Body JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 675 of 1803

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

OVERSHOOT/UNDERSHOOT

If the vehicle operator repeatedly presses and

releases the SET button with their foot off of the

accelerator (referred to as a ªlift foot setº), the vehicle

may accelerate and exceed the desired set speed by

up to 5 mph (8 km/h). It may also decelerate to less

than the desired set speed, before finally achieving

the desired set speed.

The Speed Control System has an adaptive strat-

egy that compensates for vehicle-to-vehicle variations

in speed control cable lengths. When the speed con-

trol is set with the vehicle operators foot off of the

accelerator pedal, the speed control thinks there is

excessive speed control cable slack and adapts

accordingly. If the ªlift foot setsº are continually used,

a speed control overshoot/undershoot condition will

develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed using

the accelerator pedal (not decelerating or accelerat-

ing), and then turning the cruise control switch to

the OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road testshould include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8J,

Instrument Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo. Corrosion should be removed from

electrical terminals and a light coating of Mopar

MultiPurpose Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment of both ends of the speed con-

trol servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS

TORQUE - SPEED CONTROL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Servo Mounting Bracket-to-Servo Nuts 9 - 75

Servo Mounting Bracket-to-Body Bolts 12 - 105

Speed Control Switch Mounting Screws 1.5 - 14

Vacuum Reservoir Mounting Screws 3 - 20

8P - 2 SPEED CONTROLKJ

SPEED CONTROL (Continued)

Page 676 of 1803

CABLE

DESCRIPTION

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage.

OPERATION

This cable causes the throttle control linkage to

open or close the throttle valve in response to move-

ment of the vacuum servo diaphragm.

REMOVAL - 3.7L

(1) Disconnect negative battery cable at battery.

(2) Remove air filter resonator at throttle body.

The accelerator cable must be partially removed to

gain access to speed control cable.

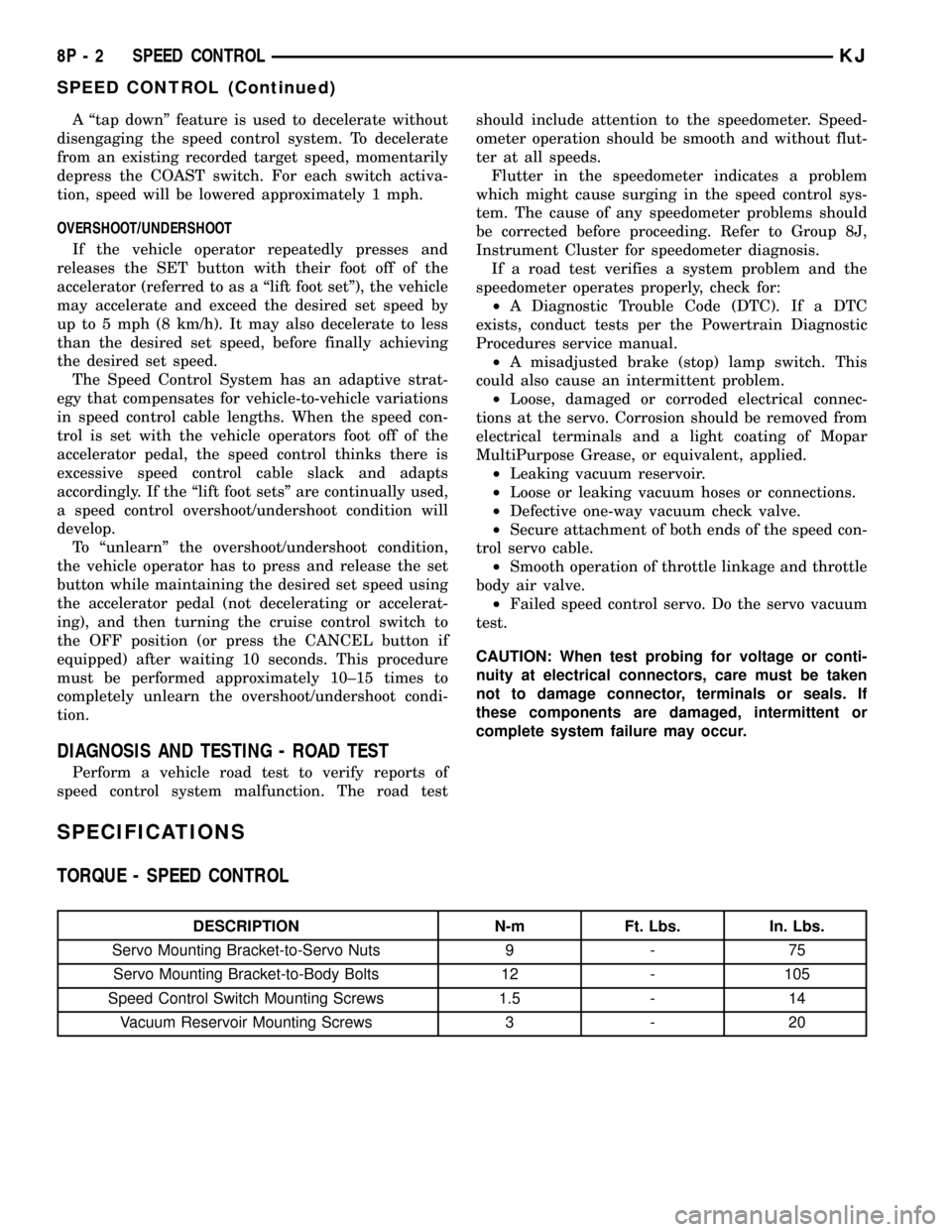

(3) Hold throttle in wide open position. While held

in this position, slide throttle cable pin (Fig. 1) from

throttle body bellcrank.

