interior JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1638 of 1803

WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

²URETHANE ADHESIVES ARE APPLIED AS A

SYSTEM. USE GLASS CLEANER, GLASS PREP

SOLVENT, GLASS PRIMER, PVC (VINYL) PRIMER

AND PINCH WELD (FENCE) PRIMER PROVIDED BY

THE ADHESIVE MANUFACTURER. IF NOT, STRUC-

TURAL INTEGRITY COULD BE COMPROMISED.

²DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

²BE SURE TO REFER TO THE URETHANE MAN-

UFACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

²VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

²SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

²ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

REMOVAL

(1) Remove inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR -

REMOVAL)

(2) Remove cowl cover. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL)(3) Remove screws attaching windshield side mold-

ing to A-pillar.

(4) Remove upper windshield molding.

(5) Cut urethane bonding from around windshield

using a suitable sharp cold knife. A pneumatic cut-

ting device can be used if available.

(6) Separate windshield from vehicle.

INSTALLATION

WARNING: REVIEW ALL WARNINGS AND CAU-

TIONS IN THIS GROUP BEFORE PRECEDING WITH

INSTALLATION.

CAUTION: Open a window before installing wind-

shield. This will avoid pressurizing the passenger

compartment. If a door or swing gate flip-up glass

is slammed before urethane is cured, water leaks

can result.

The windshield fence should be cleaned of old ure-

thane bonding material. Support spacers should be

cleaned and properly installed on weld studs or

repair screws at bottom of windshield opening.

(1) Place replacement windshield into windshield

opening. Position glass in the center of the opening

against the support spacers. Mark the glass at the

support spacers with a grease pencil or masking tape

and ink pen to use as a reference for installation.

Remove replacement windshield from windshield

opening.

(2) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart.

(3) Clean inside of windshield with Mopar Glass

Cleaner and lint-free cloth.

(4) Apply clear glass primer 25 mm (1 in.) wide

around edge of windshield. Wipe with clean/dry lint-

free cloth.

(5) Apply black-out primer 15 mm (.75 in.) wide on

top and sides of windshield and 25 mm (1 in.) on bot-

tom of windshield. Allow at least three minutes dry-

ing time.

(6) Position windshield spacers on lower fence

above support spacers at the edge of the windshield

opening.

(7) Align the dot on the upper molding to the tick

mark in the center of the glass and install upper

molding onto windshield.

(8) Apply a 10 mm (0.4 in.) bead of urethane

around perimeter of windshield along the inside of

the moldings. Apply two beads along the bottom

edge.

KJSTATIONARY GLASS 23 - 173

Page 1639 of 1803

(9) Apply fence primer around the perimeter of the

windshield opening fence. Allow at least 18 minutes

drying time.

(10) With aid of a helper, position windshield over

windshield opening. Align reference marks at bottom

of windshield to support spacers.

(11) Slowly lower windshield glass to windshield

opening fence. Guide top molding into proper position

if necessary. Push windshield inward to fence spacers

at bottom and until top molding is flush to roof line.

(12) Clean excess urethane from exterior with

Mopar Super Clean or equivalent.(13) Install windshield side moldings. (Refer to 23

- BODY/WEATHERSTRIP/SEALS/WINDSHIELD

A-PILLAR WEATHERSTRIP - INSTALLATION)

(14) Install cowl grille. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION)

(15) Install inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR - INSTAL-

LATION)

(16) After urethane has cured, water test wind-

shield to verify repair.

23 - 174 STATIONARY GLASSKJ

WINDSHIELD (Continued)

Page 1650 of 1803

WEATHERSTRIP/SEALS

TABLE OF CONTENTS

page page

A-PILLAR SEAL

REMOVAL............................185

INSTALLATION........................185

COWL WEATHERSTRIP

REMOVAL............................185

INSTALLATION........................185

DOOR PRIMARY WEATHERSTRIP

REMOVAL............................185

INSTALLATION........................185

DOOR LOWER WEATHERSTRIP

REMOVAL............................186

INSTALLATION........................186

FRONT DOOR OUTER BELT MOLDING

REMOVAL............................186

INSTALLATION........................186

SWING GATE BELTLINE WEATHERSTRIP

REMOVAL............................186

INSTALLATION........................186

SWING GATE OPENING WEATHERSTRIP

REMOVAL............................186INSTALLATION........................186

REAR DOOR OUTER BELT MOLDING

REMOVAL............................186

INSTALLATION........................186

SIDE RAIL WEATHERSTRIP/RETAINER

REMOVAL............................186

INSTALLATION........................186

WINDSHIELD A-PILLAR WEATHERSTRIP/

RETAINER

REMOVAL............................186

INSTALLATION........................187

COWL/PLENUM SEAL

REMOVAL............................187

INSTALLATION........................187

COWL/PLENUM WINDOW BAFFLE SEAL

REMOVAL............................187

INSTALLATION........................187

A-PILLAR SEAL

REMOVAL

(1) Open the doors and peal the seal away from

the a-pillar/windshield and the side rail weather

strip flanges.

INSTALLATION

(1) Position the a-pillar seal over the windshield/a-

pillar and the side rail weatherstrip flanges and seat

fully.

COWL WEATHERSTRIP

REMOVAL

(1) Open the hood and peal the cowl seal from the

cowl panel and cowl flange.

INSTALLATION

(1) Position the weatherstrip over the cowl flange

and the cowl grille and seat fully.

DOOR PRIMARY

WEATHERSTRIP

REMOVAL

(1) Remove the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL)

(2) Peal seal off of the door opening flange.

INSTALLATION

(1) Position the seal to the bottom of the door

opening, with bulb facing outboard, starting the

installation at the center of the lower flange. Press

the seal onto the sill flange and work around the

perimeter of the door opening until fully seated.

Work in one direction, smoothing the seal to avoid

puckers or wrinkles.

(2) Install the lower b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

INSTALLATION)

(3) When installing a new weatherstrip on the

front door opening, remove the tear strip starting at

the splice and moving around the front of the door to

the back of the opening.

KJWEATHERSTRIP/SEALS 23 - 185

Page 1654 of 1803

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system, to

ensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

The heater and optional air conditioner are blend-

air type systems. In a blend-air system, a blend door

controls the amount of unconditioned air (or cooled

air from the evaporator on models with air condition-

ing) that is allowed to flow through, or around, the

heater core. A temperature control knob on the A/C

Heater control panel determines the discharge air

temperature by controlling an electric actuator,

which moves the blend door. This allows an almost

immediate control of the output air temperature of

the system.

The mode control knob on the heater-only or A/C

Heater control panel is used to direct the conditioned

air to the selected system outlets. Both mode control

switches use engine vacuum to control the mode

doors, which are operated by vacuum actuators.

On all vehicles, the outside air intake can be shut

off by selecting the Recirculation Mode with the

mode control knob. This will operate a vacuum actu-

ated recirculation door that closes off the outside

fresh air intake and recirculates the air that is

already inside the vehicle.

The optional air conditioner for all models is

designed for the use of non-CFC, R-134a refrigerant.

The air conditioning system has an evaporator to cool

and dehumidify the incoming air prior to blending it

with the heated air. This air conditioning system

uses a fixed orifice tube in the liquid line near the

condenser outlet tube to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

A/C low pressure switch on the accumulator cycles

the compressor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the

refrigerant line, near the discharge port of the com-

pressor. The low pressure service port is located on

the liquid line at the side of the engine compartment,

near the condensor.Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Remov-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from the

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

24 - 2 HEATING & AIR CONDITIONINGKJ

HEATING & AIR CONDITIONING (Continued)

