ECU JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 468 of 1803

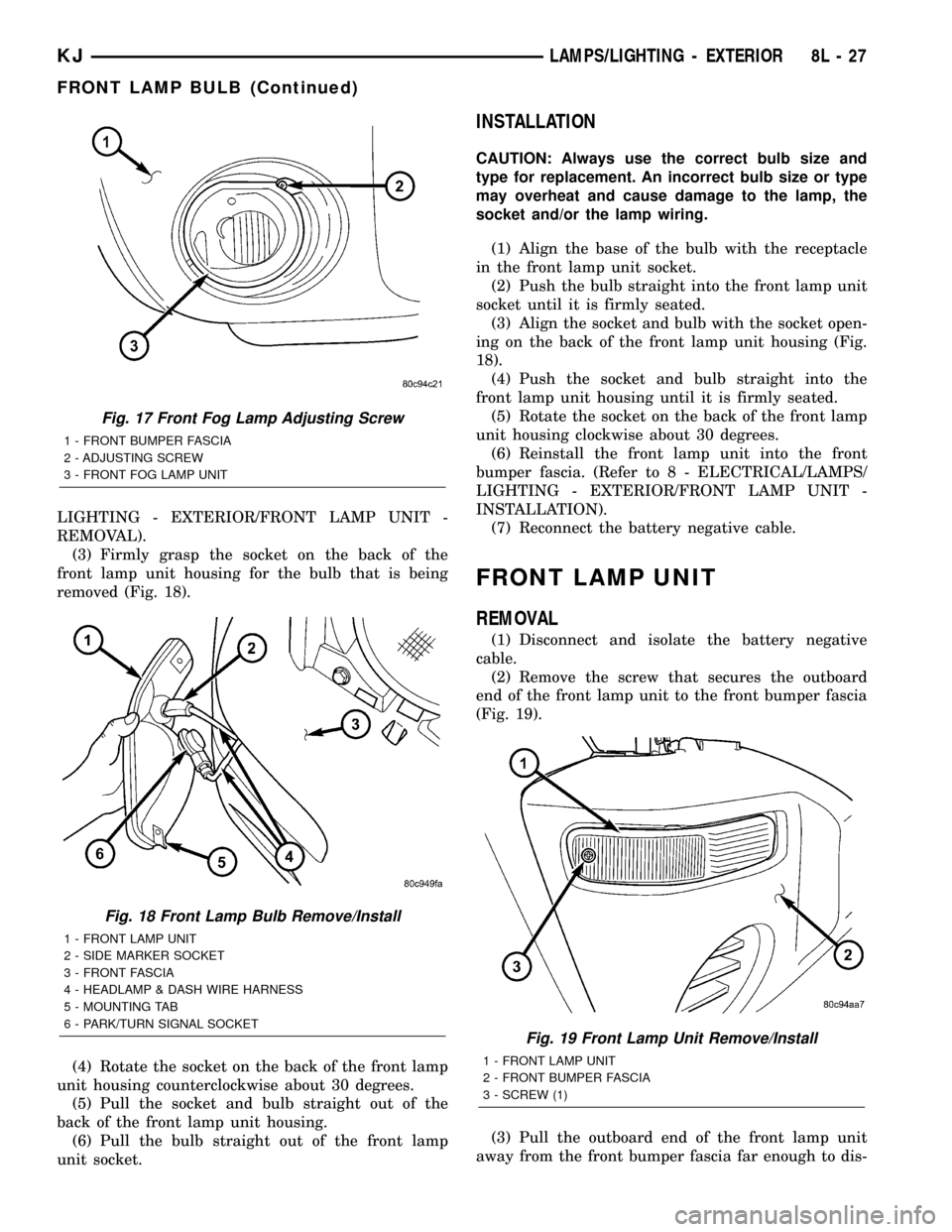

LIGHTING - EXTERIOR/FRONT LAMP UNIT -

REMOVAL).

(3) Firmly grasp the socket on the back of the

front lamp unit housing for the bulb that is being

removed (Fig. 18).

(4) Rotate the socket on the back of the front lamp

unit housing counterclockwise about 30 degrees.

(5) Pull the socket and bulb straight out of the

back of the front lamp unit housing.

(6) Pull the bulb straight out of the front lamp

unit socket.

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the bulb with the receptacle

in the front lamp unit socket.

(2) Push the bulb straight into the front lamp unit

socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing on the back of the front lamp unit housing (Fig.

18).

(4) Push the socket and bulb straight into the

front lamp unit housing until it is firmly seated.

(5) Rotate the socket on the back of the front lamp

unit housing clockwise about 30 degrees.

(6) Reinstall the front lamp unit into the front

bumper fascia. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/FRONT LAMP UNIT -

INSTALLATION).

(7) Reconnect the battery negative cable.

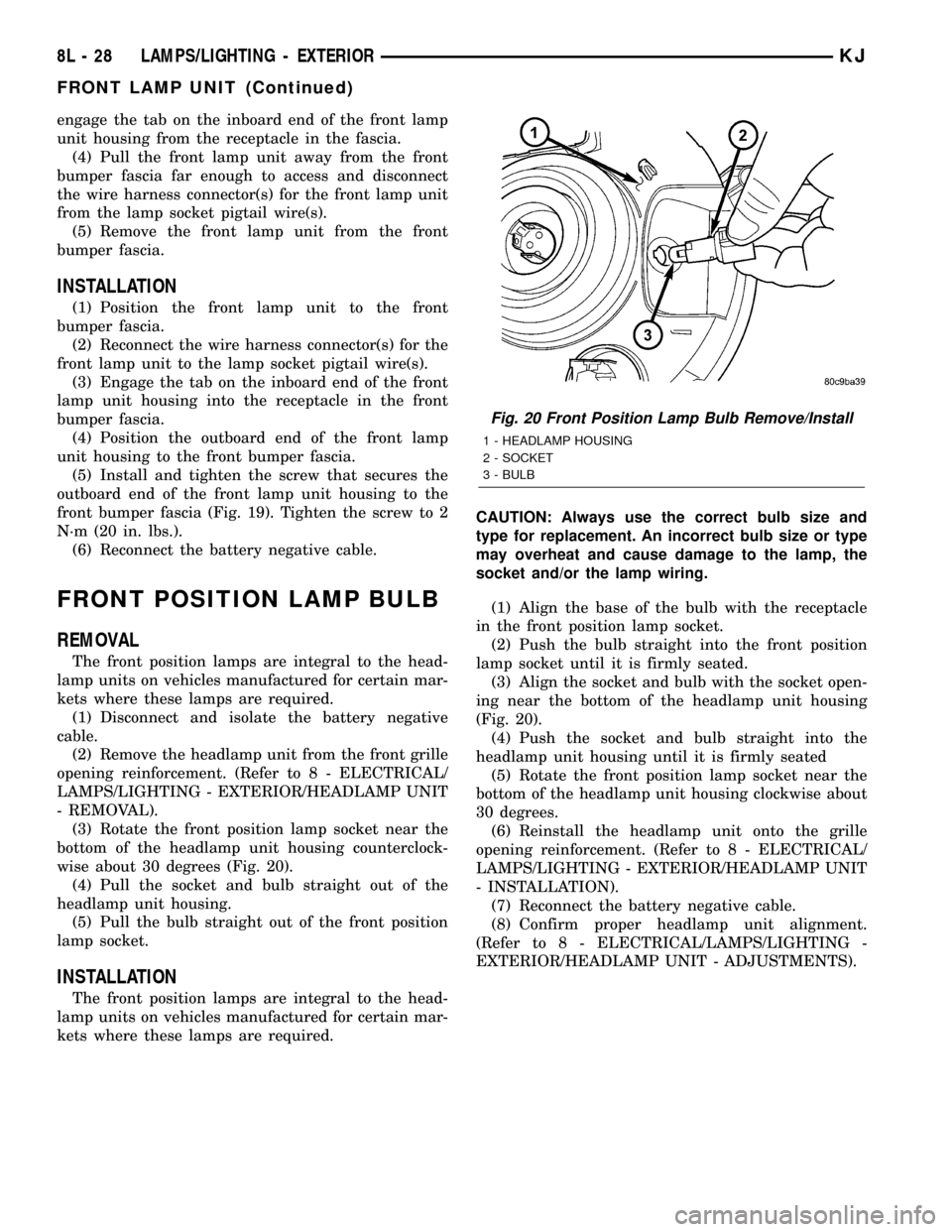

FRONT LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the screw that secures the outboard

end of the front lamp unit to the front bumper fascia

(Fig. 19).

