torque JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1960 of 2199

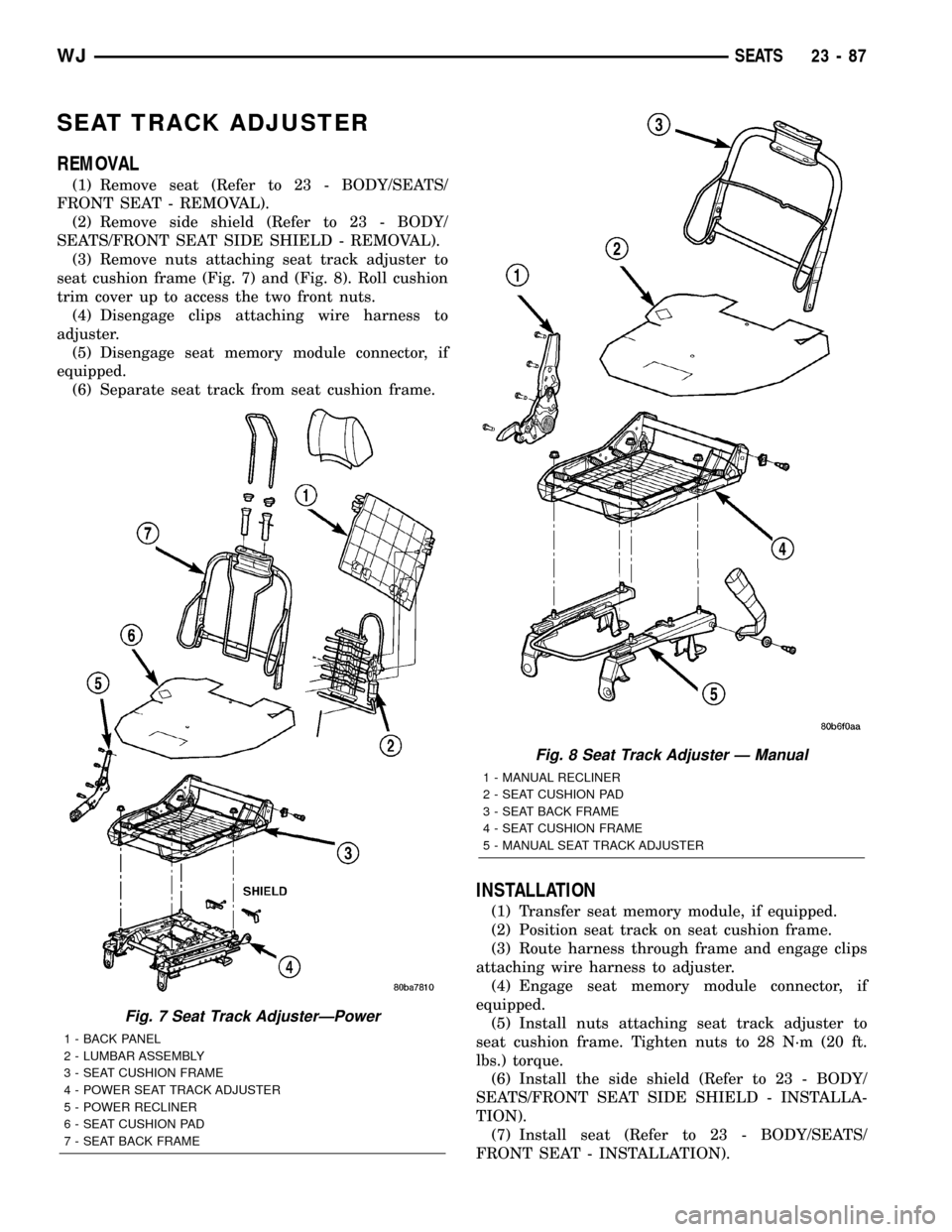

SEAT TRACK ADJUSTER

REMOVAL

(1) Remove seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - REMOVAL).

(2) Remove side shield (Refer to 23 - BODY/

SEATS/FRONT SEAT SIDE SHIELD - REMOVAL).

(3) Remove nuts attaching seat track adjuster to

seat cushion frame (Fig. 7) and (Fig. 8). Roll cushion

trim cover up to access the two front nuts.

(4) Disengage clips attaching wire harness to

adjuster.

(5) Disengage seat memory module connector, if

equipped.

(6) Separate seat track from seat cushion frame.

INSTALLATION

(1) Transfer seat memory module, if equipped.

(2) Position seat track on seat cushion frame.

(3) Route harness through frame and engage clips

attaching wire harness to adjuster.

(4) Engage seat memory module connector, if

equipped.

(5) Install nuts attaching seat track adjuster to

seat cushion frame. Tighten nuts to 28 N´m (20 ft.

lbs.) torque.

(6) Install the side shield (Refer to 23 - BODY/

SEATS/FRONT SEAT SIDE SHIELD - INSTALLA-

TION).

(7) Install seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - INSTALLATION).

Fig. 7 Seat Track AdjusterÐPower

1 - BACK PANEL

2 - LUMBAR ASSEMBLY

3 - SEAT CUSHION FRAME

4 - POWER SEAT TRACK ADJUSTER

5 - POWER RECLINER

6 - SEAT CUSHION PAD

7 - SEAT BACK FRAME

Fig. 8 Seat Track Adjuster Ð Manual

1 - MANUAL RECLINER

2 - SEAT CUSHION PAD

3 - SEAT BACK FRAME

4 - SEAT CUSHION FRAME

5 - MANUAL SEAT TRACK ADJUSTER

WJSEATS 23 - 87

Page 1962 of 2199

REAR HEADREST SLEEVE

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Remove head rest (Refer to 23 - BODY/SEATS/

REAR HEADREST - REMOVAL).

(3) Remove head rest caps.

(4) Remove seat back cover (Refer to 23 - BODY/

SEATS/REAR SEAT BACK COVER - REMOVAL).

(5) Rotate head rest sleeve 1/4 turn counter-clock-

wise to release retaining tab.

(6) Pull sleeve from seat back frame.

INSTALLATION

(1) Position sleeve in seat back frame.

