Throttle pos JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1430 of 1803

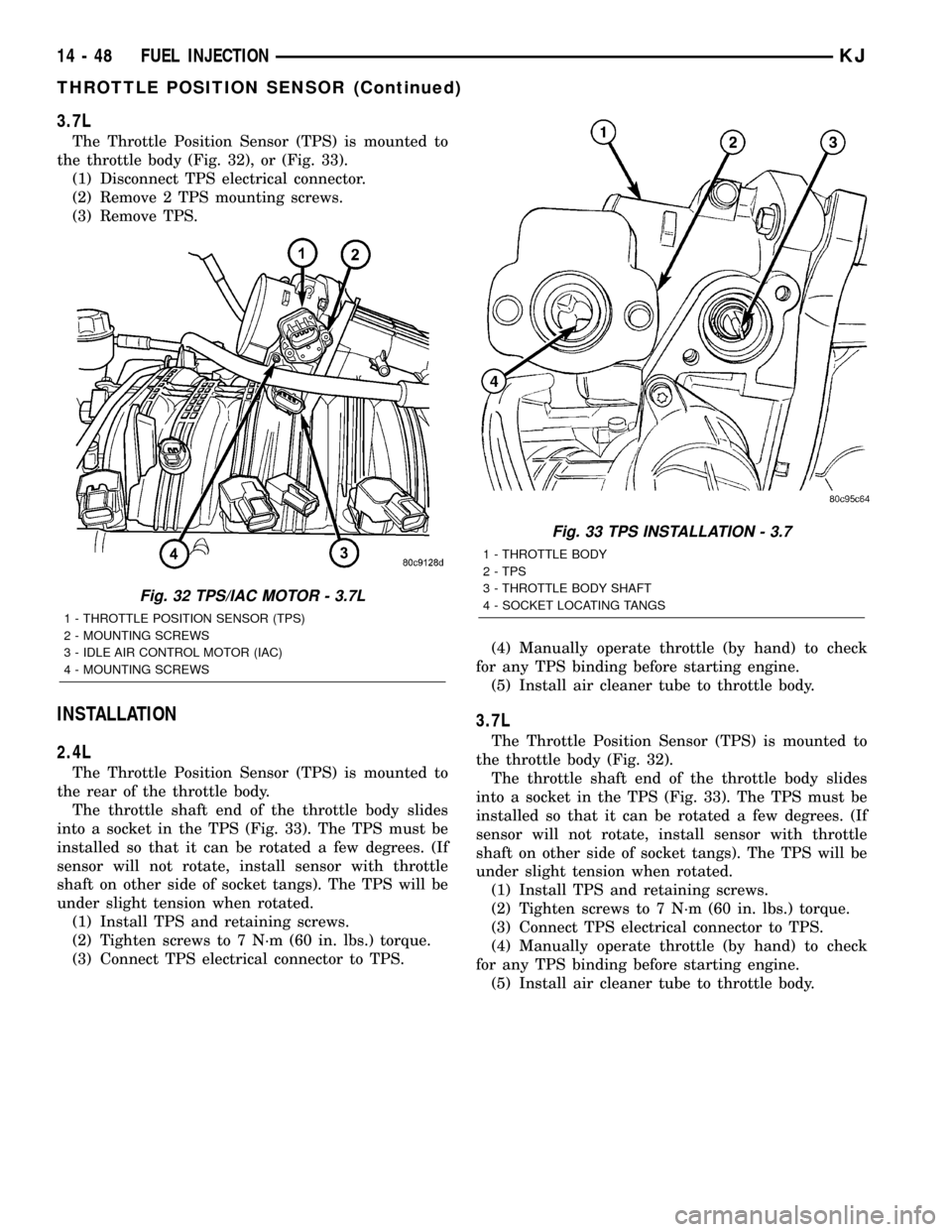

3.7L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 32), or (Fig. 33).

(1) Disconnect TPS electrical connector.

(2) Remove 2 TPS mounting screws.

(3) Remove TPS.

INSTALLATION

2.4L

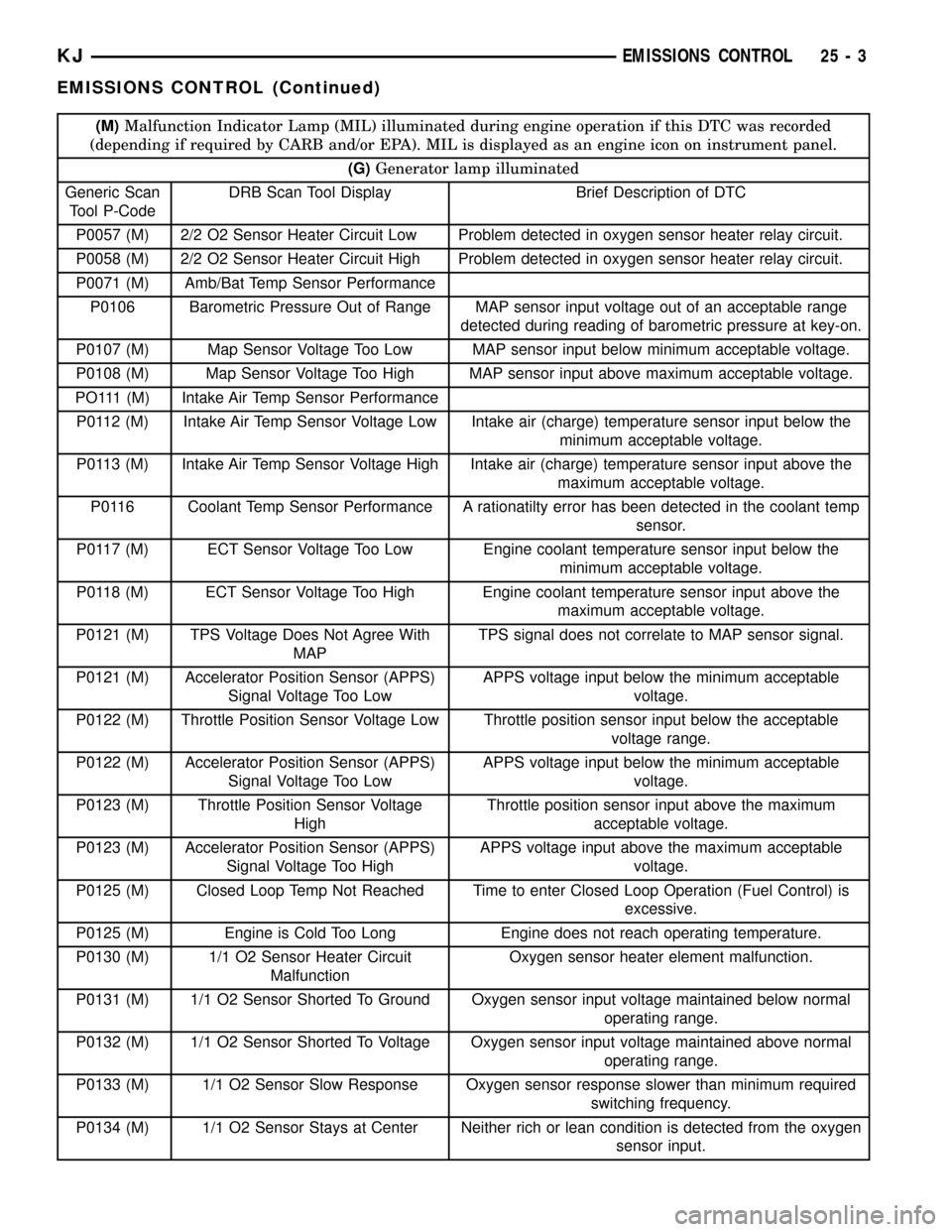

The Throttle Position Sensor (TPS) is mounted to

the rear of the throttle body.

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 33). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

3.7L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 32).

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 33). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

Fig. 32 TPS/IAC MOTOR - 3.7L

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

Fig. 33 TPS INSTALLATION - 3.7

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

14 - 48 FUEL INJECTIONKJ

THROTTLE POSITION SENSOR (Continued)

Page 1709 of 1803

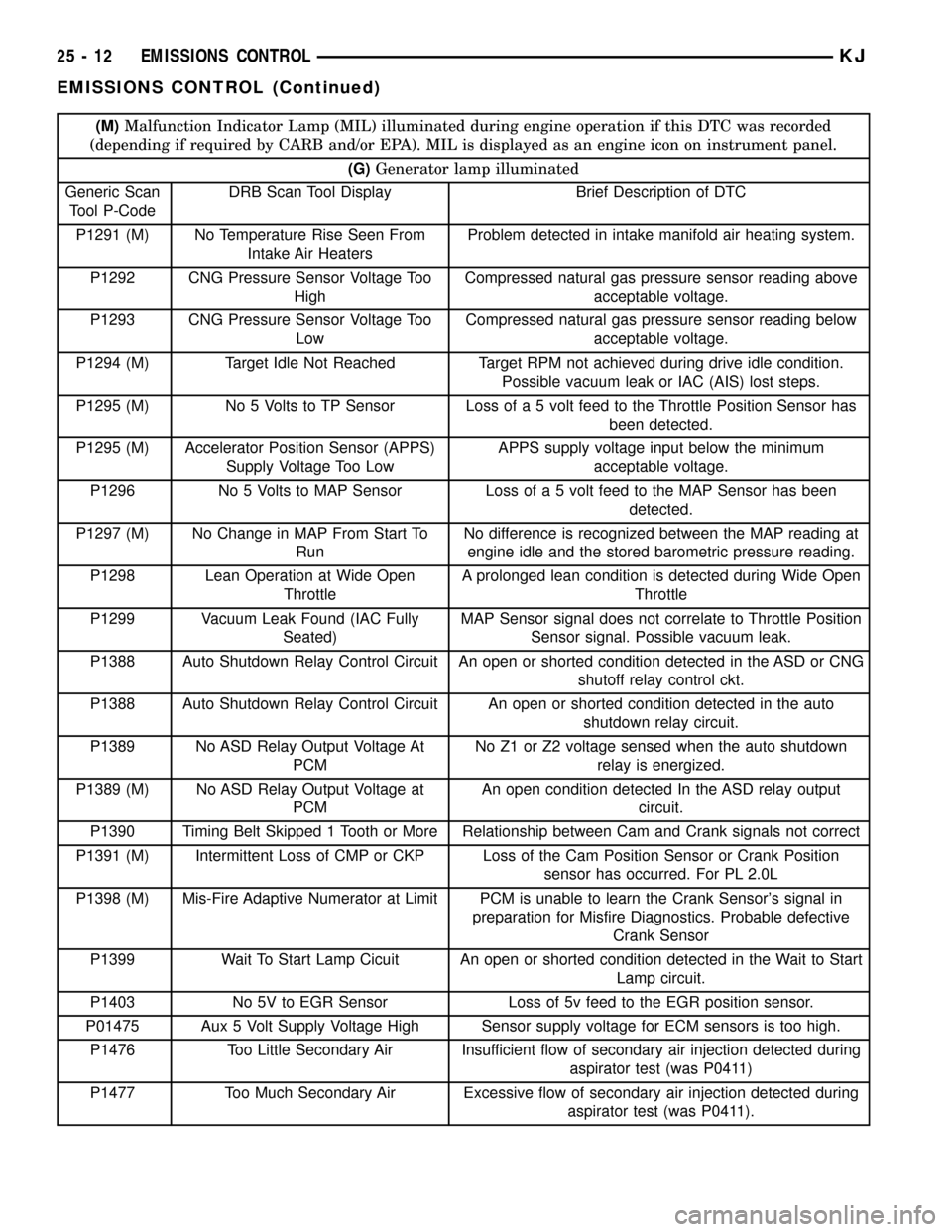

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0057 (M) 2/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0058 (M) 2/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0071 (M) Amb/Bat Temp Sensor Performance

P0106 Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

PO111 (M) Intake Air Temp Sensor Performance

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage High Intake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 Coolant Temp Sensor Performance A rationatilty error has been detected in the coolant temp

sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the

minimum acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0121 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too LowAPPS voltage input below the minimum acceptable

voltage.