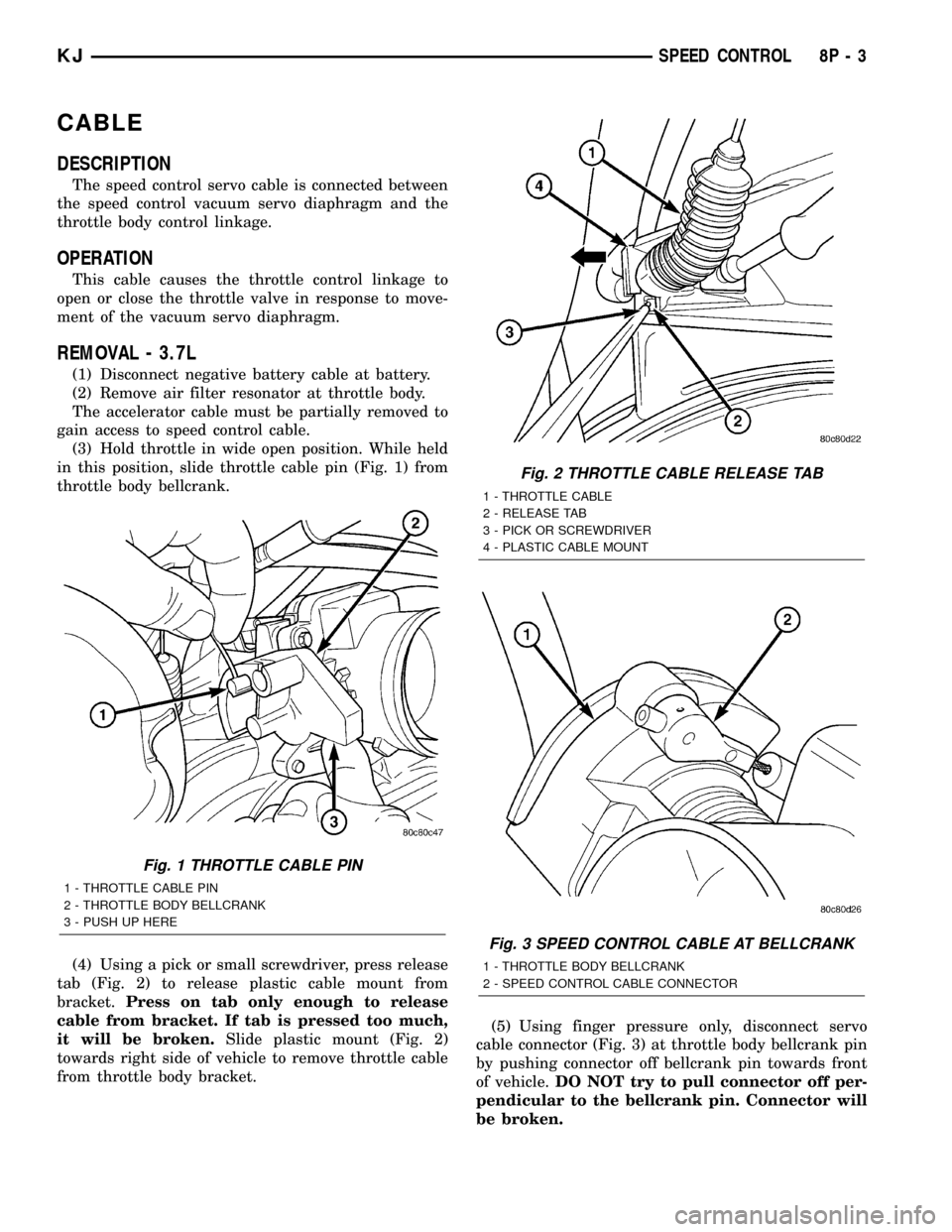

(4) Using a pick or small screwdriver, press release

tab (Fig. 2) to release plastic cable mount from

bracket.Press on tab only enough to release

cable from bracket. If tab is pressed too much,

it will be broken.Slide plastic mount (Fig. 2)

towards right side of vehicle to remove throttle cable

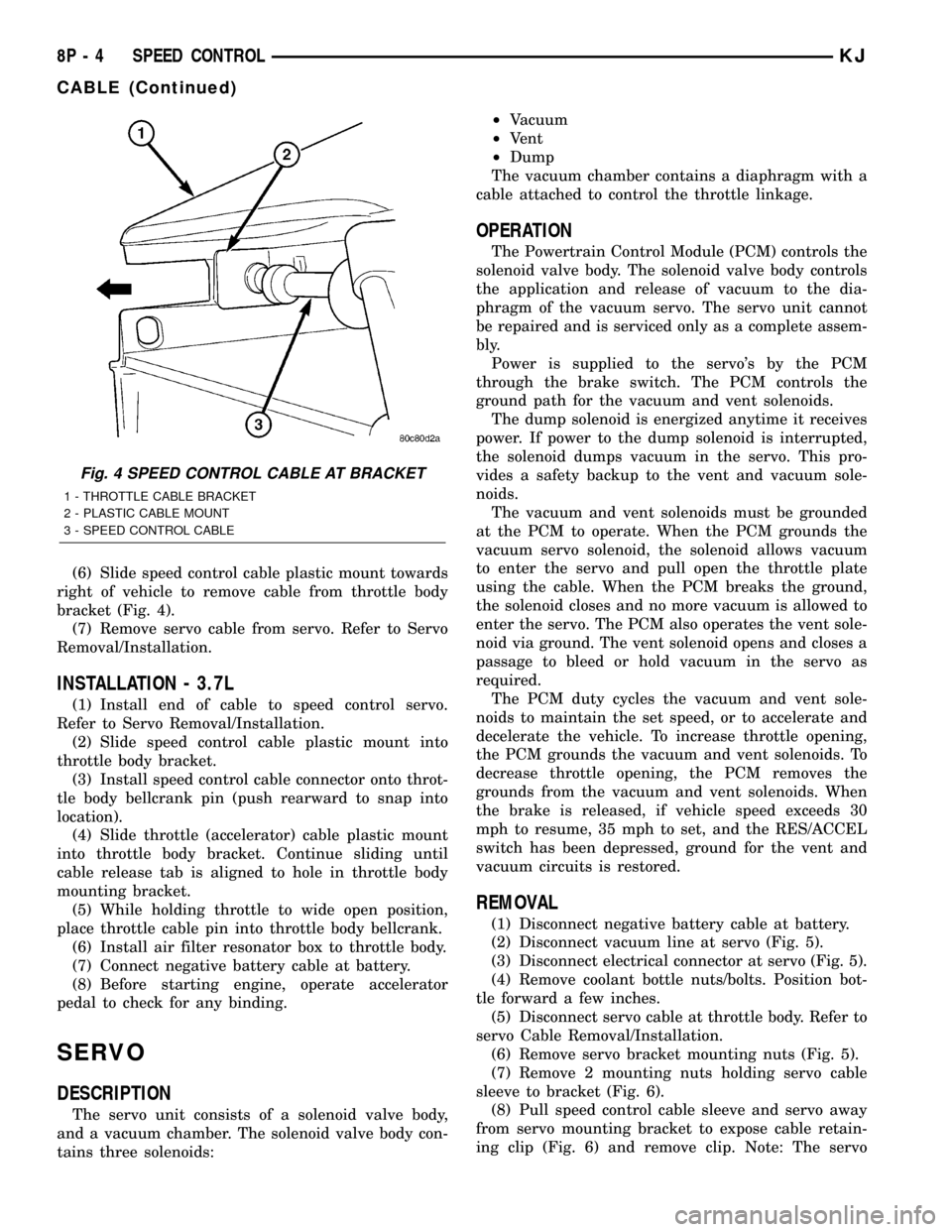

from throttle body bracket.(5) Using finger pressure only, disconnect servo

cable connector (Fig. 3) at throttle body bellcrank pin

by pushing connector off bellcrank pin towards front

of vehicle.DO NOT try to pull connector off per-

pendicular to the bellcrank pin. Connector will

be broken.