(3) Pull the outboard end of the front lamp unit

away from the front bumper fascia far enough to dis-

Fig. 17 Front Fog Lamp Adjusting Screw

1 - FRONT BUMPER FASCIA

2 - ADJUSTING SCREW

3 - FRONT FOG LAMP UNIT

Fig. 18 Front Lamp Bulb Remove/Install

1 - FRONT LAMP UNIT

2 - SIDE MARKER SOCKET

3 - FRONT FASCIA

4 - HEADLAMP & DASH WIRE HARNESS

5 - MOUNTING TAB

6 - PARK/TURN SIGNAL SOCKET

Fig. 19 Front Lamp Unit Remove/Install

1 - FRONT LAMP UNIT

2 - FRONT BUMPER FASCIA

3 - SCREW (1)

KJLAMPS/LIGHTING - EXTERIOR 8L - 27

FRONT LAMP BULB (Continued)

Page 469 of 1803

engage the tab on the inboard end of the front lamp

unit housing from the receptacle in the fascia.

(4) Pull the front lamp unit away from the front

bumper fascia far enough to access and disconnect

the wire harness connector(s) for the front lamp unit

from the lamp socket pigtail wire(s).

(5) Remove the front lamp unit from the front

bumper fascia.

INSTALLATION

(1) Position the front lamp unit to the front

bumper fascia.

(2) Reconnect the wire harness connector(s) for the

front lamp unit to the lamp socket pigtail wire(s).

(3) Engage the tab on the inboard end of the front

lamp unit housing into the receptacle in the front

bumper fascia.

(4) Position the outboard end of the front lamp

unit housing to the front bumper fascia.

(5) Install and tighten the screw that secures the

outboard end of the front lamp unit housing to the

front bumper fascia (Fig. 19). Tighten the screw to 2

N´m (20 in. lbs.).

(6) Reconnect the battery negative cable.

FRONT POSITION LAMP BULB

REMOVAL

The front position lamps are integral to the head-

lamp units on vehicles manufactured for certain mar-

kets where these lamps are required.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp unit from the front grille

opening reinforcement. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/HEADLAMP UNIT

- REMOVAL).

(3) Rotate the front position lamp socket near the

bottom of the headlamp unit housing counterclock-

wise about 30 degrees (Fig. 20).

(4) Pull the socket and bulb straight out of the

headlamp unit housing.

(5) Pull the bulb straight out of the front position

lamp socket.

INSTALLATION

The front position lamps are integral to the head-

lamp units on vehicles manufactured for certain mar-

kets where these lamps are required.CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the bulb with the receptacle

in the front position lamp socket.

(2) Push the bulb straight into the front position

lamp socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing near the bottom of the headlamp unit housing

(Fig. 20).

(4) Push the socket and bulb straight into the

headlamp unit housing until it is firmly seated

(5) Rotate the front position lamp socket near the

bottom of the headlamp unit housing clockwise about

30 degrees.

(6) Reinstall the headlamp unit onto the grille

opening reinforcement. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/HEADLAMP UNIT

- INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Confirm proper headlamp unit alignment.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/HEADLAMP UNIT - ADJUSTMENTS).

Fig. 20 Front Position Lamp Bulb Remove/Install

1 - HEADLAMP HOUSING

2 - SOCKET

3 - BULB

8L - 28 LAMPS/LIGHTING - EXTERIORKJ

FRONT LAMP UNIT (Continued)

Page 470 of 1803

HAZARD SWITCH

DESCRIPTION

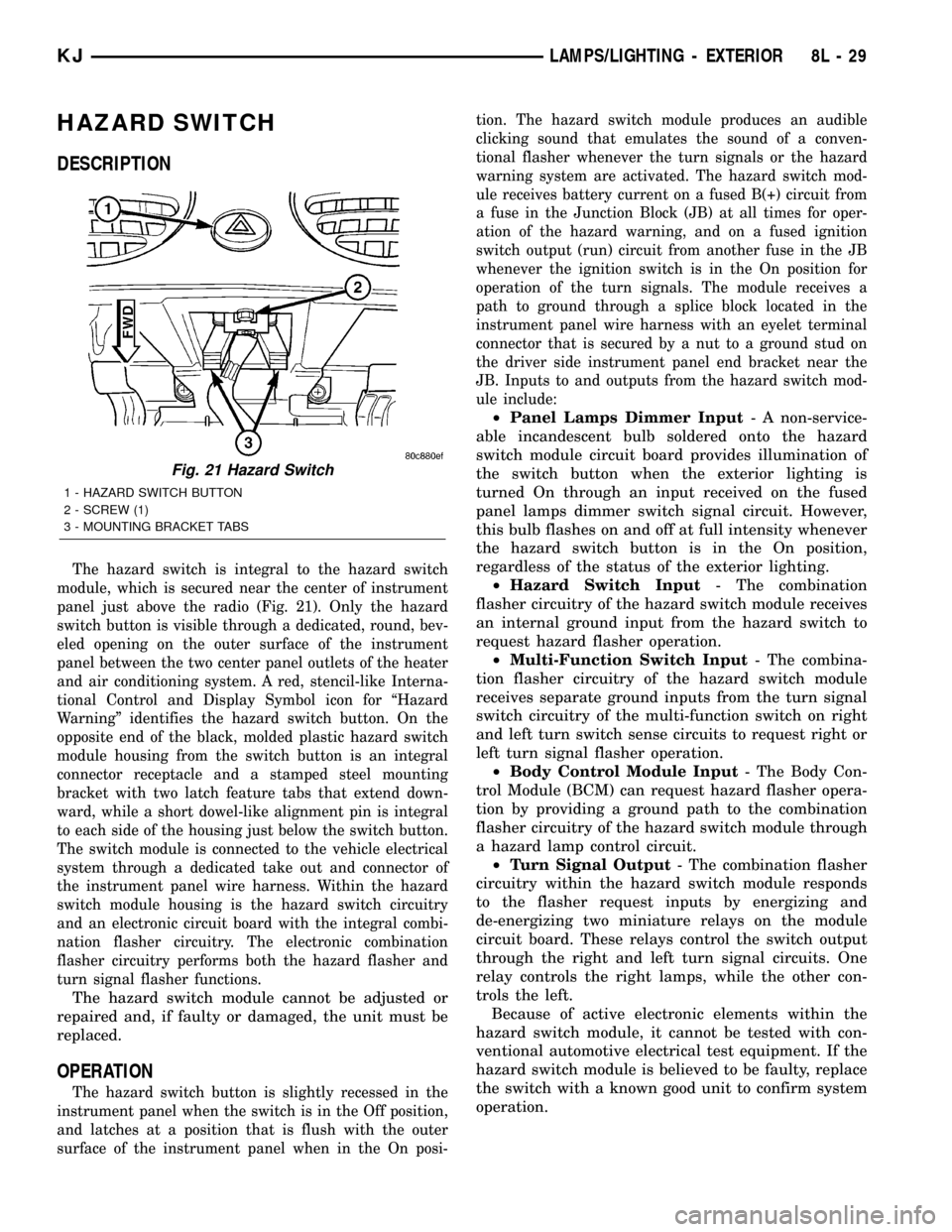

The hazard switch is integral to the hazard switch

module, which is secured near the center of instrument

panel just above the radio (Fig. 21). Only the hazard

switch button is visible through a dedicated, round, bev-

eled opening on the outer surface of the instrument

panel between the two center panel outlets of the heater

and air conditioning system. A red, stencil-like Interna-

tional Control and Display Symbol icon for ªHazard

Warningº identifies the hazard switch button. On the

opposite end of the black, molded plastic hazard switch

module housing from the switch button is an integral

connector receptacle and a stamped steel mounting

bracket with two latch feature tabs that extend down-

ward, while a short dowel-like alignment pin is integral

to each side of the housing just below the switch button.

