Throttle pos JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 397 of 1803

cylinders 1 and 4, and coil number two fires cylinders

2 and 3.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil(s). The

PCM will de-energize the ASD relay if it does not

receive the crankshaft position sensor and camshaft

position sensor inputs.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine oper-

ating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Spark plug cables (secondary wires or cables) are

used with the 2.4L engine.

3.7L

Battery voltage is supplied to the 6 ignition coils

from the ASD relay. The Powertrain Control Module

(PCM) opens and closes each ignition coil ground cir-

cuit at a determined time for ignition coil operation.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine oper-

ating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Because of coil design, spark plug cables (second-

ary cables) are not used with the 3.7L engine.

REMOVAL

2.4L

(1) Disconnect electrical connector at rear of coil.

(2) Remove all secondary cables from coil.

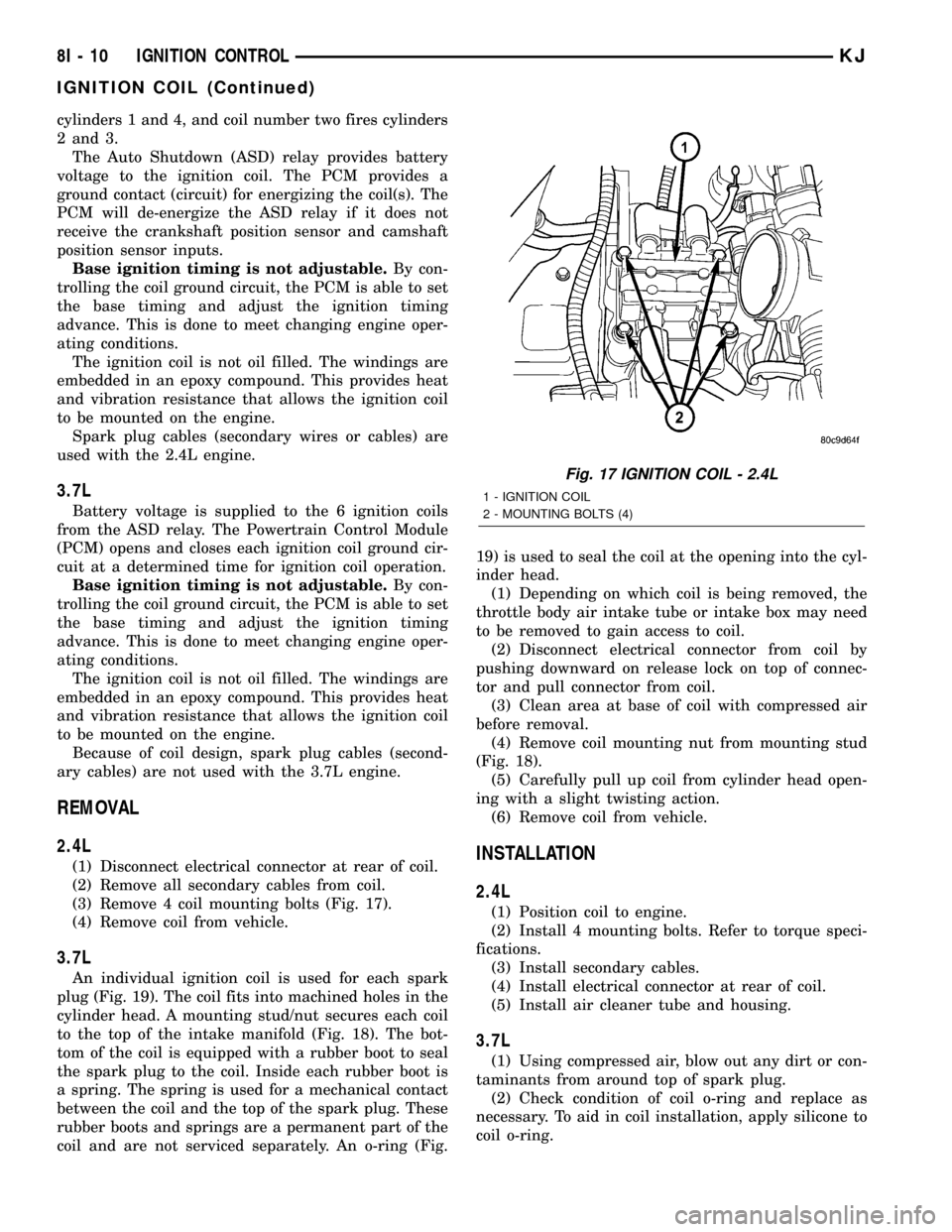

(3) Remove 4 coil mounting bolts (Fig. 17).

(4) Remove coil from vehicle.

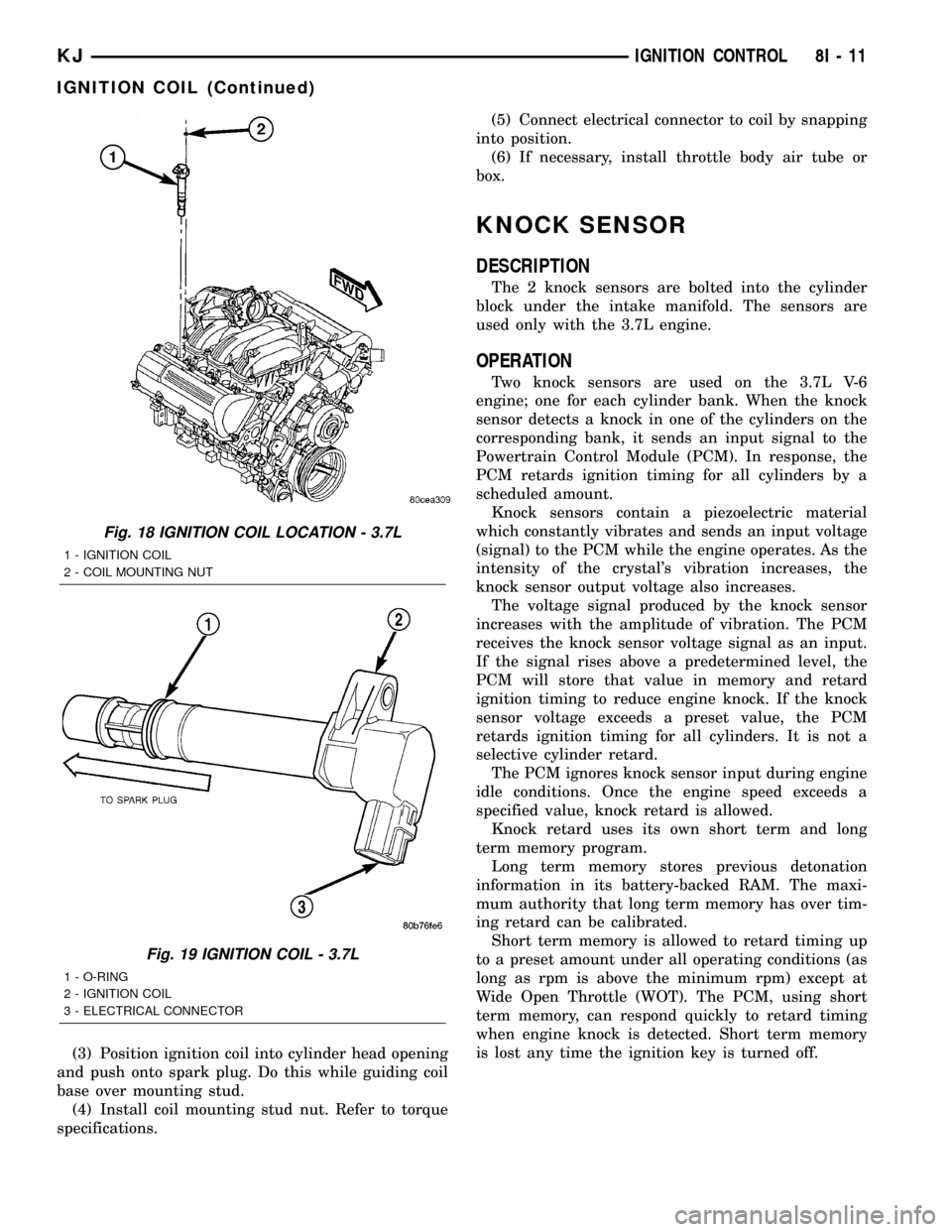

3.7L

An individual ignition coil is used for each spark

plug (Fig. 19). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 18). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.19) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector from coil by

pushing downward on release lock on top of connec-

tor and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 18).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

INSTALLATION

2.4L

(1) Position coil to engine.

