ECU JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 571 of 1803

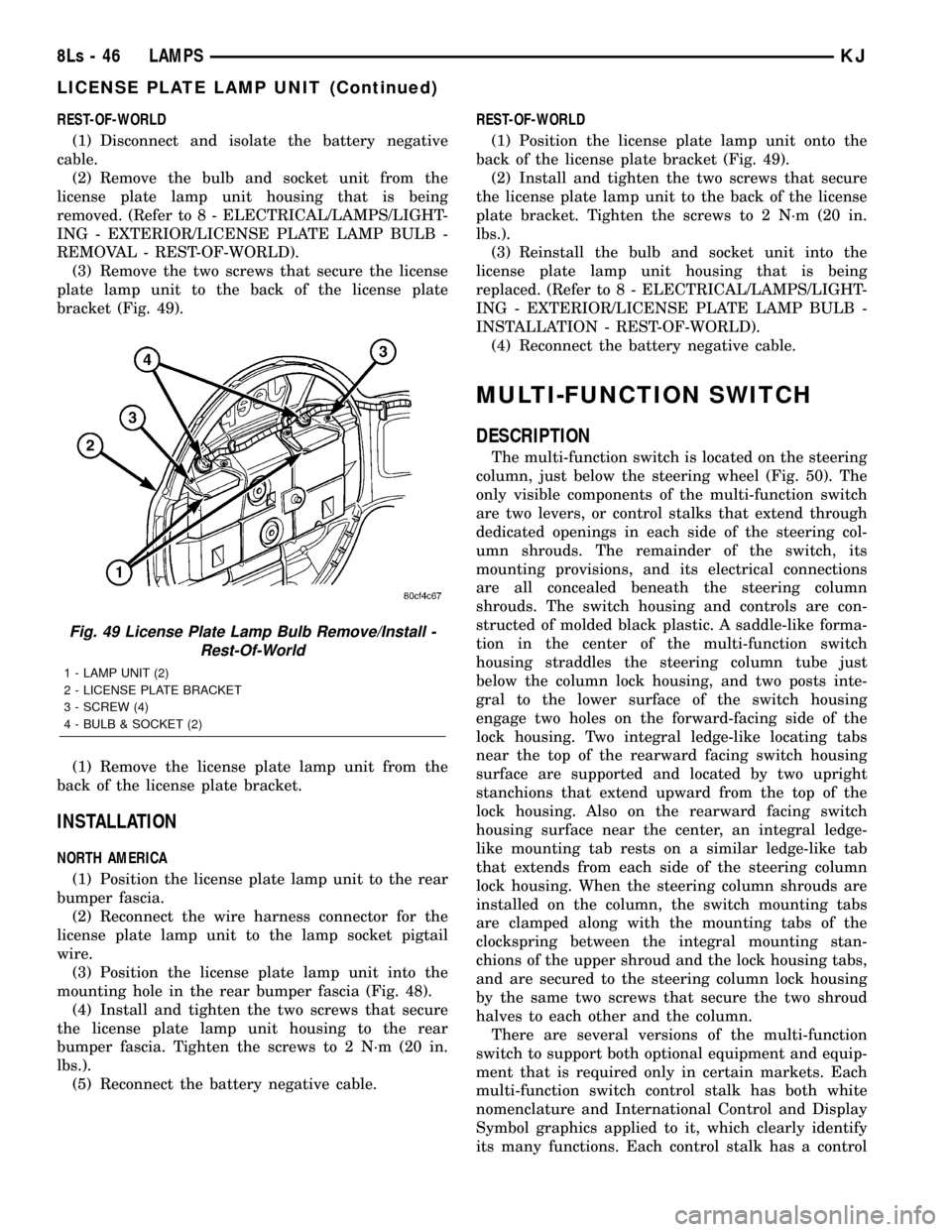

REST-OF-WORLD

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the bulb and socket unit from the

license plate lamp unit housing that is being

removed. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/LICENSE PLATE LAMP BULB -

REMOVAL - REST-OF-WORLD).

(3) Remove the two screws that secure the license

plate lamp unit to the back of the license plate

bracket (Fig. 49).

(1) Remove the license plate lamp unit from the

back of the license plate bracket.

INSTALLATION

NORTH AMERICA

(1) Position the license plate lamp unit to the rear

bumper fascia.

(2) Reconnect the wire harness connector for the

license plate lamp unit to the lamp socket pigtail

wire.

(3) Position the license plate lamp unit into the

mounting hole in the rear bumper fascia (Fig. 48).

(4) Install and tighten the two screws that secure

the license plate lamp unit housing to the rear

bumper fascia. Tighten the screws to 2 N´m (20 in.

lbs.).

(5) Reconnect the battery negative cable.REST-OF-WORLD

(1) Position the license plate lamp unit onto the

back of the license plate bracket (Fig. 49).

(2) Install and tighten the two screws that secure

the license plate lamp unit to the back of the license

plate bracket. Tighten the screws to 2 N´m (20 in.

lbs.).

(3) Reinstall the bulb and socket unit into the

license plate lamp unit housing that is being

replaced. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/LICENSE PLATE LAMP BULB -

INSTALLATION - REST-OF-WORLD).

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION

The multi-function switch is located on the steering

column, just below the steering wheel (Fig. 50). The

only visible components of the multi-function switch

are two levers, or control stalks that extend through

dedicated openings in each side of the steering col-

umn shrouds. The remainder of the switch, its

mounting provisions, and its electrical connections

are all concealed beneath the steering column

shrouds. The switch housing and controls are con-

structed of molded black plastic. A saddle-like forma-

tion in the center of the multi-function switch

housing straddles the steering column tube just

below the column lock housing, and two posts inte-

gral to the lower surface of the switch housing

engage two holes on the forward-facing side of the

lock housing. Two integral ledge-like locating tabs

near the top of the rearward facing switch housing

surface are supported and located by two upright

stanchions that extend upward from the top of the

lock housing. Also on the rearward facing switch

housing surface near the center, an integral ledge-

like mounting tab rests on a similar ledge-like tab

that extends from each side of the steering column

lock housing. When the steering column shrouds are

installed on the column, the switch mounting tabs

are clamped along with the mounting tabs of the

clockspring between the integral mounting stan-

chions of the upper shroud and the lock housing tabs,

and are secured to the steering column lock housing

by the same two screws that secure the two shroud

halves to each other and the column.

There are several versions of the multi-function

switch to support both optional equipment and equip-

ment that is required only in certain markets. Each

multi-function switch control stalk has both white

nomenclature and International Control and Display

Symbol graphics applied to it, which clearly identify

its many functions. Each control stalk has a control

Fig. 49 License Plate Lamp Bulb Remove/Install -

Rest-Of-World

1 - LAMP UNIT (2)

2 - LICENSE PLATE BRACKET

3 - SCREW (4)

4 - BULB & SOCKET (2)

8Ls - 46 LAMPSKJ

LICENSE PLATE LAMP UNIT (Continued)

Page 573 of 1803

²Parade Mode- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

trol stalk provide detent switching for a parade mode

that maximizes the illumination intensity of all

instrument panel lighting for visibility when driving

in daylight with the exterior lamps turned on.

²Park Lamps- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

trol stalk provide detent switching for the park

lamps.

²Rear Fog Lamps- For vehicles so equipped,

the internal circuitry and hardware of the multi-

function switch left (lighting) control stalk provide

detent switching for the optional rear fog lamps.

Rear fog lamps are optional only for vehicles manu-

factured for certain markets, where they are

required.

²Turn Signal Control- The internal circuitry

and hardware of the multi-function switch left (light-

ing) control stalk provide both momentary non-detent

switching and detent switching with automatic can-

cellation for both the left and right turn signal

lamps.

RIGHT CONTROL STALK The right (wiper) con-

trol stalk of the multi-function switch supports the

following functions and features:

²Continuous Front Wipe Modes- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide two continuous

front wipe switch positions, low speed or high speed.

