engine JEEP GRAND CHEROKEE 2017 WK2 / 4.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 244 of 372

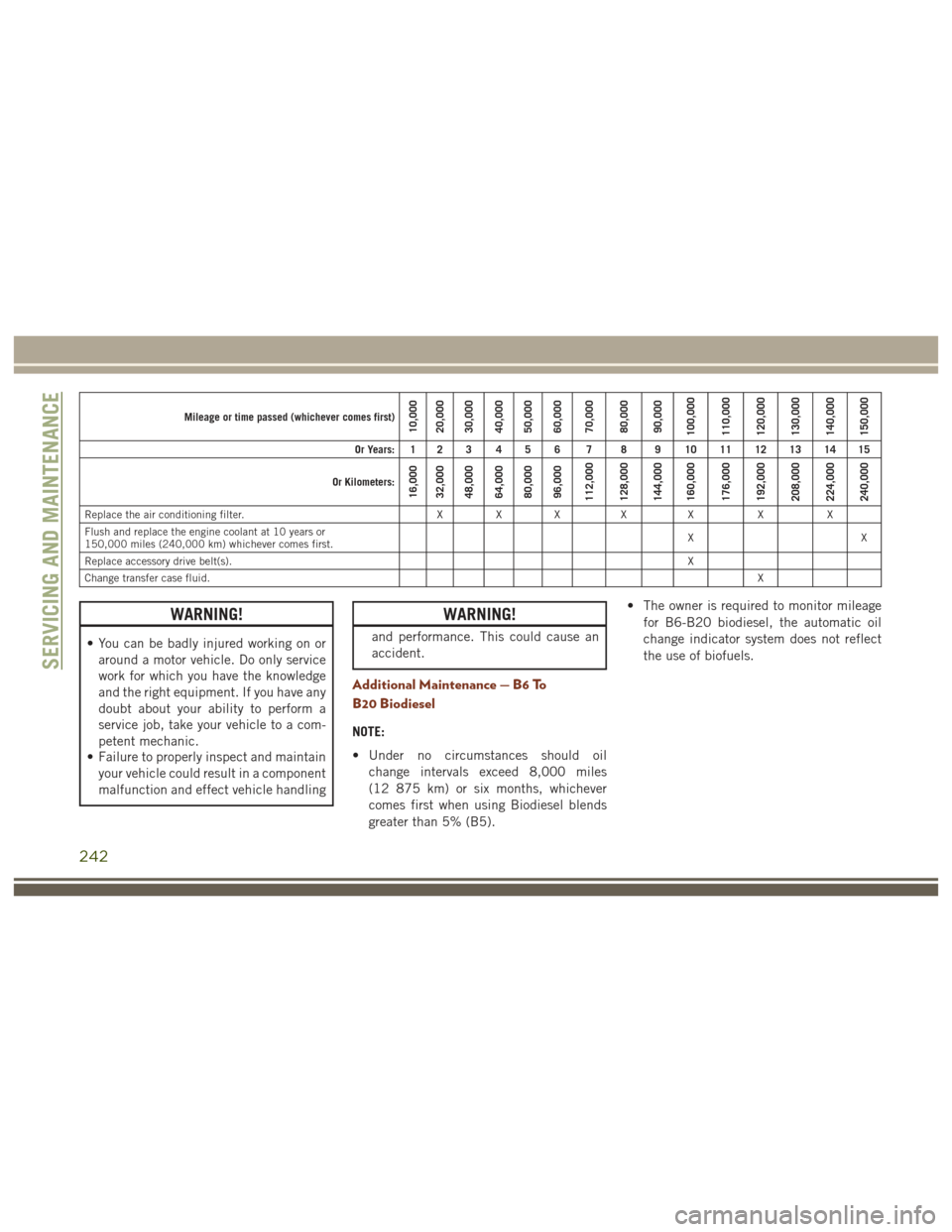

Mileage or time passed (whichever comes first)10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Replace the air conditioning filter. X X XXX XX

Flush and replace the engine coolant at 10 years or

150,000 miles (240,000 km) whichever comes first. XX

Replace accessory drive belt(s). X

Change transfer case fluid. X

WARNING!

• You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

WARNING!

and performance. This could cause an

accident.

Additional Maintenance — B6 To

B20 Biodiesel

NOTE:

• Under no circumstances should oil

change intervals exceed 8,000 miles

(12 875 km) or six months, whichever

comes first when using Biodiesel blends

greater than 5% (B5). • The owner is required to monitor mileage

for B6-B20 biodiesel, the automatic oil

change indicator system does not reflect

the use of biofuels.