P0122 (M) Throttle Position Sensor Voltage Low Throttle position sensor input below the acceptable

voltage range.

P0122 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too LowAPPS voltage input below the minimum acceptable

voltage.

P0123 (M) Throttle Position Sensor Voltage

HighThrottle position sensor input above the maximum

acceptable voltage.

P0123 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too HighAPPS voltage input above the maximum acceptable

voltage.

P0125 (M) Closed Loop Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0125 (M) Engine is Cold Too Long Engine does not reach operating temperature.

P0130 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionOxygen sensor heater element malfunction.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

KJEMISSIONS CONTROL 25 - 3

EMISSIONS CONTROL (Continued)

Page 1718 of 1803

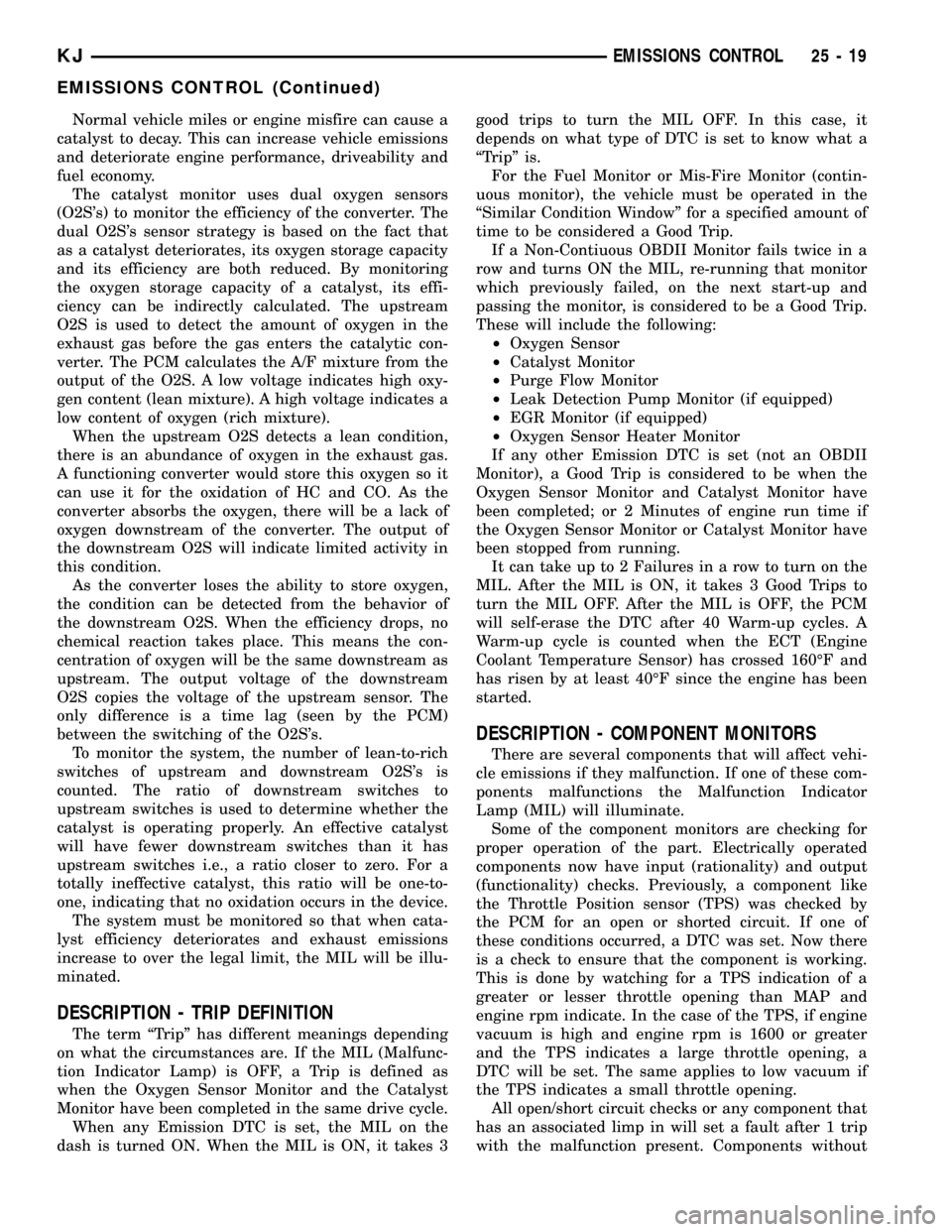

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1291 (M) No Temperature Rise Seen From

Intake Air HeatersProblem detected in intake manifold air heating system.

P1292 CNG Pressure Sensor Voltage Too

HighCompressed natural gas pressure sensor reading above

acceptable voltage.

P1293 CNG Pressure Sensor Voltage Too

LowCompressed natural gas pressure sensor reading below

acceptable voltage.

P1294 (M) Target Idle Not Reached Target RPM not achieved during drive idle condition.

Possible vacuum leak or IAC (AIS) lost steps.

P1295 (M) No 5 Volts to TP Sensor Loss of a 5 volt feed to the Throttle Position Sensor has

been detected.

P1295 (M) Accelerator Position Sensor (APPS)

Supply Voltage Too LowAPPS supply voltage input below the minimum

acceptable voltage.

P1296 No 5 Volts to MAP Sensor Loss of a 5 volt feed to the MAP Sensor has been

detected.

P1297 (M) No Change in MAP From Start To

RunNo difference is recognized between the MAP reading at

engine idle and the stored barometric pressure reading.

P1298 Lean Operation at Wide Open

ThrottleA prolonged lean condition is detected during Wide Open

Throttle

P1299 Vacuum Leak Found (IAC Fully

Seated)MAP Sensor signal does not correlate to Throttle Position

Sensor signal. Possible vacuum leak.

P1388 Auto Shutdown Relay Control Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P1388 Auto Shutdown Relay Control Circuit An open or shorted condition detected in the auto

shutdown relay circuit.

P1389 No ASD Relay Output Voltage At

PCMNo Z1 or Z2 voltage sensed when the auto shutdown

relay is energized.

P1389 (M) No ASD Relay Output Voltage at

PCMAn open condition detected In the ASD relay output

circuit.

P1390 Timing Belt Skipped 1 Tooth or More Relationship between Cam and Crank signals not correct

P1391 (M) Intermittent Loss of CMP or CKP Loss of the Cam Position Sensor or Crank Position

sensor has occurred. For PL 2.0L

P1398 (M) Mis-Fire Adaptive Numerator at Limit PCM is unable to learn the Crank Sensor's signal in

preparation for Misfire Diagnostics. Probable defective

Crank Sensor

P1399 Wait To Start Lamp Cicuit An open or shorted condition detected in the Wait to Start

Lamp circuit.

P1403 No 5V to EGR Sensor Loss of 5v feed to the EGR position sensor.

P01475 Aux 5 Volt Supply Voltage High Sensor supply voltage for ECM sensors is too high.

P1476 Too Little Secondary Air Insufficient flow of secondary air injection detected during

aspirator test (was P0411)

P1477 Too Much Secondary Air Excessive flow of secondary air injection detected during

aspirator test (was P0411).

25 - 12 EMISSIONS CONTROLKJ

EMISSIONS CONTROL (Continued)

Page 1725 of 1803

Normal vehicle miles or engine misfire can cause a

catalyst to decay. This can increase vehicle emissions

and deteriorate engine performance, driveability and

fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's sensor strategy is based on the fact that

as a catalyst deteriorates, its oxygen storage capacity

and its efficiency are both reduced. By monitoring

the oxygen storage capacity of a catalyst, its effi-

ciency can be indirectly calculated. The upstream

O2S is used to detect the amount of oxygen in the

exhaust gas before the gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3good trips to turn the MIL OFF. In this case, it

depends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks or any component that

has an associated limp in will set a fault after 1 trip

with the malfunction present. Components without

KJEMISSIONS CONTROL 25 - 19

EMISSIONS CONTROL (Continued)

