JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 271 of 1803

(8) Disconnect the power steering cooler line from

cooler.

(9) Disconnect the radiator upper and lower hoses.

(10) Disconnect the overflow hose from radiator.

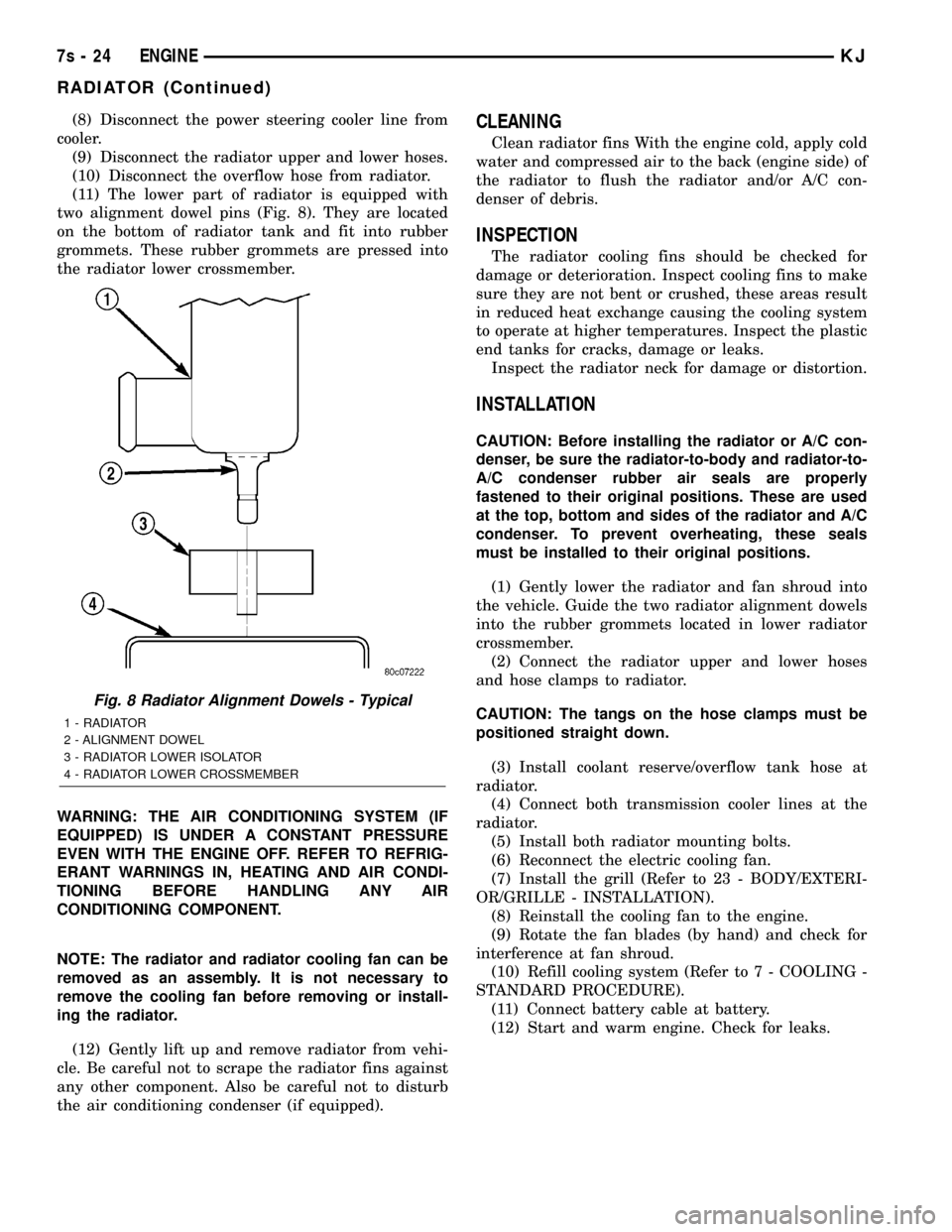

(11) The lower part of radiator is equipped with

two alignment dowel pins (Fig. 8). They are located

on the bottom of radiator tank and fit into rubber

grommets. These rubber grommets are pressed into

the radiator lower crossmember.

WARNING: THE AIR CONDITIONING SYSTEM (IF

EQUIPPED) IS UNDER A CONSTANT PRESSURE

EVEN WITH THE ENGINE OFF. REFER TO REFRIG-

ERANT WARNINGS IN, HEATING AND AIR CONDI-

TIONING BEFORE HANDLING ANY AIR

CONDITIONING COMPONENT.

NOTE: The radiator and radiator cooling fan can be

removed as an assembly. It is not necessary to

remove the cooling fan before removing or install-

ing the radiator.

(12) Gently lift up and remove radiator from vehi-

cle. Be careful not to scrape the radiator fins against

any other component. Also be careful not to disturb

the air conditioning condenser (if equipped).CLEANING

Clean radiator fins With the engine cold, apply cold

water and compressed air to the back (engine side) of

the radiator to flush the radiator and/or A/C con-

denser of debris.

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals are properly

fastened to their original positions. These are used

at the top, bottom and sides of the radiator and A/C

condenser. To prevent overheating, these seals

must be installed to their original positions.

(1) Gently lower the radiator and fan shroud into

the vehicle. Guide the two radiator alignment dowels

into the rubber grommets located in lower radiator

crossmember.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator.

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator.

(4) Connect both transmission cooler lines at the

radiator.

(5) Install both radiator mounting bolts.

(6) Reconnect the electric cooling fan.

(7) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(8) Reinstall the cooling fan to the engine.

(9) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(10) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Connect battery cable at battery.

(12) Start and warm engine. Check for leaks.

