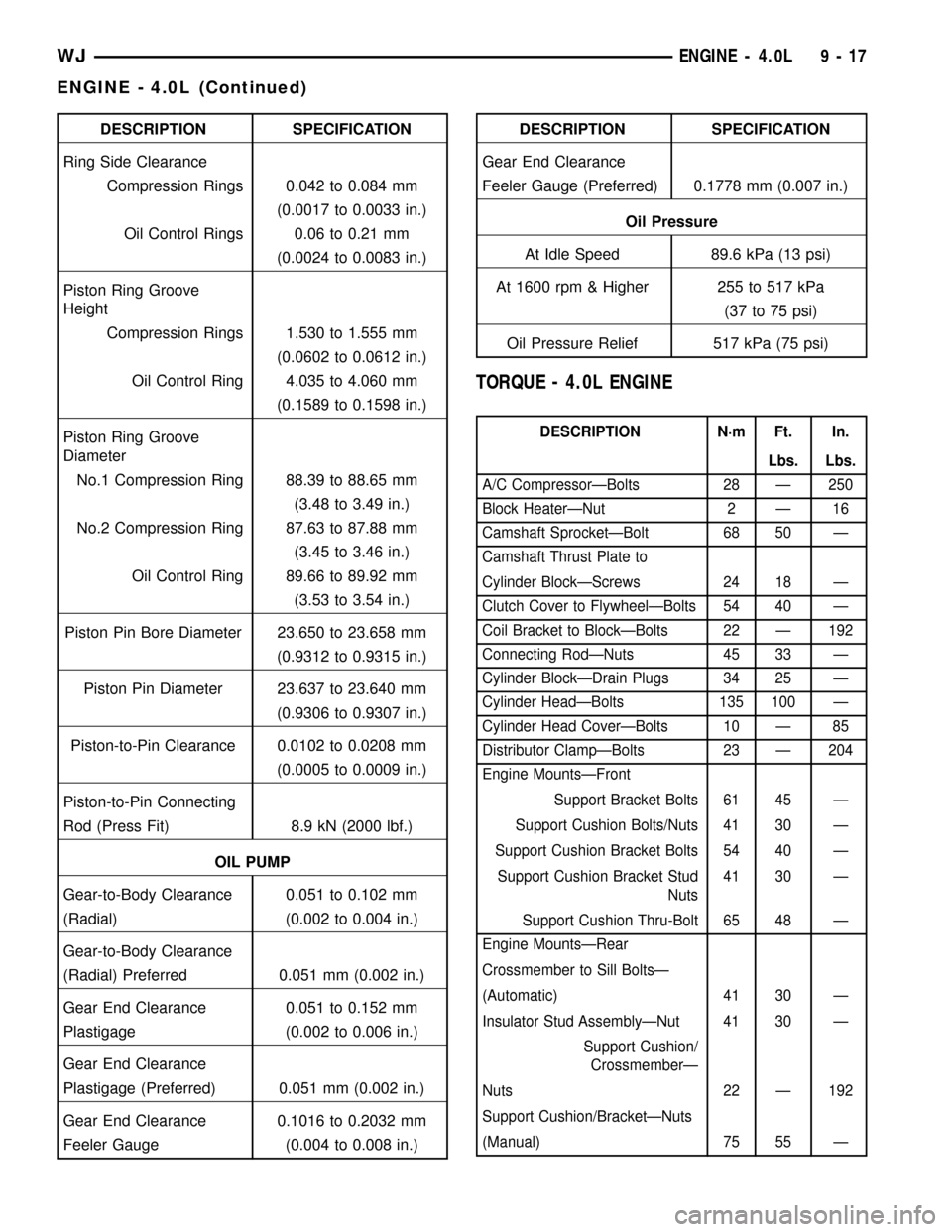

DESCRIPTION SPECIFICATION

Ring Side Clearance

Compression Rings 0.042 to 0.084 mm

(0.0017 to 0.0033 in.)

Oil Control Rings 0.06 to 0.21 mm

(0.0024 to 0.0083 in.)

Piston Ring Groove

Height

Compression Rings 1.530 to 1.555 mm

(0.0602 to 0.0612 in.)

Oil Control Ring 4.035 to 4.060 mm

(0.1589 to 0.1598 in.)

