Body JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 611 of 1803

REMOTE KEYLESS ENTRY

TRANSMITTER

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY TRANSMITTER

The most reliable, efficient, and accurate means to

diagnose the remote keyless entry transmitter

requires the use of a DRBIIItscan tool and the

proper Diagnostic Procedures manual. The DRBIIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE TRANSMITTER

BATTERIES

The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:(1) Using a thin coin, gently pry at the notch in

the center seam of the RKE transmitter case halves

near the key ring until the two halves unsnap.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.

(4) Replace the two batteries with new Panasonic

2016, or equivalent. Be certain that the batteries are

installed with their polarity correctly oriented.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together until they snap back into place.

STANDARD PROCEDURE - RKE TRANSMITTER

CUSTOMER PREFERENCES

AUTOMATIC (ROLLING) LOCKS

The rolling locks feature can be toggled ON/OFF

by using the DRB IIItonly.

HORN CHIRP DISABLING / ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter.

To DISABLE (cancel) the horn chirp feature, press

and hold the transmitter LOCK button for four to ten

seconds. While pressing the LOCK button in, press

the UNLOCK button. Release both buttons.

To ENABLE the horn chirp feature, repeat the

above procedure.

OPTICAL CHIRP (FLASH) DISABLING / ENABLING

The optical chirp can be toggled using a DRB IIIt

or by using the Remote Keyless Entry (RKE) trans-

mitter.

To DISABLE (cancel) the optical chirp feature,

press and hold the transmitter LOCK button for four

to ten seconds. While pressing the LOCK button in,

press the TAILGATE RELEASE button. Release both

buttons.

To ENABLE the optical chirp feature, repeat the

above procedure.

TAIL GATE RELEASE DELAY

Press the UNLOCK button for four to ten seconds.

While pressing the UNLOCK button, press the TAIL

GATE RELEASE button. Release both buttons.

This will toggle between PRESS AND HOLD and

PRESS (no delay).

UNLOCK SEQUENCE

The unlock sequence can be toggled using a DRB

IIItor by using the Remote Keyless Entry (RKE)

transmitter.

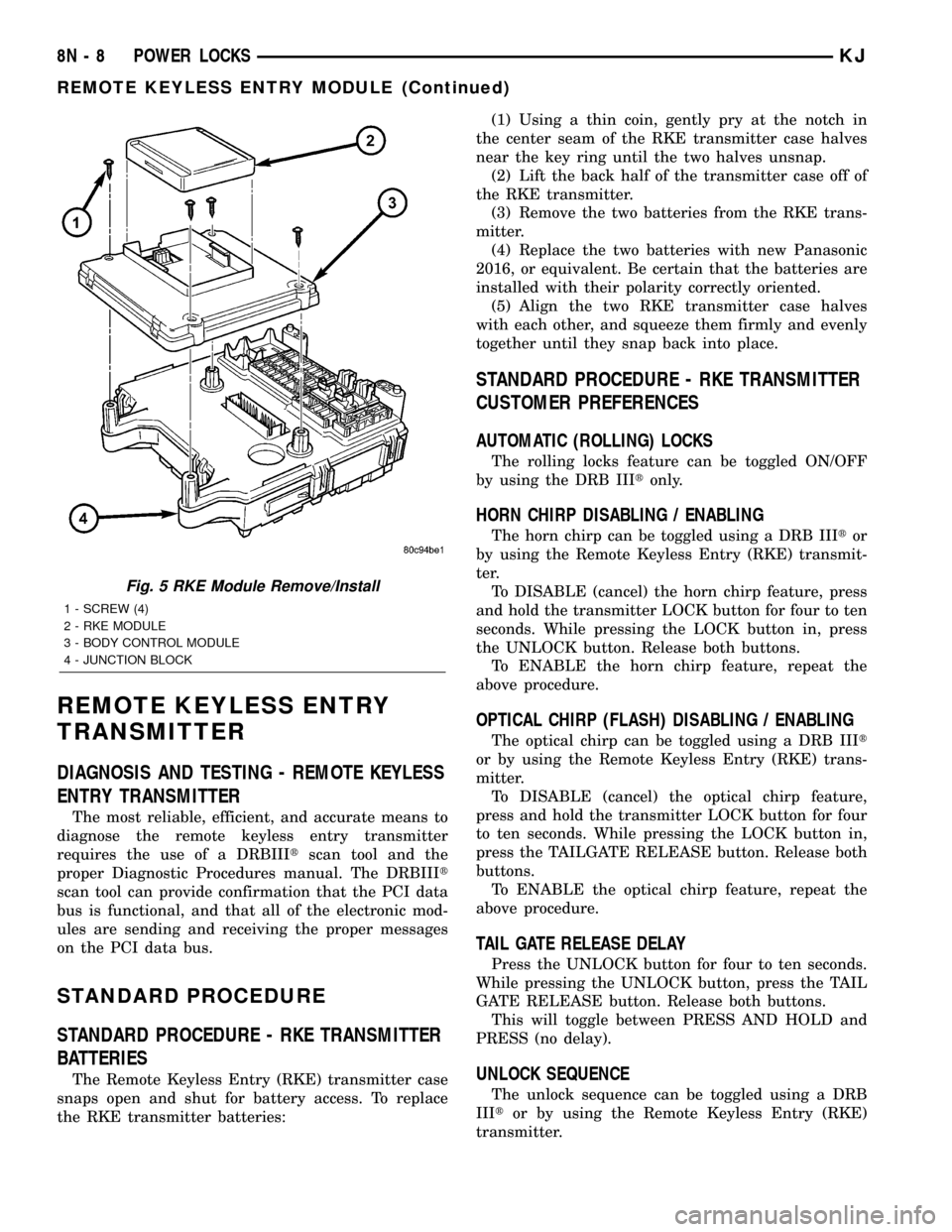

Fig. 5 RKE Module Remove/Install

1 - SCREW (4)

2 - RKE MODULE

3 - BODY CONTROL MODULE

4 - JUNCTION BLOCK

8N - 8 POWER LOCKSKJ

REMOTE KEYLESS ENTRY MODULE (Continued)

Page 612 of 1803

Press and hold the transmitter UNLOCK button

for four to ten seconds. While pressing the UNLOCK

button in, press the LOCK button. Release both but-

tons.

This will toggle between Driver door first and

Unlock all doors function.

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

New Remote Keyless Entry (RKE) transmitters can

be programed using the DRBIIItscan tool and the

proper Diagnostic Procedures manual. The DRBIIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.

The following procedure can be used as long as one

functioning transmitter is available:

(1) Using the original transmitter, press the

UNLOCK button for 4 to 10 seconds.

(2) Without releasing the UNLOCK button, press

the PANIC button (within the 4 to 10 second inter-

val).