Fig. 8 Radiator Alignment Dowels - Typical

1 - RADIATOR

2 - ALIGNMENT DOWEL

3 - RADIATOR LOWER ISOLATOR

4 - RADIATOR LOWER CROSSMEMBER

7s - 24 ENGINEKJ

RADIATOR (Continued)

Page 272 of 1803

RADIATOR PRESSURE CAP

DESCRIPTION

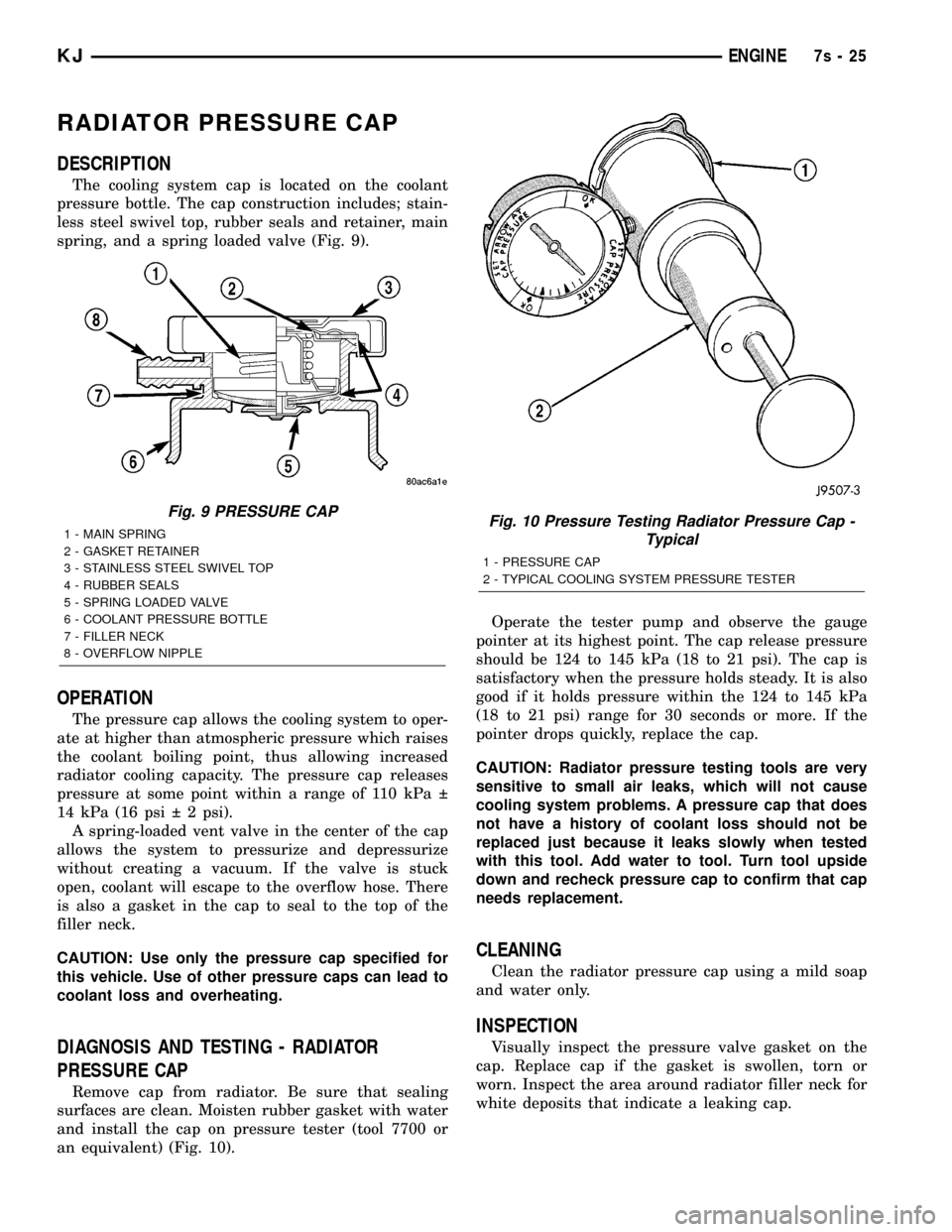

The cooling system cap is located on the coolant

pressure bottle. The cap construction includes; stain-

less steel swivel top, rubber seals and retainer, main

spring, and a spring loaded valve (Fig. 9).

OPERATION

The pressure cap allows the cooling system to oper-

ate at higher than atmospheric pressure which raises

the coolant boiling point, thus allowing increased

radiator cooling capacity. The pressure cap releases

pressure at some point within a range of 110 kPa

14 kPa (16 psi 2 psi).

A spring-loaded vent valve in the center of the cap

allows the system to pressurize and depressurize

without creating a vacuum. If the valve is stuck

open, coolant will escape to the overflow hose. There

is also a gasket in the cap to seal to the top of the

filler neck.

CAUTION: Use only the pressure cap specified for

this vehicle. Use of other pressure caps can lead to

coolant loss and overheating.

DIAGNOSIS AND TESTING - RADIATOR

PRESSURE CAP

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 10).Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 124 to 145 kPa (18 to 21 psi). The cap is

satisfactory when the pressure holds steady. It is also

good if it holds pressure within the 124 to 145 kPa

(18 to 21 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.

CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not cause

cooling system problems. A pressure cap that does

not have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

CLEANING

Clean the radiator pressure cap using a mild soap

and water only.

INSPECTION

Visually inspect the pressure valve gasket on the

cap. Replace cap if the gasket is swollen, torn or

worn. Inspect the area around radiator filler neck for

white deposits that indicate a leaking cap.