Fig. 1 THROTTLE CABLE PIN

1 - THROTTLE CABLE PIN

2 - THROTTLE BODY BELLCRANK

3 - PUSH UP HERE

Fig. 2 THROTTLE CABLE RELEASE TAB

1 - THROTTLE CABLE

2 - RELEASE TAB

3 - PICK OR SCREWDRIVER

4 - PLASTIC CABLE MOUNT

Fig. 3 SPEED CONTROL CABLE AT BELLCRANK

1 - THROTTLE BODY BELLCRANK

2 - SPEED CONTROL CABLE CONNECTOR

KJSPEED CONTROL 8P - 3

Page 677 of 1803

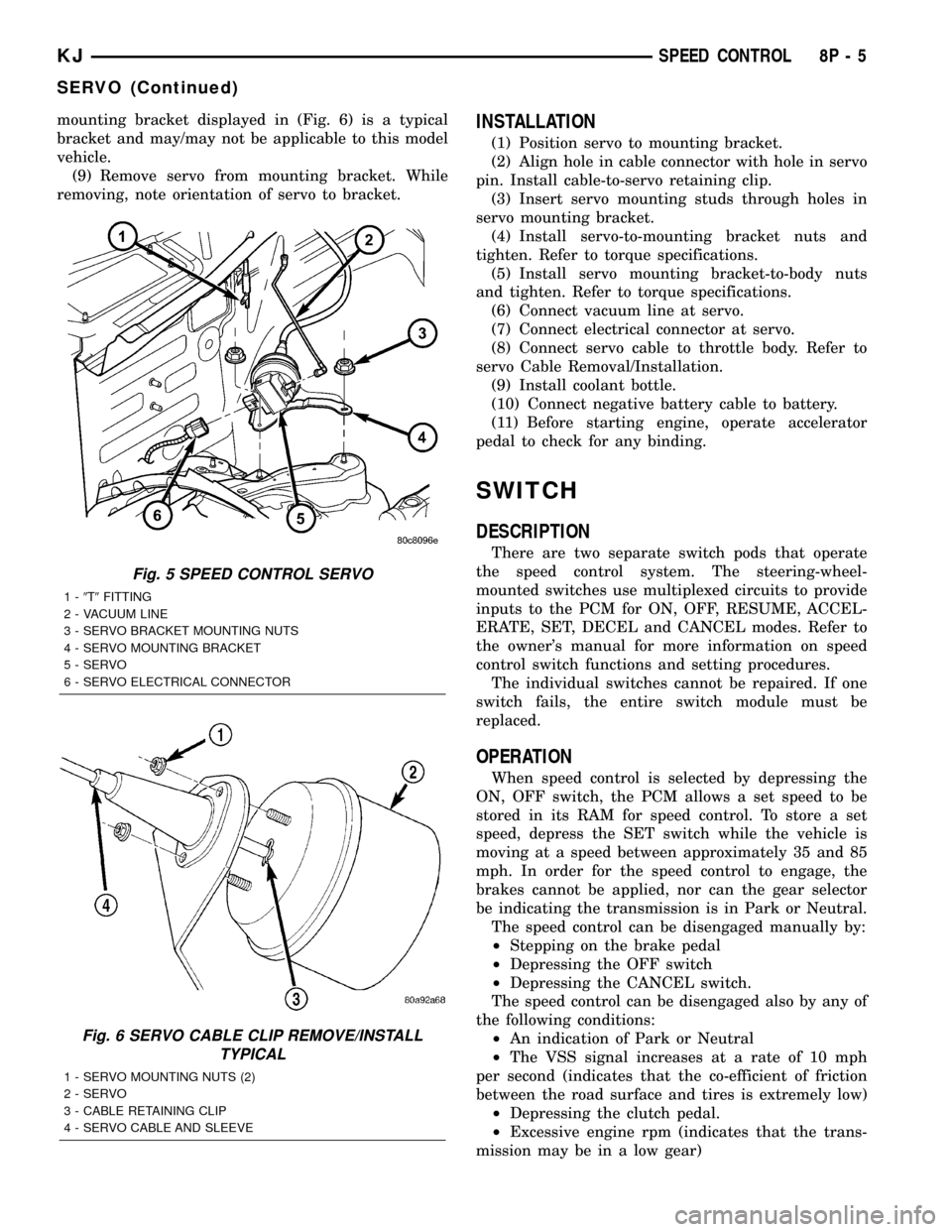

(6) Slide speed control cable plastic mount towards

right of vehicle to remove cable from throttle body

bracket (Fig. 4).

(7) Remove servo cable from servo. Refer to Servo

Removal/Installation.

INSTALLATION - 3.7L

(1) Install end of cable to speed control servo.

Refer to Servo Removal/Installation.

(2) Slide speed control cable plastic mount into

throttle body bracket.

(3) Install speed control cable connector onto throt-

tle body bellcrank pin (push rearward to snap into

location).

(4) Slide throttle (accelerator) cable plastic mount

into throttle body bracket. Continue sliding until

cable release tab is aligned to hole in throttle body

mounting bracket.

(5) While holding throttle to wide open position,

place throttle cable pin into throttle body bellcrank.

(6) Install air filter resonator box to throttle body.

(7) Connect negative battery cable at battery.

(8) Before starting engine, operate accelerator

pedal to check for any binding.

SERVO

DESCRIPTION

The servo unit consists of a solenoid valve body,

and a vacuum chamber. The solenoid valve body con-

tains three solenoids:²Vacuum

²Vent

²Dump

The vacuum chamber contains a diaphragm with a

cable attached to control the throttle linkage.

OPERATION

The Powertrain Control Module (PCM) controls the

solenoid valve body. The solenoid valve body controls

the application and release of vacuum to the dia-

phragm of the vacuum servo. The servo unit cannot

be repaired and is serviced only as a complete assem-

bly.

Power is supplied to the servo's by the PCM

through the brake switch. The PCM controls the

ground path for the vacuum and vent solenoids.