(3) Release both buttons.

(4) Press LOCK and UNLOCK simultaneously on

the original transmitter.

(5) Release both buttons.

(6) Press any button on the ORIGINAL transmit-

ter. A chime tone from the instrument cluster will

confirm the programming of the ORIGINAL trans-

mitter.

(7) On NEW transmitter, press LOCK and

UNLOCK simultaneously.

(8) Release both buttons.

(9) Press any button on the NEW transmitter. A

chime tone from the instrument cluster will confirm

the programming of the NEW transmitter.

(10) Up to four transmitters can be programed for

one vehicle.

SPECIFICATIONS - REMOTE KEYLESS ENTRY

TRANSMITTER

RANGE

Normal operation range is up to a distance of 3 to

7 meters (10 to 23 ft.) of the vehicle. Range may be

better or worse depending on the environment

around the vehicle.

TAILGATE CYLINDER LOCK

SWITCH

DESCRIPTION

The tailgate cylinder lock switch is integral to the

key lock cylinder inside the tailgate. The tailgate cyl-

inder lock switch is a normally-open momentary

switch that is hard wired directly to the Body Con-

trol Module (BCM), and closes a path to ground

through an internal resistor when the lock cylinder is

rotated to the unlock or lock position.

The tailgate cylinder lock switch cannot be

adjusted or repaired.

OPERATION

The tailgate cylinder lock switch is actuated when

the key is inserted in the lock cylinder and turned to

the unlock or lock position. The tailgate cylinder lock

switch closes a path to ground through an internal

resistor for the Body Control Module (BCM) when

the tailgate key lock cylinder is in the lock or unlock

position, and opens the ground path when the lock

cylinder is in the neutral position. The BCM reads

the switch status, then sends the proper switch sta-

tus messages to other electronic modules over the

Programmable Communications Interface (PCI) data

bus network. The tailgate cylinder lock switch unlock

status message is used by the BCM as an input for

Vehicle Theft Security System (VTSS) operation and

to tell the BCM to lock or unlock the tailgate. There

is no mechanical linkage between the tailgate key

cylinder and the latches.

DIAGNOSIS AND TESTING - TAILGATE

CYLINDER LOCK SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Remove tailgate trim panel (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Disconnect tailgate cylinder lock switch har-

ness connector.

(4) Using a ohmmeter, test for resistances as

shown in the Tailgate Cylinder Lock Switch Table.

KJPOWER LOCKS 8N - 9

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 613 of 1803

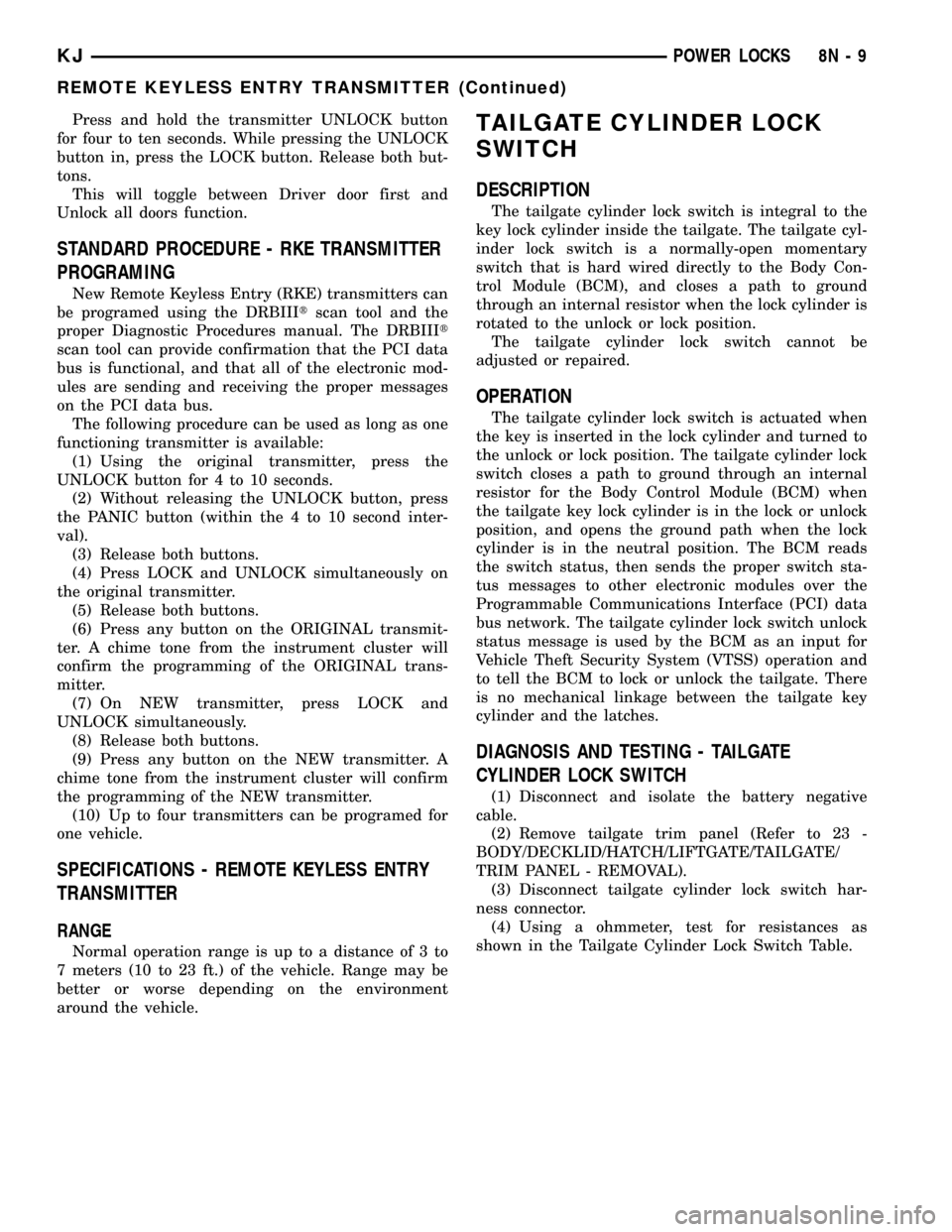

TAILGATE CYLINDER LOCK SWITCH TABLE

SWITCH POSITION RESISTANCE

NEUTRAL 0 OHMS

LOCK (CLOCKWISE) 2 K OHMS 10 %

UNLOCK (COUNTER-

CLOCKWISE)470 OHMS 10 %

(5) If switch resistance is not correct, replace

switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the tailgate trim panel.(Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Remove the retainer clip from the pin on the

back of the door lock cylinder (Fig. 6).

(4) Remove the washer from the pin on the back of

the door lock cylinder.

