PCM JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 298 of 1803

ever occurs first. The overspeed warning feature is

only enabled on a BCM that has been programmed

with a Middle East Gulf Coast Country (GCC) coun-

try code.

²No Airbag Indicator Message Warning- The

EMIC chime tone generator will generate one, short,

ªbong-likeº chime tone and turn on the ªAirbagº indi-

cator when the ignition switch is in the On position,

and a PCI data bus ªAirbagº indicator on or off mes-

sage is not received from the ACM for six consecutive

seconds.

²No Antilock Brake Indicator Message Warn-

ing- The EMIC chime tone generator will generate

one, short, ªbong-likeº chime tone and turn on the

ªABSº indicator when the ignition switch is in the On

position, and a PCI data bus ªABSº indicator on or

off message is not received from the CAB for six con-

secutive seconds.

²No Fuel Level Message Warning- The EMIC

chime tone generator will generate one, short, ªbong-

likeº chime tone and turn on the ªLow Fuelº indica-

tor when the ignition switch is in the On position,

and a PCI data bus fuel level message is not received

from the PCM for twelve consecutive seconds.

²Remote Keyless Entry Transmitter Pro-

gramming- On vehicles so equipped, the EMIC

chime tone generator will generate a single ªbong-

likeº chime tone when an electronic message is

received over the PCI data bus from the BCM indi-

cating that a Remote Keyless Entry (RKE) transmit-

ter has been successfully programmed by the

customer into the RKE module memory.

²Sentry Key Immobilizer System Transpon-

der Programming- On vehicles so equipped, the

EMIC chime tone generator will generate a single

ªbong-likeº chime tone when an electronic message is

received over PCI data bus message from the Sentry

Key Immobilizer Module (SKIM) indicating that the

Sentry Key Immobilizer System (SKIS) has been

placed in the ªCustomer Learnº programming mode,

and again each time a new SKIS transponder has

been successfully programmed by the customer.

²Turn Signal Cancel Warning- The EMIC

chime tone generator will generate repetitive ªbong-

likeº chime tones at a slow rate when the vehicle is

driven for a distance of about 3.2 kilometers (about

two miles) with a turn signal indicator flashing. The

EMIC uses an electronic message received over the

PCI data bus from the PCM, and a hard wired input

from the turn signal switch circuitry of the multi-

function switch to determine when to sound the turn

signal cancel warning. The PCM uses internal pro-

gramming and distance pulse information received

over a hard wired vehicle speed pulse input from the

BCM to determine the proper vehicle speed messages

to send to the EMIC. The BCM uses an internallyprogrammed electronic pinion factor and a hard

wired input from the rear wheel speed sensor to cal-

culate the proper distance pulse information to send

to the PCM. The electronic pinion factor represents

the proper tire size and axle ratio information for the

vehicle. These chimes will continue to sound until

the turn signal is turned Off, until the hazard warn-

ing system is turned On, or until the ignition switch

is turned to the Off position, whichever occurs first.

²Water-In-Fuel Warning- On vehicles equipped

with a diesel engine, each time the ignition switch is

turned to the On position, the EMIC chime tone gen-

erator will generate a single ªbong-likeº chime tone

the first time an electronic message is received over

the PCI data bus from the PCM requesting ªWater-

in-Fuelº indicator illumination. The PCM uses inter-

nal programming and a hard wired input from the

water-in-fuel sensor to determine the proper water-

in-fuel messages to send to the EMIC. This warning

will only occur once during an ignition cycle.

The EMIC provides chime service for all available

features in the chime warning system. The EMIC

relies upon its internal programming and hard wired

inputs from the turn signal (multi-function) switch,

the washer fluid level switch, and the engine coolant

level sensor (diesel engine only) to provide chime ser-

vice for the turn signal cancel warning, the low

washer fluid warning, and the low coolant warning

respectively. The EMIC relies upon electronic mes-

sage inputs received from other electronic modules

over the PCI data bus network to provide chime ser-

vice for all of the remaining chime warning system

features. Upon receiving the proper inputs, the EMIC

activates the integral chime tone generator to pro-

vide the audible chime warning to the vehicle opera-

tor. The internal programming of the EMIC

determines the priority of each chime request input

that is received, as well as the rate and duration of

each chime tone that is to be generated. See the own-

er's manual in the vehicle glove box for more infor-

mation on the features provided by the chime

warning system.

The hard wired chime warning system inputs to

the EMIC, as well as other hard wired circuits for

this system may be diagnosed and tested using con-

ventional diagnostic tools and procedures. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the EMIC, the PCI data

bus network, or the electronic message inputs used

by the EMIC to provide chime warning system ser-

vice. The most reliable, efficient, and accurate means

to diagnose the EMIC, the PCI data bus network,

and the electronic message inputs for the chime

warning system requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

KJCHIME/BUZZER 8B - 5

CHIME WARNING SYSTEM (Continued)

Page 300 of 1803

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................1

BODY CONTROL MODULE

DESCRIPTION..........................2

OPERATION............................5

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE.............................7

REMOVAL.............................7

INSTALLATION..........................7

COMMUNICATION

DESCRIPTION..........................8

OPERATION............................8

CONTROLLER ANTILOCK BRAKE

REMOVAL.............................10

INSTALLATION.........................10

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR....10

OPERATION - DATA LINK CONNECTOR......10

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION - PCM..................11

DESCRIPTION - MODES OF OPERATION . . . 11

DESCRIPTION - 5 VOLT SUPPLIES.......13

DESCRIPTION - IGNITION CIRCUIT SENSE . 13DESCRIPTION - POWER GROUNDS......13

DESCRIPTION - SENSOR RETURN.......14

OPERATION

OPERATION - PCM....................14

OPERATION - 5 VOLT SUPPLIES.........15

OPERATION - IGNITION CIRCUIT SENSE . . . 15

REMOVAL.............................15

INSTALLATION.........................15

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................15

OPERATION...........................16

REMOVAL.............................17

INSTALLATION.........................18

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................18

OPERATION...........................18

STANDARD PROCEDURE - TCM QUICK

LEARN..............................21

HEATED SEAT MODULE

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE............................22

REMOVAL.............................24

INSTALLATION.........................24

ELECTRONIC CONTROL

MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: Before replacing the PCM for a failed driver,

control circuit, or ground circuit, be sure to check

the related component/circuit integrity for failures

not detected due to a double fault in the circuit.

