Seats JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 621 of 1803

SWITCH

POSITIONCONTINUITY BETWEEN PINS

DRIVER SEAT PASSENGER

SEAT

OFF PIN1to3 PIN1to3

PIN1to6 PIN1to6

PIN1to7 PIN1to7

PIN1to8 PIN1to8

PIN1to9 PIN1to9

PIN1to10 PIN1to10

FRONT RISER

UPPIN1to8 PIN1to8

PIN5to9 PIN5to9

FRONT RISER

DOWNPIN1to9 PIN1to9

PIN5to8 PIN5to8

CENTER

SWITCH

FORWARDPIN1to6 PIN1to6

PIN5to3 PIN5to3

CENTER

SWITCH

REARWARDPIN1to3 PIN1to3

PIN5to6 PIN5to6

REAR RISER

UPPIN1to7 PIN1to7

PIN5to10 PIN5to10

REAR RISER

DOWNPIN1to10 PIN1to10

PIN5to7 PIN5to7

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

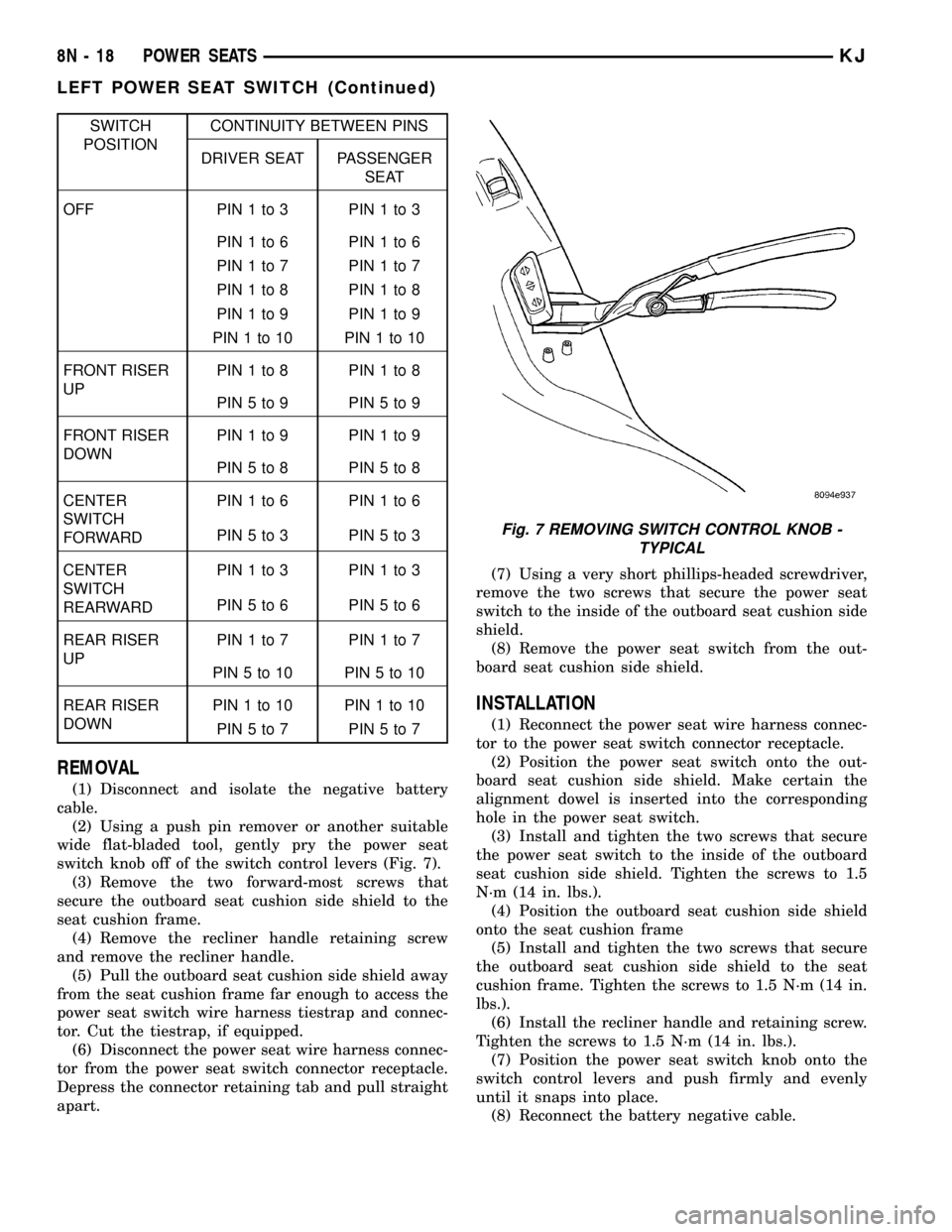

(2) Using a push pin remover or another suitable

wide flat-bladed tool, gently pry the power seat

switch knob off of the switch control levers (Fig. 7).

(3) Remove the two forward-most screws that

secure the outboard seat cushion side shield to the

seat cushion frame.

(4) Remove the recliner handle retaining screw

and remove the recliner handle.

(5) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness tiestrap and connec-

tor. Cut the tiestrap, if equipped.

(6) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

Depress the connector retaining tab and pull straight

apart.(7) Using a very short phillips-headed screwdriver,

remove the two screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield.

(8) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(2) Position the power seat switch onto the out-

board seat cushion side shield. Make certain the

alignment dowel is inserted into the corresponding

hole in the power seat switch.

(3) Install and tighten the two screws that secure

the power seat switch to the inside of the outboard

seat cushion side shield. Tighten the screws to 1.5

N´m (14 in. lbs.).

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the two screws that secure

the outboard seat cushion side shield to the seat

cushion frame. Tighten the screws to 1.5 N´m (14 in.

lbs.).

(6) Install the recliner handle and retaining screw.

Tighten the screws to 1.5 N´m (14 in. lbs.).

(7) Position the power seat switch knob onto the

switch control levers and push firmly and evenly

until it snaps into place.

(8) Reconnect the battery negative cable.

Fig. 7 REMOVING SWITCH CONTROL KNOB -

TYPICAL

8N - 18 POWER SEATSKJ

LEFT POWER SEAT SWITCH (Continued)

Page 622 of 1803

RIGHT POWER SEAT SWITCH

DESCRIPTION

Vehicles equipped with the power seat option uti-

lize a six-way power seat switch. This six-way power

seat switch features one seat cushion shaped knob,

visible on the outboard seat cushion side shield.

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knob must be removed before the seat switch can be

removed from the side shield.

The individual switches internal to the power seat

switch cannot be repaired. If one switch is damaged

or faulty, the entire power seat switch unit must be

replaced.

OPERATION

The power seat tracks can be adjusted in six differ-

ent ways using the power seat switches. See the own-

er's manual in the vehicle glove box for more

information on the power seat switch functions and

the seat adjusting procedures.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track adjuster motor. The selected adjuster motor

operates to move the seat track through its drive

unit in the selected direction until the switch is

released, or until the travel limit of the seat track is

reached. When the switch is moved in the opposite

direction, the battery feed and ground path to the

motor are reversed through the switch contacts. This

causes the adjuster motor to run in the opposite

direction.