²Continuous Rear Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide one continuous

rear wipe switch position.

²Front Washer Mode- The internal circuitry

and hardware of the multi-function switch right

(wiper) control stalk switch provide front washer sys-

tem operation.

²Front Wipe-After-Wash Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide a wipe-after-wash

mode.

²Front Wiper Mist Mode- The internal cir-

cuitry and hardware of the multi-function switch

right (wiper) control stalk provide a front wiper sys-

tem mist mode.

²Intermittent Front Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide an intermittent

front wipe mode with five delay interval positions.

²Intermittent Rear Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide one fixed interval

intermittent rear wipe mode switch position.²Rear Washer Mode- The internal circuitry and

hardware of the multi-function switch right (wiper)

control stalk provide rear washer system operation.

OPERATION

The multi-function switch uses a combination of

resistor multiplexed and conventionally switched out-

puts to control the many functions and features it

provides. The switch receives battery current on a

fused ignition switch output (run-acc) circuit from a

fuse in the Junction Block (JB) whenever the ignition

switch is in the On or Accessory positions. The switch

receives a path to ground at all times through a

splice block located in the instrument panel wire har-

ness with an eyelet terminal connector that is

secured by a nut to a ground stud on the driver side

instrument panel end bracket near the Junction

Block (JB). Following are descriptions of how each of

the two multi-function switch control stalks operate

to control the functions and features they provide.

LEFT CONTROL STALK The left (lighting) control

stalk of the multi-function switch operates as follows:

²Front Fog Lamps- For vehicles so equipped,

the control knob on the end of the multi-function

switch left (lighting) control stalk is pulled outward

to activate the optional front fog lamps. The control

knob is mechanically keyed so that it cannot be

pulled outward unless it is first rotated to turn on

the exterior lighting. The multi-function switch pro-

vides a resistor multiplexed output to the Body Con-

trol Module (BCM) on a fog lamp switch sense

circuit, and the BCM responds by energizing or de-

energizing the front fog lamp relay in the Junction

Block (JB) as required.

²Headlamps-

The control knob on the end of the

multi-function switch left (lighting) control stalk is

rotated forward (counterclockwise) to its second detent

position to activate the headlamps. The multi-function

switch provides a resistor multiplexed output to the

Body Control Module (BCM) on a headlamp switch

sense circuit, and the BCM responds by energizing or

de-energizing the selected low or high beam relay

(Daytime Running Lamp relay in Canadian vehicles)

in the Junction Block (JB) as required.

²Headlamp Beam Selection-The left (lighting)

control stalk of the multi-function switch is pulled

towards the steering wheel past a detent to actuate

the integral beam select switch circuitry. Each time the

control stalk is activated in this manner, the opposite

headlamp beam from what is currently selected will be

energized. The multi-function switch provides a ground

output to the Body Control Module (BCM) on a high

beam switch sense circuit, and the BCM responds by

energizing or de-energizing the selected low or high

beam relay (Daytime Running Lamp relay in Canadian

vehicles) in the Junction Block (JB) as required.

8Ls - 48 LAMPSKJ

MULTI-FUNCTION SWITCH (Continued)

Page 578 of 1803

(4) If the multi-function switch fails any of the

continuity or resistance tests, replace the faulty

switch unit as required.

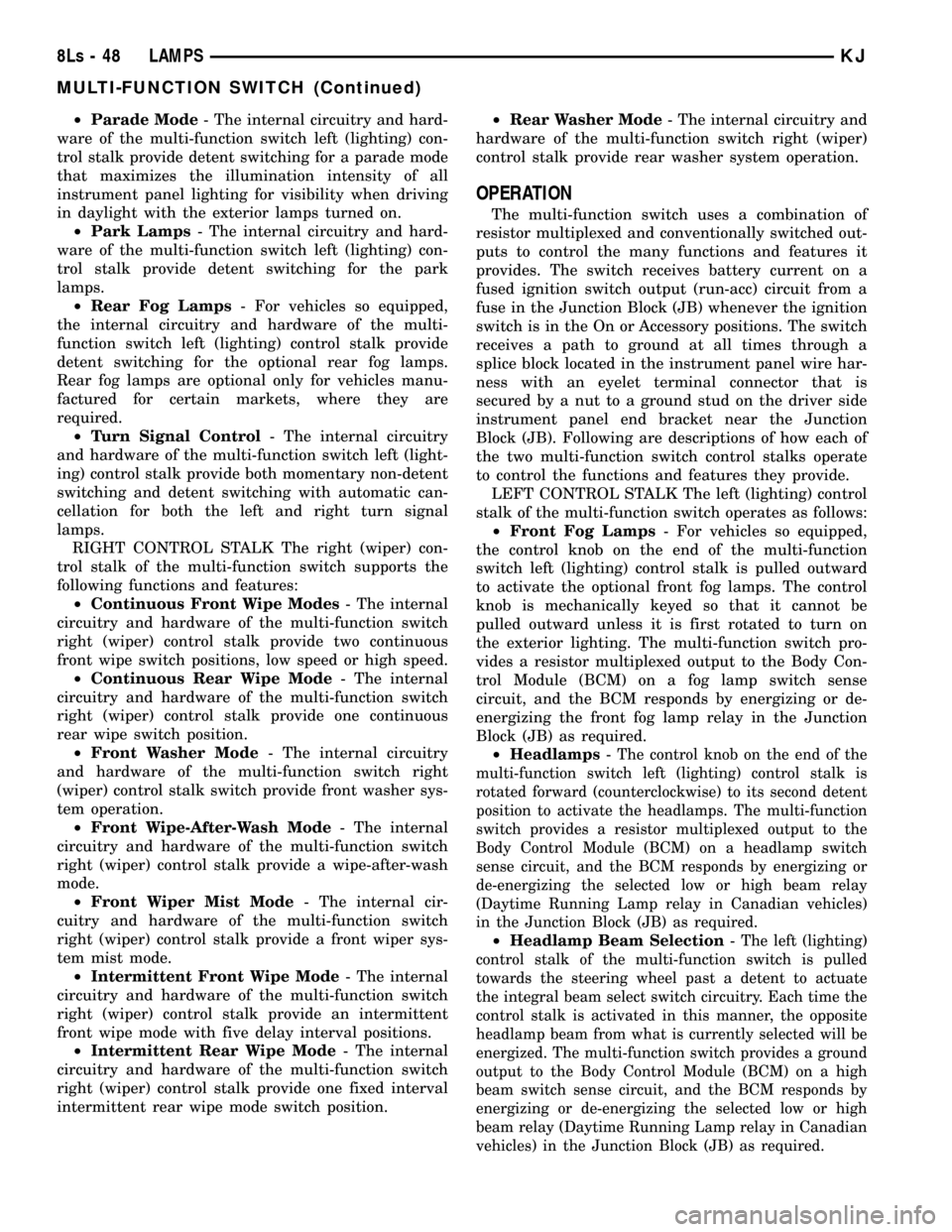

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully lowered position and leave the tilt release lever

in the released (down) position.

(3) From below the steering column, remove the

two screws that secure the lower shroud to the upper

shroud (Fig. 52).

(4) Using hand pressure, push gently inward on

both sides of the upper shroud near the parting line

between the upper and lower shrouds to release the

snap features that secure the two halves to each

other.

(5) Remove both the upper and lower shrouds from

the steering column.

(6) Disconnect the two instrument panel wire har-

ness connectors for the multi-function switch from

the two connector receptacles on the back of the

switch housing.

(7) Remove the multi-function switch from the

steering column lock housing by carefully rocking the

switch and pulling the switch housing upward far

enough to disengage its alignment posts and locator

tabs from the lock housing.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Before attempting to install the multi-

function switch, be certain that the left control stalk

is in the neutral turn signal position and the turn

signal cancel actuator is in the retracted (neutral)

position.