Page 1683 of 1803

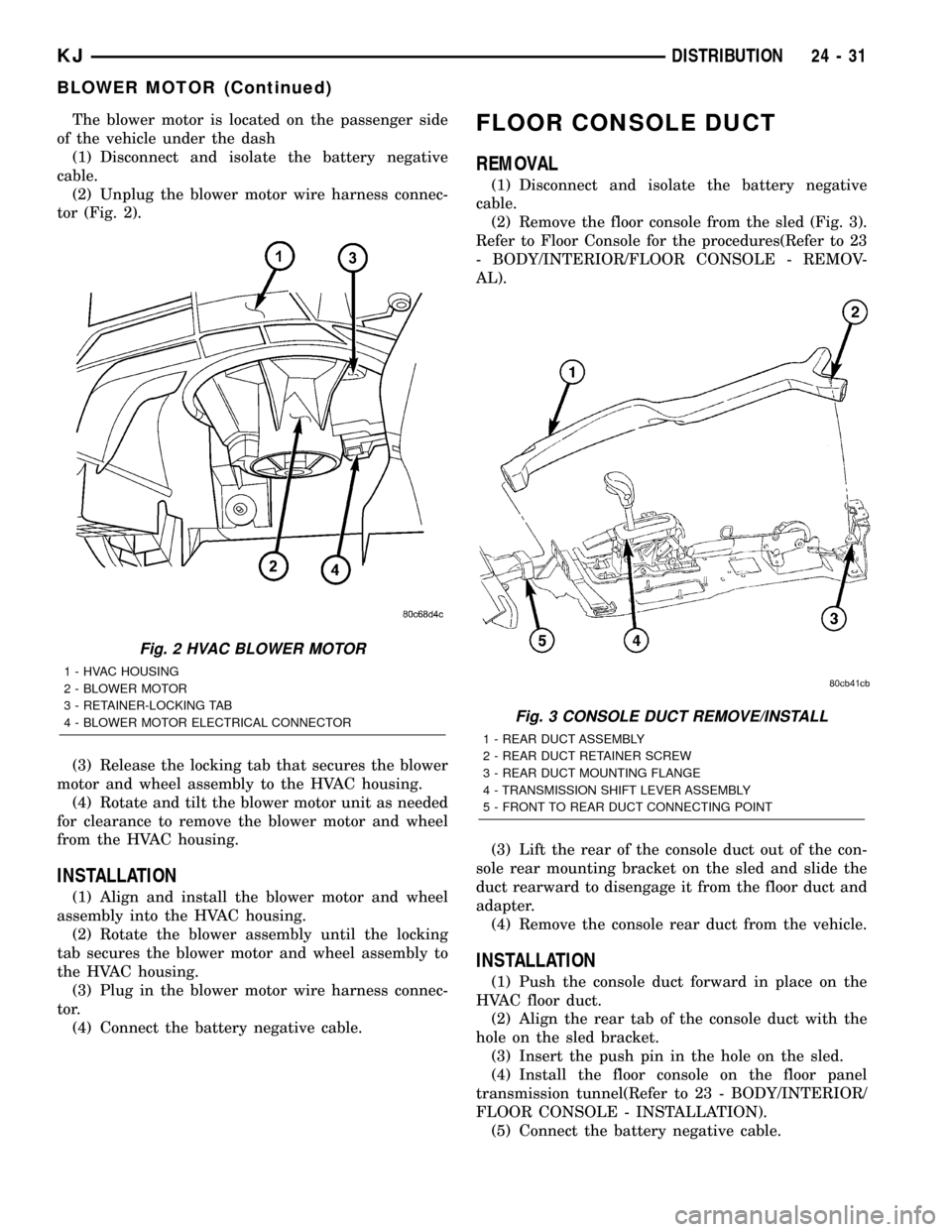

The blower motor is located on the passenger side

of the vehicle under the dash

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the blower motor wire harness connec-

tor (Fig. 2).

(3) Release the locking tab that secures the blower

motor and wheel assembly to the HVAC housing.

(4) Rotate and tilt the blower motor unit as needed

for clearance to remove the blower motor and wheel

from the HVAC housing.

INSTALLATION

(1) Align and install the blower motor and wheel

assembly into the HVAC housing.

(2) Rotate the blower assembly until the locking

tab secures the blower motor and wheel assembly to

the HVAC housing.

(3) Plug in the blower motor wire harness connec-

tor.

(4) Connect the battery negative cable.

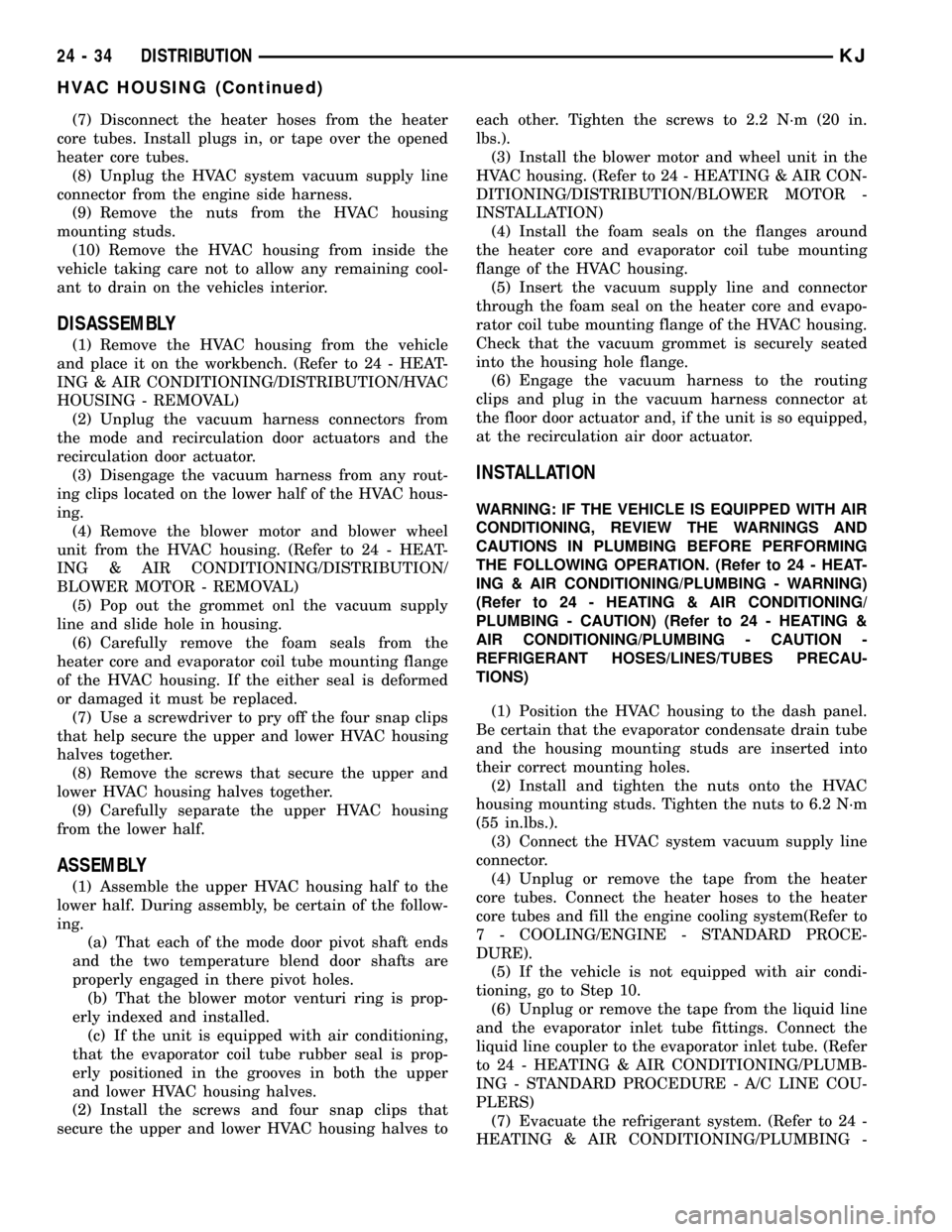

FLOOR CONSOLE DUCT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the floor console from the sled (Fig. 3).

Refer to Floor Console for the procedures(Refer to 23

- BODY/INTERIOR/FLOOR CONSOLE - REMOV-

AL).

(3) Lift the rear of the console duct out of the con-

sole rear mounting bracket on the sled and slide the

duct rearward to disengage it from the floor duct and

adapter.

(4) Remove the console rear duct from the vehicle.

INSTALLATION

(1) Push the console duct forward in place on the

HVAC floor duct.

(2) Align the rear tab of the console duct with the

hole on the sled bracket.

(3) Insert the push pin in the hole on the sled.

(4) Install the floor console on the floor panel

transmission tunnel(Refer to 23 - BODY/INTERIOR/

FLOOR CONSOLE - INSTALLATION).

(5) Connect the battery negative cable.