Fig. 9 PRESSURE CAP

1 - MAIN SPRING

2 - GASKET RETAINER

3 - STAINLESS STEEL SWIVEL TOP

4 - RUBBER SEALS

5 - SPRING LOADED VALVE

6 - COOLANT PRESSURE BOTTLE

7 - FILLER NECK

8 - OVERFLOW NIPPLEFig. 10 Pressure Testing Radiator Pressure Cap -

Typical

1 - PRESSURE CAP

2 - TYPICAL COOLING SYSTEM PRESSURE TESTER

KJENGINE7s-25

Page 273 of 1803

RADIATOR FAN - ELECTRIC

DESCRIPTION

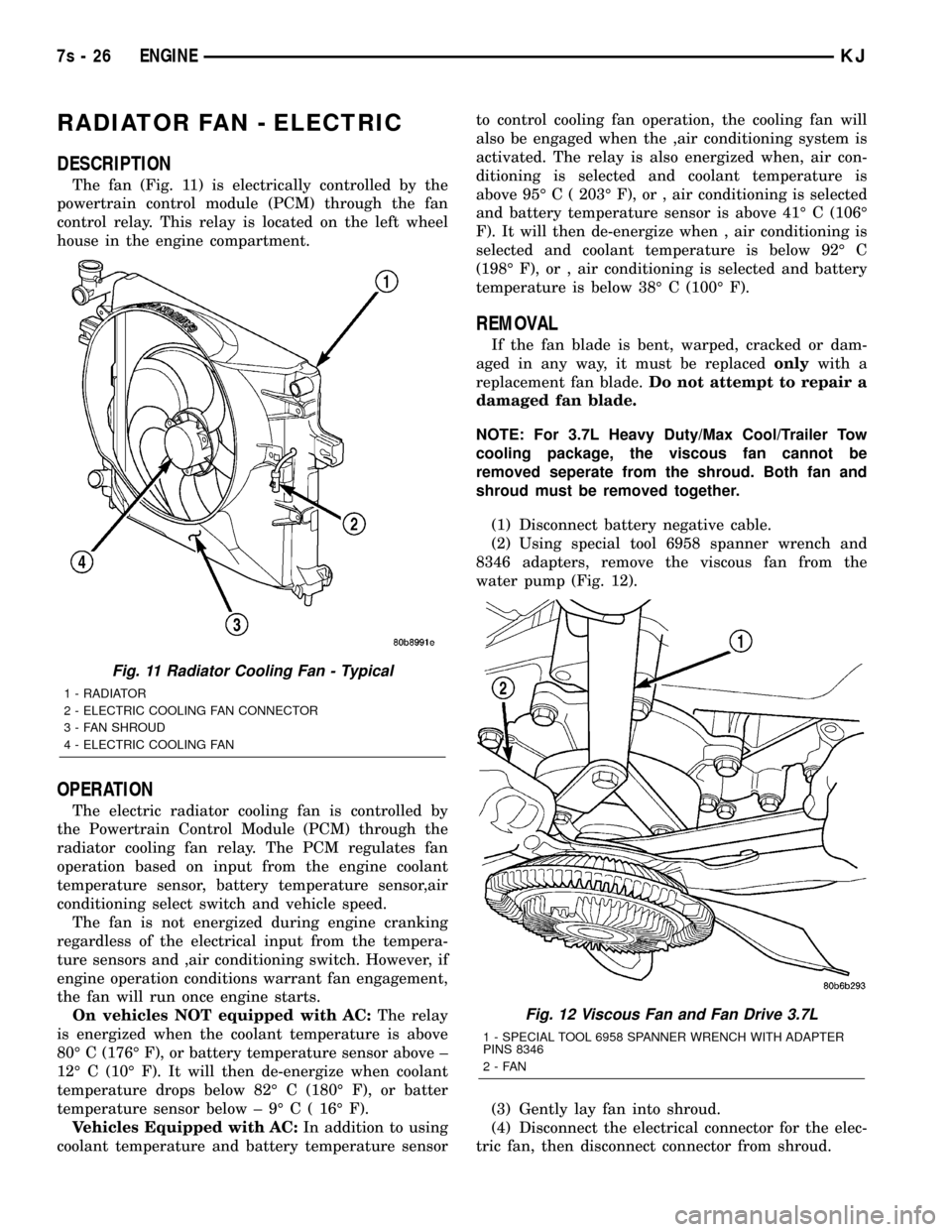

The fan (Fig. 11) is electrically controlled by the

powertrain control module (PCM) through the fan

control relay. This relay is located on the left wheel

house in the engine compartment.

OPERATION

The electric radiator cooling fan is controlled by

the Powertrain Control Module (PCM) through the

radiator cooling fan relay. The PCM regulates fan

operation based on input from the engine coolant

temperature sensor, battery temperature sensor,air

conditioning select switch and vehicle speed.

The fan is not energized during engine cranking

regardless of the electrical input from the tempera-

ture sensors and ,air conditioning switch. However, if

engine operation conditions warrant fan engagement,

the fan will run once engine starts.

On vehicles NOT equipped with AC:The relay

is energized when the coolant temperature is above

80É C (176É F), or battery temperature sensor above ±

12É C (10É F). It will then de-energize when coolant

temperature drops below 82É C (180É F), or batter

temperature sensor below ± 9É C ( 16É F).

Vehicles Equipped with AC:In addition to using

coolant temperature and battery temperature sensorto control cooling fan operation, the cooling fan will

also be engaged when the ,air conditioning system is

activated. The relay is also energized when, air con-

ditioning is selected and coolant temperature is

above 95É C ( 203É F), or , air conditioning is selected

and battery temperature sensor is above 41É C (106É

F). It will then de-energize when , air conditioning is

selected and coolant temperature is below 92É C

(198É F), or , air conditioning is selected and battery

temperature is below 38É C (100É F).

REMOVAL

If the fan blade is bent, warped, cracked or dam-

aged in any way, it must be replacedonlywith a

replacement fan blade.Do not attempt to repair a

damaged fan blade.

NOTE: For 3.7L Heavy Duty/Max Cool/Trailer Tow

cooling package, the viscous fan cannot be

removed seperate from the shroud. Both fan and

shroud must be removed together.

(1) Disconnect battery negative cable.

(2) Using special tool 6958 spanner wrench and

8346 adapters, remove the viscous fan from the

water pump (Fig. 12).

(3) Gently lay fan into shroud.

(4) Disconnect the electrical connector for the elec-

tric fan, then disconnect connector from shroud.

Fig. 11 Radiator Cooling Fan - Typical

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

Fig. 12 Viscous Fan and Fan Drive 3.7L

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

7s - 26 ENGINEKJ

Page 274 of 1803

(5) Remove the two fan shroud mounting bolts con-

necting the fan shroud to the radiator (Fig. 13).

(6) Remove the shroud and fan from the vehicle.

INSTALLATION

NOTE: For 3.7L Heavy Duty/Max Cool/Trailer Tow

cooling package, the viscous fan cannot be

installed seperate from the shroud. Both fan and

shroud must be installed together.

(1) Gently lay viscous fan into shroud.

(2) Install fan shroud assembly into the vehicle.

Tighten fan shroud to radiator bolts to (5.5 N´m (50

in. lbs.).

(3) Using special tool 6958 spanner wrench and

8346 adapters, install the viscous fan on the water

pump.

(4) Connect fan motor wire connector to harness

connector, and attach connector to shroud.

(5) Connect battery negative cable.

(6) Start engine and check fan operation.

