JEEP GRAND CHEROKEE 2023 Owners Manual

Manufacturer: JEEP, Model Year: 2023, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2023Pages: 424, PDF Size: 15.48 MB

Page 351 of 424

SERVICING AND MAINTENANCE349

coolant (antifreeze) in the bottle should be

between the ranges indicated on the bottle.

The radiator normally remains completely full, so

there is no need to remove the radiator/coolant

pressure cap unless checking for engine coolant

freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine

operating temperature is satisfactory, the coolant

bottle need only be checked once a month.

When additional engine coolant is needed to

maintain the proper level, only OAT coolant that

meets the requirements of the manufacturer

Material Standard MS.90032 should be added to

the coolant bottle. Do not overfill.

Engine Coolant Level — 2.0L

With the engine OFF and cold, the level of the

engine coolant should be within the OK range

between the ADD and FULL range on the dipstick.

1. Remove the cap with level dipstick from the engine coolant bottle.

2. Clean off the coolant from the dipstick.

3. Rest the cap on the opening of the coolant bottle without tightening the cap.

4. Remove the cap with dipstick and check the coolant level on the dipstick.

The radiator normally remains completely full, so

there is no need to remove the radiator/coolant

pressure cap unless checking for engine coolant

freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine

operating temperature is satisfactory, the coolant

bottle need only be checked once a month.

When additional engine coolant is needed to

maintain the proper level, only OAT coolant that

meets the requirements of the manufacturer

Material Standard MS.90032 should be added to

the coolant bottle. Do not overfill.Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilo -

meters of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to

enter the radiator.

If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

aluminum components.

WARNING!

Do not open a hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated engine.

Heat causes pressure to build up in the

cooling system. To prevent scalding or injury,

do not remove the pressure cap while the

system is hot or under pressure.

Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or

engine damage may result.

8

23_WL_OM_EN_USC_t.book Page 349

Page 352 of 424

350SERVICING AND MAINTENANCE

(Continued)

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces-

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Ú page 331.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the Brake System Warning Light is

on. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes, fluid level can be expected to fall

as the brake pads wear. Brake fluid level should be

checked when pads are replaced. If the brake fluid

is abnormally low, check the system for leaks.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended brake

fluid Ú page 402. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum-based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

23_WL_OM_EN_USC_t.book Page 350

Page 353 of 424

SERVICING AND MAINTENANCE351

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission.

Avoid using transmission sealers as they may

adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid And Filter Changes

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer's specified

transmission fluid Úpage 402. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid.

NOTE:No chemical flushes should be used in any trans -

mission; only the approved lubricant should be

used.

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks are

not required. When the vehicle is serviced for other

reasons the exterior surfaces of the axle assembly

should be inspected. If gear oil leakage is

suspected inspect the fluid level.

Front Axle Fluid Level Check

The front axle oil level needs to be no lower than

1/8 inch (3 mm) below the bottom of the fill hole.

The front axle fill and drain plugs should be

tightened to 22 to 29 ft-lb (30 to 40 N·m).

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder.

CAUTION!

Do not overtighten the plugs as it could damage

them and cause them to leak.

8

23_WL_OM_EN_USC_t.book Page 351

Page 354 of 424

352SERVICING AND MAINTENANCE

Rear Axle Fluid Level Check

The rear axle oil level needs to be no lower than

1/8 inch (3 mm) below the bottom of the fill hole.

The rear axle fill and drain plugs should be

tightened to 22 to 29 ft-lb (30 to 40 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended fluid

Úpage 402.

TRANSFER CASE

Fluid Level Check

For normal service, periodic fluid level checks are

not required. When the vehicle is serviced for other

reasons the exterior surfaces of the transfer case

assembly should be inspected. If oil leakage is

suspected inspect the fluid level.

Adding Fluid

Add fluid at the filler hole, until it runs out of the

hole, when the vehicle is in a level position.

Drain

First remove fill plug, then remove drain plug.

Recommended tightening torque for drain and fill

plugs is 15 to 25 ft-lb (20 to 34 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended fluid

Úpage 402.

