section 8 JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1474 of 1803

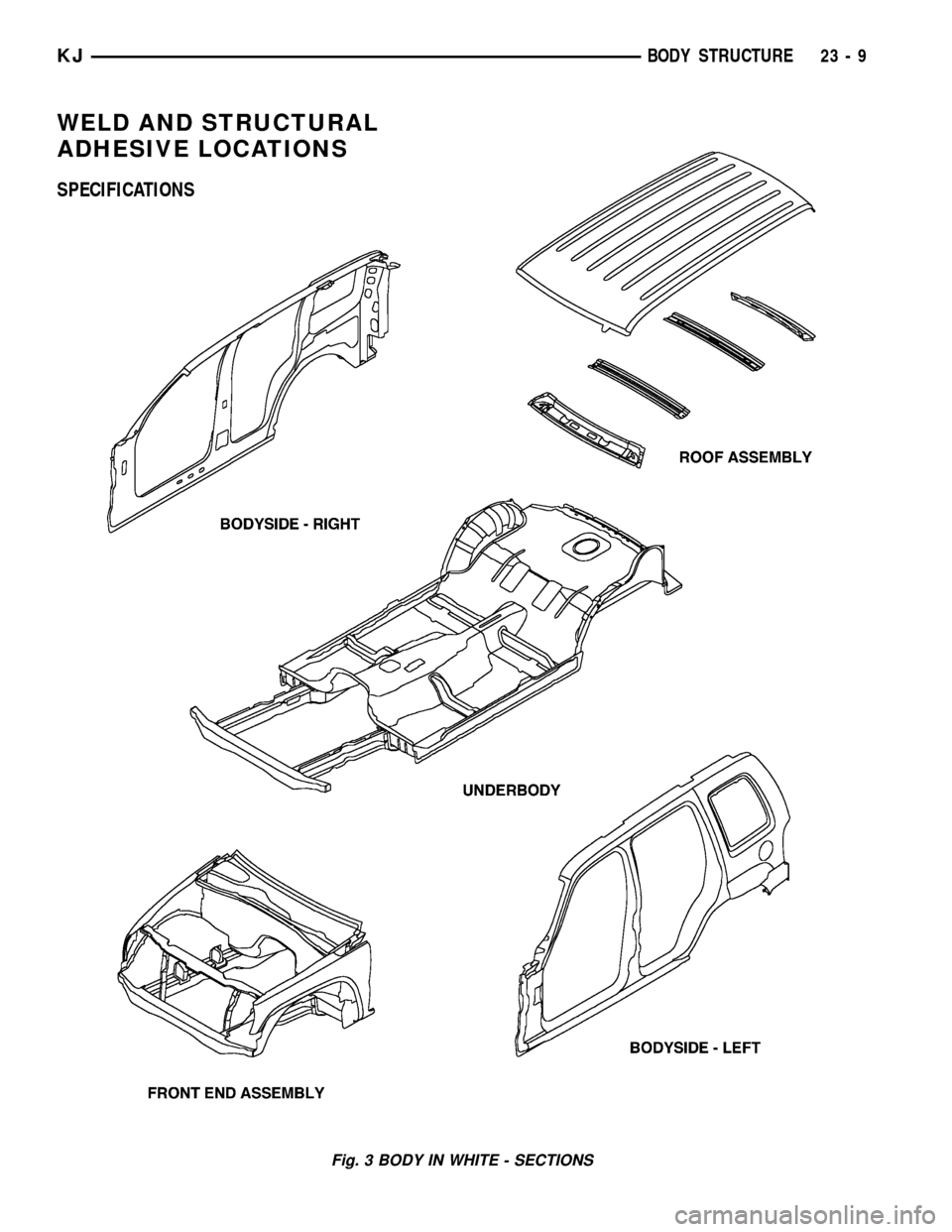

WELD AND STRUCTURAL

ADHESIVE LOCATIONS

SPECIFICATIONS

Fig. 3 BODY IN WHITE - SECTIONS

KJBODY STRUCTURE 23 - 9

Page 1661 of 1803

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6)

To locate a leak in a vacuum line, leave one end

of the line plugged and connect the test set hose or

probe to the other end of the line. Run your fingers

slowly along the line while watching the test set gauge.

The vacuum reading will fluctuate when your fingers

contact the source of the leak. To repair the vacuum

line, cut out the leaking section of the line. Then, insert

the loose ends of the line into a suitable length of 3 mil-

limeter (0.125 inch) inside diameter rubber hose.