WATER PUMP - 2.4L

DESCRIPTION

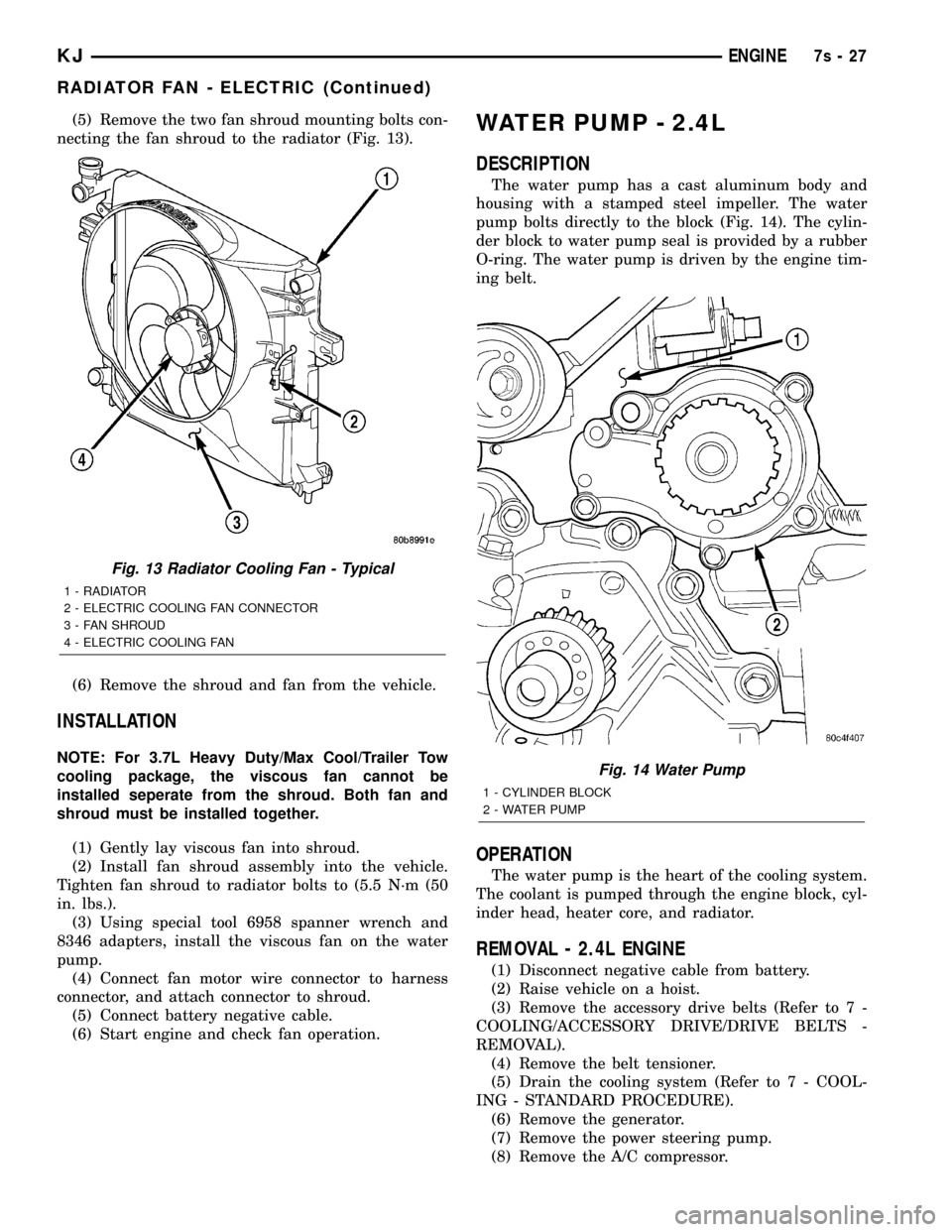

The water pump has a cast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 14). The cylin-

der block to water pump seal is provided by a rubber

O-ring. The water pump is driven by the engine tim-

ing belt.

OPERATION

The water pump is the heart of the cooling system.

The coolant is pumped through the engine block, cyl-

inder head, heater core, and radiator.

REMOVAL - 2.4L ENGINE

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist.

(3) Remove the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the belt tensioner.

(5) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(6) Remove the generator.

(7) Remove the power steering pump.

(8) Remove the A/C compressor.

Fig. 13 Radiator Cooling Fan - Typical

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

Fig. 14 Water Pump

1 - CYLINDER BLOCK

2 - WATER PUMP

KJENGINE7s-27

RADIATOR FAN - ELECTRIC (Continued)

Page 275 of 1803

(9) Remove the accessory drive bracket.

(10) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- REMOVAL).

(11) Remove timing belt idler pulley.

(12) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(13) Remove the timing belt rear cover (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - REMOVAL).