Page 1732 of 1803

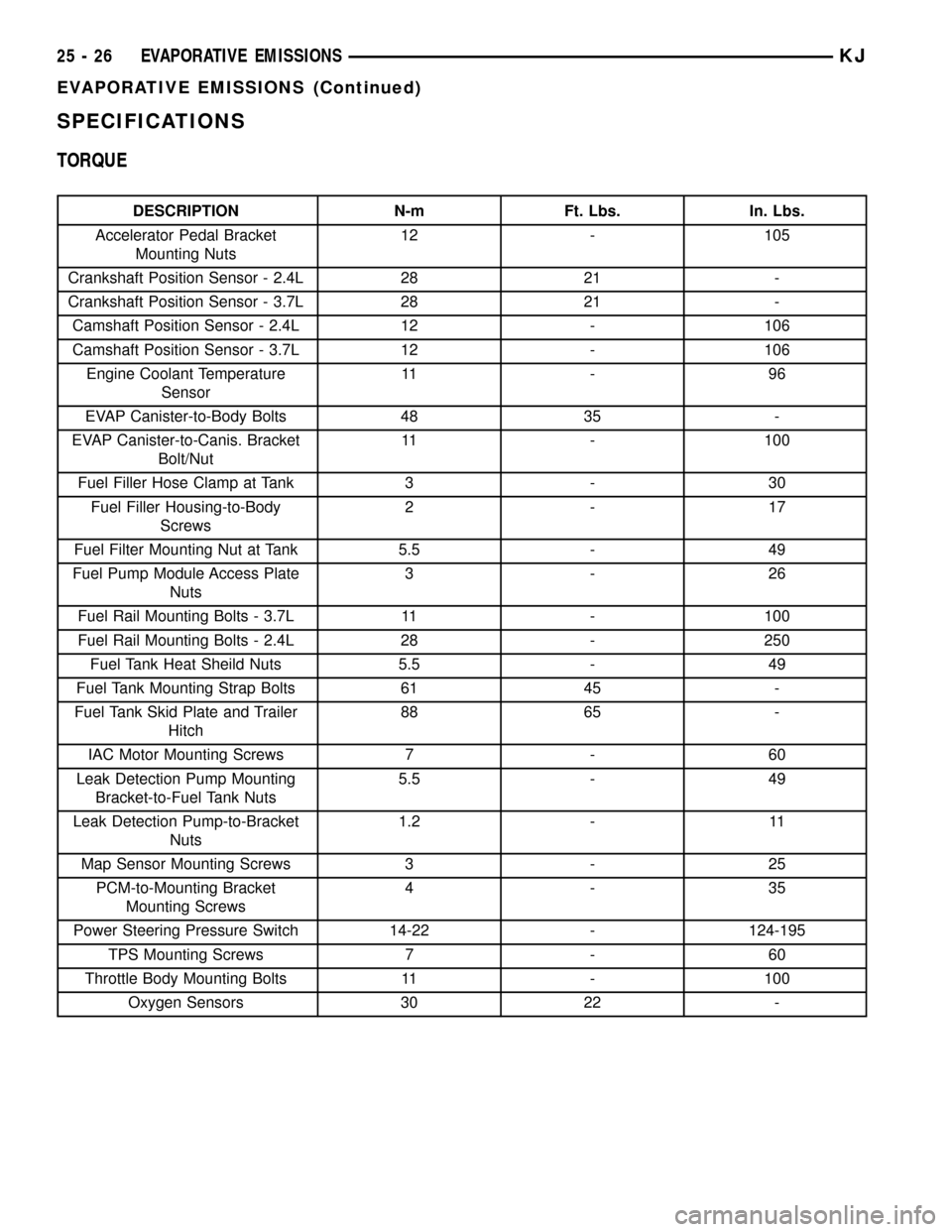

SPECIFICATIONS

TORQUE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting Nuts12 - 105

Crankshaft Position Sensor - 2.4L 28 21 -

Crankshaft Position Sensor - 3.7L 28 21 -

Camshaft Position Sensor - 2.4L 12 - 106

Camshaft Position Sensor - 3.7L 12 - 106

Engine Coolant Temperature

Sensor11 - 9 6

EVAP Canister-to-Body Bolts 48 35 -

EVAP Canister-to-Canis. Bracket

Bolt/Nut11 - 100

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body

Screws2-17

Fuel Filter Mounting Nut at Tank 5.5 - 49

Fuel Pump Module Access Plate

Nuts3-26

Fuel Rail Mounting Bolts - 3.7L 11 - 100

Fuel Rail Mounting Bolts - 2.4L 28 - 250

Fuel Tank Heat Sheild Nuts 5.5 - 49

Fuel Tank Mounting Strap Bolts 61 45 -

Fuel Tank Skid Plate and Trailer

Hitch88 65 -

IAC Motor Mounting Screws 7 - 60

Leak Detection Pump Mounting

Bracket-to-Fuel Tank Nuts5.5 - 49

Leak Detection Pump-to-Bracket

Nuts1.2 - 11

Map Sensor Mounting Screws 3 - 25

PCM-to-Mounting Bracket

Mounting Screws4-35

Power Steering Pressure Switch 14-22 - 124-195

TPS Mounting Screws 7 - 60

Throttle Body Mounting Bolts 11 - 100

Oxygen Sensors 30 22 -

25 - 26 EVAPORATIVE EMISSIONSKJ

EVAPORATIVE EMISSIONS (Continued)

Page 1743 of 1803

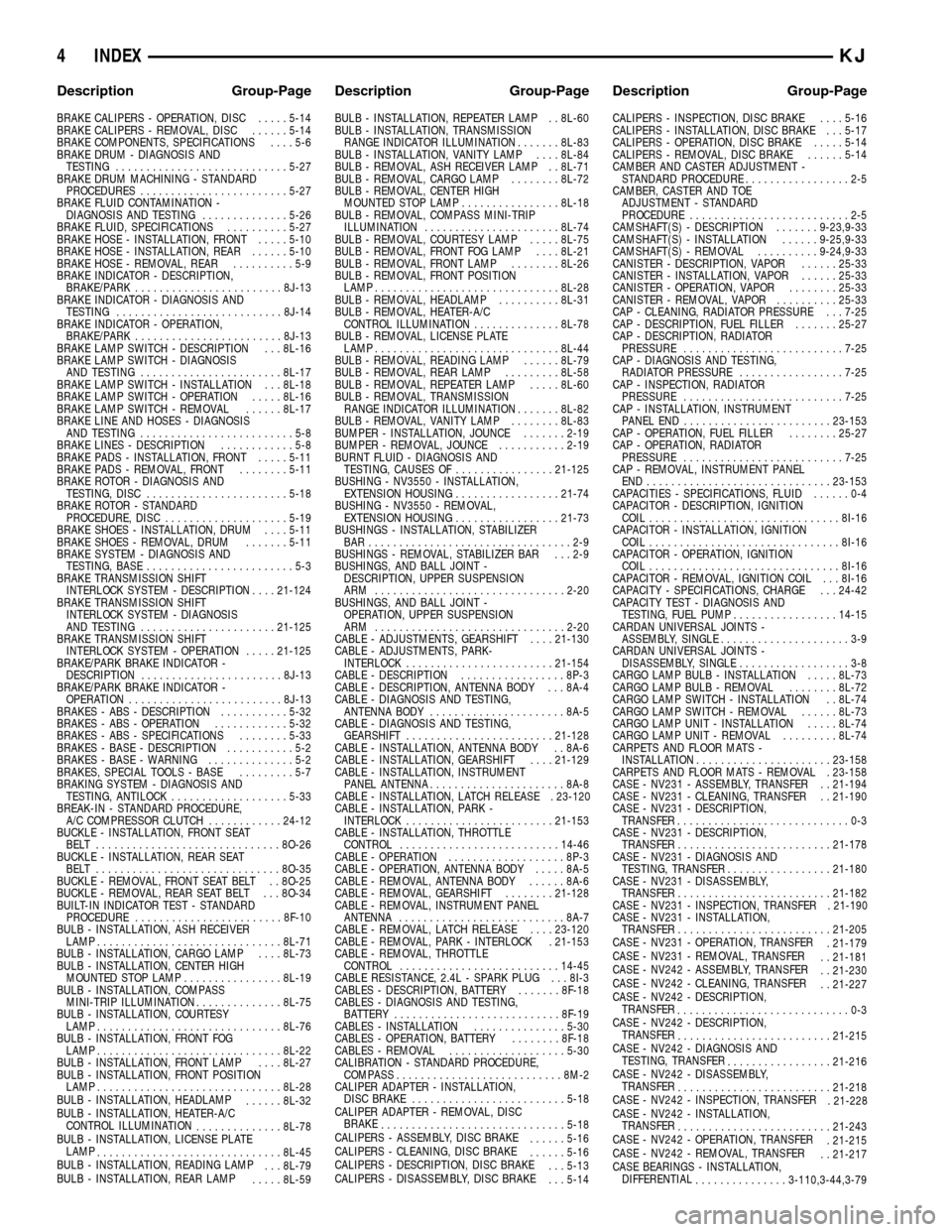

BRAKE CALIPERS - OPERATION, DISC.....5-14

BRAKE CALIPERS - REMOVAL, DISC......5-14

BRAKE COMPONENTS, SPECIFICATIONS....5-6

BRAKE DRUM - DIAGNOSIS AND

TESTING............................5-27

BRAKE DRUM MACHINING - STANDARD

PROCEDURES........................5-27

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-26

BRAKE FLUID, SPECIFICATIONS..........5-27

BRAKE HOSE - INSTALLATION, FRONT.....5-10

BRAKE HOSE - INSTALLATION, REAR......5-10

BRAKE HOSE - REMOVAL, REAR..........5-9

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-13

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-14

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-13

BRAKE LAMP SWITCH - DESCRIPTION . . . 8L-16

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-17

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-18

BRAKE LAMP SWITCH - OPERATION.....8L-16

BRAKE LAMP SWITCH - REMOVAL......8L-17

BRAKE LINE AND HOSES - DIAGNOSIS

AND TESTING.........................5-8

BRAKE LINES - DESCRIPTION............5-8

BRAKE PADS - INSTALLATION, FRONT.....5-11

BRAKE PADS - REMOVAL, FRONT........5-11

BRAKE ROTOR - DIAGNOSIS AND

TESTING, DISC.......................5-18

BRAKE ROTOR - STANDARD

PROCEDURE, DISC....................5-19

BRAKE SHOES - INSTALLATION, DRUM....5-11

BRAKE SHOES - REMOVAL, DRUM.......5-11

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-3

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION....21-124

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DIAGNOSIS

AND TESTING......................21-125

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-125

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-13

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-13

BRAKES - ABS - DESCRIPTION...........5-32

BRAKES - ABS - OPERATION............5-32

BRAKES - ABS - SPECIFICATIONS........5-33

BRAKES - BASE - DESCRIPTION...........5-2

BRAKES - BASE - WARNING..............5-2

BRAKES, SPECIAL TOOLS - BASE.........5-7

BRAKING SYSTEM - DIAGNOSIS AND

TESTING, ANTILOCK...................5-33

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-12

BUCKLE - INSTALLATION, FRONT SEAT

BELT ..............................8O-26

BUCKLE - INSTALLATION, REAR SEAT

BELT ..............................8O-35

BUCKLE - REMOVAL, FRONT SEAT BELT . . 8O-25

BUCKLE - REMOVAL, REAR SEAT BELT . . . 8O-34

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE........................8F-10

BULB - INSTALLATION, ASH RECEIVER

LAMP..............................8L-71

BULB - INSTALLATION, CARGO LAMP....8L-73

BULB - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP................8L-19

BULB - INSTALLATION, COMPASS

MINI-TRIP ILLUMINATION..............8L-75

BULB - INSTALLATION, COURTESY

LAMP..............................8L-76

BULB - INSTALLATION, FRONT FOG

LAMP..............................8L-22

BULB - INSTALLATION, FRONT LAMP....8L-27

BULB - INSTALLATION, FRONT POSITION

LAMP..............................8L-28

BULB - INSTALLATION, HEADLAMP

......8L-32

BULB - INSTALLATION, HEATER-A/C

CONTROL ILLUMINATION

..............8L-78

BULB - INSTALLATION, LICENSE PLATE

LAMP

..............................8L-45

BULB - INSTALLATION, READING LAMP

. . . 8L-79

BULB - INSTALLATION, REAR LAMP

.....8L-59BULB - INSTALLATION, REPEATER LAMP . . 8L-60

BULB - INSTALLATION, TRANSMISSION

RANGE INDICATOR ILLUMINATION.......8L-83

BULB - INSTALLATION, VANITY LAMP....8L-84

BULB - REMOVAL, ASH RECEIVER LAMP . . 8L-71

BULB - REMOVAL, CARGO LAMP........8L-72

BULB - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP................8L-18

BULB - REMOVAL, COMPASS MINI-TRIP

ILLUMINATION......................8L-74

BULB - REMOVAL, COURTESY LAMP.....8L-75

BULB - REMOVAL, FRONT FOG LAMP....8L-21

BULB - REMOVAL, FRONT LAMP........8L-26

BULB - REMOVAL, FRONT POSITION

LAMP..............................8L-28

BULB - REMOVAL, HEADLAMP..........8L-31

BULB - REMOVAL, HEATER-A/C

CONTROL ILLUMINATION..............8L-78

BULB - REMOVAL, LICENSE PLATE

LAMP..............................8L-44

BULB - REMOVAL, READING LAMP......8L-79

BULB - REMOVAL, REAR LAMP.........8L-58

BULB - REMOVAL, REPEATER LAMP.....8L-60

BULB - REMOVAL, TRANSMISSION

RANGE INDICATOR ILLUMINATION.......8L-82

BULB - REMOVAL, VANITY LAMP........8L-83

BUMPER - INSTALLATION, JOUNCE.......2-19

BUMPER - REMOVAL, JOUNCE...........2-19

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF................21-125

BUSHING - NV3550 - INSTALLATION,

EXTENSION HOUSING.................21-74

BUSHING - NV3550 - REMOVAL,

EXTENSION HOUSING.................21-73

BUSHINGS - INSTALLATION, STABILIZER

BAR.................................2-9

BUSHINGS - REMOVAL, STABILIZER BAR . . . 2-9

BUSHINGS, AND BALL JOINT -

DESCRIPTION, UPPER SUSPENSION

ARM ...............................2-20

BUSHINGS, AND BALL JOINT -

OPERATION, UPPER SUSPENSION

ARM ...............................2-20

CABLE - ADJUSTMENTS, GEARSHIFT....21-130

CABLE - ADJUSTMENTS, PARK-

INTERLOCK........................21-154

CABLE - DESCRIPTION.................8P-3

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-5

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT........................21-128

