Panel JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 304 of 2199

INSTALLATION

INSTALLATION - REAR DOOR SPEAKER

(1) Position the speaker to the rear door inner

panel.

(2) Reconnect the rear door wire harness connector

to the speaker connector receptacle.

(3) Position the speaker onto the rear door inner

panel.

(4) Install and tighten the three screws that secure

the speaker to the rear door inner panel. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(5) Install the trim panel onto the rear door. (Refer

to 23 - BODY/DOORS - REAR/TRIM PANEL -

INSTALLATION) for the procedures.

(6) Reconnect the battery negative cable.

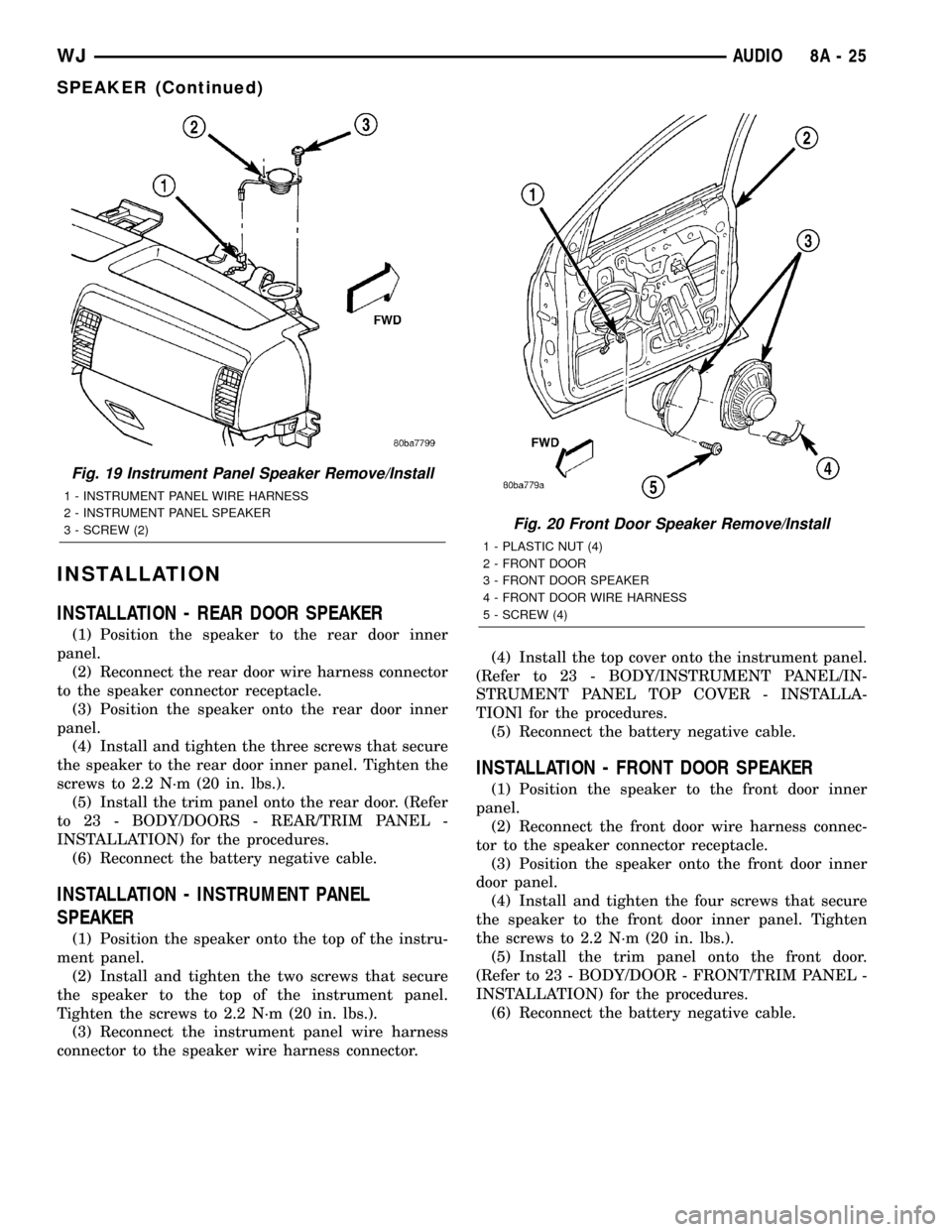

INSTALLATION - INSTRUMENT PANEL

SPEAKER

(1) Position the speaker onto the top of the instru-

ment panel.

(2) Install and tighten the two screws that secure

the speaker to the top of the instrument panel.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reconnect the instrument panel wire harness

connector to the speaker wire harness connector.(4) Install the top cover onto the instrument panel.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL TOP COVER - INSTALLA-

TIONl for the procedures.

(5) Reconnect the battery negative cable.

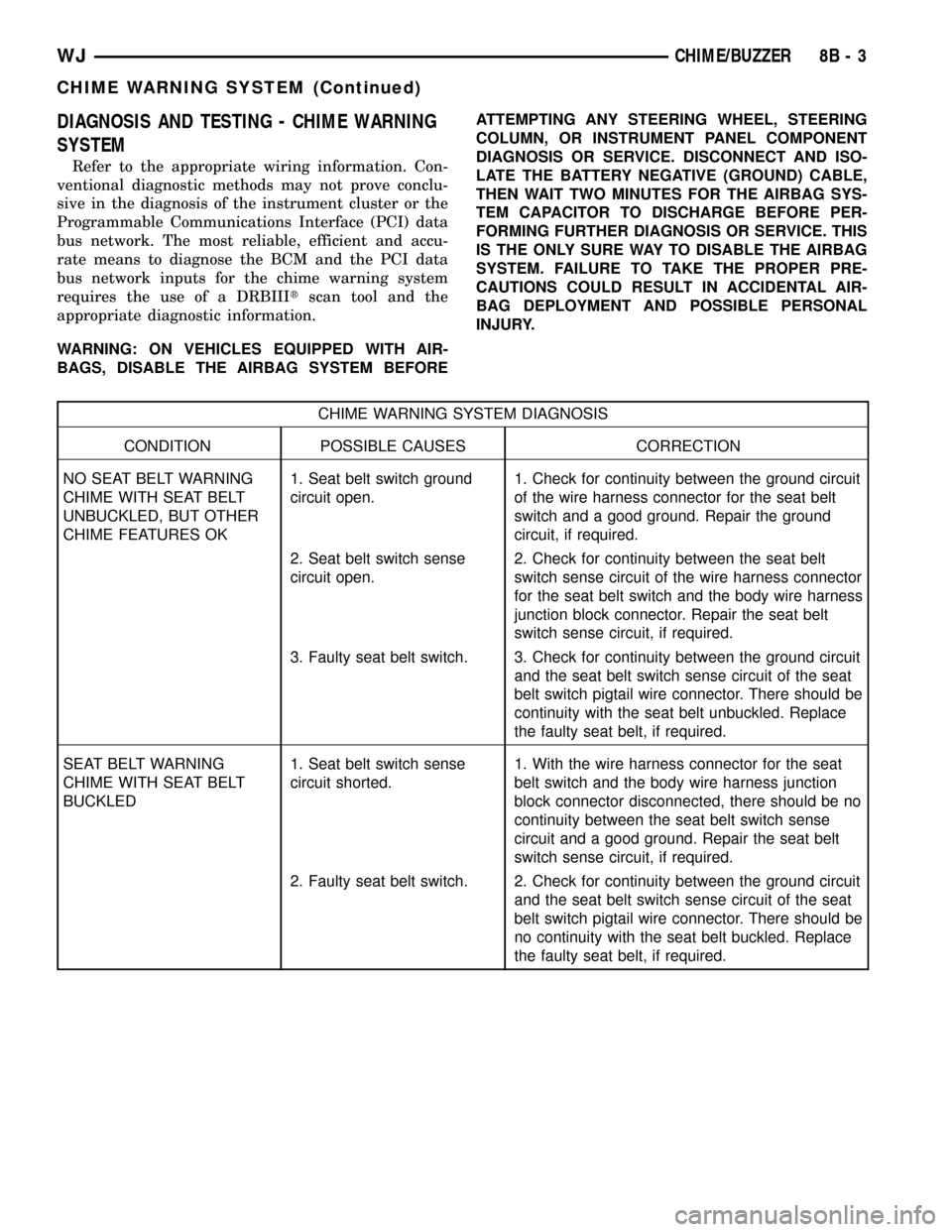

INSTALLATION - FRONT DOOR SPEAKER

(1) Position the speaker to the front door inner

panel.

