Seats JEEP LIBERTY 2002 KJ / 1.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1249 of 1803

(6) Position the camshaft drive gear into the tim-

ing chain aligning the V6 mark between the two

marked chain links (Two links marked during remov-

al).

(7) Using Special Tool 8428 Camshaft Wrench,

rotate the camshaft until the camshaft sprocket

dowel is aligned with the slot in the camshaft

sprocket. Install the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt over-

torque resulting in bolt failure.

(8) Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.

(9) Remove timing chain wedge special tool 8379.

(10) Using Special Tool 6958 spanner wrench with

adapter pins 8346, torque the camshaft sprocket

retaining bolt to 122 N´m (90 ft. lbs.).

(11) Install the camshaft position sensor.

(12) Install the cylinder head cover.

CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Drain cooling system, below the level of the

heater hoses. Refer to COOLING SYSTEM.(4) Remove accessory drive belt.

(5) Remove air conditioning compressor retaining

bolts and move compressor to the left.

(6) Remove heater hoses.

(7) Disconnect injector and ignition coil connectors.

(8) Disconnect and remove positive crankcase ven-

tilation (PCV) hose.

(9) Remove oil fill tube.

(10) Un-clip injector and ignition coil harness and

move away from cylinder head cover.

(11) Remove right rear breather tube and filter

assembly.

(12) Remove cylinder head cover retaining bolts.

(13) Remove cylinder head cover.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(3) Install right rear breather tube and filter

assembly.

(4) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(5) Install the oil fill tube.

(6) Install PCV hose.

(7) Install heater hoses.

(8) Install air conditioning compressor retaining

bolts.

(9) Install accessory drive belt

(10) Fill Cooling system

(11) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(12) Connect battery negative cable.

