lighting JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 606 of 2199

cluster circuitry that controls the lamp, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). If the instrument cluster turns

on the SKIS indicator lamp after the bulb test, either

solid or flashing, it indicates that a SKIS malfunction

has occurred or that the SKIS is inoperative. For

proper diagnosis of the SKIS, the PCI data bus, or

the message inputs to the instrument cluster that

control the SKIS indicator lamp, a DRBIIItscan tool

and the appropriate diagnostic information are

required.

TRANSPONDER KEY

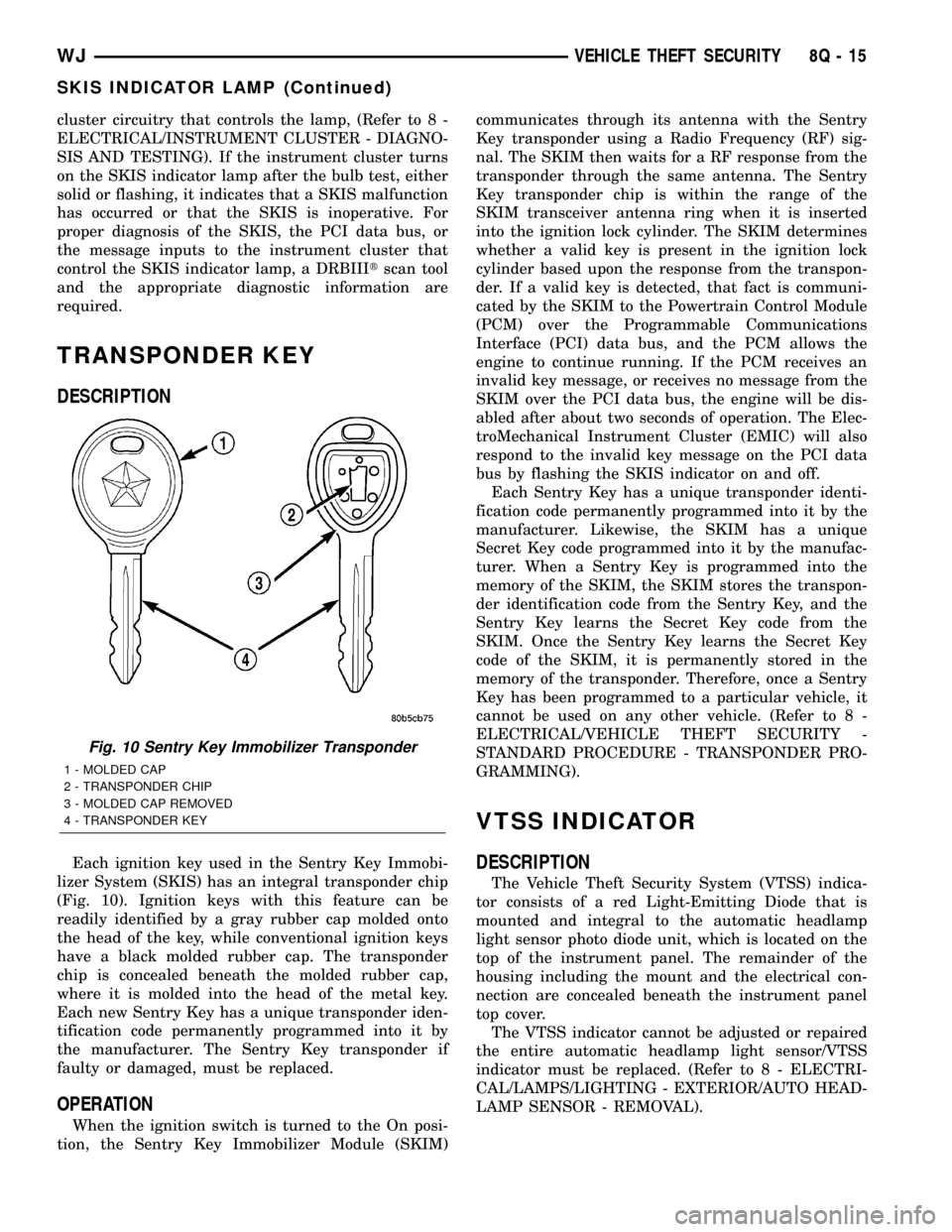

DESCRIPTION

Each ignition key used in the Sentry Key Immobi-

lizer System (SKIS) has an integral transponder chip

(Fig. 10). Ignition keys with this feature can be

readily identified by a gray rubber cap molded onto

the head of the key, while conventional ignition keys

have a black molded rubber cap. The transponder

chip is concealed beneath the molded rubber cap,

where it is molded into the head of the metal key.

Each new Sentry Key has a unique transponder iden-

tification code permanently programmed into it by

the manufacturer. The Sentry Key transponder if

faulty or damaged, must be replaced.

OPERATION

When the ignition switch is turned to the On posi-

tion, the Sentry Key Immobilizer Module (SKIM)communicates through its antenna with the Sentry

Key transponder using a Radio Frequency (RF) sig-

nal. The SKIM then waits for a RF response from the

transponder through the same antenna. The Sentry

Key transponder chip is within the range of the

SKIM transceiver antenna ring when it is inserted

into the ignition lock cylinder. The SKIM determines

whether a valid key is present in the ignition lock

cylinder based upon the response from the transpon-

der. If a valid key is detected, that fact is communi-

cated by the SKIM to the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus, and the PCM allows the

engine to continue running. If the PCM receives an

invalid key message, or receives no message from the

SKIM over the PCI data bus, the engine will be dis-

abled after about two seconds of operation. The Elec-

troMechanical Instrument Cluster (EMIC) will also

respond to the invalid key message on the PCI data

bus by flashing the SKIS indicator on and off.