The dump solenoid is energized anytime it receives

power. If power to the dump solenoid is interrupted,

the solenoid dumps vacuum in the servo. This pro-

vides a safety backup to the vent and vacuum sole-

noids.

The vacuum and vent solenoids must be grounded

at the PCM to operate. When the PCM grounds the

vacuum servo solenoid, the solenoid allows vacuum

to enter the servo and pull open the throttle plate

using the cable. When the PCM breaks the ground,

the solenoid closes and no more vacuum is allowed to

enter the servo. The PCM also operates the vent sole-

noid via ground. The vent solenoid opens and closes a

passage to bleed or hold vacuum in the servo as

required.

The PCM duty cycles the vacuum and vent sole-

noids to maintain the set speed, or to accelerate and

decelerate the vehicle. To increase throttle opening,

the PCM grounds the vacuum and vent solenoids. To

decrease throttle opening, the PCM removes the

grounds from the vacuum and vent solenoids. When

the brake is released, if vehicle speed exceeds 30

mph to resume, 35 mph to set, and the RES/ACCEL

switch has been depressed, ground for the vent and

vacuum circuits is restored.

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Disconnect vacuum line at servo (Fig. 5).

(3) Disconnect electrical connector at servo (Fig. 5).

(4) Remove coolant bottle nuts/bolts. Position bot-

tle forward a few inches.

(5) Disconnect servo cable at throttle body. Refer to

servo Cable Removal/Installation.

(6) Remove servo bracket mounting nuts (Fig. 5).

(7) Remove 2 mounting nuts holding servo cable

sleeve to bracket (Fig. 6).

(8) Pull speed control cable sleeve and servo away

from servo mounting bracket to expose cable retain-

ing clip (Fig. 6) and remove clip. Note: The servo

Fig. 4 SPEED CONTROL CABLE AT BRACKET

1 - THROTTLE CABLE BRACKET

2 - PLASTIC CABLE MOUNT

3 - SPEED CONTROL CABLE

8P - 4 SPEED CONTROLKJ

CABLE (Continued)

Page 678 of 1803

mounting bracket displayed in (Fig. 6) is a typical

bracket and may/may not be applicable to this model

vehicle.

(9) Remove servo from mounting bracket. While

removing, note orientation of servo to bracket.INSTALLATION

(1) Position servo to mounting bracket.

(2) Align hole in cable connector with hole in servo

pin. Install cable-to-servo retaining clip.

(3) Insert servo mounting studs through holes in

servo mounting bracket.

(4) Install servo-to-mounting bracket nuts and

tighten. Refer to torque specifications.

(5) Install servo mounting bracket-to-body nuts

and tighten. Refer to torque specifications.

(6) Connect vacuum line at servo.

(7) Connect electrical connector at servo.

(8) Connect servo cable to throttle body. Refer to

servo Cable Removal/Installation.

(9) Install coolant bottle.

(10) Connect negative battery cable to battery.

(11) Before starting engine, operate accelerator

pedal to check for any binding.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system. The steering-wheel-

mounted switches use multiplexed circuits to provide

inputs to the PCM for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

OPERATION

When speed control is selected by depressing the

ON, OFF switch, the PCM allows a set speed to be

stored in its RAM for speed control. To store a set

speed, depress the SET switch while the vehicle is

moving at a speed between approximately 35 and 85

mph. In order for the speed control to engage, the

brakes cannot be applied, nor can the gear selector

be indicating the transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal.

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

Fig. 5 SPEED CONTROL SERVO

1-9T9FITTING

2 - VACUUM LINE

3 - SERVO BRACKET MOUNTING NUTS

4 - SERVO MOUNTING BRACKET

5 - SERVO

6 - SERVO ELECTRICAL CONNECTOR

Fig. 6 SERVO CABLE CLIP REMOVE/INSTALL

TYPICAL

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

KJSPEED CONTROL 8P - 5

SERVO (Continued)

