Jack located JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 17 of 2199

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationCD or higherorCCML

D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is

recommended that SAE Grade 10W-40 engine oils

that meet Chrysler material standard MS-6395, be

used. European Grade 10W-40 oils are also accept-

able.

Oils of the SAE 5W-40 or 8W-80 grade number are

preferred when minimum temperatures consistently

fall below -12ÉC.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

FLUID FILL/CHECK

LOCATIONS

INSPECTION - FLUID FILL/CHECK LOCATIONS

The fluid fill/check locations and lubrication points

are located in each applicable group.

MAINTENANCE SCHEDULES

DESCRIPTION

9Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.9

LIFT POINTS

STANDARD PROCEDURE - HOISTING AND

JACKING RECOMMENDATIONS

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a WJ vehicle (Fig. 7). Support the vehicle in

the raised position with jack stands at the front and

rear ends of the frame rails.

CAUTION: Do not attempt to lift a vehicle with a

floor jack positioned under:

²An axle tube.

²Aluminum differential.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 7).

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

0 - 6 LUBRICATION & MAINTENANCEWJ

FLUID TYPES (Continued)

Page 34 of 2199

OPERATION

The coil springs control ride quality and maintain

proper ride height. The isolators provide road noise

isolation.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assemblies.

(3) Position a hydraulic jack under the axle to sup-

port it.

(4) Remove shock absorbers lower mounting nuts

from the axle brackets.

(5) Remove the track bar mounting bolt from the

axle bracket.

NOTE: Make sure the lower part of the shock does

not hold tension on the brake lines at the axle tube

housing located at the lower shock mounting area.

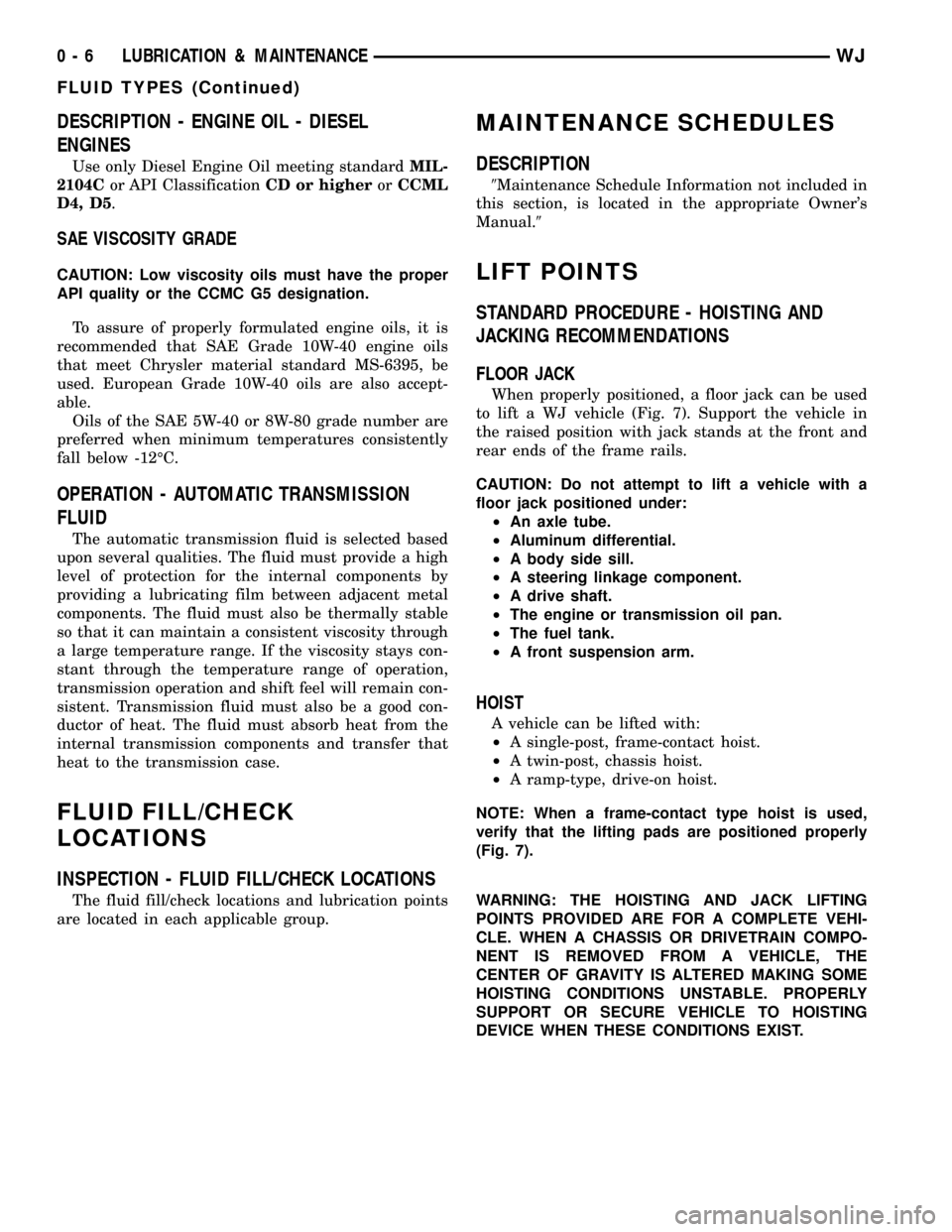

(6) Lower the axle until the spring is free from the

upper mount and isolator (Fig. 10).

(7) Remove the spring from the vehicle.

(8) Remove and inspect the upper and lower

spring isolators.