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

Secret Key code programmed into it by the manufac-

turer. When a Sentry Key is programmed into the

memory of the SKIM, the SKIM stores the transpon-

der identification code from the Sentry Key, and the

Sentry Key learns the Secret Key code from the

SKIM. Once the Sentry Key learns the Secret Key

code of the SKIM, it is permanently stored in the

memory of the transponder. Therefore, once a Sentry

Key has been programmed to a particular vehicle, it

cannot be used on any other vehicle. (Refer to 8 -

ELECTRICAL/VEHICLE THEFT SECURITY -

STANDARD PROCEDURE - TRANSPONDER PRO-

GRAMMING).

VTSS INDICATOR

DESCRIPTION

The Vehicle Theft Security System (VTSS) indica-

tor consists of a red Light-Emitting Diode that is

mounted and integral to the automatic headlamp

light sensor photo diode unit, which is located on the

top of the instrument panel. The remainder of the

housing including the mount and the electrical con-

nection are concealed beneath the instrument panel

top cover.

The VTSS indicator cannot be adjusted or repaired

the entire automatic headlamp light sensor/VTSS

indicator must be replaced. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/AUTO HEAD-

LAMP SENSOR - REMOVAL).

Fig. 10 Sentry Key Immobilizer Transponder

1 - MOLDED CAP

2 - TRANSPONDER CHIP

3 - MOLDED CAP REMOVED

4 - TRANSPONDER KEY

WJVEHICLE THEFT SECURITY 8Q - 15

SKIS INDICATOR LAMP (Continued)

Page 642 of 2199

stalk is moved to the rear Wash position, the Wash

position circuitry within the switch directs battery

current to the rear washer pump/motor unit, and to

both the rear wiper motor control and rear washer

switch output signal inputs of the rear wiper module

electronic circuitry, which causes the wiper motor to

run at a fixed cycle for as long as the Wash mode is

selected plus about three additional fixed wipe cycles.

The rear wiper module electronic circuitry controls

the switching of battery current to the rear wiper

motor brush, which controls wiper motor operation.

The intermittent wipe and wipe-after-wash features

of the rear wiper and washer system are both pro-

vided by the rear wiper module electronic circuitry.

The rear wiper module electronic circuitry also mon-

itors the liftgate flip-up glass ajar switch and will

park the rear wiper blade off of the glass any time it

senses that the liftgate flip-up glass is ajar, the igni-

tion switch is turned to the Off position, or the right

multi-function switch control sleeve is moved to the

Off position. This feature ensures that the rear wiper

blade will not interfere with or be damaged by the

operation of the liftgate flip-up glass. However, if the

ignition switch is turned to the Off position or the

liftgate flip-up glass is opened while the rear wiper is

operating, the right multi-function switch control

sleeve must be cycled to the Off position and back to

the On or Delay position after the ignition switch is

turned back On or the liftgate flip-up glass is closed

before the rear wiper will operate again.

Refer to the owner's manual in the vehicle glove

box for more information on the features and opera-

tion of the rear wiper and washer system.

DIAGNOSIS AND TESTING - REAR WIPER &

WASHER SYSTEM

WIPER SYSTEM

The diagnosis found here addresses an electrically

inoperative rear wiper system. If the rear wiper

motor operates, but the wiper does not move on the

liftgate glass, replace the faulty rear wiper module. If

the wiper operates, but chatters, lifts, or does not

clear the glass, clean and inspect the wiper system

components as required. (Refer to 8 - ELECTRICAL/

REAR WIPERS/WASHERS - INSPECTION) and

(Refer to 8 - ELECTRICAL/REAR WIPERS/WASH-

ERS - CLEANING). Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check that the interior lighting switch on the

control stalk of the left multi-function switch is not

in the dome lamp disable position. With all four

doors and the liftgate closed, open the liftgate flip-up

glass. The interior lamps should light. If not, depress

the cargo lamp lens to actuate the cargo lamp defeat

switch and the interior lamps should light. Close all

four doors, the liftgate and the liftgate flip-up glass.

Note whether the interior lamps remain lighted.

They should turn off after about thirty seconds. If

OK, go to Step 2. If not OK, go to Step 9.

(2) Check the fused B(+) fuse (Fuse8-15ampere)

in the Junction Block (JB). If OK, go to Step 3. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(3) Check for battery voltage at the fused B(+) fuse

(Fuse8-15ampere) in the JB. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(4) Check the fused ignition switch output (run-

acc) fuse (Fuse 29 - 10 ampere) in the JB. If OK, go

to Step 5. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-acc) fuse (Fuse 29 - 10 ampere) in the

JB. If OK, turn the ignition switch to the Off position

and go to Step 6. If not OK, repair the open fused

ignition switch output (run-acc) circuit between the

JB and the ignition switch as required.

(6) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the right multi-function switch from the

switch connector receptacle. Reconnect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run-acc) circuit cavity of the

instrument panel wire harness connector for the

right multi-function switch. If OK, go to Step 7. If

not OK, repair the open fused ignition switch output

WJREAR WIPERS/WASHERS 8R - 35

REAR WIPERS/WASHERS (Continued)