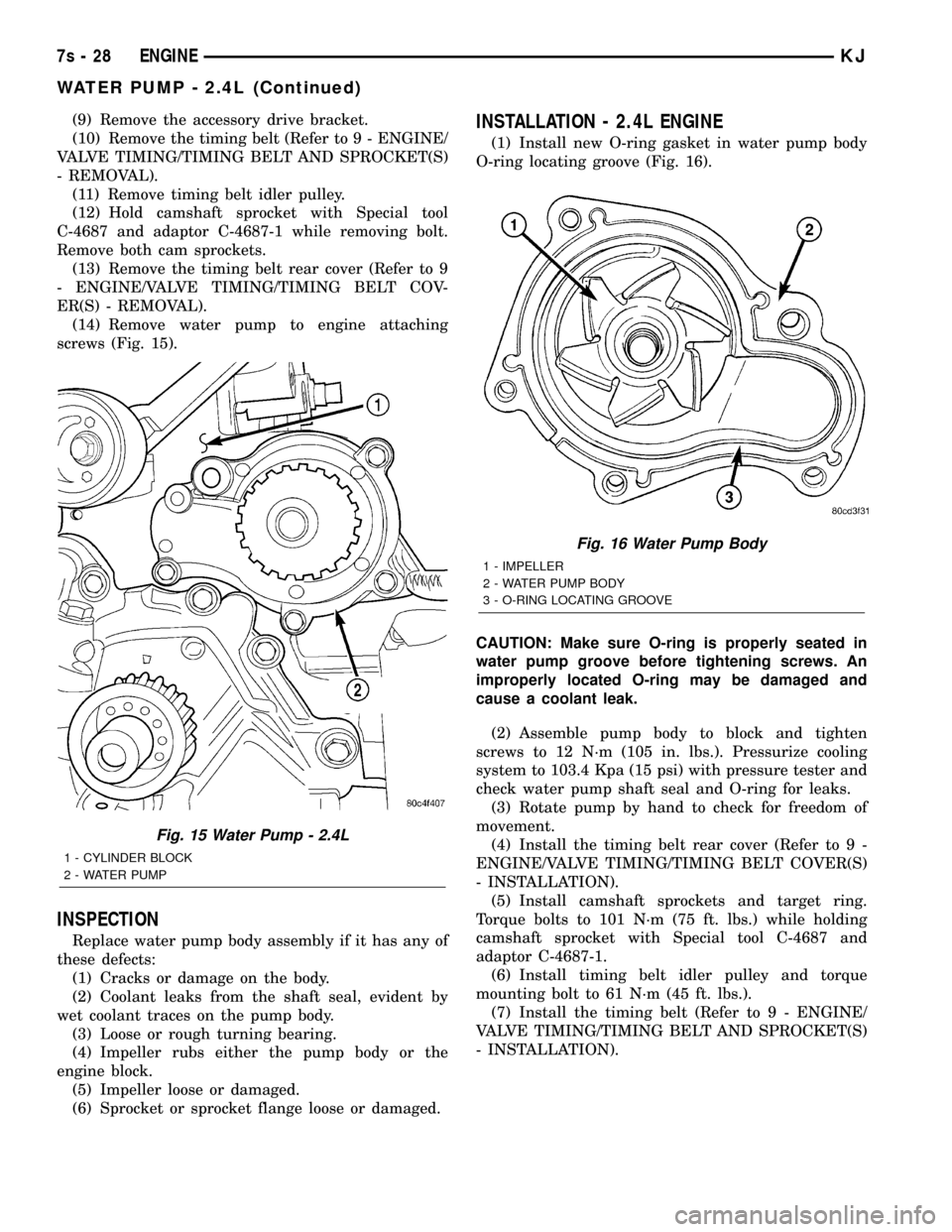

(14) Remove water pump to engine attaching

screws (Fig. 15).

INSPECTION

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

wet coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

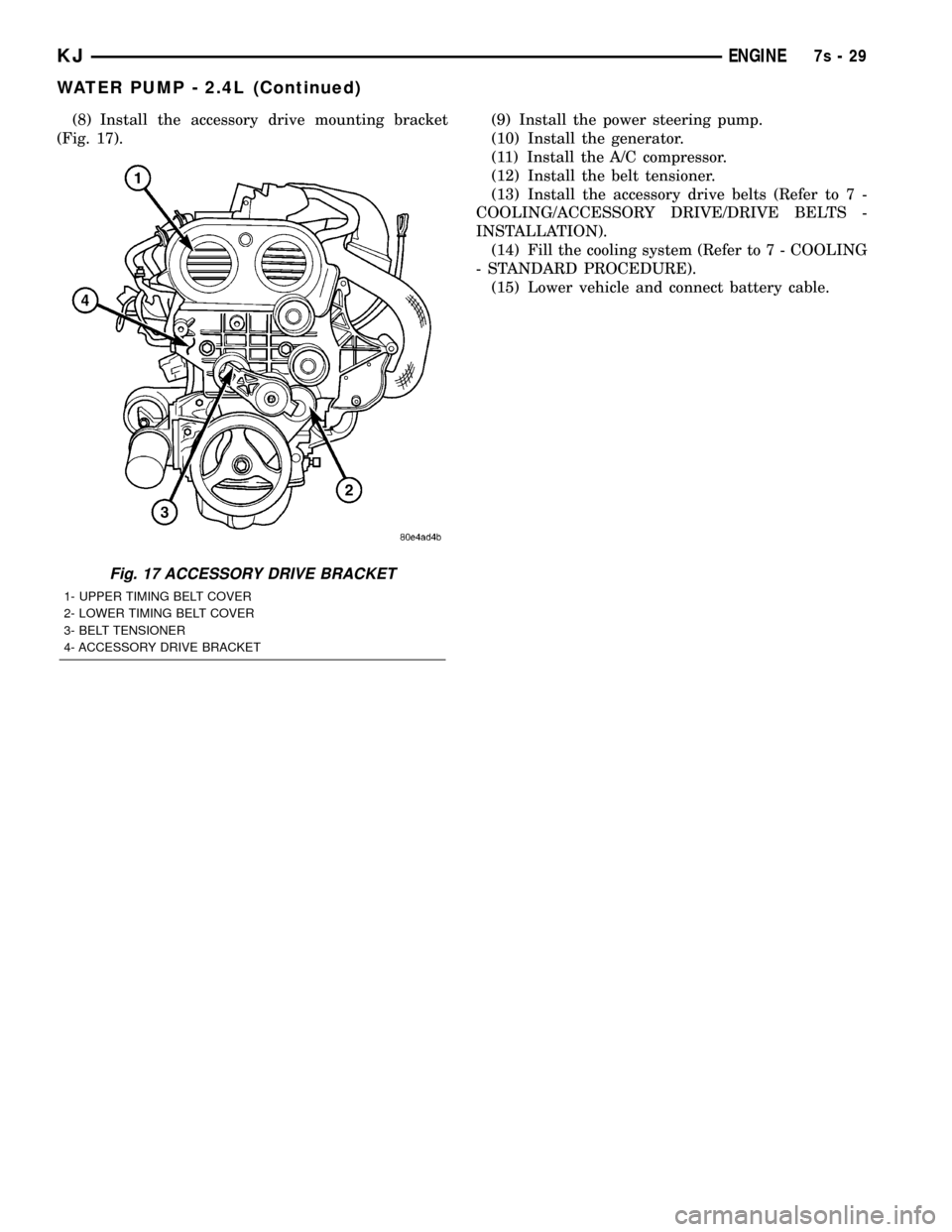

INSTALLATION - 2.4L ENGINE

(1) Install new O-ring gasket in water pump body

O-ring locating groove (Fig. 16).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may be damaged and

cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 103.4 Kpa (15 psi) with pressure tester and

check water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(5) Install camshaft sprockets and target ring.

Torque bolts to 101 N´m (75 ft. lbs.) while holding

camshaft sprocket with Special tool C-4687 and

adaptor C-4687-1.