(1) Position the multi-function switch to the steer-

ing column.

(2) Reconnect the two instrument panel wire har-

ness connectors for the multi-function switch to the

two connector receptacles on the back of the switch

housing (Fig. 52).

Fig. 52 Multi-Function Switch Remove/Install

1 - UPPER SHROUD

2 - MULTI-FUNCTION SWITCH

3 - CLOCKSPRING

4 - LOWER SHROUD

5 - SCREW (2)

6 - STEERING COLUMN

7 - WIRE HARNESS CONNECTOR (2)

KJLAMPS8Ls-53

MULTI-FUNCTION SWITCH (Continued)

Page 579 of 1803

(3) Position the multi-function switch onto the

steering column lock housing. Be certain that the

switch alignment posts and locator tabs are fully

seated on the lock housing.

(4) Position the upper and lower shrouds onto the

steering column.

(5) Align the snap features on the lower shroud

with the receptacles on the upper shroud and apply

hand pressure to snap them together.

(6) From below the steering column, install and

tighten the two screws that secure the lower shroud

to the upper shroud. Tighten the screws to 2 N´m (20

in. lbs.).

(7) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column back

to the fully raised position and move the tilt release

lever into the locked (up) position.

(8) Reconnect the battery negative cable.

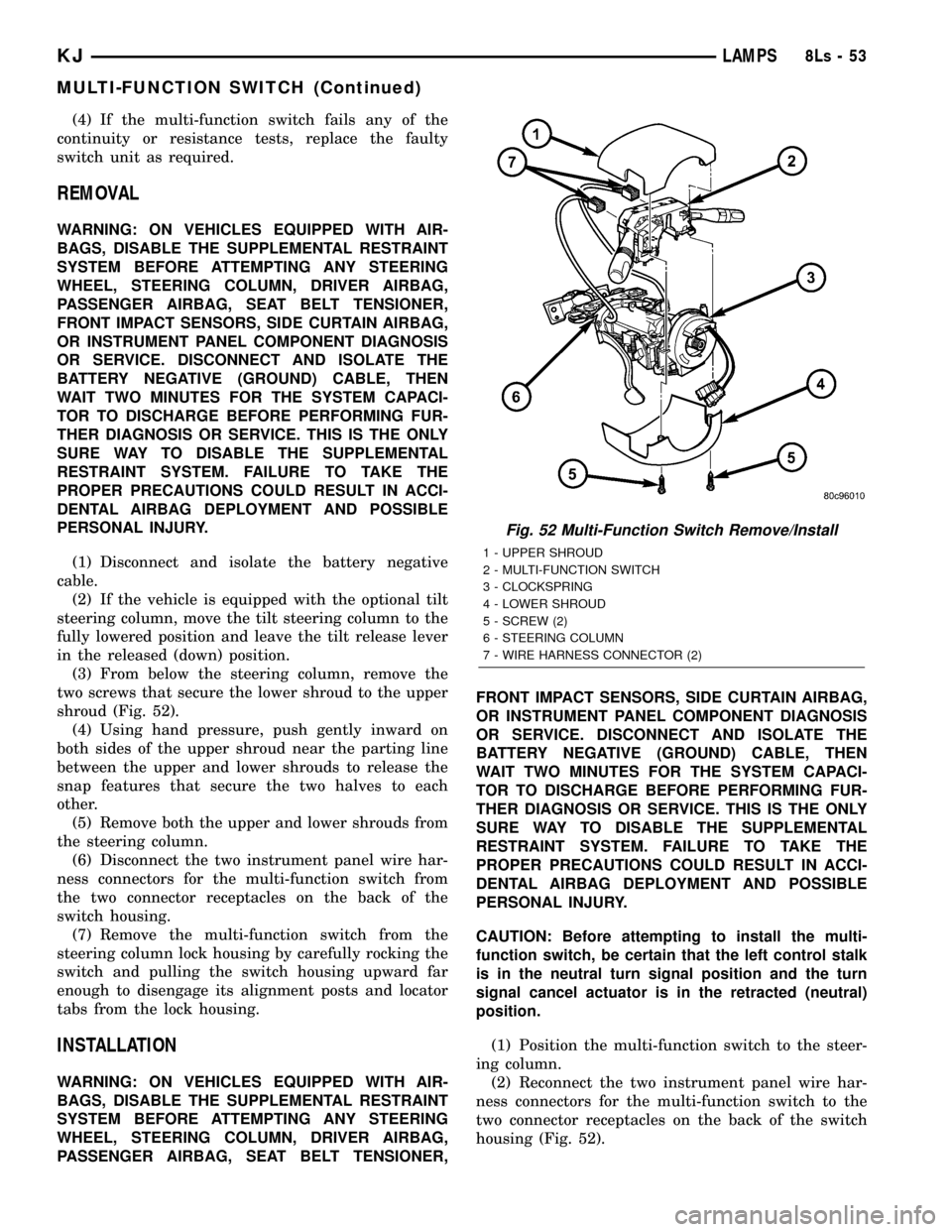

PARK LAMP RELAY

DESCRIPTION

The park lamp relay is located in the Junction

Block (JB) below the driver side outboard end of the

instrument panel in the passenger compartment of

the vehicle. The park lamp relay is a conventional

International Standards Organization (ISO) micro

relay (Fig. 53). Relays conforming to the ISO specifi-

cations have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

The relay is contained within a small, rectangular,

molded plastic housing and is connected to all of therequired inputs and outputs by five integral male

spade-type terminals that extend from the bottom of

the relay base.

The park lamp relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The park lamp relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the park lamps. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The park lamp relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Junction Block (JB). The inputs and

outputs of the park lamp relay include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the park lamps through

the park lamp relay output circuit and provides

ground to the park lamps when the relay is de-ener-

gized, and battery current to the park lamps when-

ever the relay is energized.

²Coil Ground Terminal-

The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a park lamp relay con-

trol circuit. The BCM controls park lamp operation by

controlling a ground path through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the PDC through a fused B(+) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a fuse in the Power Distribution Center (PDC)

through a fused B(+) circuit.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to ground at all

times through a ground circuit that receives ground

through a splice block located in the instrument

panel wire harness with an eyelet terminal connector

that is secured by a nut to a ground stud on the

driver side instrument panel end bracket near the

Junction Block (JB).

Fig. 53 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

8Ls - 54 LAMPSKJ

MULTI-FUNCTION SWITCH (Continued)