(2) Rotate head rest sleeve 1/4 turn clockwise to

engage retaining tab.

(3) Install seat back cover (Refer to 23 - BODY/

SEATS/REAR SEAT BACK COVER - INSTALLA-

TION).

(4) Install head rest caps.

NOTE: The head rest cap with the taller button is

always on the inboard side of the seat back.

(5) Install the head rest (Refer to 23 - BODY/

SEATS/REAR HEADREST - INSTALLATION).

NOTE: The folding head rest release knob is always

on the outboard side.

(6) Install the seat back (Refer to 23 - BODY/

SEATS/REAR SEAT BACK - INSTALLATION).

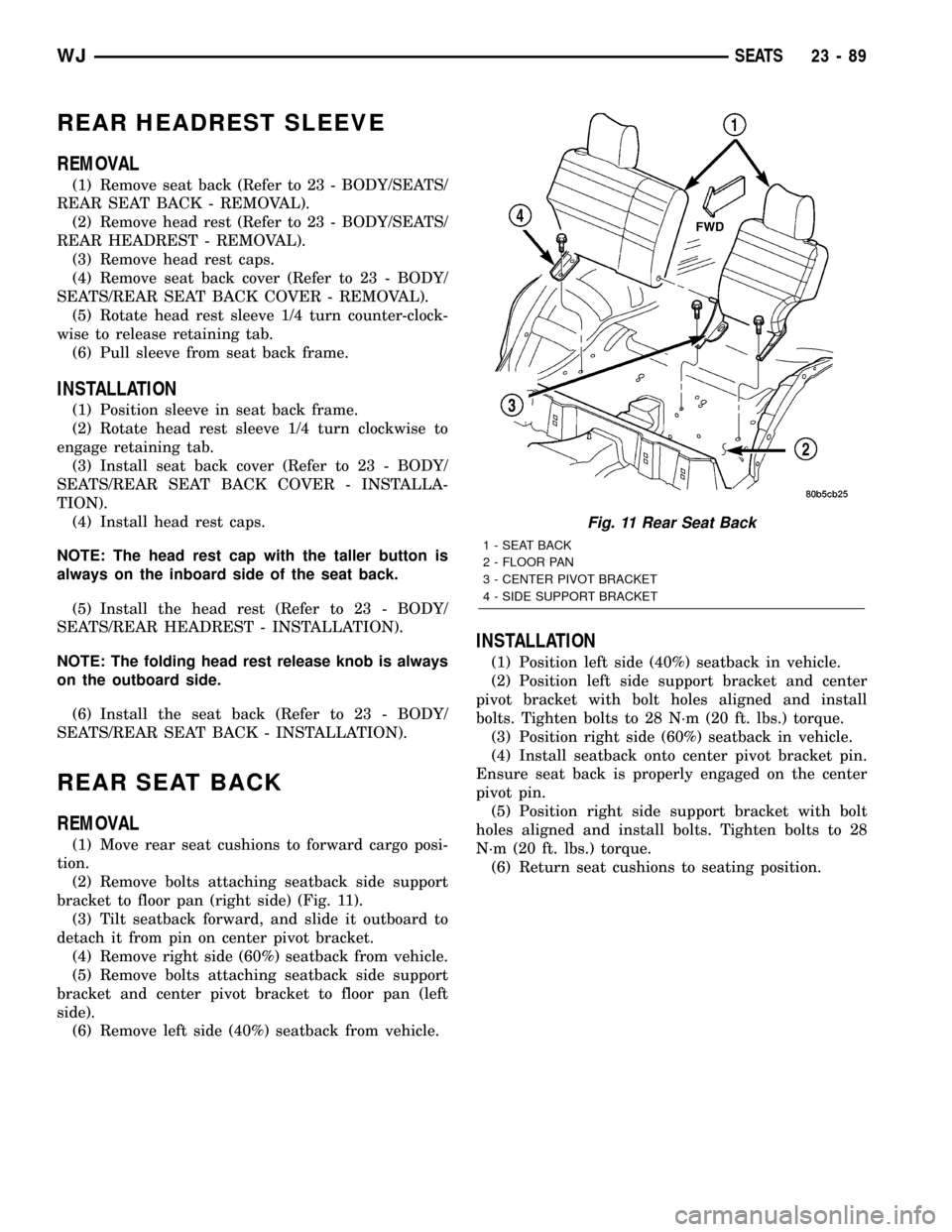

REAR SEAT BACK

REMOVAL

(1) Move rear seat cushions to forward cargo posi-

tion.

(2) Remove bolts attaching seatback side support

bracket to floor pan (right side) (Fig. 11).

(3) Tilt seatback forward, and slide it outboard to

detach it from pin on center pivot bracket.

(4) Remove right side (60%) seatback from vehicle.

(5) Remove bolts attaching seatback side support

bracket and center pivot bracket to floor pan (left

side).

(6) Remove left side (40%) seatback from vehicle.

INSTALLATION

(1) Position left side (40%) seatback in vehicle.

(2) Position left side support bracket and center

pivot bracket with bolt holes aligned and install

bolts. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Position right side (60%) seatback in vehicle.

(4) Install seatback onto center pivot bracket pin.

Ensure seat back is properly engaged on the center

pivot pin.

(5) Position right side support bracket with bolt

holes aligned and install bolts. Tighten bolts to 28

N´m (20 ft. lbs.) torque.

(6) Return seat cushions to seating position.