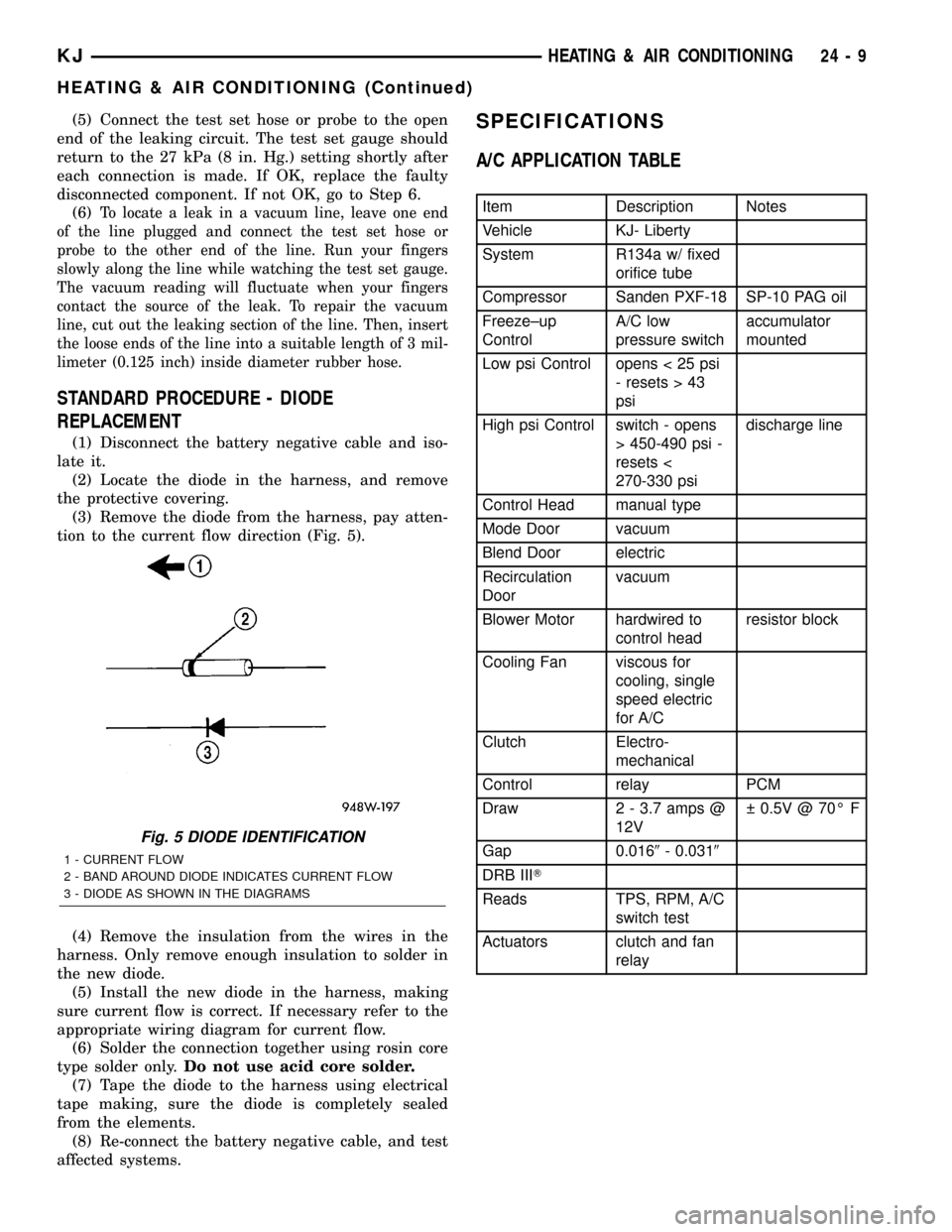

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect the battery negative cable and iso-

late it.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 5).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery negative cable, and test

affected systems.

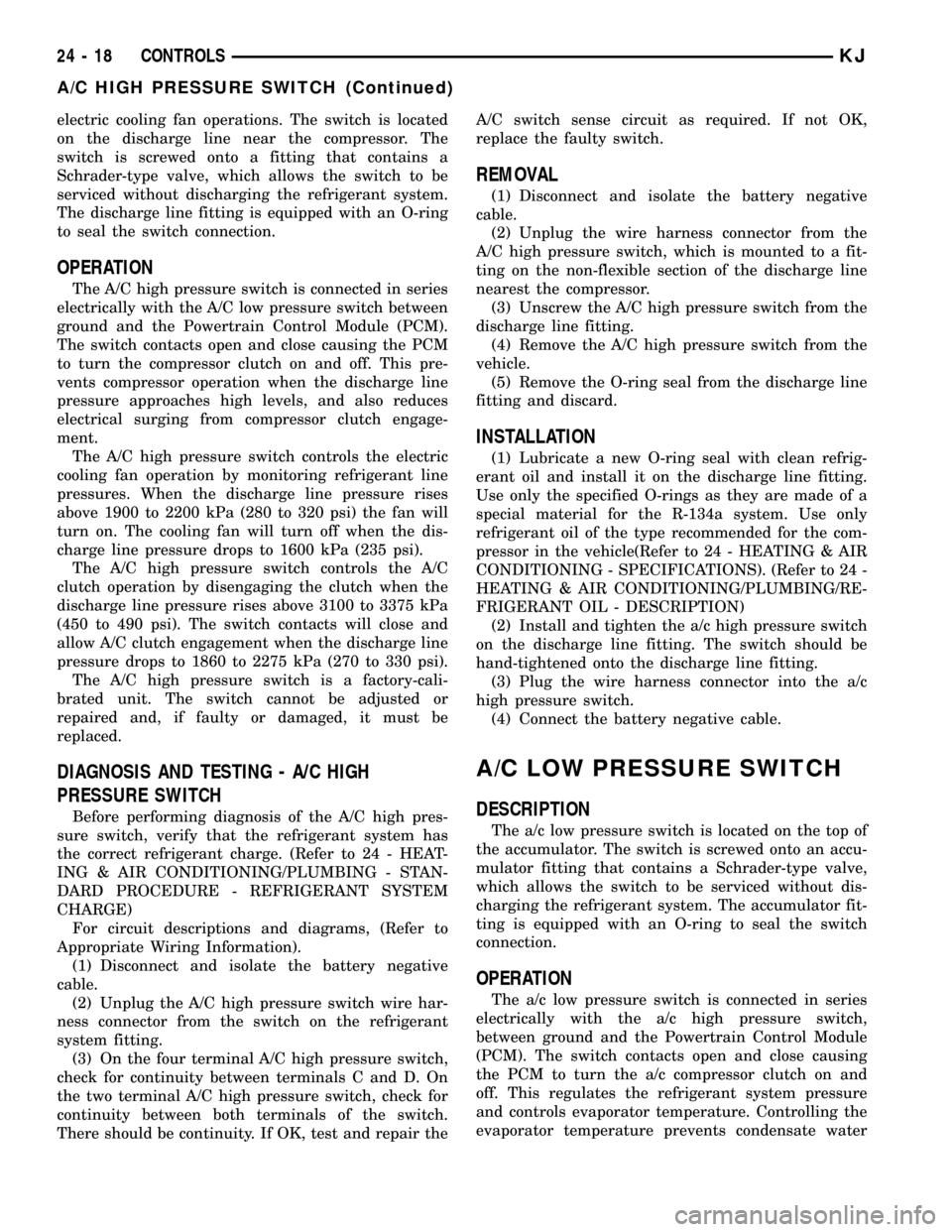

SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

Vehicle KJ- Liberty

System R134a w/ fixed

orifice tube

Compressor Sanden PXF-18 SP-10 PAG oil

Freeze±up

ControlA/C low

pressure switchaccumulator

mounted

Low psi Control opens < 25 psi

- resets > 43

psi

High psi Control switch - opens

> 450-490 psi -

resets <

270-330 psidischarge line

Control Head manual type

Mode Door vacuum

Blend Door electric

Recirculation

Doorvacuum

Blower Motor hardwired to

control headresistor block

Cooling Fan viscous for

cooling, single

speed electric

for A/C

Clutch Electro-

mechanical

Control relay PCM

Draw 2 - 3.7 amps @

12V 0.5V @ 70É F

Gap 0.0169- 0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch test

Actuators clutch and fan

relay

Fig. 5 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

KJHEATING & AIR CONDITIONING 24 - 9

HEATING & AIR CONDITIONING (Continued)

Page 1670 of 1803

electric cooling fan operations. The switch is located

on the discharge line near the compressor. The

switch is screwed onto a fitting that contains a

Schrader-type valve, which allows the switch to be

serviced without discharging the refrigerant system.

The discharge line fitting is equipped with an O-ring

to seal the switch connection.

OPERATION

The A/C high pressure switch is connected in series

electrically with the A/C low pressure switch between

ground and the Powertrain Control Module (PCM).

The switch contacts open and close causing the PCM

to turn the compressor clutch on and off. This pre-

vents compressor operation when the discharge line

pressure approaches high levels, and also reduces

electrical surging from compressor clutch engage-

ment.

The A/C high pressure switch controls the electric

cooling fan operation by monitoring refrigerant line

pressures. When the discharge line pressure rises

above 1900 to 2200 kPa (280 to 320 psi) the fan will

turn on. The cooling fan will turn off when the dis-

charge line pressure drops to 1600 kPa (235 psi).