Most PCM driver/control circuit failures are caused

by internal component failures (i.e. relays and sole-

noids) and shorted circuits (i.e. pull-ups, drivers,

and switched circuits). These failures are difficult to

detect when a double fault has occurred and only

one DTC has been set.

When a PCM (JTEC) and the SKIM are replaced

at the same time, perform the following steps in

order:

(1) Program the new PCM (JTEC).(2) Program the new SKIM.

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (JTEC)

The SKIS Secret Key is an ID code that is unique

to each SKIM. This code is programmed and stored

in the SKIM, the PCM, and the ignition key tran-

sponder chip(s). When replacing the PCM, it is nec-

essary to program the secret key into the new PCM

using the DRBIIItscan tool. Perform the following

steps to program the secret key into the PCM.

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

KJELECTRONIC CONTROL MODULES 8E - 1

Page 301 of 1803

NOTE: If three attempts are made to enter secured

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition switch to

the ON position for one hour, then enter the correct

PIN. (Ensure all accessories are turned off. Also

monitor the battery state and connect a battery

charger if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press PAGE BACK to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIItwill ask, ªIs odometer reading

between XX and XX?º Select the YES or NO button

on the DRBIIIt. If NO is selected, the DRBIIItwill

read, ªEnter Odometer Reading (From I.P. odome-

ter)º. Enter the odometer reading from the instru-

ment cluster and press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, it cannot be changed and the SKIM must be

replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle ignition keys will need to be

replaced and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

(5) Obtain ignition keys to be programmed from

the customer (8 keys maximum).

(6) Using the DRBIIIt, erase all ignition keys by

selecting MISCELLANEOUS, and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all of the ignition keys.

If ignition key programming is unsuccessful, the

DRBIIItwill display one of the following messages:

²Programming Not Attempted- The DRBIIIt

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

²Programming Key Failed (Possible Used

Key From Wrong Vehicle)- SKIM is unable to pro-

gram an ignition key transponder due to one of the

following:

²The ignition key transponder is faulty.

²The ignition key transponder is or has been

already programmed to another vehicle.

²8 Keys Already Learned, Programming Not

Done- The SKIM transponder ID memory is full.

²Learned Key In Ignition- The ID for the igni-

tion key transponder currently in the ignition lock

cylinder is already programmed in SKIM memory.

BODY CONTROL MODULE

DESCRIPTION

A Body Control Module (BCM) is concealed behind

the driver side end of the instrument panel in the

passenger compartment, where it is secured to the

fuse panel side of the Junction Block (JB) with four

screws (Fig. 1). The JB is the interface between the

body, the instrument panel, and the headlamp and

dash wire harnesses. The JB also contains the fuses

and relays used for the interior electrical system of

the vehicle. The BCM is enclosed in a molded plastic

housing with two integral external connector recepta-

cles that connect it to the vehicle electrical system

through two take outs with connectors from the

instrument panel wire harness (Fig. 2). The BCM

also has an integral interface connector concealed on

the back side of the unit that joins it through a con-

nector receptacle that is integral to the JB housing to

the circuitry within the JB. This connector is referred

to as the JB-BCM connector. The combined BCM and

JB are sometimes referred to as the Junction Block

Module (JBM).

8E - 2 ELECTRONIC CONTROL MODULESKJ

ELECTRONIC CONTROL MODULES (Continued)

Page 303 of 1803

²Fog Lamp Control- The premium BCM pro-

vides fog lamp control for front fog lamps (optional),

and rear fog lamps (in required markets only).

²Front Wiper System Status- The BCM moni-

tors the status of the front wiper motor park switch.

²Fuel Economy and Distance to Empty Cal-

culations- The BCM calculates and transmits the

fuel economy and Distance To Empty (DTE) data.

²Headlamp Time Delay- The BCM provides a

headlamp time delay feature with the ignition switch

in the Off position.

²Heated Rear Glass Control- The BCM pro-

vides control and timer functions for the heated rear

glass feature and transmits the system status.

²Ignition On/Off Timer- The BCM monitors

and transmits the elapsed ignition On timer data

and monitors the ignition Off time.

²Ignition Switch Position Status- The BCM

monitors and transmits the status of the ignition

switch.

²Instrument Panel Dimming- The BCM mon-

itors and transmits the selected illumination inten-

sity level of the panel lamps dimmer switch.

²Interior Lamp Load Shedding- The BCM

provides a battery saver feature which will automat-

ically turn off all interior lamps that remain on after

a timed interval.

²Interior Lighting Control- The BCM moni-

tors inputs from the interior lighting switch, the door

ajar switches, the flip-up glass ajar switch, the tail-

gate ajar switch, the cargo lamp switch, the reading

lamp switches, and the Remote Keyless Entry (RKE)

module to provide courtesy lamp control. This

includes support for timed illuminated entry with

theater-style fade-to-off and courtesy illumination

defeat features.

²Intermittent Wipe and Front Wiper System

Control- The BCM monitors inputs from the front

wiper and washer switch and the front wiper motor

park switch to provide front wiper system control

through the wiper on/off and high/low relays. This

includes support for adjustable intermittent wipe,

mist wipe (also known as pulse wipe), and wipe-after-

wash features.

²Key-In-Ignition Switch Status- The BCM

monitors and transmits the status of the key-in-igni-

tion switch.

²Panic Mode- The BCM provides support for

the Remote Keyless Entry (RKE) system panic mode

feature.

²Parade Mode- The BCM provides a parade

mode (also known as funeral mode) that allows the

interior Vacuum Fluorescent Displays (VFD) to be

illuminated at full intensity while driving in daylight

with the exterior lamps On.²Power Locks- The BCM monitors inputs from

the power lock switches and the Remote Keyless

Entry (RKE) module (optional) to provide control of

the power lock motors through outputs to the lock,

unlock, and driver unlock (RKE only) relays. This

includes support for rolling door locks (also known as

automatic door locks) and a door lock inhibit mode.