Fig. 11 Rear Seat Back

1 - SEAT BACK

2 - FLOOR PAN

3 - CENTER PIVOT BRACKET

4 - SIDE SUPPORT BRACKET

WJSEATS 23 - 89

Page 1963 of 2199

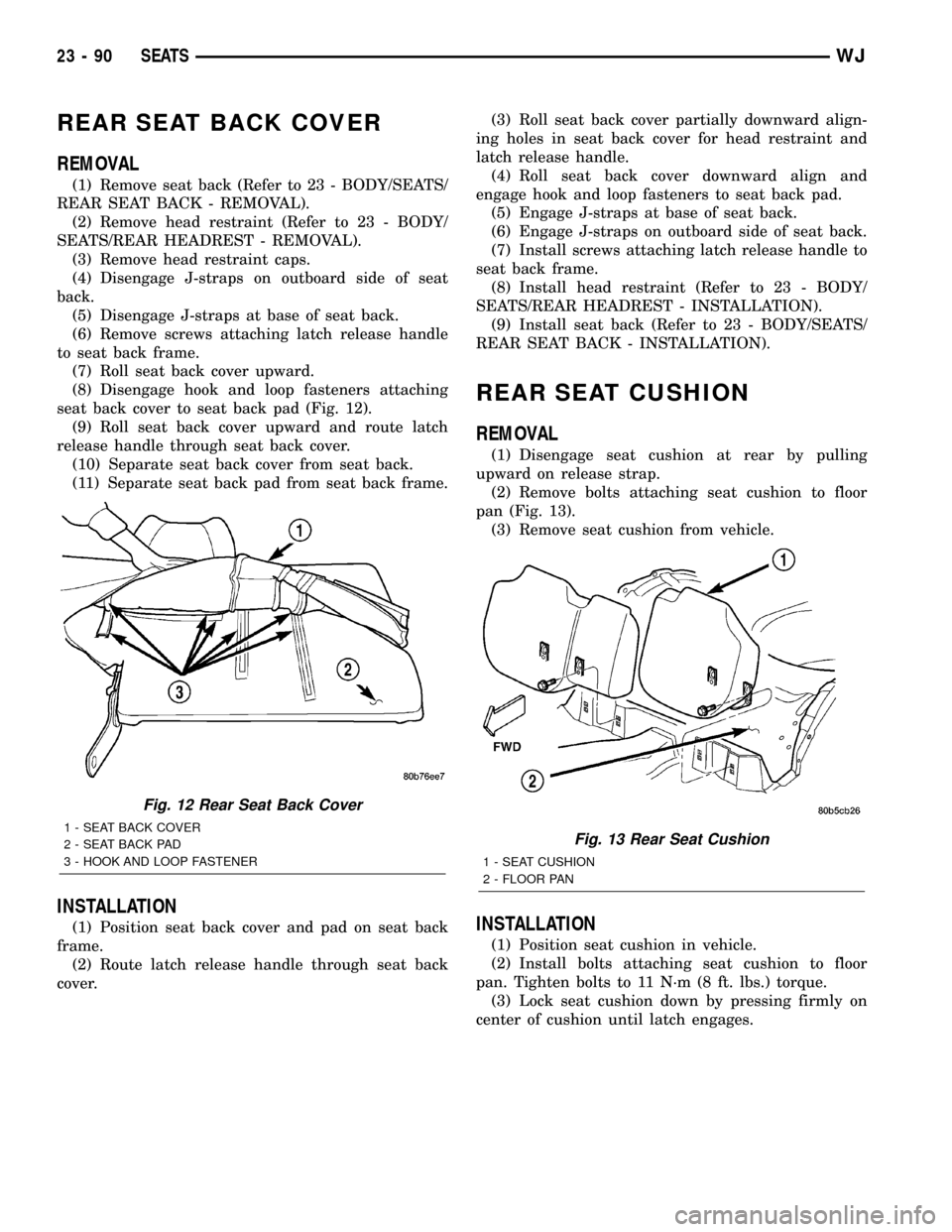

REAR SEAT BACK COVER

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Remove head restraint (Refer to 23 - BODY/

SEATS/REAR HEADREST - REMOVAL).

(3) Remove head restraint caps.

(4) Disengage J-straps on outboard side of seat

back.

(5) Disengage J-straps at base of seat back.

(6) Remove screws attaching latch release handle

to seat back frame.

(7) Roll seat back cover upward.

(8) Disengage hook and loop fasteners attaching

seat back cover to seat back pad (Fig. 12).

(9) Roll seat back cover upward and route latch

release handle through seat back cover.

(10) Separate seat back cover from seat back.

(11) Separate seat back pad from seat back frame.

INSTALLATION

(1) Position seat back cover and pad on seat back

frame.

(2) Route latch release handle through seat back

cover.(3) Roll seat back cover partially downward align-

ing holes in seat back cover for head restraint and

latch release handle.

(4) Roll seat back cover downward align and

engage hook and loop fasteners to seat back pad.

(5) Engage J-straps at base of seat back.

(6) Engage J-straps on outboard side of seat back.

(7) Install screws attaching latch release handle to

seat back frame.

(8) Install head restraint (Refer to 23 - BODY/

SEATS/REAR HEADREST - INSTALLATION).

(9) Install seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - INSTALLATION).

REAR SEAT CUSHION

REMOVAL

(1) Disengage seat cushion at rear by pulling

upward on release strap.

(2) Remove bolts attaching seat cushion to floor

pan (Fig. 13).

(3) Remove seat cushion from vehicle.

INSTALLATION

(1) Position seat cushion in vehicle.

(2) Install bolts attaching seat cushion to floor

pan. Tighten bolts to 11 N´m (8 ft. lbs.) torque.

(3) Lock seat cushion down by pressing firmly on

center of cushion until latch engages.