Page 584 of 1803

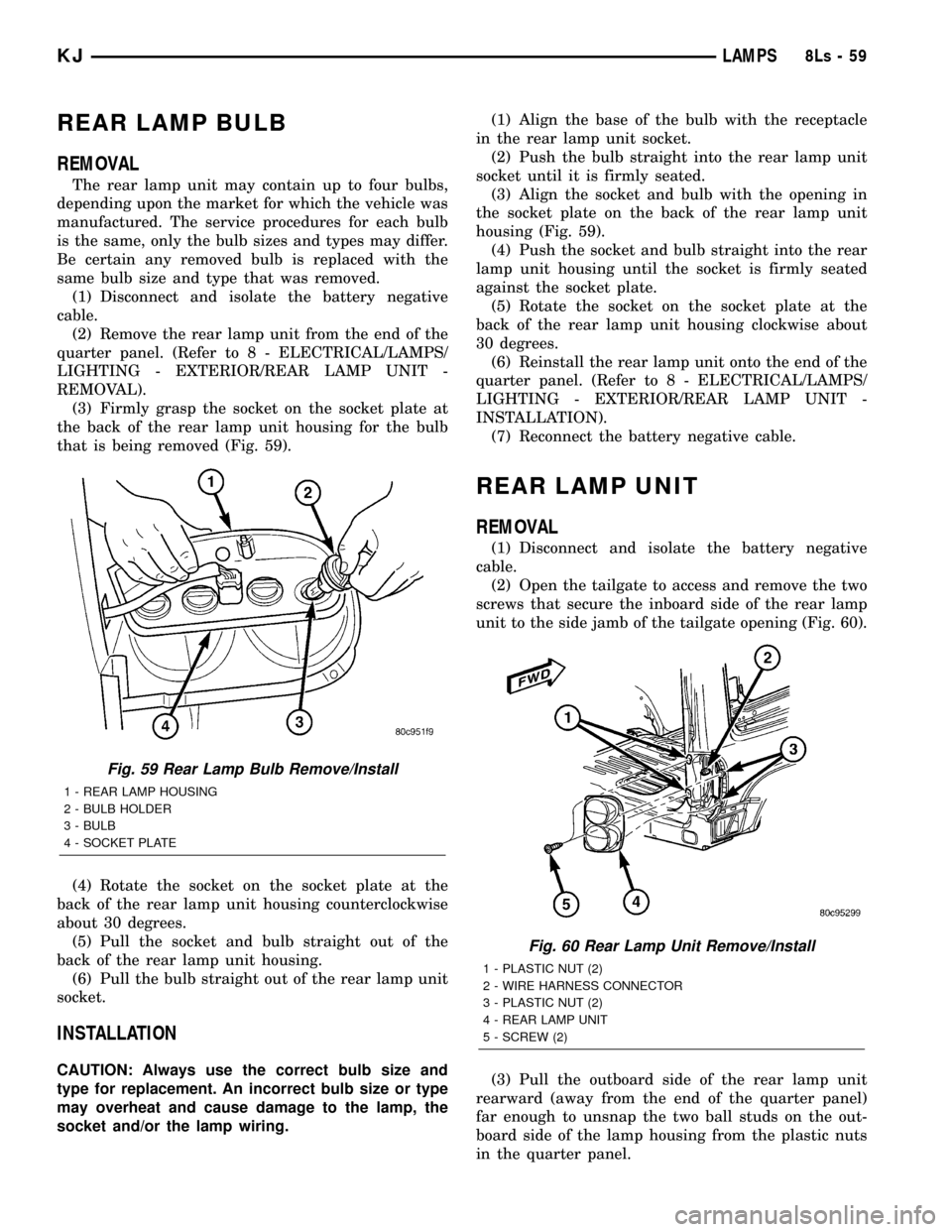

REAR LAMP BULB

REMOVAL

The rear lamp unit may contain up to four bulbs,

depending upon the market for which the vehicle was

manufactured. The service procedures for each bulb

is the same, only the bulb sizes and types may differ.

Be certain any removed bulb is replaced with the

same bulb size and type that was removed.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear lamp unit from the end of the

quarter panel. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/REAR LAMP UNIT -

REMOVAL).

(3) Firmly grasp the socket on the socket plate at

the back of the rear lamp unit housing for the bulb

that is being removed (Fig. 59).

(4) Rotate the socket on the socket plate at the

back of the rear lamp unit housing counterclockwise

about 30 degrees.

(5) Pull the socket and bulb straight out of the

back of the rear lamp unit housing.

(6) Pull the bulb straight out of the rear lamp unit

socket.

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.(1) Align the base of the bulb with the receptacle

in the rear lamp unit socket.

(2) Push the bulb straight into the rear lamp unit

socket until it is firmly seated.

(3) Align the socket and bulb with the opening in

the socket plate on the back of the rear lamp unit

housing (Fig. 59).

(4) Push the socket and bulb straight into the rear

lamp unit housing until the socket is firmly seated

against the socket plate.

(5) Rotate the socket on the socket plate at the

back of the rear lamp unit housing clockwise about

30 degrees.

(6) Reinstall the rear lamp unit onto the end of the

quarter panel. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/REAR LAMP UNIT -

INSTALLATION).

(7) Reconnect the battery negative cable.

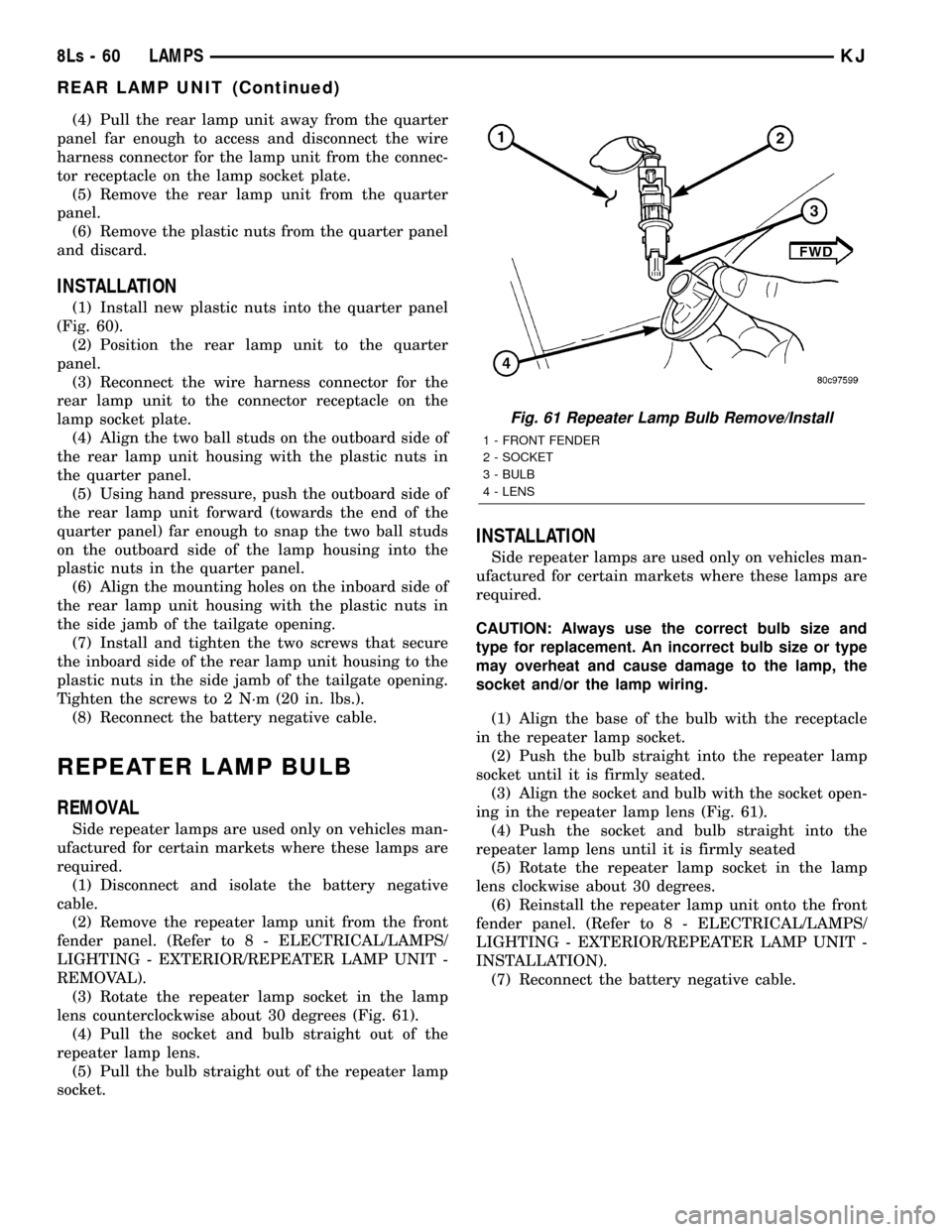

REAR LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open the tailgate to access and remove the two

screws that secure the inboard side of the rear lamp

unit to the side jamb of the tailgate opening (Fig. 60).

(3) Pull the outboard side of the rear lamp unit

rearward (away from the end of the quarter panel)

far enough to unsnap the two ball studs on the out-

board side of the lamp housing from the plastic nuts

in the quarter panel.