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

(7) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- INSTALLATION).

Fig. 15 Water Pump - 2.4L

1 - CYLINDER BLOCK

2 - WATER PUMP

Fig. 16 Water Pump Body

1 - IMPELLER

2 - WATER PUMP BODY

3 - O-RING LOCATING GROOVE

7s - 28 ENGINEKJ

WATER PUMP - 2.4L (Continued)

Page 276 of 1803

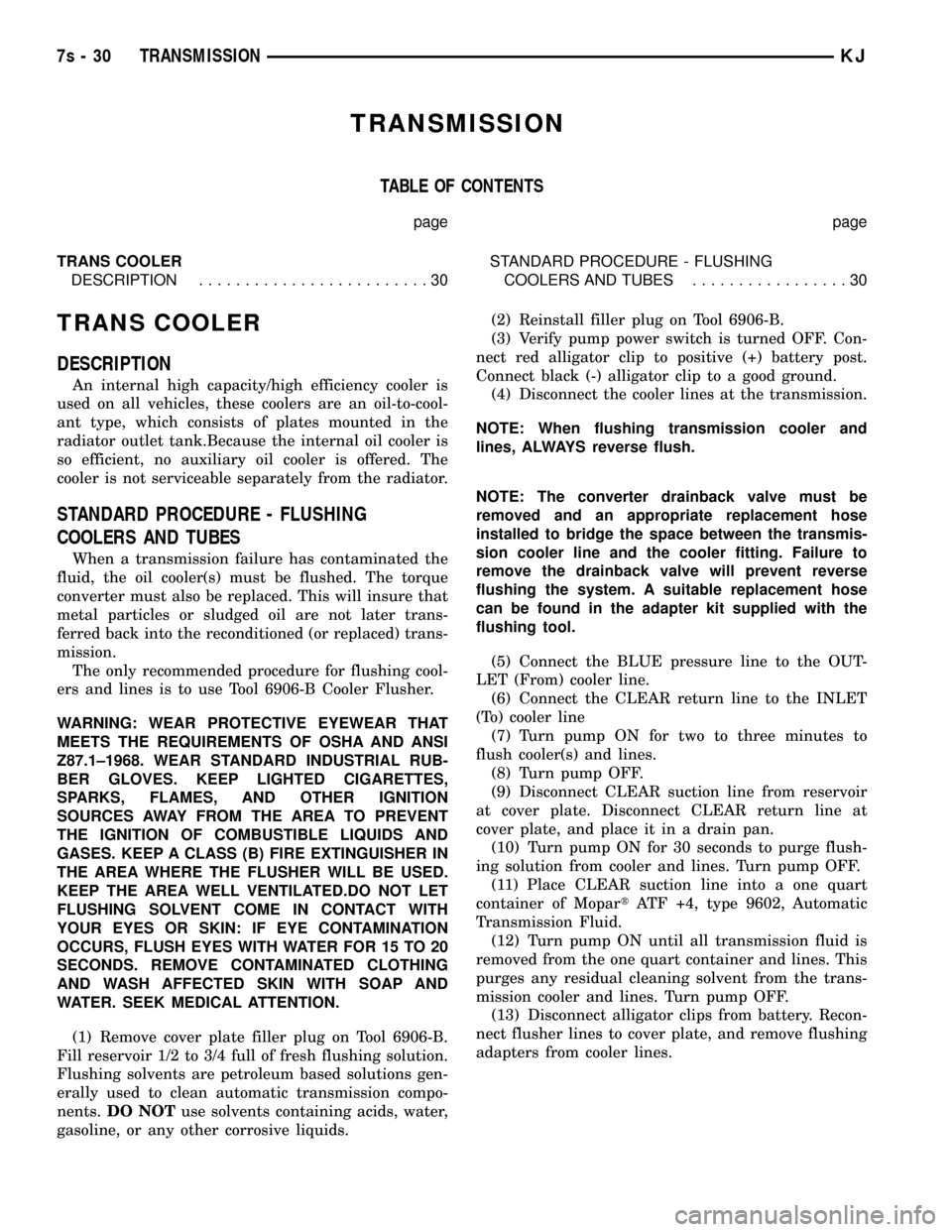

(8) Install the accessory drive mounting bracket

(Fig. 17).(9) Install the power steering pump.

(10) Install the generator.

(11) Install the A/C compressor.

(12) Install the belt tensioner.

(13) Install the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(14) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(15) Lower vehicle and connect battery cable.

Fig. 17 ACCESSORY DRIVE BRACKET

1- UPPER TIMING BELT COVER

2- LOWER TIMING BELT COVER

3- BELT TENSIONER

4- ACCESSORY DRIVE BRACKET

KJENGINE7s-29

WATER PUMP - 2.4L (Continued)

Page 277 of 1803

TRANSMISSION

TABLE OF CONTENTS

page page

TRANS COOLER

DESCRIPTION.........................30STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES.................30

TRANS COOLER

DESCRIPTION

An internal high capacity/high efficiency cooler is

used on all vehicles, these coolers are an oil-to-cool-

ant type, which consists of plates mounted in the

radiator outlet tank.Because the internal oil cooler is

so efficient, no auxiliary oil cooler is offered. The

cooler is not serviceable separately from the radiator.

STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES

When a transmission failure has contaminated the

fluid, the oil cooler(s) must be flushed. The torque

converter must also be replaced. This will insure that

metal particles or sludged oil are not later trans-

ferred back into the reconditioned (or replaced) trans-

mission.

The only recommended procedure for flushing cool-

ers and lines is to use Tool 6906-B Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES. KEEP LIGHTED CIGARETTES,

SPARKS, FLAMES, AND OTHER IGNITION

SOURCES AWAY FROM THE AREA TO PREVENT

THE IGNITION OF COMBUSTIBLE LIQUIDS AND

GASES. KEEP A CLASS (B) FIRE EXTINGUISHER IN

THE AREA WHERE THE FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.DO NOT LET

FLUSHING SOLVENT COME IN CONTACT WITH

YOUR EYES OR SKIN: IF EYE CONTAMINATION

OCCURS, FLUSH EYES WITH WATER FOR 15 TO 20

SECONDS. REMOVE CONTAMINATED CLOTHING

AND WASH AFFECTED SKIN WITH SOAP AND

WATER. SEEK MEDICAL ATTENTION.