Page 654 of 2199

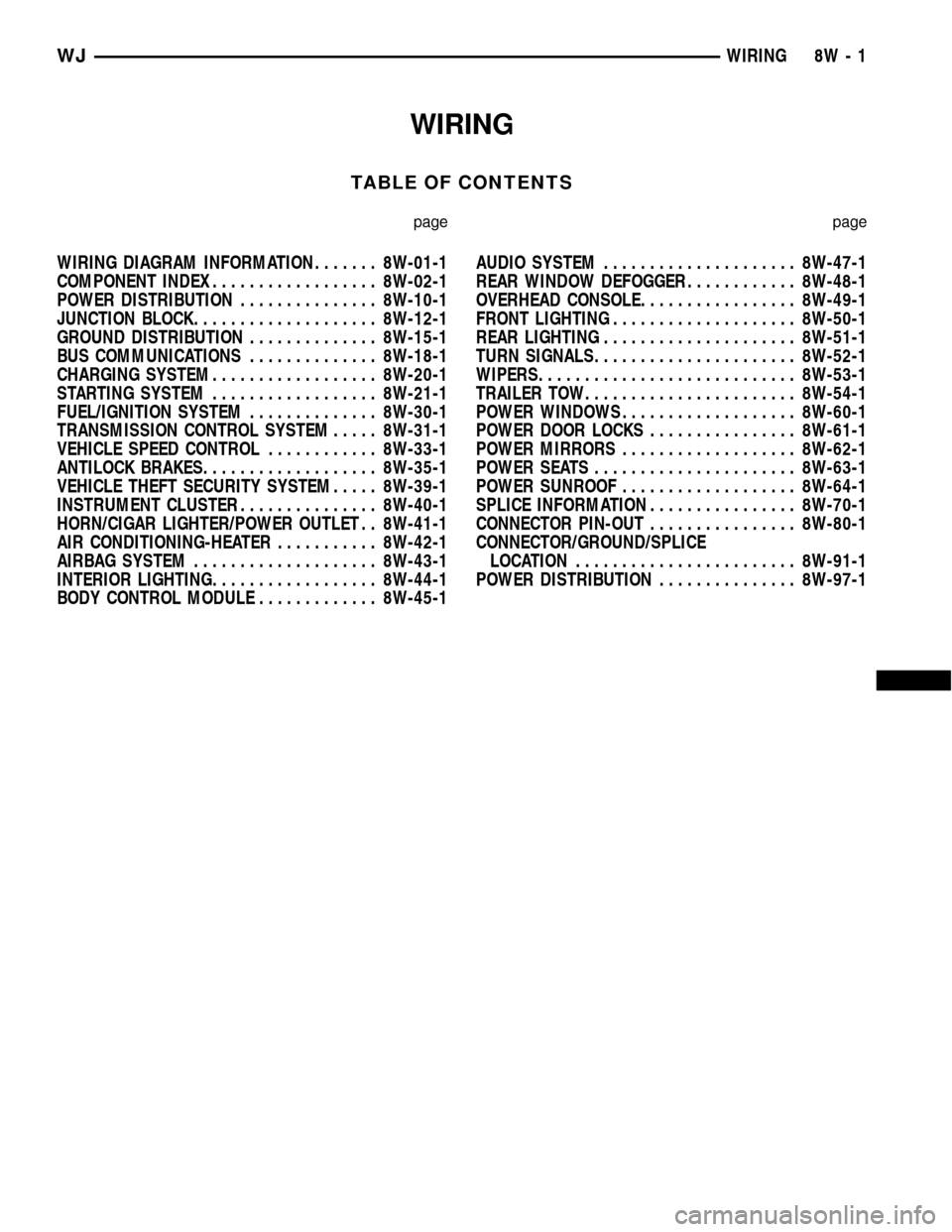

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

JUNCTION BLOCK.................... 8W-12-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUT................ 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 WJWIRING 8W - 1

Page 661 of 2199

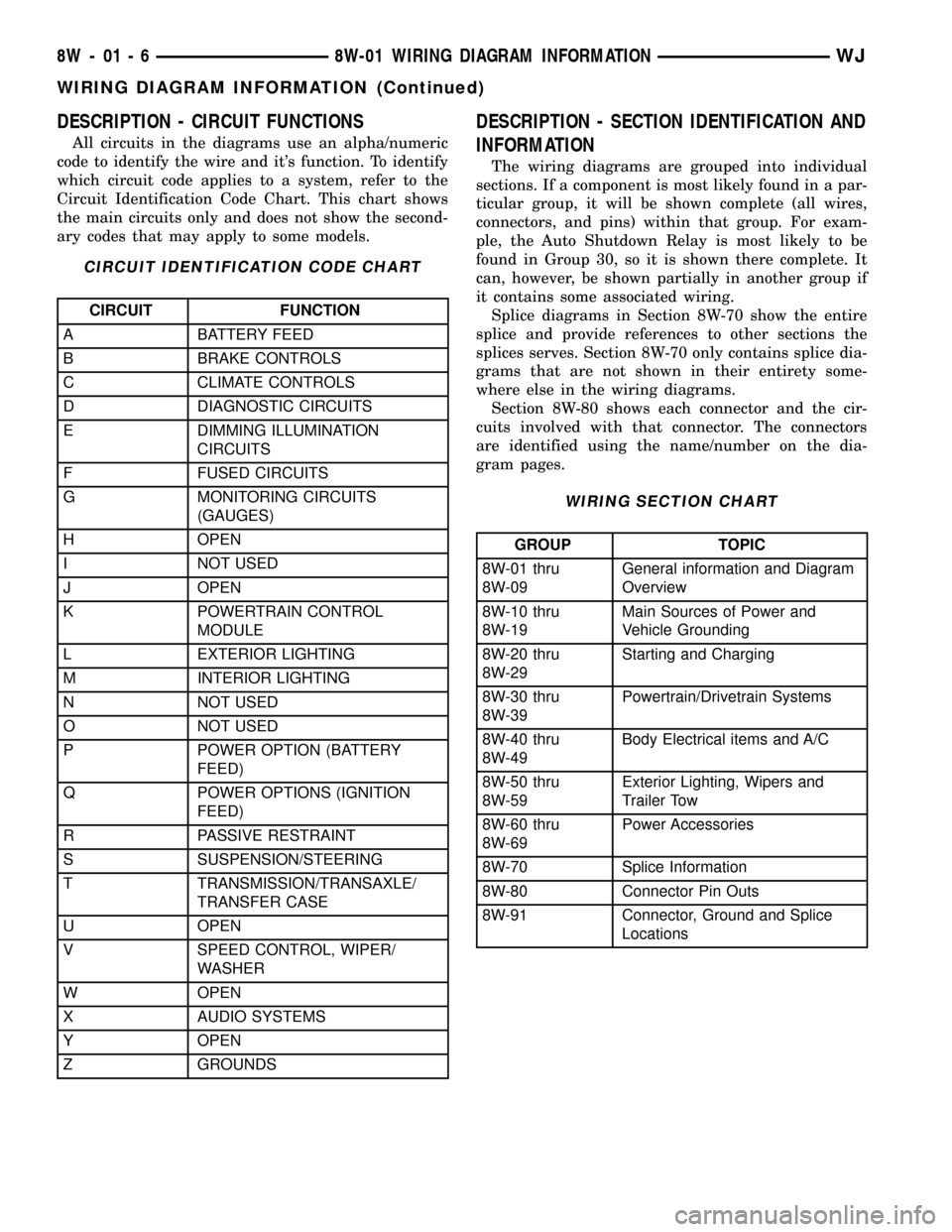

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONWJ

WIRING DIAGRAM INFORMATION (Continued)