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, GEARSHIFT....21-129

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-8

CABLE - INSTALLATION, LATCH RELEASE . 23-120

CABLE - INSTALLATION, PARK -

INTERLOCK........................21-153

CABLE - INSTALLATION, THROTTLE

CONTROL..........................14-46

CABLE - OPERATION...................8P-3

CABLE - OPERATION, ANTENNA BODY.....8A-5

CABLE - REMOVAL, ANTENNA BODY......8A-6

CABLE - REMOVAL, GEARSHIFT........21-128

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA...........................8A-7

CABLE - REMOVAL, LATCH RELEASE....23-120

CABLE - REMOVAL, PARK - INTERLOCK . 21-153

CABLE - REMOVAL, THROTTLE

CONTROL..........................14-45

CABLE RESISTANCE, 2.4L - SPARK PLUG . . . 8I-3

CABLES - DESCRIPTION, BATTERY.......8F-18

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-19

CABLES - INSTALLATION...............5-30

CABLES - OPERATION, BATTERY........8F-18

CABLES - REMOVAL...................5-30

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-2

CALIPER ADAPTER - INSTALLATION,

DISC BRAKE.........................5-18

CALIPER ADAPTER - REMOVAL, DISC

BRAKE

..............................5-18

CALIPERS - ASSEMBLY, DISC BRAKE

......5-16

CALIPERS - CLEANING, DISC BRAKE

......5-16

CALIPERS - DESCRIPTION, DISC BRAKE

. . . 5-13

CALIPERS - DISASSEMBLY, DISC BRAKE

. . . 5-14CALIPERS - INSPECTION, DISC BRAKE....5-16

CALIPERS - INSTALLATION, DISC BRAKE . . . 5-17

CALIPERS - OPERATION, DISC BRAKE.....5-14

CALIPERS - REMOVAL, DISC BRAKE......5-14

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-5

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-5

CAMSHAFT(S) - DESCRIPTION.......9-23,9-33

CAMSHAFT(S) - INSTALLATION......9-25,9-33

CAMSHAFT(S) - REMOVAL..........9-24,9-33

CANISTER - DESCRIPTION, VAPOR......25-33

CANISTER - INSTALLATION, VAPOR......25-33

CANISTER - OPERATION, VAPOR........25-33

CANISTER - REMOVAL, VAPOR..........25-33

CAP - CLEANING, RADIATOR PRESSURE . . . 7-25

CAP - DESCRIPTION, FUEL FILLER.......25-27

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-25

CAP - DIAGNOSIS AND TESTING,

RADIATOR PRESSURE.................7-25

CAP - INSPECTION, RADIATOR

PRESSURE..........................7-25

CAP - INSTALLATION, INSTRUMENT

PANEL END........................23-153

CAP - OPERATION, FUEL FILLER........25-27

CAP - OPERATION, RADIATOR

PRESSURE..........................7-25

CAP - REMOVAL, INSTRUMENT PANEL

END ..............................23-153

CAPACITIES - SPECIFICATIONS, FLUID......0-4

CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-16

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-16

CAPACITOR - OPERATION, IGNITION

COIL...............................8I-16

CAPACITOR - REMOVAL, IGNITION COIL . . . 8I-16

CAPACITY - SPECIFICATIONS, CHARGE . . . 24-42

CAPACITY TEST - DIAGNOSIS AND

TESTING, FUEL PUMP.................14-15

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, SINGLE.....................3-9

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, SINGLE..................3-8

CARGO LAMP BULB - INSTALLATION.....8L-73

CARGO LAMP BULB - REMOVAL........8L-72

CARGO LAMP SWITCH - INSTALLATION . . 8L-74

CARGO LAMP SWITCH - REMOVAL......8L-73

CARGO LAMP UNIT - INSTALLATION.....8L-74

CARGO LAMP UNIT - REMOVAL.........8L-74

CARPETS AND FLOOR MATS -

INSTALLATION......................23-158

CARPETS AND FLOOR MATS - REMOVAL . 23-158

CASE - NV231 - ASSEMBLY, TRANSFER . . 21-194

CASE - NV231 - CLEANING, TRANSFER . . 21-190

CASE - NV231 - DESCRIPTION,

TRANSFER............................0-3

CASE - NV231 - DESCRIPTION,

TRANSFER.........................21-178

CASE - NV231 - DIAGNOSIS AND

TESTING, TRANSFER.................21-180

CASE - NV231 - DISASSEMBLY,

TRANSFER.........................21-182

CASE - NV231 - INSPECTION, TRANSFER . 21-190

CASE - NV231 - INSTALLATION,

TRANSFER.........................21-205

CASE - NV231 - OPERATION, TRANSFER

. 21-179

CASE - NV231 - REMOVAL, TRANSFER

. . 21-181

CASE - NV242 - ASSEMBLY, TRANSFER

. . 21-230

CASE - NV242 - CLEANING, TRANSFER

. . 21-227

CASE - NV242 - DESCRIPTION,

TRANSFER

............................0-3

CASE - NV242 - DESCRIPTION,

TRANSFER

.........................21-215

CASE - NV242 - DIAGNOSIS AND

TESTING, TRANSFER

.................21-216

CASE - NV242 - DISASSEMBLY,

TRANSFER

.........................21-218

CASE - NV242 - INSPECTION, TRANSFER

. 21-228

CASE - NV242 - INSTALLATION,

TRANSFER

.........................21-243

CASE - NV242 - OPERATION, TRANSFER

. 21-215

CASE - NV242 - REMOVAL, TRANSFER

. . 21-217

CASE BEARINGS - INSTALLATION,

DIFFERENTIAL

...............3-110,3-44,3-79

4 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

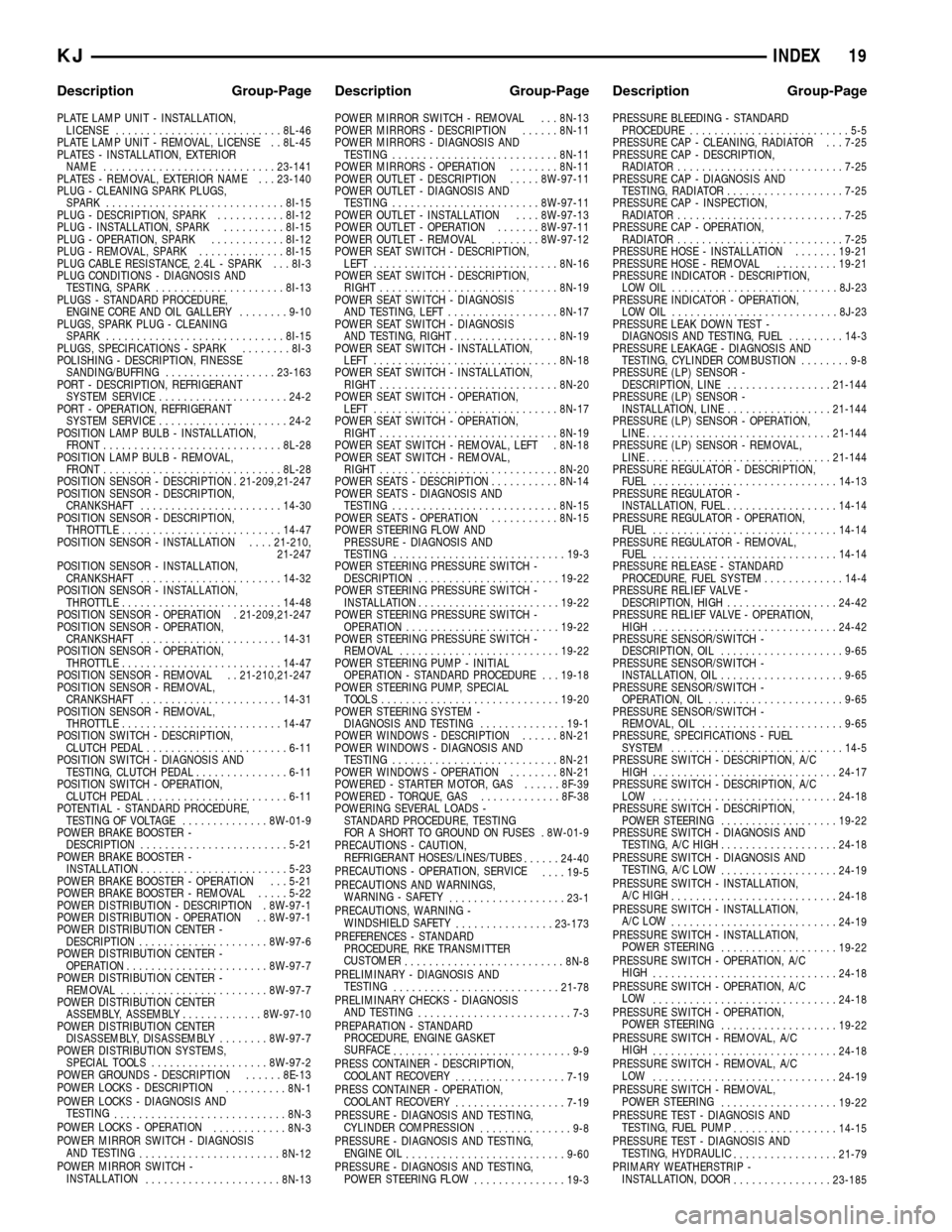

Page 1758 of 1803

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-46

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-45

PLATES - INSTALLATION, EXTERIOR

NAME............................23-141

PLATES - REMOVAL, EXTERIOR NAME . . . 23-140

PLUG - CLEANING SPARK PLUGS,

SPARK .............................8I-15

PLUG - DESCRIPTION, SPARK...........8I-12

PLUG - INSTALLATION, SPARK..........8I-15

PLUG - OPERATION, SPARK............8I-12

PLUG - REMOVAL, SPARK..............8I-15

PLUG CABLE RESISTANCE, 2.4L - SPARK . . . 8I-3

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-13

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY........9-10

PLUGS, SPARK PLUG - CLEANING

SPARK .............................8I-15

PLUGS, SPECIFICATIONS - SPARK........8I-3

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING..................23-163

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-2

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION LAMP BULB - INSTALLATION,

FRONT.............................8L-28

POSITION LAMP BULB - REMOVAL,

FRONT.............................8L-28

POSITION SENSOR - DESCRIPTION . 21-209,21-247

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT.......................14-30