The A/C high pressure switch controls the A/C

clutch operation by disengaging the clutch when the

discharge line pressure rises above 3100 to 3375 kPa

(450 to 490 psi). The switch contacts will close and

allow A/C clutch engagement when the discharge line

pressure drops to 1860 to 2275 kPa (270 to 330 psi).

The A/C high pressure switch is a factory-cali-

brated unit. The switch cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING - A/C HIGH

PRESSURE SWITCH

Before performing diagnosis of the A/C high pres-

sure switch, verify that the refrigerant system has

the correct refrigerant charge. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

CHARGE)

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the A/C high pressure switch wire har-

ness connector from the switch on the refrigerant

system fitting.

(3) On the four terminal A/C high pressure switch,

check for continuity between terminals C and D. On

the two terminal A/C high pressure switch, check for

continuity between both terminals of the switch.

There should be continuity. If OK, test and repair theA/C switch sense circuit as required. If not OK,

replace the faulty switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the

A/C high pressure switch, which is mounted to a fit-

ting on the non-flexible section of the discharge line

nearest the compressor.

(3) Unscrew the A/C high pressure switch from the

discharge line fitting.

(4) Remove the A/C high pressure switch from the

vehicle.

(5) Remove the O-ring seal from the discharge line

fitting and discard.

INSTALLATION

(1) Lubricate a new O-ring seal with clean refrig-

erant oil and install it on the discharge line fitting.

Use only the specified O-rings as they are made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the com-

pressor in the vehicle(Refer to 24 - HEATING & AIR

CONDITIONING - SPECIFICATIONS). (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/RE-

FRIGERANT OIL - DESCRIPTION)

(2) Install and tighten the a/c high pressure switch

on the discharge line fitting. The switch should be

hand-tightened onto the discharge line fitting.

(3) Plug the wire harness connector into the a/c

high pressure switch.

(4) Connect the battery negative cable.

A/C LOW PRESSURE SWITCH

DESCRIPTION

The a/c low pressure switch is located on the top of

the accumulator. The switch is screwed onto an accu-

mulator fitting that contains a Schrader-type valve,

which allows the switch to be serviced without dis-

charging the refrigerant system. The accumulator fit-

ting is equipped with an O-ring to seal the switch

connection.

OPERATION

The a/c low pressure switch is connected in series

electrically with the a/c high pressure switch,

between ground and the Powertrain Control Module

(PCM). The switch contacts open and close causing

the PCM to turn the a/c compressor clutch on and

off. This regulates the refrigerant system pressure

and controls evaporator temperature. Controlling the

evaporator temperature prevents condensate water

24 - 18 CONTROLSKJ

A/C HIGH PRESSURE SWITCH (Continued)

Page 1692 of 1803

CAUTION - REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing will

reduce the capacity of the entire system. High pressures

are produced in the system when it is operating.

Extreme care must be exercised to make sure that all

refrigerant system connections are pressure tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²

All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings that

are the correct size and approved for use with R-134a

refrigerant. Failure to do so may result in a leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

The refrigerant system will remain chemically sta-

ble as long as pure, moisture-free R-134a refrigerant

and refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles or

serious damage can occur if foreign material is

present in the refrigerant system.

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

ready. The refrigerant system should not be left open

to the atmosphere any longer than necessary. Cap or

plug all lines and fittings as soon as they are opened

to prevent the entrance of dirt and moisture. All lines

and components in parts stock should be capped or

sealed until they are to be installed.All tools, including the refrigerant recycling equip-

ment, the manifold gauge set, and test hoses should

be kept clean and dry. All tools and equipment must

be designed for R-134a refrigerant.

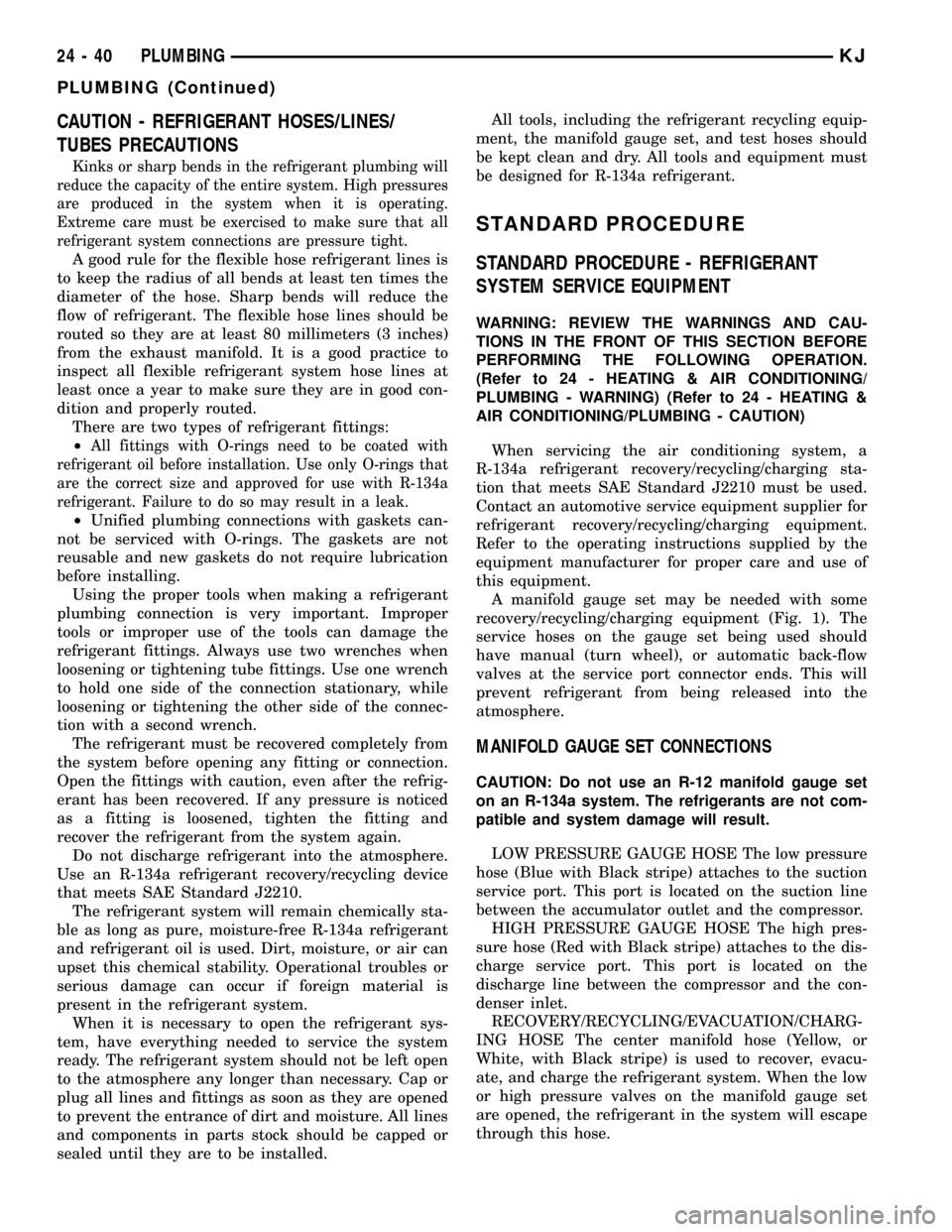

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

equipment manufacturer for proper care and use of

this equipment.