(2) Install 4 mounting bolts. Refer to torque speci-

fications.

(3) Install secondary cables.

(4) Install electrical connector at rear of coil.

(5) Install air cleaner tube and housing.

3.7L

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

Fig. 17 IGNITION COIL - 2.4L

1 - IGNITION COIL

2 - MOUNTING BOLTS (4)

8I - 10 IGNITION CONTROLKJ

IGNITION COIL (Continued)

Page 398 of 1803

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install coil mounting stud nut. Refer to torque

specifications.(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube or

box.

KNOCK SENSOR

DESCRIPTION

The 2 knock sensors are bolted into the cylinder

block under the intake manifold. The sensors are

used only with the 3.7L engine.

OPERATION

Two knock sensors are used on the 3.7L V-6

engine; one for each cylinder bank. When the knock

sensor detects a knock in one of the cylinders on the

corresponding bank, it sends an input signal to the

Powertrain Control Module (PCM). In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives the knock sensor voltage signal as an input.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except at

Wide Open Throttle (WOT). The PCM, using short

term memory, can respond quickly to retard timing

when engine knock is detected. Short term memory

is lost any time the ignition key is turned off.

Fig. 18 IGNITION COIL LOCATION - 3.7L

1 - IGNITION COIL

2 - COIL MOUNTING NUT

Fig. 19 IGNITION COIL - 3.7L

1 - O-RING

2 - IGNITION COIL

3 - ELECTRICAL CONNECTOR

KJIGNITION CONTROL 8I - 11

IGNITION COIL (Continued)

Page 402 of 1803

REMOVAL

2.4L

If spark plug for #2 or #3 cylinder is being

removed, throttle body must be removed. Refer to

Throttle Body Removal.

(1) Remove air cleaner tube and housing.

(2) Twist secondary cable at cylinder head to break

loose at spark plug. Remove cable from plug.

(3) Prior to removing spark plug, spray com-

pressed air into cylinder head opening. This will help

prevent foreign material from entering combustion

chamber.

(4) Remove spark plug from cylinder head using a

quality socket with a rubber or foam insert.

(5) Inspect spark plug condition. Refer to Spark

Plug Conditions.

3.7L

Each individual spark plug is located under each

ignition coil. Each individual ignition coil must be

removed to gain access to each spark plug. Refer to

Ignition Coil Removal/Installation.

(1) Prior to removing ignition coil, spray com-

pressed air around coil base at cylinder head.

(2) Prior to removing spark plug, spray com-

pressed air into cylinder head opening. This will help

prevent foreign material from entering combustion

chamber.

(3) Remove spark plug from cylinder head using a

quality socket with a rubber or foam insert. Also

check condition of ignition coil o-ring and replace as

necessary.

(4) Inspect spark plug condition. Refer to Spark

Plug Conditions.

CLEANING SPARK PLUGS

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After clean-

ing, file the center electrode flat with a small point

file or jewelers file before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will

remain on the spark plug insulator and will cause

plug misfire.

INSTALLATION

2.4L

CAUTION: Spark plug tightening on the 2.4L is

torque critical. The plugs are equipped with tapered

seats. Do not exceed 15 ft. lbs. torque.

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs. Refer to torque specifica-

tions.

(3) Install throttle body. Refer to Throttle Body

Installation.

(4) Install air cleaner tube and housing.