Fig. 12 Rear Seat Back Cover

1 - SEAT BACK COVER

2 - SEAT BACK PAD

3 - HOOK AND LOOP FASTENERFig. 13 Rear Seat Cushion

1 - SEAT CUSHION

2 - FLOOR PAN

23 - 90 SEATSWJ

Page 1964 of 2199

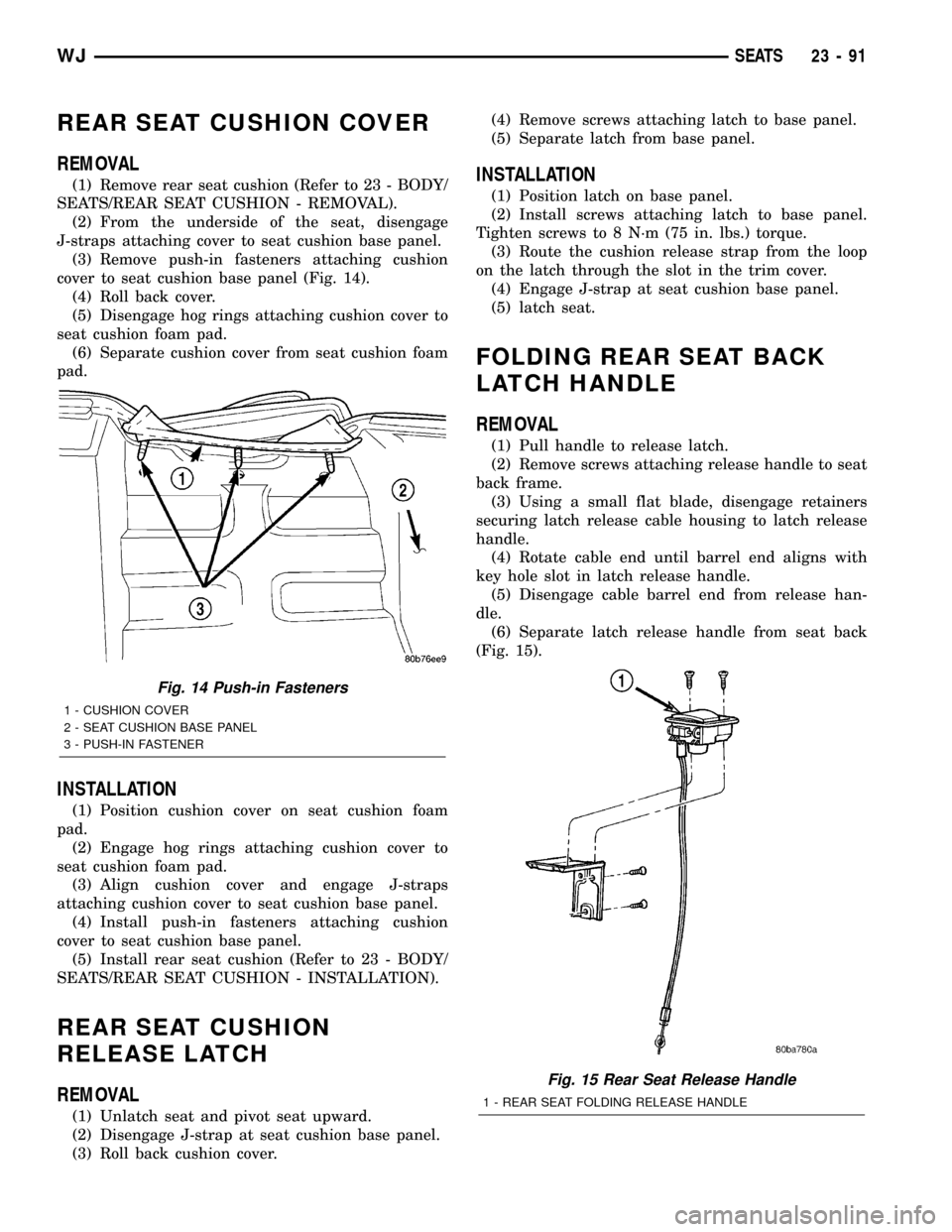

REAR SEAT CUSHION COVER

REMOVAL

(1) Remove rear seat cushion (Refer to 23 - BODY/

SEATS/REAR SEAT CUSHION - REMOVAL).

(2) From the underside of the seat, disengage

J-straps attaching cover to seat cushion base panel.

(3) Remove push-in fasteners attaching cushion

cover to seat cushion base panel (Fig. 14).

(4) Roll back cover.

(5) Disengage hog rings attaching cushion cover to

seat cushion foam pad.

(6) Separate cushion cover from seat cushion foam

pad.

INSTALLATION

(1) Position cushion cover on seat cushion foam

pad.

(2) Engage hog rings attaching cushion cover to

seat cushion foam pad.

(3) Align cushion cover and engage J-straps

attaching cushion cover to seat cushion base panel.

(4) Install push-in fasteners attaching cushion

cover to seat cushion base panel.

(5) Install rear seat cushion (Refer to 23 - BODY/

SEATS/REAR SEAT CUSHION - INSTALLATION).

REAR SEAT CUSHION

RELEASE LATCH

REMOVAL

(1) Unlatch seat and pivot seat upward.

(2) Disengage J-strap at seat cushion base panel.

(3) Roll back cushion cover.(4) Remove screws attaching latch to base panel.

(5) Separate latch from base panel.

INSTALLATION

(1) Position latch on base panel.

(2) Install screws attaching latch to base panel.

Tighten screws to 8 N´m (75 in. lbs.) torque.

(3) Route the cushion release strap from the loop

on the latch through the slot in the trim cover.

(4) Engage J-strap at seat cushion base panel.

(5) latch seat.

FOLDING REAR SEAT BACK

LATCH HANDLE

REMOVAL

(1) Pull handle to release latch.

(2) Remove screws attaching release handle to seat

back frame.

(3) Using a small flat blade, disengage retainers

securing latch release cable housing to latch release

handle.

(4) Rotate cable end until barrel end aligns with

key hole slot in latch release handle.

(5) Disengage cable barrel end from release han-

dle.

(6) Separate latch release handle from seat back

(Fig. 15).

Fig. 14 Push-in Fasteners

1 - CUSHION COVER

2 - SEAT CUSHION BASE PANEL

3 - PUSH-IN FASTENER

Fig. 15 Rear Seat Release Handle

1 - REAR SEAT FOLDING RELEASE HANDLE

WJSEATS 23 - 91

Page 1965 of 2199

INSTALLATION

(1) Route cable end into latch release handle.

(2) Rotate cable end until barrel end aligns with

key hole slot in latch release handle and insert into

handle.

(3) Engage retainers securing latch release cable

housing to latch release handle.

(4) Position latch release handle in seat back.

Ensure seat back cover is properly aligned.

(5) Install screws attaching release handle to seat

back frame.

FOLDING REAR SEAT BACK

LATCH/HINGE

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Disengage J-straps on outboard side of seat

back.

(3) Disengage release cable from latch.

(4) Remove bolts attaching latch/hinge to seat back

frame.