INSTALLATION

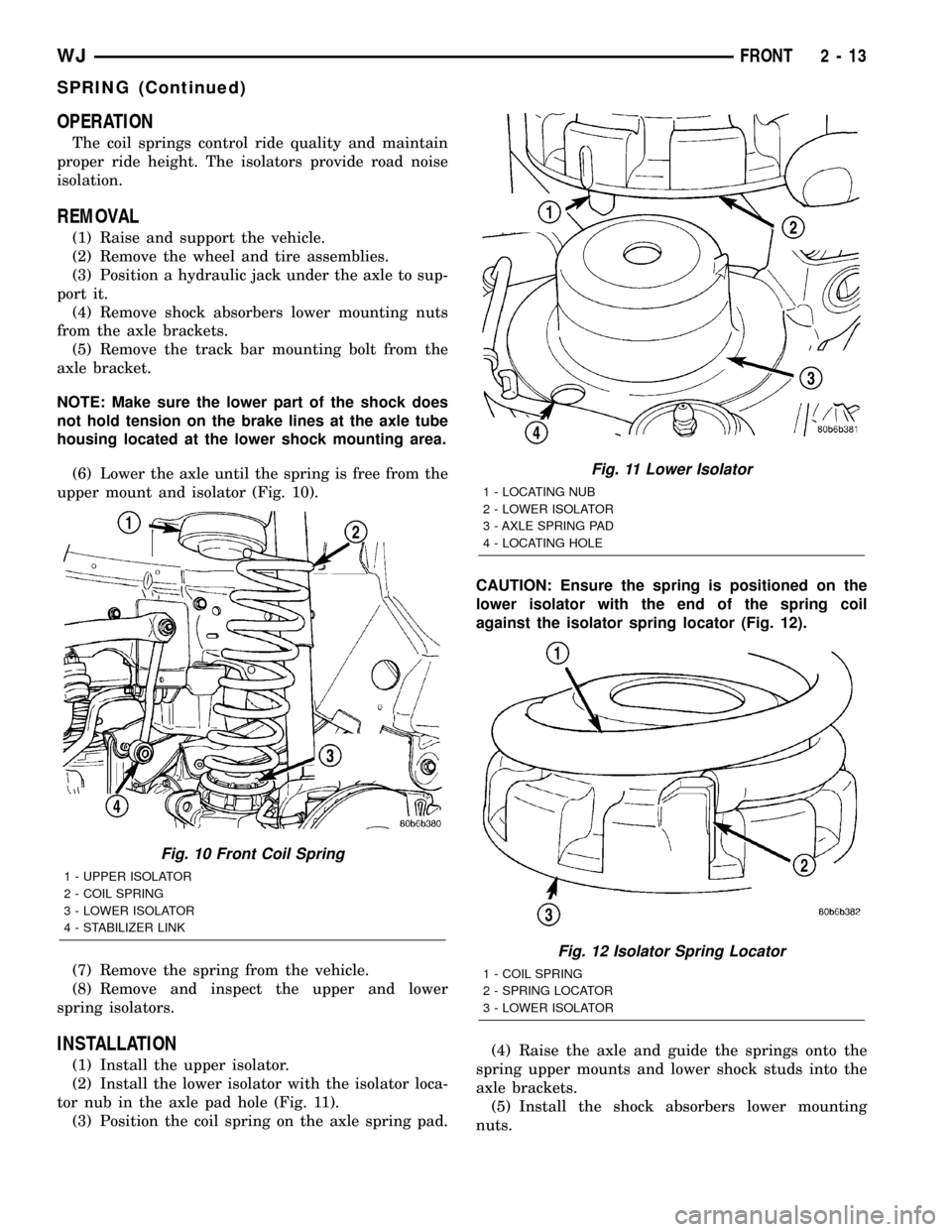

(1) Install the upper isolator.

(2) Install the lower isolator with the isolator loca-

tor nub in the axle pad hole (Fig. 11).

(3) Position the coil spring on the axle spring pad.CAUTION: Ensure the spring is positioned on the

lower isolator with the end of the spring coil

against the isolator spring locator (Fig. 12).

(4) Raise the axle and guide the springs onto the

spring upper mounts and lower shock studs into the

axle brackets.

(5) Install the shock absorbers lower mounting

nuts.

Fig. 10 Front Coil Spring

1 - UPPER ISOLATOR

2 - COIL SPRING

3 - LOWER ISOLATOR

4 - STABILIZER LINK

Fig. 11 Lower Isolator

1 - LOCATING NUB

2 - LOWER ISOLATOR

3 - AXLE SPRING PAD

4 - LOCATING HOLE

Fig. 12 Isolator Spring Locator

1 - COIL SPRING

2 - SPRING LOCATOR

3 - LOWER ISOLATOR

WJFRONT 2 - 13

SPRING (Continued)

Page 41 of 2199

SPRING

DESCRIPTION

The coil springs mount up in the wheelhouse which

is part of the unitized body bracket. A rubber dough-

nut isolator is located between the top of the spring

and the body. The bottom of the spring seats on a

axle isolator made of rubber with a steel insert. The

isolators provide road noise isolation

OPERATION

The coil springs control ride quality and maintain

proper ride height.