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-47

POSITION SENSOR - INSTALLATION....21-210,

21-247

POSITION SENSOR - INSTALLATION,

CRANKSHAFT.......................14-32

POSITION SENSOR - INSTALLATION,

THROTTLE..........................14-48

POSITION SENSOR - OPERATION . 21-209,21-247

POSITION SENSOR - OPERATION,

CRANKSHAFT.......................14-31

POSITION SENSOR - OPERATION,

THROTTLE..........................14-47

POSITION SENSOR - REMOVAL . . 21-210,21-247

POSITION SENSOR - REMOVAL,

CRANKSHAFT.......................14-31

POSITION SENSOR - REMOVAL,

THROTTLE..........................14-47

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-11

POSITION SWITCH - DIAGNOSIS AND

TESTING, CLUTCH PEDAL...............6-11

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-11

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER BRAKE BOOSTER -

DESCRIPTION........................5-21

POWER BRAKE BOOSTER -

INSTALLATION........................5-23

POWER BRAKE BOOSTER - OPERATION . . . 5-21

POWER BRAKE BOOSTER - REMOVAL.....5-22

POWER DISTRIBUTION - DESCRIPTION . 8W-97-1

POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION CENTER -

DESCRIPTION.....................8W-97-6

POWER DISTRIBUTION CENTER -

OPERATION.......................8W-97-7

POWER DISTRIBUTION CENTER -

REMOVAL........................8W-97-7

POWER DISTRIBUTION CENTER

ASSEMBLY, ASSEMBLY.............8W-97-10

POWER DISTRIBUTION CENTER

DISASSEMBLY, DISASSEMBLY........8W-97-7

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-13

POWER LOCKS - DESCRIPTION

..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING

............................8N-3

POWER LOCKS - OPERATION

............8N-3

POWER MIRROR SWITCH - DIAGNOSIS

AND TESTING

.......................8N-12

POWER MIRROR SWITCH -

INSTALLATION

......................8N-13POWER MIRROR SWITCH - REMOVAL . . . 8N-13

POWER MIRRORS - DESCRIPTION......8N-11

POWER MIRRORS - DIAGNOSIS AND

TESTING...........................8N-11

POWER MIRRORS - OPERATION........8N-11

POWER OUTLET - DESCRIPTION.....8W-97-11

POWER OUTLET - DIAGNOSIS AND

TESTING........................8W-97-11

POWER OUTLET - INSTALLATION....8W-97-13

POWER OUTLET - OPERATION.......8W-97-11

POWER OUTLET - REMOVAL........8W-97-12

POWER SEAT SWITCH - DESCRIPTION,

LEFT..............................8N-16

POWER SEAT SWITCH - DESCRIPTION,

RIGHT.............................8N-19

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, LEFT..................8N-17

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, RIGHT.................8N-19

POWER SEAT SWITCH - INSTALLATION,

LEFT..............................8N-18

POWER SEAT SWITCH - INSTALLATION,

RIGHT.............................8N-20

POWER SEAT SWITCH - OPERATION,

LEFT..............................8N-17

POWER SEAT SWITCH - OPERATION,

RIGHT.............................8N-19

POWER SEAT SWITCH - REMOVAL, LEFT . 8N-18

POWER SEAT SWITCH - REMOVAL,

RIGHT.............................8N-20

POWER SEATS - DESCRIPTION...........8N-14

POWER SEATS - DIAGNOSIS AND

TESTING...........................8N-15

POWER SEATS - OPERATION...........8N-15

POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-3

POWER STEERING PRESSURE SWITCH -

DESCRIPTION.......................19-22

POWER STEERING PRESSURE SWITCH -

INSTALLATION.......................19-22

POWER STEERING PRESSURE SWITCH -

OPERATION.........................19-22

POWER STEERING PRESSURE SWITCH -

REMOVAL..........................19-22

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE . . . 19-18

POWER STEERING PUMP, SPECIAL

TOOLS.............................19-20

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING..............19-1

POWER WINDOWS - DESCRIPTION......8N-21

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-21

POWER WINDOWS - OPERATION........8N-21

POWERED - STARTER MOTOR, GAS......8F-39

POWERED - TORQUE, GAS.............8F-38

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-9

PRECAUTIONS - CAUTION,

REFRIGERANT HOSES/LINES/TUBES

......24-40

PRECAUTIONS - OPERATION, SERVICE

....19-5

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY

...................23-1

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY

................23-173

PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER

CUSTOMER

..........................8N-8

PRELIMINARY - DIAGNOSIS AND

TESTING

...........................21-78

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING

.........................7-3

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE

.............................9-9

PRESS CONTAINER - DESCRIPTION,

COOLANT RECOVERY

..................7-19

PRESS CONTAINER - OPERATION,

COOLANT RECOVERY

..................7-19

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION

...............9-8

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL

..........................9-60

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW

...............19-3PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-5

PRESSURE CAP - CLEANING, RADIATOR . . . 7-25

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-25

PRESSURE CAP - DIAGNOSIS AND

TESTING, RADIATOR...................7-25

PRESSURE CAP - INSPECTION,

RADIATOR...........................7-25

PRESSURE CAP - OPERATION,

RADIATOR...........................7-25

PRESSURE HOSE - INSTALLATION.......19-21

PRESSURE HOSE - REMOVAL..........19-21

PRESSURE INDICATOR - DESCRIPTION,

LOW OIL ...........................8J-23

PRESSURE INDICATOR - OPERATION,

LOW OIL ...........................8J-23

PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING, FUEL.........14-3

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION........9-8

PRESSURE (LP) SENSOR -

DESCRIPTION, LINE.................21-144

PRESSURE (LP) SENSOR -

INSTALLATION, LINE.................21-144

PRESSURE (LP) SENSOR - OPERATION,

LINE..............................21-144

PRESSURE (LP) SENSOR - REMOVAL,

LINE..............................21-144

PRESSURE REGULATOR - DESCRIPTION,

FUEL..............................14-13

PRESSURE REGULATOR -

INSTALLATION, FUEL...................14-14

PRESSURE REGULATOR - OPERATION,

FUEL..............................14-14

PRESSURE REGULATOR - REMOVAL,

FUEL..............................14-14

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-4

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH..................24-42

PRESSURE RELIEF VALVE - OPERATION,

HIGH..............................24-42

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-65

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL....................9-65

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-65

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL.......................9-65

PRESSURE, SPECIFICATIONS - FUEL

SYSTEM............................14-5

PRESSURE SWITCH - DESCRIPTION, A/C

HIGH..............................24-17

PRESSURE SWITCH - DESCRIPTION, A/C

LOW ..............................24-18

PRESSURE SWITCH - DESCRIPTION,

POWER STEERING...................19-22

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C HIGH...................24-18