3.7L

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

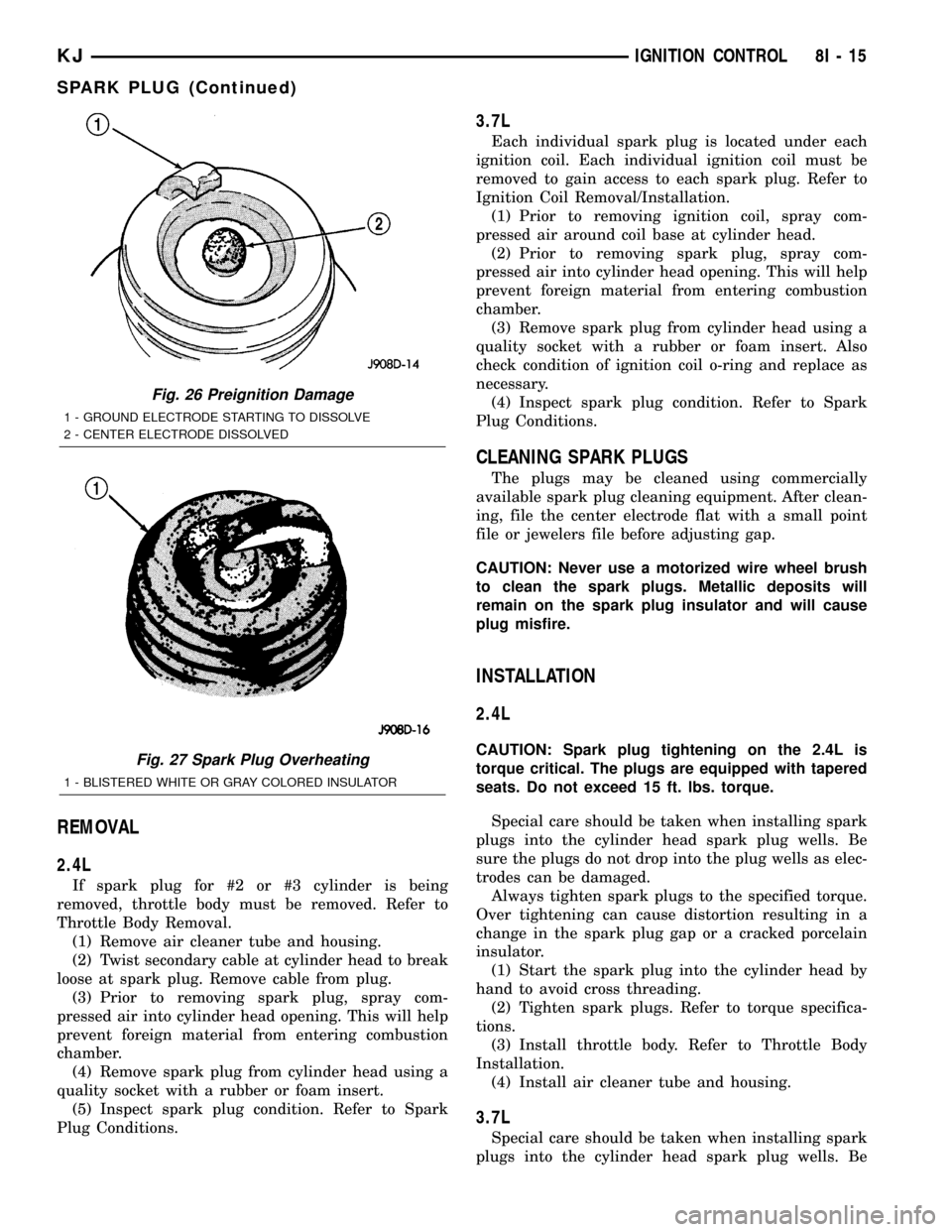

Fig. 26 Preignition Damage

1 - GROUND ELECTRODE STARTING TO DISSOLVE

2 - CENTER ELECTRODE DISSOLVED

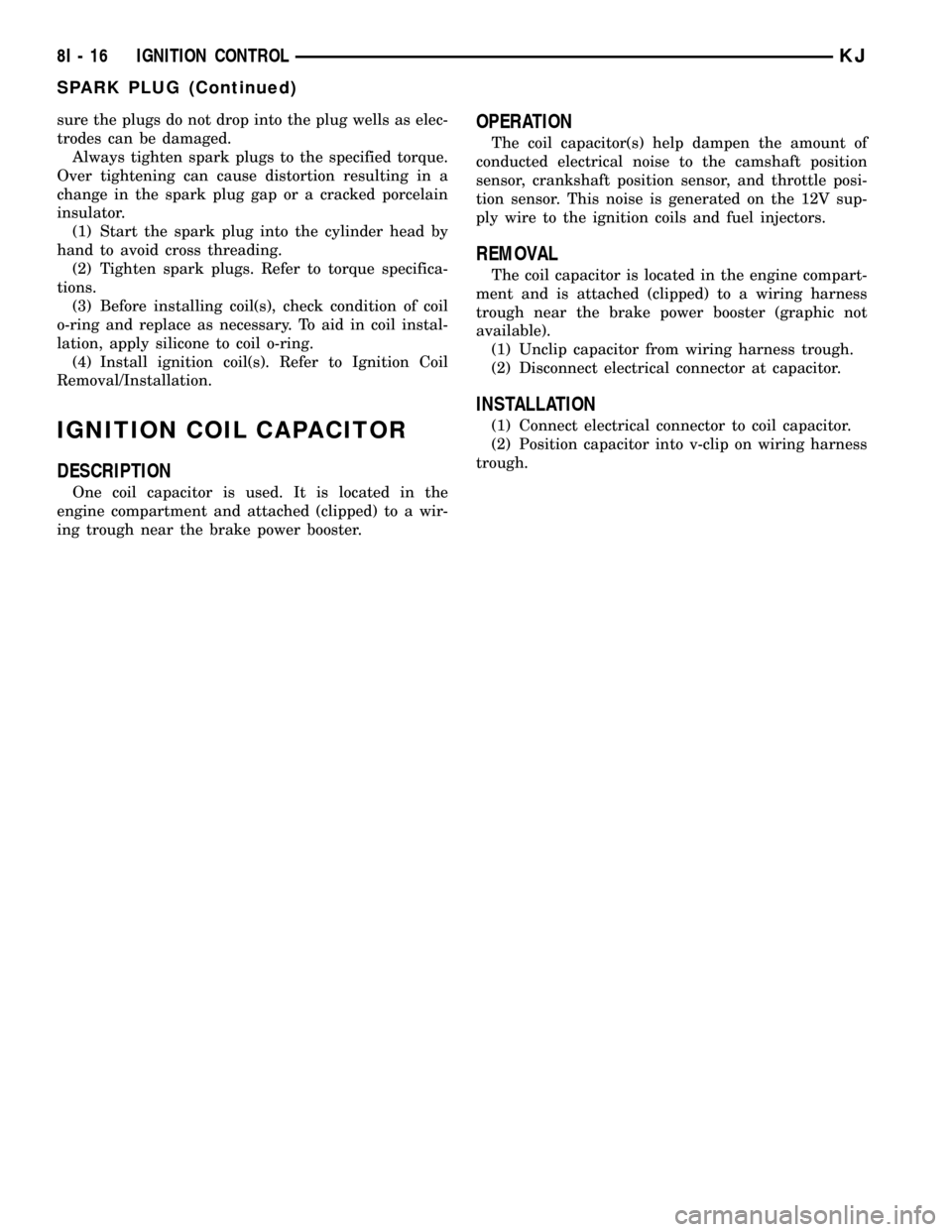

Fig. 27 Spark Plug Overheating

1 - BLISTERED WHITE OR GRAY COLORED INSULATOR

KJIGNITION CONTROL 8I - 15

SPARK PLUG (Continued)

Page 403 of 1803

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs. Refer to torque specifica-

tions.

(3) Before installing coil(s), check condition of coil

o-ring and replace as necessary. To aid in coil instal-

lation, apply silicone to coil o-ring.

(4) Install ignition coil(s). Refer to Ignition Coil

Removal/Installation.

IGNITION COIL CAPACITOR

DESCRIPTION

One coil capacitor is used. It is located in the

engine compartment and attached (clipped) to a wir-

ing trough near the brake power booster.

OPERATION

The coil capacitor(s) help dampen the amount of

conducted electrical noise to the camshaft position

sensor, crankshaft position sensor, and throttle posi-

tion sensor. This noise is generated on the 12V sup-

ply wire to the ignition coils and fuel injectors.

REMOVAL

The coil capacitor is located in the engine compart-

ment and is attached (clipped) to a wiring harness

trough near the brake power booster (graphic not

available).

(1) Unclip capacitor from wiring harness trough.

(2) Disconnect electrical connector at capacitor.

INSTALLATION

(1) Connect electrical connector to coil capacitor.

(2) Position capacitor into v-clip on wiring harness

trough.

8I - 16 IGNITION CONTROLKJ

SPARK PLUG (Continued)

Page 675 of 1803

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

OVERSHOOT/UNDERSHOOT

If the vehicle operator repeatedly presses and

releases the SET button with their foot off of the

accelerator (referred to as a ªlift foot setº), the vehicle

may accelerate and exceed the desired set speed by

up to 5 mph (8 km/h). It may also decelerate to less

than the desired set speed, before finally achieving

the desired set speed.

The Speed Control System has an adaptive strat-

egy that compensates for vehicle-to-vehicle variations

in speed control cable lengths. When the speed con-

trol is set with the vehicle operators foot off of the

accelerator pedal, the speed control thinks there is

excessive speed control cable slack and adapts

accordingly. If the ªlift foot setsº are continually used,

a speed control overshoot/undershoot condition will

develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed using

the accelerator pedal (not decelerating or accelerat-

ing), and then turning the cruise control switch to

the OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road testshould include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8J,

Instrument Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo. Corrosion should be removed from

electrical terminals and a light coating of Mopar

MultiPurpose Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment of both ends of the speed con-

trol servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS

TORQUE - SPEED CONTROL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Servo Mounting Bracket-to-Servo Nuts 9 - 75

Servo Mounting Bracket-to-Body Bolts 12 - 105

Speed Control Switch Mounting Screws 1.5 - 14

Vacuum Reservoir Mounting Screws 3 - 20

8P - 2 SPEED CONTROLKJ

SPEED CONTROL (Continued)

Page 676 of 1803

CABLE

DESCRIPTION

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage.

OPERATION

This cable causes the throttle control linkage to

open or close the throttle valve in response to move-

ment of the vacuum servo diaphragm.

REMOVAL - 3.7L

(1) Disconnect negative battery cable at battery.

(2) Remove air filter resonator at throttle body.

The accelerator cable must be partially removed to

gain access to speed control cable.