REMOVAL

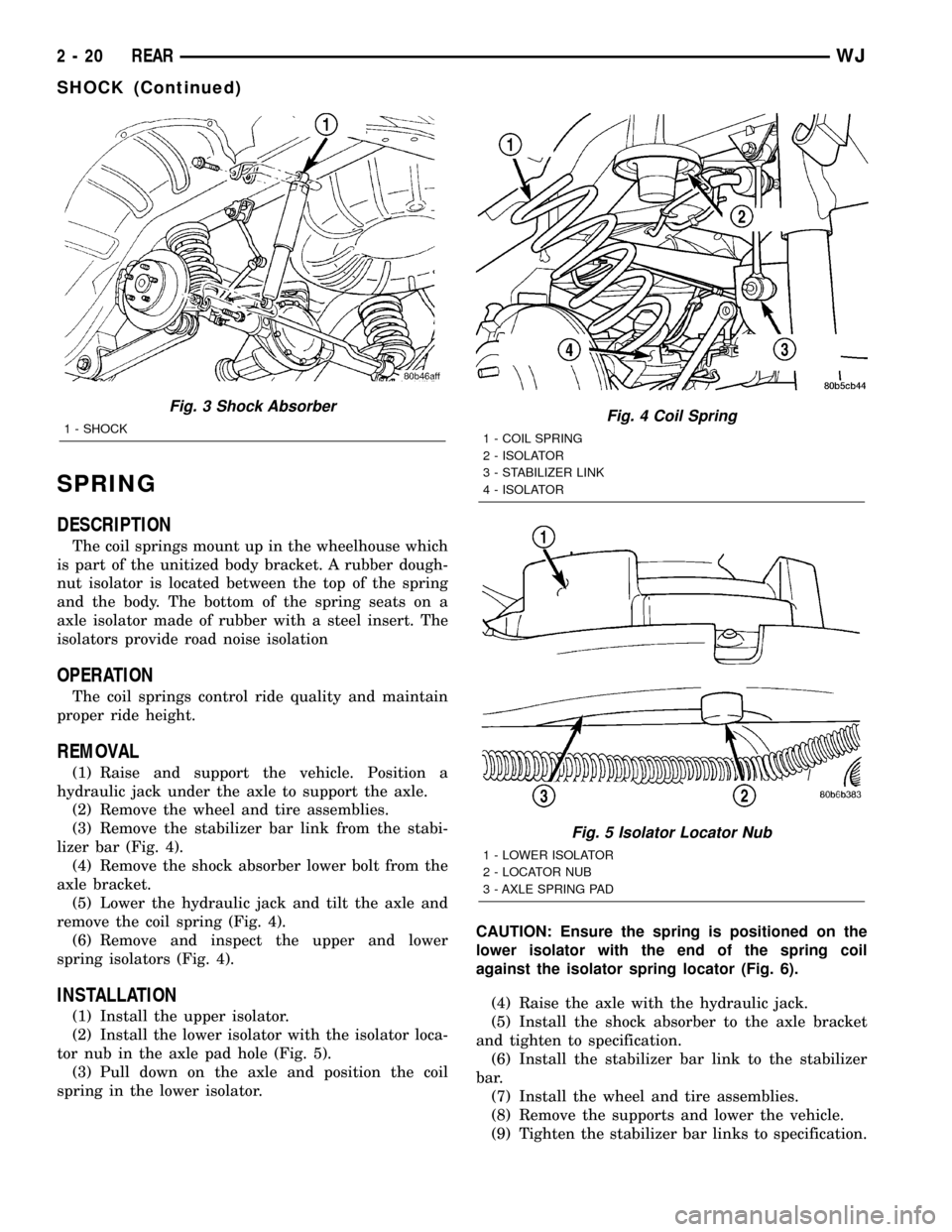

(1) Raise and support the vehicle. Position a

hydraulic jack under the axle to support the axle.

(2) Remove the wheel and tire assemblies.

(3) Remove the stabilizer bar link from the stabi-

lizer bar (Fig. 4).

(4) Remove the shock absorber lower bolt from the

axle bracket.

(5) Lower the hydraulic jack and tilt the axle and

remove the coil spring (Fig. 4).

(6) Remove and inspect the upper and lower

spring isolators (Fig. 4).

INSTALLATION

(1) Install the upper isolator.

(2) Install the lower isolator with the isolator loca-

tor nub in the axle pad hole (Fig. 5).

(3) Pull down on the axle and position the coil

spring in the lower isolator.CAUTION: Ensure the spring is positioned on the

lower isolator with the end of the spring coil

against the isolator spring locator (Fig. 6).

(4) Raise the axle with the hydraulic jack.

(5) Install the shock absorber to the axle bracket

and tighten to specification.

(6) Install the stabilizer bar link to the stabilizer

bar.

(7) Install the wheel and tire assemblies.

(8) Remove the supports and lower the vehicle.

(9) Tighten the stabilizer bar links to specification.

Fig. 3 Shock Absorber

1 - SHOCKFig. 4 Coil Spring

1 - COIL SPRING

2 - ISOLATOR

3 - STABILIZER LINK

4 - ISOLATOR

Fig. 5 Isolator Locator Nub

1 - LOWER ISOLATOR

2 - LOCATOR NUB

3 - AXLE SPRING PAD

2 - 20 REARWJ

SHOCK (Continued)