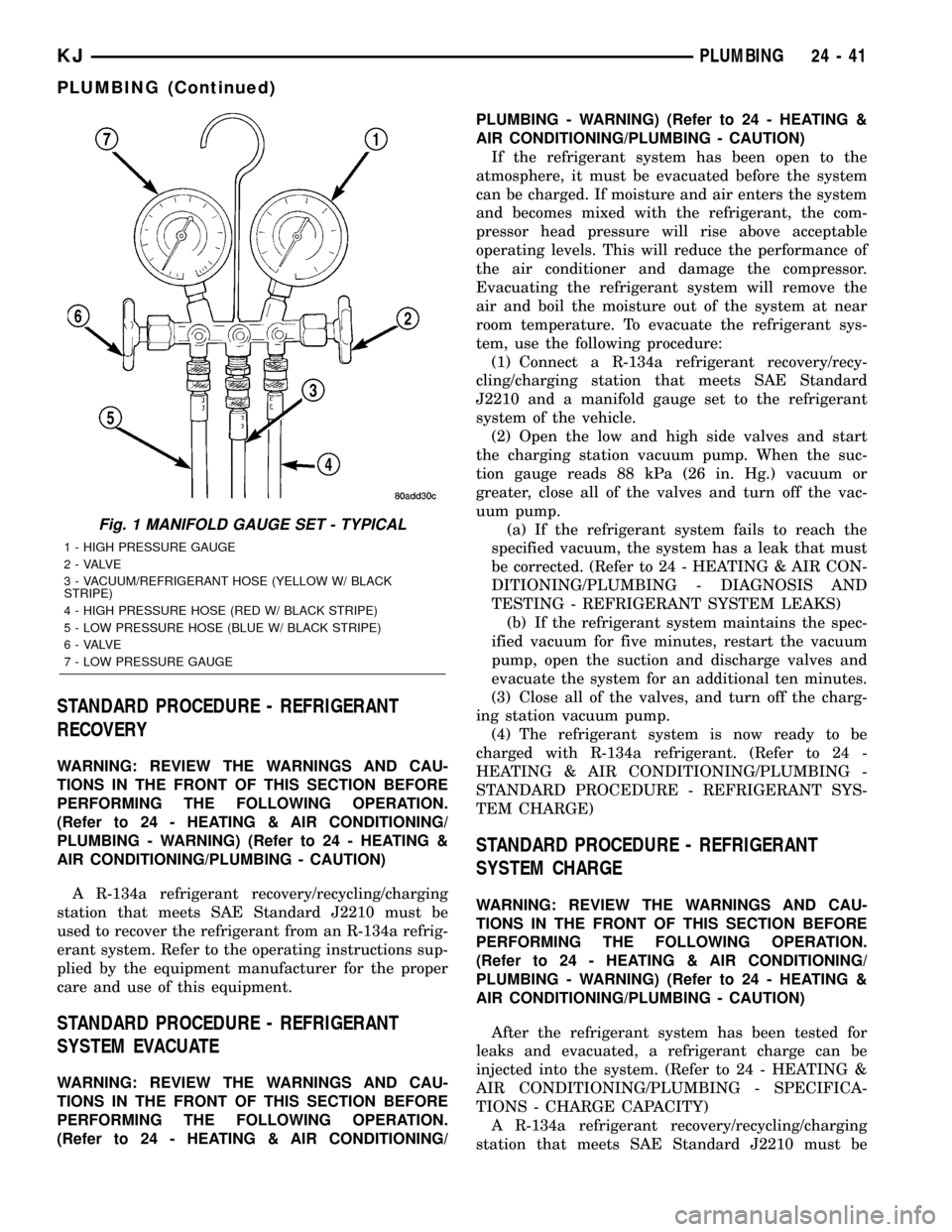

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 1). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

LOW PRESSURE GAUGE HOSE The low pressure

hose (Blue with Black stripe) attaches to the suction

service port. This port is located on the suction line

between the accumulator outlet and the compressor.

HIGH PRESSURE GAUGE HOSE The high pres-

sure hose (Red with Black stripe) attaches to the dis-

charge service port. This port is located on the

discharge line between the compressor and the con-

denser inlet.

RECOVERY/RECYCLING/EVACUATION/CHARG-

ING HOSE The center manifold hose (Yellow, or

White, with Black stripe) is used to recover, evacu-

ate, and charge the refrigerant system. When the low

or high pressure valves on the manifold gauge set

are opened, the refrigerant in the system will escape

through this hose.

24 - 40 PLUMBINGKJ

PLUMBING (Continued)

Page 1693 of 1803

STANDARD PROCEDURE - REFRIGERANT

RECOVERY

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

STANDARD PROCEDURE - REFRIGERANT

SYSTEM EVACUATE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be charged. If moisture and air enters the system

and becomes mixed with the refrigerant, the com-

pressor head pressure will rise above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor.

Evacuating the refrigerant system will remove the

air and boil the moisture out of the system at near

room temperature. To evacuate the refrigerant sys-

tem, use the following procedure:

(1) Connect a R-134a refrigerant recovery/recy-

cling/charging station that meets SAE Standard

J2210 and a manifold gauge set to the refrigerant

system of the vehicle.

(2) Open the low and high side valves and start

the charging station vacuum pump. When the suc-

tion gauge reads 88 kPa (26 in. Hg.) vacuum or

greater, close all of the valves and turn off the vac-

uum pump.

(a) If the refrigerant system fails to reach the

specified vacuum, the system has a leak that must

be corrected. (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - DIAGNOSIS AND

TESTING - REFRIGERANT SYSTEM LEAKS)

(b) If the refrigerant system maintains the spec-

ified vacuum for five minutes, restart the vacuum

pump, open the suction and discharge valves and

evacuate the system for an additional ten minutes.

(3) Close all of the valves, and turn off the charg-

ing station vacuum pump.

(4) The refrigerant system is now ready to be

charged with R-134a refrigerant. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can be

injected into the system. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - SPECIFICA-

TIONS - CHARGE CAPACITY)

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

Fig. 1 MANIFOLD GAUGE SET - TYPICAL

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/ BLACK

STRIPE)

4 - HIGH PRESSURE HOSE (RED W/ BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/ BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

KJPLUMBING 24 - 41

PLUMBING (Continued)

Page 1695 of 1803

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

to be certain that the discharge pressure does not

exceed 2760 kPa (400 psi).

(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which can

cause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAU-

TION)

(5) If the noise is from opening and closing of the

high pressure relief valve, evacuate and recharge the

refrigerant system. (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM CHARGE) If the high pressure

relief valve still does not seat properly, replace the

compressor.