(5) Separate latch/hinge from seat back frame.

INSTALLATION

(1) Position latch/hinge on seat back frame.

(2) Install bolts attaching latch/hinge to seat back

frame. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Engage latch release cable.

(4) Engage J-straps on outboard side of seat back.

(5) Install seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - INSTALLATION).

23 - 92 SEATSWJ

FOLDING REAR SEAT BACK LATCH HANDLE (Continued)

Page 1977 of 2199

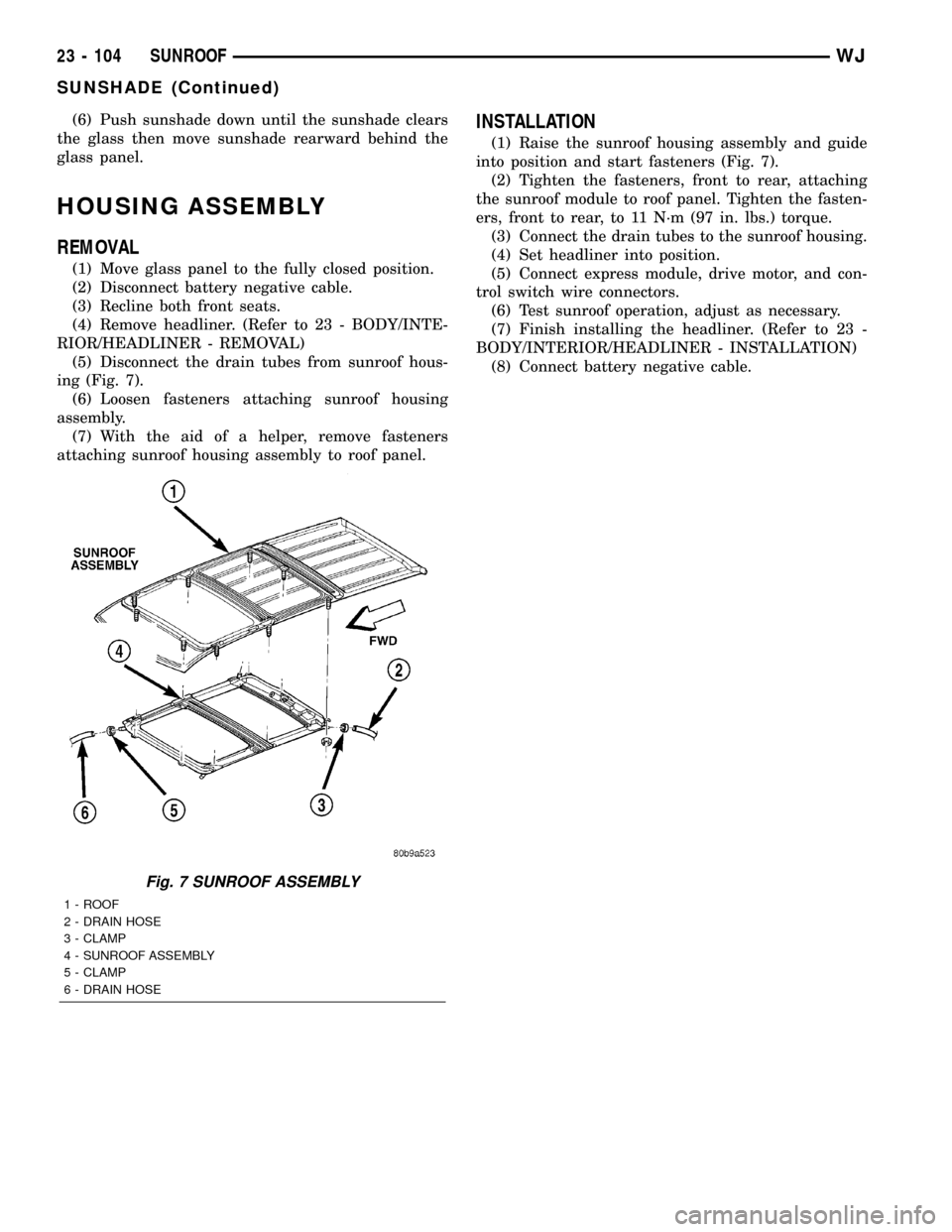

(6) Push sunshade down until the sunshade clears

the glass then move sunshade rearward behind the

glass panel.

HOUSING ASSEMBLY

REMOVAL

(1) Move glass panel to the fully closed position.

(2) Disconnect battery negative cable.

(3) Recline both front seats.

(4) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL)

(5) Disconnect the drain tubes from sunroof hous-

ing (Fig. 7).

(6) Loosen fasteners attaching sunroof housing

assembly.

(7) With the aid of a helper, remove fasteners

attaching sunroof housing assembly to roof panel.

INSTALLATION

(1) Raise the sunroof housing assembly and guide

into position and start fasteners (Fig. 7).

(2) Tighten the fasteners, front to rear, attaching

the sunroof module to roof panel. Tighten the fasten-

ers, front to rear, to 11 N´m (97 in. lbs.) torque.

(3) Connect the drain tubes to the sunroof housing.

(4) Set headliner into position.

(5) Connect express module, drive motor, and con-

trol switch wire connectors.

(6) Test sunroof operation, adjust as necessary.

(7) Finish installing the headliner. (Refer to 23 -

BODY/INTERIOR/HEADLINER - INSTALLATION)

(8) Connect battery negative cable.

Fig. 7 SUNROOF ASSEMBLY

1 - ROOF

2 - DRAIN HOSE

3 - CLAMP

4 - SUNROOF ASSEMBLY

5 - CLAMP

6 - DRAIN HOSE

23 - 104 SUNROOFWJ

SUNSHADE (Continued)

Page 2078 of 2199

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT........................1

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................2

OPERATION - REFRIGERANT SYSTEM

SERVICE PORT........................2DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................2

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................6

STANDARD PROCEDURE - DIODE

REPLACEMENT.......................6

SPECIFICATIONS

A/C APPLICATION TABLE................7

TORQUE SPECIFICATIONS..............8

CONTROLS.............................9

DISTRIBUTION..........................36

PLUMBING.............................51

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating-

air conditioning system, the engine cooling system

must be properly maintained. The use of a bug

screen is not recommended. Any obstructions in front

of the radiator or condenser will reduce the perfor-

mance of the air conditioning and engine cooling sys-

tems.