(5) Remove the door cylinder lock switch from the

back of the lock cylinder.

INSTALLATION

(1) Position the tailgate cylinder lock switch onto

the back of the lock cylinder with the wire harness

oriented toward the bottom.

(2) Position the washer over the switch.

(3) Install the retainer clip onto the pin on the

back of the tailgate lock cylinder. Be certain that thecenter tab of the retainer is engaged in the retention

hole on the lock lever.

(4) Install the trim panel (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION).

(5) Connect the battery negative cable.

Fig. 6 Lock Cylinder Switch Remove/Install -Typical

1 - LEVER

2 - RETAINER

3 - LOCK CYLINDER

4 - SWITCH

5 - PLIERS

6 - OUTSIDE DOOR HANDLE

8N - 10 POWER LOCKSKJ

TAILGATE CYLINDER LOCK SWITCH (Continued)

Page 614 of 1803

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - POWER

MIRRORS...........................11

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH............................12REMOVAL.............................13

INSTALLATION.........................13

SIDEVIEW MIRROR

REMOVAL.............................13

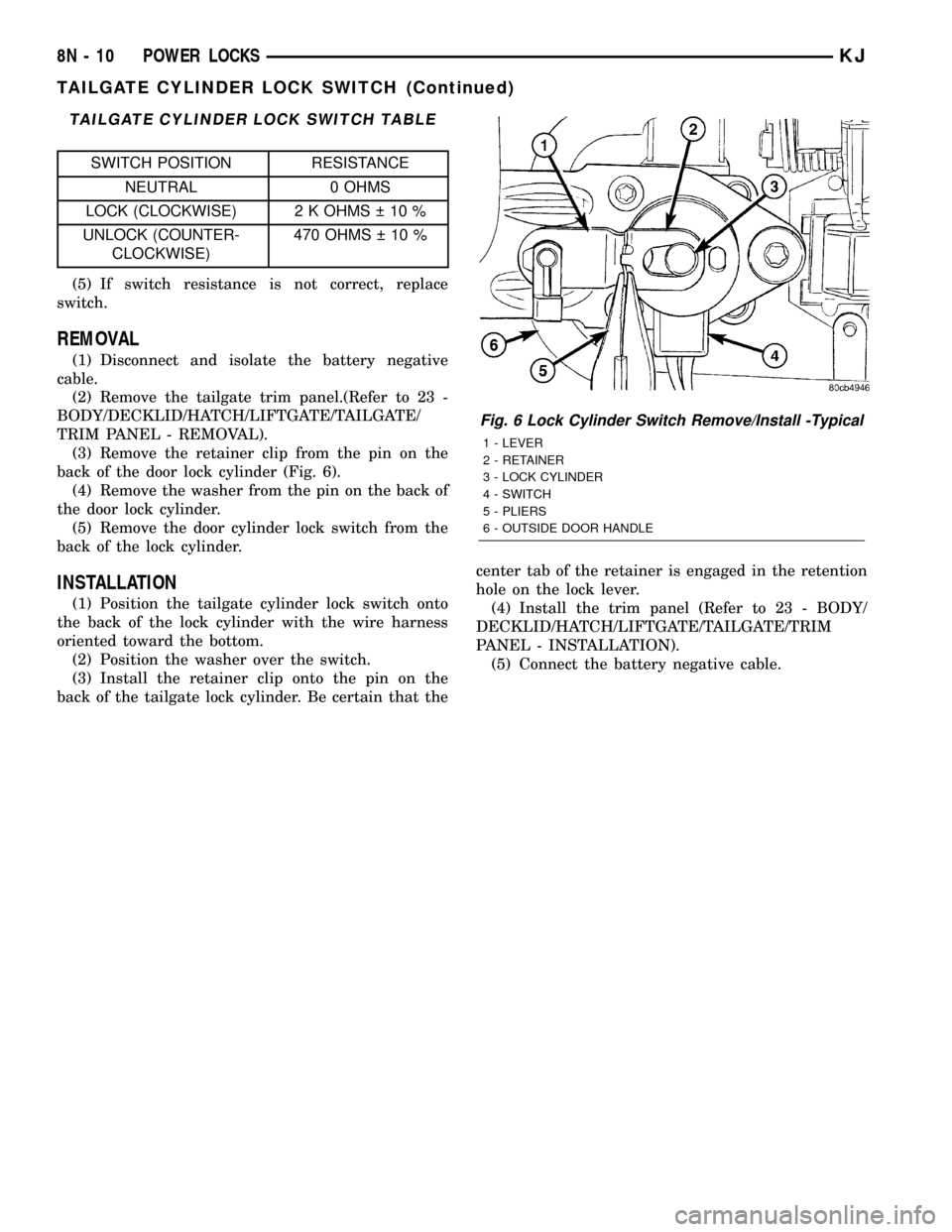

POWER MIRRORS

DESCRIPTION

The available power operated sideview mirrors

allow the driver to adjust both outside mirrors elec-

trically from the drivers seat by operating a switch

on the driver side front door trim panel (Fig. 1).

OPERATION

The power mirrors receive ignition current through

a fuse in the junction block, and will only operate

when the ignition switch is in the Run position.

DIAGNOSIS AND TESTING - POWER MIRRORS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power mirror switch (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

mirror switch.

(3) Switch ignition to the RUN position.

(4) Connect the clip end of a 12 volt test light to

Pin 5 in the harness connector at the mirror switch.

Touch the test light probe to Pin 3.

If the test light illuminates, the wiring circuit

between the battery and switch is OK.

If the lamp does not illuminate, first check fuse 25

in the Junction Block (JB). If fuse 25 is OK, then

check for a broken wire.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

POWER MIRROR MOTOR TEST

If the power mirror switch is receiving proper cur-

rent and ground and mirrors do not operate, proceed

with power mirror motor test. Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