Page 270 of 2199

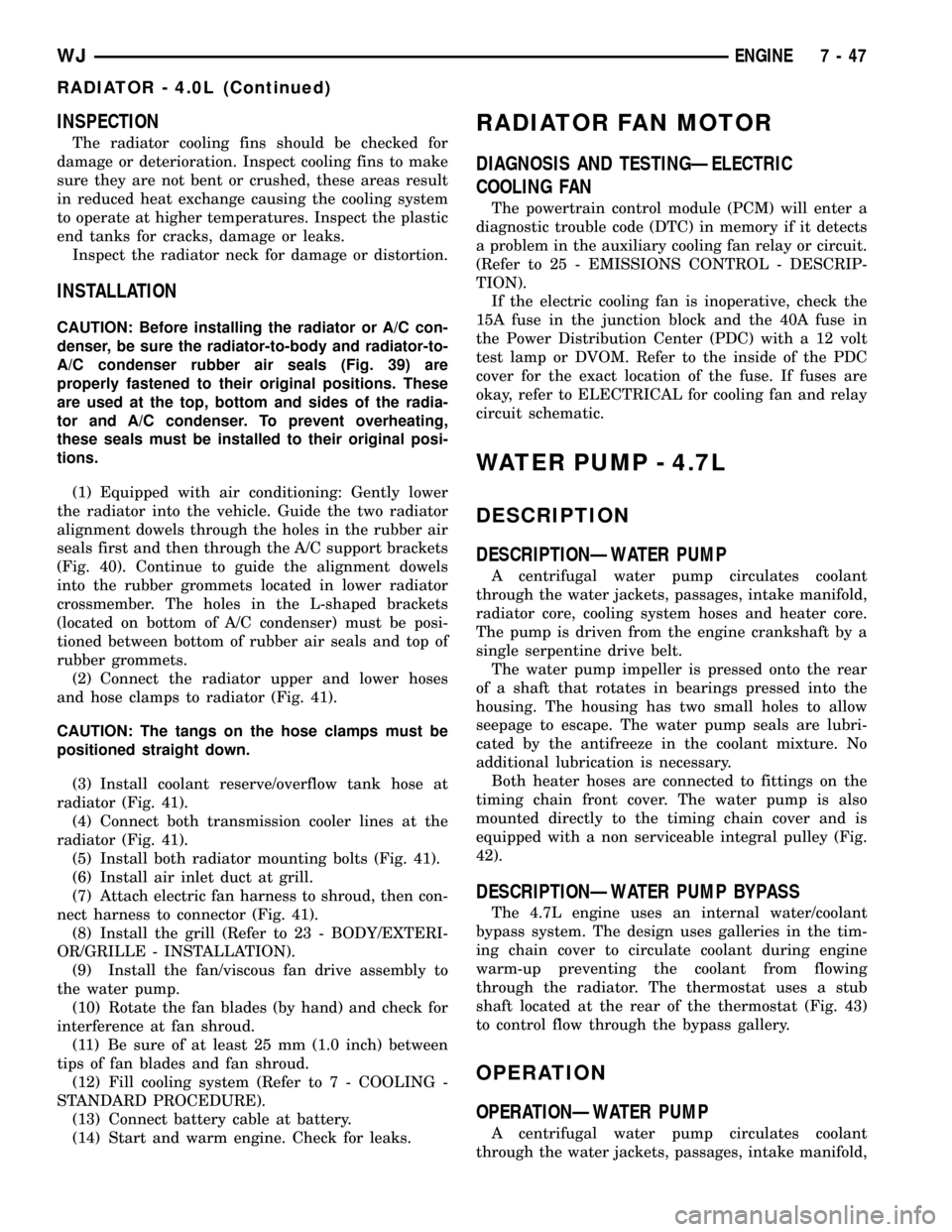

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

(1) Equipped with air conditioning: Gently lower

the radiator into the vehicle. Guide the two radiator

alignment dowels through the holes in the rubber air

seals first and then through the A/C support brackets

(Fig. 40). Continue to guide the alignment dowels

into the rubber grommets located in lower radiator

crossmember. The holes in the L-shaped brackets

(located on bottom of A/C condenser) must be posi-

tioned between bottom of rubber air seals and top of

rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator (Fig. 41).

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator (Fig. 41).

(4) Connect both transmission cooler lines at the

radiator (Fig. 41).

(5) Install both radiator mounting bolts (Fig. 41).

(6) Install air inlet duct at grill.

(7) Attach electric fan harness to shroud, then con-

nect harness to connector (Fig. 41).

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Install the fan/viscous fan drive assembly to

the water pump.

(10) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(11) Be sure of at least 25 mm (1.0 inch) between

tips of fan blades and fan shroud.

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery cable at battery.

(14) Start and warm engine. Check for leaks.

RADIATOR FAN MOTOR

DIAGNOSIS AND TESTINGÐELECTRIC

COOLING FAN

The powertrain control module (PCM) will enter a

diagnostic trouble code (DTC) in memory if it detects

a problem in the auxiliary cooling fan relay or circuit.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

If the electric cooling fan is inoperative, check the

15A fuse in the junction block and the 40A fuse in

the Power Distribution Center (PDC) with a 12 volt

test lamp or DVOM. Refer to the inside of the PDC

cover for the exact location of the fuse. If fuses are

okay, refer to ELECTRICAL for cooling fan and relay

circuit schematic.

WATER PUMP - 4.7L

DESCRIPTION

DESCRIPTIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary.

Both heater hoses are connected to fittings on the

timing chain front cover. The water pump is also

mounted directly to the timing chain cover and is

equipped with a non serviceable integral pulley (Fig.

42).

DESCRIPTIONÐWATER PUMP BYPASS

The 4.7L engine uses an internal water/coolant

bypass system. The design uses galleries in the tim-

ing chain cover to circulate coolant during engine

warm-up preventing the coolant from flowing

through the radiator. The thermostat uses a stub

shaft located at the rear of the thermostat (Fig. 43)

to control flow through the bypass gallery.

OPERATION

OPERATIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

WJENGINE 7 - 47

RADIATOR - 4.0L (Continued)