INTAKE/EXHAUST VALVES &

SEATS

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

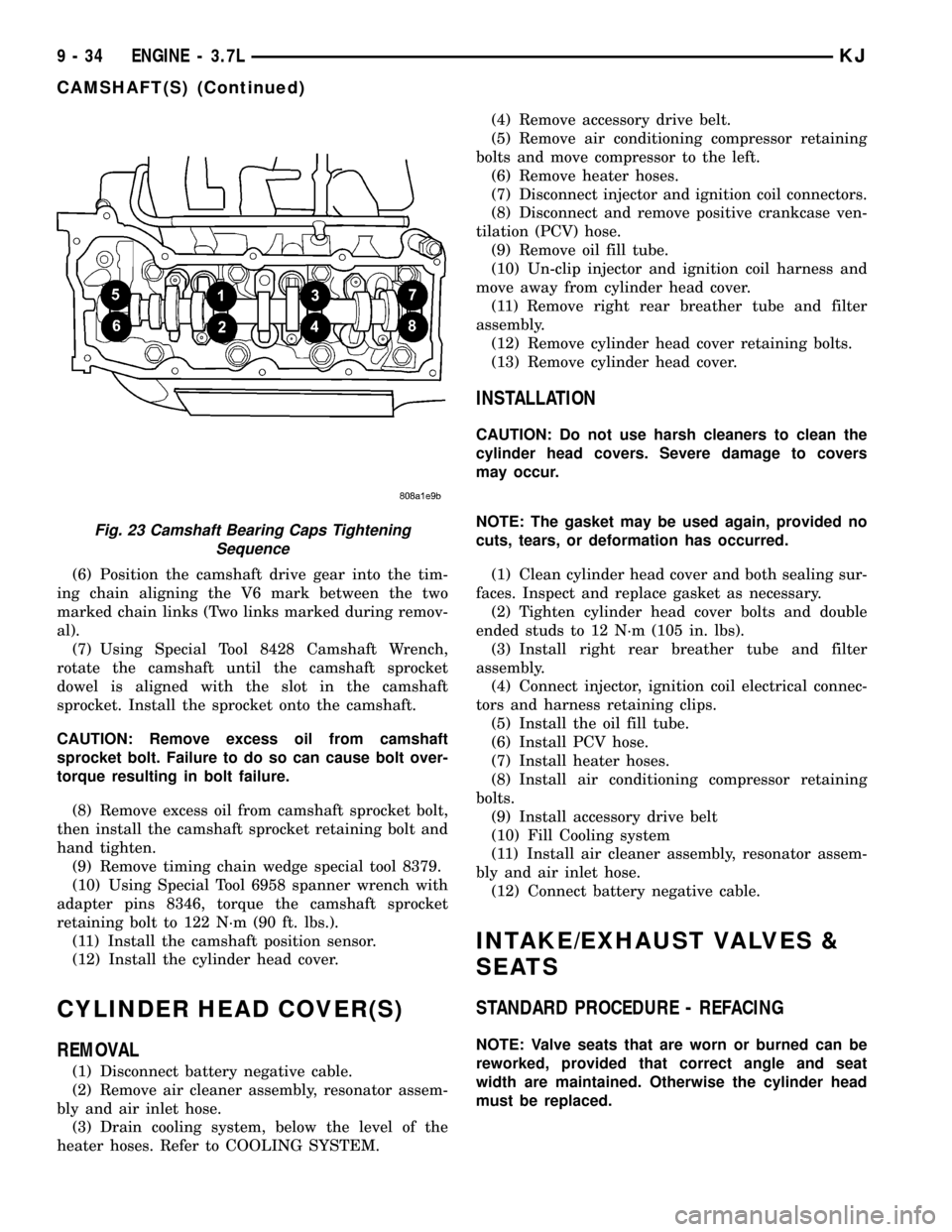

Fig. 23 Camshaft Bearing Caps Tightening

Sequence

9 - 34 ENGINE - 3.7LKJ

CAMSHAFT(S) (Continued)

Page 1250 of 1803

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 ± 2.36 mm (0.0689 ±

0.0928 in.) and the exhaust seat must be 1.71 ± 2.32

mm (0.0673 ± 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 41.44 mm (1.6315 in.).