Fig. 1 POWER MIRROR SWITCH

1 - DOOR TRIM PANEL

2 - DOOR LOCK SWITCH

3 - POWER MIRROR SWITCH

KJPOWER MIRRORS 8N - 11

Page 615 of 1803

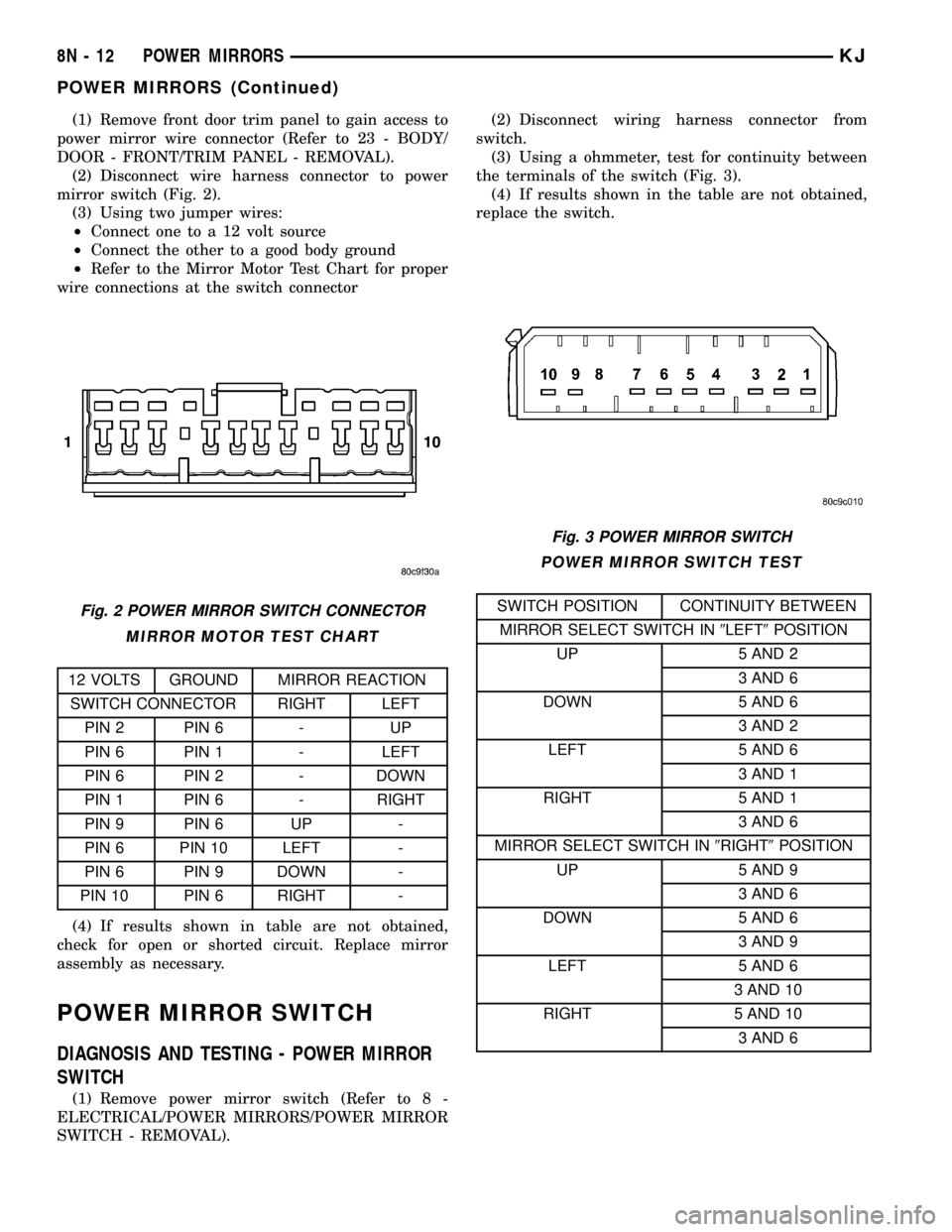

(1) Remove front door trim panel to gain access to

power mirror wire connector (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Disconnect wire harness connector to power

mirror switch (Fig. 2).

(3) Using two jumper wires:

²Connect one to a 12 volt source

²Connect the other to a good body ground

²Refer to the Mirror Motor Test Chart for proper

wire connections at the switch connector

MIRROR MOTOR TEST CHART

12 VOLTS GROUND MIRROR REACTION

SWITCH CONNECTOR RIGHT LEFT

PIN 2 PIN 6 - UP

PIN 6 PIN 1 - LEFT

PIN 6 PIN 2 - DOWN

PIN 1 PIN 6 - RIGHT

PIN 9 PIN 6 UP -

PIN 6 PIN 10 LEFT -

PIN 6 PIN 9 DOWN -

PIN 10 PIN 6 RIGHT -

(4) If results shown in table are not obtained,

check for open or shorted circuit. Replace mirror

assembly as necessary.