²Programmable Features- The BCM provides

support for several standard and optional program-

mable features, including: rolling door locks, head-

lamp time delay interval, Remote Keyless Entry

(RKE) driver-door-only or unlock-all-doors, RKE opti-

cal chirp, and RKE audible chirp.

²Remote Keyless Entry- The premium BCM

provides the optional Remote Keyless Entry (RKE)

system features, including support for the RKE Lock,

Unlock (with optional driver-door-only unlock, and

unlock-all-doors), rear flip-up glass control, Panic,

audible chirp, optical chirp, and illuminated entry

modes, as well as the ability to be programmed to

recognize up to four RKE transmitters.

²Rolling Door Locks- The BCM provides sup-

port for the power lock system rolling door locks fea-

ture (also known as automatic door locks).

²Tailgate and Flip-Up Glass Ajar Status- The

BCM monitors and transmits the status of the tail-

gate and rear flip-up glass ajar switches.

²Remote Radio Switch Interface- The pre-

mium BCM monitors and transmits the status of the

optional remote radio switches.

²Self-Diagnostics- The BCM provides support

for diagnostics through communication with the

DRBIIItscan tool over the PCI data bus network.

Each analog and digital input can be verified, and

each output can be actuated through the use of this

diagnostic protocol. The BCM also stores Diagnostic

Trouble Codes (DTCs) to assist in troubleshooting

this unit.

²Vacuum Fluorescent Display Synchroniza-

tion- The BCM transmits panel lamp intensity data

which allows modules with Vacuum Fluorescent Dis-

plays (VFD) to coordinate their illumination inten-

sity.

²Vehicle Speed System- The BCM monitors a

vehicle speed input from the vehicle speed sensor

(without Antilock Brake System [ABS]) or from the

Controller Antilock Brake (CAB)(with ABS), calcu-

lates the vehicle speed based upon a programmed

axle ratio/tire size (electronic pinion factor), and

transmits the vehicle speed information to the Pow-

ertrain Control Module (PCM) on a hard wired out-

put circuit.

²Vehicle Theft Security System- The pre-

mium BCM monitors inputs from the door cylinder

lock switches, the tailgate cylinder lock switch, the

door ajar switches, the tailgate ajar switch, the

8E - 4 ELECTRONIC CONTROL MODULESKJ

BODY CONTROL MODULE (Continued)

Page 305 of 1803

²RKE antenna (two circuits) - premium with

RKE only

²Tailgate ajar switch sense

²Tailgate cylinder lock switch sense

²Vehicle speed sensor

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS The hard wired outputs

of the BCM include the following:

²Courtesy lamp driver

²Courtesy lamp load shed

²Door lock relay control

²Driver door unlock relay control - premium

with RKE only

²Flip-up glass release motor driver

²Front fog lamp relay control - premium

with front fog lamps only

²Front wiper high/low relay control

²Front wiper on/off relay control

²Hazard lamp control

²High beam relay control

²Horn relay control - premium with RKE

only

²Instrument cluster wake up signal

²Low beam relay control

²Park lamp relay control

²Passenger door unlock relay control

²Rear fog lamp relay control - premium with

rear fog lamps in markets where required only

²Rear window defogger relay control

²RKE supply - premium with RKE only

²Tailgate lock driver

²Tailgate unlock driver

²Vehicle speed output

²Vehicle speed sensor supply

²VTSS indicator driver - premium with

VTSS only

Refer to the appropriate wiring information for

additional details.

GROUNDS The BCM receives ground through five

separate circuits, and also supplies a ground path to

several switches through the following hard wired

circuits:

²Ambient temperature sensor return

²Door lock switch ground

²Headlamp switch return

²Radio control mux return

²RKE ground - premium with RKE only

²Tailgate switch ground

Refer to the appropriate wiring information for

additional details.

COMMUNICATION Not including the two RKE

antenna circuits (RKE antenna + and ±), which

merely pass through the premium BCM from the

RKE module to the external RKE antenna in theinstrument panel wire harness, the BCM has the fol-

lowing communication circuits:

²PCI bus

²RKE program serial data - premium with

RKE only

²RKE transmit serial data - premium with

RKE only

Refer to the appropriate wiring information for

additional details.

MESSAGING The BCM uses the following mes-

sages received from other electronic modules over the

PCI data bus:

²Battery Temperature (PCM)

²Compass Mini-Trip Computer Button Sta-

tus (CMTC) - premium only

²Coolant Temperature (PCM)

²Distance Pulses (PCM)

²Engine Speed (PCM)

²Fuel Tank Level (PCM)

²Fuel Used (PCM)

²Intrusion Transceiver Module Commands

(ITM) - premium in markets where required

only

²Manifold Absolute Pressure (PCM)

²OK to Lock - Rolling Locks (PCM)

²SKIS Status (SKIM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Select Switch Status (PCM)

²Country Code (EMIC, PCM, CMTC)

²Distance to Empty (CMTC) - premium only

²Door Ajar Status (EMIC)

²Exterior Lighting Status (EMIC)

²Flip-up Glass Ajar Status (EMIC)

²Fuel Economy (Average and Instantaneous)

(CMTC) - premium only

²Hood Ajar Status (ITM) - premium in mar-

kets where required only

²Ignition On Timer (CMTC) - premium only

²Intrusion Transceiver Module Commands

(ITM) - premium in markets where required

only

²Key-In Ignition Switch Status (EMIC)

²Outside Temperature (CMTC) - premium

only

²Panel Lamp Intensity (CMTC, Radio)

²Tailgate Ajar Status (EMIC)

²Radio Mode (Radio) - premium only

²Radio Preset Scan (Radio) - premium only

²Radio Seek Down (Radio) - premium only

²Radio Seek Up (Radio) - premium only

²Radio Volume Down (Radio) - premium

only

²Radio Volume Up (Radio) - premium only

8E - 6 ELECTRONIC CONTROL MODULESKJ

BODY CONTROL MODULE (Continued)

Page 306 of 1803

²Vacuum Fluorescent Display Synchroniza-

tion (CMTC, EMIC, Radio)

²Vehicle Theft Security System Status (PCM,

ITM) - premium only

Refer to the appropriate diagnostic information for

additional details.