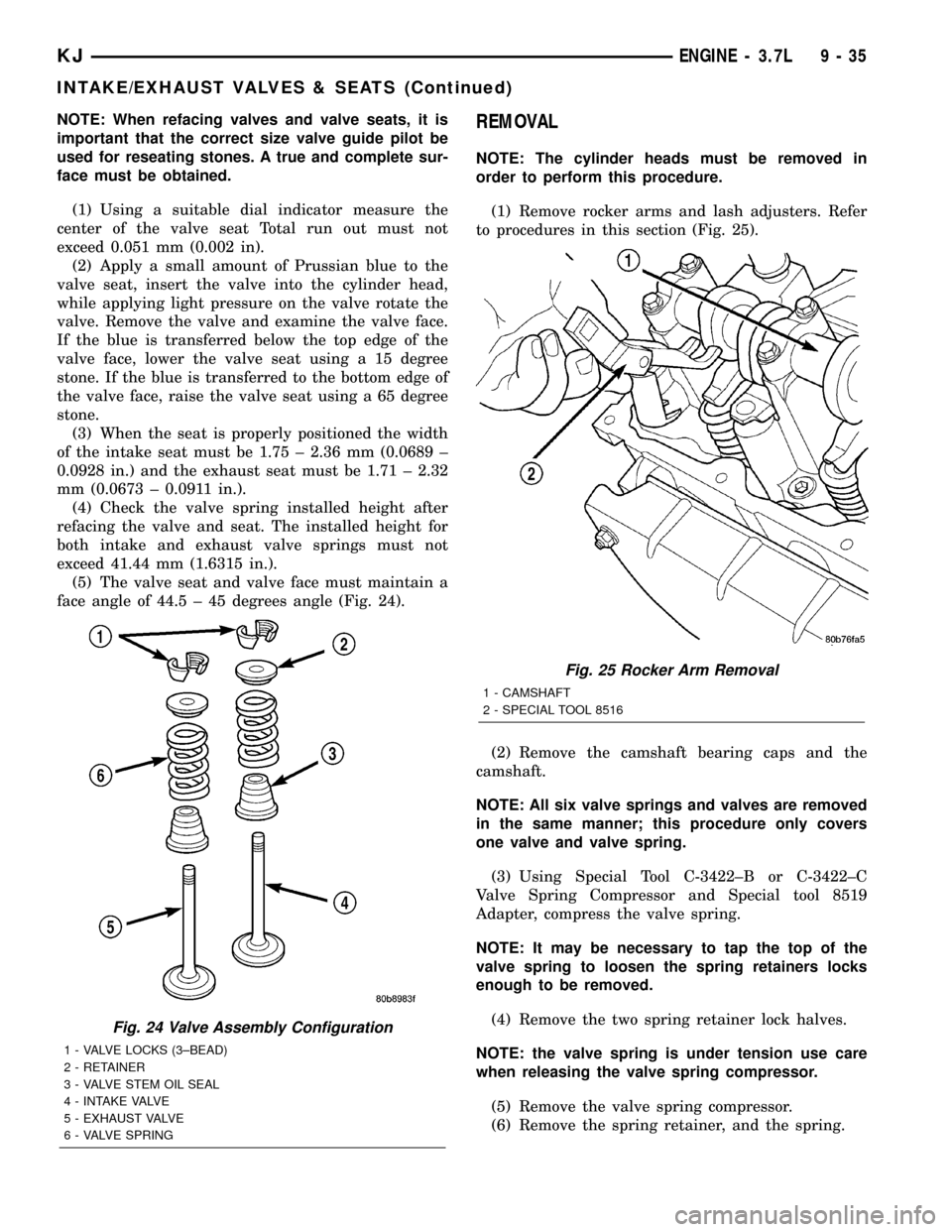

(5) The valve seat and valve face must maintain a

face angle of 44.5 ± 45 degrees angle (Fig. 24).REMOVAL

NOTE: The cylinder heads must be removed in

order to perform this procedure.