Page 912 of 2199

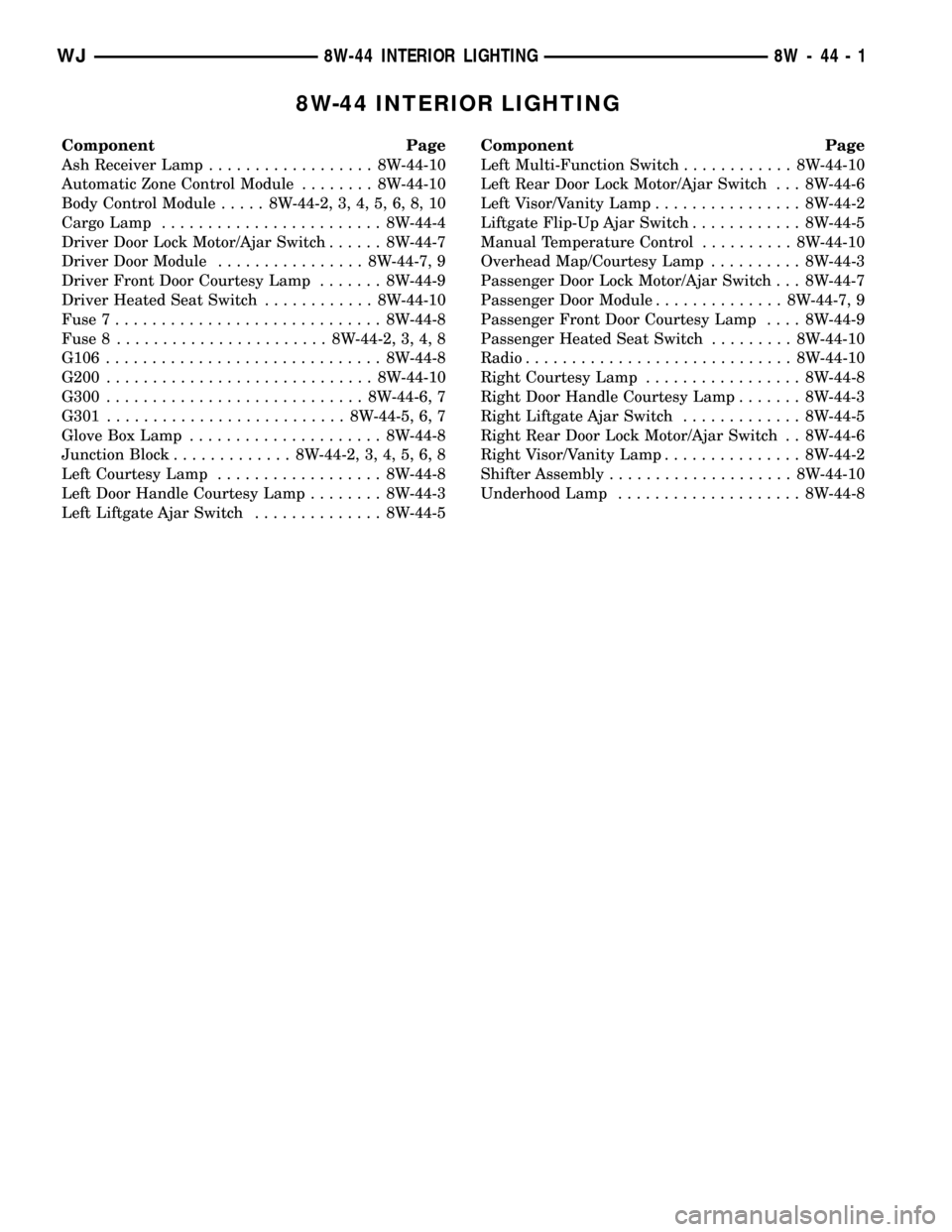

8W-44 INTERIOR LIGHTING

Component Page

Ash Receiver Lamp.................. 8W-44-10

Automatic Zone Control Module........ 8W-44-10

Body Control Module..... 8W-44-2, 3, 4, 5, 6, 8, 10

Cargo Lamp........................ 8W-44-4

Driver Door Lock Motor/Ajar Switch...... 8W-44-7

Driver Door Module................ 8W-44-7, 9

Driver Front Door Courtesy Lamp....... 8W-44-9

Driver Heated Seat Switch............ 8W-44-10

Fuse 7............................. 8W-44-8

Fuse 8....................... 8W-44-2, 3, 4, 8

G106.............................. 8W-44-8

G200............................. 8W-44-10

G300............................ 8W-44-6, 7

G301.......................... 8W-44-5, 6, 7

Glove Box Lamp..................... 8W-44-8

Junction Block............. 8W-44-2, 3, 4, 5, 6, 8

Left Courtesy Lamp.................. 8W-44-8

Left Door Handle Courtesy Lamp........ 8W-44-3

Left Liftgate Ajar Switch.............. 8W-44-5Component Page

Left Multi-Function Switch............ 8W-44-10

Left Rear Door Lock Motor/Ajar Switch . . . 8W-44-6

Left Visor/Vanity Lamp................ 8W-44-2

Liftgate Flip-Up Ajar Switch............ 8W-44-5

Manual Temperature Control.......... 8W-44-10

Overhead Map/Courtesy Lamp.......... 8W-44-3

Passenger Door Lock Motor/Ajar Switch . . . 8W-44-7

Passenger Door Module.............. 8W-44-7, 9

Passenger Front Door Courtesy Lamp.... 8W-44-9

Passenger Heated Seat Switch......... 8W-44-10