No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

DIAGNOSIS AND TESTING - RIGHT POWER

SEAT SWITCH

For complete circuit diagrams, refer toPower

Seatin Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the power seat switch from the out-

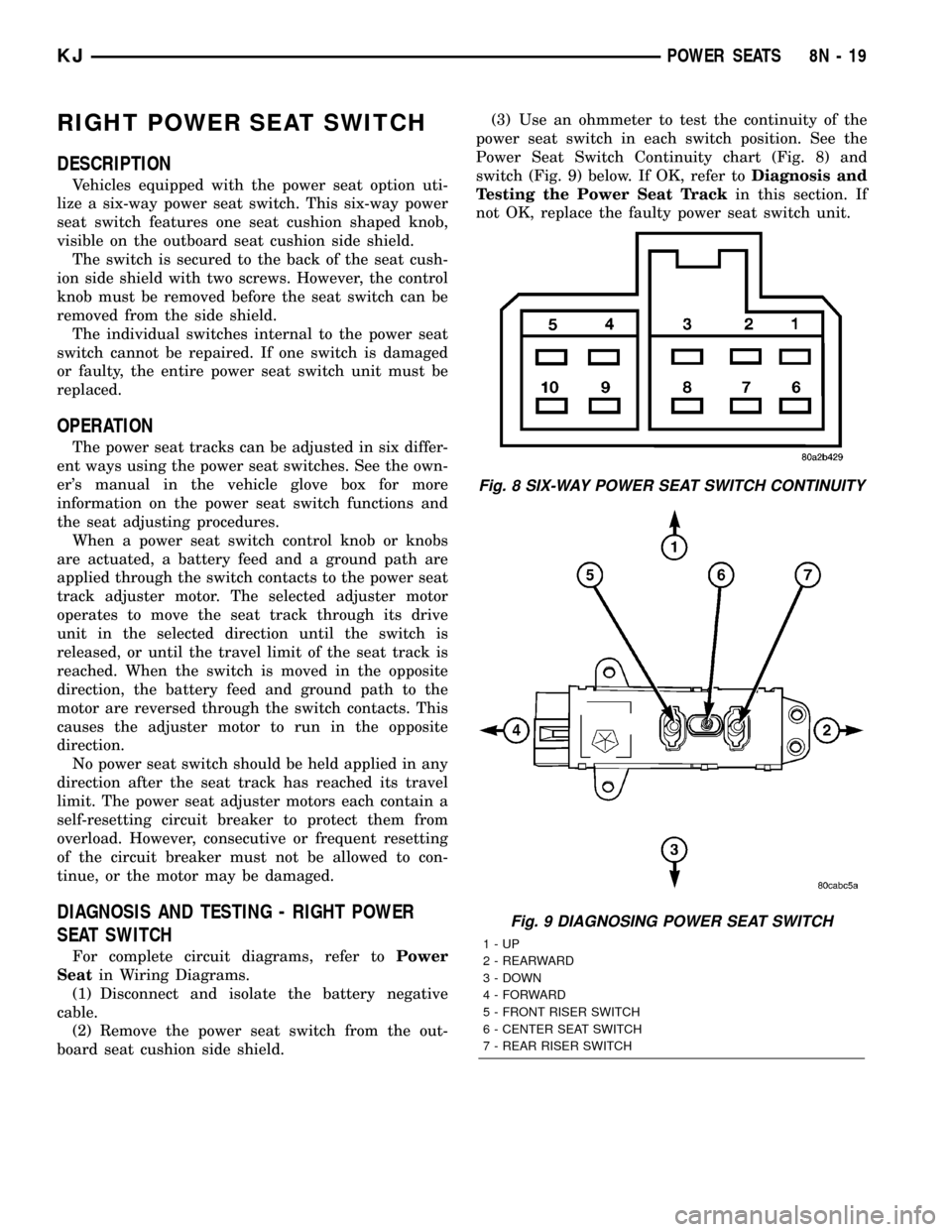

board seat cushion side shield.(3) Use an ohmmeter to test the continuity of the

power seat switch in each switch position. See the

Power Seat Switch Continuity chart (Fig. 8) and

switch (Fig. 9) below. If OK, refer toDiagnosis and

Testing the Power Seat Trackin this section. If

not OK, replace the faulty power seat switch unit.

Fig. 8 SIX-WAY POWER SEAT SWITCH CONTINUITY

Fig. 9 DIAGNOSING POWER SEAT SWITCH

1-UP

2 - REARWARD

3 - DOWN

4 - FORWARD

5 - FRONT RISER SWITCH

6 - CENTER SEAT SWITCH

7 - REAR RISER SWITCH

KJPOWER SEATS 8N - 19

Page 623 of 1803

SWITCH

POSITIONCONTINUITY BETWEEN PINS

DRIVER SEAT PASSENGER

SEAT

OFF PIN1to3 PIN1to3

PIN1to6 PIN1to6

PIN1to7 PIN1to7

PIN1to8 PIN1to8

PIN1to9 PIN1to9

PIN1to10 PIN1to10

FRONT RISER

UPPIN1to8 PIN1to8

PIN5to9 PIN5to9

FRONT RISER

DOWNPIN1to9 PIN1to9

PIN5to8 PIN5to8

CENTER

SWITCH

FORWARDPIN1to6 PIN1to6

PIN5to3 PIN5to3

CENTER

SWITCH

REARWARDPIN1to3 PIN1to3

PIN5to6 PIN5to6

REAR RISER

UPPIN1to7 PIN1to7

PIN5to10 PIN5to10

REAR RISER

DOWNPIN1to10 PIN1to10

PIN5to7 PIN5to7

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

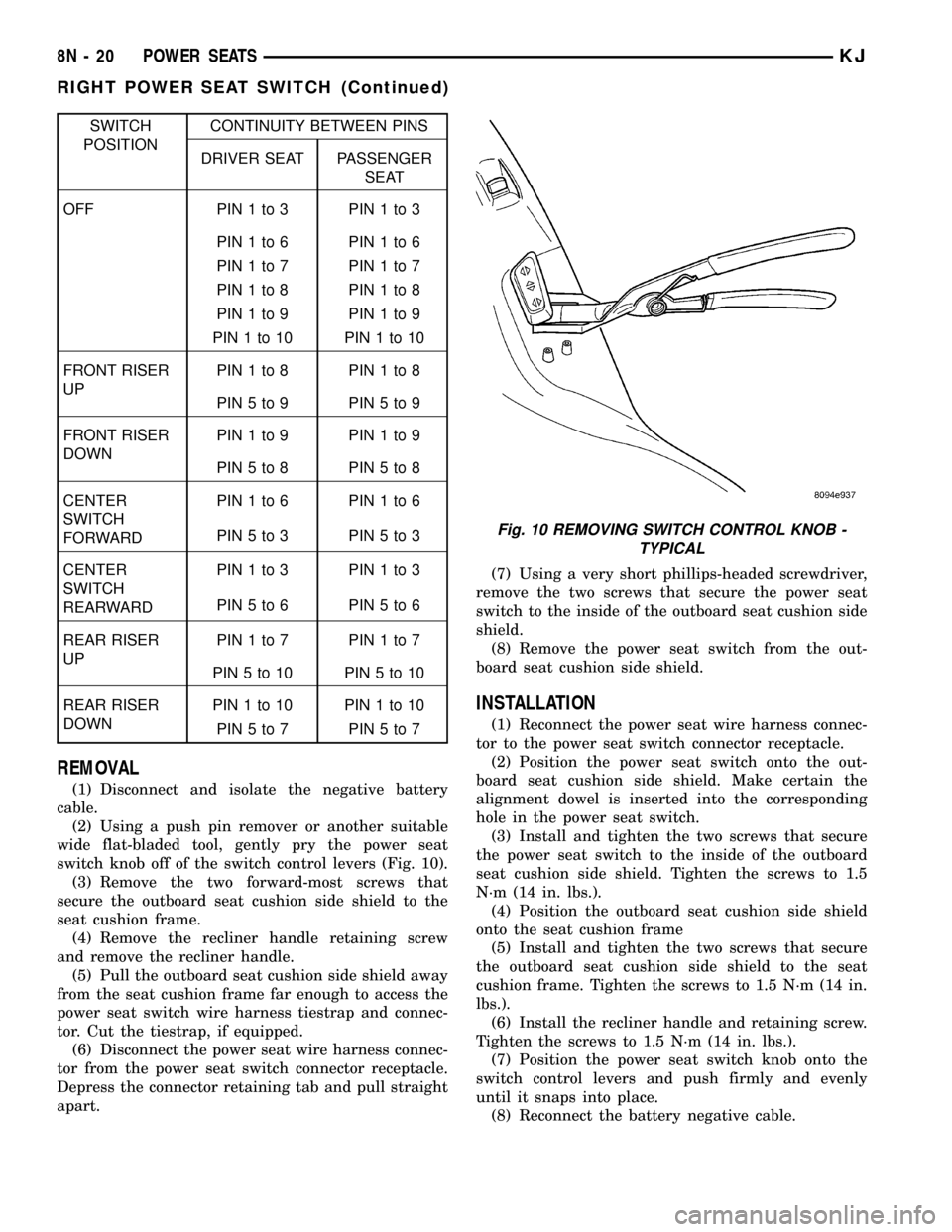

(2) Using a push pin remover or another suitable

wide flat-bladed tool, gently pry the power seat

switch knob off of the switch control levers (Fig. 10).