(2) Reconnect the front door wire harness connec-

tor to the speaker connector receptacle.

(3) Position the speaker onto the front door inner

door panel.

(4) Install and tighten the four screws that secure

the speaker to the front door inner panel. Tighten

the screws to 2.2 N´m (20 in. lbs.).

(5) Install the trim panel onto the front door.

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

INSTALLATION) for the procedures.

(6) Reconnect the battery negative cable.

Fig. 19 Instrument Panel Speaker Remove/Install

1 - INSTRUMENT PANEL WIRE HARNESS

2 - INSTRUMENT PANEL SPEAKER

3 - SCREW (2)

Fig. 20 Front Door Speaker Remove/Install

1 - PLASTIC NUT (4)

2 - FRONT DOOR

3 - FRONT DOOR SPEAKER

4 - FRONT DOOR WIRE HARNESS

5 - SCREW (4)

WJAUDIO 8A - 25

SPEAKER (Continued)

Page 308 of 2199

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

Refer to the appropriate wiring information. Con-

ventional diagnostic methods may not prove conclu-

sive in the diagnosis of the instrument cluster or the

Programmable Communications Interface (PCI) data

bus network. The most reliable, efficient and accu-

rate means to diagnose the BCM and the PCI data

bus network inputs for the chime warning system

requires the use of a DRBIIItscan tool and the

appropriate diagnostic information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFOREATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

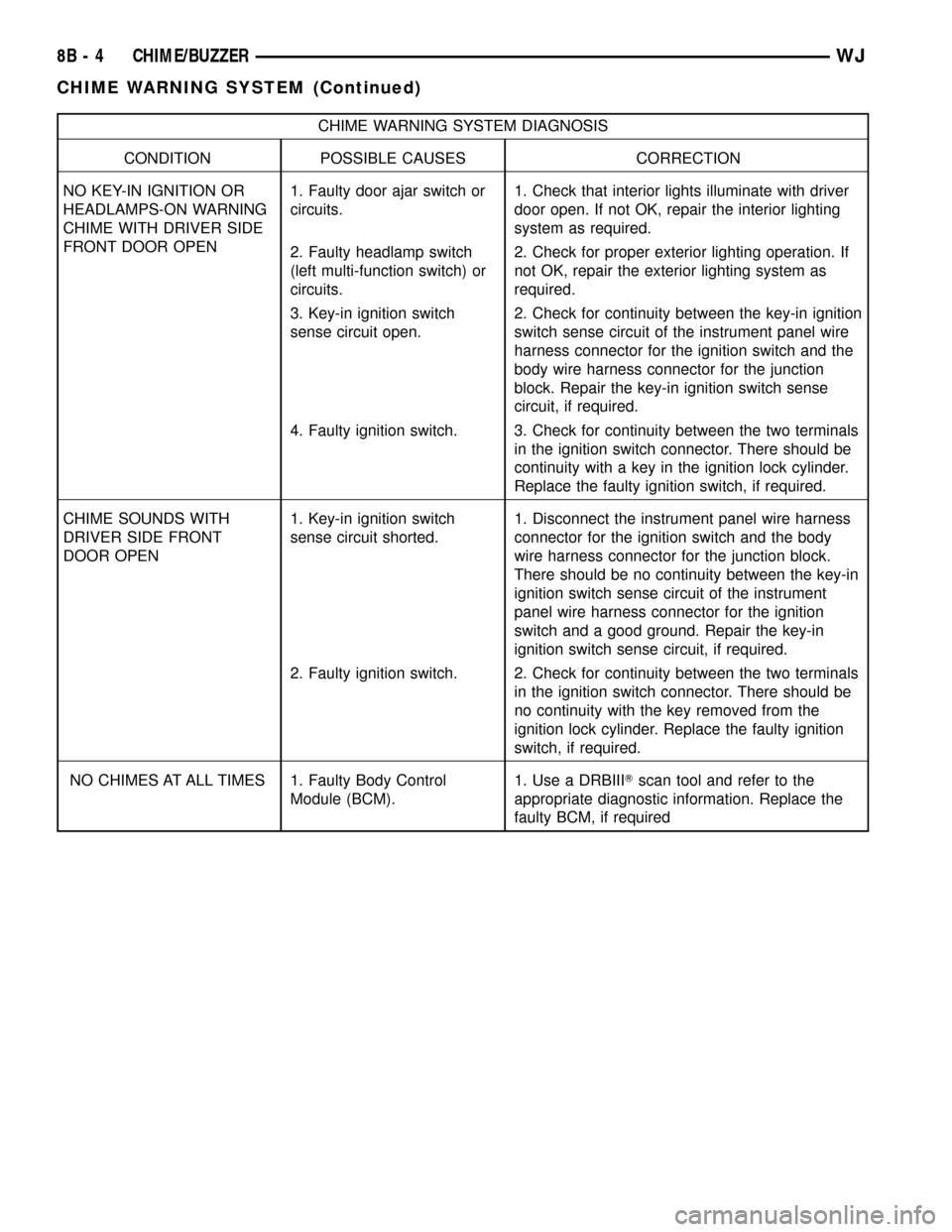

CHIME WARNING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO SEAT BELT WARNING

CHIME WITH SEAT BELT

UNBUCKLED, BUT OTHER

CHIME FEATURES OK1. Seat belt switch ground

circuit open.1. Check for continuity between the ground circuit

of the wire harness connector for the seat belt

switch and a good ground. Repair the ground

circuit, if required.

2. Seat belt switch sense

circuit open.2. Check for continuity between the seat belt

switch sense circuit of the wire harness connector

for the seat belt switch and the body wire harness

junction block connector. Repair the seat belt

switch sense circuit, if required.

3. Faulty seat belt switch. 3. Check for continuity between the ground circuit

and the seat belt switch sense circuit of the seat

belt switch pigtail wire connector. There should be

continuity with the seat belt unbuckled. Replace

the faulty seat belt, if required.

SEAT BELT WARNING

CHIME WITH SEAT BELT

BUCKLED1. Seat belt switch sense

circuit shorted.1. With the wire harness connector for the seat

belt switch and the body wire harness junction

block connector disconnected, there should be no

continuity between the seat belt switch sense

circuit and a good ground. Repair the seat belt

switch sense circuit, if required.

2. Faulty seat belt switch. 2. Check for continuity between the ground circuit

and the seat belt switch sense circuit of the seat

belt switch pigtail wire connector. There should be

no continuity with the seat belt buckled. Replace

the faulty seat belt, if required.