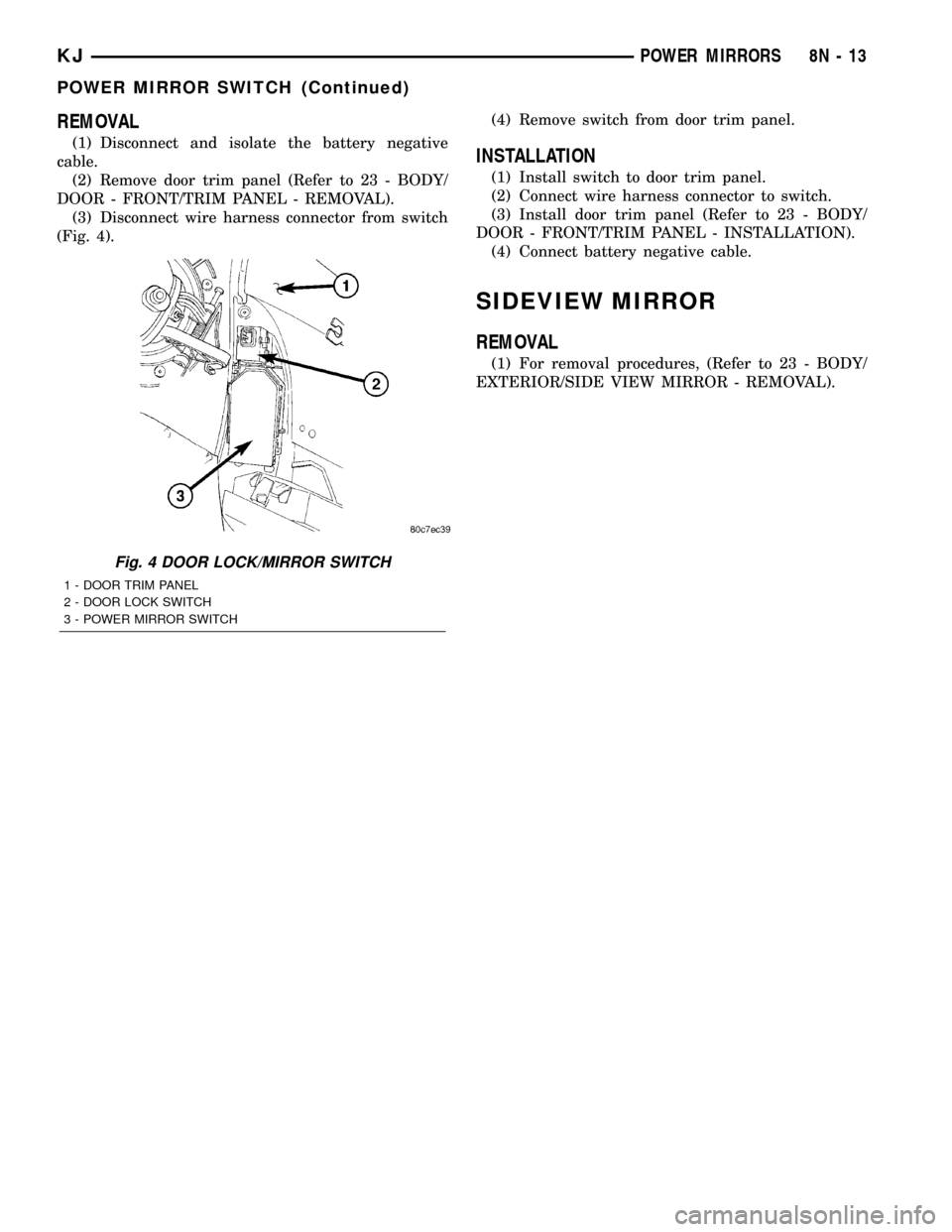

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH

(1) Remove power mirror switch (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).(2) Disconnect wiring harness connector from

switch.

(3) Using a ohmmeter, test for continuity between

the terminals of the switch (Fig. 3).

(4) If results shown in the table are not obtained,

replace the switch.

POWER MIRROR SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

MIRROR SELECT SWITCH IN9LEFT9POSITION

UP 5 AND 2

3 AND 6

DOWN 5 AND 6

3 AND 2

LEFT 5 AND 6

3 AND 1

RIGHT 5 AND 1

3 AND 6

MIRROR SELECT SWITCH IN9RIGHT9POSITION

UP 5 AND 9

3 AND 6

DOWN 5 AND 6

3 AND 9

LEFT 5 AND 6

3 AND 10

RIGHT 5 AND 10

3 AND 6Fig. 2 POWER MIRROR SWITCH CONNECTOR

Fig. 3 POWER MIRROR SWITCH

8N - 12 POWER MIRRORSKJ

POWER MIRRORS (Continued)

Page 616 of 1803

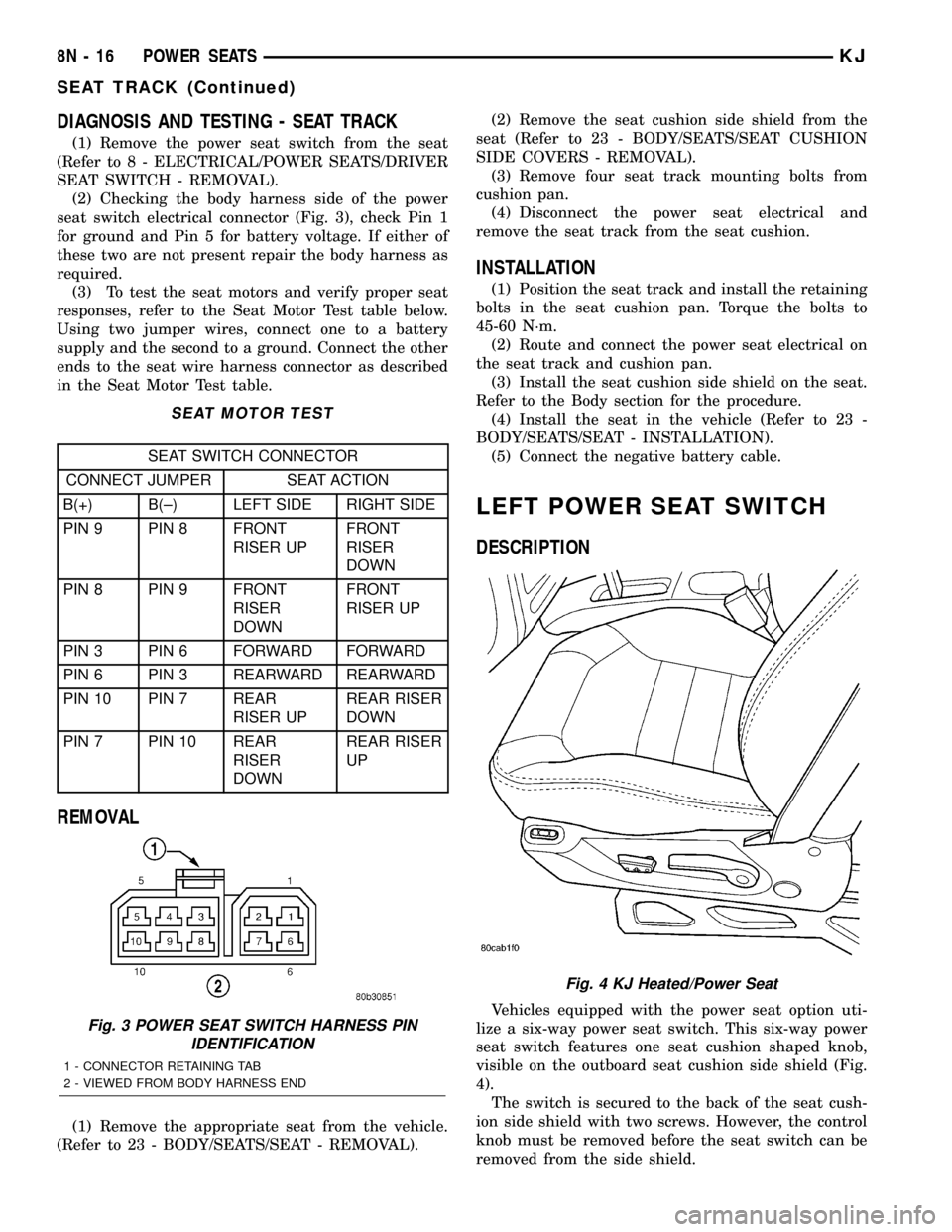

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Disconnect wire harness connector from switch

(Fig. 4).(4) Remove switch from door trim panel.INSTALLATION

(1) Install switch to door trim panel.

(2) Connect wire harness connector to switch.

(3) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

(4) Connect battery negative cable.

SIDEVIEW MIRROR

REMOVAL

(1) For removal procedures, (Refer to 23 - BODY/

EXTERIOR/SIDE VIEW MIRROR - REMOVAL).

Fig. 4 DOOR LOCK/MIRROR SWITCH

1 - DOOR TRIM PANEL

2 - DOOR LOCK SWITCH

3 - POWER MIRROR SWITCH

KJPOWER MIRRORS 8N - 13

POWER MIRROR SWITCH (Continued)

Page 619 of 1803

DIAGNOSIS AND TESTING - SEAT TRACK

(1) Remove the power seat switch from the seat

(Refer to 8 - ELECTRICAL/POWER SEATS/DRIVER

SEAT SWITCH - REMOVAL).