Radio............................. 8W-44-10

Right Courtesy Lamp................. 8W-44-8

Right Door Handle Courtesy Lamp....... 8W-44-3

Right Liftgate Ajar Switch............. 8W-44-5

Right Rear Door Lock Motor/Ajar Switch . . 8W-44-6

Right Visor/Vanity Lamp............... 8W-44-2

Shifter Assembly.................... 8W-44-10

Underhood Lamp.................... 8W-44-8

WJ8W-44 INTERIOR LIGHTING 8W - 44 - 1

Page 956 of 2199

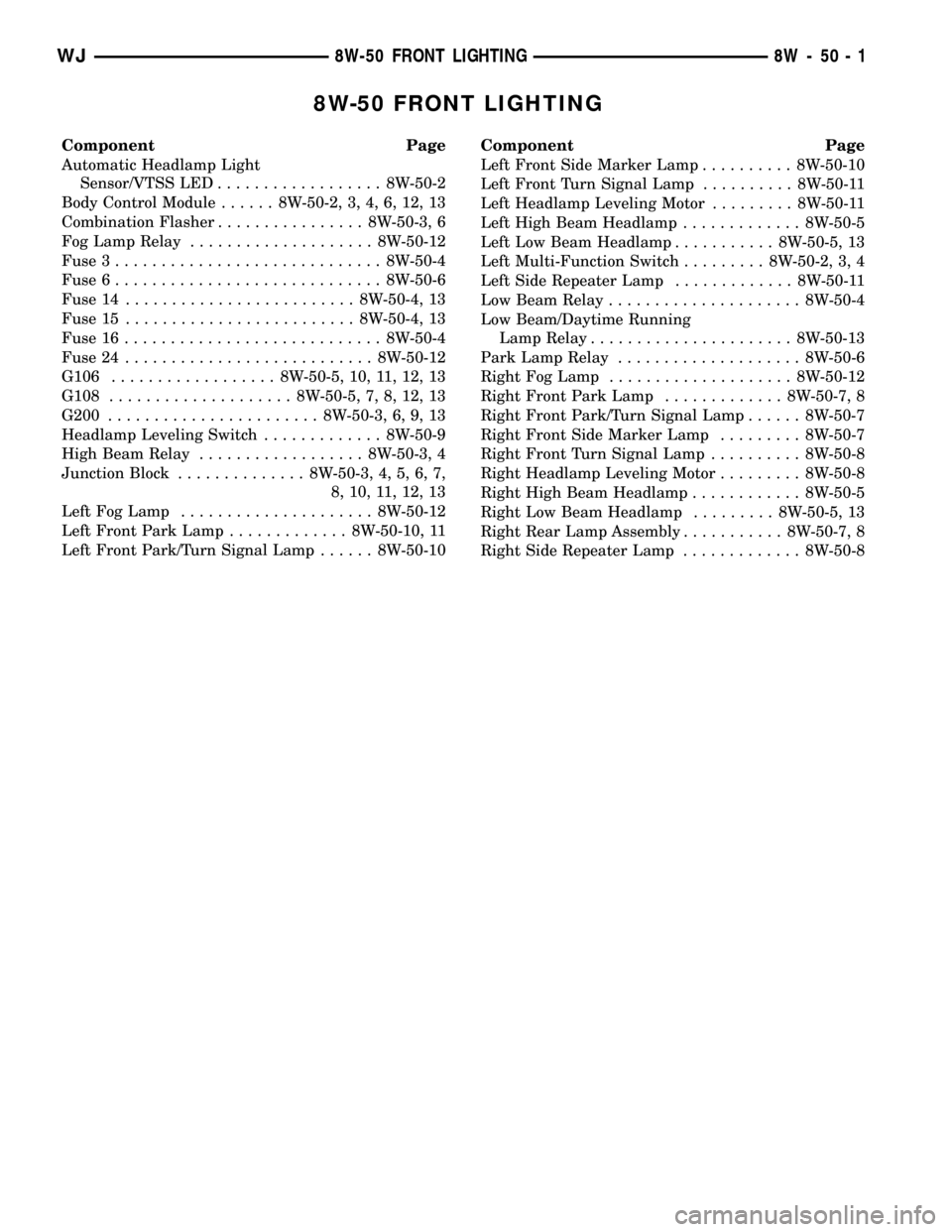

8W-50 FRONT LIGHTING

Component Page

Automatic Headlamp Light

Sensor/VTSS LED.................. 8W-50-2

Body Control Module...... 8W-50-2, 3, 4, 6, 12, 13

Combination Flasher................ 8W-50-3, 6

Fog Lamp Relay.................... 8W-50-12

Fuse 3............................. 8W-50-4

Fuse 6............................. 8W-50-6

Fuse 14......................... 8W-50-4, 13

Fuse 15......................... 8W-50-4, 13

Fuse 16............................ 8W-50-4

Fuse 24........................... 8W-50-12

G106.................. 8W-50-5, 10, 11, 12, 13

G108.................... 8W-50-5, 7, 8, 12, 13

G200....................... 8W-50-3, 6, 9, 13

Headlamp Leveling Switch............. 8W-50-9

High Beam Relay.................. 8W-50-3, 4

Junction Block.............. 8W-50-3, 4, 5, 6, 7,

8, 10, 11, 12, 13

Left Fog Lamp..................... 8W-50-12

Left Front Park Lamp............. 8W-50-10, 11

Left Front Park/Turn Signal Lamp...... 8W-50-10Component Page

Left Front Side Marker Lamp.......... 8W-50-10