Page 683 of 1803

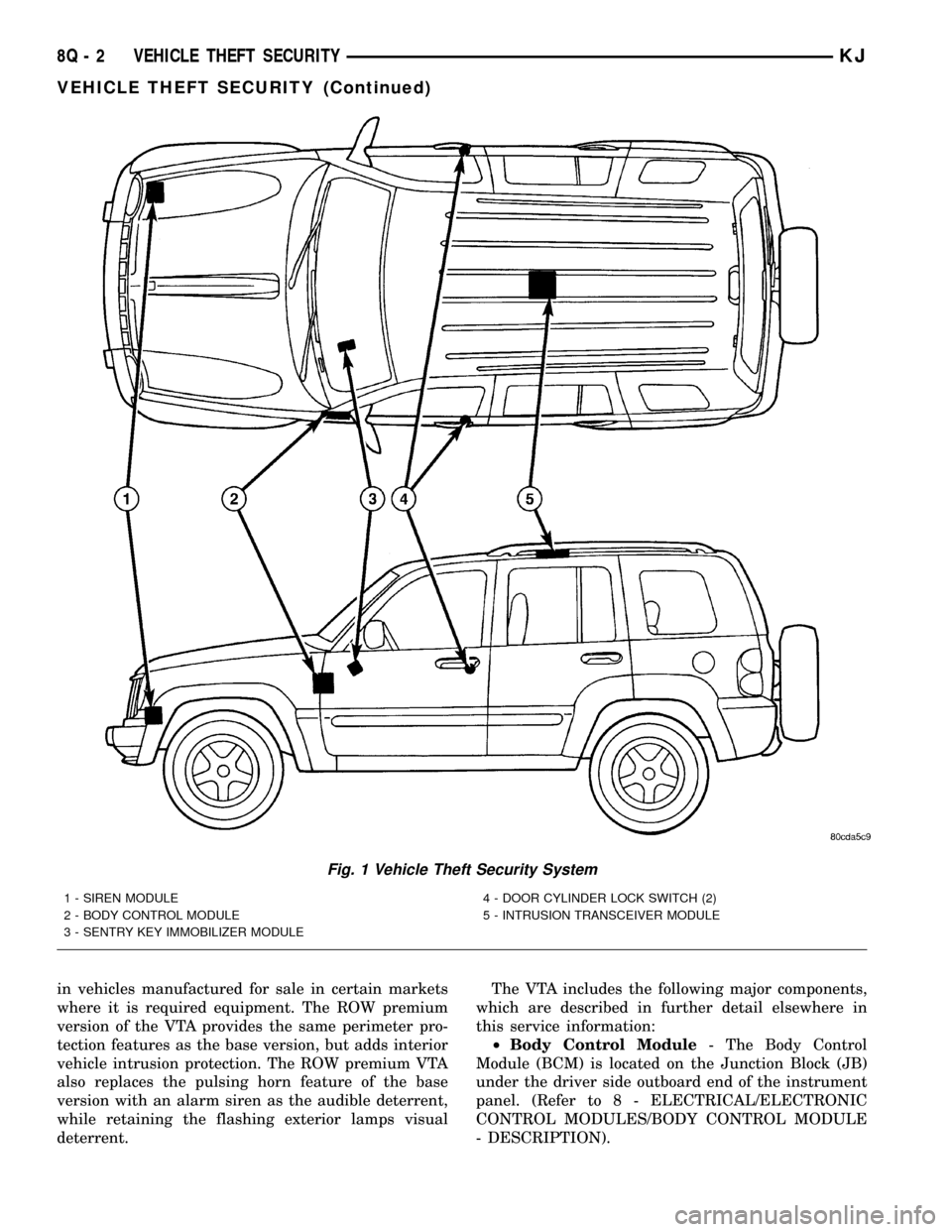

in vehicles manufactured for sale in certain markets

where it is required equipment. The ROW premium

version of the VTA provides the same perimeter pro-

tection features as the base version, but adds interior

vehicle intrusion protection. The ROW premium VTA

also replaces the pulsing horn feature of the base

version with an alarm siren as the audible deterrent,

while retaining the flashing exterior lamps visual

deterrent.The VTA includes the following major components,

which are described in further detail elsewhere in

this service information:

²Body Control Module- The Body Control

Module (BCM) is located on the Junction Block (JB)

under the driver side outboard end of the instrument

panel. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/BODY CONTROL MODULE

- DESCRIPTION).

Fig. 1 Vehicle Theft Security System

1 - SIREN MODULE

2 - BODY CONTROL MODULE

3 - SENTRY KEY IMMOBILIZER MODULE4 - DOOR CYLINDER LOCK SWITCH (2)

5 - INTRUSION TRANSCEIVER MODULE

8Q - 2 VEHICLE THEFT SECURITYKJ

VEHICLE THEFT SECURITY (Continued)

Page 684 of 1803

²Combination Flasher- An electronic combina-

tion flasher is integral to the hazard switch located

in the center of the instrument panel above the

radio. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/COMBINATION FLASHER -

DESCRIPTION).

²Door Ajar Switch- A door ajar switch is inte-

gral to the latch of each door in the vehicle. (Refer to

8 - ELECTRICAL/LAMPS/LIGHTING - INTERIOR/

DOOR AJAR SWITCH - DESCRIPTION).

²Door Cylinder Lock Switch- For North

American vehicles only, a door cylinder lock switch is

located on the back of the lock cylinder of each front

door. (Refer to 8 - ELECTRICAL/VEHICLE THEFT

SECURITY/DOOR CYLINDER LOCK SWITCH -

DESCRIPTION).

²Flip-Up Glass Ajar Switch- A flip-up glass

ajar switch is integral to the rear flip-up glass latch,

located on the top of the tailgate near the center.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/FLIP-UP GLASS AJAR SWITCH -

DESCRIPTION).

²Hood Ajar Switch- A hood ajar switch is

located beneath the hood panel on the right inner

fender side shield of vehicles built for sale in certain

markets where it is required equipment. (Refer to 8 -

ELECTRICAL/VEHICLE THEFT SECURITY/HOOD

AJAR SWITCH - DESCRIPTION).

²Horn Relay- A horn relay is located on the

Junction Block (JB) under the driver side outboard

end of the instrument panel. (Refer to 8 - ELECTRI-

CAL/HORN/HORN RELAY - DESCRIPTION).

²Intrusion Transceiver Module- An Intrusion

Transceiver Module (ITM) is located near the center

of the headliner in the passenger compartment of

vehicles built for sale in certain markets where it is

required equipment. (Refer to 8 - ELECTRICAL/VE-

HICLE THEFT SECURITY/UK SECURITY SYSTEM

MODULE - DESCRIPTION).

²Security Indicator- A security indicator is

located in the ElectroMechanical Instrument Cluster

(EMIC) on the instrument panel in front of the driver

side front seat. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER/SECURITY INDICATOR -

DESCRIPTION).

²Siren- An alarm siren is located on the front

extension of the right front wheel house panel in the

engine compartment of vehicles built for sale in cer-

tain markets where it is required equipment. (Refer

to 8 - ELECTRICAL/VEHICLE THEFT SECURITY/

SIREN - DESCRIPTION).

²Tailgate Ajar Switch- A tailgate ajar switch is

integral to the latch for the tailgate in the vehicle.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/TAILGATE AJAR SWITCH - DESCRIP-

TION).SENTRY KEY IMMOBILIZER SYSTEM The Sen-

try Key Immobilizer System (SKIS) is available as a

factory-installed option on this model. Vehicles

equipped with the Vehicle Theft Alarm (VTA) are also

equipped with SKIS. The SKIS provides passive vehi-

cle protection by preventing the engine from operat-

ing unless a valid electronically encoded key is

detected in the ignition lock cylinder. The SKIS

includes the following major components, which are

described in further detail elsewhere in this service

information:

²Powertrain Control Module- The Powertrain

Control Module (PCM) is located on the left inner

fender shield in the engine compartment near the

dash panel. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/POWERTRAIN

CONTROL MODULE - DESCRIPTION).

²Sentry Key Immobilizer Module- The Sentry

Key Immobilizer Module (SKIM) is located beneath

the steering column shrouds on the right side of the

steering column near the ignition lock cylinder hous-

ing. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/SENTRY KEY IMMOBILIZER

MODULE - DESCRIPTION).

²Sentry Key Transponder- The Sentry Key

transponder is molded into the head of the ignition

key, and concealed by a gray molded rubber cap.

(Refer to 8 - ELECTRICAL/VEHICLE THEFT SECU-

RITY/TRANSPONDER KEY - DESCRIPTION).

²SKIS Indicator- The SKIS indicator is located

in the ElectroMechanical Instrument Cluster (EMIC)

on the instrument panel in front of the driver side

front seat. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER/SPEED CONTROL INDICATOR -

DESCRIPTION).

OPERATION

The Vehicle Theft Security System (VTSS) is

divided into two basic subsystems: Vehicle Theft

Alarm (VTA) and Sentry Key Immobilizer System

(SKIS). Following are paragraphs that briefly

describe the operation of each of these two sub-

systems.