Piston Ring Groove

Diameter

No.1 Compression Ring 88.39 to 88.65 mm

(3.48 to 3.49 in.)

No.2 Compression Ring 87.63 to 87.88 mm

(3.45 to 3.46 in.)

Oil Control Ring 89.66 to 89.92 mm

(3.53 to 3.54 in.)

Piston Pin Bore Diameter 23.650 to 23.658 mm

(0.9312 to 0.9315 in.)

Piston Pin Diameter 23.637 to 23.640 mm

(0.9306 to 0.9307 in.)

Piston-to-Pin Clearance 0.0102 to 0.0208 mm

(0.0005 to 0.0009 in.)

Piston-to-Pin Connecting

Rod (Press Fit) 8.9 kN (2000 lbf.)

OIL PUMP

Gear-to-Body Clearance 0.051 to 0.102 mm

(Radial) (0.002 to 0.004 in.)

Gear-to-Body Clearance

(Radial) Preferred 0.051 mm (0.002 in.)

Gear End Clearance 0.051 to 0.152 mm

Plastigage (0.002 to 0.006 in.)

Gear End Clearance

Plastigage (Preferred) 0.051 mm (0.002 in.)

Gear End Clearance 0.1016 to 0.2032 mm

Feeler Gauge (0.004 to 0.008 in.)DESCRIPTION SPECIFICATION

Gear End Clearance

Feeler Gauge (Preferred) 0.1778 mm (0.007 in.)

Oil Pressure

At Idle Speed 89.6 kPa (13 psi)

At 1600 rpm & Higher 255 to 517 kPa

(37 to 75 psi)

Oil Pressure Relief 517 kPa (75 psi)

TORQUE - 4.0L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

A/C CompressorÐBolts 28 Ð 250

Block HeaterÐNut 2 Ð 16

Camshaft SprocketÐBolt 68 50 Ð

Camshaft Thrust Plate to

Cylinder BlockÐScrews 24 18 Ð

Clutch Cover to FlywheelÐBolts 54 40 Ð

Coil Bracket to BlockÐBolts 22 Ð 192

Connecting RodÐNuts 45 33 Ð

Cylinder BlockÐDrain Plugs 34 25 Ð

Cylinder HeadÐBolts 135 100 Ð

Cylinder Head CoverÐBolts 10 Ð 85

Distributor ClampÐBolts 23 Ð 204

Engine MountsÐFront

Support Bracket Bolts 61 45 Ð

Support Cushion Bolts/Nuts 41 30 Ð

Support Cushion Bracket Bolts 54 40 Ð

Support Cushion Bracket Stud

Nuts41 30 Ð

Support Cushion Thru-Bolt 65 48 Ð

Engine MountsÐRear

Crossmember to Sill BoltsÐ

(Automatic) 41 30 Ð

Insulator Stud AssemblyÐNut 41 30 Ð

Support Cushion/

CrossmemberÐ

Nuts 22 Ð 192

Support Cushion/BracketÐNuts

(Manual) 75 55 Ð

WJENGINE - 4.0L 9 - 17

ENGINE - 4.0L (Continued)

Page 1261 of 2199

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Transmission Support Bracket

ÐBolt (Manual) 46 34 Ð

Transmission Support Bracket/

CushionÐBolt (4WD Auto) 75 55 Ð

Transmission Support Adaptor

BracketÐBolts (2WD Auto) 75 55 Ð

Exhaust Manifold/PipeÐNuts 27 20 Ð

Intake/Exhaust Manifold

Fasteners #1-5 33 24 Ð

Fasteners #6 and 7 14 Ð 126

Fasteners #8-11 33 24 Ð

Flywheel to Converter

HousingÐBolts38 28 Ð

Flywheel to CrankshaftÐBolts 143 105 Ð

Front Cover to BlockÐBolts

1/4-20 7 Ð 60

5/16-18 22 Ð 192

Fuel RailÐBolts/Stud 12 Ð 108

GeneratorÐBolts 57 42 Ð

Generator Bracket to EngineÐ

Bolts47 35 Ð

Idler Pulley to Cylinder

HeadÐBolt47 35 Ð

Main Bearing CapÐBolts 108 80 Ð

Oil Filter 18 Ð 156

Oil Filter Connector to

Adaptor 47 35 Ð

Block 68 50 Ð

Adaptor Bolts 102 50 Ð

Oil GalleyÐPlug 41 30 Ð

Oil PanÐBolts

1/4-20 9.5 Ð 84

5/16-18 15 Ð 132

Oil PanÐDrain Plug 34 25 Ð

Oil Pump

Mounting Bolts 23 Ð 204

Cover Bolts 8 Ð 70

Rocker Arm Assembly to

Cylinder

HeadÐCapscrews 30 21 Ð

Spark Plugs 37 27 ÐDESCRIPTION N´m Ft. In.