Page 349 of 2199

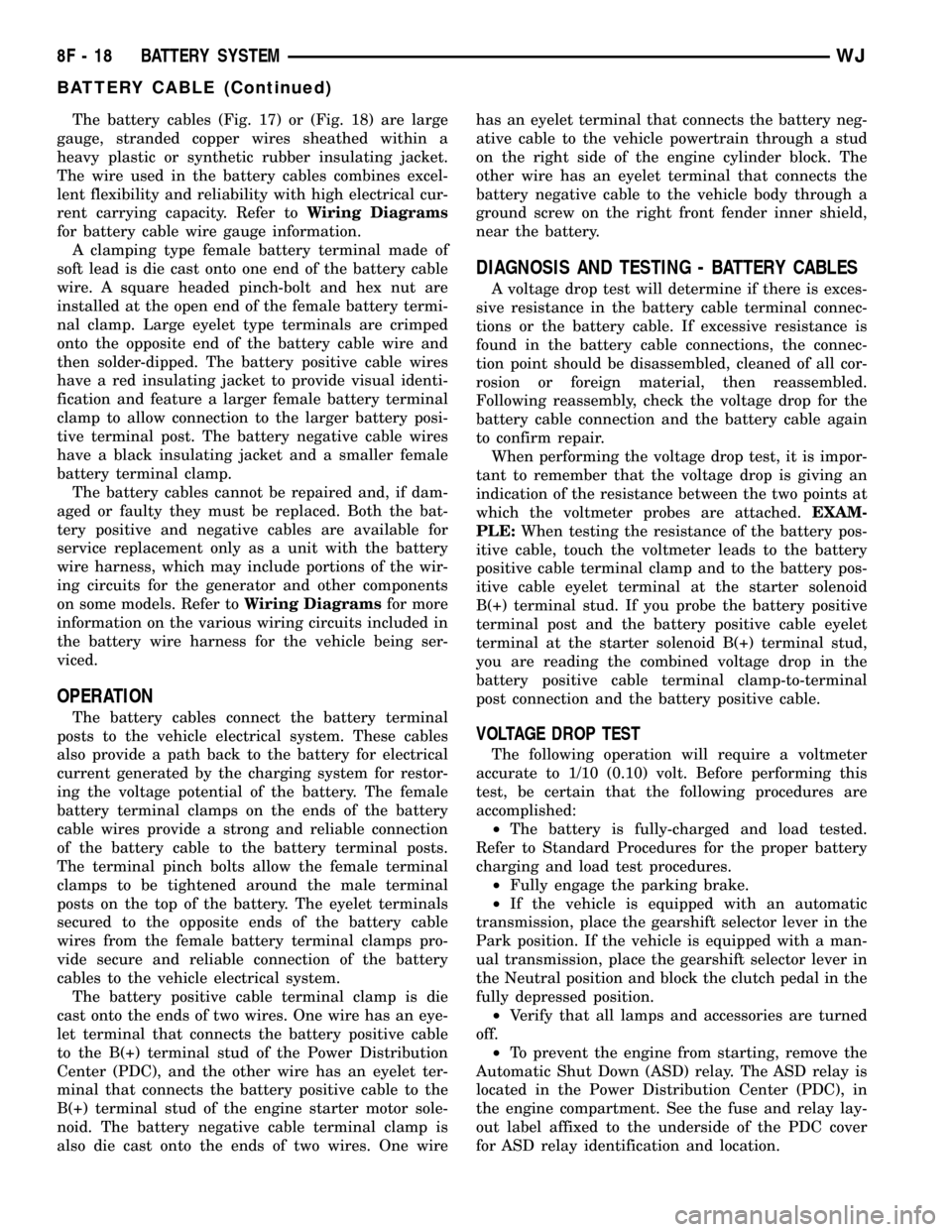

The battery cables (Fig. 17) or (Fig. 18) are large

gauge, stranded copper wires sheathed within a

heavy plastic or synthetic rubber insulating jacket.

The wire used in the battery cables combines excel-

lent flexibility and reliability with high electrical cur-

rent carrying capacity. Refer toWiring Diagrams

for battery cable wire gauge information.

A clamping type female battery terminal made of

soft lead is die cast onto one end of the battery cable

wire. A square headed pinch-bolt and hex nut are

installed at the open end of the female battery termi-

nal clamp. Large eyelet type terminals are crimped

onto the opposite end of the battery cable wire and

then solder-dipped. The battery positive cable wires

have a red insulating jacket to provide visual identi-

fication and feature a larger female battery terminal

clamp to allow connection to the larger battery posi-

tive terminal post. The battery negative cable wires

have a black insulating jacket and a smaller female

battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsfor more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the Power Distribution

Center (PDC), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wirehas an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the right side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the right front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. See the fuse and relay lay-

out label affixed to the underside of the PDC cover

for ASD relay identification and location.

8F - 18 BATTERY SYSTEMWJ

BATTERY CABLE (Continued)

Page 555 of 2199

(3) Align and seat the one pin and the two mount-

ing ears on the clockspring case to their respective

holes in the multi-function switch mounting housing.

(4) Install and tighten the two clockspring mount-

ing screws. Tighten the screws to 2.5 N´m (22 in.

lbs.).

(5) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring case.

(6) Position the lower tilting steering column

shroud onto the steering column (Fig. 16).

(7) Install and tighten the screw that secures the

lower tilting steering column shroud to the multi-

function switch mounting housing. Tighten the screw

to 2 N´m (17 in. lbs.).

(8) Position the upper tilting column shroud onto

the steering column with the hazard warning switch

button inserted through the hole in the upper surface

of the shroud. Align the upper tilting steering column

shroud to the lower shroud and snap the two shroud

halves together.

(9) Align the snap features on the upper and lower

shrouds and apply hand pressure to snap them

together.

(10) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(11)

Reconnect the steering wheel wire harness con-

nectors to the upper clockspring connector receptacles.