FUSES

General Information

CAUTION!

Do not overtighten the plugs as it could damage

them and cause them to leak.CAUTION!

When installing plugs, do not overtighten. You

could damage them and cause them to leak.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

The use of a fuse with a rating other than indi -

cated may result in a dangerous electrical

system overload. If a properly rated fuse

continues to blow, it indicates a problem in the

circuit that must be corrected. Never replace a

blown fuse with metal wires or any other mate -

rial. Do not place a fuse inside a circuit

breaker cavity or vice versa. Failure to use

proper fuses may result in serious personal

injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, transmission

system) or steering system blows, contact an

authorized dealer.

23_WL_OM_EN_USC_t.book Page 352

Page 355 of 424

SERVICING AND MAINTENANCE353

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check the

fuse element inside the blade fuse for a break/

melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may

result in vehicle battery discharge.

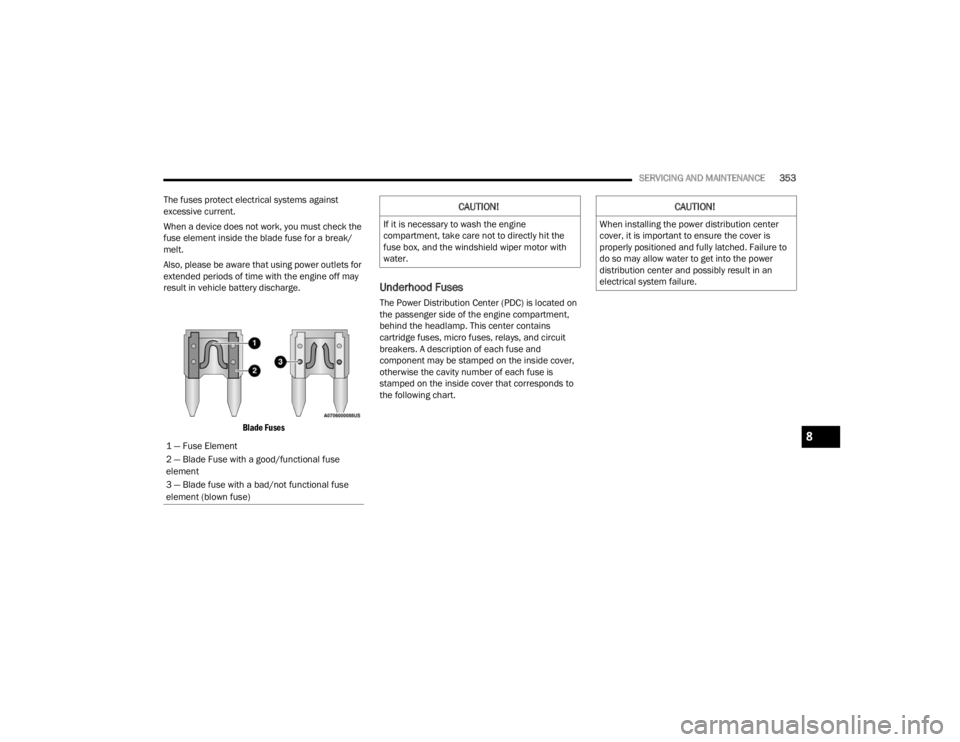