Left Front Turn Signal Lamp.......... 8W-50-11

Left Headlamp Leveling Motor......... 8W-50-11

Left High Beam Headlamp............. 8W-50-5

Left Low Beam Headlamp........... 8W-50-5, 13

Left Multi-Function Switch......... 8W-50-2, 3, 4

Left Side Repeater Lamp............. 8W-50-11

Low Beam Relay..................... 8W-50-4

Low Beam/Daytime Running

Lamp Relay...................... 8W-50-13

Park Lamp Relay.................... 8W-50-6

Right Fog Lamp.................... 8W-50-12

Right Front Park Lamp............. 8W-50-7, 8

Right Front Park/Turn Signal Lamp...... 8W-50-7

Right Front Side Marker Lamp......... 8W-50-7

Right Front Turn Signal Lamp.......... 8W-50-8

Right Headlamp Leveling Motor......... 8W-50-8

Right High Beam Headlamp............ 8W-50-5

Right Low Beam Headlamp......... 8W-50-5, 13

Right Rear Lamp Assembly........... 8W-50-7, 8

Right Side Repeater Lamp............. 8W-50-8

WJ8W-50 FRONT LIGHTING 8W - 50 - 1

Page 970 of 2199

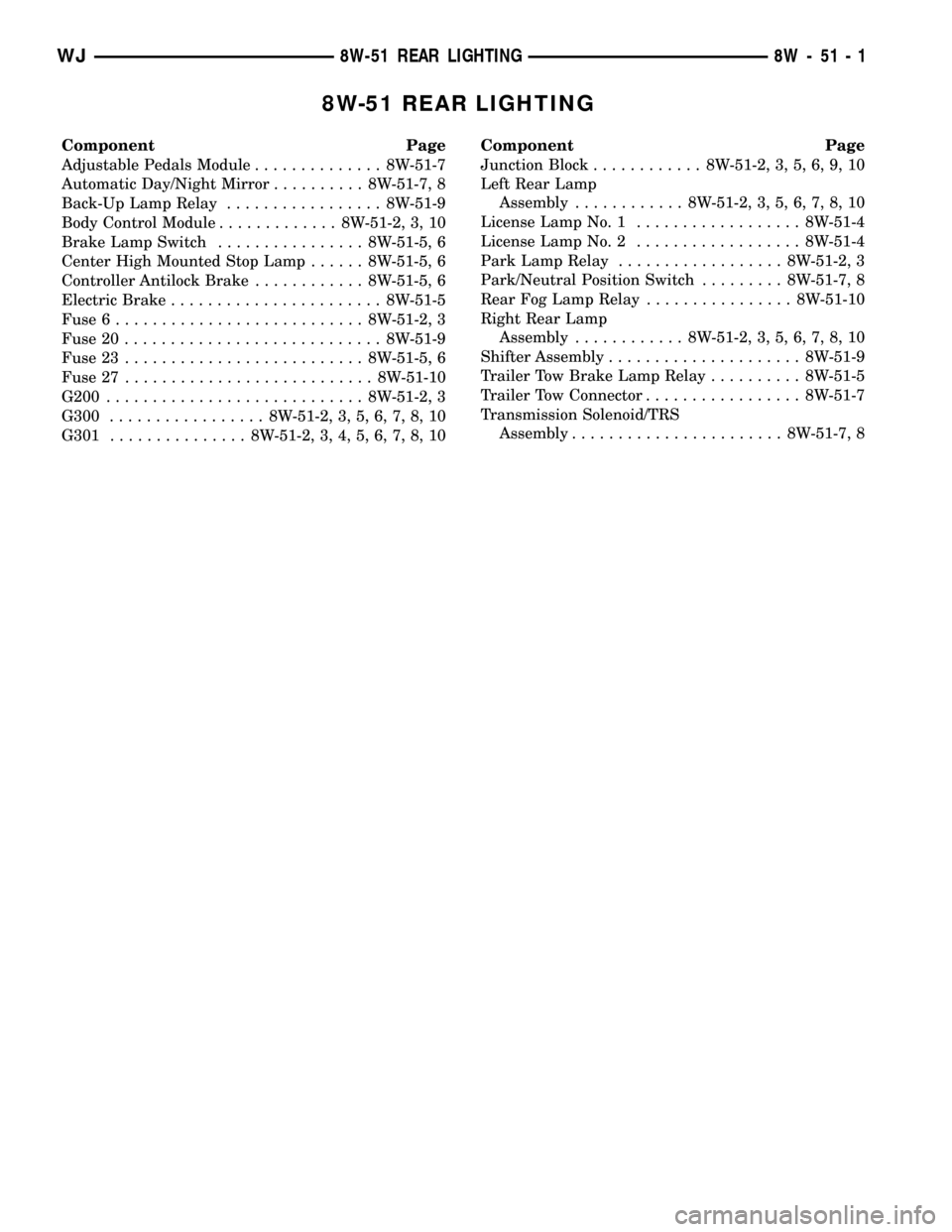

8W-51 REAR LIGHTING

Component Page

Adjustable Pedals Module.............. 8W-51-7

Automatic Day/Night Mirror.......... 8W-51-7, 8

Back-Up Lamp Relay................. 8W-51-9

Body Control Module............. 8W-51-2, 3, 10

Brake Lamp Switch................ 8W-51-5, 6

Center High Mounted Stop Lamp...... 8W-51-5, 6

Controller Antilock Brake............ 8W-51-5, 6

Electric Brake....................... 8W-51-5

Fuse 6........................... 8W-51-2, 3