Fig. 2 HVAC BLOWER MOTOR

1 - HVAC HOUSING

2 - BLOWER MOTOR

3 - RETAINER-LOCKING TAB

4 - BLOWER MOTOR ELECTRICAL CONNECTOR

Fig. 3 CONSOLE DUCT REMOVE/INSTALL

1 - REAR DUCT ASSEMBLY

2 - REAR DUCT RETAINER SCREW

3 - REAR DUCT MOUNTING FLANGE

4 - TRANSMISSION SHIFT LEVER ASSEMBLY

5 - FRONT TO REAR DUCT CONNECTING POINT

KJDISTRIBUTION 24 - 31

BLOWER MOTOR (Continued)

Page 1686 of 1803

(7) Disconnect the heater hoses from the heater

core tubes. Install plugs in, or tape over the opened

heater core tubes.

(8) Unplug the HVAC system vacuum supply line

connector from the engine side harness.

(9) Remove the nuts from the HVAC housing

mounting studs.

(10) Remove the HVAC housing from inside the

vehicle taking care not to allow any remaining cool-

ant to drain on the vehicles interior.

DISASSEMBLY

(1) Remove the HVAC housing from the vehicle

and place it on the workbench. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - REMOVAL)

(2) Unplug the vacuum harness connectors from

the mode and recirculation door actuators and the

recirculation door actuator.

(3) Disengage the vacuum harness from any rout-

ing clips located on the lower half of the HVAC hous-

ing.

(4) Remove the blower motor and blower wheel

unit from the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/

BLOWER MOTOR - REMOVAL)

(5) Pop out the grommet onl the vacuum supply

line and slide hole in housing.

(6) Carefully remove the foam seals from the

heater core and evaporator coil tube mounting flange

of the HVAC housing. If the either seal is deformed

or damaged it must be replaced.

(7) Use a screwdriver to pry off the four snap clips

that help secure the upper and lower HVAC housing

halves together.

(8) Remove the screws that secure the upper and

lower HVAC housing halves together.

(9) Carefully separate the upper HVAC housing

from the lower half.

ASSEMBLY

(1) Assemble the upper HVAC housing half to the

lower half. During assembly, be certain of the follow-

ing.

(a) That each of the mode door pivot shaft ends

and the two temperature blend door shafts are

properly engaged in there pivot holes.

(b) That the blower motor venturi ring is prop-

erly indexed and installed.

(c) If the unit is equipped with air conditioning,

that the evaporator coil tube rubber seal is prop-

erly positioned in the grooves in both the upper

and lower HVAC housing halves.

(2) Install the screws and four snap clips that

secure the upper and lower HVAC housing halves toeach other. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(3) Install the blower motor and wheel unit in the

HVAC housing. (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/BLOWER MOTOR -

INSTALLATION)

(4) Install the foam seals on the flanges around

the heater core and evaporator coil tube mounting

flange of the HVAC housing.

(5) Insert the vacuum supply line and connector

through the foam seal on the heater core and evapo-

rator coil tube mounting flange of the HVAC housing.

Check that the vacuum grommet is securely seated

into the housing hole flange.

(6) Engage the vacuum harness to the routing

clips and plug in the vacuum harness connector at

the floor door actuator and, if the unit is so equipped,

at the recirculation air door actuator.

INSTALLATION

WARNING: IF THE VEHICLE IS EQUIPPED WITH AIR

CONDITIONING, REVIEW THE WARNINGS AND

CAUTIONS IN PLUMBING BEFORE PERFORMING

THE FOLLOWING OPERATION. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - WARNING)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION -

REFRIGERANT HOSES/LINES/TUBES PRECAU-

TIONS)

(1) Position the HVAC housing to the dash panel.

Be certain that the evaporator condensate drain tube

and the housing mounting studs are inserted into

their correct mounting holes.

(2) Install and tighten the nuts onto the HVAC

housing mounting studs. Tighten the nuts to 6.2 N´m

(55 in.lbs.).

(3) Connect the HVAC system vacuum supply line

connector.

(4) Unplug or remove the tape from the heater

core tubes. Connect the heater hoses to the heater

core tubes and fill the engine cooling system(Refer to

7 - COOLING/ENGINE - STANDARD PROCE-

DURE).

(5) If the vehicle is not equipped with air condi-

tioning, go to Step 10.

(6) Unplug or remove the tape from the liquid line

and the evaporator inlet tube fittings. Connect the

liquid line coupler to the evaporator inlet tube. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS)

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

24 - 34 DISTRIBUTIONKJ

HVAC HOUSING (Continued)

Page 1753 of 1803

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING........................9-68

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION........................9-26

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION....................9-28,9-36

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL.......................9-27,9-35

INTERIOR - DESCRIPTION, LAMPS/

LIGHTING..........................8L-65

INTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING....................8L-68

INTERIOR - OPERATION, LAMPS/

LIGHTING..........................8L-67

INTERIOR - SPECIFICATIONS,

LAMPS/LIGHTING....................8L-71

INTERLOCK CABLE - INSTALLATION,

PARK .............................21-153

INTERLOCK CABLE - REMOVAL, PARK . . . 21-153

INTERLOCK SYSTEM - DESCRIPTION,

BRAKE TRANSMISSION SHIFT.........21-124

INTERLOCK SYSTEM - DIAGNOSIS AND

TESTING, BRAKE TRANSMISSION

SHIFT.............................21-125

INTERLOCK SYSTEM - OPERATION,

BRAKE TRANSMISSION SHIFT.........21-125

INTERMEDIATE SHAFT - INSTALLATION . . . 19-11

INTERMEDIATE SHAFT - REMOVAL......19-11

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-4

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-1

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS............9-4

INTRUSION TRANSCEIVER MODULE -

DESCRIPTION.......................8Q-14

INTRUSION TRANSCEIVER MODULE -

INSTALLATION......................8Q-16

INTRUSION TRANSCEIVER MODULE -

OPERATION.........................8Q-15

INTRUSION TRANSCEIVER MODULE -

REMOVAL..........................8Q-15

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE..................5-8

IOD FUSE - DESCRIPTION...........8W-97-3

IOD FUSE - INSTALLATION...........8W-97-3

IOD FUSE - OPERATION.............8W-97-3

IOD FUSE - REMOVAL..............8W-97-3

ISO FLARING - STANDARD PROCEDURE....5-8

JOINT - DESCRIPTION, UPPER

SUSPENSION ARM, BUSHINGS, AND

BALL...............................2-20

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - INSTALLATION, UPPER BALL.....2-20