Blade Fuses

Underhood Fuses

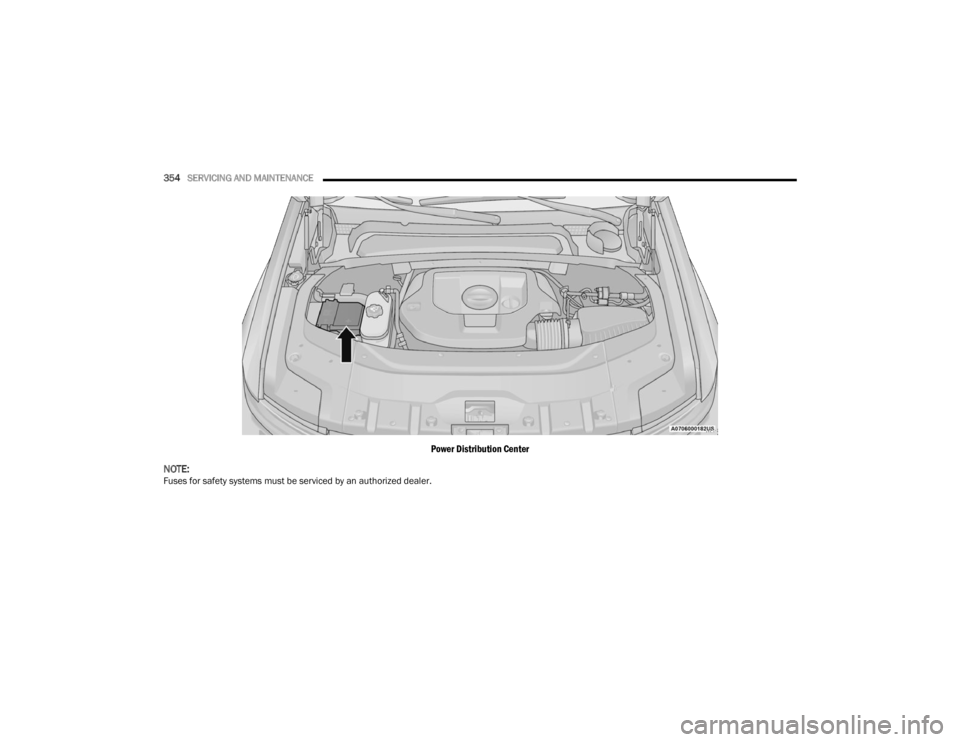

The Power Distribution Center (PDC) is located on

the passenger side of the engine compartment,

behind the headlamp. This center contains

cartridge fuses, micro fuses, relays, and circuit

breakers. A description of each fuse and

component may be stamped on the inside cover,

otherwise the cavity number of each fuse is

stamped on the inside cover that corresponds to

the following chart.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

CAUTION!

If it is necessary to wash the engine

compartment, take care not to directly hit the

fuse box, and the windshield wiper motor with

water.

CAUTION!

When installing the power distribution center

cover, it is important to ensure the cover is

properly positioned and fully latched. Failure to

do so may allow water to get into the power

distribution center and possibly result in an

electrical system failure.

8

23_WL_OM_EN_USC_t.book Page 353

Page 356 of 424

354SERVICING AND MAINTENANCE

Power Distribution Center

NOTE:

Fuses for safety systems must be serviced by an authorized dealer.