The switch module is connected to the vehicle electrical

system through a dedicated take out and connector of

the instrument panel wire harness. Within the hazard

switch module housing is the hazard switch circuitry

and an electronic circuit board with the integral combi-

nation flasher circuitry. The electronic combination

flasher circuitry performs both the hazard flasher and

turn signal flasher functions.

The hazard switch module cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The hazard switch button is slightly recessed in the

instrument panel when the switch is in the Off position,

and latches at a position that is flush with the outer

surface of the instrument panel when in the On posi-tion. The hazard switch module produces an audible

clicking sound that emulates the sound of a conven-

tional flasher whenever the turn signals or the hazard

warning system are activated. The hazard switch mod-

ule receives battery current on a fused B(+) circuit from

a fuse in the Junction Block (JB) at all times for oper-

ation of the hazard warning, and on a fused ignition

switch output (run) circuit from another fuse in the JB

whenever the ignition switch is in the On position for

operation of the turn signals. The module receives a

path to ground through a splice block located in the

instrument panel wire harness with an eyelet terminal

connector that is secured by a nut to a ground stud on

the driver side instrument panel end bracket near the

JB. Inputs to and outputs from the hazard switch mod-

ule include:

²Panel Lamps Dimmer Input- A non-service-

able incandescent bulb soldered onto the hazard

switch module circuit board provides illumination of

the switch button when the exterior lighting is

turned On through an input received on the fused

panel lamps dimmer switch signal circuit. However,

this bulb flashes on and off at full intensity whenever

the hazard switch button is in the On position,

regardless of the status of the exterior lighting.

²Hazard Switch Input- The combination

flasher circuitry of the hazard switch module receives

an internal ground input from the hazard switch to

request hazard flasher operation.

²Multi-Function Switch Input- The combina-

tion flasher circuitry of the hazard switch module

receives separate ground inputs from the turn signal

switch circuitry of the multi-function switch on right

and left turn switch sense circuits to request right or

left turn signal flasher operation.

²Body Control Module Input- The Body Con-

trol Module (BCM) can request hazard flasher opera-

tion by providing a ground path to the combination

flasher circuitry of the hazard switch module through

a hazard lamp control circuit.

²Turn Signal Output- The combination flasher

circuitry within the hazard switch module responds

to the flasher request inputs by energizing and

de-energizing two miniature relays on the module

circuit board. These relays control the switch output

through the right and left turn signal circuits. One

relay controls the right lamps, while the other con-

trols the left.

Because of active electronic elements within the

hazard switch module, it cannot be tested with con-

ventional automotive electrical test equipment. If the

hazard switch module is believed to be faulty, replace

the switch with a known good unit to confirm system

operation.

Fig. 21 Hazard Switch

1 - HAZARD SWITCH BUTTON

2 - SCREW (1)

3 - MOUNTING BRACKET TABS

KJLAMPS/LIGHTING - EXTERIOR 8L - 29

Page 471 of 1803

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, DRIVER AIRBAG, PASSENGER

AIRBAG, SEAT BELT TENSIONER, FRONT IMPACT

SENSORS, SIDE CURTAIN AIRBAG, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE. DIS-

CONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE SUP-

PLEMENTAL RESTRAINT SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

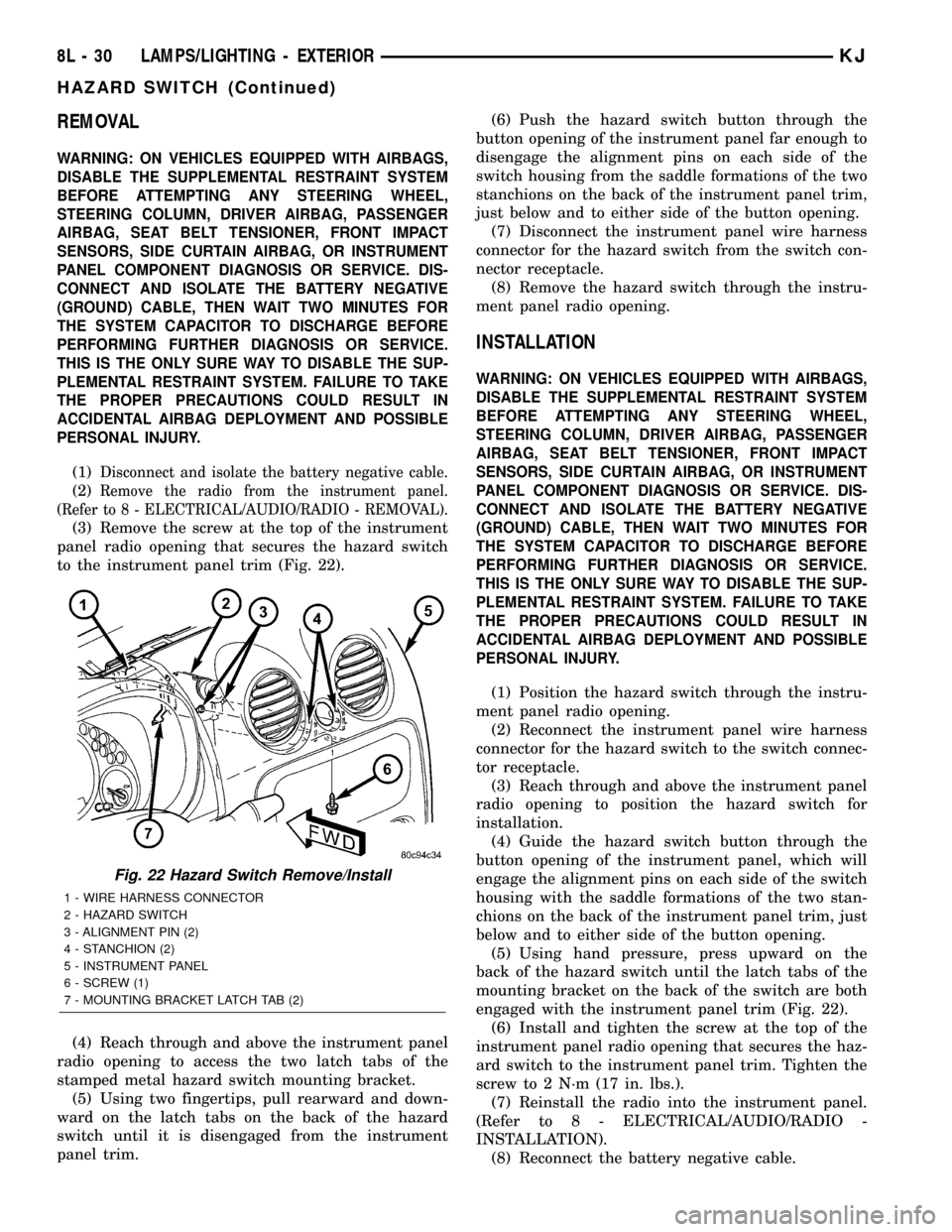

(1)Disconnect and isolate the battery negative cable.

(2)Remove the radio from the instrument panel.

(Refer to 8 - ELECTRICAL/AUDIO/RADIO - REMOVAL).

(3) Remove the screw at the top of the instrument

panel radio opening that secures the hazard switch

to the instrument panel trim (Fig. 22).

(4) Reach through and above the instrument panel

radio opening to access the two latch tabs of the

stamped metal hazard switch mounting bracket.