(3) Remove the two forward-most screws that

secure the outboard seat cushion side shield to the

seat cushion frame.

(4) Remove the recliner handle retaining screw

and remove the recliner handle.

(5) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness tiestrap and connec-

tor. Cut the tiestrap, if equipped.

(6) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

Depress the connector retaining tab and pull straight

apart.(7) Using a very short phillips-headed screwdriver,

remove the two screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield.

(8) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(2) Position the power seat switch onto the out-

board seat cushion side shield. Make certain the

alignment dowel is inserted into the corresponding

hole in the power seat switch.

(3) Install and tighten the two screws that secure

the power seat switch to the inside of the outboard

seat cushion side shield. Tighten the screws to 1.5

N´m (14 in. lbs.).

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the two screws that secure

the outboard seat cushion side shield to the seat

cushion frame. Tighten the screws to 1.5 N´m (14 in.

lbs.).

(6) Install the recliner handle and retaining screw.

Tighten the screws to 1.5 N´m (14 in. lbs.).

(7) Position the power seat switch knob onto the

switch control levers and push firmly and evenly

until it snaps into place.

(8) Reconnect the battery negative cable.

Fig. 10 REMOVING SWITCH CONTROL KNOB -

TYPICAL

8N - 20 POWER SEATSKJ

RIGHT POWER SEAT SWITCH (Continued)

Page 652 of 1803

(6) Install and tighten the nut that secures the

seat belt turning loop to the height adjuster stud.

Tighten the nut to 34 N´m (25 ft. lbs.).

(7) Fold and snap the trim cover back into place to

conceal the nut that secures the front seat belt turn-

ing loop to the height adjuster on the upper B-pillar.

(8) Position the front seat belt lower anchor to the

bracket on the outboard side of the front seat cushion

frame (Fig. 19).

(9) Install and tighten the screw that secures the

lower anchor to the bracket on the outboard side of

the front seat cushion frame. Tighten the screw to 43

N´m (32 ft. lbs.).

(10) Align the plug that covers the front seat belt

lower anchor screw with the hole near the rear of the

outboard seat side shield. Using hand pressure, press

firmly and evenly on the plug until it snaps into

place.

(11) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

supplemental restraint system component. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - VERIFICATION TEST).

FRONT SEAT BELT BUCKLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the front seat and seat track from the

floor panel as a unit. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - REMOVAL).

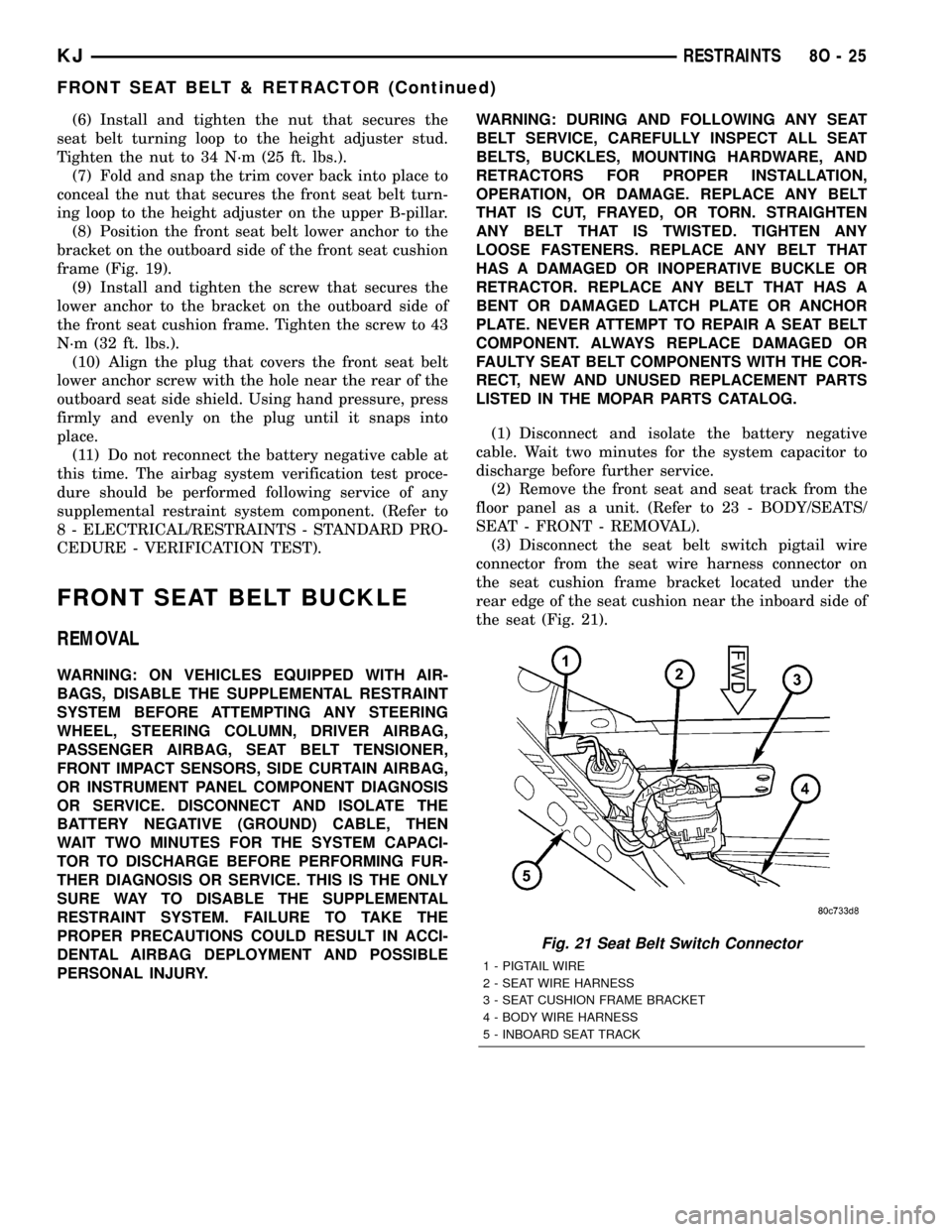

(3) Disconnect the seat belt switch pigtail wire

connector from the seat wire harness connector on

the seat cushion frame bracket located under the

rear edge of the seat cushion near the inboard side of

the seat (Fig. 21).