Fig. 59 Rear Lamp Bulb Remove/Install

1 - REAR LAMP HOUSING

2 - BULB HOLDER

3 - BULB

4 - SOCKET PLATE

Fig. 60 Rear Lamp Unit Remove/Install

1 - PLASTIC NUT (2)

2 - WIRE HARNESS CONNECTOR

3 - PLASTIC NUT (2)

4 - REAR LAMP UNIT

5 - SCREW (2)

KJLAMPS8Ls-59

Page 585 of 1803

(4) Pull the rear lamp unit away from the quarter

panel far enough to access and disconnect the wire

harness connector for the lamp unit from the connec-

tor receptacle on the lamp socket plate.

(5) Remove the rear lamp unit from the quarter

panel.

(6) Remove the plastic nuts from the quarter panel

and discard.

INSTALLATION

(1) Install new plastic nuts into the quarter panel

(Fig. 60).

(2) Position the rear lamp unit to the quarter

panel.

(3) Reconnect the wire harness connector for the

rear lamp unit to the connector receptacle on the

lamp socket plate.

(4) Align the two ball studs on the outboard side of

the rear lamp unit housing with the plastic nuts in

the quarter panel.

(5) Using hand pressure, push the outboard side of

the rear lamp unit forward (towards the end of the

quarter panel) far enough to snap the two ball studs

on the outboard side of the lamp housing into the

plastic nuts in the quarter panel.

(6) Align the mounting holes on the inboard side of

the rear lamp unit housing with the plastic nuts in

the side jamb of the tailgate opening.

(7) Install and tighten the two screws that secure

the inboard side of the rear lamp unit housing to the

plastic nuts in the side jamb of the tailgate opening.

Tighten the screws to 2 N´m (20 in. lbs.).

(8) Reconnect the battery negative cable.

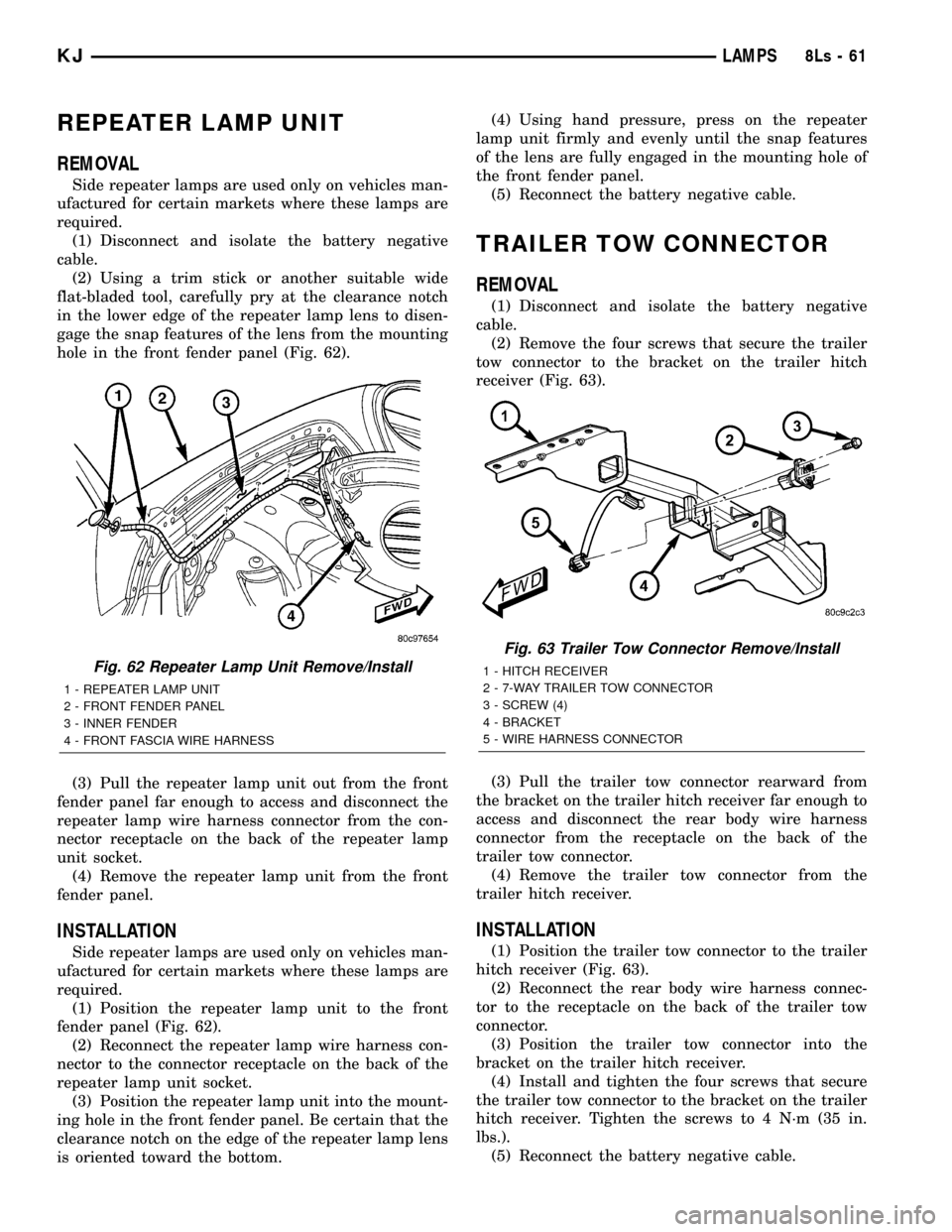

REPEATER LAMP BULB

REMOVAL

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the repeater lamp unit from the front

fender panel. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/REPEATER LAMP UNIT -

REMOVAL).

(3) Rotate the repeater lamp socket in the lamp

lens counterclockwise about 30 degrees (Fig. 61).

(4) Pull the socket and bulb straight out of the

repeater lamp lens.

(5) Pull the bulb straight out of the repeater lamp

socket.

INSTALLATION

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the bulb with the receptacle

in the repeater lamp socket.

(2) Push the bulb straight into the repeater lamp

socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing in the repeater lamp lens (Fig. 61).

(4) Push the socket and bulb straight into the

repeater lamp lens until it is firmly seated

(5) Rotate the repeater lamp socket in the lamp

lens clockwise about 30 degrees.

(6) Reinstall the repeater lamp unit onto the front

fender panel. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/REPEATER LAMP UNIT -

INSTALLATION).

(7) Reconnect the battery negative cable.

Fig. 61 Repeater Lamp Bulb Remove/Install

1 - FRONT FENDER

2 - SOCKET

3 - BULB

4 - LENS

8Ls - 60 LAMPSKJ

REAR LAMP UNIT (Continued)

Page 586 of 1803

REPEATER LAMP UNIT

REMOVAL

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide

flat-bladed tool, carefully pry at the clearance notch

in the lower edge of the repeater lamp lens to disen-

gage the snap features of the lens from the mounting

hole in the front fender panel (Fig. 62).

(3) Pull the repeater lamp unit out from the front

fender panel far enough to access and disconnect the

repeater lamp wire harness connector from the con-

nector receptacle on the back of the repeater lamp

unit socket.

(4) Remove the repeater lamp unit from the front

fender panel.

INSTALLATION

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

(1) Position the repeater lamp unit to the front

fender panel (Fig. 62).

(2) Reconnect the repeater lamp wire harness con-

nector to the connector receptacle on the back of the

repeater lamp unit socket.

(3) Position the repeater lamp unit into the mount-

ing hole in the front fender panel. Be certain that the

clearance notch on the edge of the repeater lamp lens

is oriented toward the bottom.(4) Using hand pressure, press on the repeater

lamp unit firmly and evenly until the snap features

of the lens are fully engaged in the mounting hole of

the front fender panel.