(1) Remove cover plate filler plug on Tool 6906-B.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.(2) Reinstall filler plug on Tool 6906-B.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

NOTE: The converter drainback valve must be

removed and an appropriate replacement hose

installed to bridge the space between the transmis-

sion cooler line and the cooler fitting. Failure to

remove the drainback valve will prevent reverse

flushing the system. A suitable replacement hose

can be found in the adapter kit supplied with the

flushing tool.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of MopartATF +4, type 9602, Automatic

Transmission Fluid.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

7s - 30 TRANSMISSIONKJ

Page 278 of 1803

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - AUDIO..........2

AMPLIFIER CHOKE AND RELAY

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING - AMPLIFIER

CHOKE AND RELAY....................4

REMOVAL.............................4

INSTALLATION..........................4

ANTENNA BODY & CABLE

DESCRIPTION..........................4

OPERATION............................5

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................5

REMOVAL.............................6

INSTALLATION..........................6

CD CHANGER

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................7INSTALLATION..........................8

RADIO

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................9

INSTALLATION..........................9

RADIO NOISE SUPPRESSION GROUND STRAP

DESCRIPTION..........................9

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................11

REMOTE SWITCHES

DESCRIPTION.........................11

OPERATION...........................12

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................12

REMOVAL.............................13

INSTALLATION.........................13

SPEAKER

DESCRIPTION.........................13

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................15

AUDIO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model. Several combinations of

radio receivers and speaker systems are offered on

this model. The audio system uses an ignition

switched source of battery current so that the system

will only operate when the ignition switch is in the

RUN or ACCESSORY positions.

The audio system includes the following compo-

nents:

²Amplifier choke and relay

²Antenna

²Compact disc changer (if equipped)

²Power amplifier mounted to each front door

speaker (with premium speaker system only)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (if equipped)

²SpeakersCertain functions and features of the audio system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munication Interface (PCI) bus network. The data

bus network allows the sharing of sensor informa-

tion. For diagnosis of these electronic modules or of

the data bus network, the use of a DRB scan tool and

the proper Diagnostic Procedures manual are recom-

mended.

Refer to the appropriate wiring information for

complete standard and premium audio system circuit

diagrams. The wiring information includes proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

OPERATION

The audio system components are designed to pro-

vide audio entertainment and information through

the reception, tuning and amplification of locally

broadcast radio signals in both the Amplitude Modu-

KJAUDIO 8A - 1

Page 279 of 1803

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges.

The audio system components operate on battery

current received through a fuse in the Junction Block

(JB) on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the Run or Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the Body Control Module

(BCM) receives hard wired resistor multiplexed

inputs from the remote radio switches. The program-

ming in the BCM allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.

Refer to the owner's manual for more information

on the features, use and operation of each of the

available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB diagnostic tool.For information on the use of the DRB, refer to

the appropriate Diagnostic Service Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

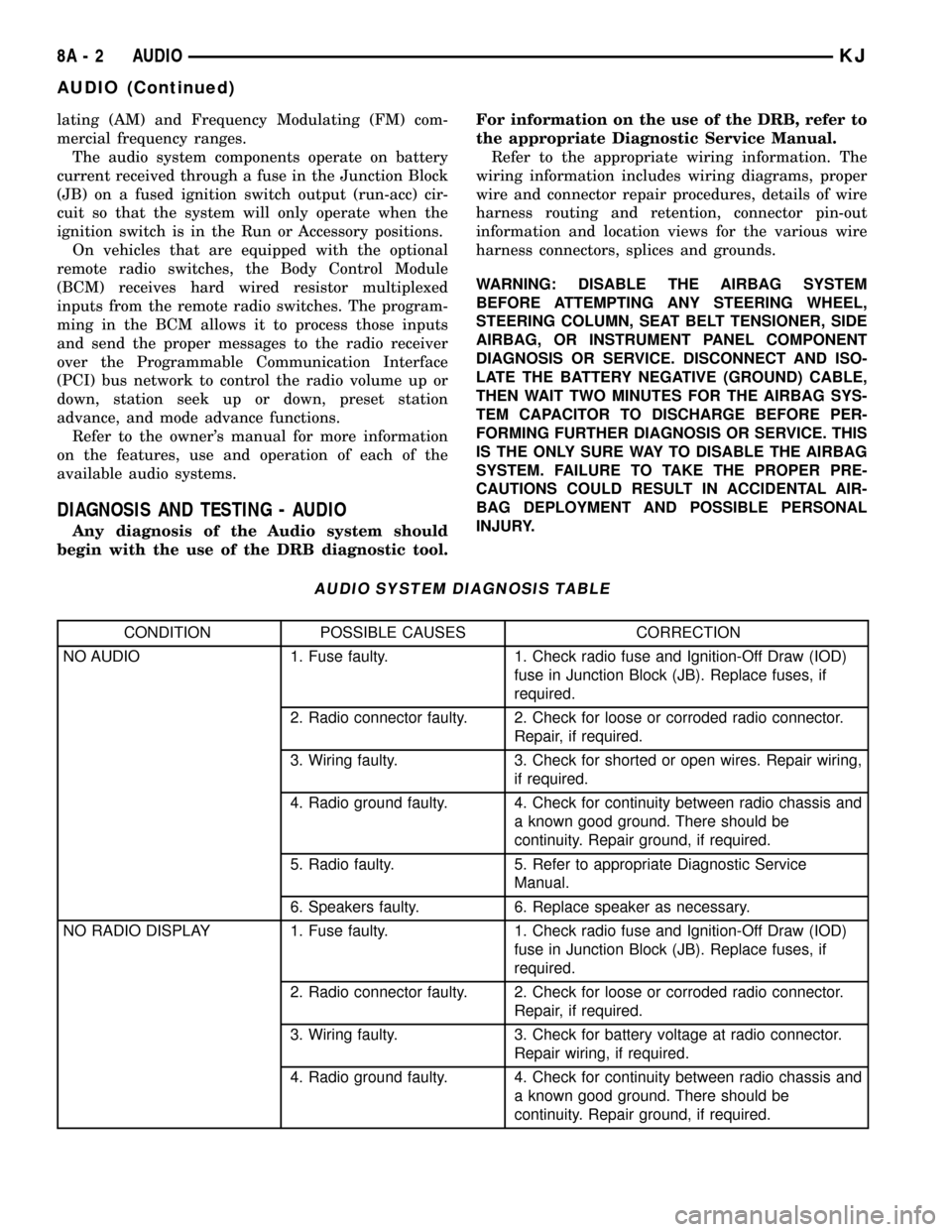

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Junction Block (JB). Replace fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Junction Block (JB). Replace fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