(12) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

DRIVER AIRBAG

DESCRIPTION

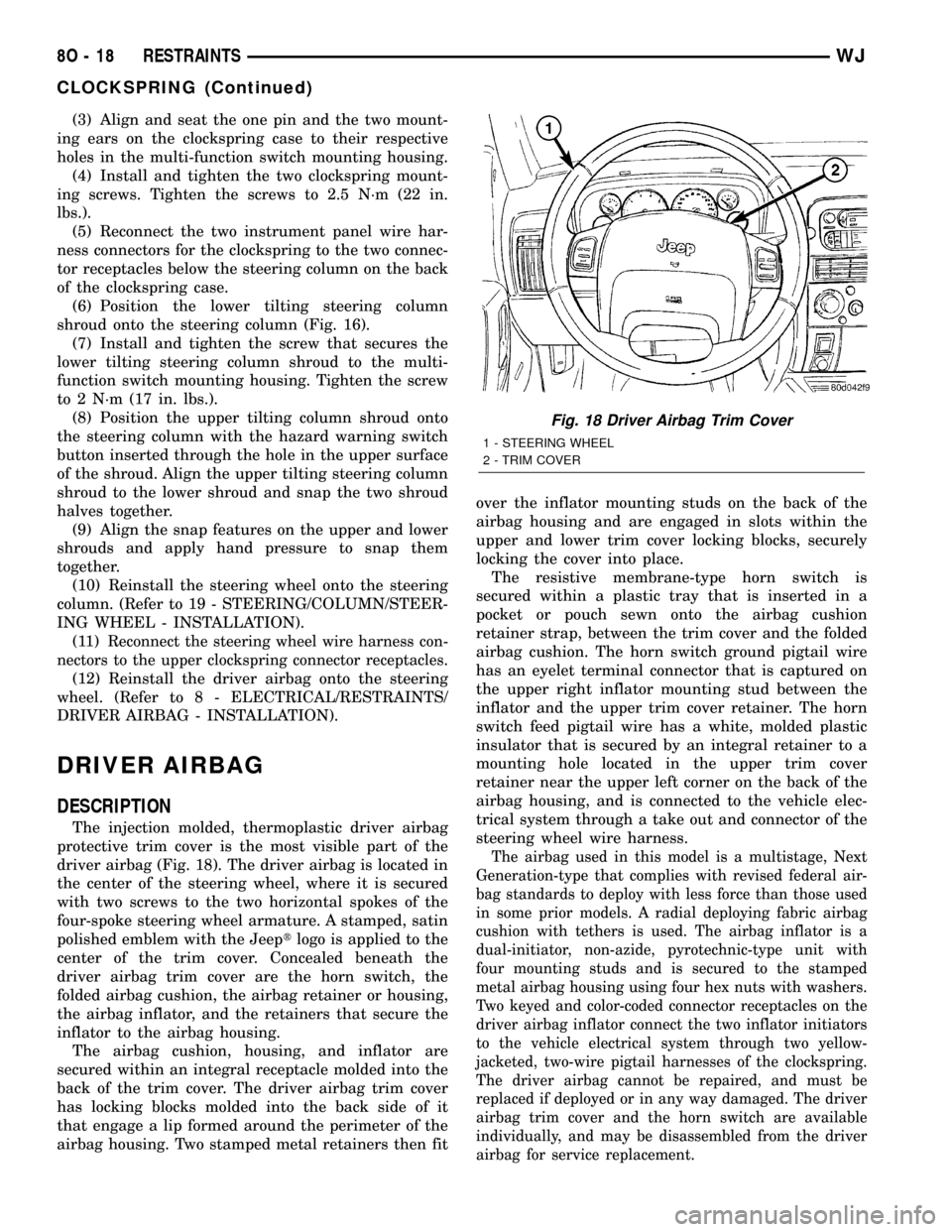

The injection molded, thermoplastic driver airbag

protective trim cover is the most visible part of the

driver airbag (Fig. 18). The driver airbag is located in

the center of the steering wheel, where it is secured

with two screws to the two horizontal spokes of the

four-spoke steering wheel armature. A stamped, satin

polished emblem with the Jeeptlogo is applied to the

center of the trim cover. Concealed beneath the

driver airbag trim cover are the horn switch, the

folded airbag cushion, the airbag retainer or housing,

the airbag inflator, and the retainers that secure the

inflator to the airbag housing.

The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover. The driver airbag trim cover

has locking blocks molded into the back side of it

that engage a lip formed around the perimeter of the

airbag housing. Two stamped metal retainers then fitover the inflator mounting studs on the back of the

airbag housing and are engaged in slots within the

upper and lower trim cover locking blocks, securely

locking the cover into place.

The resistive membrane-type horn switch is

secured within a plastic tray that is inserted in a

pocket or pouch sewn onto the airbag cushion

retainer strap, between the trim cover and the folded

airbag cushion. The horn switch ground pigtail wire

has an eyelet terminal connector that is captured on

the upper right inflator mounting stud between the

inflator and the upper trim cover retainer. The horn

switch feed pigtail wire has a white, molded plastic

insulator that is secured by an integral retainer to a

mounting hole located in the upper trim cover

retainer near the upper left corner on the back of the

airbag housing, and is connected to the vehicle elec-

trical system through a take out and connector of the

steering wheel wire harness.

The airbag used in this model is a multistage, Next

Generation-type that complies with revised federal air-

bag standards to deploy with less force than those used

in some prior models. A radial deploying fabric airbag

cushion with tethers is used. The airbag inflator is a

dual-initiator, non-azide, pyrotechnic-type unit with

four mounting studs and is secured to the stamped

metal airbag housing using four hex nuts with washers.

Two keyed and color-coded connector receptacles on the

driver airbag inflator connect the two inflator initiators

to the vehicle electrical system through two yellow-

jacketed, two-wire pigtail harnesses of the clockspring.

The driver airbag cannot be repaired, and must be

replaced if deployed or in any way damaged. The driver

airbag trim cover and the horn switch are available

individually, and may be disassembled from the driver

airbag for service replacement.

Fig. 18 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

8O - 18 RESTRAINTSWJ

CLOCKSPRING (Continued)

Page 1299 of 2199

(9) Lower the engine until it is properly located on

the engine mounts.

(10) Install the through bolts and tighten the nuts.

(11) Lower the jack stand and remove the piece of

wood.

(12) Install the engine flywheel and transmission

torque converter housing access cover.

(13) Install the engine starter motor. (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(14) Connect the exhaust pipe to the hanger and to

the engine exhaust manifold.

(15) Install transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

attach to the oil pan studs.

(16) Install the oil pan drain plug (Fig. 81).

Tighten the plug to 34 N´m (25 ft. lbs.) torque.

(17) Lower the vehicle.

(18) Connect negative cable to battery.

(19) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(20) Start the engine and inspect for leaks.

ENGINE OIL PRESSURE

SENSOR

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to theinstrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