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE

The hard wired inputs to and outputs from the

Body Control Module (BCM), as well as other hard

wired circuits for this module may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

BCM, the Programmable Communications Interface

(PCI) data bus network, or the electronic messages

received and transmitted by the BCM over the PCI

data bus. The most reliable, efficient, and accurate

means to diagnose the BCM and the PCI data bus

network inputs to and outputs from this module

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: Before replacing a Body Control Module

(BCM), use a DRBIIITscan tool to retrieve the cur-

rent settings for the BCM programmable features

and the axle ratio/tire size (electronic pinion factor).

Refer to the appropriate diagnostic information.

These settings should be duplicated in the replace-

ment BCM using the DRBIIITscan tool before

returning the vehicle to service.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Junction Block Module (JBM) from

the instrument panel end bracket on the driver side

of the vehicle. (Refer to 8 - ELECTRICAL/POWER

DISTRIBUTION/JUNCTION BLOCK - REMOVAL).

(3) Remove the four screws that secure the BCM

to the Junction Block (JB) (Fig. 3).

(4) Remove the BCM from the JB.

(5) If the vehicle is equipped with the optional

Remote Keyless Entry (RKE) system, remove the

RKE module from the receptacle on the BCM. (Refer

to 8 - ELECTRICAL/POWER LOCKS/REMOTE KEY-

LESS ENTRY MODULE - REMOVAL).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

KJELECTRONIC CONTROL MODULES 8E - 7

BODY CONTROL MODULE (Continued)

Page 308 of 1803

ison, the prior two-wire Chrysler Collision Detection

(CCD) data bus system is designed to run at 7.8125

Kbps.

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. There are two

types of nodes on the bus. The dominant node termi-

nates the bus througha1KWresistor and a 3300 pF

capacitor. The Powertrain Control Module (PCM) is

the only dominant node for the PCI data bus system.

A standard node terminates the bus through an 11

KW resistor and a 330 pF capacitor.

The modules bias the bus when transmitting a

message. The PCI bus uses low and high voltage lev-

els to generate signals. Low voltage is around zero

volts and the high voltage is about seven and one-

half volts. The low and high voltage levels are gener-

ated by means of variable-pulse width modulation to

form signals of varying length. The Variable Pulse

Width Modulation (VPWM) used in PCI bus messag-

ing is a method in which both the state of the bus

and the width of the pulse are used to encode bit

information. A9zero9bit is defined as a short low

pulse or a long high pulse. A9one9bit is defined as a

long low pulse or a short high pulse. A low (passive)

state on the bus does not necessarily mean a zero bit.

It also depends upon pulse width. If the width is

short, it stands for a zero bit. If the width is long, it

stands for a one bit. Similarly, a high (active) state

does not necessarily mean a one bit. This too depends

upon pulse width. If the width is short, it stands for

a one bit. If the width is long, it stands for a zero bit.

In the case where there are successive zero or one

data bits, both the state of the bus and the width of

the pulse are changed alternately. This encoding

scheme is used for two reasons. First, this ensures

that only one symbol per transition and one transi-

tion per symbol exists. On each transition, every

transmitting module must decode the symbol on the

bus and begin timing of the next symbol. Since tim-

ing of the next symbol begins with the last transition

detected on the bus, all of the modules are re-syn-

chronized with each symbol. This ensures that thereare no accumulated timing errors during PCI data

bus communication.

The second reason for this encoding scheme is to

guarantee that the zero bit is the dominant bit on

the bus. When two modules are transmitting simul-

taneously on the bus, there must be some form of

arbitration to determine which module will gain con-

trol. A data collision occurs when two modules are

transmitting different messages at the same time.

When a module is transmitting on the bus, it is read-

ing the bus at the same time to ensure message

integrity. When a collision is detected, the module

that transmitted the one bit stops sending messages

over the bus until the bus becomes idle.

Each module is capable of transmitting and receiv-

ing data simultaneously. The typical PCI bus mes-

sage has the following four components:

²Message Header- One to three bytes in length.

The header contains information identifying the mes-

sage type and length, message priority, target mod-

ule(s) and sending module.

²Data Byte(s)- This is the actual message that

is being sent.

²Cyclic Redundancy Check (CRC) Byte- This

byte is used to detect errors during a message trans-

mission.

²In-Frame Response (IFR) byte(s)-Ifa

response is required from the target module(s), it can

be sent during this frame. This function is described

in greater detail in the following paragraph.

The IFR consists of one or more bytes, which are

transmitted during a message. If the sending module

requires information to be received immediately, the

target module(s) can send data over the bus during

the original message. This allows the sending module

to receive time-critical information without having to

wait for the target module to access the bus. After

the IFR is received, the sending module broadcasts

an End of Frame (EOF) message and releases control

of the bus.

The PCI data bus can be monitored using the

DRBIIItscan tool. It is possible, however, for the bus

to pass all DRBIIIttests and still be faulty if the

voltage parameters are all within the specified range

and false messages are being sent.

KJELECTRONIC CONTROL MODULES 8E - 9

COMMUNICATION (Continued)

Page 309 of 1803

CONTROLLER ANTILOCK

BRAKE

REMOVAL

(1) Install the prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the negative battery cable from the

battery.

(3) Pull up on the CAB harness connector release

(Fig. 4)and remove connector.

(4) Remove the pump connector from the CAB.

