lock JEEP GRAND CHEROKEE 2012 WK2 / 4.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2012, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2012 WK2 / 4.GPages: 148, PDF Size: 5.91 MB

Page 87 of 148

Shifting Procedures

4WD HI To 4WD LOW• With the vehicle at speeds of 0 to 3 mph (0 to 5 km/h), the ignition switch in the ON/RUN position or the engine running, shift the

transmission into NEUTRAL, and press the “4WD LOW” button once on

the transfer case switch. The “4WD LOW” indicator light in the

instrument cluster will begin to flash and remain on solid when the shift

is complete.

4WD LOW To 4WD HI • With the vehicle at speeds of 0 to 3 mph (0 to 5 km/h), the ignition switch in the ON/RUN position or the engine running, shift the

transmission into NEUTRAL, and press the “4WD LOW” button once on

the transfer case switch. The “4WD LOW” indicator light in the

instrument cluster will flash and turn off when the shift is complete.

NOTE:

• If the shift conditions/interlocks are not met, or a transfer case motor temperature protection exists, a “For 4x4 Low Slow Below 5 MPH or 8 KPH

Put Trans in N Press 4 Low” message will flash on the Electronic Vehicle

Information Center (EVIC).

• Shifting into or out of 4WD LOW is possible with the vehicle completely stopped; however, d ifficulty may occur due to the mating clutch teeth not

being properly aligned. Several attempts may be required for clutch teeth

alignment and shift completion to occur. The preferred method is with the

vehicle rolling 0 to 3 mph (0 to 5 km/h). If the vehicle is moving faster than

3 mph (5 km/h), the transfer case will not allow the shift.

NEUTRAL Shift Procedure

• Turn the ignition switch to the ON/RUN position, engine off.

• Vehicle stopped, with foot on brake.

• Place the transmission into NEUTRAL.

• Press and hold the NEUTRAL button located near the 4WD mode control knob with a pen or similar object for four seconds. The indicator light will

begin to flash indicating the shift is in progress. The light will stop

blinking (stay on solid) when the NEUTRAL shift is complete. A “4WD

SYSTEM IN NEUTRAL” message will display on the Electronic Vehicle

Information Center (EVIC).

• Repeat these Steps to shift out of NEUTRAL.

OFF-ROAD CAPABILITIES

85

Page 100 of 148

• Your vehicle has also been equipped with a TPMS malfunction indicatorto indicate when the system is not operating properly. The TPMS

malfunction indicator is combined with the low tire pressure telltale.

When the system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously illuminated. This

sequence will continue each time the vehicle is restarted as long as the

malfunction exists.

• When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions

may occur for a variety of reasons, including the installation of

replacement or alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS malfunction

telltale after replacing one or more tires or wheels on your vehicle, to

ensure that the replacement or alternate tires and wheels allow the TPMS

to continue to function properly.

NOTE: Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C)

of air temperature change. Keep this in mind when checking tire pressure

inside a garage, especially in the Winter. Example: If garage temperature is

68°F (20°C) and the outside temperature is 32°F (0°C), then the cold tire

inflation pressure should be increased by 3 psi (21 kPa), which equals 1 psi

(7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and

wheels. TPMS pressures and warning have been established for the

tire size equipped on your vehicle. Undesirable system operation or

sensor damage may result when using replacement equipment that is

not of the same size, type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or balance beads if

your vehicle is equipped with a TPMS, as damage to the sensors may

result.

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or the parking brake is applied. If the light is on and the

parking brake is not applied, it indicates a possible brake hydraulic

malfunction, brake booster problem or an Anti-Lock Brake System

problem.

• Please have your vehicle serviced immediately.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the

brake system may have failed. It will take longer to stop the vehicle.

You could have a collision. Have the vehicle checked immediately.

WHAT TO DO IN EMERGENCIES

98

Page 101 of 148

- Malfunction Indicator Light (MIL)

• Certain conditions, such as a loose or missing gas cap, poor fuel quality,etc., may illuminate the MIL after engine start. The vehicle should be

serviced if the light stays on through several typical driving cycles. In

most situations, the vehicle will drive normally and not require towing.

• If the MIL flashes when the engine is running, serious conditions may exist that could lead to immediate loss of power or severe catalytic

converter damage. We recommend you do not operate the vehicle. Have

the vehicle serviced immediately.

- Electronic Stability Control (ESC) Activation/MalfunctionIndicator Light

• If the “ESC Activation/Malfunction Indicator Light” comes on

continuously with the engine running, a malfunction has been detected

in the ESC system. If this light remains on after several ignition cycles,

and the vehicle has been driven several miles (kilometers) at speeds

greater than 30 mph (48 km/h), we recommend you drive to the nearest

service center and have the vehicle serviced immediately.