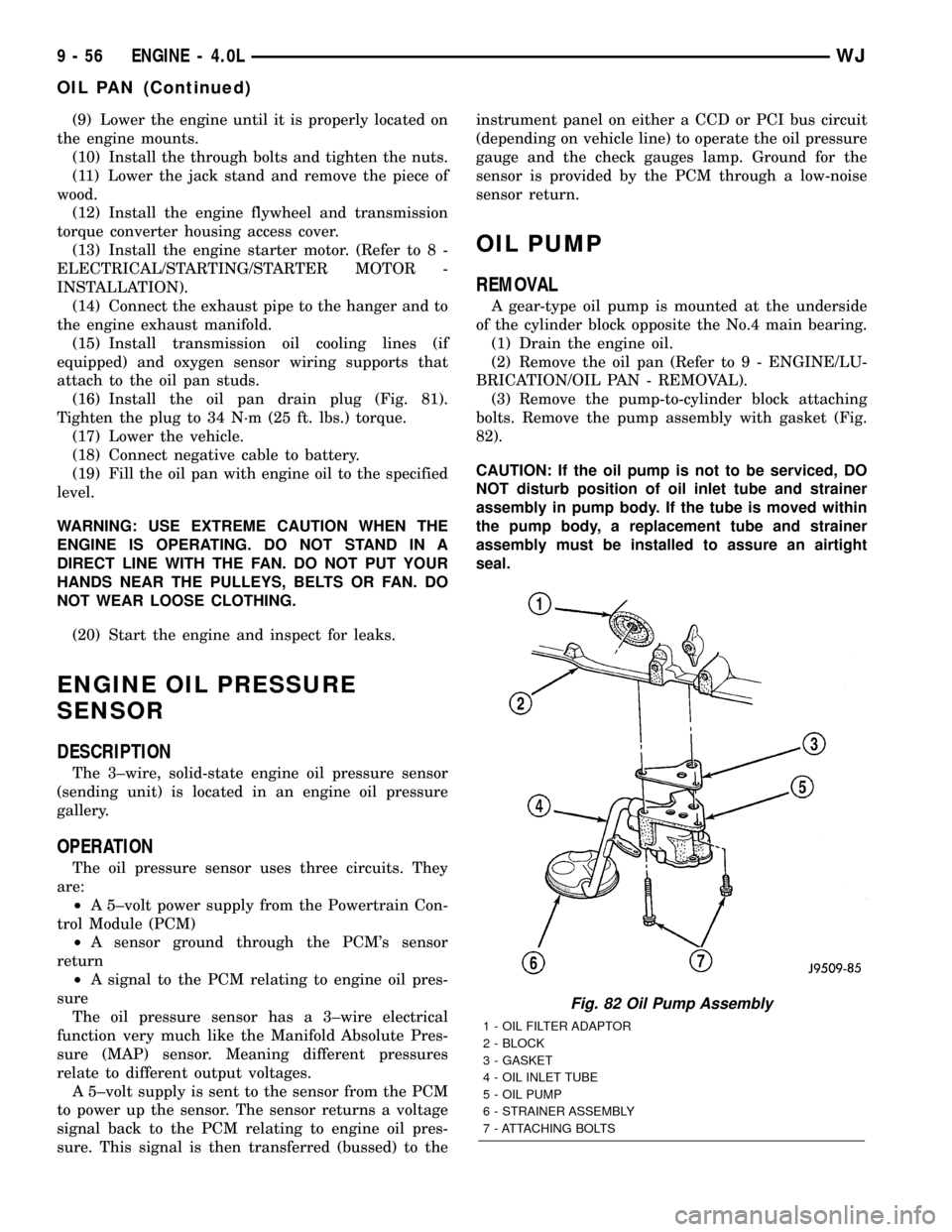

OIL PUMP

REMOVAL

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Drain the engine oil.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

82).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer

assembly must be installed to assure an airtight

seal.

Fig. 82 Oil Pump Assembly

1 - OIL FILTER ADAPTOR

2 - BLOCK

3 - GASKET

4 - OIL INLET TUBE

5 - OIL PUMP

6 - STRAINER ASSEMBLY

7 - ATTACHING BOLTS

9 - 56 ENGINE - 4.0LWJ

OIL PAN (Continued)

Page 1328 of 2199

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(8) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(9) Remove the power steering pump and set

aside.

(10) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

9).

WJENGINE - 4.7L 9 - 85

CYLINDER HEAD - LEFT (Continued)

Page 1340 of 2199

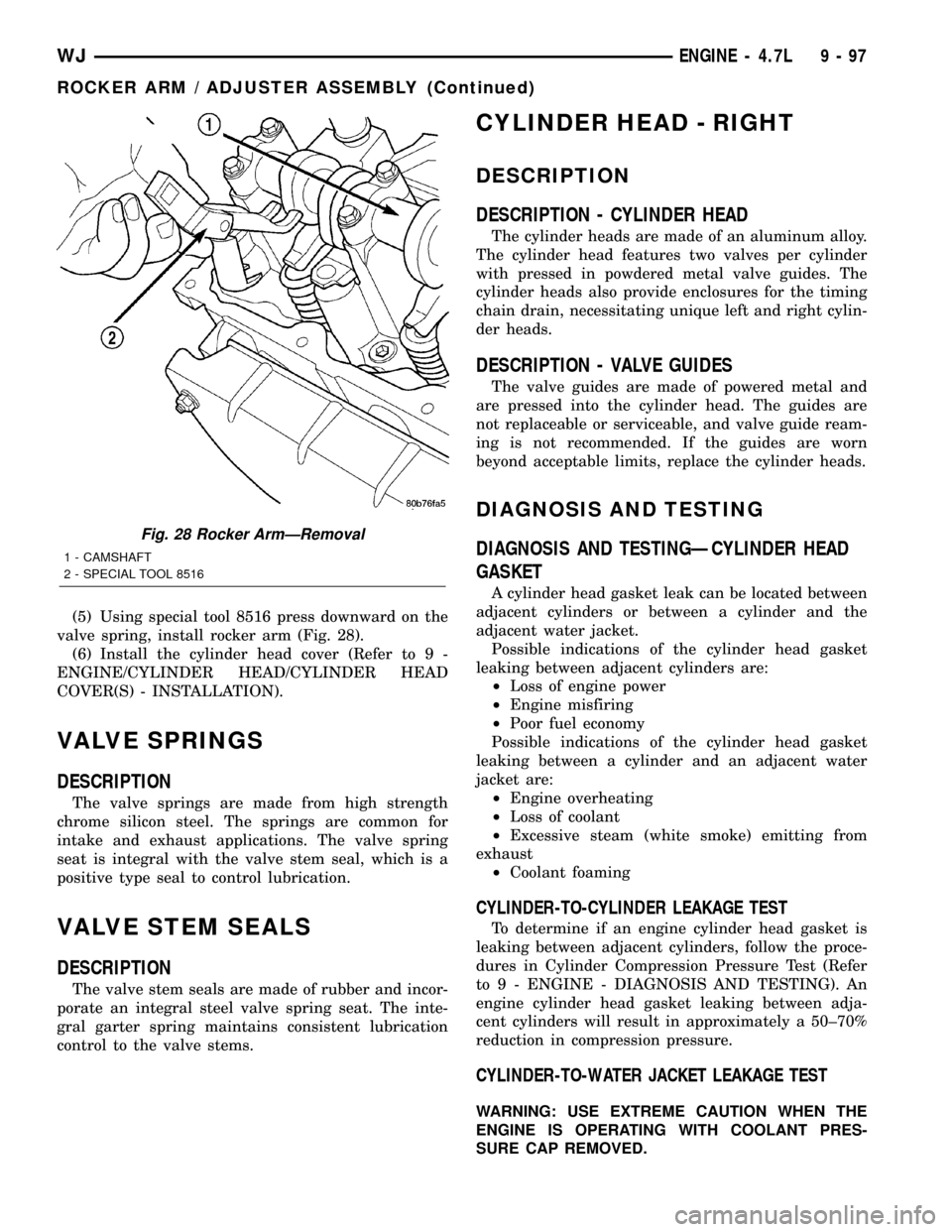

(5) Using special tool 8516 press downward on the

valve spring, install rocker arm (Fig. 28).