(6) If the noise is from liquid slugging on the suc-

tion line, replace the accumulator. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR - REMOVAL) Check the refrigerant oil

level and the refrigerant system charge. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

REFRIGERANT OIL - STANDARD PROCEDURE)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - SPECIFICATIONS - CHARGE

CAPACITY) If the liquid slugging condition continues

following accumulator replacement, replace the com-

pressor. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL)

(7) If the noise continues, replace the compressor

and repeat Step 1.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

The compressor may be removed and repositioned

without disconnecting the refrigerant lines or dis-

charging the refrigerant system. Discharging is not

necessary if servicing the compressor clutch or clutch

coil, the engine, the cylinder head, or the generator.

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)(2) Disconnect and isolate the battery negative

cable.

(3) Remove the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Unplug the compressor clutch coil wire harness

connector.

(5) Remove the suction and discharge refrigerant

line manifold from the compressor. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

SUCTION LINE - REMOVAL) (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - REMOVAL) Install plugs in, or

tape over all of the opened refrigerant fittings.

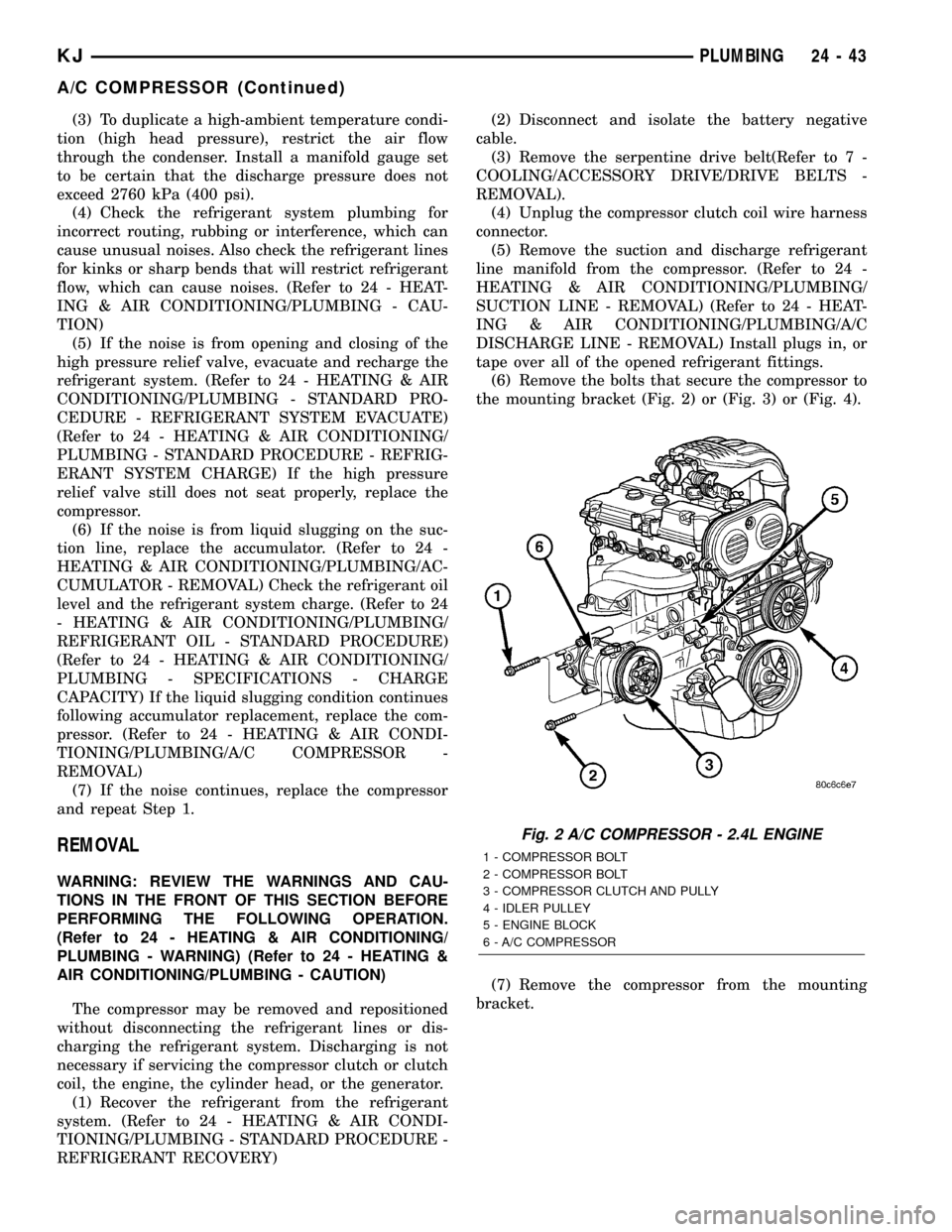

(6) Remove the bolts that secure the compressor to

the mounting bracket (Fig. 2) or (Fig. 3) or (Fig. 4).

(7) Remove the compressor from the mounting

bracket.

Fig. 2 A/C COMPRESSOR - 2.4L ENGINE

1 - COMPRESSOR BOLT

2 - COMPRESSOR BOLT

3 - COMPRESSOR CLUTCH AND PULLY

4 - IDLER PULLEY

5 - ENGINE BLOCK

6 - A/C COMPRESSOR

KJPLUMBING 24 - 43

A/C COMPRESSOR (Continued)

Page 1696 of 1803

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

The compressor may be removed and repositioned

without disconnecting the refrigerant lines or dis-

charging the refrigerant system. Discharging is not

necessary if servicing the compressor clutch or clutch

coil, the engine, the cylinder head, or the generator.

NOTE: If a replacement compressor is being

installed, be certain to check the refrigerant oil

level. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - STANDARD PRO-

CEDURE - REFRIGERANT OIL LEVEL) Use only

refrigerant oil of the type recommended for the

compressor in the vehicle. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/REFRIGERANT OIL -