• The “ESC Activation/Malfunction Indicator Light” starts to flash as soon as the tires lose traction and the ESC system becomes active. If the light

begins to flash during acceleration, ease up on the accelerator and apply

as little throttle as possible. Be sure to adapt your speed and driving to

the prevailing road conditions. The light also flashes when TCS is active.

To improve the vehicle's traction when starting off in deep snow, sand or

gravel, it may be desirable to switch the ESC system to Partial Off mode

by momentarily pressing the ESC Off

switch located below the

climate controls, on the switch panel.

- Charging System Light

• This light shows the status of the electrical charging system. If the charging system light remains on, it means that the vehicle is

experiencing a problem with the charging system.

• We recommend you do not continue driving if the charging system light is on. Have the vehicle serviced immediately.

- Oil Pressure Warning Light

• This light indicates low engine oil pressure. If the light turns on whiledriving, stop the vehicle and shut off the engine as soon as possible. A

chime will sound for four minutes when this light turns on.

• We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving,we recommend you drive to the nearest service center and have the

vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

99

Page 102 of 148

- Electronic Throttle Control (ETC) Light

• This light informs you of a problem with the Electronic Throttle Control(ETC) system.

• If a problem is detected, the light will come on while the engine is running. Cycle the ignition key when the vehicle has completely stopped

and the shift lever is placed in the PARK position; the light should turn

off.

• If the light remains lit with the engine running, your vehicle will usually be drivable; however, see an authorized service center i mmediately. If the

light is flashing when the engine is running, immediate service is required

and you may experience reduced performance, an elevated/rough idle or

engine stall and your vehicle may require towing.

- Air Bag Warning Light

• If the light is not on during starting, stays on, or turns on while driving, have the vehicle serviced by an authorized service center immediately.

Fuel Cap/Loose Gas Cap Message

• If a “gas cap” message (shown as Check Gascap) appears, tighten thegas cap until a “clicking” sound is heard.

• If the message continues to appear for more than three days after tightening the gas cap, have the vehicle serviced by an authorized

service center immediately.

Oil Change IndicatorMessage

• If an “oil change” message (shown as Oil Change Required) appears and a single chime sounds, it is time for your next required oil change.

Resetting The Light After Servicing

Vehicles Equipped With Keyless Enter-N-Go™ • Without pressing the brake pedal, push the ENGINE START/STOP button and cycle the ignition to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Without pressing the brake pedal, push the ENGINE START/STOP button once to return the ignition to the OFF/LOCK position.

Vehicles Not Equipped With Keyless Enter-N-Go™

• Turn the ignition switch to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

WHAT TO DO IN EMERGENCIES

100

Page 106 of 148

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slippery surfaces.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn the ignition OFF.

6. For vehicle equipped with Quadra-Lift® refer to “Quadra-Lift — IfEquipped” in “Starting And Operating” on the DVD for further

information on disabling automatic leveling.

Block both the front and rear of the

wheel diagonally opposite of the

jacking position. For example, if

changing the right front tire, block the

left rear wheel.

NOTE:Passengers should not remain

in the vehicle when the vehicle is

being jacked.

Jacking Instructions

1. Remove the spare tire, jack, and tools from storage.

2. Loosen (but do not remove) the wheel lug nuts by turning them to

the left, one turn, while the wheel

is still on the ground.