(6) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are common for

intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

VALVE STEM SEALS

DESCRIPTION

The valve stem seals are made of rubber and incor-

porate an integral steel valve spring seat. The inte-

gral garter spring maintains consistent lubrication

control to the valve stems.

CYLINDER HEAD - RIGHT

DESCRIPTION

DESCRIPTION - CYLINDER HEAD

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylin-

der heads.

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

Fig. 28 Rocker ArmÐRemoval

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

WJENGINE - 4.7L 9 - 97

ROCKER ARM / ADJUSTER ASSEMBLY (Continued)

Page 1439 of 2199

(19) Disconnect fuel return line at fuel filter/fuel

pressure regulator (Fig. 36). Refer to Quick-Connect

Fittings for procedures.

(20) Disconnect fuel pressure line at fuel filter/fuel

pressure regulator (Fig. 36). Refer to Quick-Connect

Fittings for procedures.

(21) Disconnect EVAP canister vent line near front

of tank (Fig. 36).

(22) Disconnect fuel pump module electrical con-

nector (pigtail harness) near front of tank (Fig. 36).

Harness connector is clipped to body.

(23) Remove left / front tank support bracket bolt

at frame (Fig. 37).

(24)WITHOUT TRAILER HITCH:Remove tank-

to-frame mounting bolts (Fig. 39). Remove rear tank

support bracket bolts at frame (Fig. 38). Carefully

lower tank until clear of vehicle. Place tank on floor.

(25)WITH TRAILER HITCH:Remove tank /

hitch mounting bolts (Fig. 40). Carefully lower tank

until clear of vehicle. Place tank on floor.

(26) If necessary, separate skid plate from fuel

tank by removing 2 fuel tank strap nuts (Fig. 39) and

remove 2 tank straps.

(27) If fuel pump module removal is necessary,

refer to Fuel Pump Module Removal/Installation.

(28) If hoses are to be removed at fuel tank end,

note painted alignment (indexing) markings on

hoses, and molded indexing tangs on tank before

removal. Remove hoses.

(29) If necessary, remove 3 fuel filler tube assem-

bly mounting bolts (Fig. 41) and remove fuel filler

tube.

INSTALLATION

CAUTION: HANDLE EVAP, LDP AND ORVR VAPOR /

VACUUM LINES VERY CAREFULLY. THESE LINES

AND HOSES MUST BE FIRMLY CONNECTED.

CHECK THE VAPOR/VACUUM LINES AT THE LDP,

LDP FILTER, EVAP CANISTER, EVAP CANISTER

PURGE SOLENOID AND ORVR COMPONENTS FOR

DAMAGE OR LEAKS. IF A LEAK IS PRESENT, A

DIAGNOSTIC TROUBLE CODE (DTC) MAY BE SET.

(1) If necessary, position fuel filler tube assembly

to body. Install 3 bolts and tighten to 2 N´m (15 in.

lbs.) torque.

(2) If necessary, connect quick-connect fittings to

fuel pump module.

(3) If fuel pump module is being installed, refer to

Fuel Pump Module Removal/Installation.

(4) Install fuel fill/vent hoses to tank fittings. To

prevent hoses from kinking, rotate each hose until

painted indexing mark on hose is aligned to molded

indexing tang on tank.

(5) Install hose clamps to hoses. Refer to Torque

Specifications.(6) If necessary, position fuel tank into skid plate.

Install 2 tank straps and 2 strap nuts (Fig. 39). Refer

to Torque Specifications.

(7) Position fuel tank / skid plate assembly to

hydraulic jack.

(8) Raise tank into position to frame.

(9)WITH TRAILER HITCH:Position trailer

hitch and tow hooks (Fig. 40) to bottom of fuel tank.

Install bolts and nuts loosely.

(10)WITHOUT TRAILER HITCH:Install 2 rear

tank support brackets and bolts (Fig. 38). Install

tank-to-frame bolts. Do not tighten bolts / nuts at

this time.

(11) Install 1 left / front tank support bracket and

bolts / nuts (Fig. 37). Do not tighten bolts / nuts at

this time.

(12) Be sure fuel tank is properly aligned to frame

and body. Tighten all tank, tow hook and trailer

hitch bolts / nuts except for 3 support brackets.

Tighten all 3 (2 rear and 1 left / front) support

bracket bolts / nuts last. Refer to Torque Specifica-

tions.

(13)

(14) Connect fuel pump module pigtail harness

electrical connector near front of tank.

(15) Connect both fuel lines to fuel filter/fuel pres-

sure regulator. Refer to Quick-Connect Fittings for

procedures.

(16) Connect EVAP hose near front of tank.

(17) Position rear axle vent hose and install new

tie strap (Fig. 32).

(18) Install heat shield nuts / bolts (Fig. 35). Refer

to Torque Specifications.

(19) Connect ORVR hose elbow (Fig. 33) to top of

EVAP canister.

(20) Connect fuel vent hose to fuel vent tube (Fig.

32).

(21) Install fuel fill hose and clamp to fuel fill tube

(Fig. 32).

(22) Install 3 LDP mounting bolts (Fig. 29).

(23) While raising support bracket, connect LDP

wiring clip (Fig. 31). Install front section of two-piece

support bracket to rear section with 3 attaching bolts

located on bottom of support bracket (Fig. 30).

(24) Install support bracket brace bolt (Fig. 30).

(25) Tighten 2 support bracket nuts at frame rail

(Fig. 29).

(26) Install fuel tank-to-rear bumper fascia clips

(Fig. 34).

(27) Using new plastic rivets, install stone shield

behind left/rear wheel (Fig. 28).

(28) Install left rear wheel/tire.

(29) Lower vehicle and connect negative battery

cable to battery.

(30) Fill tank with fuel and check for leaks.

14 - 20 FUEL DELIVERYWJ

FUEL TANK (Continued)