Fig. 21 Seat Belt Switch Connector

1 - PIGTAIL WIRE

2 - SEAT WIRE HARNESS

3 - SEAT CUSHION FRAME BRACKET

4 - BODY WIRE HARNESS

5 - INBOARD SEAT TRACK

KJRESTRAINTS 8O - 25

FRONT SEAT BELT & RETRACTOR (Continued)

Page 653 of 1803

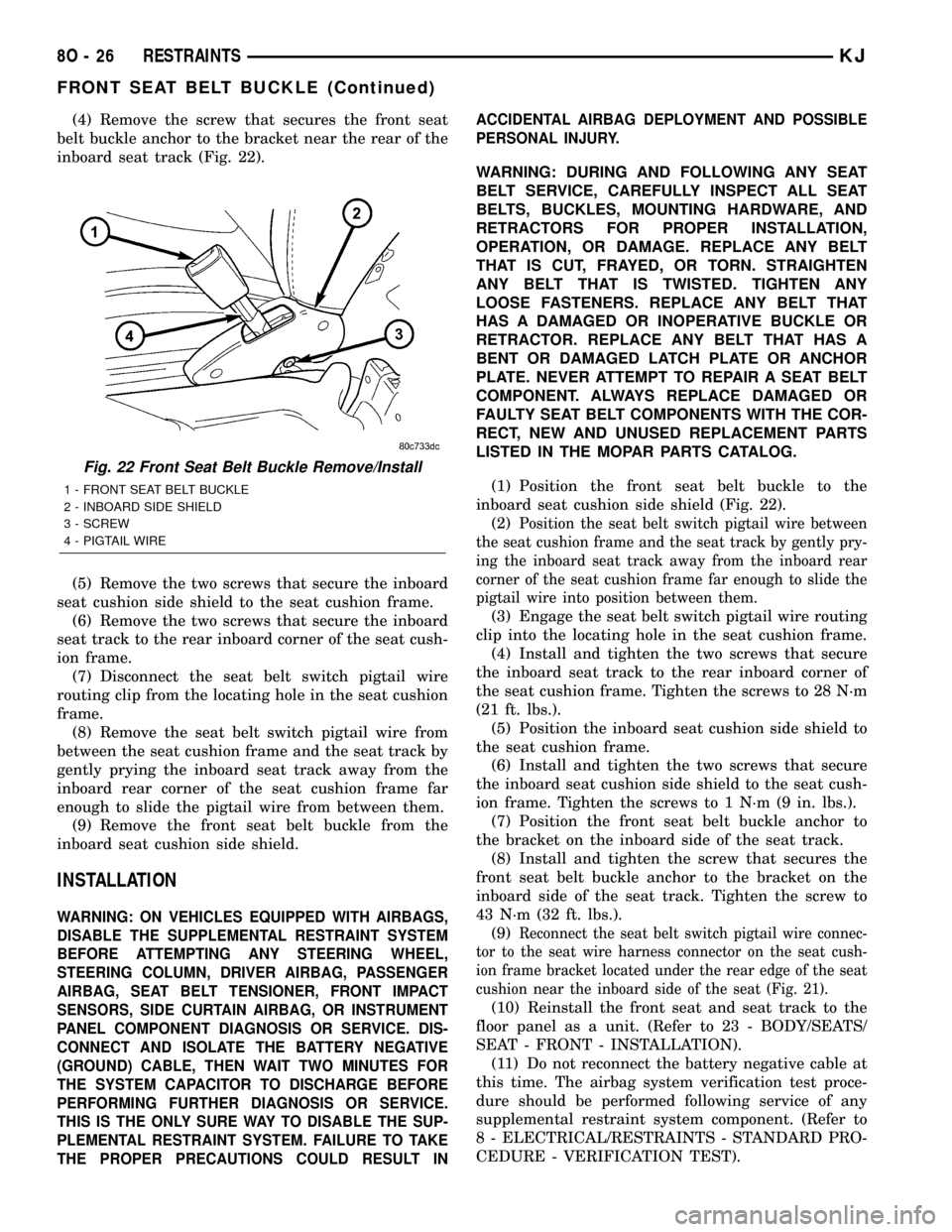

(4) Remove the screw that secures the front seat

belt buckle anchor to the bracket near the rear of the

inboard seat track (Fig. 22).

(5) Remove the two screws that secure the inboard

seat cushion side shield to the seat cushion frame.

(6) Remove the two screws that secure the inboard

seat track to the rear inboard corner of the seat cush-

ion frame.

(7) Disconnect the seat belt switch pigtail wire

routing clip from the locating hole in the seat cushion

frame.

(8) Remove the seat belt switch pigtail wire from

between the seat cushion frame and the seat track by

gently prying the inboard seat track away from the

inboard rear corner of the seat cushion frame far

enough to slide the pigtail wire from between them.

(9) Remove the front seat belt buckle from the

inboard seat cushion side shield.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, DRIVER AIRBAG, PASSENGER

AIRBAG, SEAT BELT TENSIONER, FRONT IMPACT

SENSORS, SIDE CURTAIN AIRBAG, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE. DIS-

CONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE SUP-

PLEMENTAL RESTRAINT SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT INACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front seat belt buckle to the

inboard seat cushion side shield (Fig. 22).

(2)

Position the seat belt switch pigtail wire between

the seat cushion frame and the seat track by gently pry-

ing the inboard seat track away from the inboard rear

corner of the seat cushion frame far enough to slide the

pigtail wire into position between them.

(3) Engage the seat belt switch pigtail wire routing

clip into the locating hole in the seat cushion frame.

(4) Install and tighten the two screws that secure

the inboard seat track to the rear inboard corner of

the seat cushion frame. Tighten the screws to 28 N´m

(21 ft. lbs.).

(5) Position the inboard seat cushion side shield to

the seat cushion frame.

(6) Install and tighten the two screws that secure

the inboard seat cushion side shield to the seat cush-

ion frame. Tighten the screws to 1 N´m (9 in. lbs.).

(7) Position the front seat belt buckle anchor to

the bracket on the inboard side of the seat track.

(8) Install and tighten the screw that secures the

front seat belt buckle anchor to the bracket on the

inboard side of the seat track. Tighten the screw to

43 N´m (32 ft. lbs.).

(9)

Reconnect the seat belt switch pigtail wire connec-

tor to the seat wire harness connector on the seat cush-

ion frame bracket located under the rear edge of the seat

cushion near the inboard side of the seat (Fig. 21).

(10) Reinstall the front seat and seat track to the

floor panel as a unit. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - INSTALLATION).

(11) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

supplemental restraint system component. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - VERIFICATION TEST).

Fig. 22 Front Seat Belt Buckle Remove/Install

1 - FRONT SEAT BELT BUCKLE

2 - INBOARD SIDE SHIELD

3 - SCREW

4 - PIGTAIL WIRE

8O - 26 RESTRAINTSKJ

FRONT SEAT BELT BUCKLE (Continued)

Page 659 of 1803

REAR CENTER SEAT BELT &

RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the right center seat belt buckle unit

from the floor panel. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/REAR SEAT BELT BUCKLE - REMOV-

AL).

(2) Unlatch and fold the right rear seat back for-

ward and separate the cargo area carpet from the

base of the seat back panel.