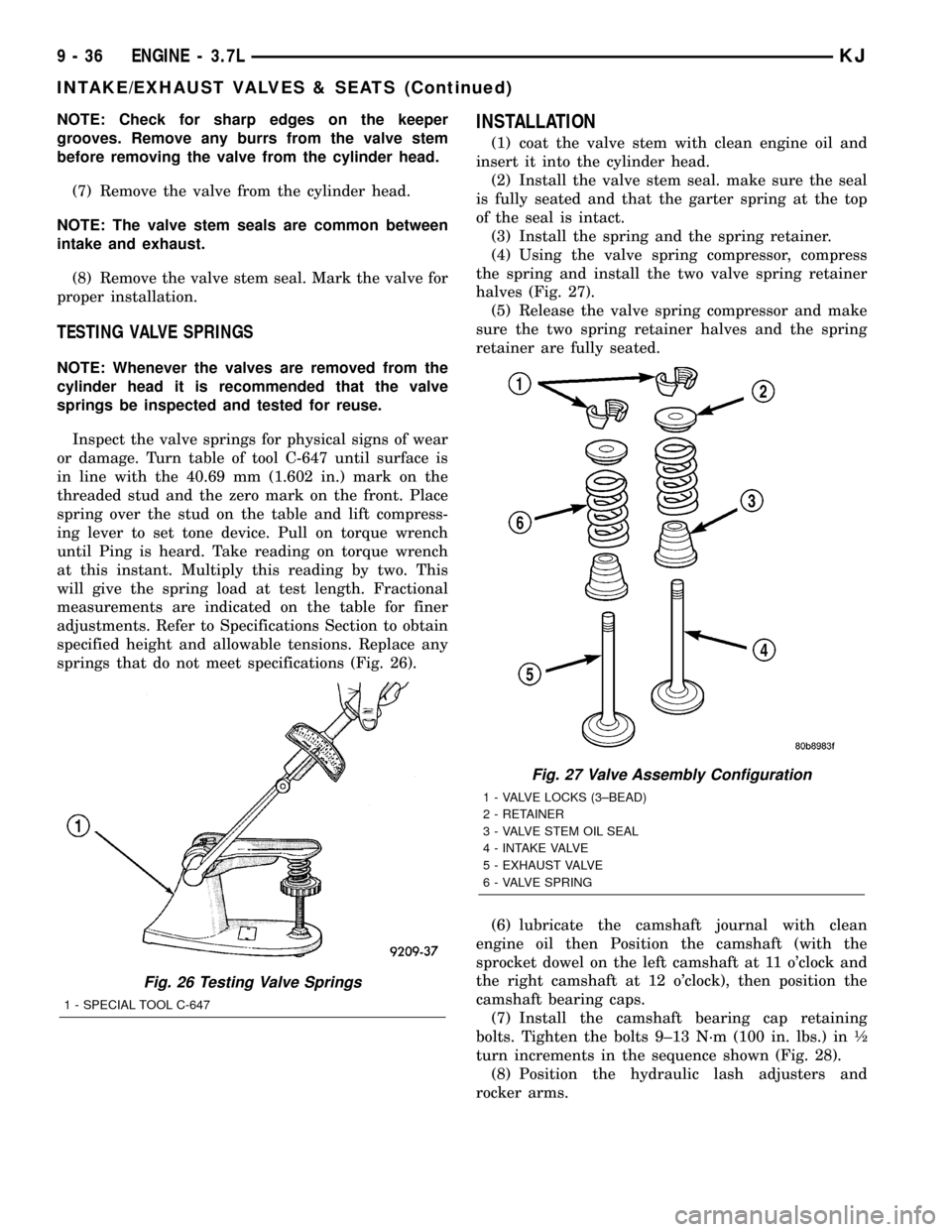

(1) Remove rocker arms and lash adjusters. Refer

to procedures in this section (Fig. 25).

(2) Remove the camshaft bearing caps and the

camshaft.

NOTE: All six valve springs and valves are removed

in the same manner; this procedure only covers

one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(4) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(5) Remove the valve spring compressor.

(6) Remove the spring retainer, and the spring.

Fig. 24 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 25 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

KJENGINE - 3.7L 9 - 35

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1251 of 1803

NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.69 mm (1.602 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications (Fig. 26).

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

(3) Install the spring and the spring retainer.

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves (Fig. 27).

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.