(2) Checking the body harness side of the power

seat switch electrical connector (Fig. 3), check Pin 1

for ground and Pin 5 for battery voltage. If either of

these two are not present repair the body harness as

required.

(3) To test the seat motors and verify proper seat

responses, refer to the Seat Motor Test table below.

Using two jumper wires, connect one to a battery

supply and the second to a ground. Connect the other

ends to the seat wire harness connector as described

in the Seat Motor Test table.

SEAT MOTOR TEST

SEAT SWITCH CONNECTOR

CONNECT JUMPER SEAT ACTION

B(+) B(±) LEFT SIDE RIGHT SIDE

PIN 9 PIN 8 FRONT

RISER UPFRONT

RISER

DOWN

PIN 8 PIN 9 FRONT

RISER

DOWNFRONT

RISER UP

PIN 3 PIN 6 FORWARD FORWARD

PIN 6 PIN 3 REARWARD REARWARD

PIN 10 PIN 7 REAR

RISER UPREAR RISER

DOWN

PIN 7 PIN 10 REAR

RISER

DOWNREAR RISER

UP

REMOVAL

(1) Remove the appropriate seat from the vehicle.

(Refer to 23 - BODY/SEATS/SEAT - REMOVAL).(2) Remove the seat cushion side shield from the

seat (Refer to 23 - BODY/SEATS/SEAT CUSHION

SIDE COVERS - REMOVAL).

(3) Remove four seat track mounting bolts from

cushion pan.

(4) Disconnect the power seat electrical and

remove the seat track from the seat cushion.

INSTALLATION

(1) Position the seat track and install the retaining

bolts in the seat cushion pan. Torque the bolts to

45-60 N´m.

(2) Route and connect the power seat electrical on

the seat track and cushion pan.

(3) Install the seat cushion side shield on the seat.

Refer to the Body section for the procedure.

(4) Install the seat in the vehicle (Refer to 23 -

BODY/SEATS/SEAT - INSTALLATION).

(5) Connect the negative battery cable.

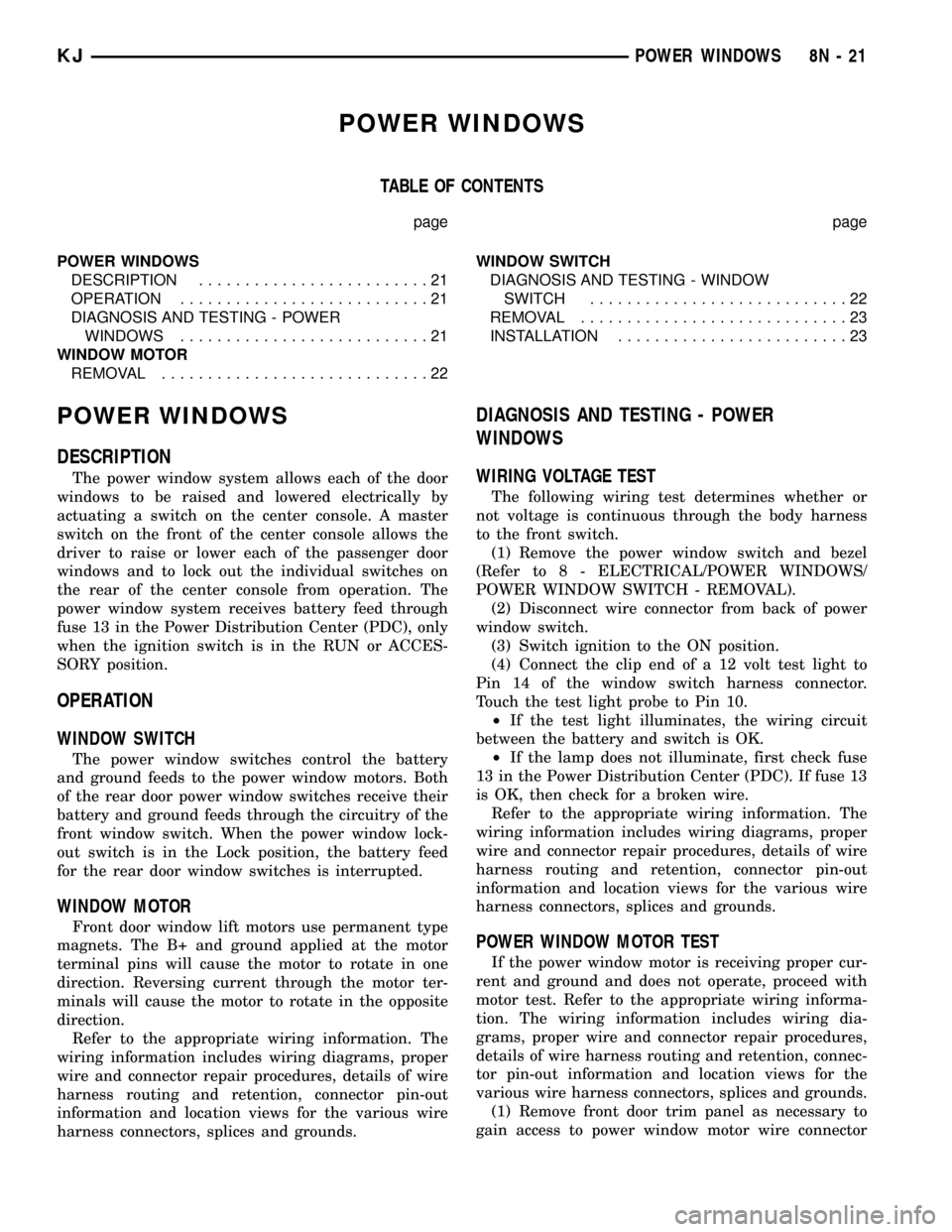

LEFT POWER SEAT SWITCH

DESCRIPTION

Vehicles equipped with the power seat option uti-

lize a six-way power seat switch. This six-way power

seat switch features one seat cushion shaped knob,

visible on the outboard seat cushion side shield (Fig.

4).

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knob must be removed before the seat switch can be

removed from the side shield.

Fig. 3 POWER SEAT SWITCH HARNESS PIN

IDENTIFICATION

1 - CONNECTOR RETAINING TAB

2 - VIEWED FROM BODY HARNESS END

Fig. 4 KJ Heated/Power Seat

8N - 16 POWER SEATSKJ

SEAT TRACK (Continued)

Page 624 of 1803

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................21

WINDOW MOTOR

REMOVAL.............................22WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................22

REMOVAL.............................23

INSTALLATION.........................23

POWER WINDOWS

DESCRIPTION

The power window system allows each of the door

windows to be raised and lowered electrically by

actuating a switch on the center console. A master

switch on the front of the center console allows the

driver to raise or lower each of the passenger door

windows and to lock out the individual switches on

the rear of the center console from operation. The

power window system receives battery feed through

fuse 13 in the Power Distribution Center (PDC), only

when the ignition switch is in the RUN or ACCES-

SORY position.