Lbs. Lbs.

Starter MotorÐMounting Bolts 45 33 Ð

Thermostat HousingÐBolts 18 Ð 156

Throttle BodyÐBolts 10 Ð 90

Vibration DamperÐBolt 108 80 Ð

Water Pump to BlockÐBolts 23 17 Ð

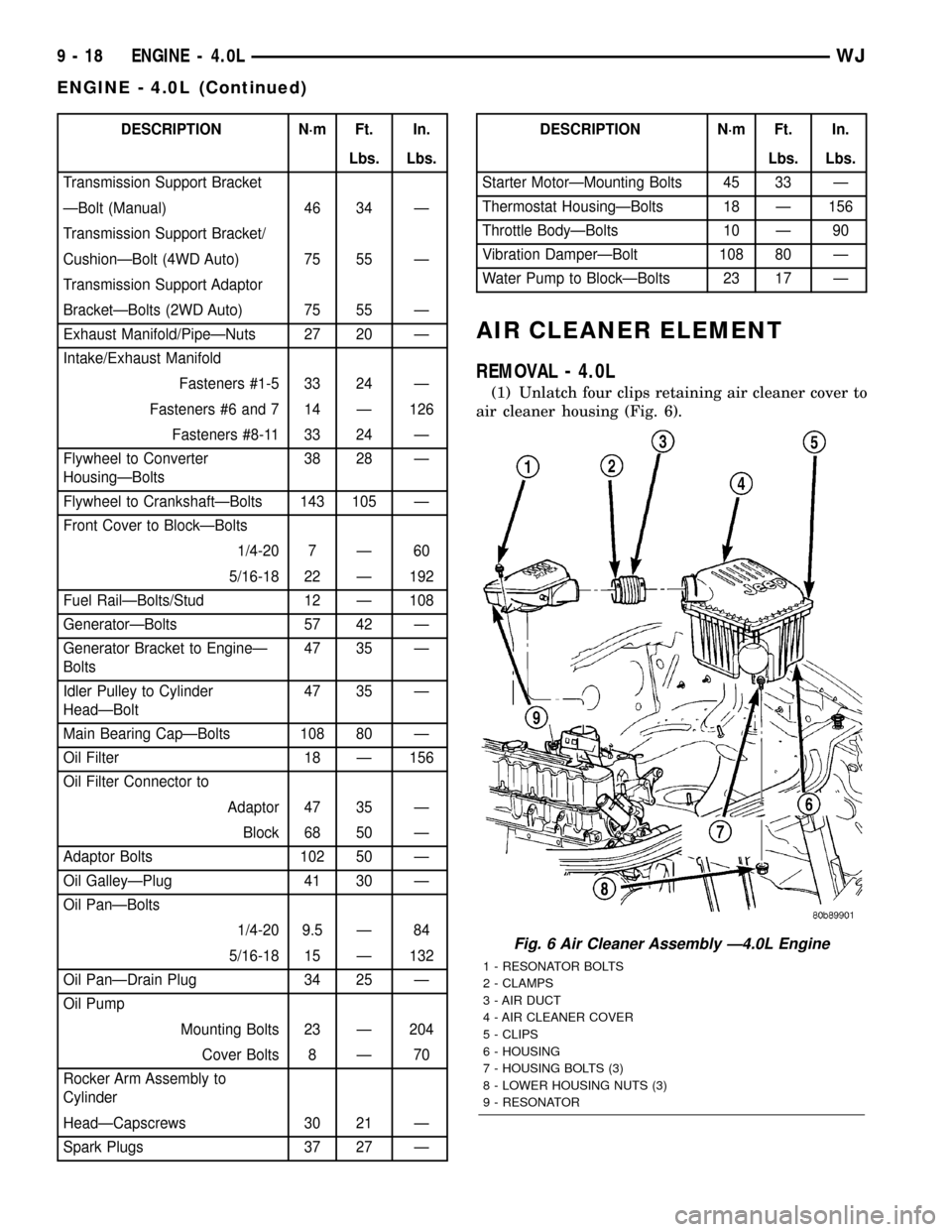

AIR CLEANER ELEMENT

REMOVAL - 4.0L

(1) Unlatch four clips retaining air cleaner cover to

air cleaner housing (Fig. 6).