The engine cooling system includes the heater core

and the heater hoses. Refer to Cooling for more infor-

mation before opening, or attempting any service to

the engine cooling system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

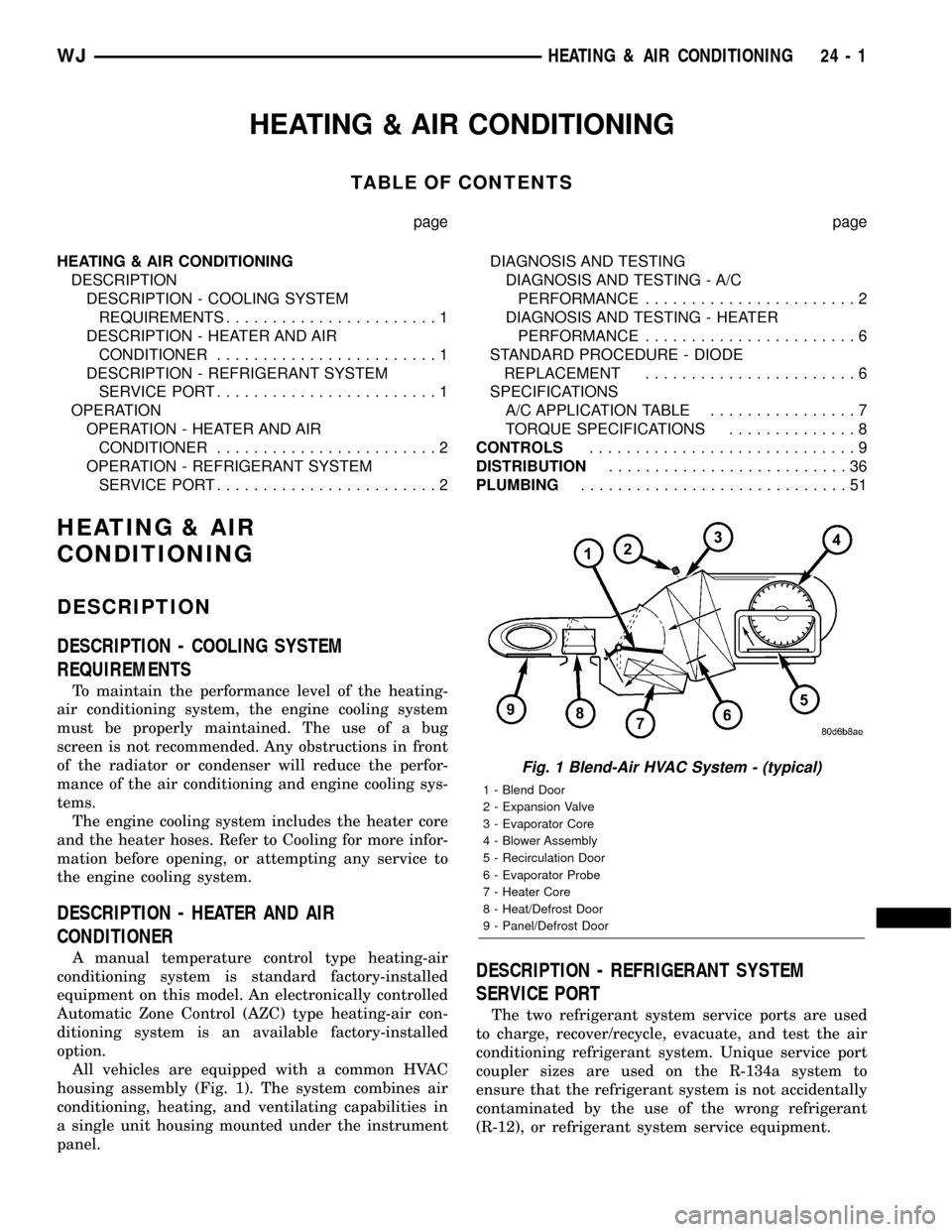

A manual temperature control type heating-air

conditioning system is standard factory-installed

equipment on this model. An electronically controlled

Automatic Zone Control (AZC) type heating-air con-

ditioning system is an available factory-installed

option.

All vehicles are equipped with a common HVAC

housing assembly (Fig. 1). The system combines air

conditioning, heating, and ventilating capabilities in

a single unit housing mounted under the instrument

panel.DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system to

ensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

Fig. 1 Blend-Air HVAC System - (typical)