SERVICING AND MAINTENANCE

242

Page 246 of 372

ENGINE COMPARTMENT

3.6L Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Engine Oil Filter Access

4 — Engine Oil Fill 9 — Engine Coolant Reservoir

5 — Brake Fluid Reservoir 10 — Remote Jump Start Negative Terminal

SERVICING AND MAINTENANCE

244

Page 247 of 372

5.7L Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Coolant Pressure Cap (Radiator)

4 — Engine Oil Fill 9 — Engine Coolant Reservoir

5 — Brake Fluid Reservoir 10— Remote Jump Start Negative Terminal

245

Page 248 of 372

6.4L Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Coolant Pressure Cap (Radiator)

4 — Engine Oil Fill 9 — Engine Coolant Reservoir

5 — Brake Fluid Reservoir 10 — Remote Jump Start Negative Terminal

SERVICING AND MAINTENANCE

246

Page 249 of 372

3.0L Diesel Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Coolant Pressure Reservoir

4 — Engine Oil Fill 9 — Remote Jump Start Negative Terminal

5 — Brake Fluid Reservoir

247

Page 250 of 372

Checking Oil Level — Gasoline Engine

To assure proper lubrication of your vehicle’s

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals, such as every fuel stop. The best

time to check the engine oil level is about five

minutes after a fully warmed up engine is

shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Always maintain the oil level

within the SAFE zone on the dipstick. Adding

one quart of oil when the reading is at the

bottom of the SAFE zone will result in a

reading at the top of the safe zone on these

engines.

CAUTION!

Overfilling or underfilling the crankcase

will cause aeration or loss of oil pressure.

This could damage your engine.

Checking Oil Level — Diesel Engine

To assure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals. The best time to check the oil level

is before starting the engine after it has been

parked overnight. When checking oil after

operating the engine, first ensure the engine

is at full operating temperature, then wait for

five minutes after engine shutdown to check

the oil.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Add oil only when the level on

the dipstick is below the “MIN” mark. The

total capacity from the MIN mark to the MAX

mark is 1.7 qts (1.6L).

CAUTION!

Overfilling or underfilling the crankcase

will cause oil aeration or loss of oil pres-

sure. This could damage your engine.NOTE:

It is possible for your oil level to be slightly

higher than a previous check. This would be

due to diesel fuel that may temporarily be in

the crankcase due to operation of the diesel

particulate filter regeneration strategy. This

fuel will evaporate out under normal opera-

tion.

Never operate the engine with oil level below

the “MIN” mark or above the upper “MAX”

mark.

Adding Washer Fluid

The instrument cluster display will indicate

when the washer fluid level is low. When the

sensor detects a low fluid level, the wind-

shield will light on the vehicle graphic outline

and the “WASHER FLUID LOW” message

will be displayed.

The fluid reservoir for the windshield washers

and the rear window washer is shared. The

fluid reservoir is located in the engine com-

partment, be sure to check the fluid level at

regular intervals. Fill the reservoir with wind-

shield washer solvent only (not radiator anti-

freeze). When refilling the washer fluid reser-

SERVICING AND MAINTENANCE

248

Page 255 of 372

6. Remove the A/C air filter by pulling itstraight out of the housing.

7. Install the A/C air filter with the arrow on the filter pointing toward the floor. When

installing the filter cover, make sure the

retaining tabs fully engage the cover.

CAUTION!

The cabin air filter is identified with an

arrow to indicate airflow direction through

the filter. Failure to properly install the

filter will result in the need to replace it

more often.

8. Reinstall the glove compartment door on the glove compartment door hinge and

reattach the glove compartment tension

tether by inserting the tether clip in the

glove compartment and sliding the clip

away from the face of the glove compart-

ment door.

9. Push the door to the near closed position to reengage the glove compartment travel

stops.

NOTE:

Ensure the glove compartment door

hinges and glove compartment travel

stops are fully engaged.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades

and the windshield periodically with a sponge

or soft cloth and a mild nonabrasive cleaner.

This will remove accumulations of salt or road

film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using

the wipers to remove salt or dirt from a dry

windshield.

Avoid using the wiper blades to remove frost

or ice from the windshield. Keep the blade

rubber out of contact with petroleum prod-

ucts such as engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies de-

pending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary.

A/C Air Filter Cover

1 — Retaining Tab

2 — Mid Way Snap

3 — Filter Cover Hinge

253

Page 259 of 372

Installing The Rear Wiper

1. Lift the rear wiper arm pivot cap awayfrom the glass to allow the rear wiper

blade to be raised off of the glass.

NOTE:

The rear wiper arm cannot be fully raised

off the glass unless the wiper arm pivot

cap is unsnapped first. Attempting to fully

raise the rear wiper arm without unsnap-

ping the wiper arm pivot cap may damage

the vehicle.