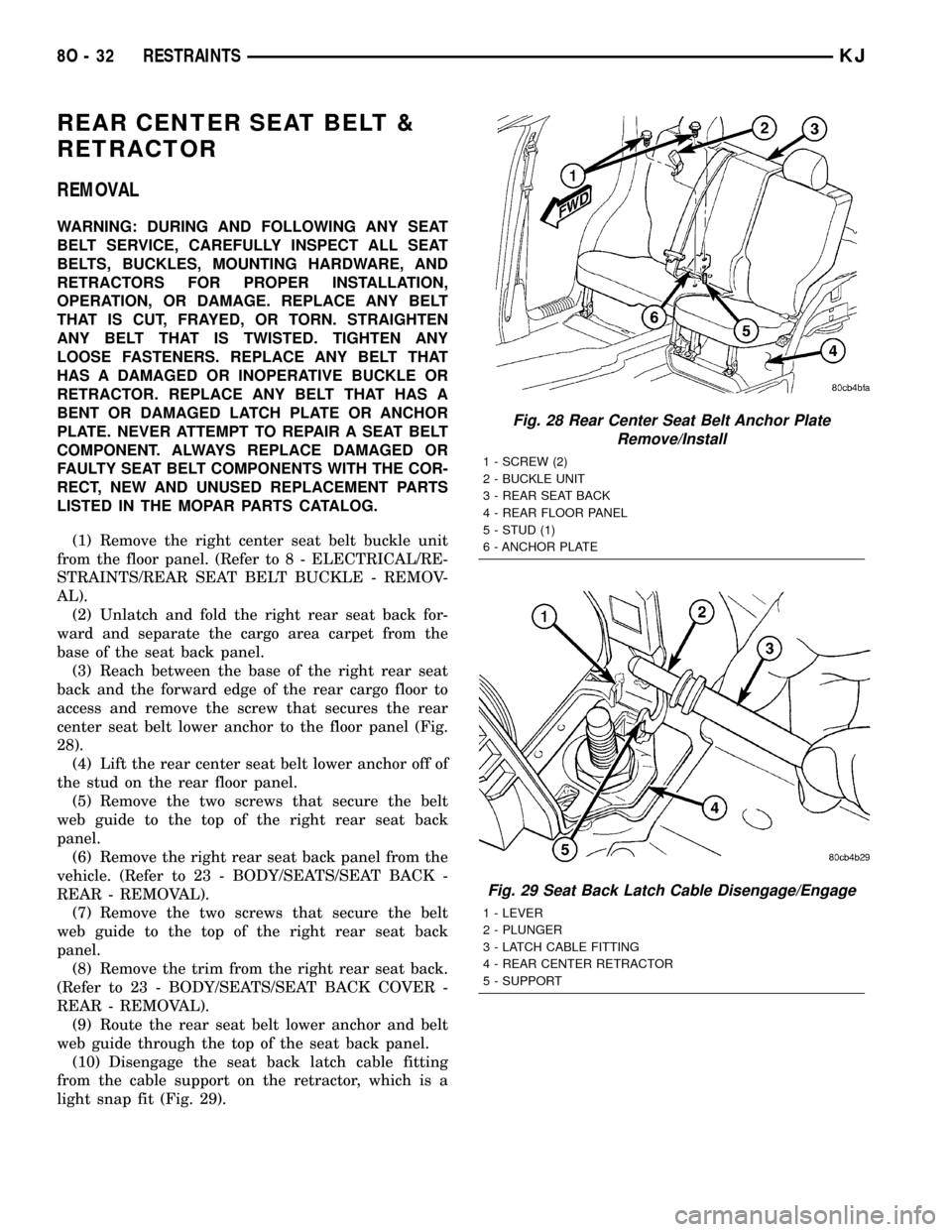

(3) Reach between the base of the right rear seat

back and the forward edge of the rear cargo floor to

access and remove the screw that secures the rear

center seat belt lower anchor to the floor panel (Fig.

28).

(4) Lift the rear center seat belt lower anchor off of

the stud on the rear floor panel.

(5) Remove the two screws that secure the belt

web guide to the top of the right rear seat back

panel.

(6) Remove the right rear seat back panel from the

vehicle. (Refer to 23 - BODY/SEATS/SEAT BACK -

REAR - REMOVAL).

(7) Remove the two screws that secure the belt

web guide to the top of the right rear seat back

panel.

(8) Remove the trim from the right rear seat back.

(Refer to 23 - BODY/SEATS/SEAT BACK COVER -

REAR - REMOVAL).

(9) Route the rear seat belt lower anchor and belt

web guide through the top of the seat back panel.

(10) Disengage the seat back latch cable fitting

from the cable support on the retractor, which is a

light snap fit (Fig. 29).

Fig. 28 Rear Center Seat Belt Anchor Plate

Remove/Install

1 - SCREW (2)

2 - BUCKLE UNIT

3 - REAR SEAT BACK

4 - REAR FLOOR PANEL

5 - STUD (1)

6 - ANCHOR PLATE

Fig. 29 Seat Back Latch Cable Disengage/Engage

1 - LEVER

2 - PLUNGER

3 - LATCH CABLE FITTING

4 - REAR CENTER RETRACTOR

5 - SUPPORT

8O - 32 RESTRAINTSKJ

Page 660 of 1803

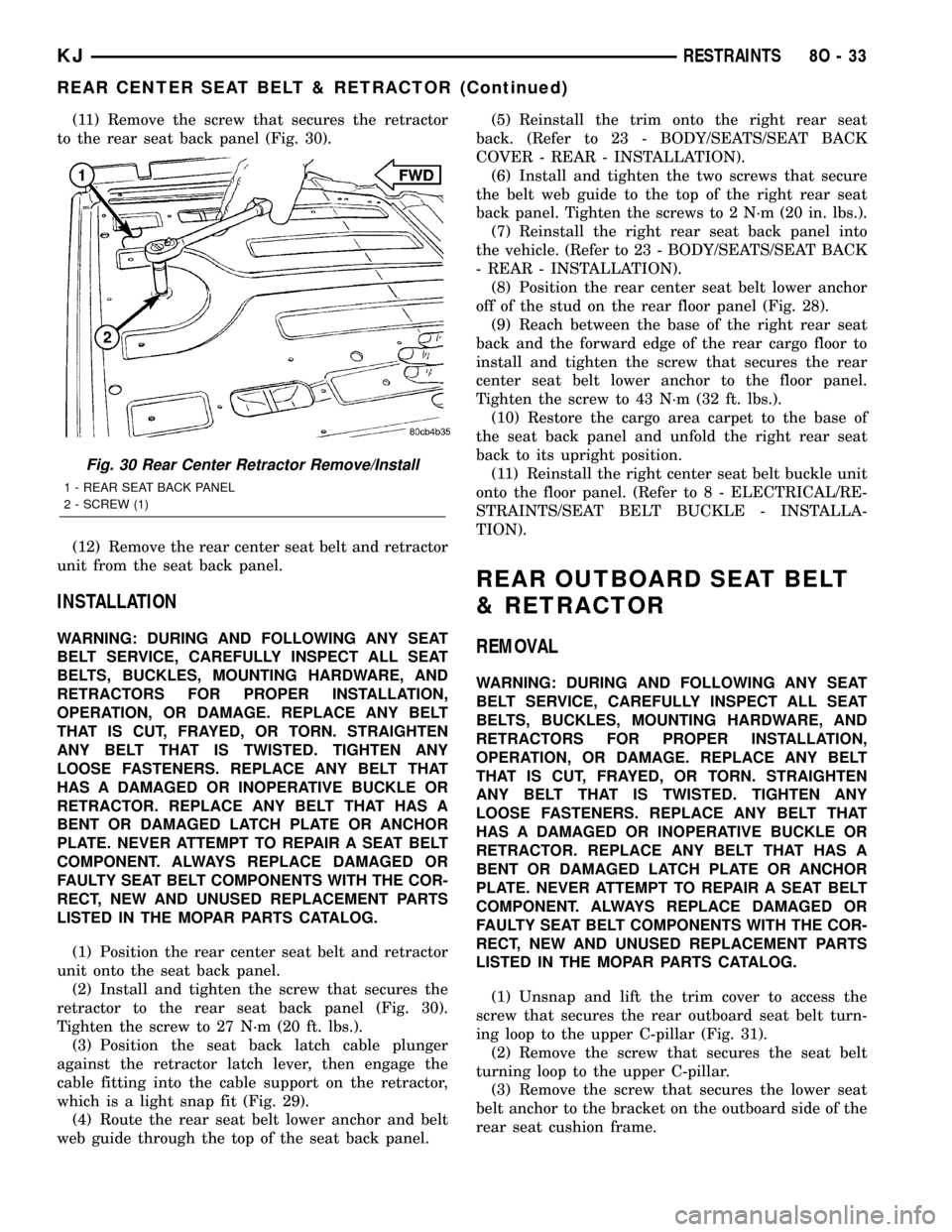

(11) Remove the screw that secures the retractor

to the rear seat back panel (Fig. 30).

(12) Remove the rear center seat belt and retractor

unit from the seat back panel.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the rear center seat belt and retractor

unit onto the seat back panel.

(2) Install and tighten the screw that secures the

retractor to the rear seat back panel (Fig. 30).

Tighten the screw to 27 N´m (20 ft. lbs.).

(3) Position the seat back latch cable plunger

against the retractor latch lever, then engage the

cable fitting into the cable support on the retractor,

which is a light snap fit (Fig. 29).

(4) Route the rear seat belt lower anchor and belt

web guide through the top of the seat back panel.(5) Reinstall the trim onto the right rear seat

back. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - REAR - INSTALLATION).

(6) Install and tighten the two screws that secure

the belt web guide to the top of the right rear seat

back panel. Tighten the screws to 2 N´m (20 in. lbs.).

(7) Reinstall the right rear seat back panel into

the vehicle. (Refer to 23 - BODY/SEATS/SEAT BACK

- REAR - INSTALLATION).