(5) Using two fingertips, pull rearward and down-

ward on the latch tabs on the back of the hazard

switch until it is disengaged from the instrument

panel trim.(6) Push the hazard switch button through the

button opening of the instrument panel far enough to

disengage the alignment pins on each side of the

switch housing from the saddle formations of the two

stanchions on the back of the instrument panel trim,

just below and to either side of the button opening.

(7) Disconnect the instrument panel wire harness

connector for the hazard switch from the switch con-

nector receptacle.

(8) Remove the hazard switch through the instru-

ment panel radio opening.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, DRIVER AIRBAG, PASSENGER

AIRBAG, SEAT BELT TENSIONER, FRONT IMPACT

SENSORS, SIDE CURTAIN AIRBAG, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE. DIS-

CONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE SUP-

PLEMENTAL RESTRAINT SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the hazard switch through the instru-

ment panel radio opening.

(2) Reconnect the instrument panel wire harness

connector for the hazard switch to the switch connec-

tor receptacle.

(3) Reach through and above the instrument panel

radio opening to position the hazard switch for

installation.

(4) Guide the hazard switch button through the

button opening of the instrument panel, which will

engage the alignment pins on each side of the switch

housing with the saddle formations of the two stan-

chions on the back of the instrument panel trim, just

below and to either side of the button opening.

(5) Using hand pressure, press upward on the

back of the hazard switch until the latch tabs of the

mounting bracket on the back of the switch are both

engaged with the instrument panel trim (Fig. 22).

(6) Install and tighten the screw at the top of the

instrument panel radio opening that secures the haz-

ard switch to the instrument panel trim. Tighten the

screw to 2 N´m (17 in. lbs.).

(7) Reinstall the radio into the instrument panel.

(Refer to 8 - ELECTRICAL/AUDIO/RADIO -

INSTALLATION).

(8) Reconnect the battery negative cable.

Fig. 22 Hazard Switch Remove/Install

1 - WIRE HARNESS CONNECTOR

2 - HAZARD SWITCH

3 - ALIGNMENT PIN (2)

4 - STANCHION (2)

5 - INSTRUMENT PANEL

6 - SCREW (1)

7 - MOUNTING BRACKET LATCH TAB (2)

8L - 30 LAMPS/LIGHTING - EXTERIORKJ

HAZARD SWITCH (Continued)

Page 476 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

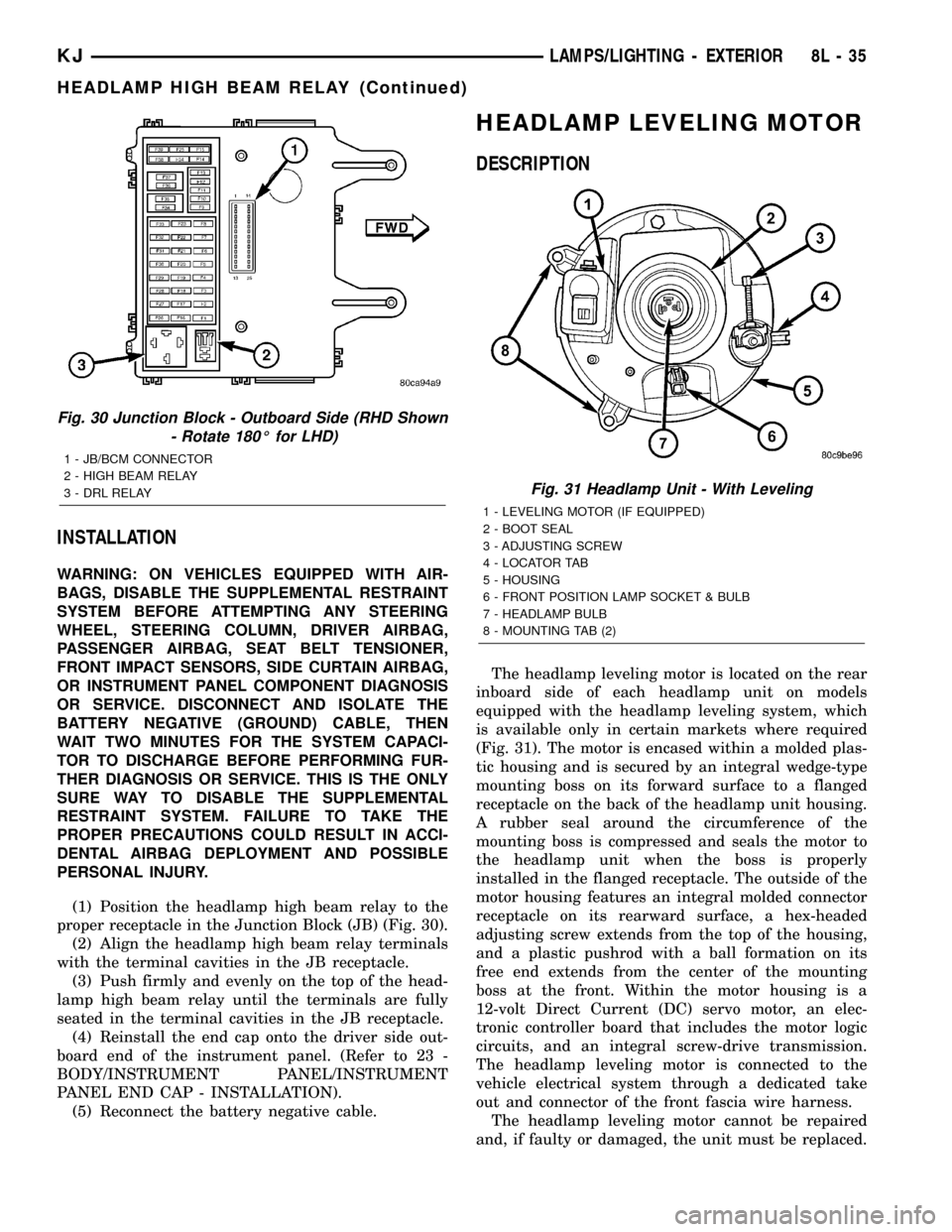

(1) Position the headlamp high beam relay to the

proper receptacle in the Junction Block (JB) (Fig. 30).

(2) Align the headlamp high beam relay terminals

with the terminal cavities in the JB receptacle.

(3) Push firmly and evenly on the top of the head-

lamp high beam relay until the terminals are fully

seated in the terminal cavities in the JB receptacle.

(4) Reinstall the end cap onto the driver side out-

board end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - INSTALLATION).

(5) Reconnect the battery negative cable.