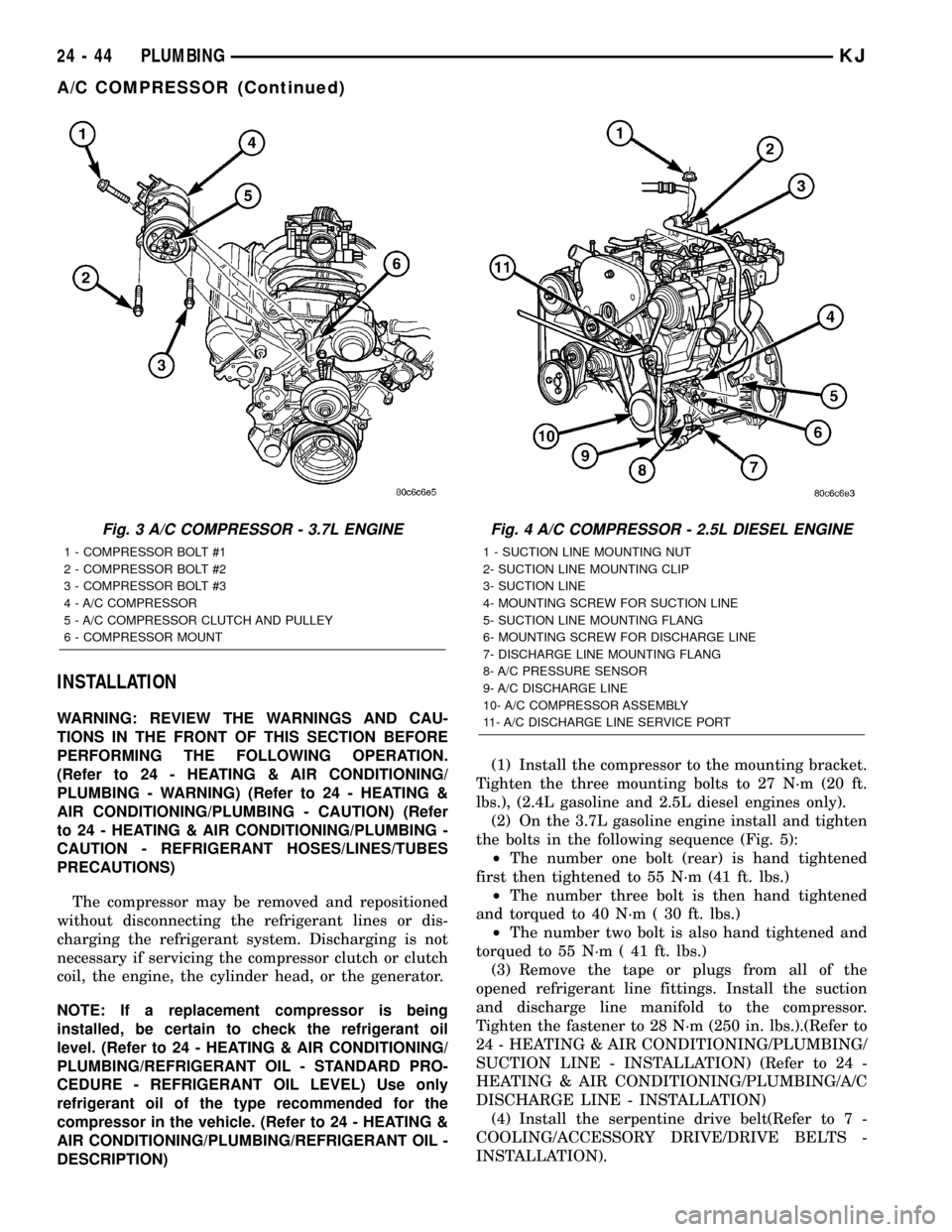

DESCRIPTION)(1) Install the compressor to the mounting bracket.

Tighten the three mounting bolts to 27 N´m (20 ft.

lbs.), (2.4L gasoline and 2.5L diesel engines only).

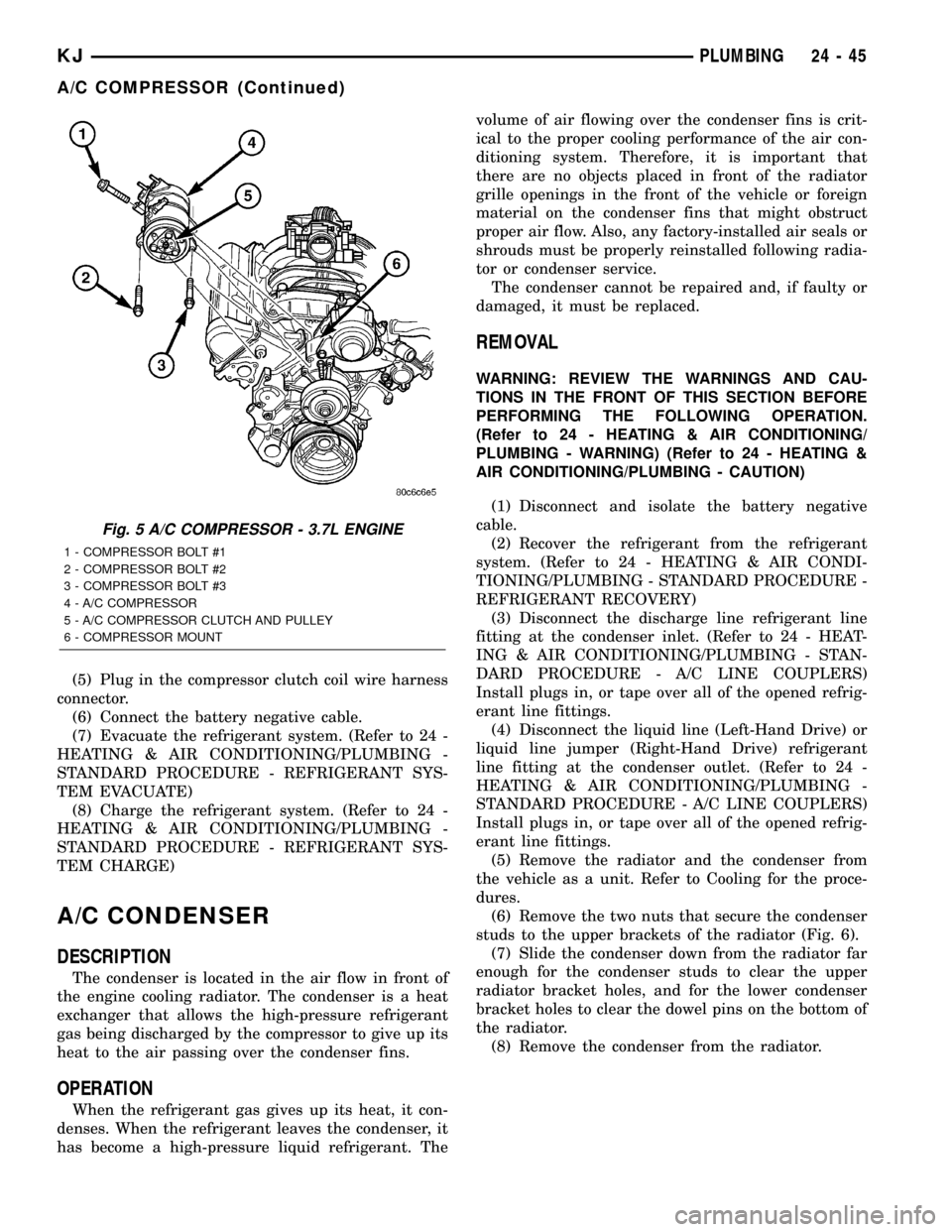

(2) On the 3.7L gasoline engine install and tighten

the bolts in the following sequence (Fig. 5):

²The number one bolt (rear) is hand tightened

first then tightened to 55 N´m (41 ft. lbs.)

²The number three bolt is then hand tightened

and torqued to 40 N´m ( 30 ft. lbs.)

²The number two bolt is also hand tightened and

torqued to 55 N´m ( 41 ft. lbs.)