VEHICLE THEFT ALARM The Body Control Mod-

ule (BCM) is used on this model to control and inte-

grate many of the electronic functions and features

included in the Vehicle Theft Alarm (VTA). The BCM

receives hard wired inputs indicating the status of

the door ajar switches, the door cylinder lock

switches, the ignition switch, the tailgate ajar switch,

the tailgate cylinder lock switch, the flip-up glass

ajar switch, the power lock switches and, in vehicles

built for certain markets where it is required, the

hood ajar switch. The programming in the BCM

allows it to process the information from all of these

inputs and send control outputs to energize or de-en-

KJVEHICLE THEFT SECURITY 8Q - 3

VEHICLE THEFT SECURITY (Continued)

Page 685 of 1803

ergize the combination flasher, the horn relay (except

vehicles with the Rest-Of-World or ROW premium

version of the VTA), and the security indicator. In

addition, in vehicles built for certain markets where

the ROW premium version of the VTA is required,

the BCM also exchanges electronic messages with

the Intrusion Transceiver Module (ITM) over the Pro-

grammable Communications Interface (PCI) data bus

network to provide the features found in this version

of the VTA.

The hard wired circuits and components of the

VTA may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods may not prove conclusive

in the diagnosis of the Body Control Module (BCM),

the ElectroMechanical Instrument Cluster (EMIC),

the Intrusion Transceiver Module (ITM), or the Pro-

grammable Communications Interface (PCI) data bus

network. The most reliable, efficient, and accurate

means to diagnose the BCM, the EMIC, the ITM,

and the PCI data bus network inputs and outputs

related to the VTA requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Following are paragraphs that briefly

describe the operation of each of the VTA features.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the VTA.

²ENABLING- The BCM must have the VTA

function electronically enabled in order for the VTA

to perform as designed. The logic in the BCM keeps

its VTA function dormant until it is enabled using a

DRBIIItscan tool. The VTA function of the BCM is

enabled on vehicles equipped with the VTA option at

the factory, but a service replacement BCM must be

VTA-enabled by the dealer using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

²PRE-ARMING- The VTA has a pre-arming

sequence. Pre-arming occurs when a door, the tail-

gate, or the flip-up glass is open when the vehicle is

locked using a power lock switch, or when the ªLockº

button on the Remote Keyless Entry (RKE) transmit-

ter is depressed. The power lock switch will not ini-

tiate the pre-arming sequence if the key is in the

ignition switch. When the VTA is pre-armed, the

arming sequence is delayed until all of the doors, the

tailgate, and the flip-up glass are closed.

²ARMING- Passive arming of the VTA occurs

when the vehicle is exited with the key removed from

the ignition switch and the doors are locked while

they are open using the power lock switch (see Pre-

Arming). Active arming of the VTA occurs when the

ªLockº button on the Remote Keyless Entry (RKE)

transmitter is depressed to lock the vehicle after all

of the doors, the tailgate, and the flip-up glass are

closed. The VTA will not arm if the doors are lockedusing the key in a lock cylinder or using a mechani-

cal lock button. Once the VTA begins the passive or

active arming sequence, the security indicator in the

instrument cluster will flash rapidly for about six-

teen seconds. This indicates that the VTA arming

sequence is in progress. If the ignition switch is

turned to the On position, if a door is unlocked with

the power lock switch or the RKE transmitter, or if

the tailgate is unlocked by any means during the six-

teen second arming sequence, the security indicator

will stop flashing and the VTA arming sequence will

abort. On vehicles equipped with the hood ajar

switch, the VTA arming sequence will occur regard-

less of whether the hood is open or closed, but the

underhood area will not be protected unless the hood

is closed when the VTA arming sequence begins.

Also, if the status of the hood ajar switch changes

from open (hood closed) to closed (hood open) during

the sixteen second arming sequence, the security

indicator will stop flashing and the VTA arming

sequence will abort. Once the sixteen second arming

sequence is successfully completed, the security indi-

cator will flash at a slower rate, indicating that the

VTA is armed.

²DISARMING- For vehicles built for the North

American market, disarming of the VTA occurs when

the vehicle is unlocked using the key to unlock a door

or the tailgate. Disarming of the VTA for any market

also occurs when the vehicle is unlocked by depress-

ing the ªUnlockº button of the Remote Keyless Entry

(RKE) transmitter, or by turning the ignition switch

to the On position using a valid Sentry Key Immobi-

lizer System (SKIS) key. Once the alarm has been

activated, any of these disarming methods will also

deactivate the alarm.

²POWER-UP MODE- When the armed VTA

senses that the battery has been disconnected and

reconnected, it enters its power-up mode. In the pow-

er-up mode the alarm system returns to the mode

that was last selected prior to the battery failure or

disconnect. If the VTA was armed prior to the battery

disconnect or failure, the technician or vehicle opera-

tor will have to actively or passively disarm the sys-

tem after the battery is reconnected. The power-up

mode will also apply if the battery goes dead while

the system is armed, and battery jump-starting is

then attempted. The VTA will remain armed until

the technician or vehicle operator has actively or pas-

sively disarmed the system. If the VTA is in the dis-

armed mode prior to a battery disconnect or failure,

it will remain disarmed after the battery is recon-

nected or replaced, or if jump-starting is attempted.

²ALARM- The VTA alarm output varies by the

version of the VTA with which the vehicle is

equipped. In all cases, the alarm provides both visual

and audible outputs; however, the time intervals of

8Q - 4 VEHICLE THEFT SECURITYKJ

VEHICLE THEFT SECURITY (Continued)

Page 687 of 1803

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

divided into two basic subsystems: Vehicle Theft

Alarm (VTA) and Sentry Key Immobilizer System

(SKIS). Following are the recommended procedures

for diagnosis and testing of each of these two sub-

systems.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

VEHICLE THEFT ALARM

Models equipped with the Rest-Of-World (ROW)

premium version of the Vehicle Theft Alarm (VTA)

provide some preliminary diagnostic feedback by illu-minating the security indicator located in the Elec-

troMechanical Instrument Cluster (EMIC). If the

security indicator illuminates with the ignition

switch in the On position, it indicates that there is a

communication problem between the Intrusion

Transceiver Module (ITM) and the Body Control

Module (BCM), or between the ITM and the siren

module. The BCM will also turn on the security indi-

cator if it receives a message from the ITM indicating

that the ITM has stored a Diagnostic Trouble Code

(DTC) for a siren module fault.