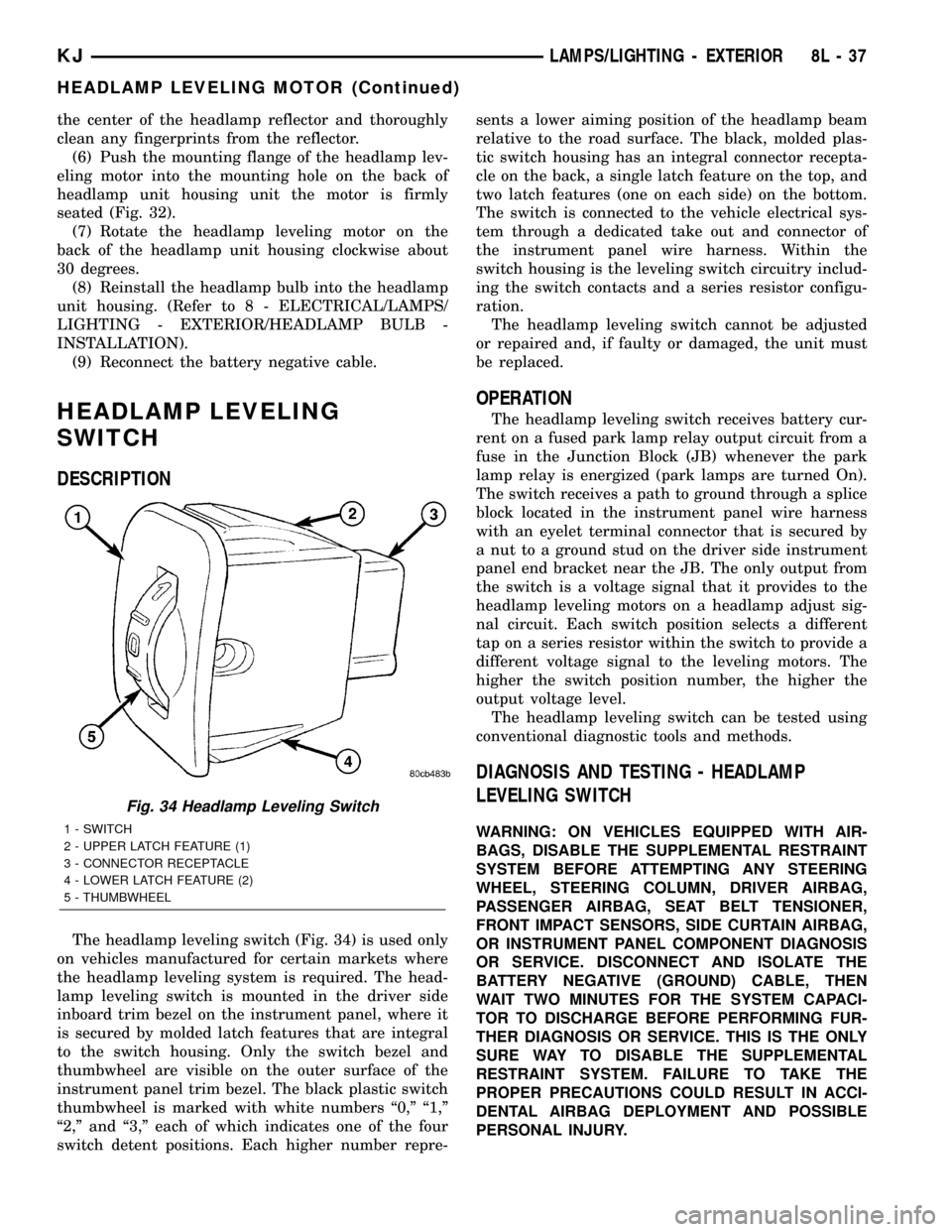

HEADLAMP LEVELING MOTOR

DESCRIPTION

The headlamp leveling motor is located on the rear

inboard side of each headlamp unit on models

equipped with the headlamp leveling system, which

is available only in certain markets where required

(Fig. 31). The motor is encased within a molded plas-

tic housing and is secured by an integral wedge-type

mounting boss on its forward surface to a flanged

receptacle on the back of the headlamp unit housing.

A rubber seal around the circumference of the

mounting boss is compressed and seals the motor to

the headlamp unit when the boss is properly

installed in the flanged receptacle. The outside of the

motor housing features an integral molded connector

receptacle on its rearward surface, a hex-headed

adjusting screw extends from the top of the housing,

and a plastic pushrod with a ball formation on its

free end extends from the center of the mounting

boss at the front. Within the motor housing is a

12-volt Direct Current (DC) servo motor, an elec-

tronic controller board that includes the motor logic

circuits, and an integral screw-drive transmission.

The headlamp leveling motor is connected to the

vehicle electrical system through a dedicated take

out and connector of the front fascia wire harness.

The headlamp leveling motor cannot be repaired

and, if faulty or damaged, the unit must be replaced.

Fig. 30 Junction Block - Outboard Side (RHD Shown

- Rotate 180É for LHD)

1 - JB/BCM CONNECTOR

2 - HIGH BEAM RELAY

3 - DRL RELAY

Fig. 31 Headlamp Unit - With Leveling

1 - LEVELING MOTOR (IF EQUIPPED)

2 - BOOT SEAL

3 - ADJUSTING SCREW

4 - LOCATOR TAB

5 - HOUSING

6 - FRONT POSITION LAMP SOCKET & BULB

7 - HEADLAMP BULB

8 - MOUNTING TAB (2)

KJLAMPS/LIGHTING - EXTERIOR 8L - 35

HEADLAMP HIGH BEAM RELAY (Continued)

Page 478 of 1803

the center of the headlamp reflector and thoroughly

clean any fingerprints from the reflector.

(6) Push the mounting flange of the headlamp lev-

eling motor into the mounting hole on the back of

headlamp unit housing unit the motor is firmly

seated (Fig. 32).

(7) Rotate the headlamp leveling motor on the

back of the headlamp unit housing clockwise about

30 degrees.

(8) Reinstall the headlamp bulb into the headlamp

unit housing. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/HEADLAMP BULB -

INSTALLATION).

(9) Reconnect the battery negative cable.

HEADLAMP LEVELING

SWITCH

DESCRIPTION

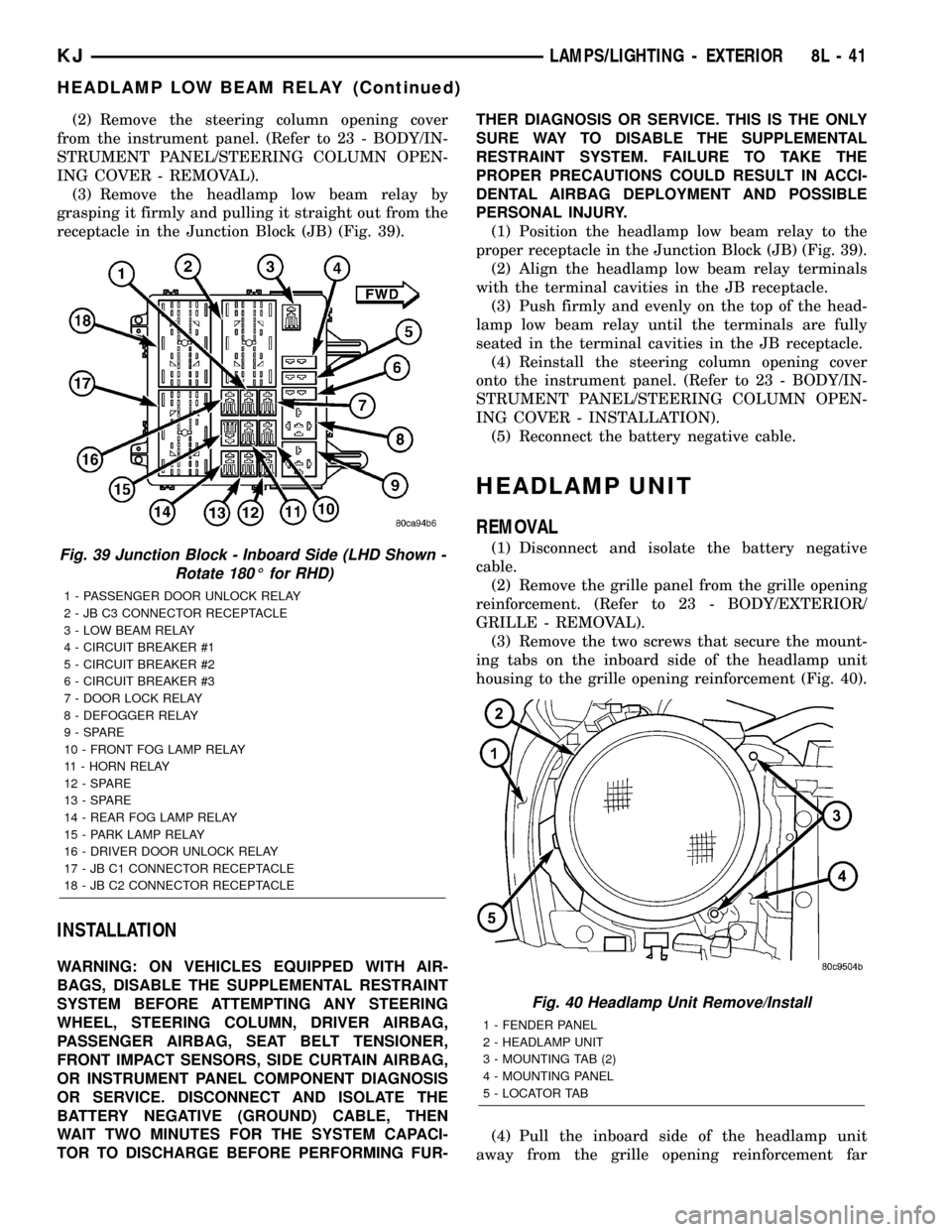

The headlamp leveling switch (Fig. 34) is used only

on vehicles manufactured for certain markets where

the headlamp leveling system is required. The head-

lamp leveling switch is mounted in the driver side

inboard trim bezel on the instrument panel, where it

is secured by molded latch features that are integral

to the switch housing. Only the switch bezel and

thumbwheel are visible on the outer surface of the

instrument panel trim bezel. The black plastic switch

thumbwheel is marked with white numbers ª0,º ª1,º

ª2,º and ª3,º each of which indicates one of the four

switch detent positions. Each higher number repre-sents a lower aiming position of the headlamp beam

relative to the road surface. The black, molded plas-

tic switch housing has an integral connector recepta-

cle on the back, a single latch feature on the top, and

two latch features (one on each side) on the bottom.