Fuse 20............................ 8W-51-9

Fuse 23.......................... 8W-51-5, 6

Fuse 27........................... 8W-51-10

G200............................ 8W-51-2, 3

G300................. 8W-51-2, 3, 5, 6, 7, 8, 10

G301............... 8W-51-2, 3, 4, 5, 6, 7, 8, 10Component Page

Junction Block............ 8W-51-2, 3, 5, 6, 9, 10

Left Rear Lamp

Assembly............ 8W-51-2, 3, 5, 6, 7, 8, 10

License Lamp No. 1.................. 8W-51-4

License Lamp No. 2.................. 8W-51-4

Park Lamp Relay.................. 8W-51-2, 3

Park/Neutral Position Switch......... 8W-51-7, 8

Rear Fog Lamp Relay................ 8W-51-10

Right Rear Lamp

Assembly............ 8W-51-2, 3, 5, 6, 7, 8, 10

Shifter Assembly..................... 8W-51-9

Trailer Tow Brake Lamp Relay.......... 8W-51-5

Trailer Tow Connector................. 8W-51-7

Transmission Solenoid/TRS

Assembly....................... 8W-51-7, 8

WJ8W-51 REAR LIGHTING 8W - 51 - 1

Page 1081 of 2199

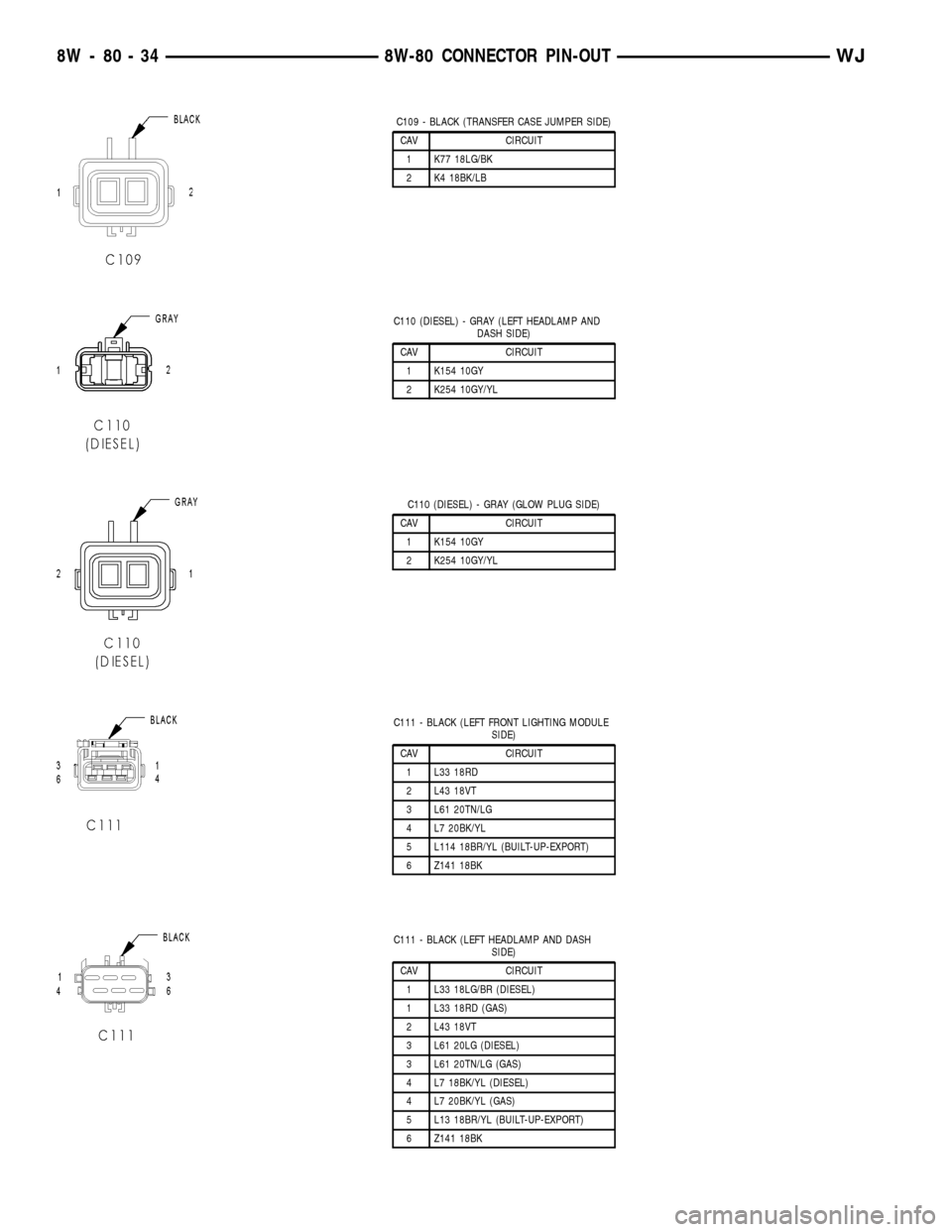

C109 - BLACK (TRANSFER CASE JUMPER SIDE)

CAV CIRCUIT

1 K77 18LG/BK

2 K4 18BK/LB

C110 (DIESEL) - GRAY (LEFT HEADLAMP AND

DASH SIDE)

CAV CIRCUIT

1 K154 10GY

2 K254 10GY/YL

C110 (DIESEL) - GRAY (GLOW PLUG SIDE)

CAV CIRCUIT

1 K154 10GY

2 K254 10GY/YL

C111 - BLACK (LEFT FRONT LIGHTING MODULE

SIDE)

CAV CIRCUIT

1 L33 18RD

2 L43 18VT

3 L61 20TN/LG

4 L7 20BK/YL

5 L114 18BR/YL (BUILT-UP-EXPORT)

6 Z141 18BK

C111 - BLACK (LEFT HEADLAMP AND DASH

SIDE)