23_WL_OM_EN_USC_t.book Page 354

Page 357 of 424

SERVICING AND MAINTENANCE355

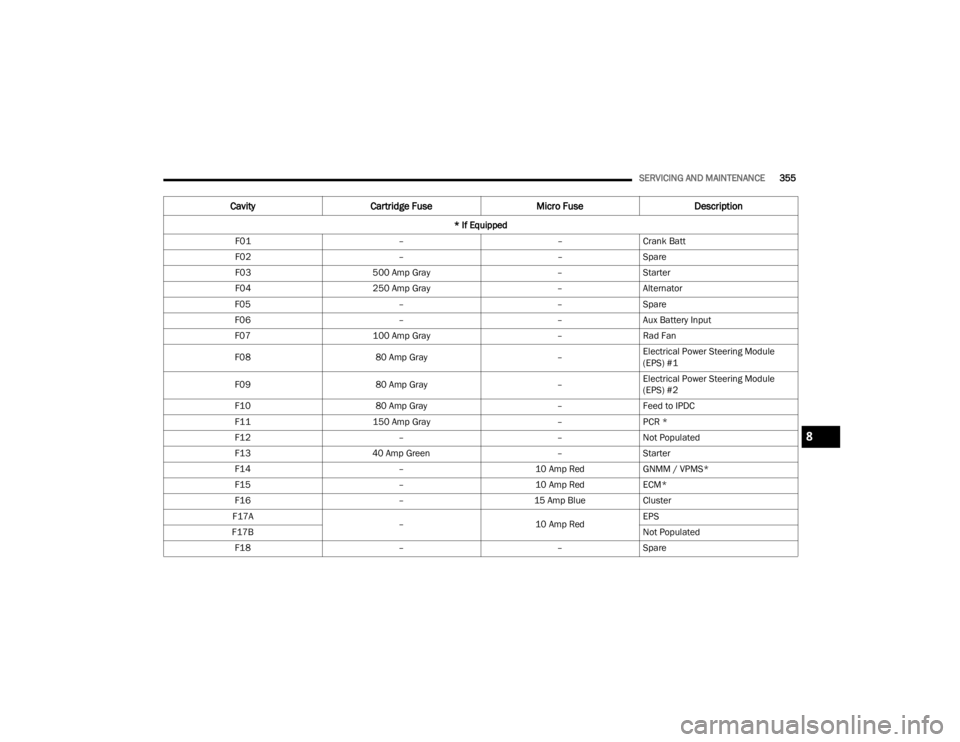

CavityCartridge Fuse Micro FuseDescription

* If Equipped

F01 ––Crank Batt

F02 ––Spare

F03 500 Amp Gray –Starter

F04 250 Amp Gray –Alternator

F05 ––Spare

F06 ––Aux Battery Input

F07 100 Amp Gray –Rad Fan

F08 80 Amp Gray –Electrical Power Steering Module

(EPS) #1

F09 80 Amp Gray –Electrical Power Steering Module

(EPS) #2

F10 80 Amp Gray –Feed to IPDC

F11 150 Amp Gray –PCR *

F12 ––Not Populated

F13 40 Amp Green –Starter

F14 –10 Amp RedGNMM / VPMS*

F15 –10 Amp RedECM*

F16 –15 Amp BlueCluster

F17A –10 Amp RedEPS

F17B Not Populated

F18 ––Spare

8

23_WL_OM_EN_USC_t.book Page 355

Page 358 of 424

356SERVICING AND MAINTENANCE

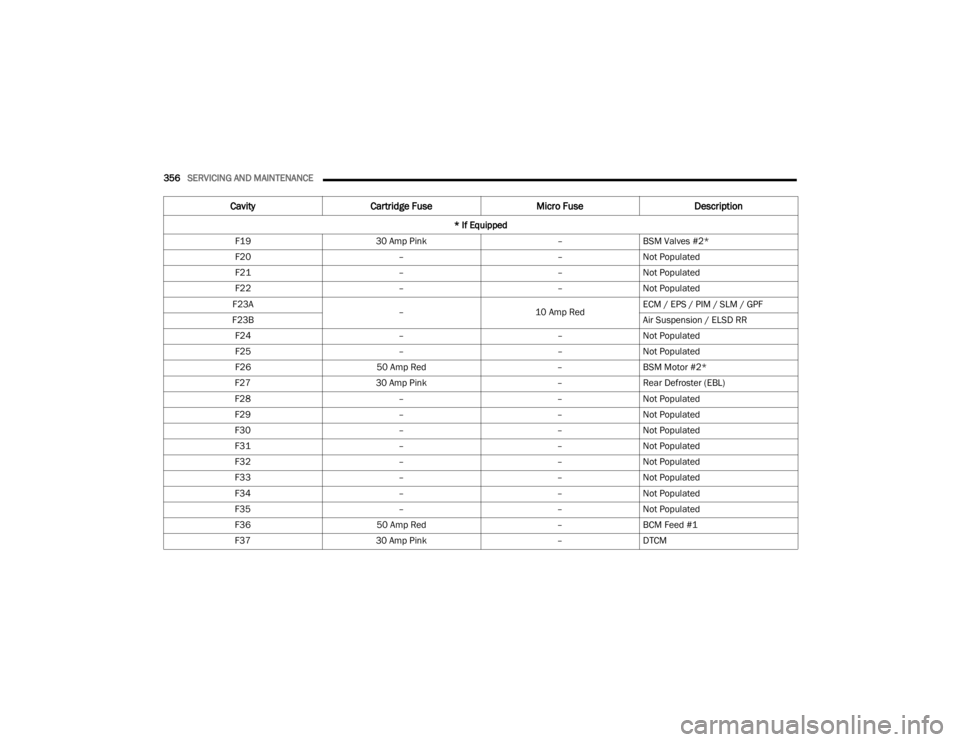

F19 30 Amp Pink –BSM Valves #2*