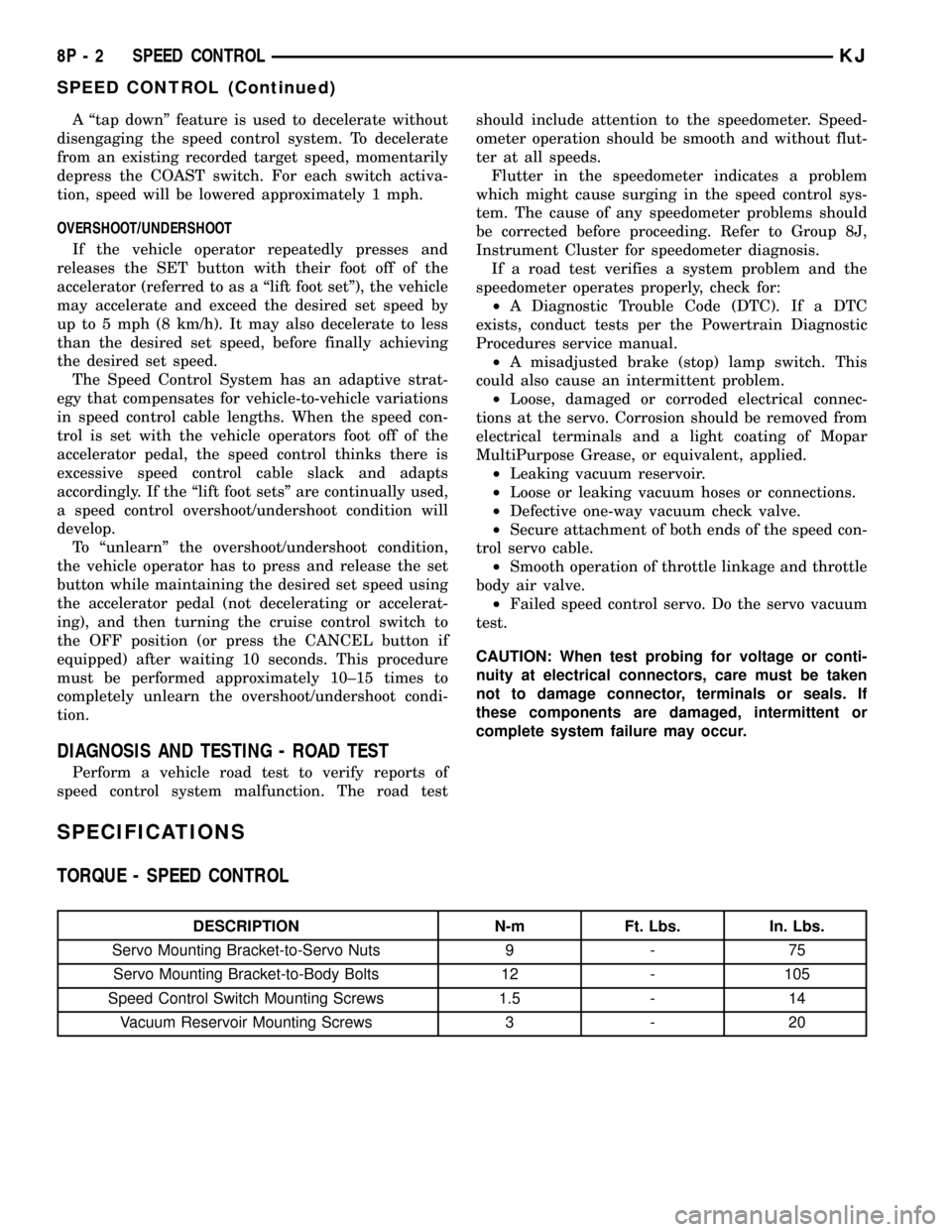

(3) Hold throttle in wide open position. While held

in this position, slide throttle cable pin (Fig. 1) from

throttle body bellcrank.

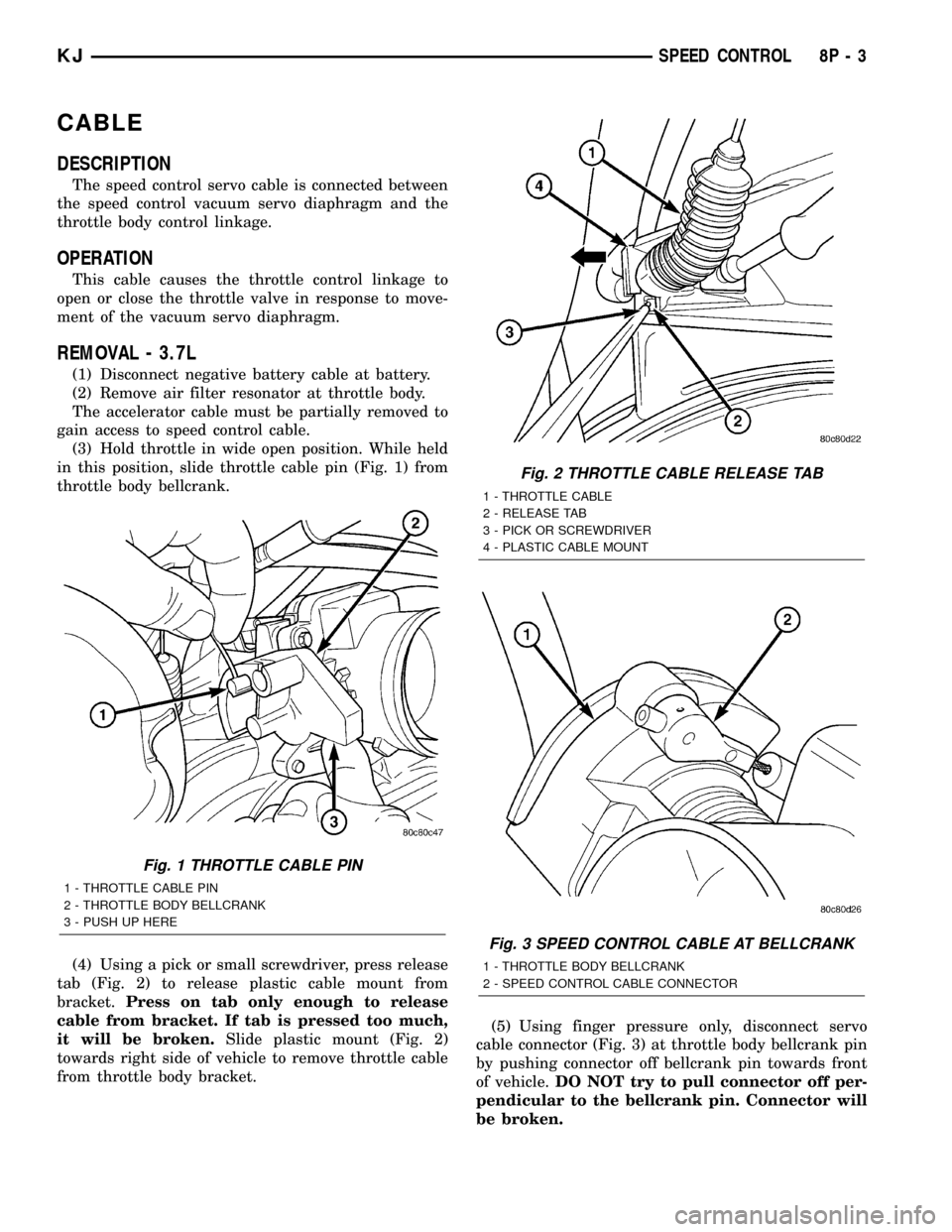

(4) Using a pick or small screwdriver, press release

tab (Fig. 2) to release plastic cable mount from

bracket.Press on tab only enough to release

cable from bracket. If tab is pressed too much,

it will be broken.Slide plastic mount (Fig. 2)