3. Assemble the jack and jacking tools.

WHAT TO DO IN EMERGENCIES

104

Page 108 of 148

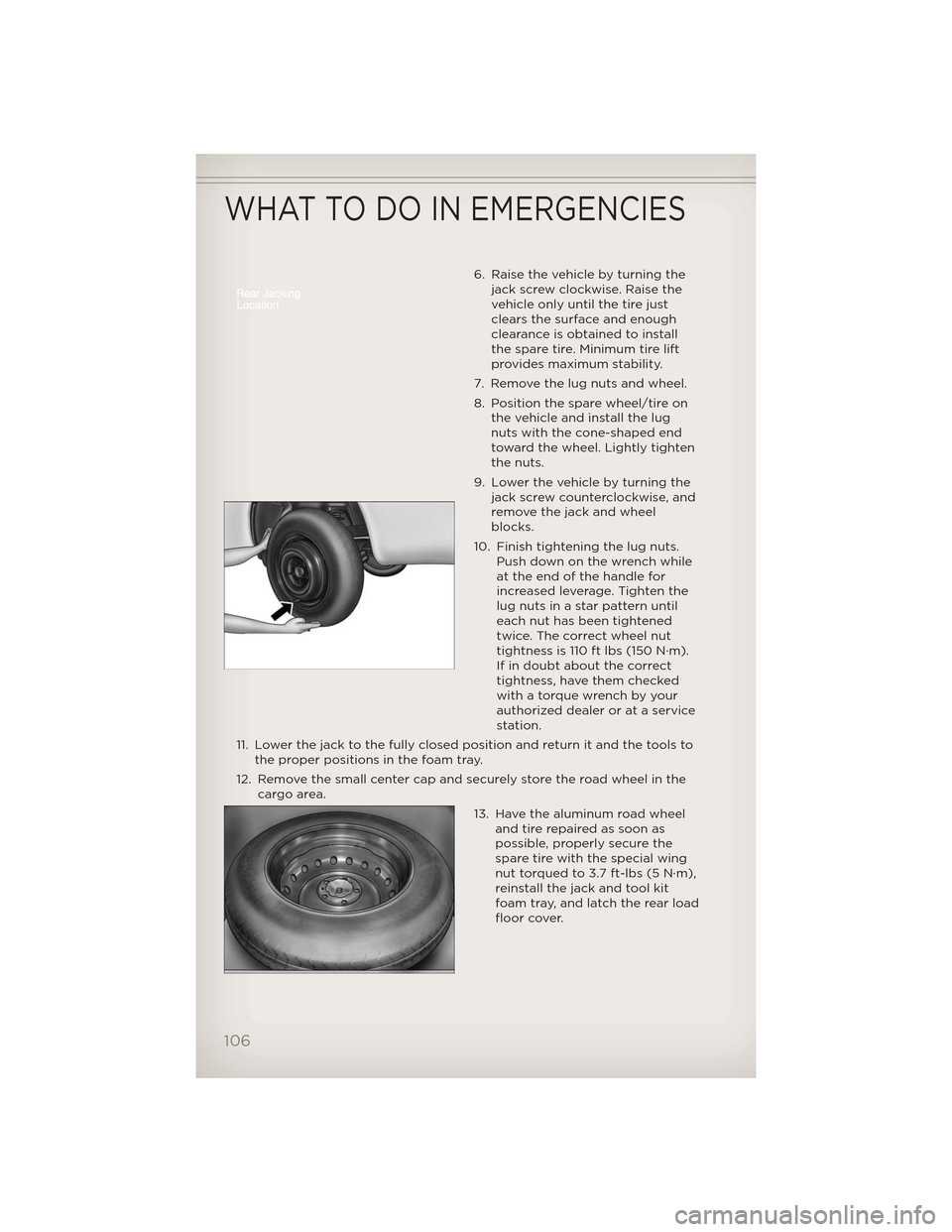

6. Raise the vehicle by turning thejack screw clockwise. Raise the

vehicle only until the tire just

clears the surface and enough

clearance is obtained to install

the spare tire. Minimum tire lift

provides maximum stability.

7. Remove the lug nuts and wheel.

8. Position the spare wheel/tire on the vehicle and install the lug

nuts with the cone-shaped end

toward the wheel. Lightly tighten

the nuts.

9. Lower the vehicle by turning the jack screw counterclockwise, and

remove the jack and wheel

blocks.

10. Finish tightening the lug nuts. Push down on the wrench while

at the end of the handle for

increased leverage. Tighten the

lug nuts in a star pattern until

each nut has been tightened

twice. The correct wheel nut

tightness is 110 ft lbs (150 N·m).

If in doubt about the correct

tightness, have them checked

with a torque wrench by your

authorized dealer or at a service

station.

11. Lower the jack to the fully closed position and return it and the tools to the proper positions in the foam tray.

12. Remove the small center cap and securely store the road wheel in the cargo area.

13. Have the aluminum road wheeland tire repaired as soon as

possible, properly secure the

spare tire with the special wing

nut torqued to 3.7 ft-lbs (5 N·m),

reinstall the jack and tool kit

foam tray, and latch the rear load

floor cover.

WHAT TO DO IN EMERGENCIES

106

Page 109 of 148

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nuttoward the wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star

pattern until each nut has been tightened twice. The correct tightness of

each lug nut is 110 ft/lbs (150 N·m). If in doubt about the correct

tightness, have them checked with a torque wrench by your authorized

dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

CAUTION!

• Do not attempt to raise the vehicle by jacking on locations otherthan those indicated in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle could be damaged if the spare tire is mounted

incorrectly.

WARNING!