OPERATION

WINDOW SWITCH

The power window switches control the battery

and ground feeds to the power window motors. Both

of the rear door power window switches receive their

battery and ground feeds through the circuitry of the

front window switch. When the power window lock-

out switch is in the Lock position, the battery feed

for the rear door window switches is interrupted.

WINDOW MOTOR

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor

terminal pins will cause the motor to rotate in one

direction. Reversing current through the motor ter-

minals will cause the motor to rotate in the opposite

direction.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - POWER

WINDOWS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the front switch.

(1) Remove the power window switch and bezel

(Refer to 8 - ELECTRICAL/POWER WINDOWS/

POWER WINDOW SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition to the ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 14 of the window switch harness connector.

Touch the test light probe to Pin 10.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check fuse

13 in the Power Distribution Center (PDC). If fuse 13

is OK, then check for a broken wire.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove front door trim panel as necessary to

gain access to power window motor wire connector

KJPOWER WINDOWS 8N - 21

Page 625 of 1803

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WINDOW MOTOR

REMOVAL

The window motor is incorporated into the window

regulator assembly. If the window motor requires

replacement, the window regulator must be replaced.

(Refer to 23 - BODY/DOOR - FRONT/WINDOW

REGULATOR - REMOVAL) or (Refer to 23 - BODY/

DOORS - REAR/WINDOW REGULATOR - REMOV-

AL).

WINDOW SWITCH

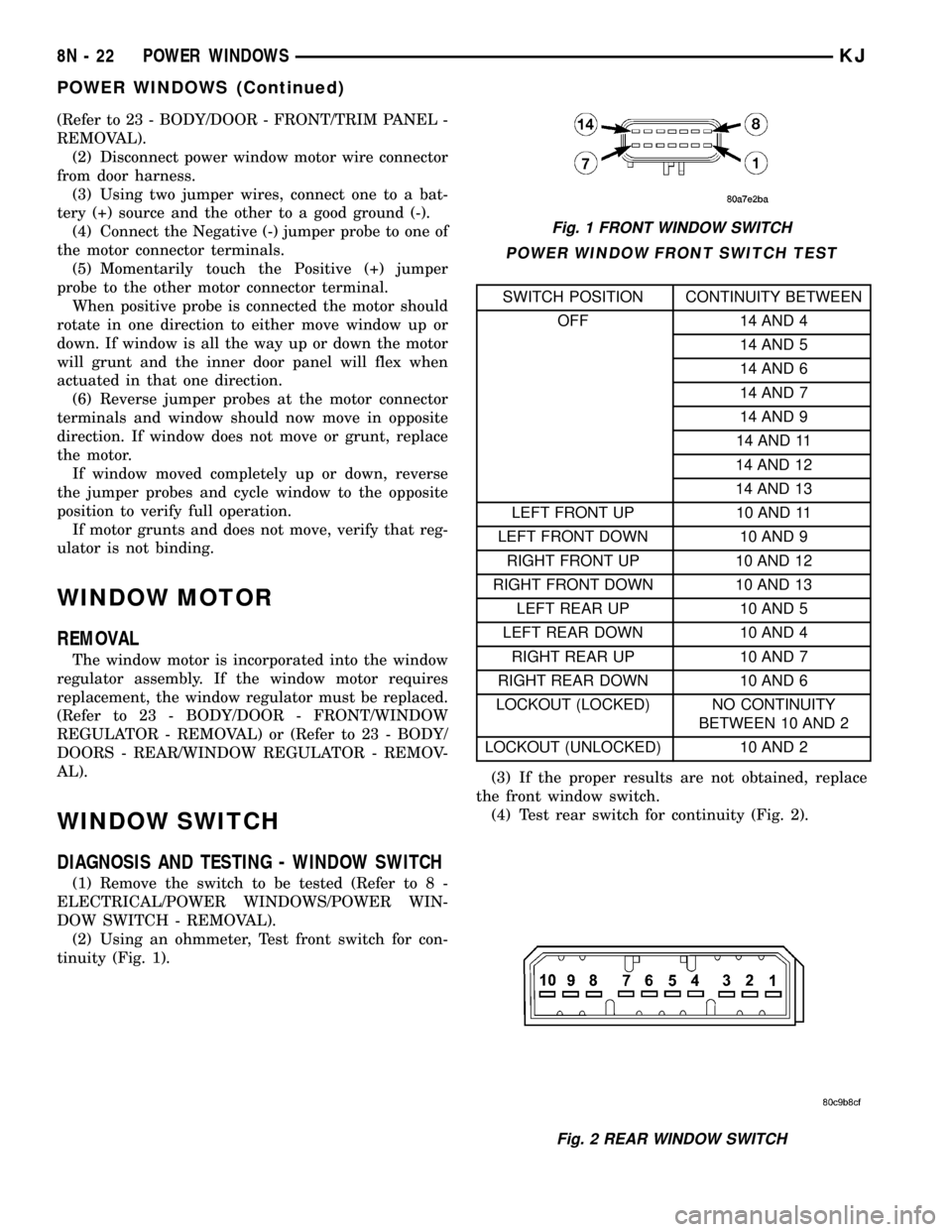

DIAGNOSIS AND TESTING - WINDOW SWITCH

(1) Remove the switch to be tested (Refer to 8 -

ELECTRICAL/POWER WINDOWS/POWER WIN-

DOW SWITCH - REMOVAL).

(2) Using an ohmmeter, Test front switch for con-

tinuity (Fig. 1).

POWER WINDOW FRONT SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 14 AND 4

14 AND 5

14 AND 6

14 AND 7

14 AND 9

14 AND 11

14 AND 12

14 AND 13

LEFT FRONT UP 10 AND 11

LEFT FRONT DOWN 10 AND 9

RIGHT FRONT UP 10 AND 12

RIGHT FRONT DOWN 10 AND 13

LEFT REAR UP 10 AND 5

LEFT REAR DOWN 10 AND 4

RIGHT REAR UP 10 AND 7

RIGHT REAR DOWN 10 AND 6

LOCKOUT (LOCKED) NO CONTINUITY

BETWEEN 10 AND 2

LOCKOUT (UNLOCKED) 10 AND 2

(3) If the proper results are not obtained, replace

the front window switch.