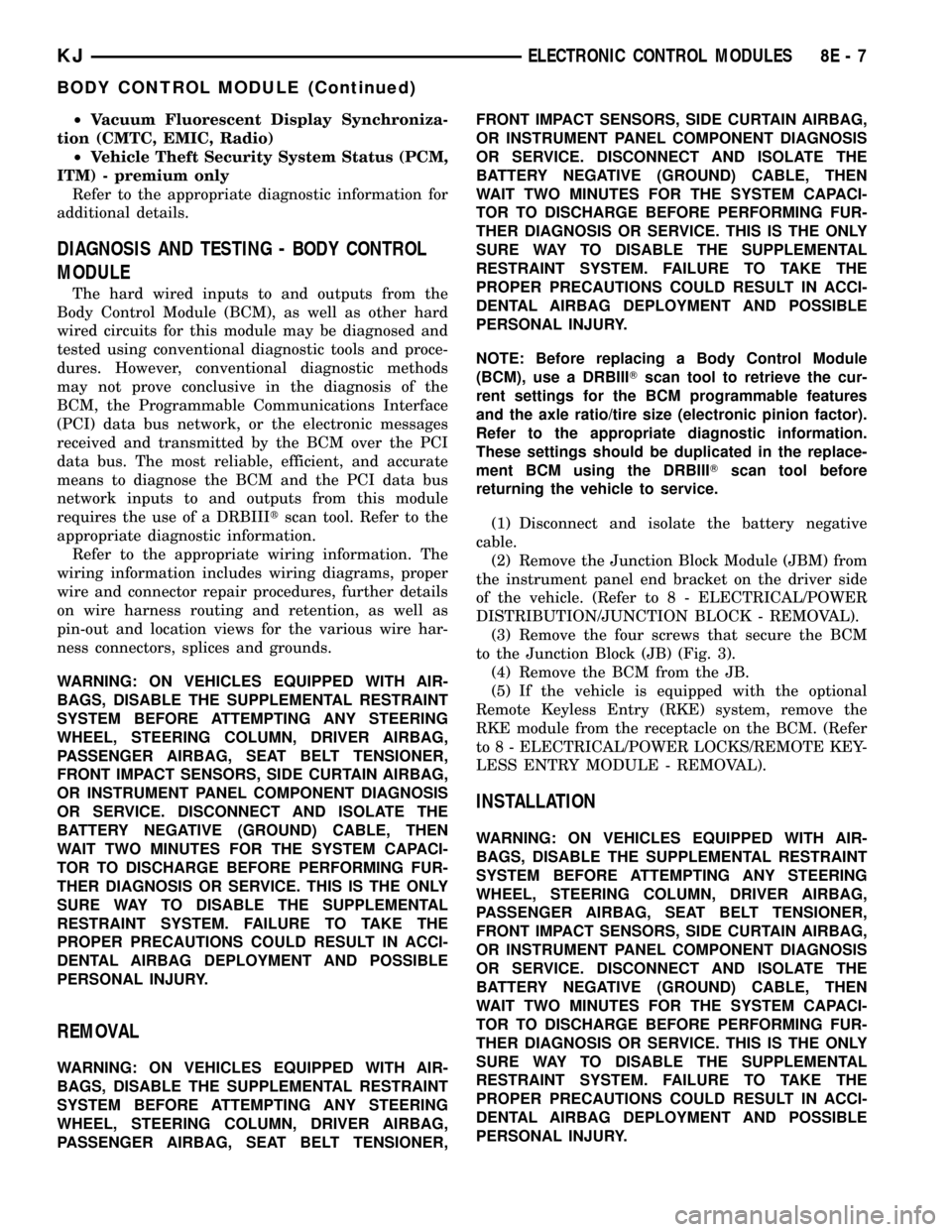

(5) Remove the CAB mounting bolts (Fig. 5).

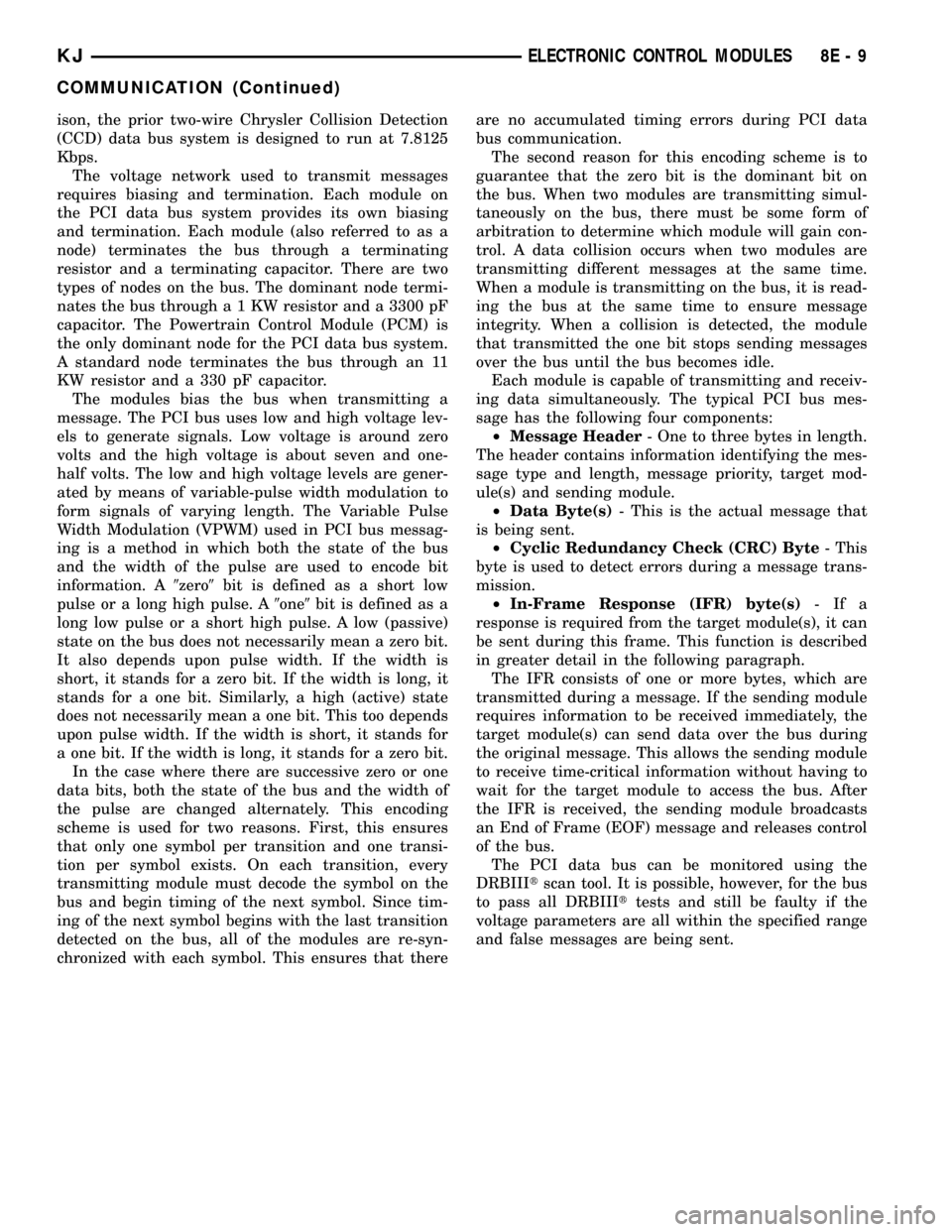

(6) Remove the CAB from the HCU (Fig. 6).