towards right side of vehicle to remove throttle cable

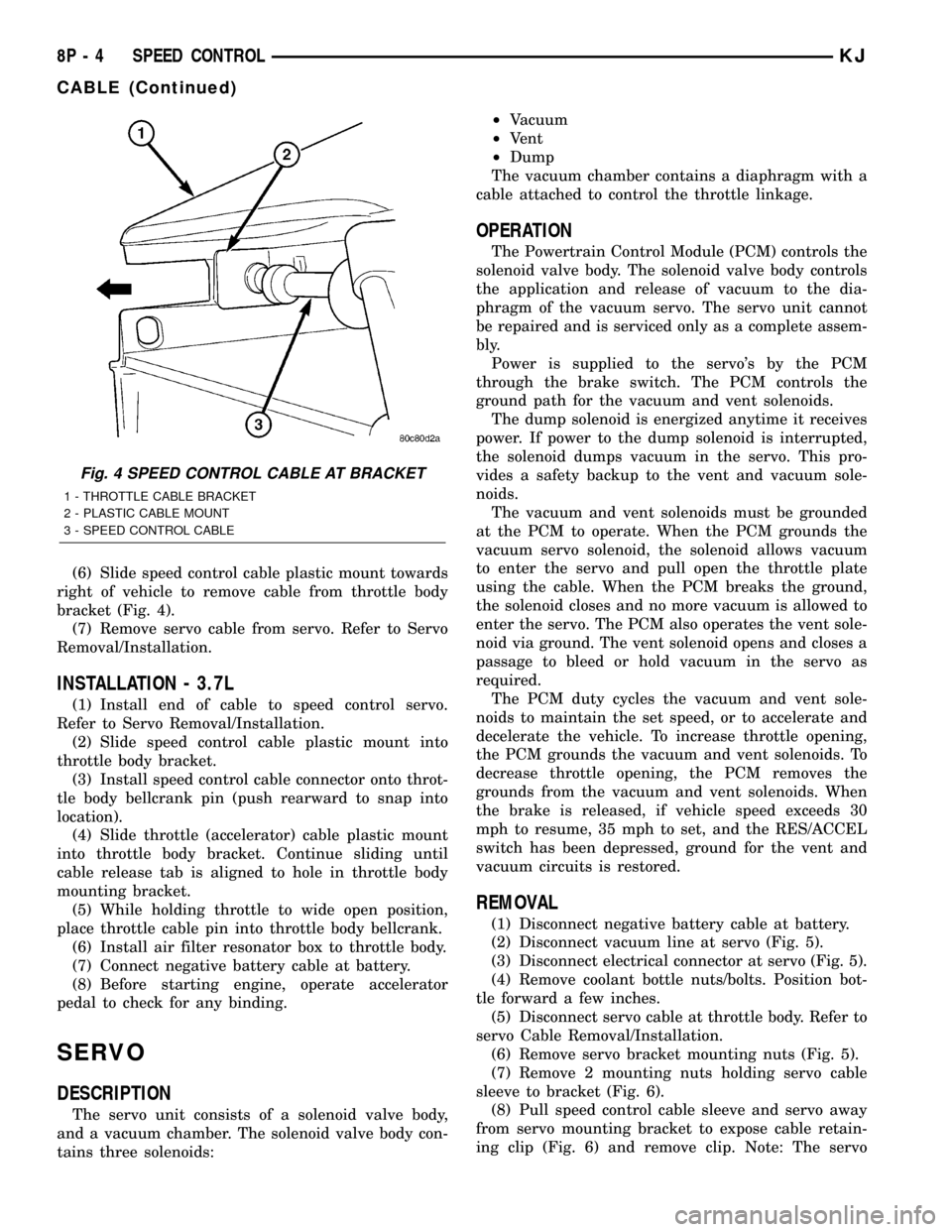

from throttle body bracket.(5) Using finger pressure only, disconnect servo

cable connector (Fig. 3) at throttle body bellcrank pin

by pushing connector off bellcrank pin towards front

of vehicle.DO NOT try to pull connector off per-

pendicular to the bellcrank pin. Connector will

be broken.

Fig. 1 THROTTLE CABLE PIN

1 - THROTTLE CABLE PIN

2 - THROTTLE BODY BELLCRANK

3 - PUSH UP HERE

Fig. 2 THROTTLE CABLE RELEASE TAB

1 - THROTTLE CABLE

2 - RELEASE TAB

3 - PICK OR SCREWDRIVER

4 - PLASTIC CABLE MOUNT

Fig. 3 SPEED CONTROL CABLE AT BELLCRANK

1 - THROTTLE BODY BELLCRANK

2 - SPEED CONTROL CABLE CONNECTOR

KJSPEED CONTROL 8P - 3

Page 677 of 1803

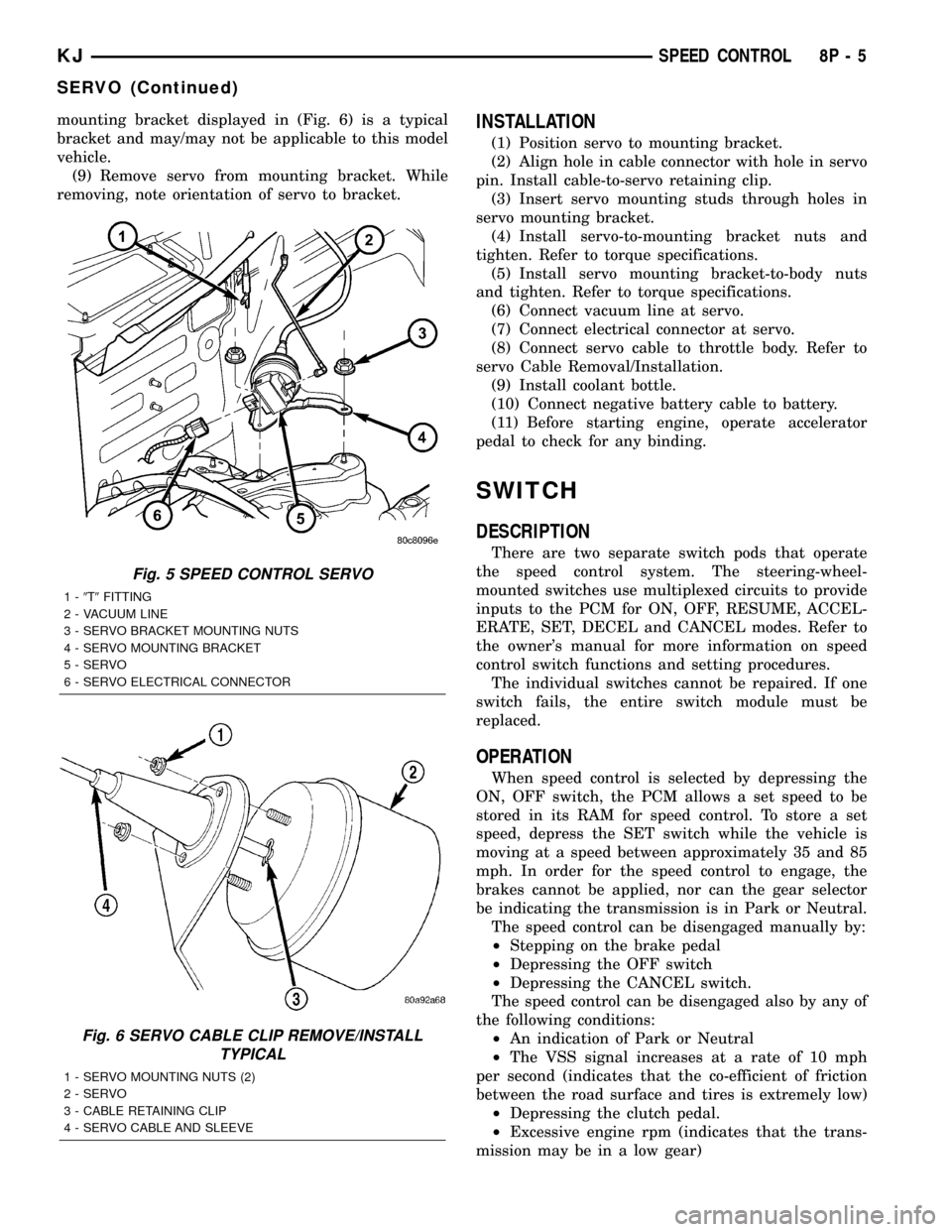

(6) Slide speed control cable plastic mount towards

right of vehicle to remove cable from throttle body

bracket (Fig. 4).