The hard wired circuits and components of the

VTA may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods may not prove conclusive

in the diagnosis of the Body Control Module (BCM),

the ElectroMechanical Instrument Cluster (EMIC),

the Intrusion Transceiver Module (ITM), or the Pro-

grammable Communications Interface (PCI) data bus

network. The most reliable, efficient, and accurate

means to diagnose the BCM, the EMIC, the ITM,

and the PCI data bus network inputs and outputs

related to the VTA requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

8Q - 6 VEHICLE THEFT SECURITYKJ

VEHICLE THEFT SECURITY (Continued)

Page 691 of 1803

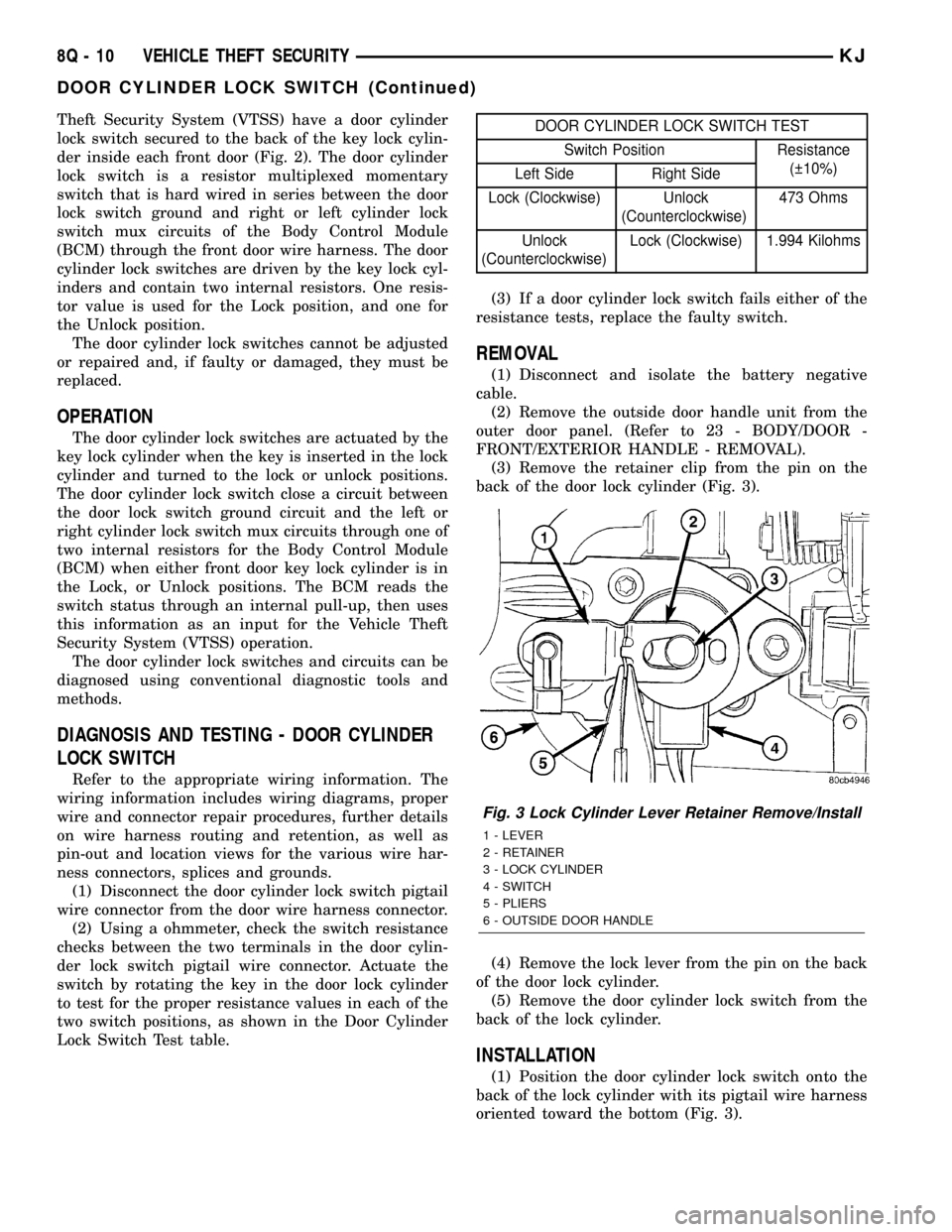

Theft Security System (VTSS) have a door cylinder

lock switch secured to the back of the key lock cylin-

der inside each front door (Fig. 2). The door cylinder

lock switch is a resistor multiplexed momentary

switch that is hard wired in series between the door

lock switch ground and right or left cylinder lock

switch mux circuits of the Body Control Module

(BCM) through the front door wire harness. The door

cylinder lock switches are driven by the key lock cyl-

inders and contain two internal resistors. One resis-

tor value is used for the Lock position, and one for

the Unlock position.

The door cylinder lock switches cannot be adjusted

or repaired and, if faulty or damaged, they must be

replaced.

OPERATION

The door cylinder lock switches are actuated by the

key lock cylinder when the key is inserted in the lock

cylinder and turned to the lock or unlock positions.

The door cylinder lock switch close a circuit between

the door lock switch ground circuit and the left or

right cylinder lock switch mux circuits through one of

two internal resistors for the Body Control Module

(BCM) when either front door key lock cylinder is in

the Lock, or Unlock positions. The BCM reads the

switch status through an internal pull-up, then uses

this information as an input for the Vehicle Theft

Security System (VTSS) operation.

The door cylinder lock switches and circuits can be

diagnosed using conventional diagnostic tools and

methods.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

(1) Disconnect the door cylinder lock switch pigtail

wire connector from the door wire harness connector.

(2) Using a ohmmeter, check the switch resistance

checks between the two terminals in the door cylin-

der lock switch pigtail wire connector. Actuate the

switch by rotating the key in the door lock cylinder

to test for the proper resistance values in each of the

two switch positions, as shown in the Door Cylinder

Lock Switch Test table.

DOOR CYLINDER LOCK SWITCH TEST

Switch Position Resistance

( 10%)

Left Side Right Side

Lock (Clockwise) Unlock

(Counterclockwise)473 Ohms

Unlock

(Counterclockwise)Lock (Clockwise) 1.994 Kilohms

(3) If a door cylinder lock switch fails either of the

resistance tests, replace the faulty switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the outside door handle unit from the

outer door panel. (Refer to 23 - BODY/DOOR -

FRONT/EXTERIOR HANDLE - REMOVAL).

(3) Remove the retainer clip from the pin on the

back of the door lock cylinder (Fig. 3).

(4) Remove the lock lever from the pin on the back

of the door lock cylinder.

(5) Remove the door cylinder lock switch from the

back of the lock cylinder.