The switch is connected to the vehicle electrical sys-

tem through a dedicated take out and connector of

the instrument panel wire harness. Within the

switch housing is the leveling switch circuitry includ-

ing the switch contacts and a series resistor configu-

ration.

The headlamp leveling switch cannot be adjusted

or repaired and, if faulty or damaged, the unit must

be replaced.

OPERATION

The headlamp leveling switch receives battery cur-

rent on a fused park lamp relay output circuit from a

fuse in the Junction Block (JB) whenever the park

lamp relay is energized (park lamps are turned On).

The switch receives a path to ground through a splice

block located in the instrument panel wire harness

with an eyelet terminal connector that is secured by

a nut to a ground stud on the driver side instrument

panel end bracket near the JB. The only output from

the switch is a voltage signal that it provides to the

headlamp leveling motors on a headlamp adjust sig-

nal circuit. Each switch position selects a different

tap on a series resistor within the switch to provide a

different voltage signal to the leveling motors. The

higher the switch position number, the higher the

output voltage level.

The headlamp leveling switch can be tested using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - HEADLAMP

LEVELING SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 34 Headlamp Leveling Switch

1 - SWITCH

2 - UPPER LATCH FEATURE (1)

3 - CONNECTOR RECEPTACLE

4 - LOWER LATCH FEATURE (2)

5 - THUMBWHEEL

KJLAMPS/LIGHTING - EXTERIOR 8L - 37

HEADLAMP LEVELING MOTOR (Continued)

Page 482 of 1803

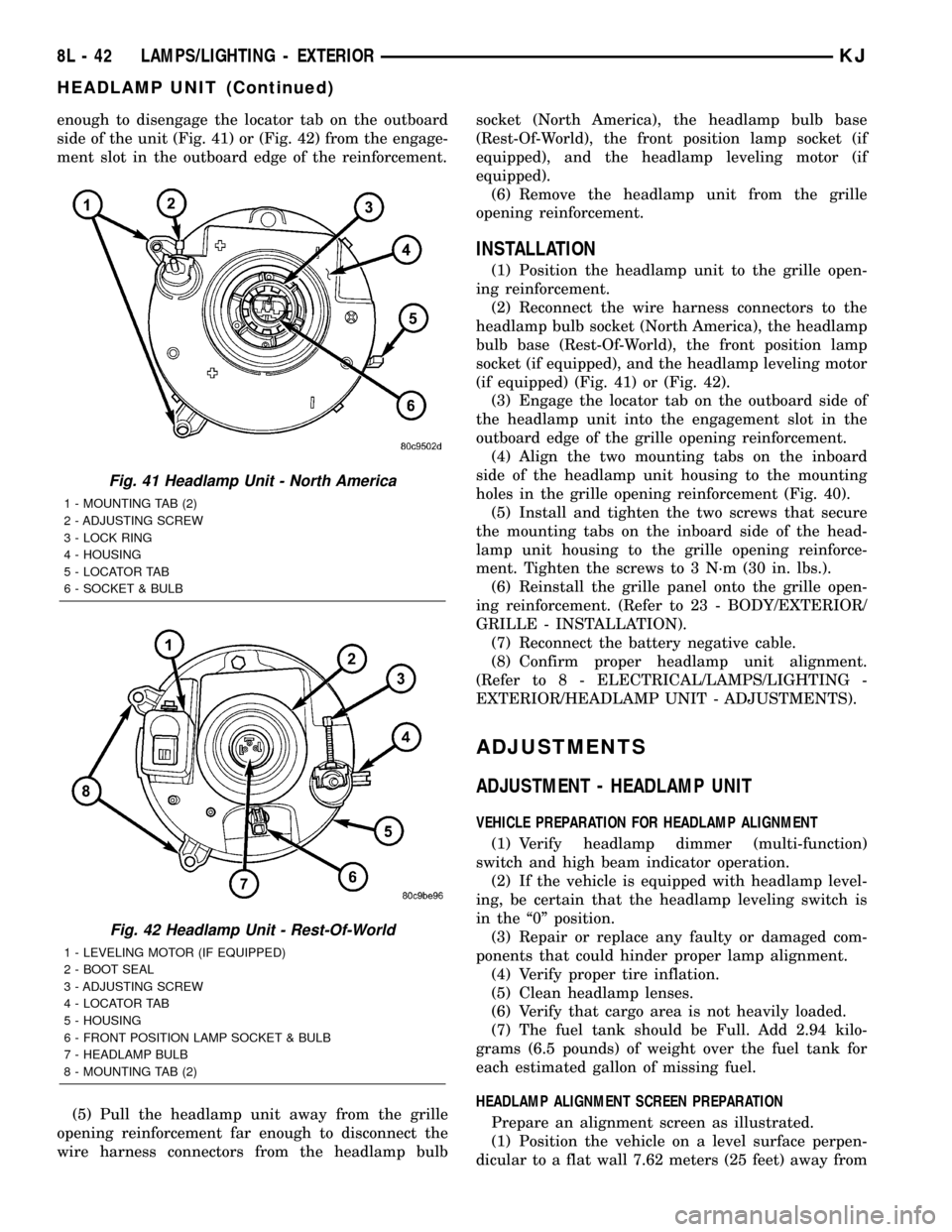

(2) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(3) Remove the headlamp low beam relay by

grasping it firmly and pulling it straight out from the

receptacle in the Junction Block (JB) (Fig. 39).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the headlamp low beam relay to the

proper receptacle in the Junction Block (JB) (Fig. 39).

(2) Align the headlamp low beam relay terminals

with the terminal cavities in the JB receptacle.

(3) Push firmly and evenly on the top of the head-

lamp low beam relay until the terminals are fully

seated in the terminal cavities in the JB receptacle.

(4) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(5) Reconnect the battery negative cable.

HEADLAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the grille panel from the grille opening

reinforcement. (Refer to 23 - BODY/EXTERIOR/

GRILLE - REMOVAL).

(3) Remove the two screws that secure the mount-

ing tabs on the inboard side of the headlamp unit

housing to the grille opening reinforcement (Fig. 40).

(4) Pull the inboard side of the headlamp unit

away from the grille opening reinforcement farFig. 39 Junction Block - Inboard Side (LHD Shown -

Rotate 180É for RHD)

1 - PASSENGER DOOR UNLOCK RELAY

2 - JB C3 CONNECTOR RECEPTACLE

3 - LOW BEAM RELAY

4 - CIRCUIT BREAKER #1

5 - CIRCUIT BREAKER #2

6 - CIRCUIT BREAKER #3

7 - DOOR LOCK RELAY

8 - DEFOGGER RELAY

9-SPARE

10 - FRONT FOG LAMP RELAY

11 - HORN RELAY

12 - SPARE

13 - SPARE

14 - REAR FOG LAMP RELAY

15 - PARK LAMP RELAY

16 - DRIVER DOOR UNLOCK RELAY

17 - JB C1 CONNECTOR RECEPTACLE

18 - JB C2 CONNECTOR RECEPTACLE

Fig. 40 Headlamp Unit Remove/Install

1 - FENDER PANEL

2 - HEADLAMP UNIT

3 - MOUNTING TAB (2)

4 - MOUNTING PANEL

5 - LOCATOR TAB

KJLAMPS/LIGHTING - EXTERIOR 8L - 41

HEADLAMP LOW BEAM RELAY (Continued)

Page 483 of 1803

enough to disengage the locator tab on the outboard

side of the unit (Fig. 41) or (Fig. 42) from the engage-

ment slot in the outboard edge of the reinforcement.