(8) Position the rear center seat belt lower anchor

off of the stud on the rear floor panel (Fig. 28).

(9) Reach between the base of the right rear seat

back and the forward edge of the rear cargo floor to

install and tighten the screw that secures the rear

center seat belt lower anchor to the floor panel.

Tighten the screw to 43 N´m (32 ft. lbs.).

(10) Restore the cargo area carpet to the base of

the seat back panel and unfold the right rear seat

back to its upright position.

(11) Reinstall the right center seat belt buckle unit

onto the floor panel. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT BUCKLE - INSTALLA-

TION).

REAR OUTBOARD SEAT BELT

& RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Unsnap and lift the trim cover to access the

screw that secures the rear outboard seat belt turn-

ing loop to the upper C-pillar (Fig. 31).

(2) Remove the screw that secures the seat belt

turning loop to the upper C-pillar.

(3) Remove the screw that secures the lower seat

belt anchor to the bracket on the outboard side of the

rear seat cushion frame.

Fig. 30 Rear Center Retractor Remove/Install

1 - REAR SEAT BACK PANEL

2 - SCREW (1)

KJRESTRAINTS 8O - 33

REAR CENTER SEAT BELT & RETRACTOR (Continued)

Page 710 of 1803

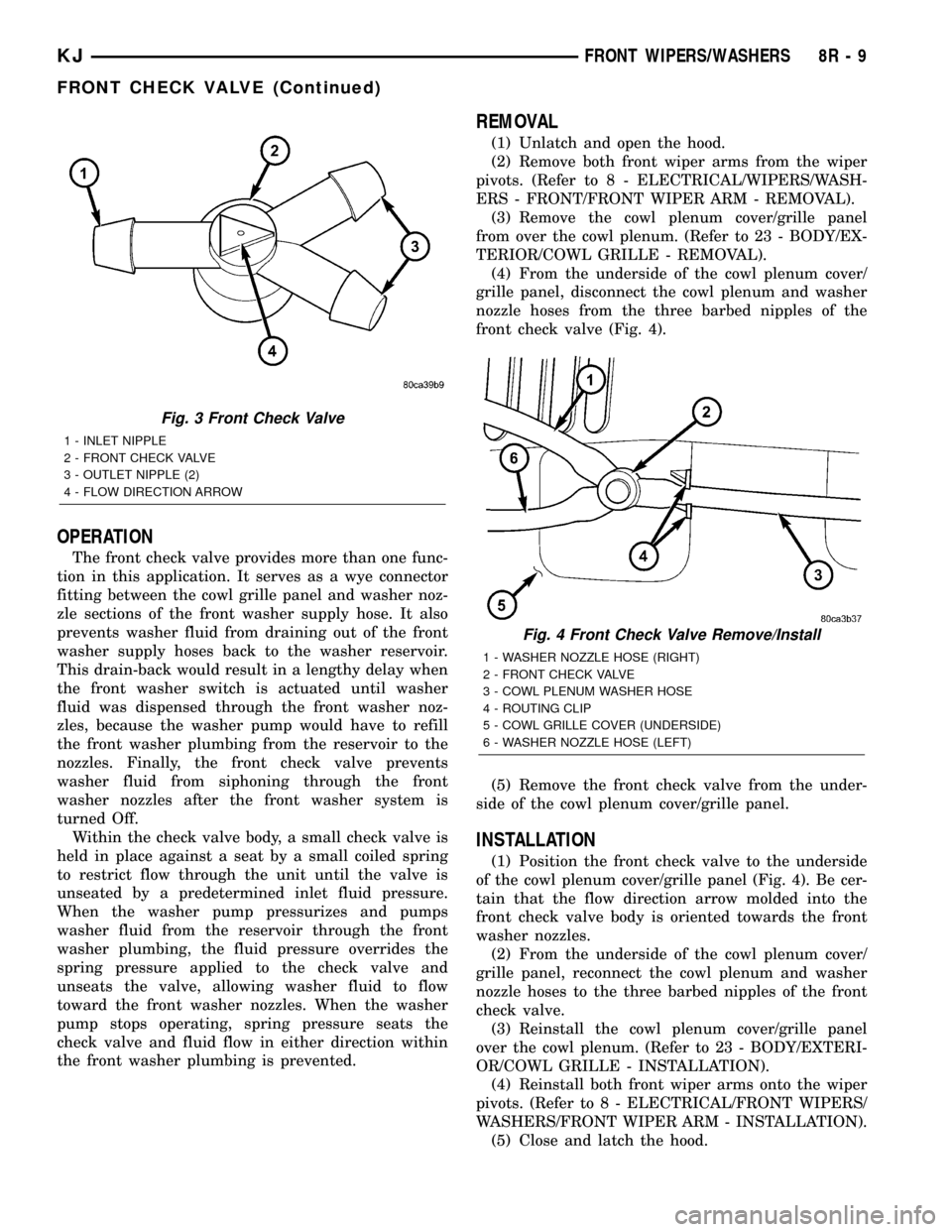

OPERATION

The front check valve provides more than one func-

tion in this application. It serves as a wye connector

fitting between the cowl grille panel and washer noz-

zle sections of the front washer supply hose. It also

prevents washer fluid from draining out of the front

washer supply hoses back to the washer reservoir.

This drain-back would result in a lengthy delay when

the front washer switch is actuated until washer

fluid was dispensed through the front washer noz-

zles, because the washer pump would have to refill

the front washer plumbing from the reservoir to the

nozzles. Finally, the front check valve prevents

washer fluid from siphoning through the front

washer nozzles after the front washer system is

turned Off.

Within the check valve body, a small check valve is

held in place against a seat by a small coiled spring

to restrict flow through the unit until the valve is

unseated by a predetermined inlet fluid pressure.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the front

washer plumbing, the fluid pressure overrides the

spring pressure applied to the check valve and

unseats the valve, allowing washer fluid to flow

toward the front washer nozzles. When the washer

pump stops operating, spring pressure seats the

check valve and fluid flow in either direction within

the front washer plumbing is prevented.

REMOVAL

(1) Unlatch and open the hood.

(2) Remove both front wiper arms from the wiper

pivots. (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS - FRONT/FRONT WIPER ARM - REMOVAL).

(3) Remove the cowl plenum cover/grille panel

from over the cowl plenum. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - REMOVAL).

(4) From the underside of the cowl plenum cover/

grille panel, disconnect the cowl plenum and washer

nozzle hoses from the three barbed nipples of the

front check valve (Fig. 4).

(5) Remove the front check valve from the under-

side of the cowl plenum cover/grille panel.

INSTALLATION

(1) Position the front check valve to the underside

of the cowl plenum cover/grille panel (Fig. 4). Be cer-

tain that the flow direction arrow molded into the

front check valve body is oriented towards the front

washer nozzles.

(2) From the underside of the cowl plenum cover/

grille panel, reconnect the cowl plenum and washer

nozzle hoses to the three barbed nipples of the front

check valve.

(3) Reinstall the cowl plenum cover/grille panel

over the cowl plenum. (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

(4) Reinstall both front wiper arms onto the wiper

pivots. (Refer to 8 - ELECTRICAL/FRONT WIPERS/

WASHERS/FRONT WIPER ARM - INSTALLATION).

(5) Close and latch the hood.

Fig. 3 Front Check Valve

1 - INLET NIPPLE

2 - FRONT CHECK VALVE

3 - OUTLET NIPPLE (2)

4 - FLOW DIRECTION ARROW

Fig. 4 Front Check Valve Remove/Install

1 - WASHER NOZZLE HOSE (RIGHT)

2 - FRONT CHECK VALVE

3 - COWL PLENUM WASHER HOSE

4 - ROUTING CLIP

5 - COWL GRILLE COVER (UNDERSIDE)

6 - WASHER NOZZLE HOSE (LEFT)

KJFRONT WIPERS/WASHERS 8R - 9

FRONT CHECK VALVE (Continued)

Page 735 of 1803

REAR WASHER SYSTEM

The washer system components should be

inspected periodically, not just when washer perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Check for ice or other foreign material in the

washer reservoir. If contaminated, clean and flush

the washer system. (Refer to 8 - ELECTRICAL/

REAR WIPERS/WASHERS - CLEANING).