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C LOW

...................24-19

PRESSURE SWITCH - INSTALLATION,

A/C HIGH

...........................24-18

PRESSURE SWITCH - INSTALLATION,

A/C LOW

...........................24-19

PRESSURE SWITCH - INSTALLATION,

POWER STEERING

...................19-22

PRESSURE SWITCH - OPERATION, A/C

HIGH

..............................24-18

PRESSURE SWITCH - OPERATION, A/C

LOW

..............................24-18

PRESSURE SWITCH - OPERATION,

POWER STEERING

...................19-22

PRESSURE SWITCH - REMOVAL, A/C

HIGH

..............................24-18

PRESSURE SWITCH - REMOVAL, A/C

LOW

..............................24-19

PRESSURE SWITCH - REMOVAL,

POWER STEERING

...................19-22

PRESSURE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP

.................14-15

PRESSURE TEST - DIAGNOSIS AND

TESTING, HYDRAULIC

.................21-79

PRIMARY WEATHERSTRIP -

INSTALLATION, DOOR

................23-185

KJINDEX 19

Description Group-Page Description Group-Page Description Group-Page

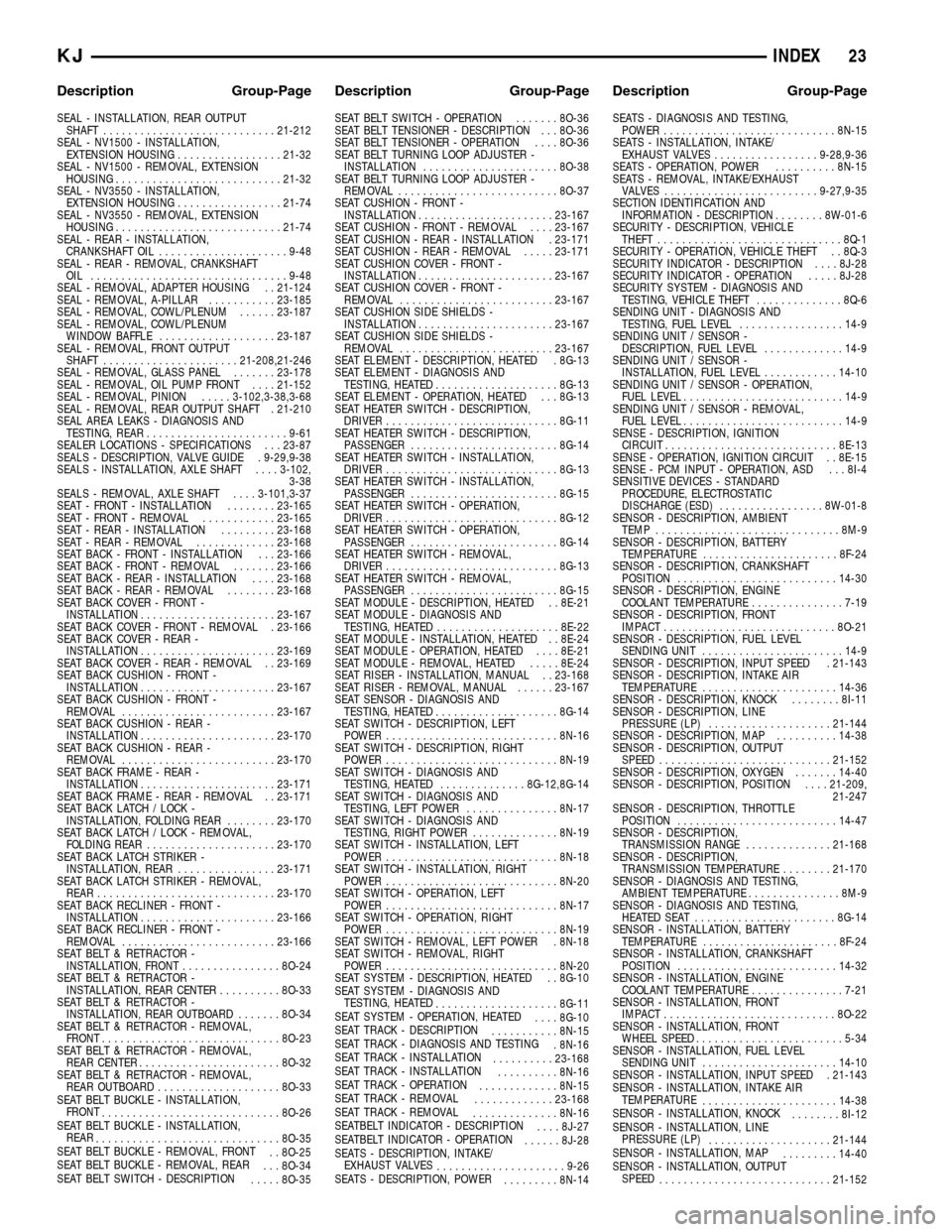

Page 1762 of 1803

SEAL - INSTALLATION, REAR OUTPUT

SHAFT............................21-212

SEAL - NV1500 - INSTALLATION,

EXTENSION HOUSING.................21-32

SEAL - NV1500 - REMOVAL, EXTENSION

HOUSING...........................21-32

SEAL - NV3550 - INSTALLATION,

EXTENSION HOUSING.................21-74

SEAL - NV3550 - REMOVAL, EXTENSION

HOUSING...........................21-74

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL.....................9-48

SEAL - REAR - REMOVAL, CRANKSHAFT

OIL ................................9-48

SEAL - REMOVAL, ADAPTER HOUSING . . 21-124

SEAL - REMOVAL, A-PILLAR...........23-185

SEAL - REMOVAL, COWL/PLENUM......23-187

SEAL - REMOVAL, COWL/PLENUM

WINDOW BAFFLE...................23-187

SEAL - REMOVAL, FRONT OUTPUT

SHAFT......................21-208,21-246

SEAL - REMOVAL, GLASS PANEL.......23-178

SEAL - REMOVAL, OIL PUMP FRONT....21-152

SEAL - REMOVAL, PINION.....3-102,3-38,3-68

SEAL - REMOVAL, REAR OUTPUT SHAFT . 21-210

SEAL AREA LEAKS - DIAGNOSIS AND

TESTING, REAR.......................9-61

SEALER LOCATIONS - SPECIFICATIONS . . . 23-87

SEALS - DESCRIPTION, VALVE GUIDE . 9-29,9-38

SEALS - INSTALLATION, AXLE SHAFT....3-102,

3-38

SEALS - REMOVAL, AXLE SHAFT....3-101,3-37

SEAT - FRONT - INSTALLATION........23-165

SEAT - FRONT - REMOVAL............23-165

SEAT - REAR - INSTALLATION.........23-168

SEAT - REAR - REMOVAL.............23-168

SEAT BACK - FRONT - INSTALLATION . . . 23-166

SEAT BACK - FRONT - REMOVAL.......23-166

SEAT BACK - REAR - INSTALLATION....23-168

SEAT BACK - REAR - REMOVAL........23-168

SEAT BACK COVER - FRONT -

INSTALLATION......................23-167

SEAT BACK COVER - FRONT - REMOVAL . 23-166

SEAT BACK COVER - REAR -

INSTALLATION......................23-169

SEAT BACK COVER - REAR - REMOVAL . . 23-169

SEAT BACK CUSHION - FRONT -

INSTALLATION......................23-167

SEAT BACK CUSHION - FRONT -

REMOVAL.........................23-167

SEAT BACK CUSHION - REAR -

INSTALLATION......................23-170

SEAT BACK CUSHION - REAR -

REMOVAL.........................23-170

SEAT BACK FRAME - REAR -

INSTALLATION......................23-171

SEAT BACK FRAME - REAR - REMOVAL . . 23-171

SEAT BACK LATCH / LOCK -

INSTALLATION, FOLDING REAR........23-170

SEAT BACK LATCH / LOCK - REMOVAL,

FOLDING REAR.....................23-170

SEAT BACK LATCH STRIKER -

INSTALLATION, REAR................23-171

SEAT BACK LATCH STRIKER - REMOVAL,

REAR.............................23-170

SEAT BACK RECLINER - FRONT -

INSTALLATION......................23-166

SEAT BACK RECLINER - FRONT -

REMOVAL.........................23-166

SEAT BELT & RETRACTOR -

INSTALLATION, FRONT................8O-24

SEAT BELT & RETRACTOR -

INSTALLATION, REAR CENTER..........8O-33

SEAT BELT & RETRACTOR -

INSTALLATION, REAR OUTBOARD.......8O-34

SEAT BELT & RETRACTOR - REMOVAL,

FRONT.............................8O-23

SEAT BELT & RETRACTOR - REMOVAL,

REAR CENTER.......................8O-32

SEAT BELT & RETRACTOR - REMOVAL,

REAR OUTBOARD....................8O-33

SEAT BELT BUCKLE - INSTALLATION,

FRONT

.............................8O-26

SEAT BELT BUCKLE - INSTALLATION,

REAR

..............................8O-35

SEAT BELT BUCKLE - REMOVAL, FRONT

. . 8O-25

SEAT BELT BUCKLE - REMOVAL, REAR

. . . 8O-34

SEAT BELT SWITCH - DESCRIPTION

.....8O-35SEAT BELT SWITCH - OPERATION.......8O-36

SEAT BELT TENSIONER - DESCRIPTION . . . 8O-36

SEAT BELT TENSIONER - OPERATION....8O-36

SEAT BELT TURNING LOOP ADJUSTER -

INSTALLATION......................8O-38

SEAT BELT TURNING LOOP ADJUSTER -

REMOVAL..........................8O-37

SEAT CUSHION - FRONT -

INSTALLATION......................23-167

SEAT CUSHION - FRONT - REMOVAL....23-167

SEAT CUSHION - REAR - INSTALLATION . 23-171

SEAT CUSHION - REAR - REMOVAL.....23-171

SEAT CUSHION COVER - FRONT -

INSTALLATION......................23-167

SEAT CUSHION COVER - FRONT -

REMOVAL.........................23-167

SEAT CUSHION SIDE SHIELDS -

INSTALLATION......................23-167

SEAT CUSHION SIDE SHIELDS -

REMOVAL.........................23-167

SEAT ELEMENT - DESCRIPTION, HEATED . 8G-13

SEAT ELEMENT - DIAGNOSIS AND

TESTING, HEATED....................8G-13

SEAT ELEMENT - OPERATION, HEATED . . . 8G-13

SEAT HEATER SWITCH - DESCRIPTION,

DRIVER............................8G-11

SEAT HEATER SWITCH - DESCRIPTION,

PASSENGER........................8G-14

SEAT HEATER SWITCH - INSTALLATION,

DRIVER............................8G-13

SEAT HEATER SWITCH - INSTALLATION,

PASSENGER........................8G-15

SEAT HEATER SWITCH - OPERATION,

DRIVER............................8G-12

SEAT HEATER SWITCH - OPERATION,

PASSENGER........................8G-14

SEAT HEATER SWITCH - REMOVAL,

DRIVER............................8G-13

SEAT HEATER SWITCH - REMOVAL,

PASSENGER........................8G-15

SEAT MODULE - DESCRIPTION, HEATED . . 8E-21

SEAT MODULE - DIAGNOSIS AND

TESTING, HEATED....................8E-22

SEAT MODULE - INSTALLATION, HEATED . . 8E-24

SEAT MODULE - OPERATION, HEATED....8E-21

SEAT MODULE - REMOVAL, HEATED.....8E-24

SEAT RISER - INSTALLATION, MANUAL . . 23-168

SEAT RISER - REMOVAL, MANUAL......23-167

SEAT SENSOR - DIAGNOSIS AND

TESTING, HEATED....................8G-14

SEAT SWITCH - DESCRIPTION, LEFT

POWER............................8N-16

SEAT SWITCH - DESCRIPTION, RIGHT

POWER............................8N-19

SEAT SWITCH - DIAGNOSIS AND

TESTING, HEATED..............8G-12,8G-14

SEAT SWITCH - DIAGNOSIS AND

TESTING, LEFT POWER...............8N-17

SEAT SWITCH - DIAGNOSIS AND

TESTING, RIGHT POWER..............8N-19

SEAT SWITCH - INSTALLATION, LEFT

POWER............................8N-18

SEAT SWITCH - INSTALLATION, RIGHT

POWER............................8N-20

SEAT SWITCH - OPERATION, LEFT

POWER............................8N-17

SEAT SWITCH - OPERATION, RIGHT

POWER............................8N-19

SEAT SWITCH - REMOVAL, LEFT POWER . 8N-18

SEAT SWITCH - REMOVAL, RIGHT

POWER............................8N-20

SEAT SYSTEM - DESCRIPTION, HEATED . . 8G-10

SEAT SYSTEM - DIAGNOSIS AND

TESTING, HEATED

....................8G-11

SEAT SYSTEM - OPERATION, HEATED

....8G-10

SEAT TRACK - DESCRIPTION

...........8N-15

SEAT TRACK - DIAGNOSIS AND TESTING

. 8N-16

SEAT TRACK - INSTALLATION

..........23-168

SEAT TRACK - INSTALLATION

..........8N-16

SEAT TRACK - OPERATION

.............8N-15

SEAT TRACK - REMOVAL

.............23-168

SEAT TRACK - REMOVAL

..............8N-16

SEATBELT INDICATOR - DESCRIPTION

....8J-27

SEATBELT INDICATOR - OPERATION

......8J-28

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES

.....................9-26

SEATS - DESCRIPTION, POWER

.........8N-14SEATS - DIAGNOSIS AND TESTING,

POWER............................8N-15

SEATS - INSTALLATION, INTAKE/

EXHAUST VALVES.................9-28,9-36

SEATS - OPERATION, POWER..........8N-15

SEATS - REMOVAL, INTAKE/EXHAUST

VALVES .........................9-27,9-35

SECTION IDENTIFICATION AND

INFORMATION - DESCRIPTION........8W-01-6

SECURITY - DESCRIPTION, VEHICLE

THEFT..............................8Q-1

SECURITY - OPERATION, VEHICLE THEFT . . 8Q-3

SECURITY INDICATOR - DESCRIPTION....8J-28

SECURITY INDICATOR - OPERATION.....8J-28

SECURITY SYSTEM - DIAGNOSIS AND

TESTING, VEHICLE THEFT..............8Q-6

SENDING UNIT - DIAGNOSIS AND

TESTING, FUEL LEVEL.................14-9

SENDING UNIT / SENSOR -

DESCRIPTION, FUEL LEVEL.............14-9

SENDING UNIT / SENSOR -

INSTALLATION, FUEL LEVEL............14-10

SENDING UNIT / SENSOR - OPERATION,

FUEL LEVEL..........................14-9

SENDING UNIT / SENSOR - REMOVAL,

FUEL LEVEL..........................14-9

SENSE - DESCRIPTION, IGNITION

CIRCUIT............................8E-13

SENSE - OPERATION, IGNITION CIRCUIT . . 8E-15

SENSE - PCM INPUT - OPERATION, ASD . . . 8I-4

SENSITIVE DEVICES - STANDARD

PROCEDURE, ELECTROSTATIC

DISCHARGE (ESD).................8W-01-8

SENSOR - DESCRIPTION, AMBIENT

TEMP..............................8M-9

SENSOR - DESCRIPTION, BATTERY

TEMPERATURE......................8F-24

SENSOR - DESCRIPTION, CRANKSHAFT

POSITION..........................14-30

SENSOR - DESCRIPTION, ENGINE

COOLANT TEMPERATURE...............7-19

SENSOR - DESCRIPTION, FRONT

IMPACT............................8O-21

SENSOR - DESCRIPTION, FUEL LEVEL

SENDING UNIT.......................14-9

SENSOR - DESCRIPTION, INPUT SPEED . 21-143

SENSOR - DESCRIPTION, INTAKE AIR

TEMPERATURE......................14-36

SENSOR - DESCRIPTION, KNOCK........8I-11

SENSOR - DESCRIPTION, LINE

PRESSURE (LP)....................21-144

SENSOR - DESCRIPTION, MAP..........14-38

SENSOR - DESCRIPTION, OUTPUT

SPEED............................21-152

SENSOR - DESCRIPTION, OXYGEN.......14-40

SENSOR - DESCRIPTION, POSITION....21-209,

21-247

SENSOR - DESCRIPTION, THROTTLE

POSITION..........................14-47

SENSOR - DESCRIPTION,

TRANSMISSION RANGE..............21-168

SENSOR - DESCRIPTION,

TRANSMISSION TEMPERATURE........21-170

SENSOR - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE...............8M-9

SENSOR - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-14

SENSOR - INSTALLATION, BATTERY

TEMPERATURE......................8F-24

SENSOR - INSTALLATION, CRANKSHAFT

POSITION..........................14-32

SENSOR - INSTALLATION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - INSTALLATION, FRONT

IMPACT............................8O-22

SENSOR - INSTALLATION, FRONT

WHEEL SPEED........................5-34

SENSOR - INSTALLATION, FUEL LEVEL

SENDING UNIT......................14-10

SENSOR - INSTALLATION, INPUT SPEED . 21-143

SENSOR - INSTALLATION, INTAKE AIR

TEMPERATURE

......................14-38

SENSOR - INSTALLATION, KNOCK

........8I-12

SENSOR - INSTALLATION, LINE

PRESSURE (LP)