(5) Reconnect the battery negative cable.

TRAILER TOW CONNECTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the four screws that secure the trailer

tow connector to the bracket on the trailer hitch

receiver (Fig. 63).

(3) Pull the trailer tow connector rearward from

the bracket on the trailer hitch receiver far enough to

access and disconnect the rear body wire harness

connector from the receptacle on the back of the

trailer tow connector.

(4) Remove the trailer tow connector from the

trailer hitch receiver.

INSTALLATION

(1) Position the trailer tow connector to the trailer

hitch receiver (Fig. 63).

(2) Reconnect the rear body wire harness connec-

tor to the receptacle on the back of the trailer tow

connector.

(3) Position the trailer tow connector into the

bracket on the trailer hitch receiver.

(4) Install and tighten the four screws that secure

the trailer tow connector to the bracket on the trailer

hitch receiver. Tighten the screws to 4 N´m (35 in.

lbs.).

(5) Reconnect the battery negative cable.

Fig. 62 Repeater Lamp Unit Remove/Install

1 - REPEATER LAMP UNIT

2 - FRONT FENDER PANEL

3 - INNER FENDER

4 - FRONT FASCIA WIRE HARNESS

Fig. 63 Trailer Tow Connector Remove/Install

1 - HITCH RECEIVER

2 - 7-WAY TRAILER TOW CONNECTOR

3 - SCREW (4)