(2) Inspect the washer plumbing for pinched, leak-

ing, deteriorated, or incorrectly routed hoses and

damaged or disconnected hose fittings. Replace dam-

aged or deteriorated hoses and hose fittings. Leaking

washer hoses can sometimes be repaired by cutting

the hose at the leak and splicing it back together

using an in-line connector fitting. Similarly, sections

of deteriorated hose can be cut out and replaced by

splicing in new sections of hose using in-line connec-

tor fittings. Whenever routing a washer hose or a

wire harness containing a washer hose, it must be

routed away from hot, sharp, or moving parts. Also,

sharp bends that might pinch the washer hose must

be avoided.

REAR CHECK VALVE

DESCRIPTION

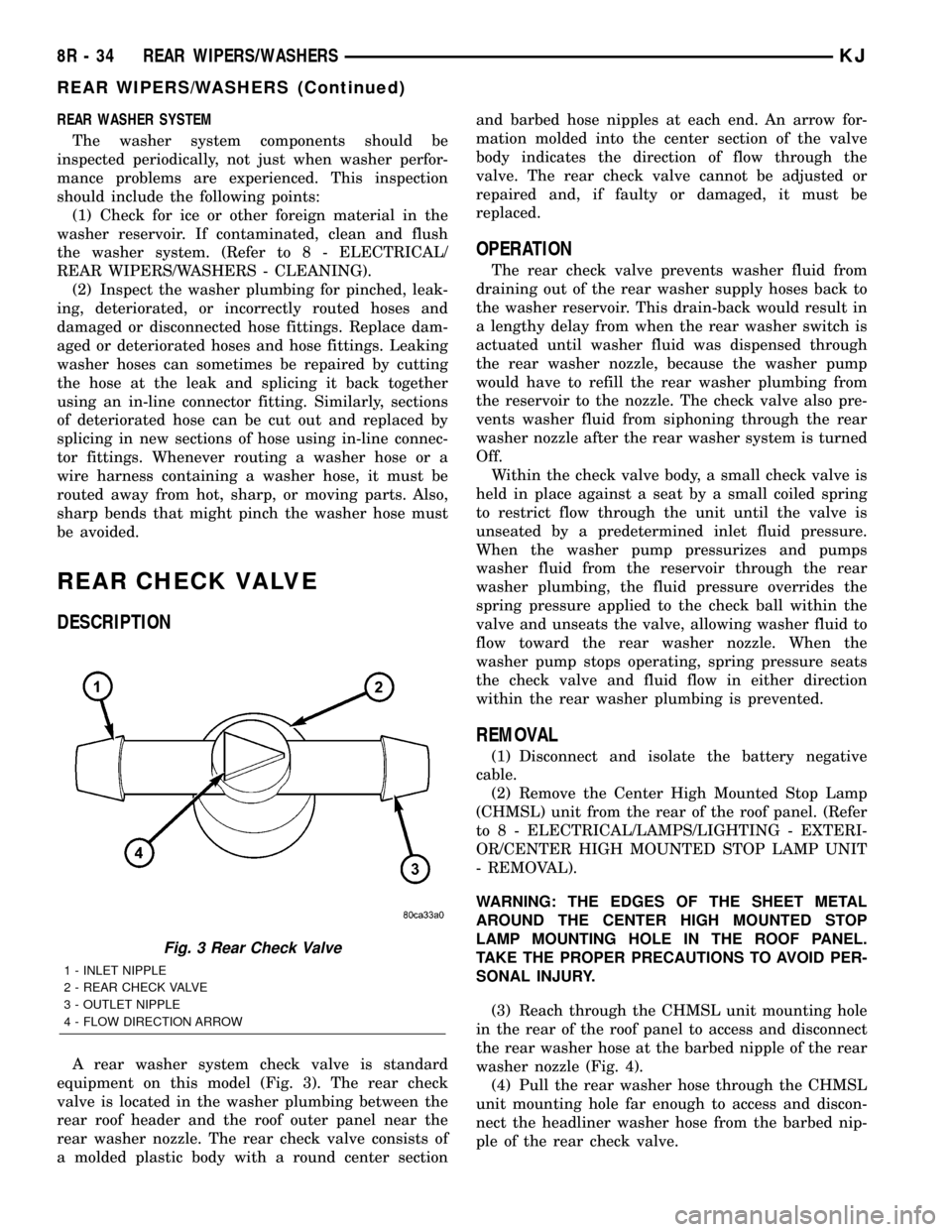

A rear washer system check valve is standard

equipment on this model (Fig. 3). The rear check

valve is located in the washer plumbing between the

rear roof header and the roof outer panel near the

rear washer nozzle. The rear check valve consists of

a molded plastic body with a round center sectionand barbed hose nipples at each end. An arrow for-

mation molded into the center section of the valve

body indicates the direction of flow through the

valve. The rear check valve cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The rear check valve prevents washer fluid from

draining out of the rear washer supply hoses back to

the washer reservoir. This drain-back would result in

a lengthy delay from when the rear washer switch is

actuated until washer fluid was dispensed through

the rear washer nozzle, because the washer pump

would have to refill the rear washer plumbing from

the reservoir to the nozzle. The check valve also pre-

vents washer fluid from siphoning through the rear

washer nozzle after the rear washer system is turned

Off.

Within the check valve body, a small check valve is

held in place against a seat by a small coiled spring

to restrict flow through the unit until the valve is

unseated by a predetermined inlet fluid pressure.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the rear

washer plumbing, the fluid pressure overrides the

spring pressure applied to the check ball within the

valve and unseats the valve, allowing washer fluid to

flow toward the rear washer nozzle. When the

washer pump stops operating, spring pressure seats

the check valve and fluid flow in either direction

within the rear washer plumbing is prevented.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Center High Mounted Stop Lamp

(CHMSL) unit from the rear of the roof panel. (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/CENTER HIGH MOUNTED STOP LAMP UNIT

- REMOVAL).

WARNING: THE EDGES OF THE SHEET METAL

AROUND THE CENTER HIGH MOUNTED STOP

LAMP MOUNTING HOLE IN THE ROOF PANEL.

TAKE THE PROPER PRECAUTIONS TO AVOID PER-

SONAL INJURY.

(3) Reach through the CHMSL unit mounting hole

in the rear of the roof panel to access and disconnect

the rear washer hose at the barbed nipple of the rear

washer nozzle (Fig. 4).

(4) Pull the rear washer hose through the CHMSL

unit mounting hole far enough to access and discon-

nect the headliner washer hose from the barbed nip-

ple of the rear check valve.

Fig. 3 Rear Check Valve

1 - INLET NIPPLE

2 - REAR CHECK VALVE

3 - OUTLET NIPPLE

4 - FLOW DIRECTION ARROW

8R - 34 REAR WIPERS/WASHERSKJ

REAR WIPERS/WASHERS (Continued)