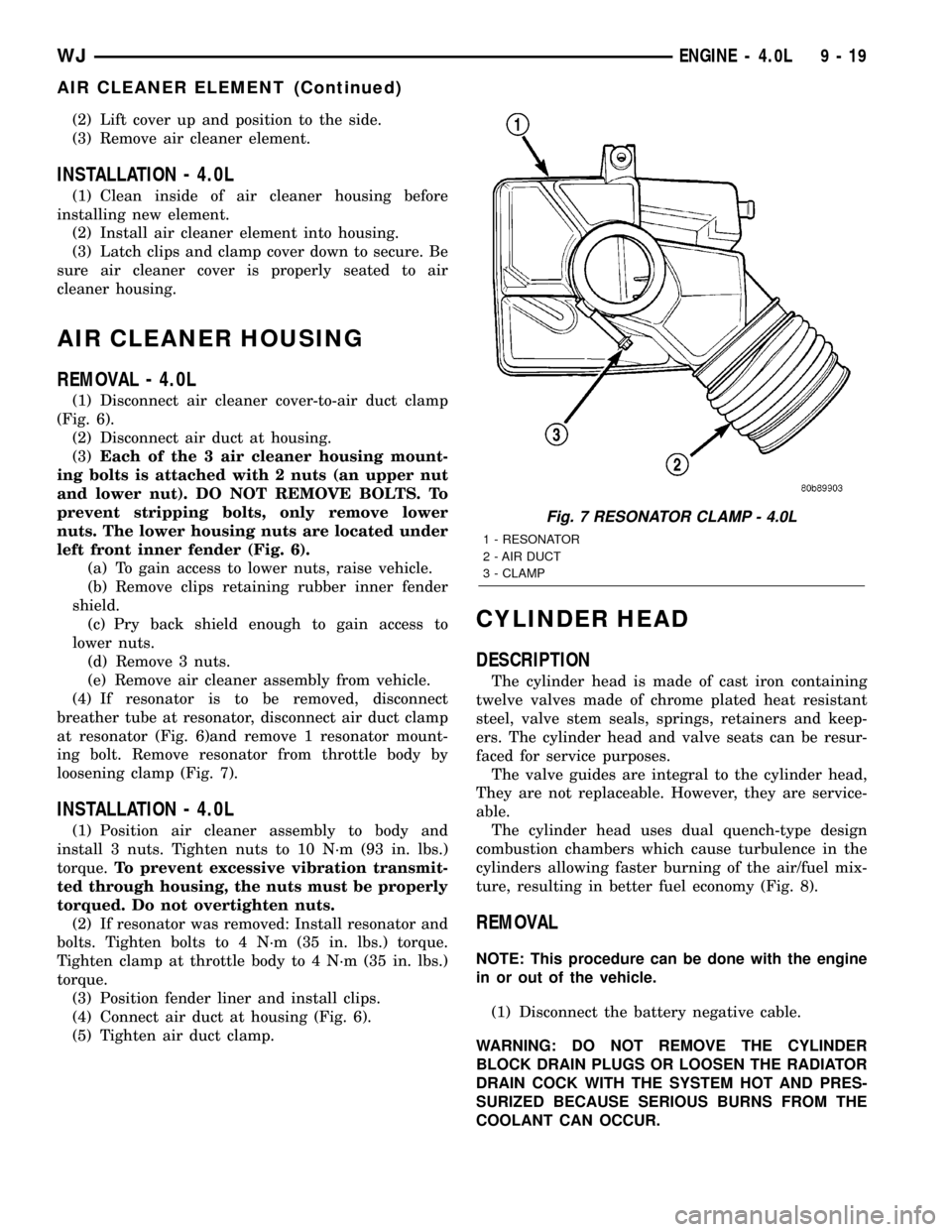

Fig. 6 Air Cleaner Assembly Ð4.0L Engine

1 - RESONATOR BOLTS

2 - CLAMPS

3 - AIR DUCT

4 - AIR CLEANER COVER

5 - CLIPS

6 - HOUSING

7 - HOUSING BOLTS (3)

8 - LOWER HOUSING NUTS (3)

9 - RESONATOR

9 - 18 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1262 of 2199

(2) Lift cover up and position to the side.