1 - Blend Door

2 - Expansion Valve

3 - Evaporator Core

4 - Blower Assembly

5 - Recirculation Door

6 - Evaporator Probe

7 - Heater Core

8 - Heat/Defrost Door

9 - Panel/Defrost Door

WJHEATING & AIR CONDITIONING 24 - 1

Page 2085 of 2199

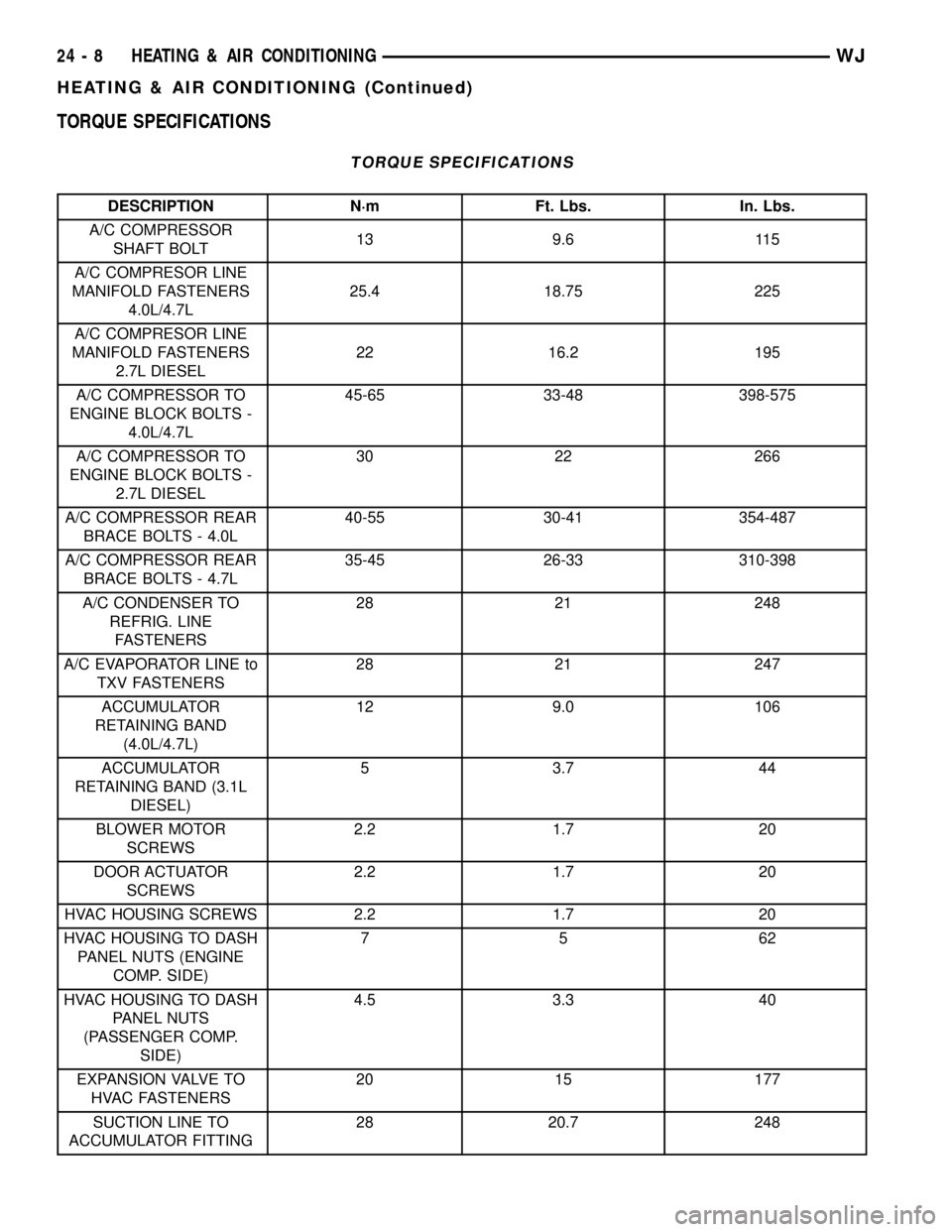

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

A/C COMPRESSOR

SHAFT BOLT13 9.6 115

A/C COMPRESOR LINE

MANIFOLD FASTENERS

4.0L/4.7L25.4 18.75 225

A/C COMPRESOR LINE

MANIFOLD FASTENERS

2.7L DIESEL22 16.2 195

A/C COMPRESSOR TO

ENGINE BLOCK BOLTS -

4.0L/4.7L45-65 33-48 398-575

A/C COMPRESSOR TO

ENGINE BLOCK BOLTS -

2.7L DIESEL30 22 266

A/C COMPRESSOR REAR

BRACE BOLTS - 4.0L40-55 30-41 354-487

A/C COMPRESSOR REAR

BRACE BOLTS - 4.7L35-45 26-33 310-398

A/C CONDENSER TO

REFRIG. LINE

FASTENERS28 21 248

A/C EVAPORATOR LINE to

TXV FASTENERS28 21 247

ACCUMULATOR

RETAINING BAND

(4.0L/4.7L)12 9.0 106

ACCUMULATOR

RETAINING BAND (3.1L

DIESEL)5 3.7 44

BLOWER MOTOR

SCREWS2.2 1.7 20

DOOR ACTUATOR

SCREWS2.2 1.7 20

HVAC HOUSING SCREWS 2.2 1.7 20

HVAC HOUSING TO DASH

PANEL NUTS (ENGINE

COMP. SIDE)75 62

HVAC HOUSING TO DASH

PANEL NUTS

(PASSENGER COMP.

SIDE)4.5 3.3 40

EXPANSION VALVE TO

HVAC FASTENERS20 15 177

SUCTION LINE TO

ACCUMULATOR FITTING28 20.7 248

24 - 8 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2091 of 2199

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C Heater control in the

Recirculation Mode, the A/C button in the on posi-

tion, the blower motor switch in the highest speed

position, and the engine speed at 1500 to 2000 rpm.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher compressor

clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, pulley, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt. Refer to

Cooling for the procedures.