JOINT - OPERATION, UPPER

SUSPENSION ARM, BUSHINGS, AND

BALL...............................2-20

JOINT - REMOVAL, UPPER BALL.........2-20

JOINT/BOOT-INNER - INSTALLATION, CV . . . 3-17

JOINT/BOOT-INNER - REMOVAL, CV.......3-15

JOINT/BOOT-OUTER - INSTALLATION, CV . . . 3-13

JOINT/BOOT-OUTER - REMOVAL, CV......3-12

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-8

JOUNCE BUMPER - INSTALLATION.......2-19

JOUNCE BUMPER - REMOVAL...........2-19

JUMP STARTING PROCEDURE -

STANDARD PROCEDURE

.................0-5

JUNCTION BLOCK - DESCRIPTION

.....8W-97-4

JUNCTION BLOCK - DESCRIPTION

........5-20

JUNCTION BLOCK - DIAGNOSIS AND

TESTING

.........................8W-97-4

JUNCTION BLOCK - INSTALLATION

.......5-20

JUNCTION BLOCK - OPERATION

......8W-97-4

JUNCTION BLOCK - OPERATION

..........5-20

JUNCTION BLOCK - REMOVAL

...........5-20

KEY - DESCRIPTION, TRANSPONDER

....8Q-18

KEY - OPERATION, TRANSPONDER

......8Q-18

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY

................8E-15

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY

...............8E-18

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY

.................8E-16KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-17

KEY TRANSPONDER PROGRAMMING -

STANDARD PROCEDURE, SENTRY........8Q-8

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-10

KEY-IN IGNITION SWITCH - DIAGNOSIS

AND TESTING.......................19-10

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-7

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-7

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-7

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE..............8N-9

KNEE BLOCKER - INSTALLATION.......23-155

KNEE BLOCKER - REMOVAL...........23-155

KNOCK SENSOR - DESCRIPTION.........8I-11

KNOCK SENSOR - INSTALLATION........8I-12

KNOCK SENSOR - OPERATION..........8I-11

KNOCK SENSOR - REMOVAL............8I-12

KNUCKLE - INSTALLATION...............2-9

KNUCKLE - REMOVAL...................2-9

LABEL - DESCRIPTION, VEHICLE

EMISSION CONTROL INFORMATION

(VECI)............................Intro.-8

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-9

LACE - INSTALLATION, OPENING TRIM . . 23-180

LACE - REMOVAL, OPENING TRIM......23-180

LAMP BULB - INSTALLATION, ASH

RECEIVER..........................8L-71

LAMP BULB - INSTALLATION, CARGO....8L-73

LAMP BULB - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-19

LAMP BULB - INSTALLATION,

COURTESY.........................8L-76

LAMP BULB - INSTALLATION, FRONT....8L-27

LAMP BULB - INSTALLATION, FRONT

FOG ...............................8L-22

LAMP BULB - INSTALLATION, FRONT

POSITION..........................8L-28

LAMP BULB - INSTALLATION, LICENSE

PLATE .............................8L-45

LAMP BULB - INSTALLATION, READING . . . 8L-79

LAMP BULB - INSTALLATION, REAR.....8L-59

LAMP BULB - INSTALLATION, REPEATER . . 8L-60

LAMP BULB - INSTALLATION, VANITY....8L-84

LAMP BULB - REMOVAL, ASH RECEIVER . . 8L-71

LAMP BULB - REMOVAL, CARGO........8L-72

LAMP BULB - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-18

LAMP BULB - REMOVAL, COURTESY.....8L-75

LAMP BULB - REMOVAL, FRONT........8L-26

LAMP BULB - REMOVAL, FRONT FOG....8L-21

LAMP BULB - REMOVAL, FRONT

POSITION..........................8L-28

LAMP BULB - REMOVAL, LICENSE

PLATE .............................8L-44

LAMP BULB - REMOVAL, READING......8L-79

LAMP BULB - REMOVAL, REAR.........8L-58

LAMP BULB - REMOVAL, REPEATER.....8L-60

LAMP BULB - REMOVAL, VANITY........8L-83

LAMP INDICATOR - DESCRIPTION,

FRONT FOG.........................8J-19

LAMP INDICATOR - DESCRIPTION, REAR

FOG ...............................8J-27

LAMP INDICATOR - OPERATION, FRONT

FOG ...............................8J-19

LAMP INDICATOR - OPERATION, REAR

FOG ...............................8J-27

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-24

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR

.............8J-24

LAMP RELAY - DESCRIPTION, DAYTIME

RUNNING

...........................8L-20

LAMP RELAY - DESCRIPTION, FRONT

FOG

...............................8L-22

LAMP RELAY - DESCRIPTION, PARK

.....8L-54

LAMP RELAY - DESCRIPTION, REAR FOG

. 8L-56LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-23

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-55

LAMP RELAY - DIAGNOSIS AND

TESTING, REAR FOG..................8L-57

LAMP RELAY - INSTALLATION, DAYTIME

RUNNING...........................8L-21

LAMP RELAY - INSTALLATION, FRONT

FOG ...............................8L-24

LAMP RELAY - INSTALLATION, PARK.....8L-56

LAMP RELAY - INSTALLATION, REAR

FOG ...............................8L-58

LAMP RELAY - OPERATION, DAYTIME

RUNNING...........................8L-20

LAMP RELAY - OPERATION, FRONT FOG . . 8L-22

LAMP RELAY - OPERATION, PARK.......8L-54

LAMP RELAY - OPERATION, REAR FOG . . . 8L-57

LAMP RELAY - REMOVAL, DAYTIME

RUNNING...........................8L-21

LAMP RELAY - REMOVAL, FRONT FOG . . . 8L-24

LAMP RELAY - REMOVAL, PARK........8L-55

LAMP RELAY - REMOVAL, REAR FOG....8L-58

LAMP REPLACEMENT - STANDARD

PROCEDURE, CMTC...................8M-2

LAMP REPLACEMENT - STANDARD

PROCEDURE, COURTESY...............8M-2

LAMP SWITCH - DESCRIPTION, BACKUP . . 8L-15

LAMP SWITCH - DESCRIPTION, BRAKE . . . 8L-16

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-15

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE.....................8L-17

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-18

LAMP SWITCH - INSTALLATION, CARGO . . 8L-74

LAMP SWITCH - INSTALLATION,

READING...........................8L-80

LAMP SWITCH - OPERATION, BACKUP . . . 8L-15

LAMP SWITCH - OPERATION, BRAKE.....8L-16

LAMP SWITCH - REMOVAL, BRAKE......8L-17

LAMP SWITCH - REMOVAL, CARGO......8L-73

LAMP SWITCH - REMOVAL, READING....8L-80

LAMP UNIT - ADJUSTMENT, FRONT FOG . . 8L-25

LAMP UNIT - INSTALLATION, ASH

RECEIVER..........................8L-72

LAMP UNIT - INSTALLATION, CARGO.....8L-74

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-19

LAMP UNIT - INSTALLATION, COURTESY . . 8L-77

LAMP UNIT - INSTALLATION, FRONT.....8L-28

LAMP UNIT - INSTALLATION, FRONT

FOG ...............................8L-25

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-46

LAMP UNIT - INSTALLATION, READING . . . 8L-81

LAMP UNIT - INSTALLATION, REAR......8L-60

LAMP UNIT - INSTALLATION, REPEATER . . 8L-61

LAMP UNIT - REMOVAL, ASH RECEIVER . . 8L-72

LAMP UNIT - REMOVAL, CARGO........8L-74

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-19

LAMP UNIT - REMOVAL, COURTESY.....8L-76

LAMP UNIT - REMOVAL, FRONT.........8L-27

LAMP UNIT - REMOVAL, FRONT FOG.....8L-25