4 - BRACKET

5 - WIRE HARNESS CONNECTOR

KJLAMPS8Ls-61

Page 590 of 1803

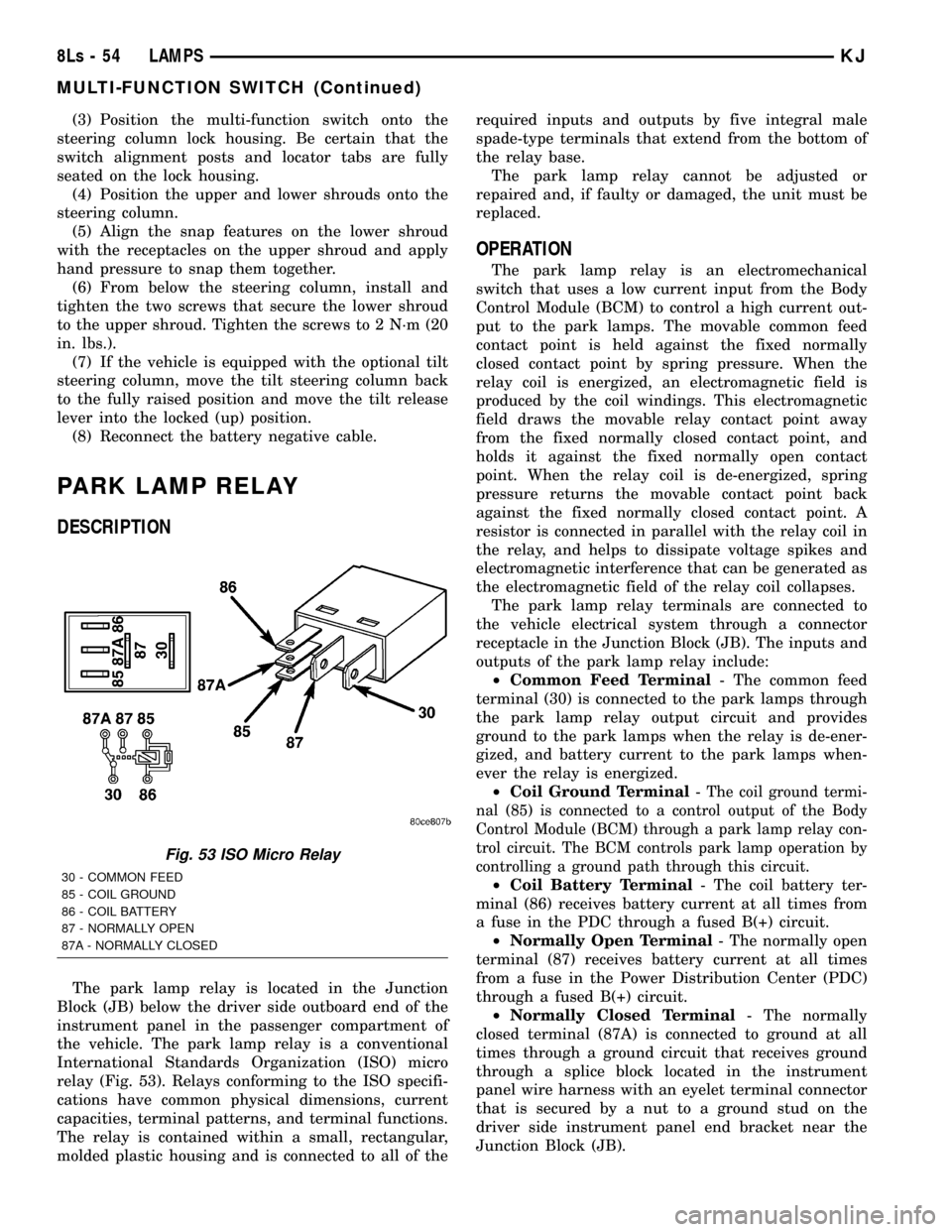

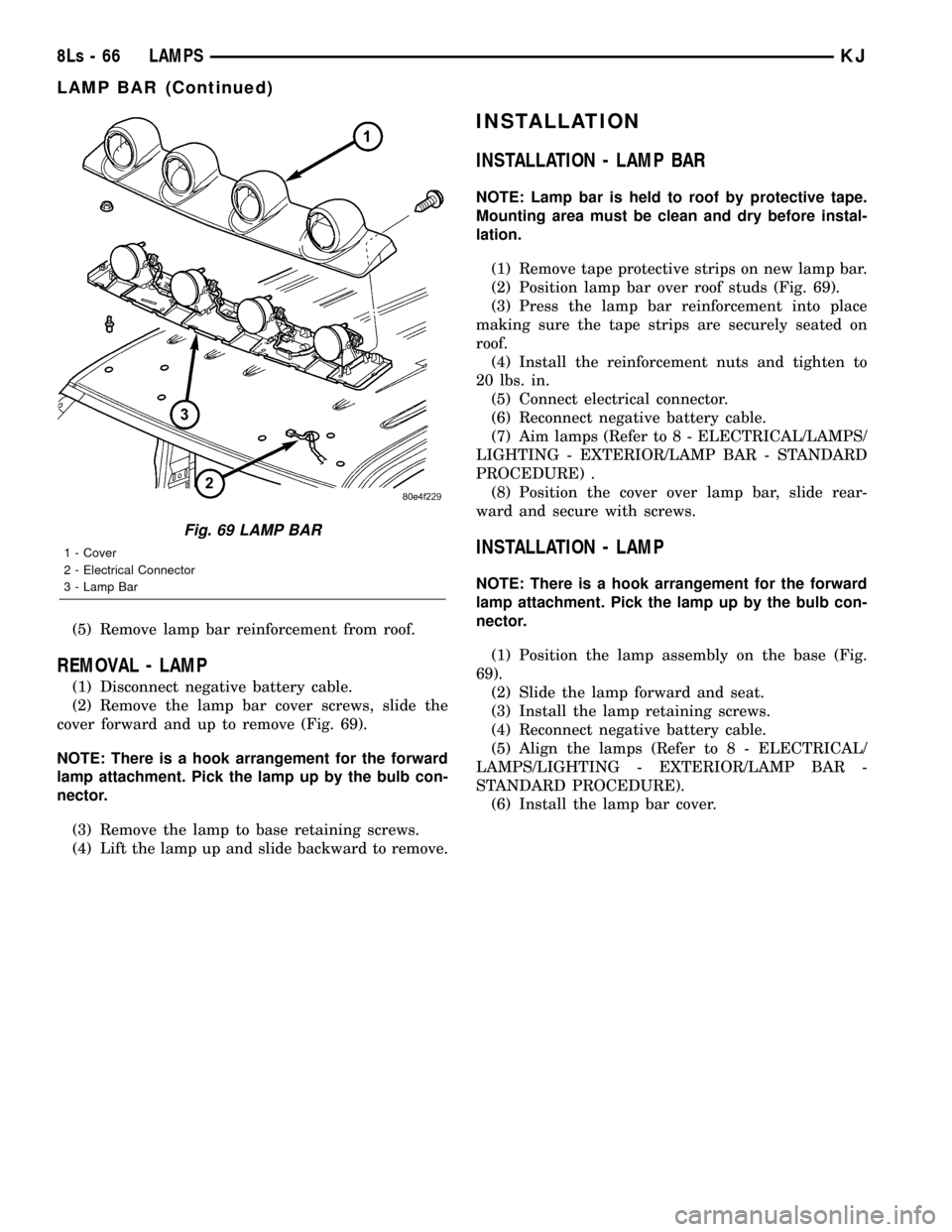

LAMP BAR

DESCRIPTION

The lamp bar is used to better illuminate the driv-

ers field of vision under certain driving conditions. It

consists of a cover, two or four lamp assemblies

(depending upon which market), and a wiring har-

ness. These components are mounted to a reinforce-

ment, then sealed and secured to the roof panel.

Lamp bar illumination is controlled by a manually

operated momentary rocker switch, mounted to the

instrument panel. The lamps are adjustable in the

vertical position only.

OPERATION

Battery and ignition voltage are supplied to the

lamp bar switch assembly. When the switch is in the

on position the internal relay contacts close, complet-

ing the circuit through the lamp bar bulbs, to

ground. The lamp bar assembly is grounded to the

chassis. The hard wired circuits of the lamp bar may

be diagnosed and tested using conventional methods

and procedures.

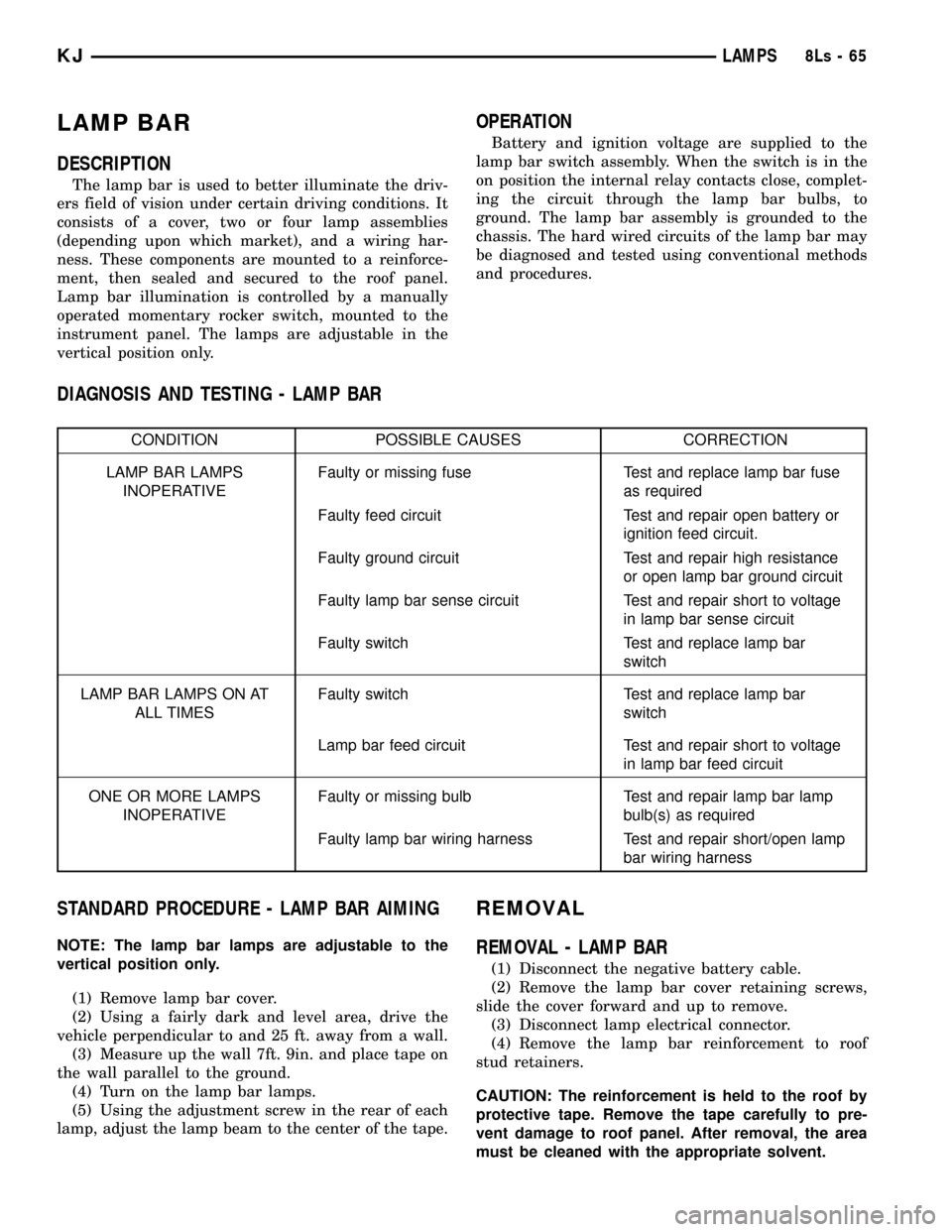

DIAGNOSIS AND TESTING - LAMP BAR

CONDITION POSSIBLE CAUSES CORRECTION

LAMP BAR LAMPS

INOPERATIVEFaulty or missing fuse Test and replace lamp bar fuse

as required

Faulty feed circuit Test and repair open battery or

ignition feed circuit.

Faulty ground circuit Test and repair high resistance

or open lamp bar ground circuit

Faulty lamp bar sense circuit Test and repair short to voltage

in lamp bar sense circuit

Faulty switch Test and replace lamp bar

switch

LAMP BAR LAMPS ON AT

ALL TIMESFaulty switch Test and replace lamp bar

switch

Lamp bar feed circuit Test and repair short to voltage

in lamp bar feed circuit

ONE OR MORE LAMPS

INOPERATIVEFaulty or missing bulb Test and repair lamp bar lamp

bulb(s) as required

Faulty lamp bar wiring harness Test and repair short/open lamp

bar wiring harness

STANDARD PROCEDURE - LAMP BAR AIMING

NOTE: The lamp bar lamps are adjustable to the

vertical position only.

(1) Remove lamp bar cover.

(2) Using a fairly dark and level area, drive the

vehicle perpendicular to and 25 ft. away from a wall.

(3) Measure up the wall 7ft. 9in. and place tape on

the wall parallel to the ground.

(4) Turn on the lamp bar lamps.

(5) Using the adjustment screw in the rear of each

lamp, adjust the lamp beam to the center of the tape.

REMOVAL

REMOVAL - LAMP BAR

(1) Disconnect the negative battery cable.

(2) Remove the lamp bar cover retaining screws,

slide the cover forward and up to remove.

(3) Disconnect lamp electrical connector.

(4) Remove the lamp bar reinforcement to roof

stud retainers.

CAUTION: The reinforcement is held to the roof by

protective tape. Remove the tape carefully to pre-

vent damage to roof panel. After removal, the area

must be cleaned with the appropriate solvent.

KJLAMPS8Ls-65

Page 591 of 1803

(5) Remove lamp bar reinforcement from roof.

REMOVAL - LAMP

(1) Disconnect negative battery cable.

(2) Remove the lamp bar cover screws, slide the

cover forward and up to remove (Fig. 69).