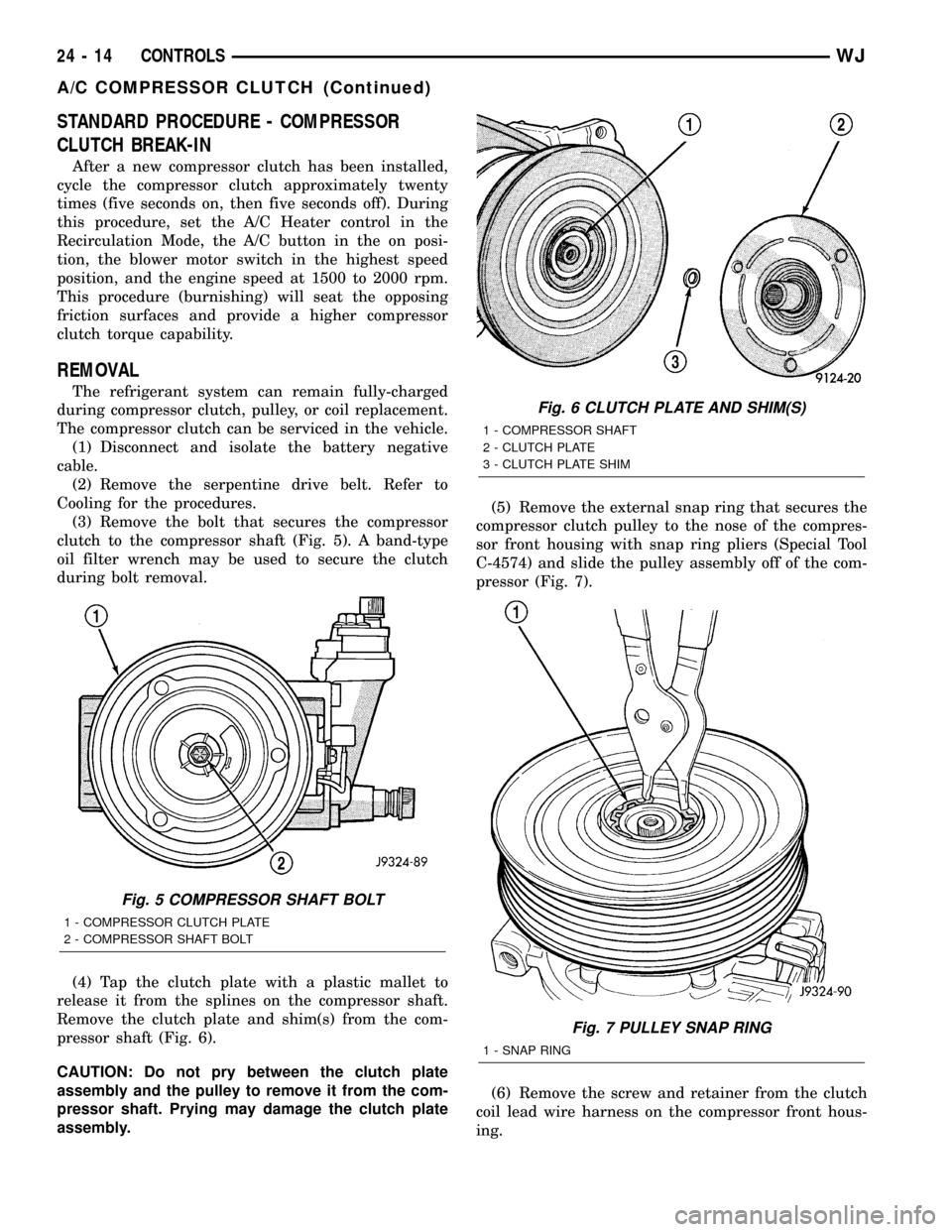

(3) Remove the bolt that secures the compressor

clutch to the compressor shaft (Fig. 5). A band-type

oil filter wrench may be used to secure the clutch

during bolt removal.

(4) Tap the clutch plate with a plastic mallet to

release it from the splines on the compressor shaft.

Remove the clutch plate and shim(s) from the com-

pressor shaft (Fig. 6).

CAUTION: Do not pry between the clutch plate

assembly and the pulley to remove it from the com-

pressor shaft. Prying may damage the clutch plate

assembly.(5) Remove the external snap ring that secures the

compressor clutch pulley to the nose of the compres-

sor front housing with snap ring pliers (Special Tool

C-4574) and slide the pulley assembly off of the com-

pressor (Fig. 7).

(6) Remove the screw and retainer from the clutch

coil lead wire harness on the compressor front hous-

ing.

Fig. 5 COMPRESSOR SHAFT BOLT

1 - COMPRESSOR CLUTCH PLATE

2 - COMPRESSOR SHAFT BOLT

Fig. 6 CLUTCH PLATE AND SHIM(S)

1 - COMPRESSOR SHAFT

2 - CLUTCH PLATE

3 - CLUTCH PLATE SHIM

Fig. 7 PULLEY SNAP RING

1 - SNAP RING

24 - 14 CONTROLSWJ

A/C COMPRESSOR CLUTCH (Continued)

Page 2130 of 2199

CAUTION

CAUTION

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with the service equipment being used.

Never add R-12 to a refrigerant system designed to

use R-134a. Damage to the system will result.

R-12 refrigerant oil must not be mixed with R-134a

refrigerant oil. They are not compatible.

Do not use R-12 equipment or parts on the R-134a

system. Damage to the system will result.

Do not overcharge the refrigerant system. This will

cause excessive compressor head pressure and

can cause noise and system failure.

Recover the refrigerant before opening any fitting

or connection. Open the fittings with caution, even

after the system has been discharged. Never open

or loosen a connection before recovering the refrig-

erant.

The refrigerant system must always be evacuated

before charging.

Do not open the refrigerant system or uncap a

replacement component until you are ready to ser-

vice the system. This will prevent contamination in

the system.

Before disconnecting a component, clean the out-

side of the fittings thoroughly to prevent contami-

nation from entering the refrigerant system.

Immediately after disconnecting a component from

the refrigerant system, seal the open fittings with a

cap or plug.

Before connecting an open refrigerant fitting,

always install a new seal or gasket. Coat the fitting

and seal with clean refrigerant oil before connect-

ing.

Do not remove the sealing caps from a replacement

component until it is to be installed.

When installing a refrigerant line, avoid sharp

bends that may restrict refrigerant flow. Position the

refrigerant lines away from exhaust system compo-

nents or any sharp edges, which may damage the

line.

Tighten refrigerant fittings only to the specified

torque. The aluminum fittings used in the refriger-

ant system will not tolerate overtightening.

When disconnecting a refrigerant fitting, use a

wrench on both halves of the fitting. This will pre-

vent twisting of the refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. Do not open a container of

refrigerant oil until you are ready to use it. Replace

the cap on the oil container immediately after using.

Store refrigerant oil only in a clean, airtight, and

moisture-free container.Keep service tools and the work area clean. Con-

tamination of the refrigerant system through care-

less work habits must be avoided.REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing

will reduce the capacity of the entire system. High

pressures are produced in the system when it is oper-

ating. Extreme care must be exercised to make sure

that all refrigerant system connections are pressure

tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings

that are the correct size and approved for use with

R-134a refrigerant. Failure to do so may result in a

leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

The refrigerant system will remain chemically sta-

ble as long as pure, moisture-free R-134a refrigerant

and refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles or

serious damage can occur if foreign material is

present in the refrigerant system.

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

WJPLUMBING 24 - 53

PLUMBING (Continued)