F20 ––Not Populated

F21 ––Not Populated

F22 ––Not Populated

F23A –10 Amp RedECM / EPS / PIM / SLM / GPF

F23B Air Suspension / ELSD RR

F24 ––Not Populated

F25 ––Not Populated

F26 50 Amp Red –BSM Motor #2*

F27 30 Amp Pink –Rear Defroster (EBL)

F28 ––Not Populated

F29 ––Not Populated

F30 ––Not Populated

F31 ––Not Populated

F32 ––Not Populated

F33 ––Not Populated

F34 ––Not Populated

F35 ––Not Populated

F36 50 Amp Red –BCM Feed #1

F37 30 Amp Pink –DTCM

Cavity Cartridge Fuse Micro FuseDescription

* If Equipped

23_WL_OM_EN_USC_t.book Page 356

Page 359 of 424

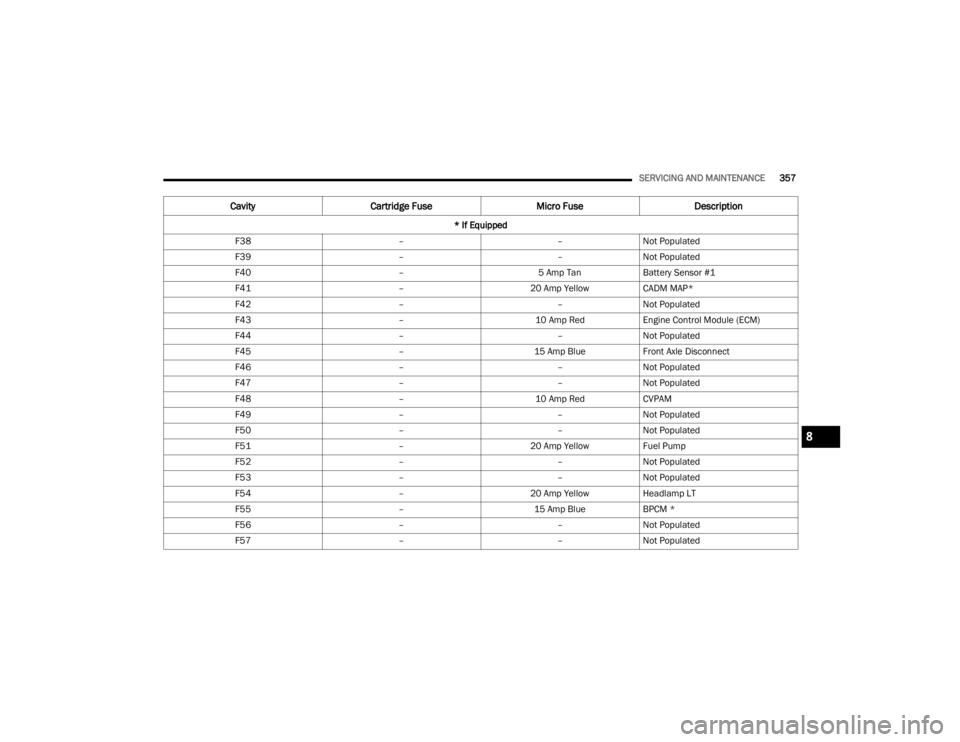

SERVICING AND MAINTENANCE357

F38 ––Not Populated

F39 ––Not Populated

F40 –5 Amp TanBattery Sensor #1

F41 –20 Amp YellowCADM MAP*

F42 ––Not Populated

F43 –10 Amp RedEngine Control Module (ECM)