(7) Remove servo cable from servo. Refer to Servo

Removal/Installation.

INSTALLATION - 3.7L

(1) Install end of cable to speed control servo.

Refer to Servo Removal/Installation.

(2) Slide speed control cable plastic mount into

throttle body bracket.

(3) Install speed control cable connector onto throt-

tle body bellcrank pin (push rearward to snap into

location).

(4) Slide throttle (accelerator) cable plastic mount

into throttle body bracket. Continue sliding until

cable release tab is aligned to hole in throttle body

mounting bracket.

(5) While holding throttle to wide open position,

place throttle cable pin into throttle body bellcrank.

(6) Install air filter resonator box to throttle body.

(7) Connect negative battery cable at battery.

(8) Before starting engine, operate accelerator

pedal to check for any binding.

SERVO

DESCRIPTION

The servo unit consists of a solenoid valve body,

and a vacuum chamber. The solenoid valve body con-

tains three solenoids:²Vacuum

²Vent

²Dump

The vacuum chamber contains a diaphragm with a

cable attached to control the throttle linkage.

OPERATION

The Powertrain Control Module (PCM) controls the

solenoid valve body. The solenoid valve body controls

the application and release of vacuum to the dia-

phragm of the vacuum servo. The servo unit cannot

be repaired and is serviced only as a complete assem-

bly.

Power is supplied to the servo's by the PCM

through the brake switch. The PCM controls the

ground path for the vacuum and vent solenoids.

The dump solenoid is energized anytime it receives

power. If power to the dump solenoid is interrupted,

the solenoid dumps vacuum in the servo. This pro-

vides a safety backup to the vent and vacuum sole-

noids.

The vacuum and vent solenoids must be grounded

at the PCM to operate. When the PCM grounds the

vacuum servo solenoid, the solenoid allows vacuum

to enter the servo and pull open the throttle plate

using the cable. When the PCM breaks the ground,

the solenoid closes and no more vacuum is allowed to

enter the servo. The PCM also operates the vent sole-

noid via ground. The vent solenoid opens and closes a

passage to bleed or hold vacuum in the servo as

required.

The PCM duty cycles the vacuum and vent sole-

noids to maintain the set speed, or to accelerate and

decelerate the vehicle. To increase throttle opening,

the PCM grounds the vacuum and vent solenoids. To

decrease throttle opening, the PCM removes the

grounds from the vacuum and vent solenoids. When

the brake is released, if vehicle speed exceeds 30

mph to resume, 35 mph to set, and the RES/ACCEL

switch has been depressed, ground for the vent and

vacuum circuits is restored.

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Disconnect vacuum line at servo (Fig. 5).

(3) Disconnect electrical connector at servo (Fig. 5).

(4) Remove coolant bottle nuts/bolts. Position bot-

tle forward a few inches.

(5) Disconnect servo cable at throttle body. Refer to

servo Cable Removal/Installation.

(6) Remove servo bracket mounting nuts (Fig. 5).

(7) Remove 2 mounting nuts holding servo cable

sleeve to bracket (Fig. 6).

(8) Pull speed control cable sleeve and servo away

from servo mounting bracket to expose cable retain-

ing clip (Fig. 6) and remove clip. Note: The servo

Fig. 4 SPEED CONTROL CABLE AT BRACKET

1 - THROTTLE CABLE BRACKET

2 - PLASTIC CABLE MOUNT

3 - SPEED CONTROL CABLE

8P - 4 SPEED CONTROLKJ

CABLE (Continued)

Page 678 of 1803

mounting bracket displayed in (Fig. 6) is a typical

bracket and may/may not be applicable to this model

vehicle.

(9) Remove servo from mounting bracket. While

removing, note orientation of servo to bracket.INSTALLATION

(1) Position servo to mounting bracket.

(2) Align hole in cable connector with hole in servo

pin. Install cable-to-servo retaining clip.

(3) Insert servo mounting studs through holes in

servo mounting bracket.

(4) Install servo-to-mounting bracket nuts and

tighten. Refer to torque specifications.

(5) Install servo mounting bracket-to-body nuts

and tighten. Refer to torque specifications.

(6) Connect vacuum line at servo.

(7) Connect electrical connector at servo.

(8) Connect servo cable to throttle body. Refer to

servo Cable Removal/Installation.

(9) Install coolant bottle.

(10) Connect negative battery cable to battery.

(11) Before starting engine, operate accelerator

pedal to check for any binding.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system. The steering-wheel-

mounted switches use multiplexed circuits to provide

inputs to the PCM for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

OPERATION

When speed control is selected by depressing the

ON, OFF switch, the PCM allows a set speed to be

stored in its RAM for speed control. To store a set

speed, depress the SET switch while the vehicle is

moving at a speed between approximately 35 and 85

mph. In order for the speed control to engage, the

brakes cannot be applied, nor can the gear selector

be indicating the transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal.

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

Fig. 5 SPEED CONTROL SERVO

1-9T9FITTING

2 - VACUUM LINE

3 - SERVO BRACKET MOUNTING NUTS

4 - SERVO MOUNTING BRACKET

5 - SERVO

6 - SERVO ELECTRICAL CONNECTOR

Fig. 6 SERVO CABLE CLIP REMOVE/INSTALL

TYPICAL

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

KJSPEED CONTROL 8P - 5

SERVO (Continued)