WJCHIME/BUZZER 8B - 3

CHIME WARNING SYSTEM (Continued)

Page 309 of 2199

CHIME WARNING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO KEY-IN IGNITION OR

HEADLAMPS-ON WARNING

CHIME WITH DRIVER SIDE

FRONT DOOR OPEN1. Faulty door ajar switch or

circuits.1. Check that interior lights illuminate with driver

door open. If not OK, repair the interior lighting

system as required.

2. Faulty headlamp switch

(left multi-function switch) or

circuits.2. Check for proper exterior lighting operation. If

not OK, repair the exterior lighting system as

required.

3. Key-in ignition switch

sense circuit open.2. Check for continuity between the key-in ignition

switch sense circuit of the instrument panel wire

harness connector for the ignition switch and the

body wire harness connector for the junction

block. Repair the key-in ignition switch sense

circuit, if required.

4. Faulty ignition switch. 3. Check for continuity between the two terminals

in the ignition switch connector. There should be

continuity with a key in the ignition lock cylinder.

Replace the faulty ignition switch, if required.

CHIME SOUNDS WITH

DRIVER SIDE FRONT

DOOR OPEN1. Key-in ignition switch

sense circuit shorted.1. Disconnect the instrument panel wire harness

connector for the ignition switch and the body

wire harness connector for the junction block.

There should be no continuity between the key-in

ignition switch sense circuit of the instrument

panel wire harness connector for the ignition

switch and a good ground. Repair the key-in

ignition switch sense circuit, if required.

2. Faulty ignition switch. 2. Check for continuity between the two terminals

in the ignition switch connector. There should be

no continuity with the key removed from the

ignition lock cylinder. Replace the faulty ignition

switch, if required.

NO CHIMES AT ALL TIMES 1. Faulty Body Control

Module (BCM).1. Use a DRBIIITscan tool and refer to the

appropriate diagnostic information. Replace the

faulty BCM, if required

8B - 4 CHIME/BUZZERWJ

CHIME WARNING SYSTEM (Continued)

Page 311 of 2199

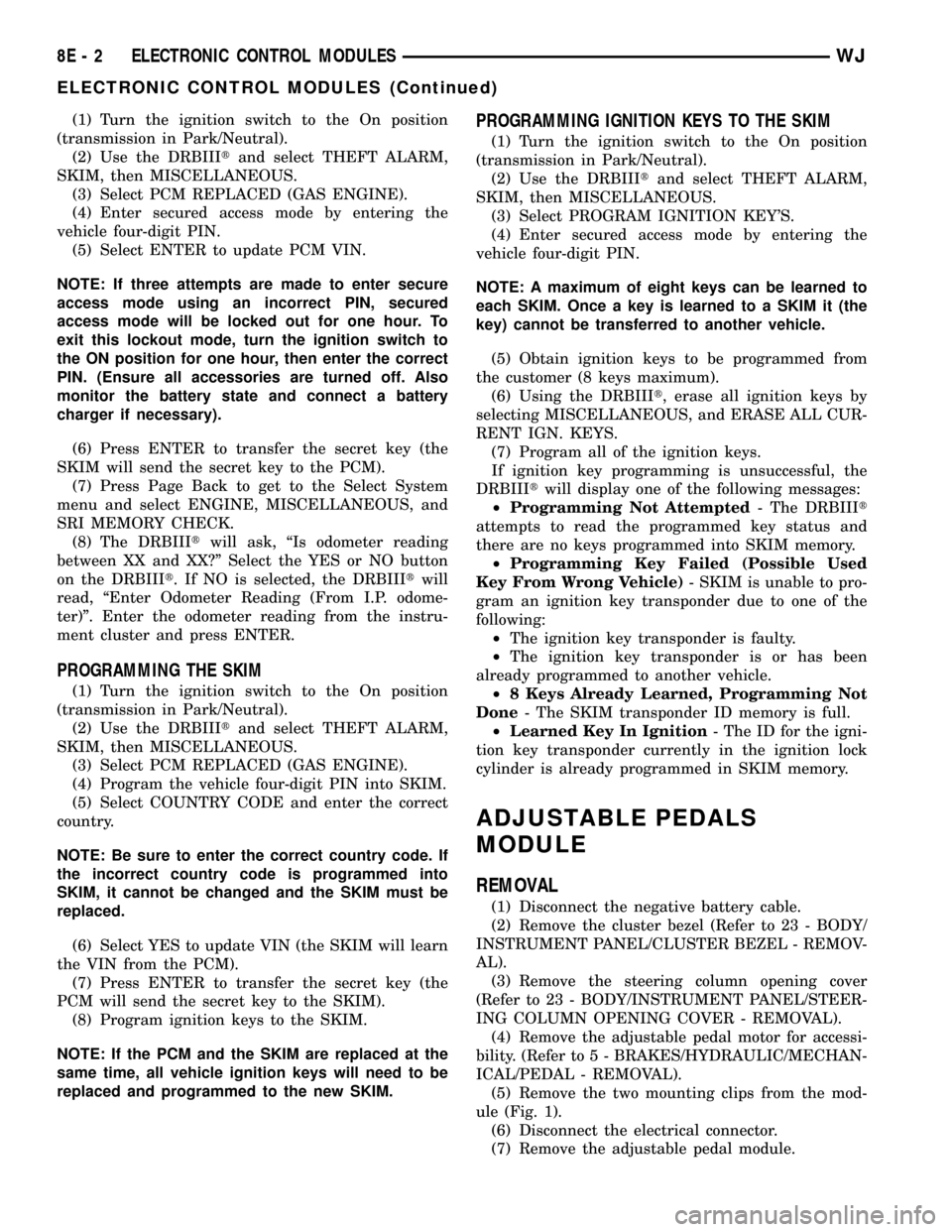

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition switch to

the ON position for one hour, then enter the correct

PIN. (Ensure all accessories are turned off. Also

monitor the battery state and connect a battery

charger if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIItwill ask, ªIs odometer reading

between XX and XX?º Select the YES or NO button

on the DRBIIIt. If NO is selected, the DRBIIItwill

read, ªEnter Odometer Reading (From I.P. odome-

ter)º. Enter the odometer reading from the instru-

ment cluster and press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, it cannot be changed and the SKIM must be

replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle ignition keys will need to be

replaced and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

(5) Obtain ignition keys to be programmed from

the customer (8 keys maximum).

(6) Using the DRBIIIt, erase all ignition keys by

selecting MISCELLANEOUS, and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all of the ignition keys.

If ignition key programming is unsuccessful, the

DRBIIItwill display one of the following messages:

²Programming Not Attempted- The DRBIIIt

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

²Programming Key Failed (Possible Used

Key From Wrong Vehicle)- SKIM is unable to pro-

gram an ignition key transponder due to one of the

following:

²The ignition key transponder is faulty.

²The ignition key transponder is or has been

already programmed to another vehicle.

²8 Keys Already Learned, Programming Not

Done- The SKIM transponder ID memory is full.

²Learned Key In Ignition- The ID for the igni-

tion key transponder currently in the ignition lock

cylinder is already programmed in SKIM memory.