INSTALLATION

(1) Install CAB to the HCU (Fig. 6).

(2) Install mounting bolts. Tighten to 2 N´m (16 in.

lbs.).

(3) Install the pump electircal connector to the

CAB (Fig. 6).

(4) Install the wiring harness connector to the

CAB and push down on the release to secure the con-

nector.

(5) Install negative battery cable to the battery.

(6) Remove the pushrod from the vehicle.

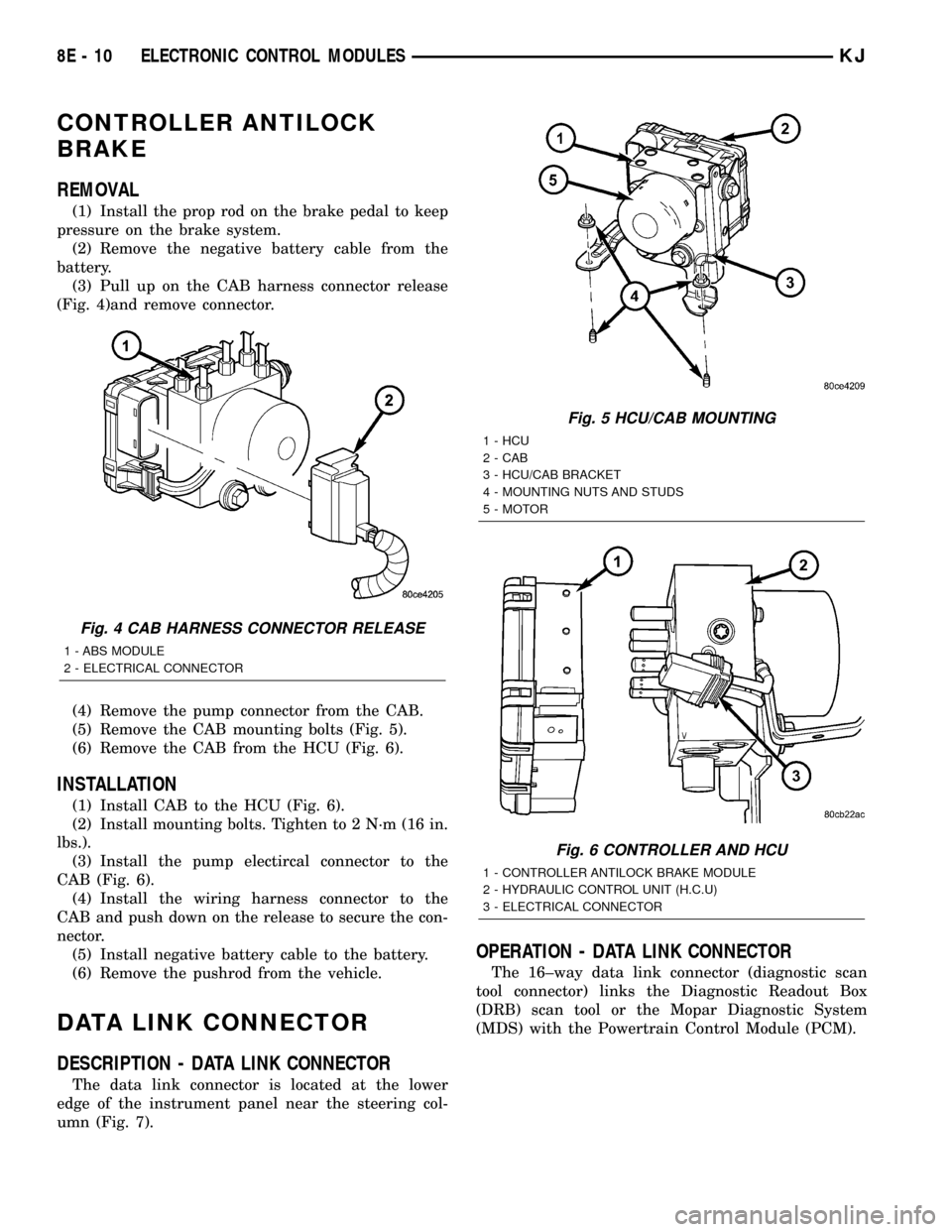

DATA LINK CONNECTOR

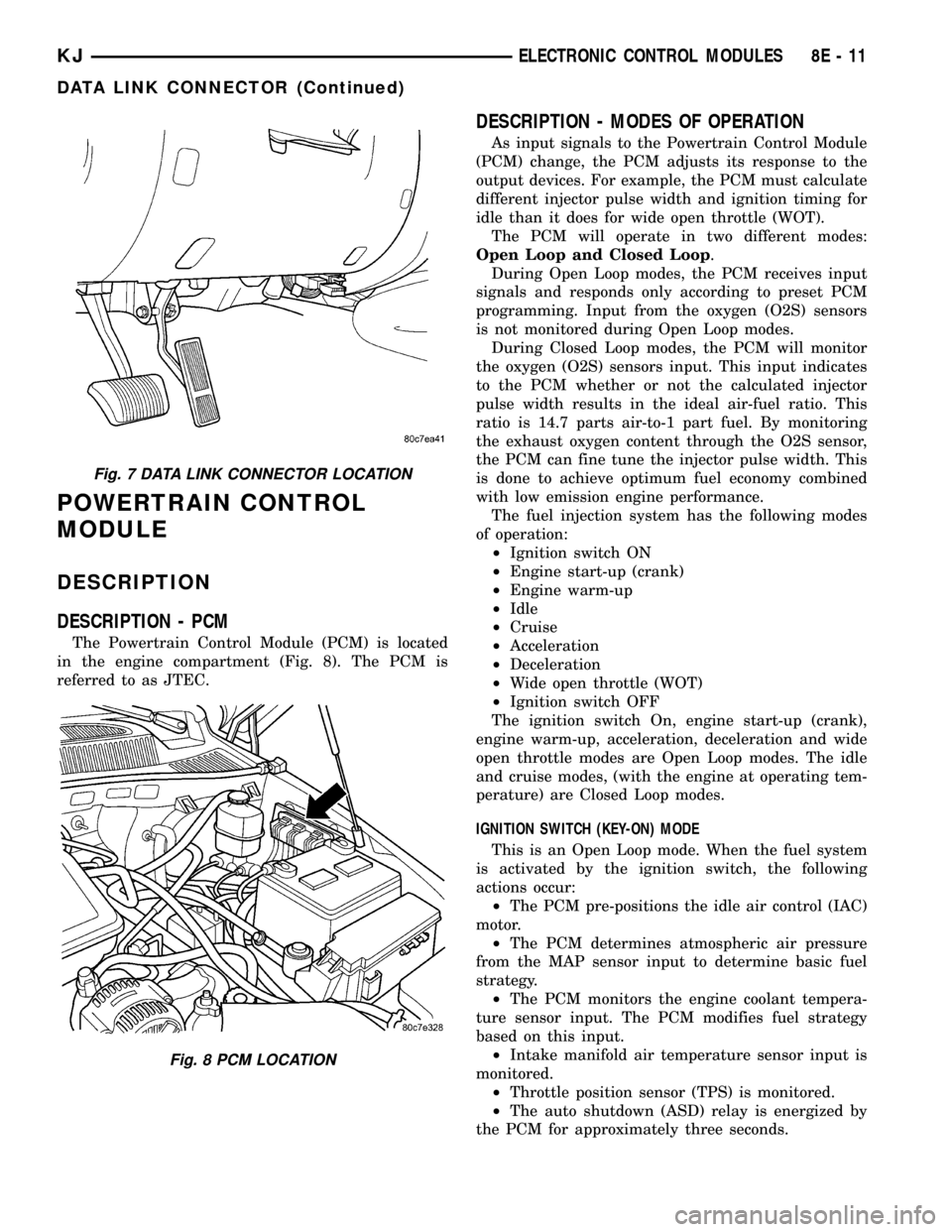

DESCRIPTION - DATA LINK CONNECTOR

The data link connector is located at the lower

edge of the instrument panel near the steering col-

umn (Fig. 7).

OPERATION - DATA LINK CONNECTOR

The 16±way data link connector (diagnostic scan

tool connector) links the Diagnostic Readout Box

(DRB) scan tool or the Mopar Diagnostic System

(MDS) with the Powertrain Control Module (PCM).