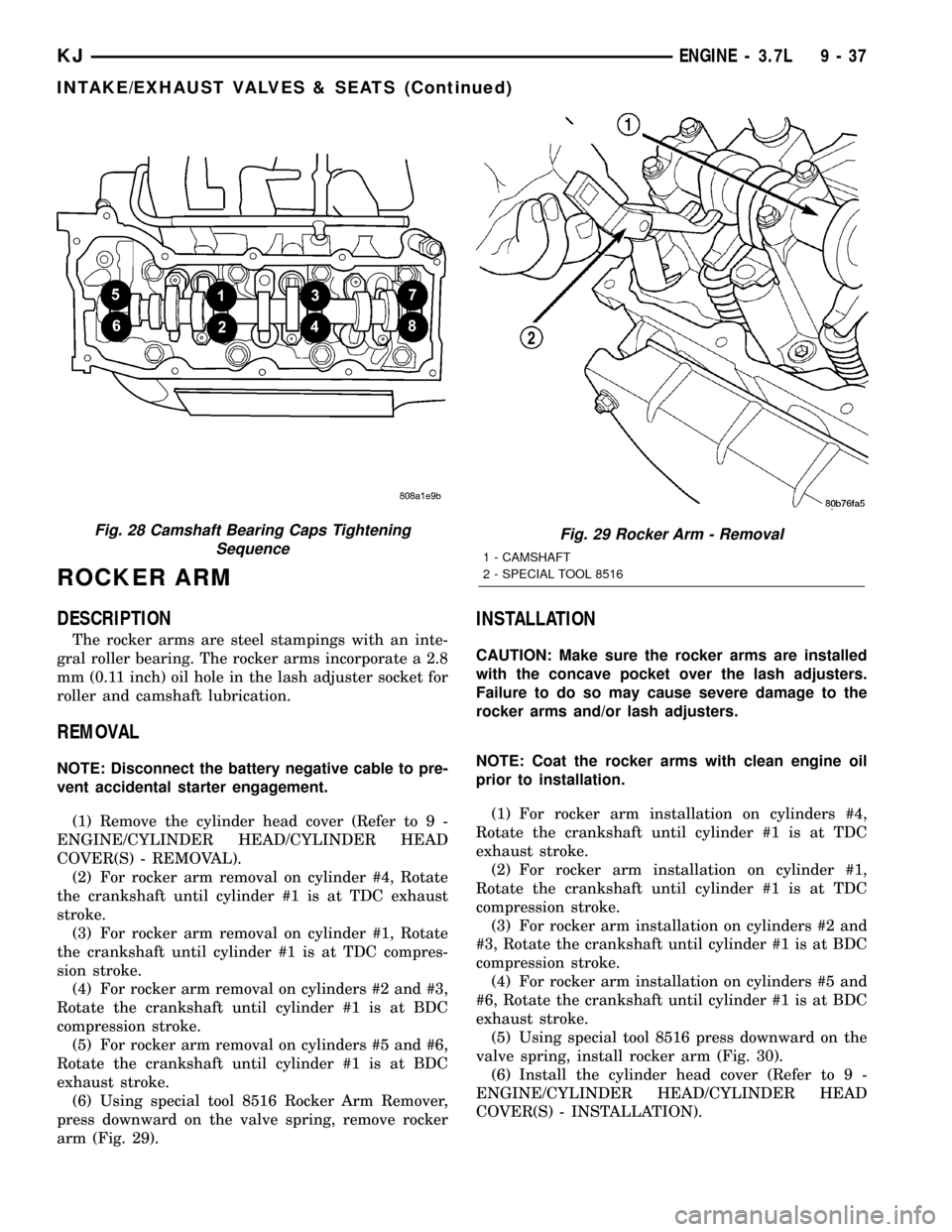

(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9±13 N´m (100 in. lbs.) in ó

turn increments in the sequence shown (Fig. 28).

(8) Position the hydraulic lash adjusters and

rocker arms.

Fig. 26 Testing Valve Springs

1 - SPECIAL TOOL C-647

Fig. 27 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

9 - 36 ENGINE - 3.7LKJ

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1252 of 1803

ROCKER ARM

DESCRIPTION

The rocker arms are steel stampings with an inte-

gral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

REMOVAL

NOTE: Disconnect the battery negative cable to pre-

vent accidental starter engagement.

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) For rocker arm removal on cylinder #4, Rotate

the crankshaft until cylinder #1 is at TDC exhaust

stroke.

(3) For rocker arm removal on cylinder #1, Rotate

the crankshaft until cylinder #1 is at TDC compres-

sion stroke.

(4) For rocker arm removal on cylinders #2 and #3,

Rotate the crankshaft until cylinder #1 is at BDC

compression stroke.

(5) For rocker arm removal on cylinders #5 and #6,

Rotate the crankshaft until cylinder #1 is at BDC

exhaust stroke.

(6) Using special tool 8516 Rocker Arm Remover,

press downward on the valve spring, remove rocker

arm (Fig. 29).

INSTALLATION

CAUTION: Make sure the rocker arms are installed

with the concave pocket over the lash adjusters.

Failure to do so may cause severe damage to the

rocker arms and/or lash adjusters.

NOTE: Coat the rocker arms with clean engine oil

prior to installation.

(1) For rocker arm installation on cylinders #4,

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(2) For rocker arm installation on cylinder #1,

Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(3) For rocker arm installation on cylinders #2 and

#3, Rotate the crankshaft until cylinder #1 is at BDC

compression stroke.

(4) For rocker arm installation on cylinders #5 and

#6, Rotate the crankshaft until cylinder #1 is at BDC

exhaust stroke.

(5) Using special tool 8516 press downward on the

valve spring, install rocker arm (Fig. 30).