2. Lift the rear wiper arm fully off the glass.

3. Insert the wiper blade pivot pin into the opening on the end of the wiper arm. Grab

the bottom end of the wiper arm with one

hand, and press the wiper blade flush with

the wiper arm until it snaps into place.

4. Lower the wiper blade onto the glass and snap the wiper arm pivot cap back into

place.Cooling System

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

pressure cap when the radiator or coolant

bottle is hot.

Engine Coolant Checks

Check the engine coolant (antifreeze) protec-

tion every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty, the sys-

tem should be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032) by an authorized dealer. Check the front of the A/C condenser for any accu-

mulation of bugs, leaves, etc. If dirty, clean

by gently spraying water from a garden hose

vertically down the face of the condenser.

Check the engine cooling system hoses for

brittle rubber, cracking, tears, cuts, and

tightness of the connection at the coolant

recovery bottle and radiator. Inspect the en-

tire system for leaks.

With the engine at normal operating tempera-

ture (but not running), check the cooling

system pressure cap for proper vacuum seal-

ing by draining a small amount of engine

coolant (antifreeze) from the radiator drain

cock. If the cap is sealing properly, the engine

coolant (antifreeze) will begin to drain from

the coolant recovery bottle. DO NOT RE-

MOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.

257

Page 269 of 372

WARNING!

The traction grade assigned to this tire is

based on straight-ahead braking traction

tests, and does not include acceleration,

cornering, hydroplaning, or peak traction

characteristics.

Temperature Grades

The temperature grades are A (the highest),

B, and C, representing the tire's resistance to

the generation of heat and its ability to dissi-

pate heat, when tested under controlled con-

ditions on a specified indoor laboratory test

wheel.

Sustained high temperature can cause the

material of the tire to degenerate and reduce

tire life, and excessive temperature can lead

to sudden tire failure. The grade C corre-

sponds to a level of performance, which all

passenger vehicle tires must meet under the

Federal Motor Vehicle Safety Standard No.

109. Grades B and A represent higher levels

of performance on the laboratory test wheel,

than the minimum required by law.

WARNING!

The temperature grade for this tire is es-

tablished for a tire that is properly inflated

and not overloaded. Excessive speed,

under-inflation, or excessive loading, ei-

ther separately or in combination, can

cause heat buildup and possible tire fail-

ure.

STORING THE VEHICLE

If the vehicle should remain stationary for

more than a month, observe the following

precautions:

• Park your vehicle in a covered, dry andpossibly airy location the windows open

slightly.

• Check that the Electric Park Brake is not engaged.

• Disconnect the negative (-) terminal from the battery post and be sure that the

battery is fully charged. During storage

check battery charge quarterly. • If you do not disconnect the battery from

the electrical system, check the battery

charge every thirty days.

• Clean and protect the painted parts by applying protective waxes.

• Clean and protect polished metal parts by applying protective waxes.

• Apply talcum powder to the front and rear wiper blades and leave raised from the

glass.

• Cover the vehicle with an appropriate cover taking care not to damage the

painted surface by dragging across dirty

surfaces. Do not use plastic sheeting

which will not allow the evaporation of

moisture present on the surface of the

vehicle.

• Inflate the tires at a pressure of +7.25 psi (+0.5 bar) higher than recommended on

the tire placard and check it periodically.

• Do not drain the engine cooling system.

• Whenever you leave the vehicle is station- ary for two weeks or more, run idle the

engine for approximately five minutes,

with the air conditioning system on and

high fan speed. This will ensure a proper

267

Page 273 of 372

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION

NUMBER................ .272

WHEEL AND TIRE TORQUE SPECI-

FICATIONS ............... .272

Torque Specifications............273

FUEL REQUIREMENTS – GASOLINE

ENGINE.................. .273

3.6L Engine.................273

5.7L Engine .................274

6.4L Engine .................274

Materials Added To Fuel .........274

FUEL REQUIREMENTS – DIESEL EN-

GINE.................... .275

Diesel Fuel Specifications........275

FLUID CAPACITIES NON-SRT . .276

SRT FLUID CAPACITIES.......276

DIESEL FLUID CAPACITIES . . . .277

FLUIDS AND LUBRICANTS NON-

SRT..................... .277

Engine.....................277

Chassis ....................279

FLUIDS AND LUBRICANTS

SRT .................... .280

Engine.....................280

Chassis ....................281

FLUIDS AND LUBRICANTS – DIESEL

ENGINE...................281

Engine.....................281

Chassis ....................283

MOPARACCESSORIES .......283

Authentic Accessories By Mopar .....283

TECHNICAL SPECIFICATIONS

271