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-45

LAMP UNIT - REMOVAL, READING.......8L-81

LAMP UNIT - REMOVAL, REAR..........8L-59

LAMP UNIT - REMOVAL, REPEATER......8L-60

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-7

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-5

LAMPS/LIGHTING - EXTERIOR -

SPECIFICATIONS.....................8L-15

LAMPS/LIGHTING - INTERIOR -

DESCRIPTION.......................8L-65

LAMPS/LIGHTING - INTERIOR -

DIAGNOSIS AND TESTING.............8L-68

LAMPS/LIGHTING - INTERIOR -

OPERATION

.........................8L-67

LAMPS/LIGHTING - INTERIOR -

SPECIFICATIONS

.....................8L-71

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC

..............9-19,9-30

LATCH - ACCESS PANEL - DESCRIPTION

. 23-139

LATCH - ACCESS PANEL - INSTALLATION

. 23-139

14 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1764 of 1803

SPARK PLUG - OPERATION.............8I-12

SPARK PLUG - REMOVAL..............8I-15

SPARK PLUG CABLE RESISTANCE, 2.4L....8I-3

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-13

SPARK PLUGS, SPARK PLUG -

CLEANING..........................8I-15

SPARK PLUGS, SPECIFICATIONS..........8I-3

SPEAKER - DESCRIPTION..............8A-13

SPEAKER - INSTALLATION.............8A-15

SPEAKER - OPERATION...............8A-14

SPEAKER - REMOVAL.................8A-14

SPECIAL TOOLS - 3.7L ENGINE..........9-15

SPECIAL TOOLS - 8 1/4 AXLE...........3-98

SPECIAL TOOLS - BASE BRAKES..........5-7

SPECIAL TOOLS - BODY................23-5

SPECIAL TOOLS - COOLING.............7-14

SPECIAL TOOLS - FRONT AXLE..........3-34

SPECIAL TOOLS - FRONT SUSPENSION.....2-8

SPECIAL TOOLS - FUEL SYSTEM.........14-6

SPECIAL TOOLS - OUTER TIE ROD END

REMOVAL TOOL.....................19-15

SPECIAL TOOLS - POWER

DISTRIBUTION SYSTEMS............8W-97-2

SPECIAL TOOLS - POWER STEERING

PUMP.............................19-20

SPECIAL TOOLS - REAR AXLE...........3-63

SPECIAL TOOLS - RFE TRANSMISSION....21-120

SPECIAL TOOLS - STEERING COLUMN....19-8

SPECIAL TOOLS - WIRING/TERMINAL . 8W-01-10

SPECIAL TOOLS, BATTERY SYSTEM.......8F-7

SPECIFICATIONS, BATTERY SYSTEM......8F-6

SPECIFICATIONS, BRAKES - ABS.........5-33

SPECIFICATIONS, CHARGE CAPACITY.....24-42

SPECIFICATIONS, CLUTCH...............6-5

SPECIFICATIONS, DIAGNOSIS AND

TESTING............................22-8

SPECIFICATIONS, FLUID CAPACITIES.......0-4

SPECIFICATIONS, FRAME DIMENSIONS....13-3

SPECIFICATIONS, FRONT AXLE...........3-33

SPECIFICATIONS, GAP AND FLUSH.....23-116

SPECIFICATIONS, IGNITION TIMING.......8I-2

SPECIFICATIONS, LAMPS/LIGHTING -

EXTERIOR..........................8L-15

SPECIFICATIONS, LAMPS/LIGHTING -

INTERIOR..........................8L-71

SPECIFICATIONS, NV1500..............21-30

SPECIFICATIONS, OPENING DIMENSIONS . 23-111

SPECIFICATIONS, PAINT CODES........23-162

SPECIFICATIONS, REAR AXLE............3-62

SPECIFICATIONS, REMOTE KEYLESS

ENTRY TRANSMITTER.................8N-9

SPECIFICATIONS, SEALER LOCATIONS....23-87

SPECIFICATIONS, SPECIFICATIONS.......24-10

SPECIFICATIONS, STANDARD

PROCEDURE.........................23-4

SPECIFICATIONS, TORQUE..............13-6

SPECIFICATIONS, WELD AND

STRUCTURAL ADHESIVE LOCATIONS......23-9

SPEED CONTROL - DESCRIPTION........8P-1

SPEED CONTROL - OPERATION..........8P-1

SPEED CONTROL - TORQUE.............8P-2

SPEED SENSOR - DESCRIPTION, INPUT . 21-143

SPEED SENSOR - DESCRIPTION,

OUTPUT...........................21-152

SPEED SENSOR - INSTALLATION, FRONT

WHEEL.............................5-34

SPEED SENSOR - INSTALLATION, INPUT . 21-143

SPEED SENSOR - INSTALLATION,

OUTPUT...........................21-152

SPEED SENSOR - INSTALLATION, REAR

WHEEL.............................5-35

SPEED SENSOR - OPERATION, INPUT . . . 21-143

SPEED SENSOR - OPERATION, OUTPUT . . 21-152

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-34

SPEED SENSOR - REMOVAL, INPUT.....21-143

SPEED SENSOR - REMOVAL, OUTPUT . . . 21-152

SPEED SENSOR - REMOVAL, REAR

WHEEL.............................5-35

SPEEDOMETER - DESCRIPTION

.........8J-32

SPEEDOMETER - OPERATION

...........8J-32

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE

................23-143

SPLASH SHIELD - INSTALLATION, REAR

WHEELHOUSE

......................23-144

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE

......................23-143SPLASH SHIELD - REMOVAL, REAR

WHEELHOUSE......................23-144

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-14

SPRING - INSTALLATION...........2-13,2-18

SPRING - REMOVAL...............2-13,2-18

SPRINGS - DESCRIPTION, VALVE.....9-29,9-38

SPRINGS - INSTALLATION, VALVE....9-29,9-38

SPRINGS - REMOVAL, VALVE........9-29,9-38

STABILIZER BAR - INSTALLATION....2-14,2-19

STABILIZER BAR - REMOVAL........2-14,2-19

STABILIZER BAR BUSHINGS -

INSTALLATION.........................2-9

STABILIZER BAR BUSHINGS - REMOVAL....2-9

STABILIZER LINK - INSTALLATION........2-14

STABILIZER LINK - REMOVAL............2-14

STAKING - STANDARD PROCEDURE,

HEAT ...............................23-3

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-39

STARTER MOTOR - INSTALLATION.......8F-41

STARTER MOTOR - REMOVAL..........8F-39

STARTER MOTOR, GAS POWERED.......8F-39

STARTER MOTOR RELAY - DESCRIPTION . 8F-41

STARTER MOTOR RELAY -

INSTALLATION.......................8F-43

STARTER MOTOR RELAY - OPERATION.....8F-42

STARTER MOTOR RELAY - REMOVAL.....8F-43

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-42

STARTING PROCEDURE - STANDARD

PROCEDURE, JUMP....................0-5

STARTING SYSTEM - DESCRIPTION......8F-32

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-33

STARTING SYSTEM - INSPECTION.......8F-37

STARTING SYSTEM - OPERATION........8F-32

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-2

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING COLUMN, SPECIAL TOOLS.....19-8

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-3

STEERING LINKAGE - STANDARD

PROCEDURE........................19-16

STEERING PRESSURE SWITCH -

DESCRIPTION, POWER................19-22

STEERING PRESSURE SWITCH -

INSTALLATION, POWER...............19-22

STEERING PRESSURE SWITCH -

OPERATION, POWER..................19-22

STEERING PRESSURE SWITCH -

REMOVAL, POWER...................19-22

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-18

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-20

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-1

STEERING SYSTEM - DIAGNOSIS AND

TESTING, SUSPENSION.................2-1

STEERING WHEEL - INSTALLATION......19-12

STEERING WHEEL - REMOVAL..........19-12

STOP LAMP BULB - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP BULB - REMOVAL, CENTER