Page 762 of 1803

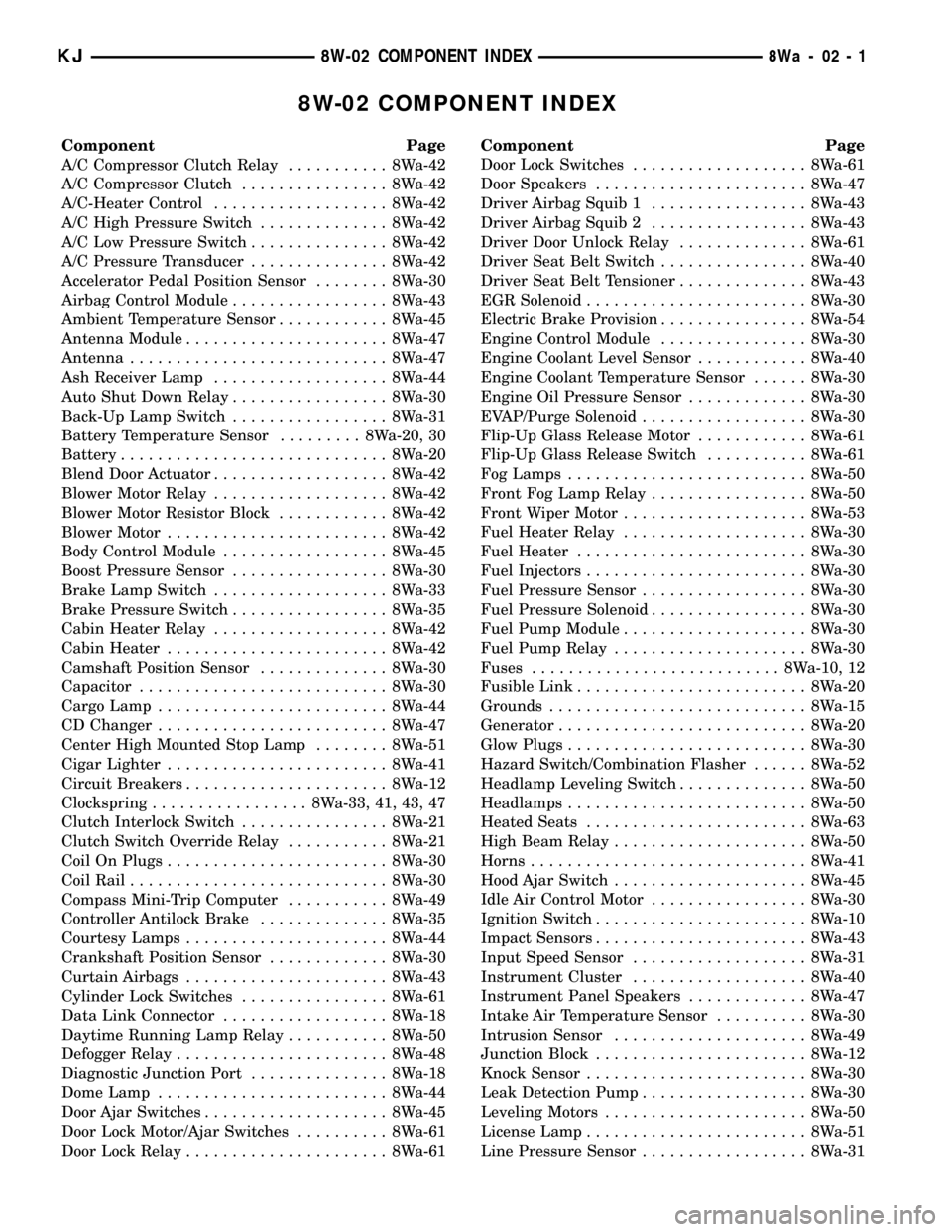

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay........... 8Wa-42

A/C Compressor Clutch................ 8Wa-42

A/C-Heater Control................... 8Wa-42

A/C High Pressure Switch.............. 8Wa-42

A/C Low Pressure Switch............... 8Wa-42

A/C Pressure Transducer............... 8Wa-42

Accelerator Pedal Position Sensor........ 8Wa-30

Airbag Control Module................. 8Wa-43

Ambient Temperature Sensor............ 8Wa-45

Antenna Module...................... 8Wa-47

Antenna............................ 8Wa-47

Ash Receiver Lamp................... 8Wa-44

Auto Shut Down Relay................. 8Wa-30

Back-Up Lamp Switch................. 8Wa-31

Battery Temperature Sensor......... 8Wa-20, 30

Battery............................. 8Wa-20

Blend Door Actuator................... 8Wa-42

Blower Motor Relay................... 8Wa-42

Blower Motor Resistor Block............ 8Wa-42

Blower Motor........................ 8Wa-42

Body Control Module.................. 8Wa-45

Boost Pressure Sensor................. 8Wa-30

Brake Lamp Switch................... 8Wa-33

Brake Pressure Switch................. 8Wa-35

Cabin Heater Relay................... 8Wa-42

Cabin Heater........................ 8Wa-42

Camshaft Position Sensor.............. 8Wa-30

Capacitor........................... 8Wa-30

Cargo Lamp......................... 8Wa-44

CD Changer......................... 8Wa-47

Center High Mounted Stop Lamp........ 8Wa-51

Cigar Lighter........................ 8Wa-41

Circuit Breakers...................... 8Wa-12

Clockspring................. 8Wa-33, 41, 43, 47

Clutch Interlock Switch................ 8Wa-21

Clutch Switch Override Relay........... 8Wa-21

Coil On Plugs........................ 8Wa-30

Coil Rail............................ 8Wa-30

Compass Mini-Trip Computer........... 8Wa-49

Controller Antilock Brake.............. 8Wa-35

Courtesy Lamps...................... 8Wa-44

Crankshaft Position Sensor............. 8Wa-30

Curtain Airbags...................... 8Wa-43

Cylinder Lock Switches................ 8Wa-61

Data Link Connector.................. 8Wa-18

Daytime Running Lamp Relay........... 8Wa-50

Defogger Relay....................... 8Wa-48

Diagnostic Junction Port............... 8Wa-18

Dome Lamp......................... 8Wa-44

Door Ajar Switches.................... 8Wa-45

Door Lock Motor/Ajar Switches.......... 8Wa-61

Door Lock Relay...................... 8Wa-61Component Page

Door Lock Switches................... 8Wa-61

Door Speakers....................... 8Wa-47

Driver Airbag Squib 1................. 8Wa-43

Driver Airbag Squib 2................. 8Wa-43

Driver Door Unlock Relay.............. 8Wa-61

Driver Seat Belt Switch................ 8Wa-40

Driver Seat Belt Tensioner.............. 8Wa-43

EGR Solenoid........................ 8Wa-30

Electric Brake Provision................ 8Wa-54

Engine Control Module................ 8Wa-30

Engine Coolant Level Sensor............ 8Wa-40

Engine Coolant Temperature Sensor...... 8Wa-30

Engine Oil Pressure Sensor............. 8Wa-30

EVAP/Purge Solenoid.................. 8Wa-30

Flip-Up Glass Release Motor............ 8Wa-61

Flip-Up Glass Release Switch........... 8Wa-61

Fog Lamps.......................... 8Wa-50

Front Fog Lamp Relay................. 8Wa-50

Front Wiper Motor.................... 8Wa-53

Fuel Heater Relay.................... 8Wa-30

Fuel Heater......................... 8Wa-30

Fuel Injectors........................ 8Wa-30

Fuel Pressure Sensor.................. 8Wa-30

Fuel Pressure Solenoid................. 8Wa-30

Fuel Pump Module.................... 8Wa-30

Fuel Pump Relay..................... 8Wa-30

Fuses........................... 8Wa-10, 12

Fusible Link......................... 8Wa-20

Grounds............................ 8Wa-15

Generator........................... 8Wa-20

Glow Plugs.......................... 8Wa-30

Hazard Switch/Combination Flasher...... 8Wa-52

Headlamp Leveling Switch.............. 8Wa-50

Headlamps.......................... 8Wa-50

Heated Seats........................ 8Wa-63

High Beam Relay..................... 8Wa-50

Horns.............................. 8Wa-41

Hood Ajar Switch..................... 8Wa-45

Idle Air Control Motor................. 8Wa-30

Ignition Switch....................... 8Wa-10

Impact Sensors....................... 8Wa-43

Input Speed Sensor................... 8Wa-31

Instrument Cluster................... 8Wa-40

Instrument Panel Speakers............. 8Wa-47

Intake Air Temperature Sensor.......... 8Wa-30

Intrusion Sensor..................... 8Wa-49

Junction Block....................... 8Wa-12

Knock Sensor........................ 8Wa-30

Leak Detection Pump.................. 8Wa-30

Leveling Motors...................... 8Wa-50

License Lamp........................ 8Wa-51

Line Pressure Sensor.................. 8Wa-31

KJ8W-02 COMPONENT INDEX8Wa-02-1