(3) Remove air cleaner element.

INSTALLATION - 4.0L

(1) Clean inside of air cleaner housing before

installing new element.

(2) Install air cleaner element into housing.

(3) Latch clips and clamp cover down to secure. Be

sure air cleaner cover is properly seated to air

cleaner housing.

AIR CLEANER HOUSING

REMOVAL - 4.0L

(1) Disconnect air cleaner cover-to-air duct clamp

(Fig. 6).

(2) Disconnect air duct at housing.

(3)Each of the 3 air cleaner housing mount-

ing bolts is attached with 2 nuts (an upper nut

and lower nut). DO NOT REMOVE BOLTS. To

prevent stripping bolts, only remove lower

nuts. The lower housing nuts are located under

left front inner fender (Fig. 6).

(a) To gain access to lower nuts, raise vehicle.

(b) Remove clips retaining rubber inner fender

shield.

(c) Pry back shield enough to gain access to

lower nuts.

(d) Remove 3 nuts.

(e) Remove air cleaner assembly from vehicle.

(4) If resonator is to be removed, disconnect

breather tube at resonator, disconnect air duct clamp

at resonator (Fig. 6)and remove 1 resonator mount-

ing bolt. Remove resonator from throttle body by

loosening clamp (Fig. 7).

INSTALLATION - 4.0L

(1) Position air cleaner assembly to body and

install 3 nuts. Tighten nuts to 10 N´m (93 in. lbs.)

torque.To prevent excessive vibration transmit-

ted through housing, the nuts must be properly

torqued. Do not overtighten nuts.

(2) If resonator was removed: Install resonator and

bolts. Tighten bolts to 4 N´m (35 in. lbs.) torque.

Tighten clamp at throttle body to 4 N´m (35 in. lbs.)

torque.

(3) Position fender liner and install clips.

(4) Connect air duct at housing (Fig. 6).

(5) Tighten air duct clamp.

CYLINDER HEAD

DESCRIPTION

The cylinder head is made of cast iron containing

twelve valves made of chrome plated heat resistant

steel, valve stem seals, springs, retainers and keep-

ers. The cylinder head and valve seats can be resur-

faced for service purposes.

The valve guides are integral to the cylinder head,

They are not replaceable. However, they are service-

able.

The cylinder head uses dual quench-type design

combustion chambers which cause turbulence in the

cylinders allowing faster burning of the air/fuel mix-

ture, resulting in better fuel economy (Fig. 8).

REMOVAL

NOTE: This procedure can be done with the engine

in or out of the vehicle.

(1) Disconnect the battery negative cable.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

Fig. 7 RESONATOR CLAMP - 4.0L

1 - RESONATOR

2 - AIR DUCT

3 - CLAMP

WJENGINE - 4.0L 9 - 19

AIR CLEANER ELEMENT (Continued)

Page 1299 of 2199

(9) Lower the engine until it is properly located on

the engine mounts.

(10) Install the through bolts and tighten the nuts.

(11) Lower the jack stand and remove the piece of

wood.

(12) Install the engine flywheel and transmission

torque converter housing access cover.

(13) Install the engine starter motor. (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(14) Connect the exhaust pipe to the hanger and to

the engine exhaust manifold.

(15) Install transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

attach to the oil pan studs.

(16) Install the oil pan drain plug (Fig. 81).

Tighten the plug to 34 N´m (25 ft. lbs.) torque.

(17) Lower the vehicle.

(18) Connect negative cable to battery.

(19) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(20) Start the engine and inspect for leaks.