(3) Remove the tape or plugs from all of the

opened refrigerant line fittings. Install the suction

and discharge line manifold to the compressor.

Tighten the fastener to 28 N´m (250 in. lbs.).(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

SUCTION LINE - INSTALLATION) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - INSTALLATION)

(4) Install the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 3 A/C COMPRESSOR - 3.7L ENGINE

1 - COMPRESSOR BOLT #1

2 - COMPRESSOR BOLT #2

3 - COMPRESSOR BOLT #3

4 - A/C COMPRESSOR

5 - A/C COMPRESSOR CLUTCH AND PULLEY

6 - COMPRESSOR MOUNT

Fig. 4 A/C COMPRESSOR - 2.5L DIESEL ENGINE

1 - SUCTION LINE MOUNTING NUT

2- SUCTION LINE MOUNTING CLIP

3- SUCTION LINE

4- MOUNTING SCREW FOR SUCTION LINE

5- SUCTION LINE MOUNTING FLANG

6- MOUNTING SCREW FOR DISCHARGE LINE

7- DISCHARGE LINE MOUNTING FLANG

8- A/C PRESSURE SENSOR

9- A/C DISCHARGE LINE

10- A/C COMPRESSOR ASSEMBLY

11- A/C DISCHARGE LINE SERVICE PORT

24 - 44 PLUMBINGKJ

A/C COMPRESSOR (Continued)

Page 1697 of 1803

(5) Plug in the compressor clutch coil wire harness

connector.

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow in front of

the engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When the refrigerant gas gives up its heat, it con-

denses. When the refrigerant leaves the condenser, it

has become a high-pressure liquid refrigerant. Thevolume of air flowing over the condenser fins is crit-

ical to the proper cooling performance of the air con-

ditioning system. Therefore, it is important that

there are no objects placed in front of the radiator

grille openings in the front of the vehicle or foreign

material on the condenser fins that might obstruct

proper air flow. Also, any factory-installed air seals or

shrouds must be properly reinstalled following radia-

tor or condenser service.

The condenser cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Disconnect the discharge line refrigerant line

fitting at the condenser inlet. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(4) Disconnect the liquid line (Left-Hand Drive) or

liquid line jumper (Right-Hand Drive) refrigerant

line fitting at the condenser outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(5) Remove the radiator and the condenser from

the vehicle as a unit. Refer to Cooling for the proce-

dures.

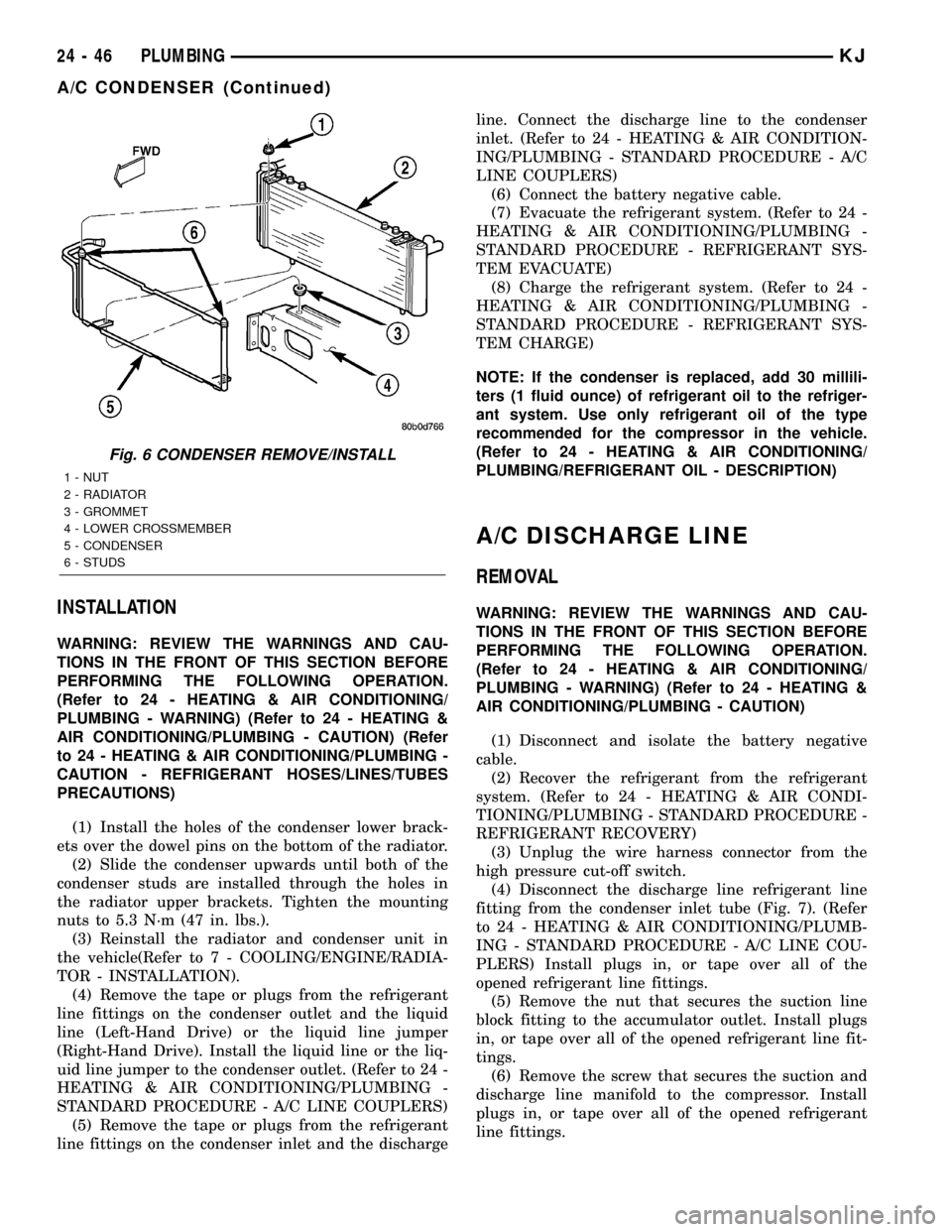

(6) Remove the two nuts that secure the condenser

studs to the upper brackets of the radiator (Fig. 6).

(7) Slide the condenser down from the radiator far

enough for the condenser studs to clear the upper

radiator bracket holes, and for the lower condenser

bracket holes to clear the dowel pins on the bottom of

the radiator.

(8) Remove the condenser from the radiator.

Fig. 5 A/C COMPRESSOR - 3.7L ENGINE

1 - COMPRESSOR BOLT #1

2 - COMPRESSOR BOLT #2

3 - COMPRESSOR BOLT #3

4 - A/C COMPRESSOR

5 - A/C COMPRESSOR CLUTCH AND PULLEY

6 - COMPRESSOR MOUNT

KJPLUMBING 24 - 45

A/C COMPRESSOR (Continued)

Page 1698 of 1803

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the holes of the condenser lower brack-

ets over the dowel pins on the bottom of the radiator.