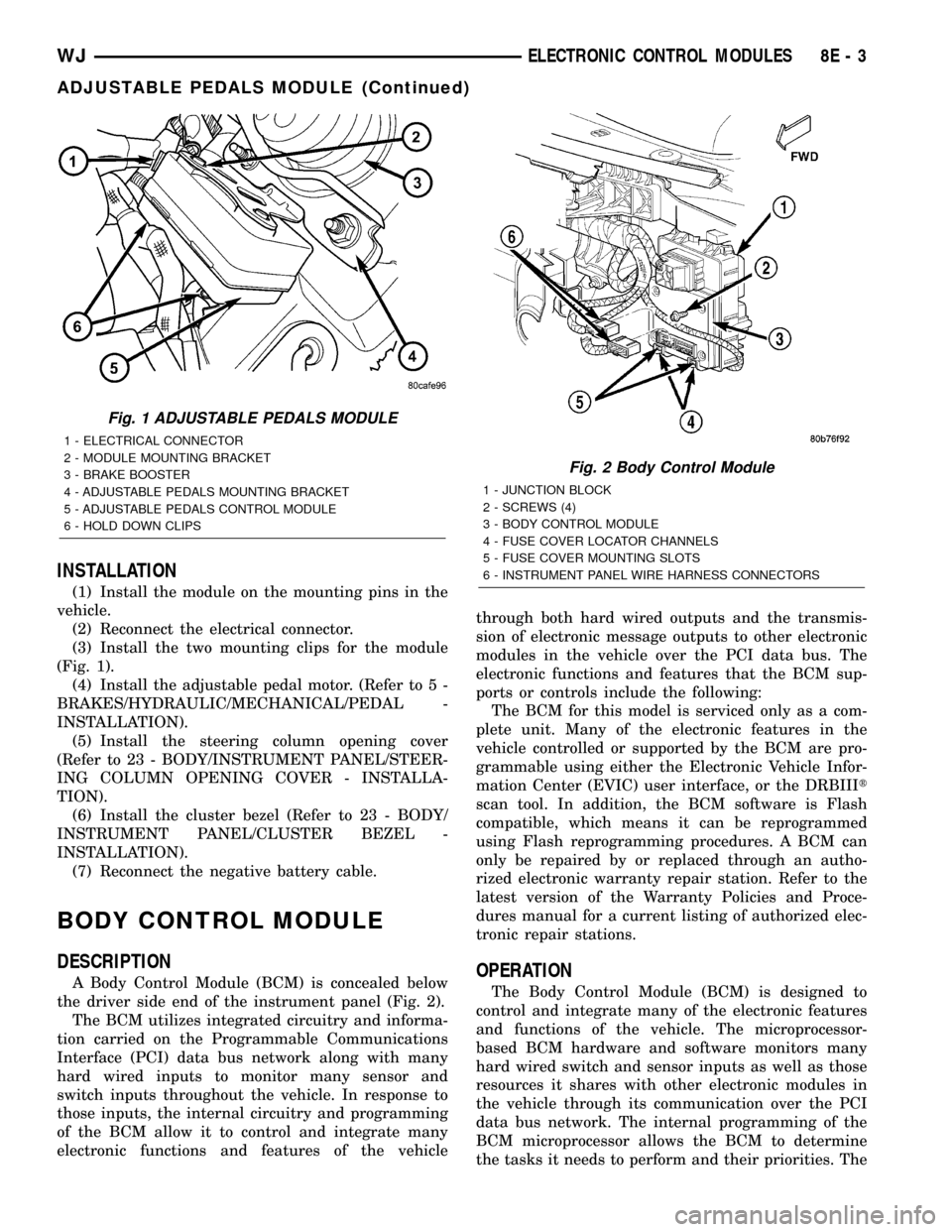

ADJUSTABLE PEDALS

MODULE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the adjustable pedal motor for accessi-

bility. (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL).

(5) Remove the two mounting clips from the mod-

ule (Fig. 1).

(6) Disconnect the electrical connector.

(7) Remove the adjustable pedal module.

8E - 2 ELECTRONIC CONTROL MODULESWJ

ELECTRONIC CONTROL MODULES (Continued)

Page 312 of 2199

INSTALLATION

(1) Install the module on the mounting pins in the

vehicle.

(2) Reconnect the electrical connector.

(3) Install the two mounting clips for the module

(Fig. 1).

(4) Install the adjustable pedal motor. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION).

(5) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(6) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(7) Reconnect the negative battery cable.

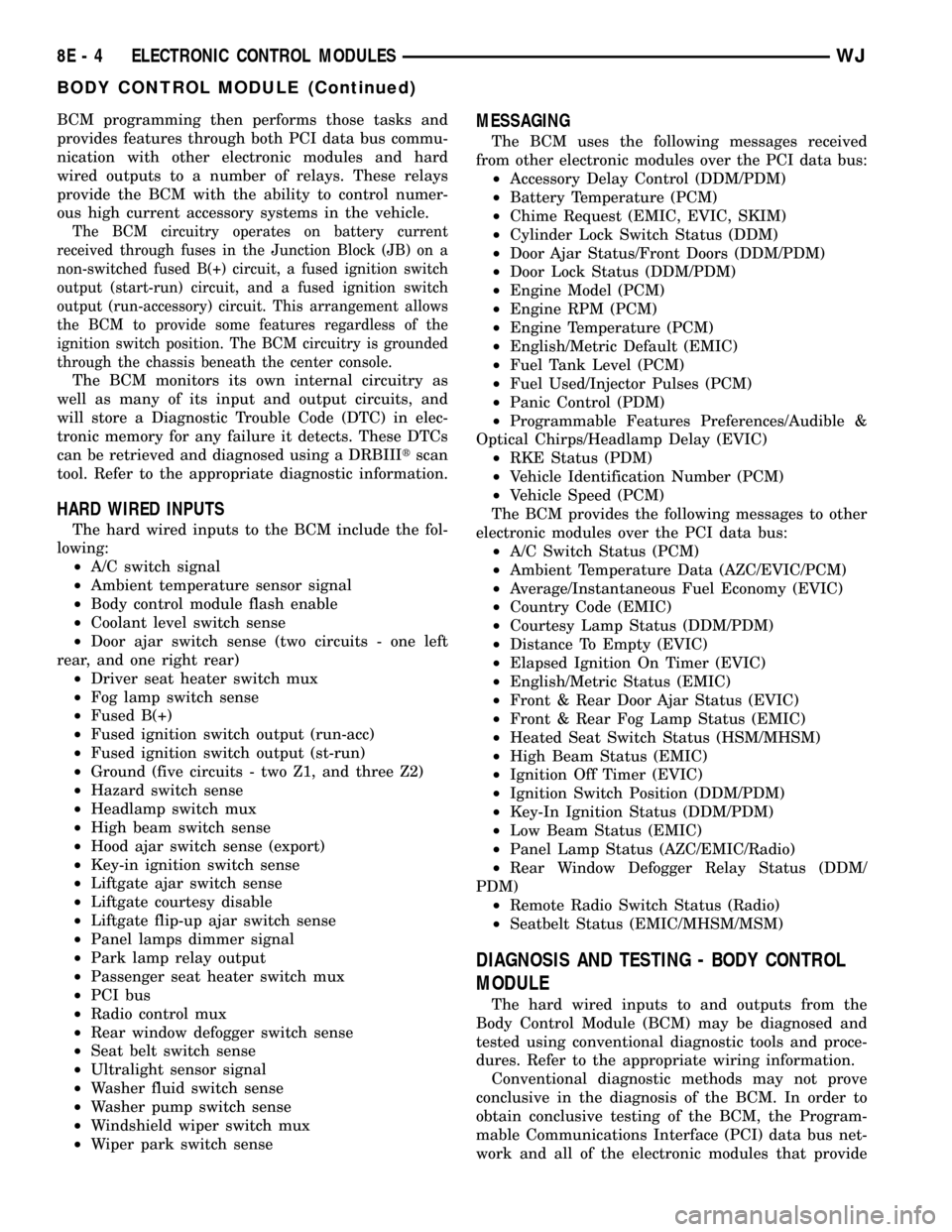

BODY CONTROL MODULE

DESCRIPTION

A Body Control Module (BCM) is concealed below

the driver side end of the instrument panel (Fig. 2).