8A - 2 AUDIOKJ

AUDIO (Continued)

Page 280 of 1803

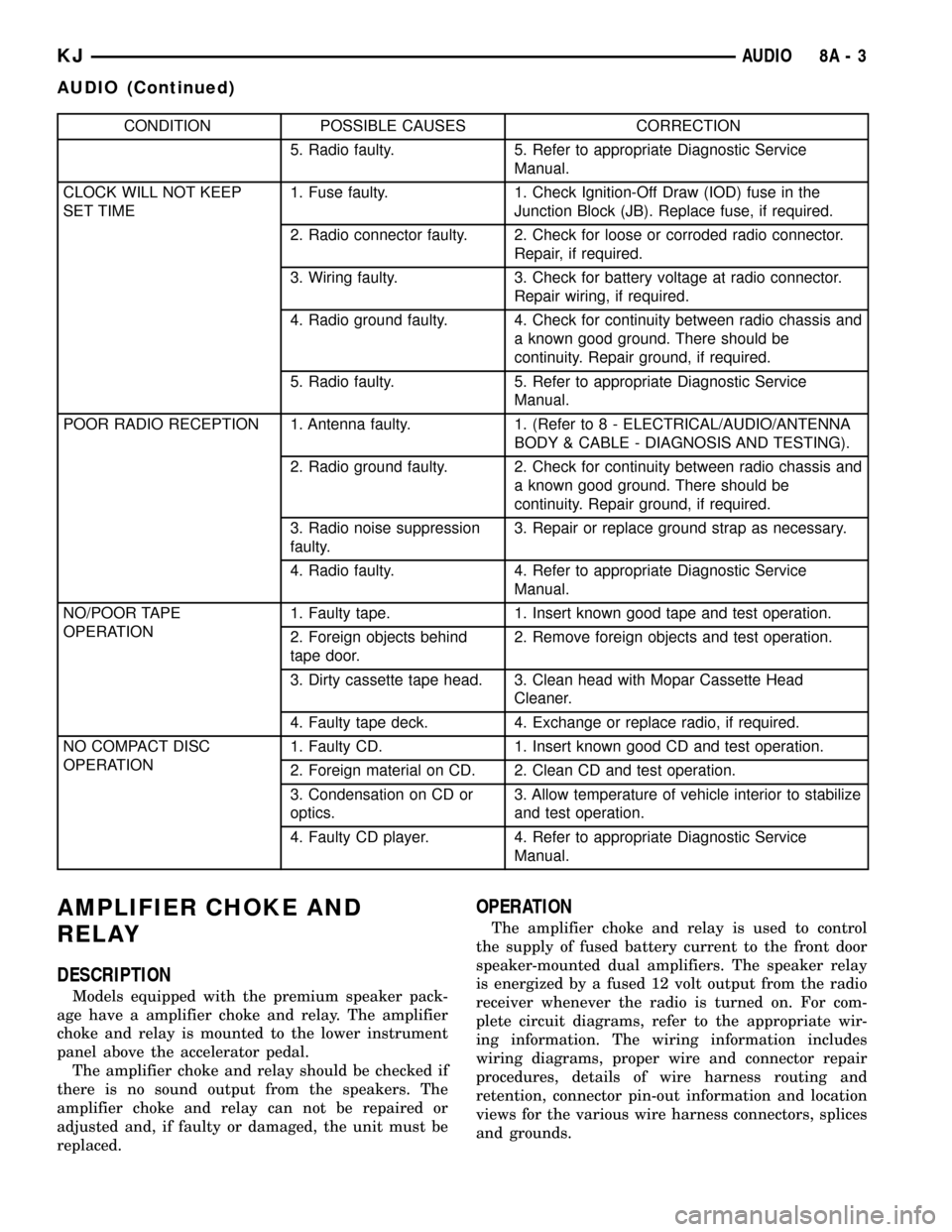

CONDITION POSSIBLE CAUSES CORRECTION

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

CLOCK WILL NOT KEEP

SET TIME1. Fuse faulty. 1. Check Ignition-Off Draw (IOD) fuse in the

Junction Block (JB). Replace fuse, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

POOR RADIO RECEPTION 1. Antenna faulty. 1. (Refer to 8 - ELECTRICAL/AUDIO/ANTENNA

BODY & CABLE - DIAGNOSIS AND TESTING).

2. Radio ground faulty. 2. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

3. Radio noise suppression

faulty.3. Repair or replace ground strap as necessary.

4. Radio faulty. 4. Refer to appropriate Diagnostic Service

Manual.

NO/POOR TAPE

OPERATION1. Faulty tape. 1. Insert known good tape and test operation.

2. Foreign objects behind

tape door.2. Remove foreign objects and test operation.

3. Dirty cassette tape head. 3. Clean head with Mopar Cassette Head

Cleaner.

4. Faulty tape deck. 4. Exchange or replace radio, if required.

NO COMPACT DISC

OPERATION1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on CD. 2. Clean CD and test operation.

3. Condensation on CD or

optics.3. Allow temperature of vehicle interior to stabilize

and test operation.

4. Faulty CD player. 4. Refer to appropriate Diagnostic Service

Manual.

AMPLIFIER CHOKE AND

RELAY

DESCRIPTION

Models equipped with the premium speaker pack-

age have a amplifier choke and relay. The amplifier

choke and relay is mounted to the lower instrument

panel above the accelerator pedal.

The amplifier choke and relay should be checked if

there is no sound output from the speakers. The

amplifier choke and relay can not be repaired or

adjusted and, if faulty or damaged, the unit must be

replaced.

OPERATION

The amplifier choke and relay is used to control

the supply of fused battery current to the front door

speaker-mounted dual amplifiers. The speaker relay

is energized by a fused 12 volt output from the radio

receiver whenever the radio is turned on. For com-

plete circuit diagrams, refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

KJAUDIO 8A - 3

AUDIO (Continued)