....................21-144

SENSOR - INSTALLATION, MAP

.........14-40

SENSOR - INSTALLATION, OUTPUT

SPEED

............................21-152

KJINDEX 23

Description Group-Page Description Group-Page Description Group-Page

Page 1763 of 1803

SENSOR - INSTALLATION, OXYGEN......14-43

SENSOR - INSTALLATION, POSITION....21-210,

21-247

SENSOR - INSTALLATION, REAR WHEEL

SPEED..............................5-35

SENSOR - INSTALLATION, THROTTLE

POSITION..........................14-48

SENSOR - OPERATION, AMBIENT TEMP . . . 8M-9

SENSOR - OPERATION, BATTERY

TEMPERATURE......................8F-24

SENSOR - OPERATION, CRANKSHAFT

POSITION..........................14-31

SENSOR - OPERATION, ENGINE

COOLANT TEMPERATURE...............7-20

SENSOR - OPERATION, FRONT IMPACT . . . 8O-21

SENSOR - OPERATION, FUEL LEVEL

SENDING UNIT.......................14-9

SENSOR - OPERATION, INPUT SPEED . . . 21-143

SENSOR - OPERATION, INTAKE AIR

TEMPERATURE......................14-36

SENSOR - OPERATION, KNOCK..........8I-11

SENSOR - OPERATION, LINE PRESSURE

(LP)..............................21-144

SENSOR - OPERATION, MAP...........14-38

SENSOR - OPERATION, OUTPUT SPEED . . 21-152

SENSOR - OPERATION, OXYGEN........14-40

SENSOR - OPERATION, POSITION......21-209,

21-247

SENSOR - OPERATION, THROTTLE

POSITION..........................14-47

SENSOR - OPERATION, TRANSMISSION

RANGE............................21-168

SENSOR - OPERATION, TRANSMISSION

TEMPERATURE.....................21-170

SENSOR - REMOVAL, BATTERY

TEMPERATURE......................8F-24

SENSOR - REMOVAL, CRANKSHAFT

POSITION..........................14-31

SENSOR - REMOVAL, ENGINE COOLANT

TEMPERATURE.......................7-20

SENSOR - REMOVAL, FRONT IMPACT....8O-22

SENSOR - REMOVAL, FRONT WHEEL

SPEED..............................5-34

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-9

SENSOR - REMOVAL, INPUT SPEED.....21-143

SENSOR - REMOVAL, INTAKE AIR

TEMPERATURE......................14-37

SENSOR - REMOVAL, KNOCK...........8I-12

SENSOR - REMOVAL, LINE PRESSURE

(LP)..............................21-144

SENSOR - REMOVAL, MAP.............14-39

SENSOR - REMOVAL, OUTPUT SPEED . . . 21-152

SENSOR - REMOVAL, OXYGEN..........14-41

SENSOR - REMOVAL, POSITION . . 21-210,21-247

SENSOR - REMOVAL, REAR WHEEL

SPEED..............................5-35

SENSOR - REMOVAL, THROTTLE

POSITION..........................14-47

SENSOR CIRCUIT - DIAGNOSIS AND

TESTING, AMBIENT TEMPERATURE.......8M-9

SENSOR RETURN - DESCRIPTION.......8E-14

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE..........................9-65

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE

..........................9-65

SENSOR/SWITCH - OPERATION, OIL

PRESSURE

..........................9-65

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE

..........................9-65

SENTRY KEY IMMOBILIZER MODULE -

DESCRIPTION

.......................8E-15

SENTRY KEY IMMOBILIZER MODULE -

INSTALLATION

.......................8E-18

SENTRY KEY IMMOBILIZER MODULE -

OPERATION

.........................8E-16

SENTRY KEY IMMOBILIZER MODULE -

REMOVAL

..........................8E-17

SENTRY KEY TRANSPONDER

PROGRAMMING - STANDARD

PROCEDURE

.........................8Q-8

SERPENTINE DRIVE BELT - DIAGNOSIS

AND TESTING

........................7-15

SERVO - DESCRIPTION

.................8P-4

SERVO - INSTALLATION

................8P-5

SERVO - OPERATION

..................8P-4

SERVO - REMOVAL

....................8P-4SETTING TRANSMITTER CODES -

STANDARD PROCEDURE...............8M-9

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO GROUND ON FUSES POWERING . . . 8W-01-9

SHAFT - CAUTION, HALF................3-10

SHAFT - DIAGNOSIS AND TESTING,

HALF...............................3-10

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-1

SHAFT - FRONT - INSTALLATION,

PROPELLER...........................3-6

SHAFT - FRONT - REMOVAL,

PROPELLER...........................3-6

SHAFT - INSTALLATION, BALANCE........9-74

SHAFT - INSTALLATION, HALF...........3-11

SHAFT - INSTALLATION, IDLER..........9-77

SHAFT - INSTALLATION, INTERMEDIATE . . 19-11

SHAFT - REAR - INSTALLATION,

PROPELLER...........................3-7

SHAFT - REAR - REMOVAL, PROPELLER....3-7

SHAFT - REMOVAL, BALANCE...........9-74

SHAFT - REMOVAL, HALF...............3-10

SHAFT - REMOVAL, IDLER..............9-77

SHAFT - REMOVAL, INTERMEDIATE......19-11

SHAFT ANGLE - STANDARD

PROCEDURES, PROPELLER..............3-3

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT.....................21-208,21-246