HIGH MOUNTED.....................8L-18

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-19

STRAP - DESCRIPTION, RADIO NOISE

SUPPRESSION GROUND................8A-9

STRAP - INSTALLATION, CHECK . 23-121,23-128,

23-135

STRAP - INSTALLATION, RADIO NOISE

SUPPRESSION GROUND

...............8A-11

STRAP - OPERATION, RADIO NOISE

SUPPRESSION GROUND

...............8A-10

STRAP - REMOVAL, CHECK

.....23-121,23-128,

23-135

STRAP - REMOVAL, RADIO NOISE

SUPPRESSION GROUND

...............8A-10

STRIKER - INSTALLATION, GLOVE BOX

LATCH

............................23-149STRIKER - INSTALLATION, HOOD AJAR

SWITCH............................8Q-14

STRIKER - INSTALLATION, LATCH......23-124,

23-132,23-137

STRIKER - INSTALLATION, REAR SEAT

BACK LATCH.......................23-171

STRIKER - REMOVAL, GLOVE BOX

LATCH ............................23-148

STRIKER - REMOVAL, HOOD AJAR

SWITCH............................8Q-13

STRIKER - REMOVAL, LATCH . . . 23-124,23-132,

23-137

STRIKER - REMOVAL, REAR SEAT BACK

LATCH ............................23-170

STRUCTURAL ADHESIVE LOCATIONS -

SPECIFICATIONS, WELD................23-9

STRUCTURAL COVER - DESCRIPTION.....9-55

STRUCTURAL COVER - INSTALLATION.....9-55

STRUCTURAL COVER - OPERATION.......9-55

STRUCTURAL COVER - REMOVAL........9-55

STUDS - INSTALLATION...............22-11

STUDS - REMOVAL...................22-11

SUCTION LINE - INSTALLATION, A/C.....24-49

SUCTION LINE - REMOVAL, A/C.........24-48

SUN VISOR - INSTALLATION..........23-160

SUN VISOR - REMOVAL..............23-160

SUN VISOR SUPPORT - INSTALLATION . . 23-160

SUN VISOR SUPPORT - REMOVAL......23-160

SUNROOF - DESCRIPTION............23-175

SUNROOF GLASS PANEL ADJUSTMENT,

ADJUSTMENTS.....................23-178

SUNSHADE - INSTALLATION...........23-179

SUNSHADE - REMOVAL..............23-179

SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A.........8O-6

SUPPLEMENTAL RESTRAINT SYSTEM -

DIAGNOSIS AND TESTING..............8O-6

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE, HANDLING

NON-DEPLOYED......................8O-6

SUPPLIES - DESCRIPTION, 5 VOLT......8E-13

SUPPLIES - OPERATION, 5 VOLT........8E-15

SUPPORT - INSTALLATION, REAR

FASCIA..............................13-3

SUPPORT - INSTALLATION, SUN VISOR . . 23-160

SUPPORT - REMOVAL, REAR FASCIA......13-3

SUPPORT - REMOVAL, SUN VISOR.....23-160

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR.................23-161

SUPPORT CYLINDER - INSTALLATION . . . 23-120

SUPPORT CYLINDER - INSTALLATION,

FLIP-UP GLASS.....................23-139

SUPPORT CYLINDER - REMOVAL.......23-120

SUPPORT CYLINDER - REMOVAL,

FLIP-UP GLASS.....................23-139

SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO NOISE............8A-9

SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO NOISE...........8A-11

SUPPRESSION GROUND STRAP -

OPERATION, RADIO NOISE.............8A-10

SUPPRESSION GROUND STRAP -

REMOVAL, RADIO NOISE..............8A-10

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET............9-9

SUSPENSION - DIAGNOSIS AND

TESTING, REAR.......................2-17

SUSPENSION AND STEERING SYSTEM -

DIAGNOSIS AND TESTING...............2-1

SUSPENSION ARM, BUSHINGS, AND

BALL JOINT - DESCRIPTION, UPPER......2-20

SUSPENSION ARM, BUSHINGS, AND

BALL JOINT - OPERATION, UPPER........2-20

SUSPENSION, SPECIAL TOOLS - FRONT....2-8

SWING GATE - INSTALLATION.........23-138

SWING GATE - REMOVAL.............23-138

SWING GATE BELTLINE WEATHERSTRIP

- INSTALLATION....................23-186

SWING GATE BELTLINE WEATHERSTRIP

- REMOVAL

........................23-186

SWING GATE OPENING WEATHERSTRIP

- INSTALLATION

....................23-186

SWING GATE OPENING WEATHERSTRIP

- REMOVAL

........................23-186

SWITCH - DESCRIPTION

................8P-5

SWITCH - DESCRIPTION, A/C HIGH

PRESSURE

.........................24-17

KJINDEX 25

Description Group-Page Description Group-Page Description Group-Page

Page 1786 of 1803

JEEP LIBERTY 2002

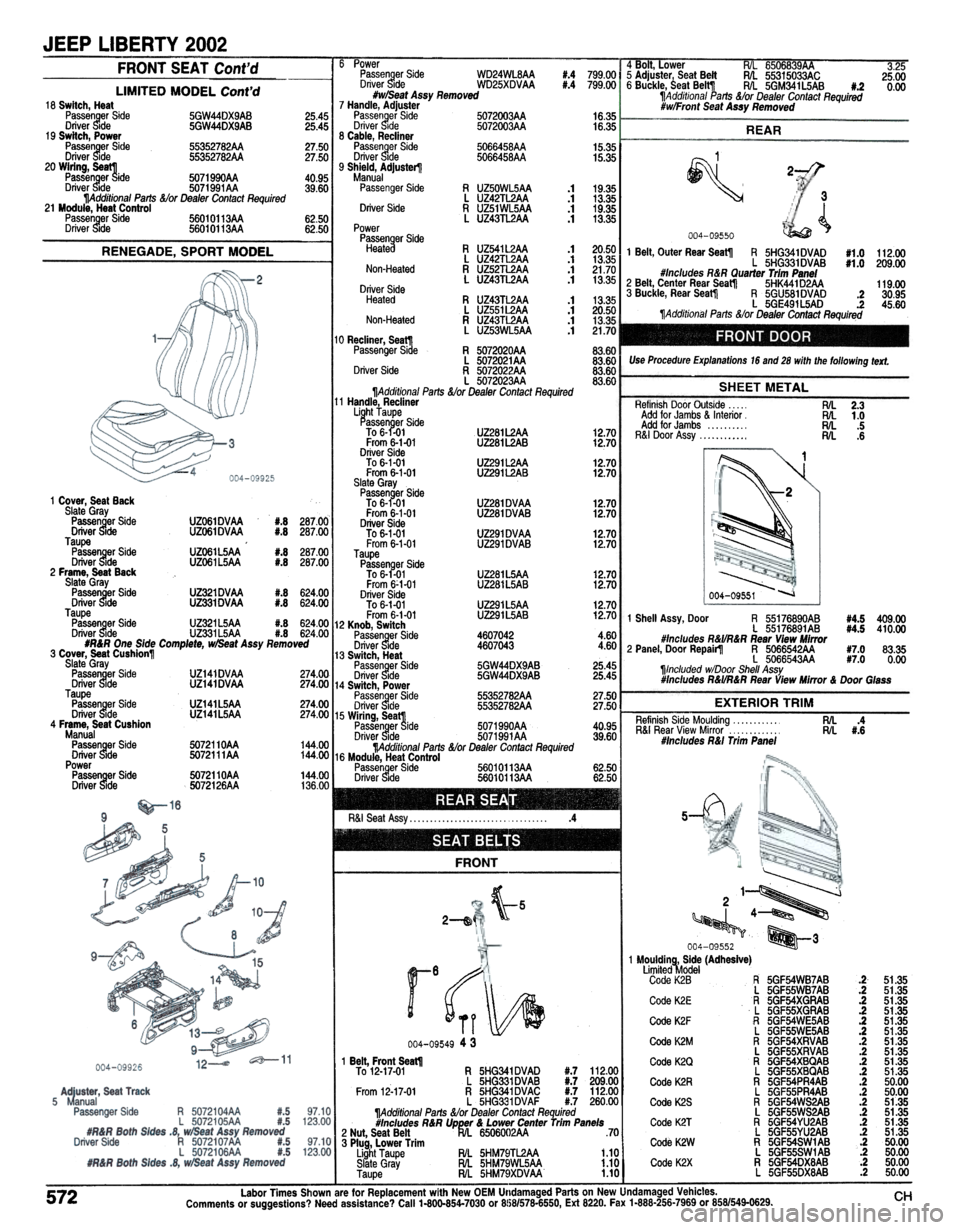

FRONT SEAT Cont'd25.000.00#.4 799.00 I 5 Adjuster;. Seat Belt R/L 55315033AC#.4 799.00 6 Buckle, :oeat Belt11 R/L 5GM341L5AB '.2lIAdditional Parls &/or Deater Contact Required#w/Front Seat ASBY RemovedLIMITED MODEL Cont'd18 Switch, HeatPassenger Side 5GW44DX9ABDriver Side 5GW44DX9AB19 Switch, PowerPassen.Qer Side 55352782AADriver Side 55352782AA20 WIring, Seet1lPassenger Side 5O71990AADriver Side 5071991AA11Additional Parts &/or Dealer Contact Required21 Module, Heat ControlPassenger Side 56010113AADriver Side 56010113AA

25.4525.45

27.5027.50

40.9539.60

REAR

1

~2~

t'ower -

Passenger Side WD24WL8AADriver Side WD25XDVAA#WISest Assy Removed7 Handle, AdjusterPassenjjer Side 5072003AADriver Side 5072003AA8 Cable, ReclinerPassenjjer Side 5066458AADriver Side 5066458AA9 Shield, Adjuster1jManualPassenger Side R UZ50WL5AA .1L UZ42TL2AA .1Driver Side R UZ51WL5AA .1L UZ43TL2AA .1PowerPassenger SideHeateiJ R UZ541L2AAL UZ42TL2AANon-Heated R UZ52TL2AAL UZ43TL2AADriver SideHeated R UZ43TL2AAL UZ551L2AANon-Heated R UZ43TL2AAL UZ53WL5AA10 Recliner, Seal11Passenger Side R 5072020AAL 5072021AADriver Side R 5072022AAL 5072023AA1]Additional Paris &lor Dealer Contact Required11 Handle, ReclinerLight TaupePassenger SideTo 6-1-01 UZ281L2AAFrom 6-1-01 UZ281L2ABDriver SideTo 6-1-01 UZ291L2AAFrom 6-1-01 UZ291L2ABSlate GrayPassenger SideTo 6-1-01 UZ281DVAAFrom 6-1-01 UZ281 DVABDriver SideTo 6-1-01 UZ291 DVAAFrom 6-1-01 UZ291 DVABTaupePassenger SideTo 6-1-01 UZ281L5AAFrom 6'1-01 UZ281L5ABDriver SideTo 6-1-01 UZ291L5AAFrom 6-1-01 UZ291L5AB12 Knob, SwitchPassenjjer Side 4607042Driver Side 460704313 Switch, HeatPassenger Side 5GW44DX9ABDriver Side 5GW44DX9AB14 Switch, PowerPassenjjer Side 55352782AADriver Side 55352782AA15 Wiring, Seal11! Passenger Side 5071990AAIDriver Side 5071991AA1]Additional Paris &lor Dealer Contact Required16 Module, Heat Control! PassenSJer Side 56010113AADriver Side 56010113AA

16.3516.35

15.3515.35

19.3513.3519.3513.35~62.5062.50

RENEGADE, SPORT MODEL.1.1.1.1.1.1.1.1

3

~004-09550 ~20.50 1 Belt, Outer Rear Seat1] R 5HG341DVAD #1.0 112.0013.35 L 5HG331DVAB #1.0 209.0021.70 #Includes R&R Quarter Trim Panel13.35 2 Belt, Center Rear Seat1] 5HK441D2AA 119.003 Buckle, Rear Seat1] R 5GU581DVAD .2 30.9513.35 L 5GE491L5AD .2 45.6020.50 ~Additional Parts &/or Dealer Contact Required

83.60 I Use Procedure Explanations 16 and 28 with the following text.83.6083.60SHEET METAL

Refinish Door Outside. ...Add for Jambs & InteriorAddforJambs R&I Door Assy .""""'"