INSTALLATION

(1) Position the door cylinder lock switch onto the

back of the lock cylinder with its pigtail wire harness

oriented toward the bottom (Fig. 3).

Fig. 3 Lock Cylinder Lever Retainer Remove/Install

1 - LEVER

2 - RETAINER

3 - LOCK CYLINDER

4 - SWITCH

5 - PLIERS

6 - OUTSIDE DOOR HANDLE

8Q - 10 VEHICLE THEFT SECURITYKJ

DOOR CYLINDER LOCK SWITCH (Continued)

Page 692 of 1803

(2) Position the lock lever onto the pin on the back

of the door lock cylinder with the lever oriented

toward the rear.

(3) Install the retainer clip onto the pin on the

back of the door lock cylinder. Be certain that the

center tab of the retainer is engaged in the retention

hole on the lock lever.

(4) Reinstall the outside door handle unit onto the

outer door panel. (Refer to 23 - BODY/DOOR -

FRONT/EXTERIOR HANDLE - INSTALLATION).

(5) Reconnect the battery negative cable.

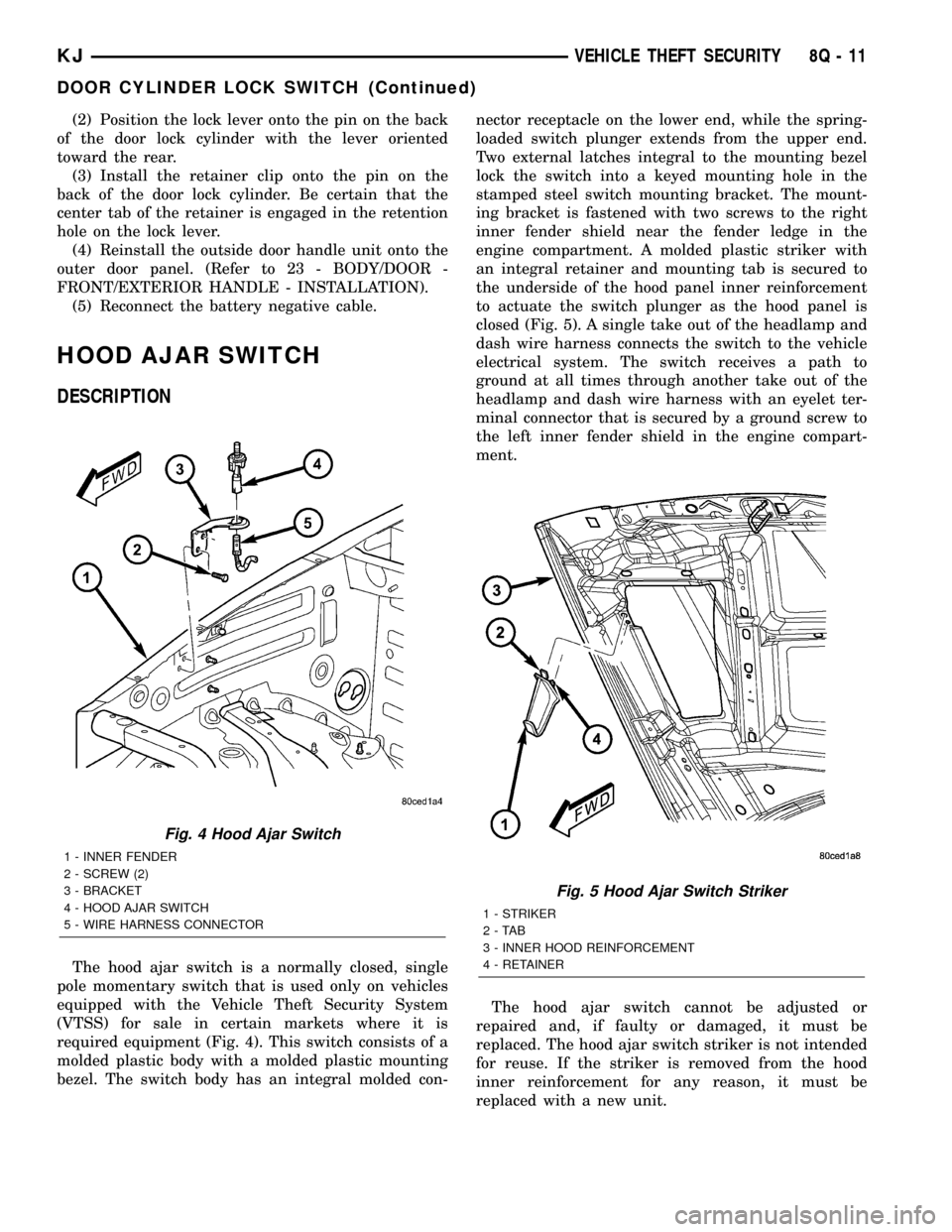

HOOD AJAR SWITCH

DESCRIPTION

The hood ajar switch is a normally closed, single

pole momentary switch that is used only on vehicles

equipped with the Vehicle Theft Security System

(VTSS) for sale in certain markets where it is

required equipment (Fig. 4). This switch consists of a

molded plastic body with a molded plastic mounting

bezel. The switch body has an integral molded con-nector receptacle on the lower end, while the spring-

loaded switch plunger extends from the upper end.

Two external latches integral to the mounting bezel

lock the switch into a keyed mounting hole in the

stamped steel switch mounting bracket. The mount-

ing bracket is fastened with two screws to the right

inner fender shield near the fender ledge in the

engine compartment. A molded plastic striker with

an integral retainer and mounting tab is secured to

the underside of the hood panel inner reinforcement

to actuate the switch plunger as the hood panel is

closed (Fig. 5). A single take out of the headlamp and

dash wire harness connects the switch to the vehicle

electrical system. The switch receives a path to

ground at all times through another take out of the

headlamp and dash wire harness with an eyelet ter-

minal connector that is secured by a ground screw to

the left inner fender shield in the engine compart-

ment.

The hood ajar switch cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced. The hood ajar switch striker is not intended

for reuse. If the striker is removed from the hood

inner reinforcement for any reason, it must be

replaced with a new unit.

Fig. 4 Hood Ajar Switch

1 - INNER FENDER

2 - SCREW (2)

3 - BRACKET

4 - HOOD AJAR SWITCH

5 - WIRE HARNESS CONNECTOR

Fig. 5 Hood Ajar Switch Striker

1 - STRIKER

2-TAB

3 - INNER HOOD REINFORCEMENT

4 - RETAINER

KJVEHICLE THEFT SECURITY 8Q - 11

DOOR CYLINDER LOCK SWITCH (Continued)