ENGINE OIL PRESSURE

SENSOR

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to theinstrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

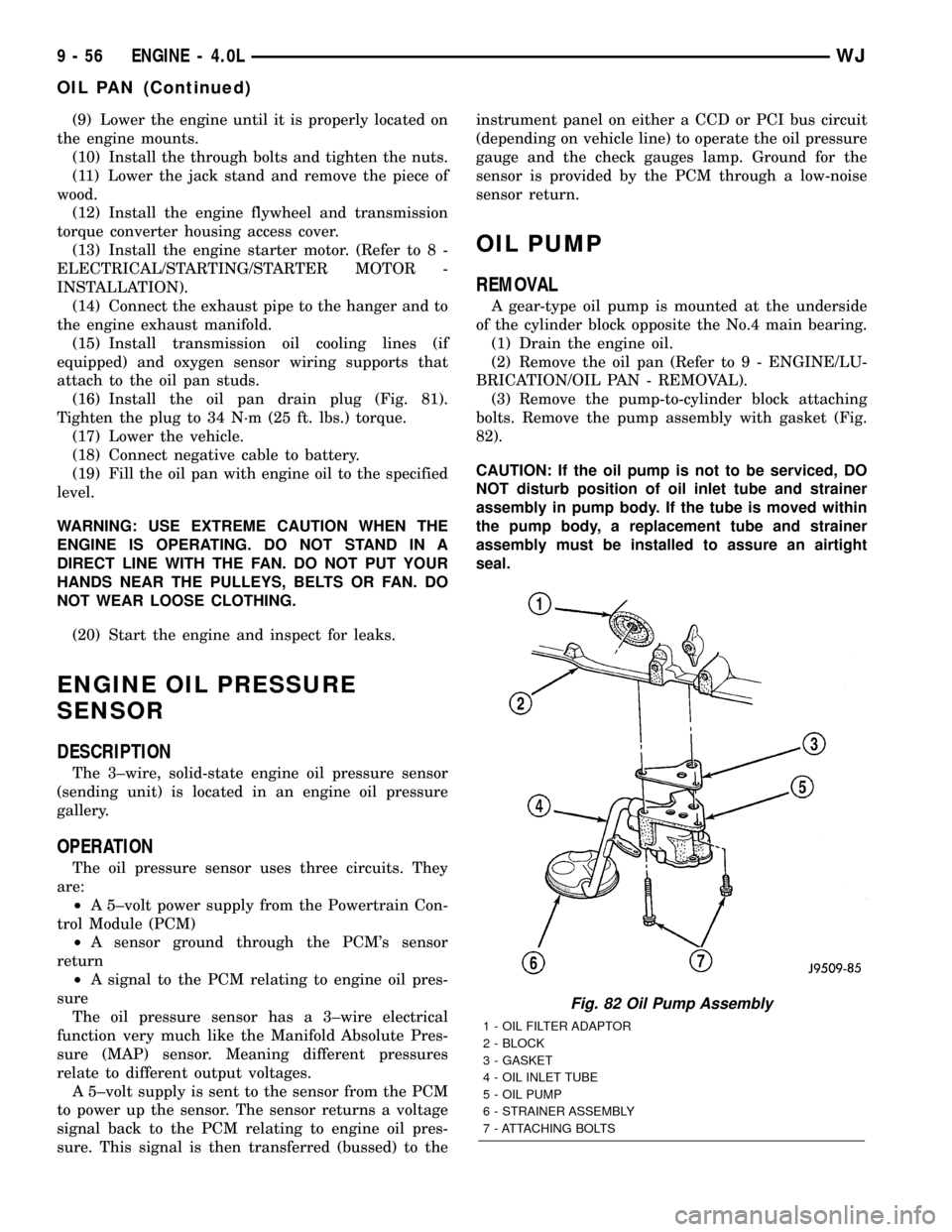

OIL PUMP

REMOVAL

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Drain the engine oil.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

82).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer

assembly must be installed to assure an airtight

seal.

Fig. 82 Oil Pump Assembly

1 - OIL FILTER ADAPTOR

2 - BLOCK

3 - GASKET

4 - OIL INLET TUBE

5 - OIL PUMP

6 - STRAINER ASSEMBLY

7 - ATTACHING BOLTS

9 - 56 ENGINE - 4.0LWJ

OIL PAN (Continued)