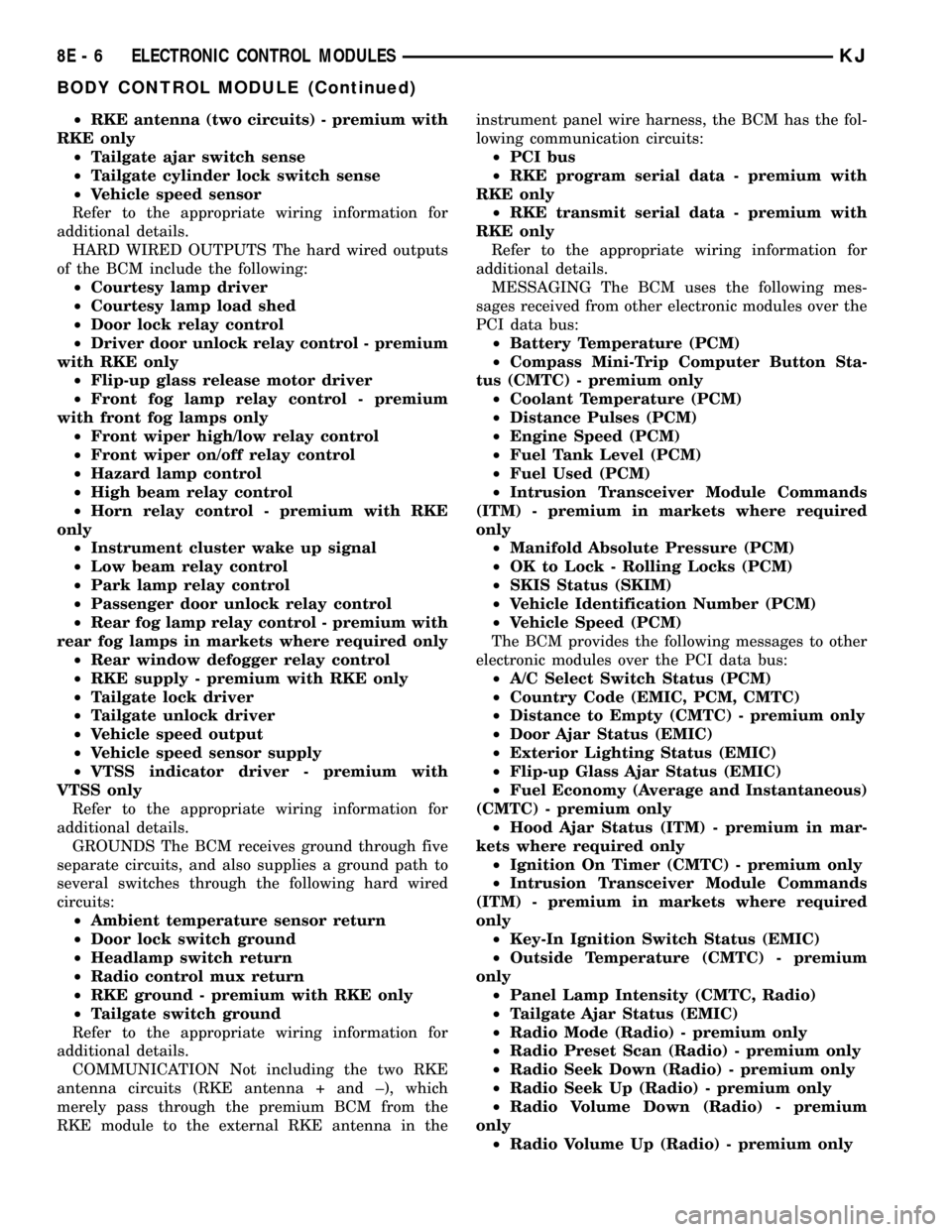

Fig. 4 CAB HARNESS CONNECTOR RELEASE

1 - ABS MODULE

2 - ELECTRICAL CONNECTOR

Fig. 5 HCU/CAB MOUNTING

1 - HCU

2 - CAB

3 - HCU/CAB BRACKET

4 - MOUNTING NUTS AND STUDS

5 - MOTOR

Fig. 6 CONTROLLER AND HCU

1 - CONTROLLER ANTILOCK BRAKE MODULE

2 - HYDRAULIC CONTROL UNIT (H.C.U)

3 - ELECTRICAL CONNECTOR

8E - 10 ELECTRONIC CONTROL MODULESKJ

Page 310 of 1803

POWERTRAIN CONTROL

MODULE

DESCRIPTION

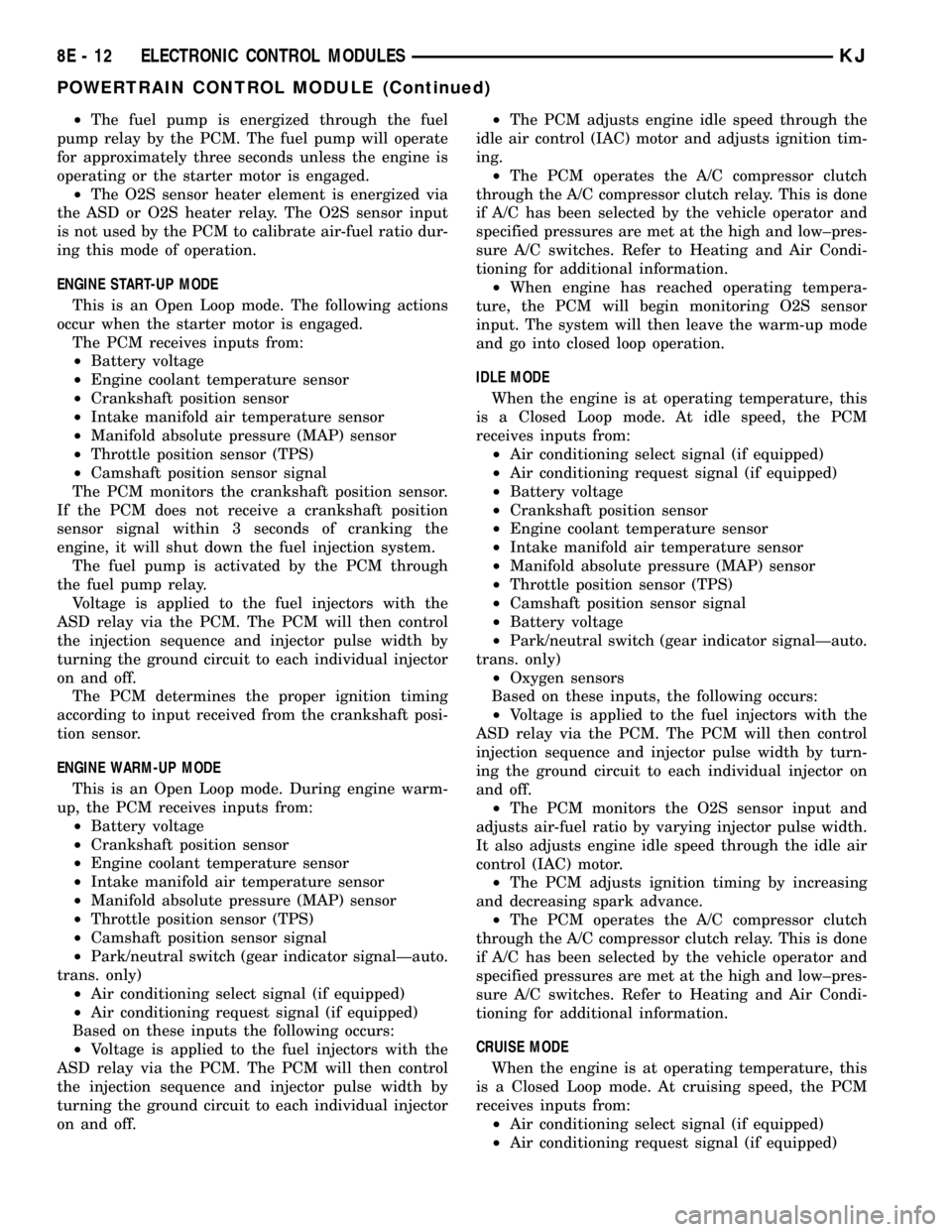

DESCRIPTION - PCM

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 8). The PCM is

referred to as JTEC.

DESCRIPTION - MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCM

programming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:

²The PCM pre-positions the idle air control (IAC)

motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant tempera-

ture sensor input. The PCM modifies fuel strategy

based on this input.

²Intake manifold air temperature sensor input is

monitored.

²Throttle position sensor (TPS) is monitored.

²The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

Fig. 7 DATA LINK CONNECTOR LOCATION

Fig. 8 PCM LOCATION

KJELECTRONIC CONTROL MODULES 8E - 11

DATA LINK CONNECTOR (Continued)

Page 311 of 1803

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the ASD or O2S heater relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio dur-

ing this mode of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

²When engine has reached operating tempera-

ture, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Battery voltage

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turn-

ing the ground circuit to each individual injector on

and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

8E - 12 ELECTRONIC CONTROL MODULESKJ

POWERTRAIN CONTROL MODULE (Continued)