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehiclethrough both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. The

electronic functions and features that the BCM sup-

ports or controls include the following:

The BCM for this model is serviced only as a com-

plete unit. Many of the electronic features in the

vehicle controlled or supported by the BCM are pro-

grammable using either the Electronic Vehicle Infor-

mation Center (EVIC) user interface, or the DRBIIIt

scan tool. In addition, the BCM software is Flash

compatible, which means it can be reprogrammed

using Flash reprogramming procedures. A BCM can

only be repaired by or replaced through an autho-

rized electronic warranty repair station. Refer to the

latest version of the Warranty Policies and Proce-

dures manual for a current listing of authorized elec-

tronic repair stations.OPERATION

The Body Control Module (BCM) is designed to

control and integrate many of the electronic features

and functions of the vehicle. The microprocessor-

based BCM hardware and software monitors many

hard wired switch and sensor inputs as well as those

resources it shares with other electronic modules in

the vehicle through its communication over the PCI

data bus network. The internal programming of the

BCM microprocessor allows the BCM to determine

the tasks it needs to perform and their priorities. The

Fig. 1 ADJUSTABLE PEDALS MODULE

1 - ELECTRICAL CONNECTOR

2 - MODULE MOUNTING BRACKET

3 - BRAKE BOOSTER

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - ADJUSTABLE PEDALS CONTROL MODULE

6 - HOLD DOWN CLIPS

Fig. 2 Body Control Module

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

WJELECTRONIC CONTROL MODULES 8E - 3

ADJUSTABLE PEDALS MODULE (Continued)

Page 313 of 2199

BCM programming then performs those tasks and

provides features through both PCI data bus commu-

nication with other electronic modules and hard

wired outputs to a number of relays. These relays

provide the BCM with the ability to control numer-

ous high current accessory systems in the vehicle.

The BCM circuitry operates on battery current

received through fuses in the Junction Block (JB) on a

non-switched fused B(+) circuit, a fused ignition switch

output (start-run) circuit, and a fused ignition switch

output (run-accessory) circuit. This arrangement allows

the BCM to provide some features regardless of the

ignition switch position. The BCM circuitry is grounded

through the chassis beneath the center console.

The BCM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the BCM include the fol-

lowing:

²A/C switch signal

²Ambient temperature sensor signal

²Body control module flash enable

²Coolant level switch sense

²Door ajar switch sense (two circuits - one left

rear, and one right rear)

²Driver seat heater switch mux

²Fog lamp switch sense

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (st-run)

²Ground (five circuits - two Z1, and three Z2)

²Hazard switch sense

²Headlamp switch mux

²High beam switch sense

²Hood ajar switch sense (export)

²Key-in ignition switch sense

²Liftgate ajar switch sense

²Liftgate courtesy disable

²Liftgate flip-up ajar switch sense

²Panel lamps dimmer signal

²Park lamp relay output

²Passenger seat heater switch mux

²PCI bus

²Radio control mux

²Rear window defogger switch sense

²Seat belt switch sense

²Ultralight sensor signal

²Washer fluid switch sense

²Washer pump switch sense

²Windshield wiper switch mux

²Wiper park switch sense

MESSAGING

The BCM uses the following messages received

from other electronic modules over the PCI data bus:

²Accessory Delay Control (DDM/PDM)

²Battery Temperature (PCM)

²Chime Request (EMIC, EVIC, SKIM)

²Cylinder Lock Switch Status (DDM)

²Door Ajar Status/Front Doors (DDM/PDM)

²Door Lock Status (DDM/PDM)

²Engine Model (PCM)

²Engine RPM (PCM)

²Engine Temperature (PCM)

²English/Metric Default (EMIC)

²Fuel Tank Level (PCM)

²Fuel Used/Injector Pulses (PCM)

²Panic Control (PDM)

²Programmable Features Preferences/Audible &

Optical Chirps/Headlamp Delay (EVIC)

²RKE Status (PDM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Switch Status (PCM)

²Ambient Temperature Data (AZC/EVIC/PCM)

²Average/Instantaneous Fuel Economy (EVIC)

²Country Code (EMIC)

²Courtesy Lamp Status (DDM/PDM)

²Distance To Empty (EVIC)

²Elapsed Ignition On Timer (EVIC)

²English/Metric Status (EMIC)

²Front & Rear Door Ajar Status (EVIC)

²Front & Rear Fog Lamp Status (EMIC)

²Heated Seat Switch Status (HSM/MHSM)

²High Beam Status (EMIC)

²Ignition Off Timer (EVIC)

²Ignition Switch Position (DDM/PDM)

²Key-In Ignition Status (DDM/PDM)

²Low Beam Status (EMIC)

²Panel Lamp Status (AZC/EMIC/Radio)

²Rear Window Defogger Relay Status (DDM/

PDM)

²Remote Radio Switch Status (Radio)

²Seatbelt Status (EMIC/MHSM/MSM)

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE

The hard wired inputs to and outputs from the

Body Control Module (BCM) may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. Refer to the appropriate wiring information.

Conventional diagnostic methods may not prove

conclusive in the diagnosis of the BCM. In order to

obtain conclusive testing of the BCM, the Program-

mable Communications Interface (PCI) data bus net-

work and all of the electronic modules that provide

8E - 4 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 314 of 2199

inputs to or receive outputs from the BCM must also

be checked. The most reliable, efficient, and accurate

means to diagnose the BCM, the PCI data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the BCM requires the use