(5) Pull the headlamp unit away from the grille

opening reinforcement far enough to disconnect the

wire harness connectors from the headlamp bulbsocket (North America), the headlamp bulb base

(Rest-Of-World), the front position lamp socket (if

equipped), and the headlamp leveling motor (if

equipped).

(6) Remove the headlamp unit from the grille

opening reinforcement.

INSTALLATION

(1) Position the headlamp unit to the grille open-

ing reinforcement.

(2) Reconnect the wire harness connectors to the

headlamp bulb socket (North America), the headlamp

bulb base (Rest-Of-World), the front position lamp

socket (if equipped), and the headlamp leveling motor

(if equipped) (Fig. 41) or (Fig. 42).

(3) Engage the locator tab on the outboard side of

the headlamp unit into the engagement slot in the

outboard edge of the grille opening reinforcement.

(4) Align the two mounting tabs on the inboard

side of the headlamp unit housing to the mounting

holes in the grille opening reinforcement (Fig. 40).

(5) Install and tighten the two screws that secure

the mounting tabs on the inboard side of the head-

lamp unit housing to the grille opening reinforce-

ment. Tighten the screws to 3 N´m (30 in. lbs.).

(6) Reinstall the grille panel onto the grille open-

ing reinforcement. (Refer to 23 - BODY/EXTERIOR/

GRILLE - INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Confirm proper headlamp unit alignment.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/HEADLAMP UNIT - ADJUSTMENTS).

ADJUSTMENTS

ADJUSTMENT - HEADLAMP UNIT

VEHICLE PREPARATION FOR HEADLAMP ALIGNMENT

(1) Verify headlamp dimmer (multi-function)

switch and high beam indicator operation.

(2) If the vehicle is equipped with headlamp level-

ing, be certain that the headlamp leveling switch is

in the ª0º position.

(3) Repair or replace any faulty or damaged com-

ponents that could hinder proper lamp alignment.

(4) Verify proper tire inflation.

(5) Clean headlamp lenses.

(6) Verify that cargo area is not heavily loaded.

(7) The fuel tank should be Full. Add 2.94 kilo-

grams (6.5 pounds) of weight over the fuel tank for

each estimated gallon of missing fuel.

HEADLAMP ALIGNMENT SCREEN PREPARATION

Prepare an alignment screen as illustrated.

(1) Position the vehicle on a level surface perpen-

dicular to a flat wall 7.62 meters (25 feet) away from

Fig. 41 Headlamp Unit - North America

1 - MOUNTING TAB (2)

2 - ADJUSTING SCREW

3 - LOCK RING

4 - HOUSING

5 - LOCATOR TAB

6 - SOCKET & BULB

Fig. 42 Headlamp Unit - Rest-Of-World

1 - LEVELING MOTOR (IF EQUIPPED)

2 - BOOT SEAL

3 - ADJUSTING SCREW

4 - LOCATOR TAB

5 - HOUSING

6 - FRONT POSITION LAMP SOCKET & BULB

7 - HEADLAMP BULB

8 - MOUNTING TAB (2)

8L - 42 LAMPS/LIGHTING - EXTERIORKJ

HEADLAMP UNIT (Continued)

Page 485 of 1803

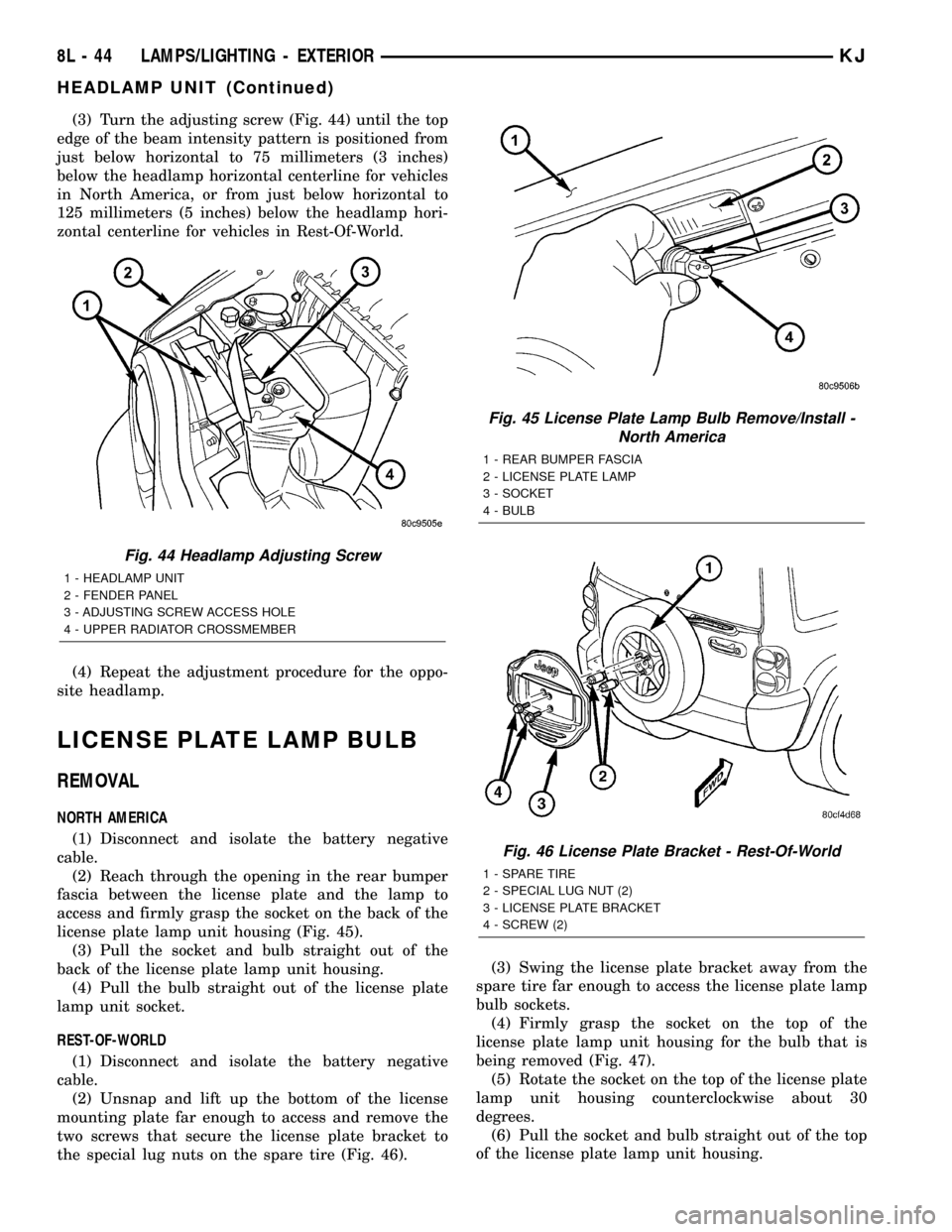

(3) Turn the adjusting screw (Fig. 44) until the top

edge of the beam intensity pattern is positioned from

just below horizontal to 75 millimeters (3 inches)

below the headlamp horizontal centerline for vehicles

in North America, or from just below horizontal to

125 millimeters (5 inches) below the headlamp hori-

zontal centerline for vehicles in Rest-Of-World.