NOTE: There is a hook arrangement for the forward

lamp attachment. Pick the lamp up by the bulb con-

nector.

(3) Remove the lamp to base retaining screws.

(4) Lift the lamp up and slide backward to remove.

INSTALLATION

INSTALLATION - LAMP BAR

NOTE: Lamp bar is held to roof by protective tape.

Mounting area must be clean and dry before instal-

lation.

(1) Remove tape protective strips on new lamp bar.

(2) Position lamp bar over roof studs (Fig. 69).

(3) Press the lamp bar reinforcement into place

making sure the tape strips are securely seated on

roof.

(4) Install the reinforcement nuts and tighten to

20 lbs. in.

(5) Connect electrical connector.

(6) Reconnect negative battery cable.

(7) Aim lamps (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/LAMP BAR - STANDARD

PROCEDURE) .

(8) Position the cover over lamp bar, slide rear-

ward and secure with screws.

INSTALLATION - LAMP

NOTE: There is a hook arrangement for the forward

lamp attachment. Pick the lamp up by the bulb con-

nector.

(1) Position the lamp assembly on the base (Fig.

69).

(2) Slide the lamp forward and seat.

(3) Install the lamp retaining screws.

(4) Reconnect negative battery cable.

(5) Align the lamps (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/LAMP BAR -

STANDARD PROCEDURE).

(6) Install the lamp bar cover.

Fig. 69 LAMP BAR

1 - Cover

2 - Electrical Connector

3 - Lamp Bar

8Ls - 66 LAMPSKJ

LAMP BAR (Continued)

Page 601 of 1803

(3) Remove the compass mini-trip computer from

the overhead console.

INSTALLATION

(1) Install the compass mini-trip computer in the

overhead console. Align the compass mini-trip com-

puter guides on the housing with the grooves of the

console.

(2) Install the mounting screws and install the

map lamp wire connector on the compass mini-trip

computer. Make sure the LOOP of wire that was

clipped into the compass mini-trip computer module

housing is properly clipped into the new module

before the console is placed back into the headliner.

(3) Install the overhead console, refer to Console

Installation in this section.

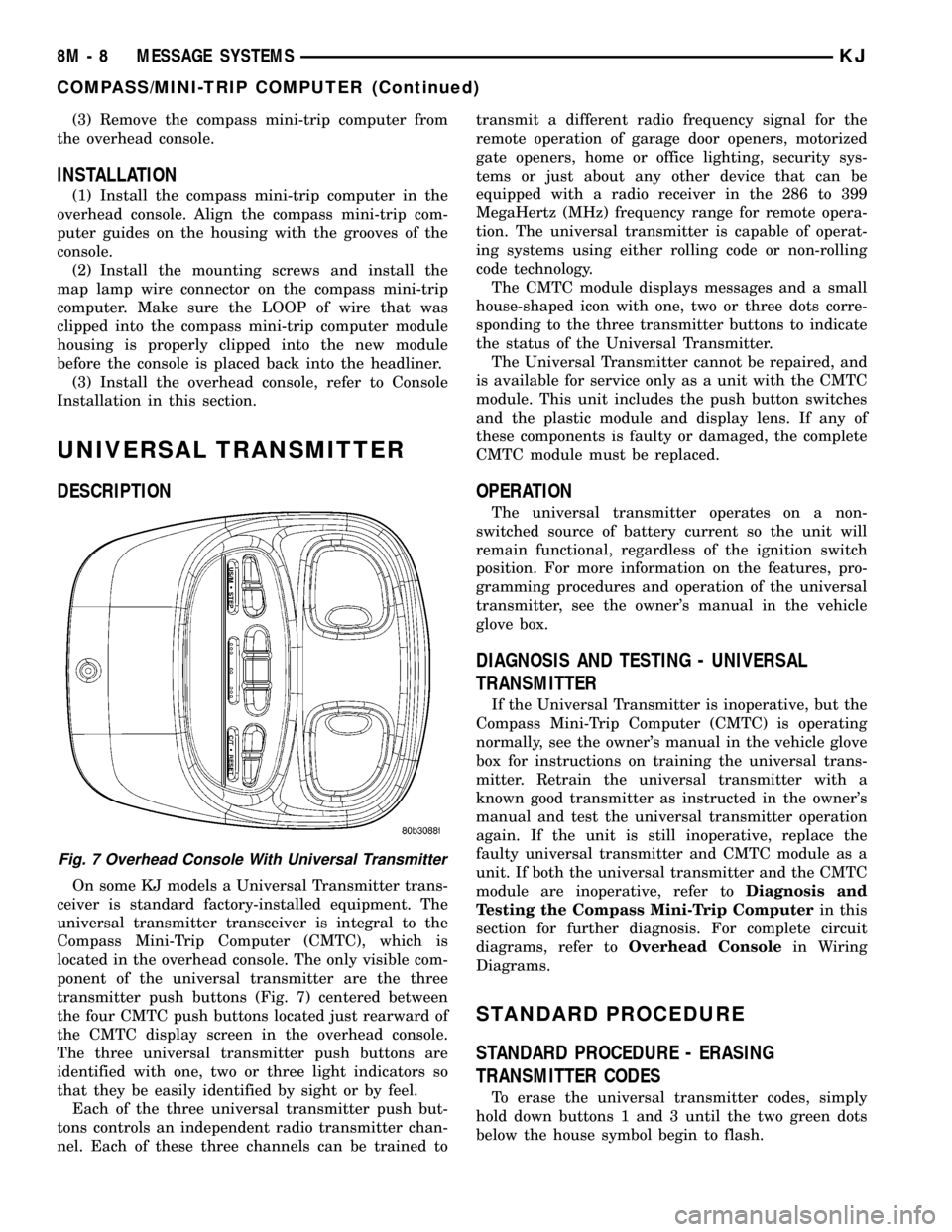

UNIVERSAL TRANSMITTER

DESCRIPTION

On some KJ models a Universal Transmitter trans-

ceiver is standard factory-installed equipment. The

universal transmitter transceiver is integral to the

Compass Mini-Trip Computer (CMTC), which is

located in the overhead console. The only visible com-

ponent of the universal transmitter are the three

transmitter push buttons (Fig. 7) centered between

the four CMTC push buttons located just rearward of

the CMTC display screen in the overhead console.

The three universal transmitter push buttons are

identified with one, two or three light indicators so

that they be easily identified by sight or by feel.

Each of the three universal transmitter push but-

tons controls an independent radio transmitter chan-

nel. Each of these three channels can be trained totransmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-

tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

tion. The universal transmitter is capable of operat-

ing systems using either rolling code or non-rolling

code technology.

The CMTC module displays messages and a small

house-shaped icon with one, two or three dots corre-

sponding to the three transmitter buttons to indicate

the status of the Universal Transmitter.

The Universal Transmitter cannot be repaired, and

is available for service only as a unit with the CMTC

module. This unit includes the push button switches

and the plastic module and display lens. If any of

these components is faulty or damaged, the complete

CMTC module must be replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Compass Mini-Trip Computer (CMTC) is operating

normally, see the owner's manual in the vehicle glove

box for instructions on training the universal trans-

mitter. Retrain the universal transmitter with a

known good transmitter as instructed in the owner's

manual and test the universal transmitter operation

again. If the unit is still inoperative, replace the

faulty universal transmitter and CMTC module as a

unit. If both the universal transmitter and the CMTC

module are inoperative, refer toDiagnosis and

Testing the Compass Mini-Trip Computerin this

section for further diagnosis. For complete circuit

diagrams, refer toOverhead Consolein Wiring

Diagrams.

STANDARD PROCEDURE

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down buttons 1 and 3 until the two green dots

below the house symbol begin to flash.

Fig. 7 Overhead Console With Universal Transmitter

8M - 8 MESSAGE SYSTEMSKJ

COMPASS/MINI-TRIP COMPUTER (Continued)