SHAFT SEAL - INSTALLATION, REAR

OUTPUT............................21-212

SHAFT SEAL - REMOVAL, FRONT

OUTPUT.....................21-208,21-246

SHAFT SEAL - REMOVAL, REAR OUTPUT . 21-210

SHAFT SEALS - INSTALLATION, AXLE....3-102,

3-38

SHAFT SEALS - REMOVAL, AXLE....3-101,3-37

SHAFT, SPECIFICATIONS - HALF..........3-11

SHAFT, SPECIFICATIONS - PROPELLER.....3-6

SHAFTS - INSTALLATION, AXLE . 3-101,3-37,3-65

SHAFTS - REMOVAL, AXLE.....3-101,3-37,3-65

SHIELD - INSTALLATION, FRONT

WHEELHOUSE SPLASH...............23-143

SHIELD - INSTALLATION, REAR

WHEELHOUSE SPLASH...............23-144

SHIELD - REMOVAL, FRONT

WHEELHOUSE SPLASH...............23-143

SHIELD - REMOVAL, REAR

WHEELHOUSE SPLASH...............23-144

SHIELDS - DESCRIPTION, HEAT..........11-4

SHIELDS - INSTALLATION, SEAT

CUSHION SIDE.....................23-167

SHIELDS - REMOVAL, SEAT CUSHION

SIDE.............................23-167

SHIFT BEZEL - INSTALLATION.........23-158

SHIFT BEZEL - REMOVAL.............23-158

SHIFT BOOT - INSTALLATION, 4WD

FLOOR............................23-156

SHIFT BOOT - REMOVAL, 4WD FLOOR . . . 23-156

SHIFT INTERLOCK SYSTEM -

DESCRIPTION, BRAKE TRANSMISSION . . 21-124

SHIFT INTERLOCK SYSTEM - DIAGNOSIS

AND TESTING, BRAKE TRANSMISSION . . 21-125

SHIFT INTERLOCK SYSTEM -

OPERATION, BRAKE TRANSMISSION....21-125

SHIFT LEVER - INSTALLATION . . . 21-214,21-249

SHIFT LEVER - REMOVAL.......21-213,21-248

SHIFT MECHANISM - DESCRIPTION.....21-160

SHIFT MECHANISM - INSTALLATION....21-160

SHIFT MECHANISM - OPERATION

......21-160

SHIFT MECHANISM - REMOVAL

........21-160

SHOCK - INSTALLATION

................2-18

SHOCK - REMOVAL

....................2-18

SHOES - INSTALLATION, DRUM BRAKE

....5-11

SHOES - REMOVAL, DRUM BRAKE

.......5-11

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A

........8W-01-9

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A

...........................8W-01-9

SIDE - INSTALLATION, LEFT

.........2-12,2-15

SIDE - INSTALLATION, RIGHT

........2-12,2-15

SIDE - REMOVAL, LEFT

.............2-11,2-15

SIDE - REMOVAL, RIGHT

...........2-11,2-14

SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL PASSENGER

......23-154SIDE BEZEL - REMOVAL, INSTRUMENT

PANEL PASSENGER..................23-154

SIDE BEZELS - INSTALLATION,

INSTRUMENT PANEL DRIVER..........23-154

SIDE BEZELS - REMOVAL, INSTRUMENT

PANEL DRIVER.....................23-153

SIDE CURTAIN AIRBAG - DESCRIPTION . . . 8O-38

SIDE CURTAIN AIRBAG - INSTALLATION . . 8O-41

SIDE CURTAIN AIRBAG - OPERATION....8O-39

SIDE CURTAIN AIRBAG - REMOVAL......8O-40

SIDE IMPACT AIRBAG CONTROL

MODULE - DESCRIPTION..............8O-43

SIDE IMPACT AIRBAG CONTROL

MODULE - INSTALLATION.............8O-45

SIDE IMPACT AIRBAG CONTROL

MODULE - OPERATION................8O-43

SIDE IMPACT AIRBAG CONTROL

MODULE - REMOVAL.................8O-44

SIDE MOLDINGS - INSTALLATION, BODY . 23-140

SIDE MOLDINGS - REMOVAL, BODY....23-140

SIDE RAIL WEATHERSTRIP/RETAINER -

INSTALLATION......................23-186

SIDE RAIL WEATHERSTRIP/RETAINER -

REMOVAL.........................23-186

SIDE SHIELDS - INSTALLATION, SEAT

CUSHION..........................23-167

SIDE SHIELDS - REMOVAL, SEAT

CUSHION..........................23-167

SIDE VIEW MIRROR - INSTALLATION....23-145

SIDE VIEW MIRROR - REMOVAL.......23-145

SIDEVIEW MIRROR - REMOVAL..........8N-13

SIGNAL INDICATOR - DESCRIPTION,

TURN..............................8J-34

SIGNAL INDICATOR - OPERATION, TURN . . 8J-34

SILL SCUFF PLATE - INSTALLATION,

DOOR............................23-157

SILL SCUFF PLATE - REMOVAL, DOOR . . . 23-157

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-8

SIREN - DESCRIPTION................8Q-16

SIREN - INSTALLATION...............8Q-17

SIREN - OPERATION..................8Q-17

SIREN - REMOVAL...................8Q-17

SKID PLATE - INSTALLATION, FRONT......13-6

SKID PLATE - INSTALLATION, FUEL

TANK ...............................13-9

SKID PLATE - INSTALLATION, TRANSFER

CASE...............................13-7

SKID PLATE - REMOVAL, FRONT.........13-6

SKID PLATE - REMOVAL, FUEL TANK......13-9

SKID PLATE - REMOVAL, TRANSFER

CASE...............................13-7

SKIS INDICATOR - DESCRIPTION........8J-31

SKIS INDICATOR - OPERATION..........8J-31

SKIS INITIALIZATION - STANDARD

PROCEDURE.........................8Q-8

SLEEVE - INSTALLATION, HEADREST....23-164

SLEEVE - REMOVAL, HEADREST.......23-164

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-27

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-27

SOLENOID - OPERATION, EVAP/PURGE . . . 25-27

SOLENOID - REMOVAL, EVAP/PURGE.....25-27

SOLENOID SWITCH VALVE -

DESCRIPTION......................21-161

SOLENOID SWITCH VALVE - OPERATION . 21-161

SOLENOIDS - DESCRIPTION...........21-161

SOLENOIDS - OPERATION.............21-162

SOLENOID/TRS ASSEMBLY -

DESCRIPTION, TRANSMISSION........21-169

SOLENOID/TRS ASSEMBLY -

INSTALLATION, TRANSMISSION........21-170

SOLENOID/TRS ASSEMBLY -

OPERATION, TRANSMISSION..........21-169

SOLENOID/TRS ASSEMBLY - REMOVAL,

TRANSMISSION.....................21-170

SPACER - INSTALLATION, COLLAPSIBLE . . . 3-70

SPACER - REMOVAL, COLLAPSIBLE.......3-70

SPARE TIRE - INSTALLATION............22-9

SPARE TIRE - REMOVAL

................22-8

SPARE TIRE &TEMPORARY -

DESCRIPTION

........................22-6

SPARK PLUG - CLEANING SPARK

PLUGS

.............................8I-15

SPARK PLUG - DESCRIPTION

...........8I-12

SPARK PLUG - INSTALLATION

...........8I-15

24 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1766 of 1803

TANK - REMOVAL, FUEL...............14-25

TANK CHECK VALVE - DESCRIPTION,

FUEL..............................14-28

TANK CHECK VALVE - INSTALLATION,

FUEL..............................14-28

TANK CHECK VALVE - OPERATION, FUEL . . 14-28

TANK CHECK VALVE - REMOVAL, FUEL . . . 14-28

TANK SKID PLATE - INSTALLATION,

FUEL...............................13-9

TANK SKID PLATE - REMOVAL, FUEL......13-9

TASK MANAGER - DESCRIPTION........25-17

TASK MANAGER - OPERATION..........25-21

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-21

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-33

TEMP INDICATOR - OPERATION, TRANS . . 8J-34

TEMP SENSOR - DESCRIPTION,

AMBIENT...........................8M-9

TEMP SENSOR - OPERATION, AMBIENT . . . 8M-9

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-18

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-18

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-24

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-19

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION.....................21-170

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT...............8M-9

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-24

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-21

TEMPERATURE SENSOR -

INSTALLATION, INTAKE AIR............14-38

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-24

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-20

TEMPERATURE SENSOR - OPERATION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION.....................21-170

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-24

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-20

TEMPERATURE SENSOR - REMOVAL,

INTAKE AIR .........................14-37

TEMPERATURE SENSOR CIRCUIT -

DIAGNOSIS AND TESTING, AMBIENT.....8M-9

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-36

TENSIONER - OPERATION, SEAT BELT....8O-36

TERMINAL - INSTALLATION.........8W-01-14

TERMINAL - REMOVAL.............8W-01-14

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN................14-3

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE....................14-16

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY.....................14-15

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE....................14-15

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE...............21-79

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-2

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-11

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-14

TEST - STANDARD PROCEDURE, LOAD . . . 8F-12

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE

...............8F-12

TEST - STANDARD PROCEDURE,

VERIFICATION

........................8O-8

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION

..........................25-2

TEST MODE - DESCRIPTION, STATE

DISPLAY

............................25-2

TESTER - STANDARD PROCEDURE,

USING MIDTRONICS ELECTRICAL

.......8F-15TETHER ANCHOR - DESCRIPTION, CHILD . 8O-13

TETHER ANCHOR - OPERATION, CHILD . . . 8O-13

THEFT SECURITY - DESCRIPTION,

VEHICLE............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-3

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE................8Q-6

THERMAL GUARD - DESCRIPTION.......8F-20

THERMAL GUARD - INSTALLATION......8F-20

THERMAL GUARD - OPERATION.........8F-20

THERMAL GUARD - REMOVAL..........8F-20

THERMOSTAT - DIAGNOSIS AND

TESTING............................7-21

THERMOSTAT - OPERATION, ENGINE

COOLANT............................7-21

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM..............21-81

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-4

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN............9-9

THROTTLE BODY - DESCRIPTION........14-43

THROTTLE BODY - INSTALLATION.......14-44

THROTTLE BODY - OPERATION.........14-43

THROTTLE BODY - REMOVAL...........14-43

THROTTLE CONTROL CABLE -

INSTALLATION.......................14-46

THROTTLE CONTROL CABLE - REMOVAL . . 14-45

THROTTLE POSITION SENSOR -

DESCRIPTION.........................14-47

THROTTLE POSITION SENSOR -

INSTALLATION.......................14-48

THROTTLE POSITION SENSOR -

OPERATION.........................14-47

THROTTLE POSITION SENSOR -

REMOVAL..........................14-47

TIE ROD END - INSTALLATION..........19-16

TIE ROD END - REMOVAL..............19-16

TIE ROD END REMOVAL TOOL, SPECIAL

TOOLS - OUTER.....................19-15

TIME INDICATOR - DESCRIPTION, FULL . . . 8J-29

TIME INDICATOR - DESCRIPTION, PART . . 8J-29

TIME INDICATOR - OPERATION, FULL....8J-30

TIME INDICATOR - OPERATION, PART....8J-29

TIMING - DESCRIPTION, VALVE..........9-71

TIMING - OPERATION, VALVE............9-71

TIMING - SPECIFICATIONS, IGNITION......8I-2

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........................9-76

TIMING BELT / CHAIN COVER(S) -

REMOVAL...........................9-74

TIMING CHAIN WEAR, STANDARD

PROCEDURE - MEASURING.............9-71

TIRE - INSTALLATION, SPARE...........22-9

TIRE - REMOVAL, SPARE...............22-8

TIRE INFLATION - DIAGNOSIS AND

TESTING............................22-7

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-8

TIRE ROTATION - STANDARD

PROCEDURE.........................22-2

TIRE &TEMPORARY - DESCRIPTION,

SPARE..............................22-6

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-8

TIRES - DESCRIPTION.................22-6

TIRES - DESCRIPTION, RADIAL-PLY.......22-6

TIRES - DESCRIPTION, REPLACEMENT....22-7

TIRES AND WHEEL RUNOUT -

DIAGNOSIS AND TESTING..............22-1

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-9

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . . 8W-01-9

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOE ADJUSTMENT - STANDARD

PROCEDURE..........................2-5

TOE ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER..........2-5

TOOL, SPECIAL TOOLS - OUTER TIE

ROD END REMOVAL..................19-15

TOOLS - 3.7L ENGINE, SPECIAL

..........9-15

TOOLS - 8 1/4 AXLE, SPECIAL

...........3-98

TOOLS - BASE BRAKES, SPECIAL

.........5-7

TOOLS - BODY, SPECIAL

................23-5

TOOLS - COOLING, SPECIAL

.............7-14TOOLS - FRONT AXLE, SPECIAL..........3-34

TOOLS - FRONT SUSPENSION, SPECIAL....2-8

TOOLS - FUEL SYSTEM, SPECIAL........14-6

TOOLS - OUTER TIE ROD END REMOVAL

TOOL, SPECIAL......................19-15

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING PUMP,

SPECIAL...........................19-20

TOOLS - REAR AXLE, SPECIAL...........3-63

TOOLS - RFE TRANSMISSION, SPECIAL . . 21-120

TOOLS - STEERING COLUMN, SPECIAL....19-8

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, BATTERY SYSTEM - SPECIAL.....8F-7

TOOLS, SPECIFICATIONS - SPECIAL....3-12,3-6

TOOLS, SPECIFICATIONS - SPECIAL......8F-24

TOP COVER - INSTALLATION,

INSTRUMENT PANEL.................23-153

TOP COVER - REMOVAL, INSTRUMENT

PANEL............................23-152

TORQUE - SPECIFICATIONS.............13-6

TORQUE CHART, SPECIFICATIONS . . 19-15,19-19,

19-8

TORQUE CHART, SPECIFICATIONS.....2-17,2-8

TORQUE CONVERTER - DESCRIPTION . . . 21-162

TORQUE CONVERTER - INSTALLATION . . . 21-167

TORQUE CONVERTER - OPERATION.....21-166

TORQUE CONVERTER - REMOVAL......21-167

TORQUE, EXCEPT DIESEL..............8F-23

TORQUE, GAS POWERED..............8F-38

TORQUE, IGNITION SYSTEM.............8I-3

TORQUE REFERENCES - DESCRIPTION . . Intro.-7

TORQUE, SPECIFICATIONS...............5-7

TORQUE, SPECIFICATIONS..............7-13

TORQUE, SPECIFICATIONS.............25-26

TORQUE, SPECIFICATIONS..............9-12

TORQUE, SPECIFICATIONS..............14-5

TORQUE, SPEED CONTROL.............8P-2

TOUCH-UP - DESCRIPTION, PAINT......23-163

TOW CONNECTOR - INSTALLATION,

TRAILER...........................8L-61

TOW CONNECTOR - REMOVAL, TRAILER . . 8L-61

TOW HOOK - INSTALLATION, FRONT......13-8

TOW HOOK - INSTALLATION, REAR.......13-8

TOW HOOK - REMOVAL, FRONT..........13-8

TOW HOOK - REMOVAL, REAR...........13-8

TOW RELAY - DESCRIPTION, TRAILER....8L-61

TOW RELAY - DIAGNOSIS AND TESTING,

TRAILER...........................8L-62

TOW RELAY - INSTALLATION, TRAILER . . . 8L-64

TOW RELAY - OPERATION, TRAILER.....8L-62

TOW RELAY - REMOVAL, TRAILER.......8L-63

TOW WIRING - DESCRIPTION, TRAILER . . 8L-64

TOWING - STANDARD PROCEDURE........0-6

TRACK - DESCRIPTION, SEAT..........8N-15

TRACK - DIAGNOSIS AND TESTING,

SEAT ..............................8N-16

TRACK - INSTALLATION, SEAT.........23-168

TRACK - INSTALLATION, SEAT..........8N-16

TRACK - OPERATION, SEAT............8N-15

TRACK - REMOVAL, SEAT.............23-168

TRACK - REMOVAL, SEAT..............8N-16

TRAC-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-109,

3-77

TRAC-LOK - CLEANING, DIFFERENTIAL . . . 3-109,

3-77

TRAC-LOK - DISASSEMBLY,

DIFFERENTIAL...................3-107,3-75

TRAC-LOK - INSPECTION, DIFFERENTIAL . 3-109,

3-77

TRAC-LOKT- DIAGNOSIS AND TESTING . . 3-106,

3-74

TRAILER HITCH - INSTALLATION.........13-9

TRAILER HITCH - REMOVAL.............13-9

TRAILER TOW CONNECTOR -

INSTALLATION.......................8L-61

TRAILER TOW CONNECTOR - REMOVAL . . 8L-61

TRAILER TOW RELAY - DESCRIPTION....8L-61

TRAILER TOW RELAY - DIAGNOSIS AND

TESTING...........................8L-62

TRAILER TOW RELAY - INSTALLATION . . . 8L-64

TRAILER TOW RELAY - OPERATION......8L-62

TRAILER TOW RELAY - REMOVAL

.......8L-63

TRAILER TOW WIRING - DESCRIPTION

. . . 8L-64

TRANS COOLER - DESCRIPTION

.........7-32

TRANS TEMP INDICATOR -

DESCRIPTION

.......................8J-33

TRANS TEMP INDICATOR - OPERATION

. . . 8J-34

KJINDEX 27

Description Group-Page Description Group-Page Description Group-Page