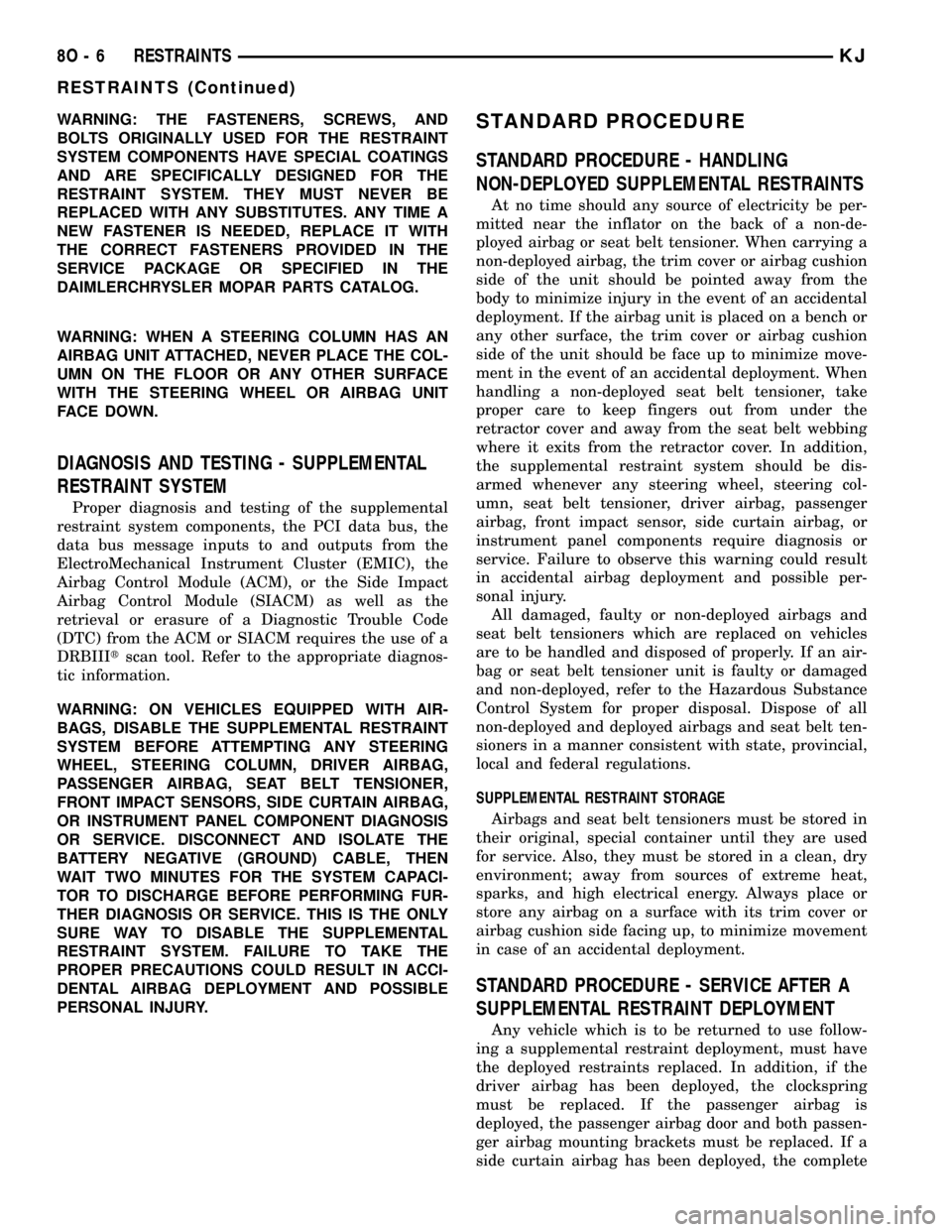

(4) Test rear switch for continuity (Fig. 2).

Fig. 1 FRONT WINDOW SWITCH

Fig. 2 REAR WINDOW SWITCH

8N - 22 POWER WINDOWSKJ

POWER WINDOWS (Continued)

Page 633 of 1803

WARNING: THE FASTENERS, SCREWS, AND

BOLTS ORIGINALLY USED FOR THE RESTRAINT

SYSTEM COMPONENTS HAVE SPECIAL COATINGS

AND ARE SPECIFICALLY DESIGNED FOR THE

RESTRAINT SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANY TIME A

NEW FASTENER IS NEEDED, REPLACE IT WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

WARNING: WHEN A STEERING COLUMN HAS AN

AIRBAG UNIT ATTACHED, NEVER PLACE THE COL-

UMN ON THE FLOOR OR ANY OTHER SURFACE

WITH THE STEERING WHEEL OR AIRBAG UNIT

FACE DOWN.

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM

Proper diagnosis and testing of the supplemental

restraint system components, the PCI data bus, the

data bus message inputs to and outputs from the

ElectroMechanical Instrument Cluster (EMIC), the

Airbag Control Module (ACM), or the Side Impact

Airbag Control Module (SIACM) as well as the

retrieval or erasure of a Diagnostic Trouble Code

(DTC) from the ACM or SIACM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag or seat belt tensioner. When carrying a

non-deployed airbag, the trim cover or airbag cushion

side of the unit should be pointed away from the

body to minimize injury in the event of an accidental

deployment. If the airbag unit is placed on a bench or

any other surface, the trim cover or airbag cushion

side of the unit should be face up to minimize move-

ment in the event of an accidental deployment. When

handling a non-deployed seat belt tensioner, take

proper care to keep fingers out from under the

retractor cover and away from the seat belt webbing

where it exits from the retractor cover. In addition,

the supplemental restraint system should be dis-

armed whenever any steering wheel, steering col-

umn, seat belt tensioner, driver airbag, passenger

airbag, front impact sensor, side curtain airbag, or

instrument panel components require diagnosis or

service. Failure to observe this warning could result

in accidental airbag deployment and possible per-

sonal injury.

All damaged, faulty or non-deployed airbags and

seat belt tensioners which are replaced on vehicles

are to be handled and disposed of properly. If an air-

bag or seat belt tensioner unit is faulty or damaged

and non-deployed, refer to the Hazardous Substance

Control System for proper disposal. Dispose of all

non-deployed and deployed airbags and seat belt ten-

sioners in a manner consistent with state, provincial,

local and federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags and seat belt tensioners must be stored in

their original, special container until they are used

for service. Also, they must be stored in a clean, dry

environment; away from sources of extreme heat,

sparks, and high electrical energy. Always place or

store any airbag on a surface with its trim cover or

airbag cushion side facing up, to minimize movement

in case of an accidental deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring

must be replaced. If the passenger airbag is

deployed, the passenger airbag door and both passen-

ger airbag mounting brackets must be replaced. If a

side curtain airbag has been deployed, the complete

8O - 6 RESTRAINTSKJ

RESTRAINTS (Continued)