• Do not attempt to change a tire on the side of the vehicle close tomoving traffic. Pull far enough off the road to avoid the danger of

being hit when operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and fall on you. You could be crushed. Never put any

part of your body under a vehicle that is on a jack. If you need to

get under a raised vehicle, take it to a service center where it can be

raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack should not be used to lift the vehicle for service purposes. The

vehicle should be jacked on a firm level surface only. Avoid ice or

slippery areas.

• Always park on a firm, level surface as far from the edge of the

roadway as possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK.

(Continued)

WHAT TO DO IN EMERGENCIES

107

Page 111 of 148

Preparations for Jump-Start

• The battery in your vehicle islocated under the passengers

front seat. There are remote

locations under the hood to assist

in jump starting.

• Set the parking brake, shift the automatic transmission into PARK

and turn the ignition to LOCK.

• Turn off the heater, radio, and all unnecessary electrical accessories.

• Remove the protective cover over the remote positive (+) battery

post. Pull upward on the cover to

remove it.

• If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the

ignition is OFF.

Jump-Starting Procedure

• Connect the positive (+)end of the jumper cable to the remote positive

(+) post of the discharged vehicle.

• Connect the opposite end of the positive (+)jumper cable to the positive

(+) post of the booster battery.

• Connect the negative end (-)of the jumper cable to the negative (-)post

of the booster battery.

• Connect the opposite end of the negative (-)jumper cable to the remote

negative (-)post of the vehicle with the discharged battery.

• Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the

discharged battery.

Once the engine is started, remove the jumper cables in the reverse

sequence:

• Disconnect the negative (-)jumper cable from the remote negative (-)

post of the vehicle with the discharged battery.

• Disconnect the negative end (-)of the jumper cable from the negative

(-) post of the booster battery.

• Disconnect the opposite end of the positive (+)jumper cable from the

positive (+)post of the booster battery.

• Disconnect the positive (+)end of the jumper cable from the remote

positive (+)post of the discharged vehicle.

• Reinstall the protective cover over the remote positive (+)battery post

of the discharged vehicle.

WHAT TO DO IN EMERGENCIES

109

Page 116 of 148

OPENING THE HOOD

• Pull the hood release lever locatedbelow the steering wheel at the

base of the instrument panel.

• Reach into the opening beneath the center of the hood and move

the safety latch lever while lifting

the hood at the same time.

WARNING!

Be sure the hood is fully latched before driving your vehicle. If the

hood is not fully latched, it could open when the vehicle is in motion

and block your vision. Failure to follow this warning could result in

serious injury or death.

FUEL DOOR RELEASE

• The fuel door release button islocated on the instrument panel

below the headlight switch.

• Push the button once and release to open the fuel door.

MAINTAINING YOUR VEHICLE

114

Page 129 of 148

Integrated Power Module (fuses)

The integrated power module is located on the right side of the engine

compartment. This center contains cartridge fuses and mini fuses. A

description of each fuse and component may be stamped on the inside

cover, otherwise the cavity number of each fuse is stamped on the inside

cover that corresponds to the following chart.

CavityCartridge

Fuse Mini Fuse Description

J01 40 Amp Green Air Suspension

J02 30 Amp Pink Power Liftgate Module

J03 30 Amp Pink Trailer Tow

J04 25 Amp Natural Driver Door Node

J05 25 Amp Natural Passenger Door Node

J06 40 Amp Green ABS Pump Feed/ESP

J07 30 Amp Pink ABS Valve Feed/ESP

J08 40 Amp Green Power Seat

J09 30 Amp Pink E-Brake

J10 30 Amp Pink Headlamp Wash Relay Contact

J11 30 Amp Pink DTCM

J13 60 Amp Yellow Streaming Video Module/

VES3 Module/VES2

Module/DISP/DVD

J14 20 Amp Blue Trailer Tow Lamps/Park Lamps

J15 40 Amp Green Rear Window Defroster

J17 40 Amp Green Starter Motor Solenoid Feed

J18 20 Amp Blue NGC/PCM Transmission Range

J19 60 Amp Yellow Rad Fan Motor HI/Rad Fan

Motor Low

J20 30 Amp Pink Front Wiper Ground

J21 20 Amp Blue Front Washer Control/Rear

Washer Control

J22 25 Amp Natural PWR Batt – Sunroof Mod

M1 15 Amp Blue Sw Stop Switch Lamp Feed

M2 20 Amp

Yellow ELSD/Air Suspension

M3 20 Amp

Yellow Liftgate Unlock/DRL Relay

M4 10 Amp Red Trailer Tow

MAINTAINING YOUR VEHICLE

127