Page 763 of 1803

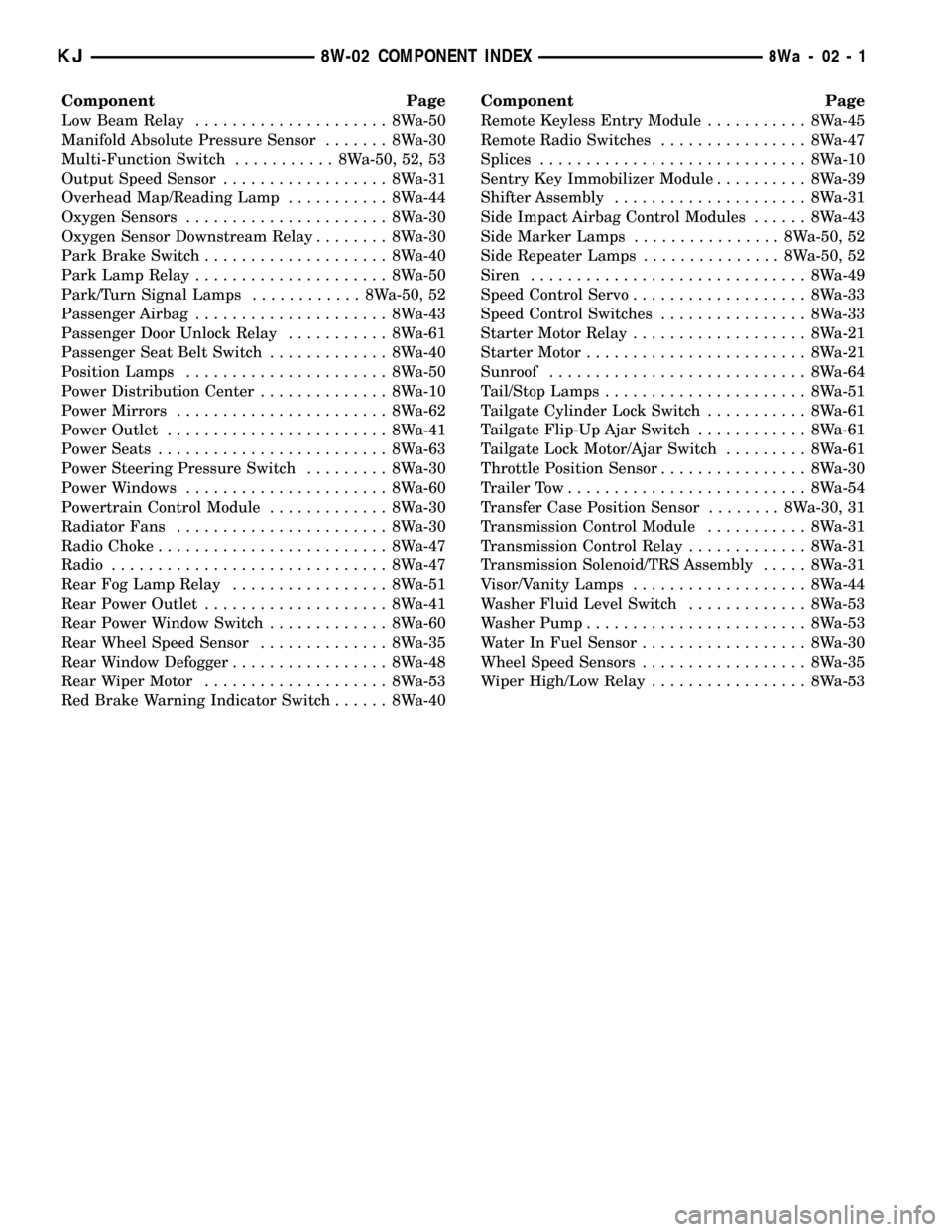

Component Page

Low Beam Relay..................... 8Wa-50

Manifold Absolute Pressure Sensor....... 8Wa-30

Multi-Function Switch........... 8Wa-50, 52, 53

Output Speed Sensor.................. 8Wa-31

Overhead Map/Reading Lamp........... 8Wa-44

Oxygen Sensors...................... 8Wa-30

Oxygen Sensor Downstream Relay........ 8Wa-30

Park Brake Switch.................... 8Wa-40

Park Lamp Relay..................... 8Wa-50

Park/Turn Signal Lamps............ 8Wa-50, 52

Passenger Airbag..................... 8Wa-43

Passenger Door Unlock Relay........... 8Wa-61

Passenger Seat Belt Switch............. 8Wa-40

Position Lamps...................... 8Wa-50

Power Distribution Center.............. 8Wa-10

Power Mirrors....................... 8Wa-62

Power Outlet........................ 8Wa-41

Power Seats......................... 8Wa-63

Power Steering Pressure Switch......... 8Wa-30

Power Windows...................... 8Wa-60

Powertrain Control Module............. 8Wa-30

Radiator Fans....................... 8Wa-30

Radio Choke......................... 8Wa-47

Radio.............................. 8Wa-47

Rear Fog Lamp Relay................. 8Wa-51

Rear Power Outlet.................... 8Wa-41

Rear Power Window Switch............. 8Wa-60

Rear Wheel Speed Sensor.............. 8Wa-35

Rear Window Defogger................. 8Wa-48

Rear Wiper Motor.................... 8Wa-53

Red Brake Warning Indicator Switch...... 8Wa-40Component Page

Remote Keyless Entry Module........... 8Wa-45

Remote Radio Switches................ 8Wa-47

Splices............................. 8Wa-10

Sentry Key Immobilizer Module.......... 8Wa-39

Shifter Assembly..................... 8Wa-31

Side Impact Airbag Control Modules...... 8Wa-43

Side Marker Lamps................ 8Wa-50, 52

Side Repeater Lamps............... 8Wa-50, 52

Siren.............................. 8Wa-49

Speed Control Servo................... 8Wa-33

Speed Control Switches................ 8Wa-33

Starter Motor Relay................... 8Wa-21

Starter Motor........................ 8Wa-21

Sunroof............................ 8Wa-64

Tail/Stop Lamps...................... 8Wa-51

Tailgate Cylinder Lock Switch........... 8Wa-61

Tailgate Flip-Up Ajar Switch............ 8Wa-61

Tailgate Lock Motor/Ajar Switch......... 8Wa-61

Throttle Position Sensor................ 8Wa-30

Trailer Tow.......................... 8Wa-54

Transfer Case Position Sensor........ 8Wa-30, 31

Transmission Control Module........... 8Wa-31

Transmission Control Relay............. 8Wa-31

Transmission Solenoid/TRS Assembly..... 8Wa-31

Visor/Vanity Lamps................... 8Wa-44

Washer Fluid Level Switch............. 8Wa-53

Washer Pump........................ 8Wa-53

Water In Fuel Sensor.................. 8Wa-30

Wheel Speed Sensors.................. 8Wa-35

Wiper High/Low Relay................. 8Wa-53

KJ8W-02 COMPONENT INDEX8Wa-02-1

Page 862 of 1803

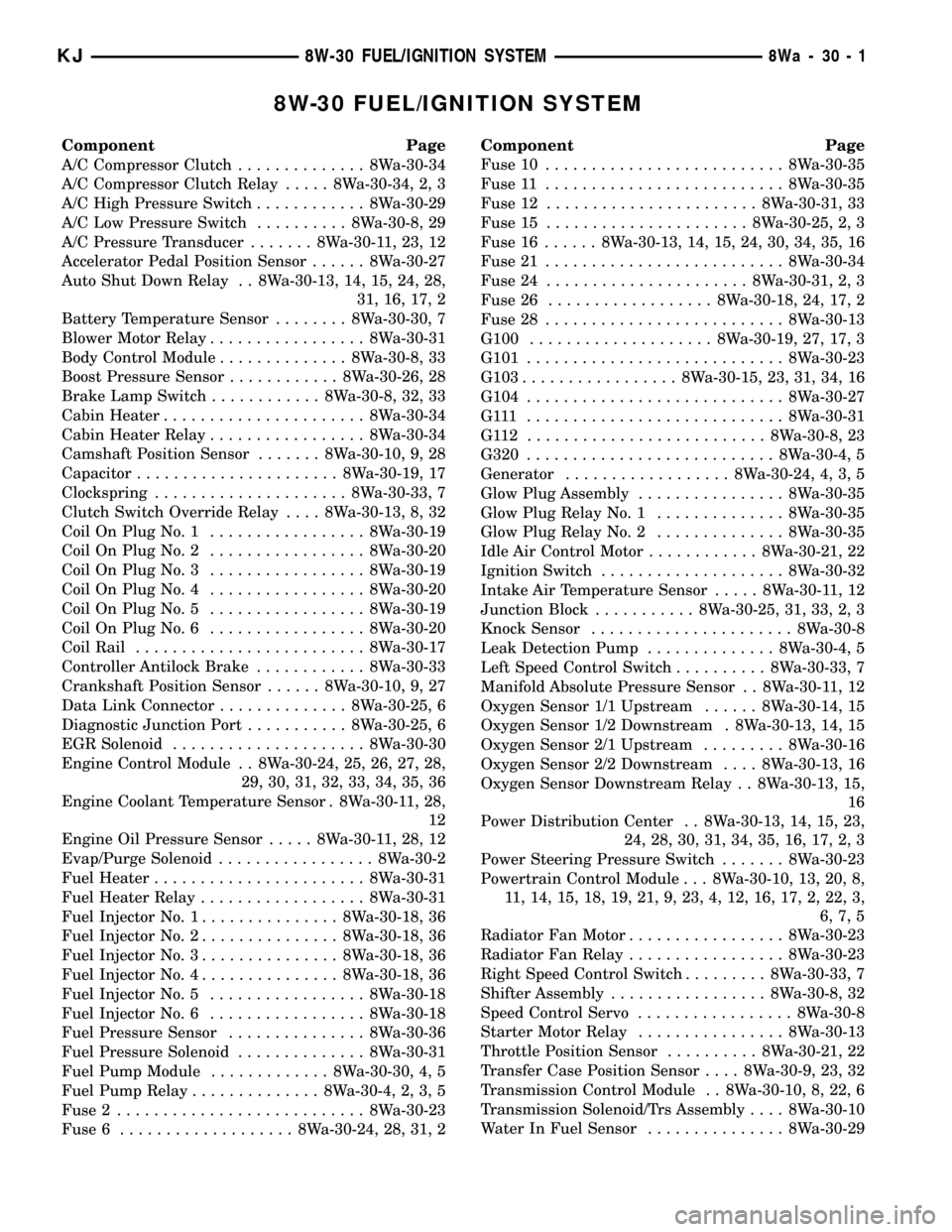

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch.............. 8Wa-30-34

A/C Compressor Clutch Relay..... 8Wa-30-34, 2, 3

A/C High Pressure Switch............ 8Wa-30-29

A/C Low Pressure Switch.......... 8Wa-30-8, 29

A/C Pressure Transducer....... 8Wa-30-11, 23, 12

Accelerator Pedal Position Sensor...... 8Wa-30-27

Auto Shut Down Relay . . 8Wa-30-13, 14, 15, 24, 28,

31, 16, 17, 2

Battery Temperature Sensor........ 8Wa-30-30, 7

Blower Motor Relay................. 8Wa-30-31

Body Control Module.............. 8Wa-30-8, 33

Boost Pressure Sensor............ 8Wa-30-26, 28

Brake Lamp Switch............ 8Wa-30-8, 32, 33

Cabin Heater...................... 8Wa-30-34

Cabin Heater Relay................. 8Wa-30-34

Camshaft Position Sensor....... 8Wa-30-10, 9, 28

Capacitor...................... 8Wa-30-19, 17

Clockspring..................... 8Wa-30-33, 7

Clutch Switch Override Relay.... 8Wa-30-13, 8, 32