F44 ––Not Populated

F45 –15 Amp BlueFront Axle Disconnect

F46 ––Not Populated

F47 ––Not Populated

F48 –10 Amp RedCVPAM

F49 ––Not Populated

F50 ––Not Populated

F51 –20 Amp YellowFuel Pump

F52 ––Not Populated

F53 ––Not Populated

F54 –20 Amp YellowHeadlamp LT

F55 –15 Amp BlueBPCM *

F56 ––Not Populated

F57 ––Not Populated

Cavity Cartridge Fuse Micro FuseDescription

* If Equipped

8

23_WL_OM_EN_USC_t.book Page 357

Page 360 of 424

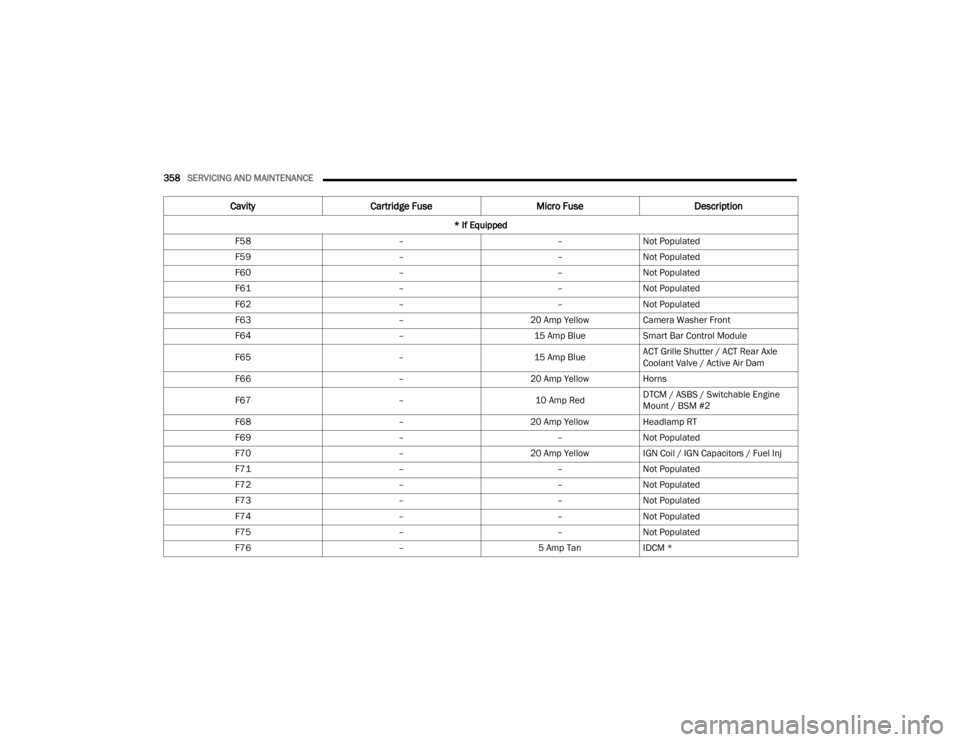

358SERVICING AND MAINTENANCE

F58 ––Not Populated

F59 ––Not Populated

F60 ––Not Populated

F61 ––Not Populated

F62 ––Not Populated

F63 –20 Amp YellowCamera Washer Front

F64 –15 Amp BlueSmart Bar Control Module

F65 –15 Amp BlueACT Grille Shutter / ACT Rear Axle

Coolant Valve / Active Air Dam

F66 –20 Amp YellowHorns

F67 –10 Amp RedDTCM / ASBS / Switchable Engine

Mount / BSM #2

F68 –20 Amp YellowHeadlamp RT

F69 ––Not Populated

F70 –20 Amp YellowIGN Coil / IGN Capacitors / Fuel Inj

F71 ––Not Populated

F72 ––Not Populated

F73 ––Not Populated

F74 ––Not Populated

F75 ––Not Populated

F76 –5 Amp TanIDCM *

Cavity Cartridge Fuse Micro FuseDescription

* If Equipped

23_WL_OM_EN_USC_t.book Page 358