of a DRBIIItscan tool and the appropriate diagnostic

information. The DRBIIItscan tool can provide con-

firmation that the PCI data bus network is func-

tional, that all of the modules are sending and

receiving the proper messages over the PCI data bus,

and that the BCM is receiving the proper hard wired

inputs and responding with the proper hard wired

outputs needed to perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

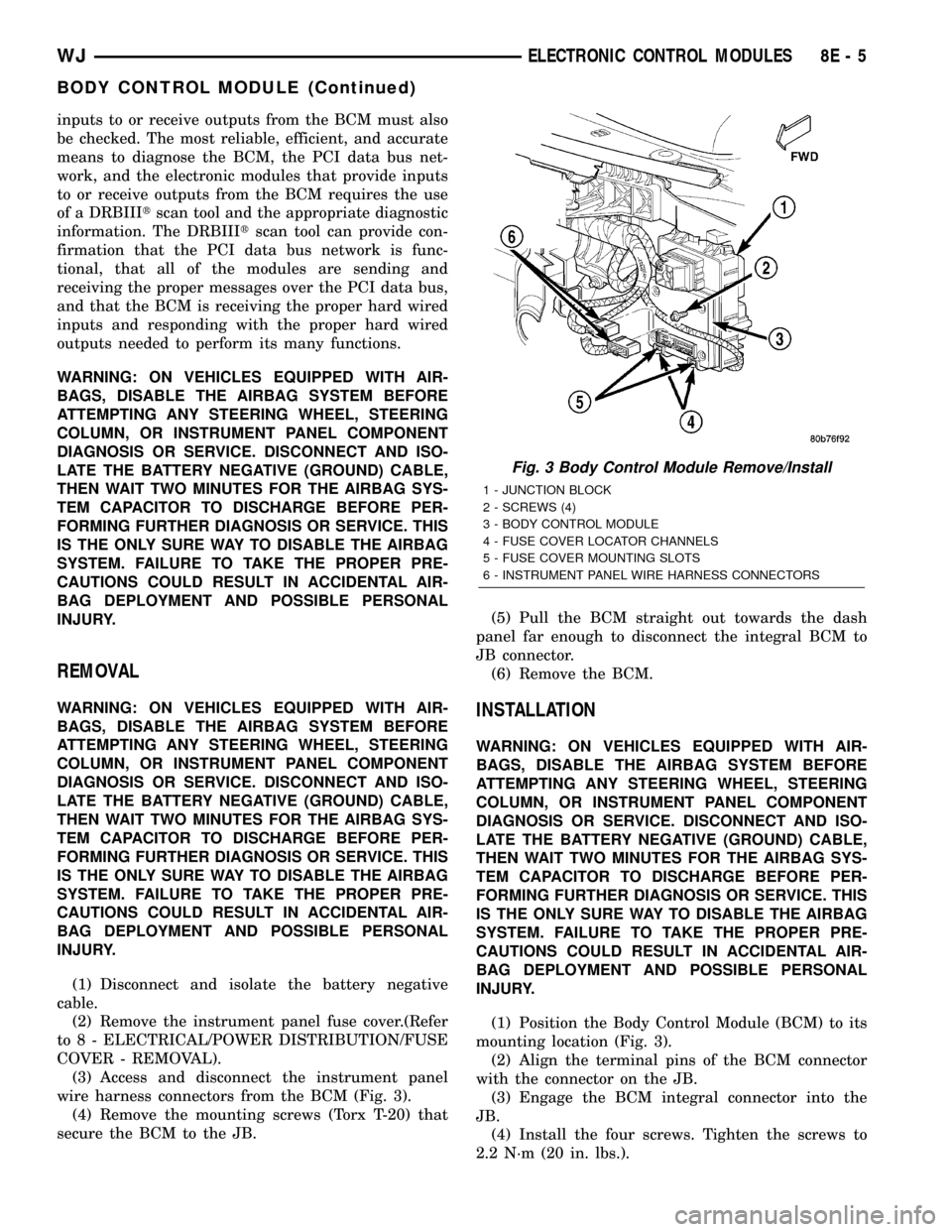

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel fuse cover.(Refer

to 8 - ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - REMOVAL).

(3) Access and disconnect the instrument panel

wire harness connectors from the BCM (Fig. 3).

(4) Remove the mounting screws (Torx T-20) that

secure the BCM to the JB.(5) Pull the BCM straight out towards the dash

panel far enough to disconnect the integral BCM to

JB connector.

(6) Remove the BCM.INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the Body Control Module (BCM) to its

mounting location (Fig. 3).

(2) Align the terminal pins of the BCM connector

with the connector on the JB.

(3) Engage the BCM integral connector into the

JB.

(4) Install the four screws. Tighten the screws to

2.2 N´m (20 in. lbs.).

Fig. 3 Body Control Module Remove/Install

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

WJELECTRONIC CONTROL MODULES 8E - 5

BODY CONTROL MODULE (Continued)

Page 315 of 2199

(5) Connect the two instrument panel wire harness

connectors to the BCM.

(6) Reinstall the instrument panel fuse cover to

the bottom of the BCM and JB unit. (Refer to 8 -

ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - INSTALLATION).

(7) Connect the battery negative cable.

COMMUNICATION

DESCRIPTION

The Programmable Communication Interface (PCI)

data bus system is a single wire multiplex system

used for vehicle communications. Multiplexing is a

system that enables the transmission of several mes-

sages over a single channel or circuit.

Many of the control modules in a vehicle require

information from the same sensing device. Multiplex-

ing reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the con-

troller sensor inputs to every other controller on the

data bus, more function and feature capabilities are

possible.

A multiplex system allows the information flowing

between controllers to be monitored using a diagnos-

tic scan tool. This system allows a control module to

broadcast message data out onto the bus where all

other control modules can read the messages that are

being sent. When a module reads a message on the

data bus that it requires, it relays that message to

its microprocessor. Each module ignores the mes-

sages on the data bus that it dosen't recognize.

OPERATION

Data exchange between modules is achieved by

serial transmission of encoded data over a single wire

broadcast network. The PCI data bus messages are

carried over the bus in the form of Variable Pulse

Width Modulated (VPWM) signals. The PCI data bus

speed is an average 10.4 Kilo-bits per second (Kbps).

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. The Powertrain

Control Module (PCM) is the only dominant node for

the PCI data bus system.

The PCI bus uses low and high voltage levels to

generate signals. The voltage on the buss varies

between zero and seven and one-half volts. The lowand high voltage levels are generated by means of

variable-pulse width modulation to form signals of

varying length.

When a module is transmitting on the bus, it is

reading the bus at the same time to ensure message

integrity.

Each module is capable of transmitting and receiv-

ing data simultaneously.

The PCI data bus can be monitored using the

DRBIIItscan tool. It is possible for the bus to pass

all DRBIIIttests and still be faulty if the voltage

parameters are all within the specified range and

false messages are being sent.