Coil On Plug No. 1................. 8Wa-30-19

Coil On Plug No. 2................. 8Wa-30-20

Coil On Plug No. 3................. 8Wa-30-19

Coil On Plug No. 4................. 8Wa-30-20

Coil On Plug No. 5................. 8Wa-30-19

Coil On Plug No. 6................. 8Wa-30-20

Coil Rail......................... 8Wa-30-17

Controller Antilock Brake............ 8Wa-30-33

Crankshaft Position Sensor...... 8Wa-30-10, 9, 27

Data Link Connector.............. 8Wa-30-25, 6

Diagnostic Junction Port........... 8Wa-30-25, 6

EGR Solenoid..................... 8Wa-30-30

Engine Control Module . . 8Wa-30-24, 25, 26, 27, 28,

29, 30, 31, 32, 33, 34, 35, 36

Engine Coolant Temperature Sensor . 8Wa-30-11, 28,

12

Engine Oil Pressure Sensor..... 8Wa-30-11, 28, 12

Evap/Purge Solenoid................. 8Wa-30-2

Fuel Heater....................... 8Wa-30-31

Fuel Heater Relay.................. 8Wa-30-31

Fuel Injector No. 1............... 8Wa-30-18, 36

Fuel Injector No. 2............... 8Wa-30-18, 36

Fuel Injector No. 3............... 8Wa-30-18, 36

Fuel Injector No. 4............... 8Wa-30-18, 36

Fuel Injector No. 5................. 8Wa-30-18

Fuel Injector No. 6................. 8Wa-30-18

Fuel Pressure Sensor............... 8Wa-30-36

Fuel Pressure Solenoid.............. 8Wa-30-31

Fuel Pump Module............. 8Wa-30-30, 4, 5

Fuel Pump Relay.............. 8Wa-30-4, 2, 3, 5

Fuse 2........................... 8Wa-30-23

Fuse 6................... 8Wa-30-24, 28, 31, 2Component Page

Fuse 10.......................... 8Wa-30-35

Fuse 11.......................... 8Wa-30-35

Fuse 12....................... 8Wa-30-31, 33

Fuse 15...................... 8Wa-30-25, 2, 3

Fuse 16...... 8Wa-30-13, 14, 15, 24, 30, 34, 35, 16

Fuse 21.......................... 8Wa-30-34

Fuse 24...................... 8Wa-30-31, 2, 3

Fuse 26.................. 8Wa-30-18, 24, 17, 2

Fuse 28.......................... 8Wa-30-13

G100.................... 8Wa-30-19, 27, 17, 3

G101............................ 8Wa-30-23

G103................. 8Wa-30-15, 23, 31, 34, 16

G104............................ 8Wa-30-27

G111 ............................ 8Wa-30-31

G112 .......................... 8Wa-30-8, 23

G320........................... 8Wa-30-4, 5

Generator.................. 8Wa-30-24, 4, 3, 5

Glow Plug Assembly................ 8Wa-30-35

Glow Plug Relay No. 1.............. 8Wa-30-35

Glow Plug Relay No. 2.............. 8Wa-30-35

Idle Air Control Motor............ 8Wa-30-21, 22

Ignition Switch.................... 8Wa-30-32

Intake Air Temperature Sensor..... 8Wa-30-11, 12

Junction Block........... 8Wa-30-25, 31, 33, 2, 3

Knock Sensor...................... 8Wa-30-8

Leak Detection Pump.............. 8Wa-30-4, 5

Left Speed Control Switch.......... 8Wa-30-33, 7

Manifold Absolute Pressure Sensor . . 8Wa-30-11, 12

Oxygen Sensor 1/1 Upstream...... 8Wa-30-14, 15

Oxygen Sensor 1/2 Downstream . 8Wa-30-13, 14, 15

Oxygen Sensor 2/1 Upstream......... 8Wa-30-16

Oxygen Sensor 2/2 Downstream.... 8Wa-30-13, 16

Oxygen Sensor Downstream Relay . . 8Wa-30-13, 15,

16

Power Distribution Center . . 8Wa-30-13, 14, 15, 23,

24, 28, 30, 31, 34, 35, 16, 17, 2, 3

Power Steering Pressure Switch....... 8Wa-30-23

Powertrain Control Module . . . 8Wa-30-10, 13, 20, 8,

11, 14, 15, 18, 19, 21, 9, 23, 4, 12, 16, 17, 2, 22, 3,

6, 7, 5

Radiator Fan Motor................. 8Wa-30-23

Radiator Fan Relay................. 8Wa-30-23

Right Speed Control Switch......... 8Wa-30-33, 7

Shifter Assembly................. 8Wa-30-8, 32

Speed Control Servo................. 8Wa-30-8

Starter Motor Relay................ 8Wa-30-13

Throttle Position Sensor.......... 8Wa-30-21, 22

Transfer Case Position Sensor.... 8Wa-30-9, 23, 32

Transmission Control Module . . 8Wa-30-10, 8, 22, 6

Transmission Solenoid/Trs Assembly.... 8Wa-30-10

Water In Fuel Sensor............... 8Wa-30-29

KJ8W-30 FUEL/IGNITION SYSTEM8Wa-30-1