AIL 2.3AIL 1.0AIL .5AIL .612.7012.70

12.7012.70

1

""-l

12.7012.70

12.7012.70

#.8 28700#.8 287.00I#.8 287.00I#.8 287.0012.12:

12:12:

4.'4.'

25.25.

27.27.

40;39.'

~~004-09551

1 Cover, Seat BackSlate GrayPassenJjer Side UZ061DVAADriver Side UZ061DVAATaupePassenger Side UZ061L5AADriver Side UZ061L5AA2 Frame, Seat BackSlate GrayPassenger Side UZ321DVAA #.8 624.00Driver Side UZ331DVAA #.8 624.00TaupePassenJjer Side UZ321L5AA #.B 624.00Driver Side UZ331 L5AA #.B 624.00#R&R One Side Complete, wlSeat Assy Removed3 Cover, Seat CushionllSlate GrayPassenJjer Side UZ141DVAA 274.00Driver Side UZ141DVAA 274.00TaupePassenJjer Side UZ141L5AA 274.00Driver Side UZ141L5AA 274.004 Freme, Seat CushionManualPassenJjer Side 5O72110AA 144.00Driver Side 5O72111AA 144.00PowerPassenger Side 5O72110AA 144.00Driver S'tde 5O72126AA

~

1 Shell Assy, Door R 55176890AB #4.5 409.00L 55176891AB #4.5 410.00"ncludes R&UR&R Resr VIew Mirror2 Panel, Door Repair11 R 5066542AA #7.0 83.35L 5066543AA #7.0 0.001]lncluded wlDoor Shell Assy"ncludes R&UR&R Resr View MI"or & Door Glsss

EXTERIOR TRIM

R/L .4AiL #.6Refinish Side Moulding R&IRearViewMirror #Includes R&I Trim Panel

62.50!62.50

5-f1R&I Seal~Y:-: ;.,...~:::.:.:::::;;:.4

FRONT

1~~~~~~~~~~-, ~2

~~4~004-09552 --31 Moulding, Side (Adhesive)Limited ModelCode K2B I

Code K2E 1

Code K2F I

Code K2M

Code K2Q

Code K2R

Code K2S

Code K2T

Code K2W

Code K2X

\-52-t\)~

8/

i ~ TI\V6I

004-0954943

1 Belt, Front Seat1JTo 12-17-01 R 5HG341DVAD #.7 112.00L 5HG331DVAB #.7 209.00From 12-17-01 R 5HG341DVAC #.7 112.00L 5HG331DVAF #.7 260,00llAdditional Palts &lor Dealer Contact Required#Includes R&R Up~r & Lower Center Trim Panels2 Nut, Seat Belt R/L 6506002AA ,3 Plug, Lower TrimLight Taupe AiL 5HM79TL2AASlate Gray R/L 5HM79WL5AATaupe AiL 5HM79XDVAA

F 5GF54WB7ABL 5GF55WB7ABR 5GF54XGRABL 5GF55XGRABR 5GF54WE5ABL 5GF55WE5ABR 5GF54XRVABL 5GF55XRVABR 5GF54XBQABL 5GF55XBQABR 5GF54PR4ABL 5GF55PR4ABR 5GF54WS2ABL 5GF55WS2ABR 5GF54YU2ABL 5GF55YU2ABR 5GF54SW1ABL 5GF55SW1ABR 5GF54DX8ABL 5GF55DX8AB

.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 50.00.2 50.00.2 5f35.2 51.35.2 51.35.2 51.35.2 50.00.2 50.00..2 50.00.2 50.00

70

1.101.10

I1.10

Labor Times Shown are for Replacement with New OEM Undamaged Parts on New Undamaged Vehicles.Comments or suggestions? Need assistance? Call 1-800-854-7030 or 8~;8/578-6550, Ext 8220. Fax 1-888-256-7969 or 858/549-0629.572CH

7070

707060

604545

50501

95601

Page 1787 of 1803

\:-- .-1'1

~

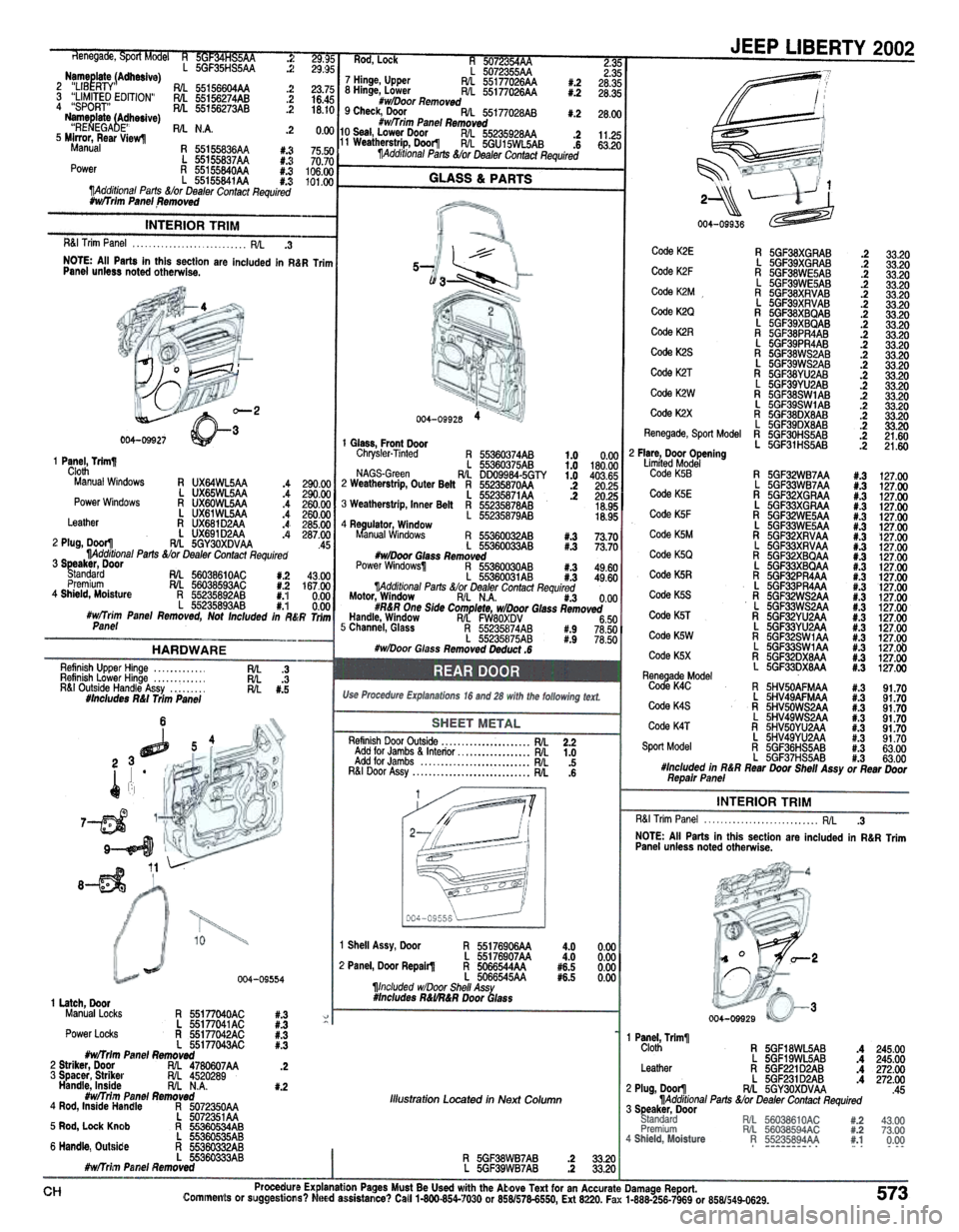

JEEP LIBERTY 2002enega e, po 5 :~5, Lock 507 3 2.35L 5GF35HS5AA .,. 29.'~5 L 5072355AA 2.35eNamapiate (Adha$lve) 7 Hinge, Upper R/L 55177026AA #.2 28.35 2 "LIBERTY" R/L 55156604AA .2 23.75 8 Hinge, Lower R/L 55177026AA #.2 28.35 I