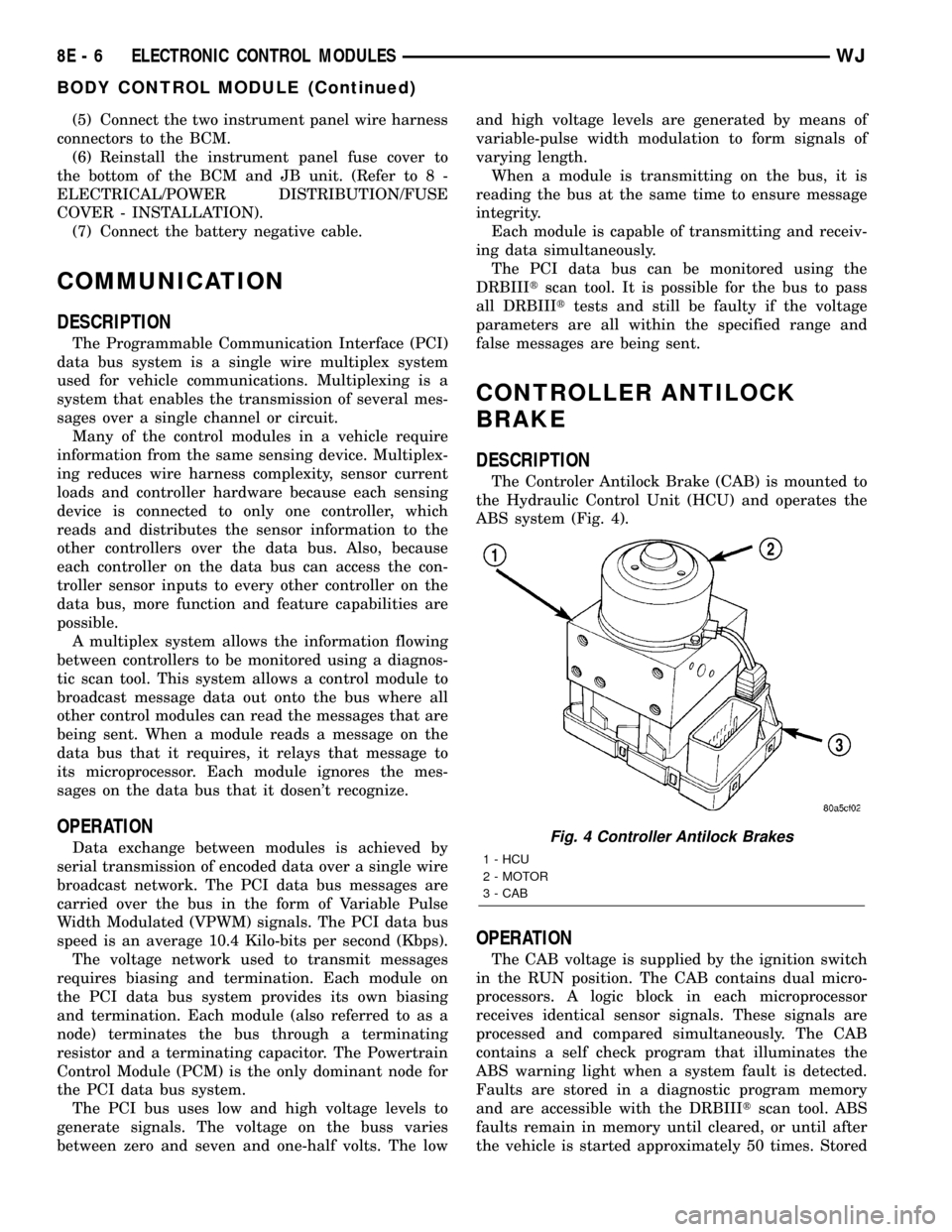

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system (Fig. 4).

OPERATION

The CAB voltage is supplied by the ignition switch

in the RUN position. The CAB contains dual micro-

processors. A logic block in each microprocessor

receives identical sensor signals. These signals are

processed and compared simultaneously. The CAB

contains a self check program that illuminates the

ABS warning light when a system fault is detected.

Faults are stored in a diagnostic program memory

and are accessible with the DRBIIItscan tool. ABS

faults remain in memory until cleared, or until after

the vehicle is started approximately 50 times. Stored

Fig. 4 Controller Antilock Brakes

1 - HCU

2 - MOTOR

3 - CAB

8E - 6 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 316 of 2199

faults arenoterased if the battery is disconnected.

(Fig. 4)

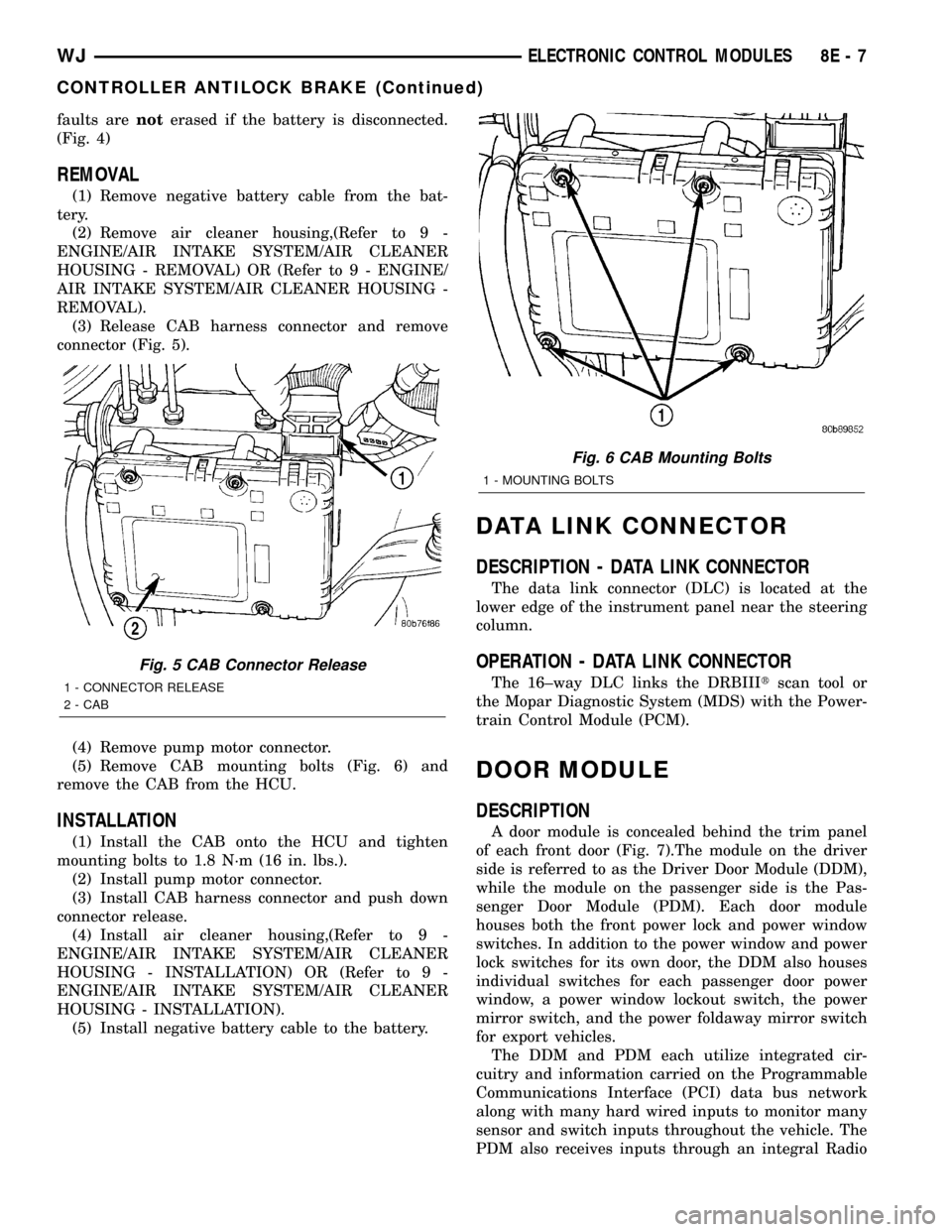

REMOVAL

(1) Remove negative battery cable from the bat-

tery.

(2) Remove air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL) OR (Refer to 9 - ENGINE/

AIR INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Release CAB harness connector and remove

connector (Fig. 5).

(4) Remove pump motor connector.