(2) Slide the condenser upwards until both of the

condenser studs are installed through the holes in

the radiator upper brackets. Tighten the mounting

nuts to 5.3 N´m (47 in. lbs.).

(3) Reinstall the radiator and condenser unit in

the vehicle(Refer to 7 - COOLING/ENGINE/RADIA-

TOR - INSTALLATION).

(4) Remove the tape or plugs from the refrigerant

line fittings on the condenser outlet and the liquid

line (Left-Hand Drive) or the liquid line jumper

(Right-Hand Drive). Install the liquid line or the liq-

uid line jumper to the condenser outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(5) Remove the tape or plugs from the refrigerant

line fittings on the condenser inlet and the dischargeline. Connect the discharge line to the condenser

inlet. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE - A/C

LINE COUPLERS)

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

A/C DISCHARGE LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

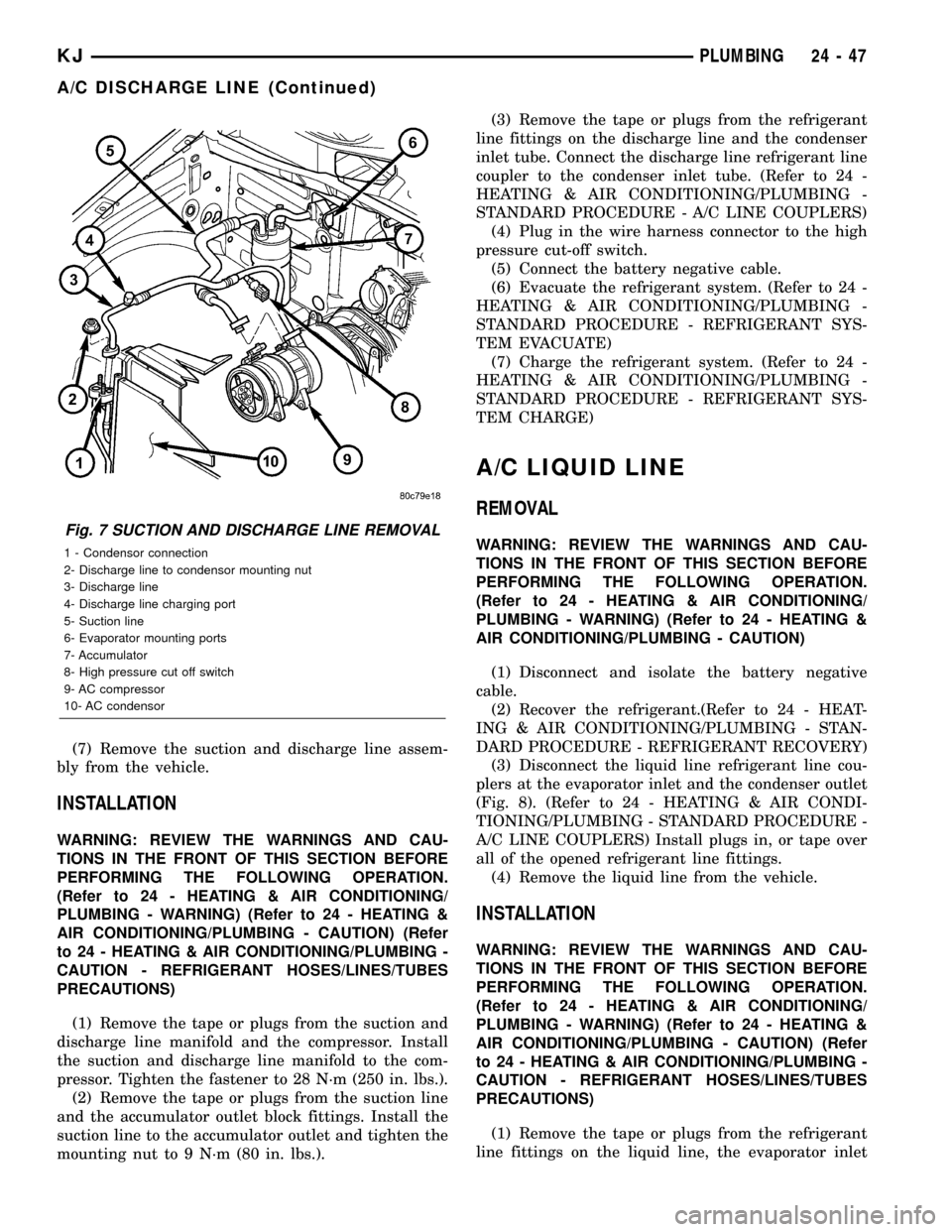

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the

high pressure cut-off switch.

(4) Disconnect the discharge line refrigerant line

fitting from the condenser inlet tube (Fig. 7). (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS) Install plugs in, or tape over all of the

opened refrigerant line fittings.

(5) Remove the nut that secures the suction line

block fitting to the accumulator outlet. Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

(6) Remove the screw that secures the suction and

discharge line manifold to the compressor. Install

plugs in, or tape over all of the opened refrigerant

line fittings.

Fig. 6 CONDENSER REMOVE/INSTALL

1 - NUT

2 - RADIATOR

3 - GROMMET

4 - LOWER CROSSMEMBER

5 - CONDENSER

6 - STUDS

24 - 46 PLUMBINGKJ

A/C CONDENSER (Continued)

Page 1699 of 1803

(7) Remove the suction and discharge line assem-

bly from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Remove the tape or plugs from the suction and

discharge line manifold and the compressor. Install

the suction and discharge line manifold to the com-

pressor. Tighten the fastener to 28 N´m (250 in. lbs.).

(2) Remove the tape or plugs from the suction line

and the accumulator outlet block fittings. Install the

suction line to the accumulator outlet and tighten the

mounting nut to 9 N´m (80 in. lbs.).(3) Remove the tape or plugs from the refrigerant

line fittings on the discharge line and the condenser

inlet tube. Connect the discharge line refrigerant line

coupler to the condenser inlet tube. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(4) Plug in the wire harness connector to the high

pressure cut-off switch.

(5) Connect the battery negative cable.

(6) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

A/C LIQUID LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant.(Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT RECOVERY)

(3) Disconnect the liquid line refrigerant line cou-

plers at the evaporator inlet and the condenser outlet

(Fig. 8). (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

A/C LINE COUPLERS) Install plugs in, or tape over

all of the opened refrigerant line fittings.

(4) Remove the liquid line from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Remove the tape or plugs from the refrigerant

line fittings on the liquid line, the evaporator inlet

Fig. 7 SUCTION AND DISCHARGE LINE REMOVAL

1 - Condensor connection

2- Discharge line to condensor mounting nut

3- Discharge line

4- Discharge line charging port

5- Suction line

6- Evaporator mounting ports

7- Accumulator

8- High pressure cut off switch

9- AC compressor

10- AC condensor

KJPLUMBING 24 - 47

A/C DISCHARGE LINE (Continued)