3 "LIMITED EDITION" R/L 55156274AB .2 16.45 #W/Door Removed4 "SPORT" R/L 55156273AB .2 18.10 9 Check, Door R/L 55177028AB #.2 28.00Namep!ate /Adhesive) #w/Trim Panel Removed"RENEGADE" R/L N.A. .2 0.00 10 Seal, Lower Door R/L 55235928AA .2 11.255 Mirror, Rear View1j 11 Weatherstrip, Door11 R/L 5GU 15WL5AB .6 63.20Manual R 55155836AA #.3 75.50 ~Addilional Parts &/or Dealer Contact Required~-- L 55155837AA #.3 70.70-Power R 55155840AA #.3 106.00 GLASS & PARTSL 55155841AA #.3 101.00~11Additional Parts &/or Dealer Contact Required 2#W/Trim Panel ,Removed

004-09936INTERIOR TRIM

R&I Trim Panel " ,. """ AIL .3

NOTE: All Par!$ in this section are included in R&R TrimPanel unless noted otherwise.

Code K2E R 5GF38XGRAB .2 33.20L 5GF39XGRAB .2 33.20Code K2F R 5GF38WE5AB .2 33.20L 5GF39WE5AB .2 33.20Code K2M R 5GF38XRVAB .2 33.20L 5GF39XRVAB .2 33.20Code K20 R 5GF38XBOAB .2 33.20L 5GF39XBOAB .2 33.20Code K2R R 5GF38PR4AB .2 33.20L 5GF39PR4AB .2 33.20Code K2S R 5GF38WS2AB .2 33.20L 5GF39WS2AB .2 33.20Code K2T R 5GF38YU2AB .2 33.20L 5GF39YU2AB .2 33.20Code K2W R 5GF38SW1AB .2 33.20L 5GF39SW1AB .2 33.20Code K2X R 5GF38DX8AB .2 33.20L 5GF39DX8AB .2 33.20Renegade, Sport Model R 5GF30HS5AB .2 21.60L 5GF31HS5AB .2 21.602 Flare! Door Openinglimited ModelCode K5B R 5GF32WB7AA #.3 127.00L 5GF33WB7AA #.3 127.00.Code K5E R 5GF32XGRAA #.3 127.00L 5GF33XGRAA #.3 127.00Code K5F R 5GF32WE5AA #.3 127.00L 5GF33WE5AA #.3 127.00Code K5M R 5GF32XRVAA #.3 127.00L 5GF33XRVAA #.3 127.00Code K50 R 5GF32XBOAA #.3 127.00L 5GF33XBQAA #.3 127.00Code K5R R 5GF32PR4AA #.3 127.00L 5GF33PR4AA #.3 127.00Code KSS R 5GF32WS2AA #.3 127.00L 5GF33WS2AA #.3 127.00Code KST R 5GF32YU2AA #.3 127.00L 5GF33YU2AA #.3 127.00Code K5W R 5GF32SW1AA #.3 127.00L 5GF33SW1AA #.3 127.00Code K5X R 5GF32DX8AA #.3 127.00L 5GF33DX8AA #.3 127.00Renegade ModelCode K4C R 5HV50AFMAA #.3 91.70L 5HV49AFMAA #.3 91.70Code K4S R 5HVSOWS2AA #.3 91.70L 5HV49WS2AA #.3 91.70Code K4T R 5HV50YU2AA #.3 91.70L 5HV49YU2AA #.3 91.70Sport Model R 5GF36HS5AB #.3 63.00L 5GF37HS5AB #.3 63.00#Included in R&R Rear Door Shell Assy or Rear DoorRepair Panel

~--::f::::' 5-i

iIl3-~~42

~~:~

004-09927

~ 0--2

~3

004-09928 4

1 Panel, TrimllClothManual Windows R UX64WL5AA .4 290.00L UX65WL5AA .4 290.00Power Windows R UXOOWL5AA .4 200.00L UX61WL5AA .4 260.00Leather R UX681D2AA .4 285.00L UX691D2AA .4 287.002 Plug, Doo~ AiL 5GY30XDVAA 451\Addilional Parts &/or Dealer Contact Required3 Speaker, DoorStandard AiL 50038610AC #.2 43.00Premium AiL 50038593AC #.2 167004 Shield, Moisture R 55235892AB #.1 0.00L 55235893AB #.1 0.00#WlTrim Panel Removed, Not Included in R~rR TrimPanel

HARDWARE

AiL .3AiL .3AiL #.5

5 4,f

INTERIOR TRIM

/jR&ITrimPanel R/L .3

NOTE: All Parts in this section are included in R&R TrimPanel unless noted otherwise.

Refinish Upper Hinge Refinish Lower Hinge R&IOulsideHandleAssy "nclude, R&I Trim Panel

6

3~2.I .

7-d'

9-ri...,..@ 1 c 1 V

8~

.11/"

0 1"70-- 2

~

1 Shell Assy, Door R 55176906AAL 55176907AA2 Panel, Door Repai~ R 5066544AAL 5066545AA1]lncluded w/Door Shell Assy#Includes R&VR&R Door Glass

4.04.0#6.5#6.5

0.000.0010.000.00--004-09554

31 latCh, DoorManual Locks

Power Locks

Nwffr/m Panel2 Striker, Door3 Spacer, StrikerHandle, InsideIwffrlm Panel4 Rod, Inside Handle

5 Rod, Lock Knob

6 Handle, Outside

#Wffrlm Panel

#.3#.3#.3#.3

.2

#.2

004-09929

Illustration Located in Next Column

R 5GF38WB7ABL 5GF39WB7AB.2 33.20.2 33.20

Procedure Explanation Pages Must Be Used with the At,ove Text for an Accurate Damage Report.Comltlenlls or suggestuons? NeEd assistance? Call1-800.854-:r030 or 858/578-6550, Ext 8220. Fro( 1-888-256-7969 or 858/549-0629.573CH

1 Glass, Front DoorChrysler-Tinted R 55360374AB 1.0 0.00L 55360375AB 1.0 180.00INAGS-Green R/L ODO9984.5GTY 1.0 403.652 Weatherstrip, Outer Belt R 55235870AA .2 20.25L 55235871AA .2 20.2513 Weatherstrip, Inner Belt R 55235878AB 18.95L 55235879AB 18.954 Regulator, Windowtl;anual Windows R 55360032AB #.3 73.70IL 55360033AB #.3 73.70#W/Door Glass RemovedPower Windows~ R 55360030AB #.3 49.60IL 55360031AB #.3 49.601!Additional Parts &/or Dealer Contact RequiredMotor, Window R/L N.A. #.3 0.00#R&R One Side Complete, w/Door Glass RemovedHandle, Window R/[ FW80>:OV 6.505 Channel, Glass R 55235874AB #.9 78.50 IL 55235875AB #.9 78.50#W/Door Glass Removed Ceduct.6

R 55177040ACL 55177041ACR 55177042ACL 55177043ACRemoved

AiL 4780607AAAiL 4520289AiL N.A.Removed

R 5072350AAL 5072351AAR 55360534ABL 55360535ABR 55360332ABL 55360333ABRemoved

1 Panel, TrlmllCloth R 5GF18WL5AB .4 245.00L 5GF19WL5AB .4 245.00Leather R 5GF221D2AB .4 272.00L 5GF231D2AB .4 272.002 Plug, Door1] AiL 5GY30XDVAA .45llAdditional Parls &/or Dealer Contact Required3 Speaker. Door

Refinish Door Outside AiL 2.2AddforJambs&lnterior AiL 1.0AddforJambs AiL .5R&IDoorAssy AiL .6