(4) Repeat the adjustment procedure for the oppo-

site headlamp.

LICENSE PLATE LAMP BULB

REMOVAL

NORTH AMERICA

(1) Disconnect and isolate the battery negative

cable.

(2) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

access and firmly grasp the socket on the back of the

license plate lamp unit housing (Fig. 45).

(3) Pull the socket and bulb straight out of the

back of the license plate lamp unit housing.

(4) Pull the bulb straight out of the license plate

lamp unit socket.

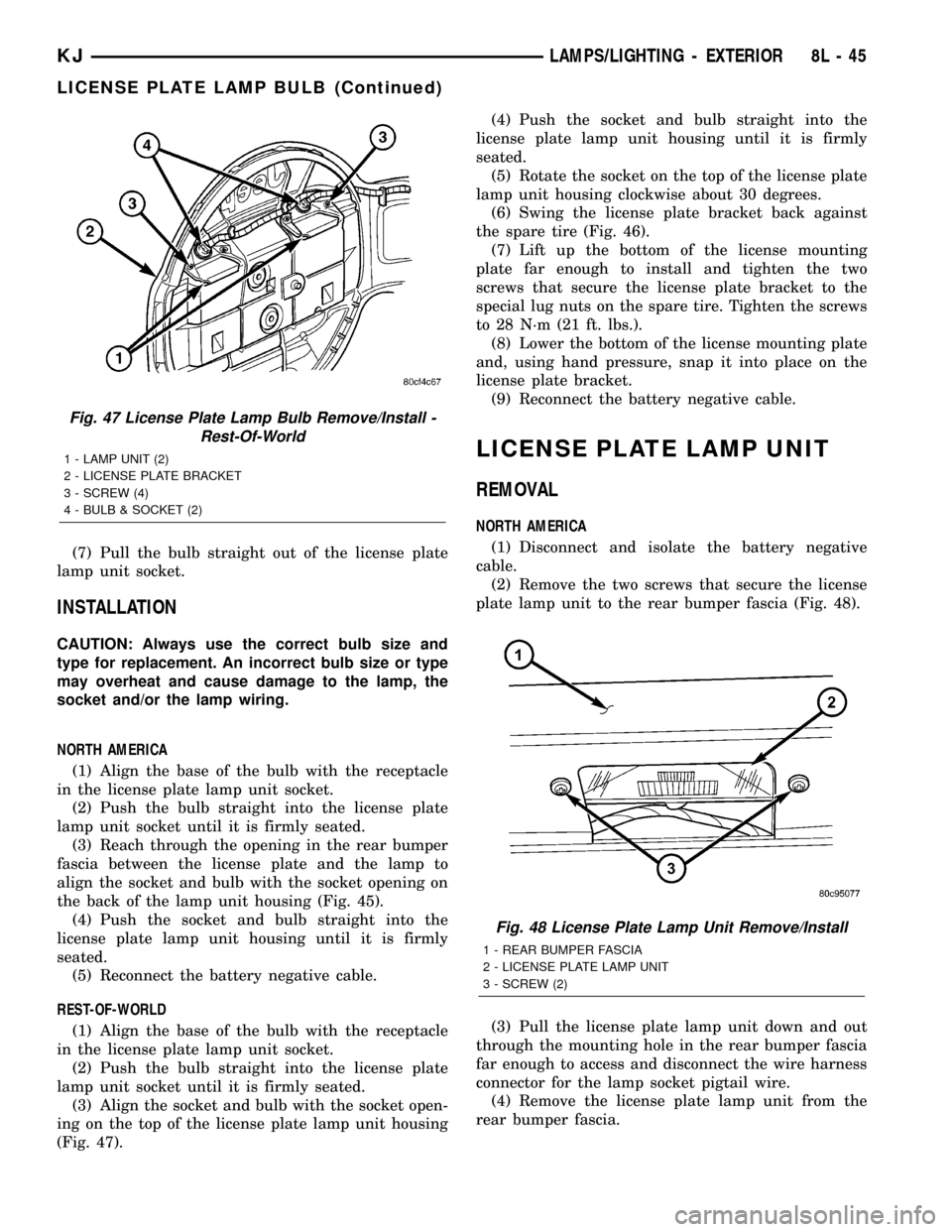

REST-OF-WORLD

(1) Disconnect and isolate the battery negative

cable.

(2) Unsnap and lift up the bottom of the license

mounting plate far enough to access and remove the

two screws that secure the license plate bracket to

the special lug nuts on the spare tire (Fig. 46).(3) Swing the license plate bracket away from the

spare tire far enough to access the license plate lamp

bulb sockets.

(4) Firmly grasp the socket on the top of the

license plate lamp unit housing for the bulb that is

being removed (Fig. 47).

(5) Rotate the socket on the top of the license plate

lamp unit housing counterclockwise about 30

degrees.

(6) Pull the socket and bulb straight out of the top

of the license plate lamp unit housing.

Fig. 44 Headlamp Adjusting Screw

1 - HEADLAMP UNIT

2 - FENDER PANEL

3 - ADJUSTING SCREW ACCESS HOLE

4 - UPPER RADIATOR CROSSMEMBER

Fig. 45 License Plate Lamp Bulb Remove/Install -

North America

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP

3 - SOCKET

4 - BULB

Fig. 46 License Plate Bracket - Rest-Of-World

1 - SPARE TIRE

2 - SPECIAL LUG NUT (2)

3 - LICENSE PLATE BRACKET

4 - SCREW (2)

8L - 44 LAMPS/LIGHTING - EXTERIORKJ

HEADLAMP UNIT (Continued)

Page 486 of 1803

(7) Pull the bulb straight out of the license plate

lamp unit socket.

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

NORTH AMERICA

(1) Align the base of the bulb with the receptacle

in the license plate lamp unit socket.

(2) Push the bulb straight into the license plate

lamp unit socket until it is firmly seated.

(3) Reach through the opening in the rear bumper

fascia between the license plate and the lamp to

align the socket and bulb with the socket opening on

the back of the lamp unit housing (Fig. 45).

(4) Push the socket and bulb straight into the

license plate lamp unit housing until it is firmly

seated.

(5) Reconnect the battery negative cable.

REST-OF-WORLD

(1) Align the base of the bulb with the receptacle

in the license plate lamp unit socket.

(2) Push the bulb straight into the license plate

lamp unit socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing on the top of the license plate lamp unit housing

(Fig. 47).(4) Push the socket and bulb straight into the

license plate lamp unit housing until it is firmly

seated.

(5) Rotate the socket on the top of the license plate

lamp unit housing clockwise about 30 degrees.

(6) Swing the license plate bracket back against

the spare tire (Fig. 46).

(7) Lift up the bottom of the license mounting

plate far enough to install and tighten the two

screws that secure the license plate bracket to the

special lug nuts on the spare tire. Tighten the screws

to 28 N´m (21 ft. lbs.).

(8) Lower the bottom of the license mounting plate

and, using hand pressure, snap it into place on the

license plate bracket.

(9) Reconnect the battery negative cable.

LICENSE PLATE LAMP UNIT

REMOVAL

NORTH AMERICA

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the license

plate lamp unit to the rear bumper fascia (Fig. 48).

(3) Pull the license plate lamp unit down and out

through the mounting hole in the rear bumper fascia

far enough to access and disconnect the wire harness

connector for the lamp socket pigtail wire.

(4) Remove the license plate lamp unit from the

rear bumper fascia.

Fig. 47 License Plate Lamp Bulb Remove/Install -

Rest-Of-World

1 - LAMP UNIT (2)

2 - LICENSE PLATE BRACKET

3 - SCREW (4)

4 - BULB & SOCKET (2)

Fig. 48 License Plate Lamp Unit Remove/Install

1 - REAR BUMPER FASCIA

2 - LICENSE PLATE LAMP UNIT

3 - SCREW (2)

KJLAMPS/LIGHTING - EXTERIOR 8L - 45

LICENSE PLATE LAMP BULB (Continued)