CAV CIRCUIT

1 L33 18LG/BR (DIESEL)

1 L33 18RD (GAS)

2 L43 18VT

3 L61 20LG (DIESEL)

3 L61 20TN/LG (GAS)

4 L7 18BK/YL (DIESEL)

4 L7 20BK/YL (GAS)

5 L13 18BR/YL (BUILT-UP-EXPORT)

6 Z141 18BK

8W - 80 - 34 8W-80 CONNECTOR PIN-OUTWJ

Page 1082 of 2199

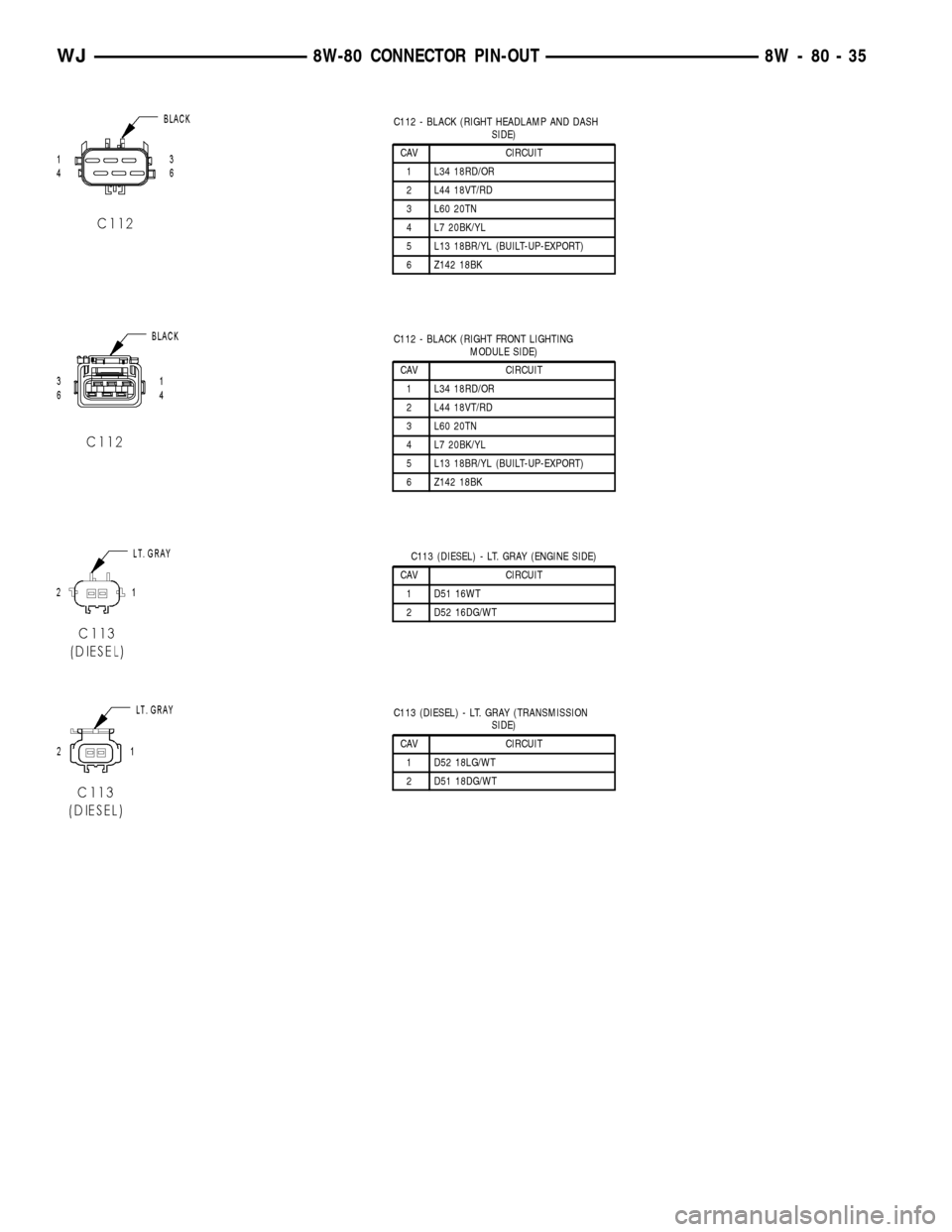

C112 - BLACK (RIGHT HEADLAMP AND DASH

SIDE)

CAV CIRCUIT

1 L34 18RD/OR

2 L44 18VT/RD

3 L60 20TN

4 L7 20BK/YL

5 L13 18BR/YL (BUILT-UP-EXPORT)

6 Z142 18BK

C112 - BLACK (RIGHT FRONT LIGHTING

MODULE SIDE)

CAV CIRCUIT

1 L34 18RD/OR

2 L44 18VT/RD

3 L60 20TN

4 L7 20BK/YL

5 L13 18BR/YL (BUILT-UP-EXPORT)

6 Z142 18BK

C113 (DIESEL) - LT. GRAY (ENGINE SIDE)

CAV CIRCUIT

1 D51 16WT

2 D52 16DG/WT

C113 (DIESEL) - LT. GRAY (TRANSMISSION

SIDE)

CAV CIRCUIT

1 D52 18LG/WT

2 D51 18DG/WT

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 35

Page 1880 of 2199

(4) Close flip up glass panel and verify proper

operation.

(5)

Install liftgate trim panel, refer to (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION).

FLIP-UP GLASS LATCH

STRIKER

REMOVAL

(1) Raise flip up glass panel.

(2) Mark the position of the handle/striker on the

glass panel.

(3) Remove the screws attaching the handle/striker

to the glass.

INSTALLATION

(1) Position the handle/striker on the glass panel

and align the reference marks.

(2) Install the screws attaching the handle/striker

to the glass panel. Tighten the fasteners to 6 N´m (60

in. lbs.).

FLIP-UP GLASS SWITCH

REMOVAL

(1) Remove license plate lamp housing/trim panel

from liftgate, refer to (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LICENSE PLATE

LAMP UNIT - REMOVAL).

(2) Squeeze the locking tabs inward to release the

switch from the housing.

(3) Disconnect the switch harness connector,

remove the switch from the housing.

INSTALLATION

(1) Install switch harness connector.(2) Position switch in housing, snap switch into

place.

(3) Install license plate lamp housing/trim panel

onto liftgate, refer to (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LICENSE PLATE

LAMP UNIT - INSTALLATION).

HINGE

REMOVAL

NOTE: It is not necessary to remove the liftgate to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Open the liftgate. Support the liftgate for ease

of repair.

(2) Remove the liftgate header trim panel.

(3) Mark the hinge location with a grease pencil or

other suitable device.

(4) Remove the hinge screws (Fig. 5).

(5) Remove hinge.

INSTALLATION

NOTE: It is not necessary to remove the liftgate to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Position the hinge on the roof panel and on the

liftgate. (Use 3MŸ Fast and Firm or equivalent on

the hinge to body mating surfaces as a sealant.

(2) Install and tighten hinge screws at roof panel

to 28N´m (21 ft. lbs.).

(3) Install hinge screws at liftgate. Tighten screws

to 28N´m (21 ft. lbs.).

(4) Install liftgate header trim panel.

(5) Check the liftgate for proper alignment and

operation.

WJDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 7

FLIP-UP GLASS LATCH (Continued)