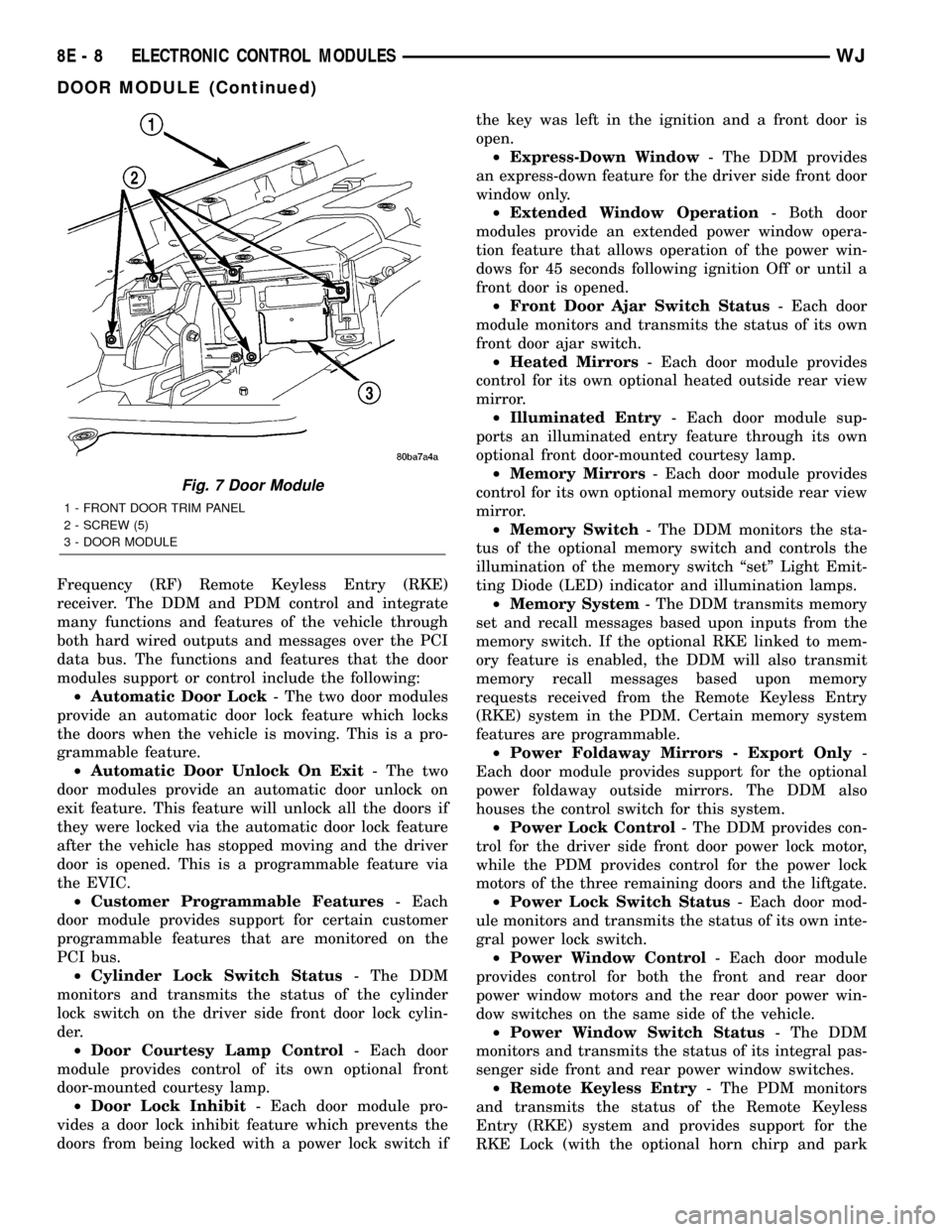

(5) Remove CAB mounting bolts (Fig. 6) and

remove the CAB from the HCU.

INSTALLATION

(1) Install the CAB onto the HCU and tighten

mounting bolts to 1.8 N´m (16 in. lbs.).

(2) Install pump motor connector.

(3) Install CAB harness connector and push down

connector release.

(4) Install air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION) OR (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(5) Install negative battery cable to the battery.

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR

The data link connector (DLC) is located at the

lower edge of the instrument panel near the steering

column.

OPERATION - DATA LINK CONNECTOR

The 16±way DLC links the DRBIIItscan tool or

the Mopar Diagnostic System (MDS) with the Power-

train Control Module (PCM).

DOOR MODULE

DESCRIPTION

A door module is concealed behind the trim panel

of each front door (Fig. 7).The module on the driver

side is referred to as the Driver Door Module (DDM),

while the module on the passenger side is the Pas-

senger Door Module (PDM). Each door module

houses both the front power lock and power window

switches. In addition to the power window and power

lock switches for its own door, the DDM also houses

individual switches for each passenger door power

window, a power window lockout switch, the power

mirror switch, and the power foldaway mirror switch

for export vehicles.

The DDM and PDM each utilize integrated cir-

cuitry and information carried on the Programmable

Communications Interface (PCI) data bus network

along with many hard wired inputs to monitor many

sensor and switch inputs throughout the vehicle. The

PDM also receives inputs through an integral Radio

Fig. 5 CAB Connector Release

1 - CONNECTOR RELEASE

2 - CAB

Fig. 6 CAB Mounting Bolts

1 - MOUNTING BOLTS

WJELECTRONIC CONTROL MODULES 8E - 7

CONTROLLER ANTILOCK BRAKE (Continued)

Page 317 of 2199

Frequency (RF) Remote Keyless Entry (RKE)

receiver. The DDM and PDM control and integrate

many functions and features of the vehicle through

both hard wired outputs and messages over the PCI

data bus. The functions and features that the door

modules support or control include the following:

²Automatic Door Lock- The two door modules

provide an automatic door lock feature which locks

the doors when the vehicle is moving. This is a pro-

grammable feature.

²Automatic Door Unlock On Exit- The two

door modules provide an automatic door unlock on

exit feature. This feature will unlock all the doors if

they were locked via the automatic door lock feature

after the vehicle has stopped moving and the driver

door is opened. This is a programmable feature via

the EVIC.

²Customer Programmable Features- Each

door module provides support for certain customer

programmable features that are monitored on the

PCI bus.

²Cylinder Lock Switch Status- The DDM

monitors and transmits the status of the cylinder

lock switch on the driver side front door lock cylin-

der.

²Door Courtesy Lamp Control- Each door

module provides control of its own optional front

door-mounted courtesy lamp.

²Door Lock Inhibit- Each door module pro-

vides a door lock inhibit feature which prevents the

doors from being locked with a power lock switch ifthe key was left in the ignition and a front door is

open.

²Express-Down Window- The DDM provides

an express-down feature for the driver side front door

window only.

²Extended Window Operation- Both door

modules provide an extended power window opera-

tion feature that allows operation of the power win-

dows for 45 seconds following ignition Off or until a

front door is opened.

²Front Door Ajar Switch Status- Each door

module monitors and transmits the status of its own

front door ajar switch.

²Heated Mirrors- Each door module provides

control for its own optional heated outside rear view

mirror.

²Illuminated Entry- Each door module sup-

ports an illuminated entry feature through its own

optional front door-mounted courtesy lamp.

²Memory Mirrors- Each door module provides

control for its own optional memory outside rear view

mirror.

²Memory Switch- The DDM monitors the sta-

tus of the optional memory switch and controls the

illumination of the memory switch ªsetº Light Emit-

ting Diode (LED) indicator and illumination lamps.

²Memory System- The DDM transmits memory

set and recall messages based upon inputs from the

memory switch. If the optional RKE linked to mem-

ory feature is enabled, the DDM will also transmit

memory recall messages based upon memory

requests received from the Remote Keyless Entry

(RKE) system in the PDM. Certain memory system

features are programmable.

²Power Foldaway Mirrors - Export Only-

Each door module provides support for the optional

power foldaway outside mirrors. The DDM also

houses the control switch for this system.

²Power Lock Control- The DDM provides con-

trol for the driver side front door power lock motor,

while the PDM provides control for the power lock

motors of the three remaining doors and the liftgate.

²Power Lock Switch Status- Each door mod-

ule monitors and transmits the status of its own inte-

gral power lock switch.

²Power Window Control- Each door module

provides control for both the front and rear door

power window motors and the rear door power win-

dow switches on the same side of the vehicle.

²Power Window Switch Status- The DDM

monitors and transmits the status of its integral pas-

senger side front and rear power window switches.

²Remote Keyless Entry- The PDM monitors

and transmits the status of the Remote Keyless

Entry (RKE) system and provides support for the

RKE Lock (with the optional horn chirp and park

Fig. 7 Door Module

1 - FRONT DOOR TRIM PANEL

2 - SCREW (5)

3 - DOOR MODULE

8E - 8 ELECTRONIC CONTROL MODULESWJ

DOOR MODULE (Continued)