(6) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

Fig. 28 Camshaft Bearing Caps Tightening

SequenceFig. 29 Rocker Arm - Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

KJENGINE - 3.7L 9 - 37

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1263 of 1803

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

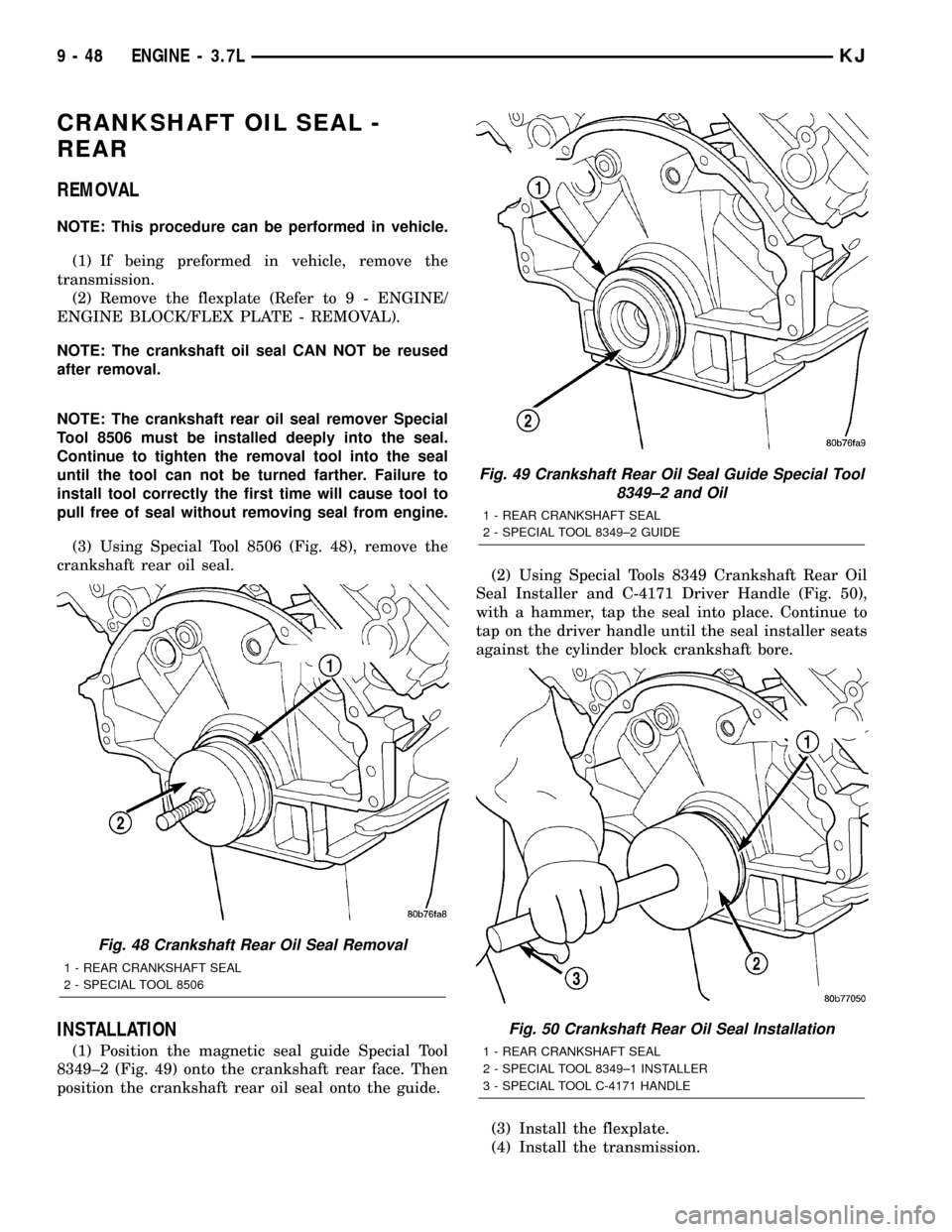

(3) Using Special Tool 8506 (Fig. 48), remove the

crankshaft rear oil seal.

INSTALLATION

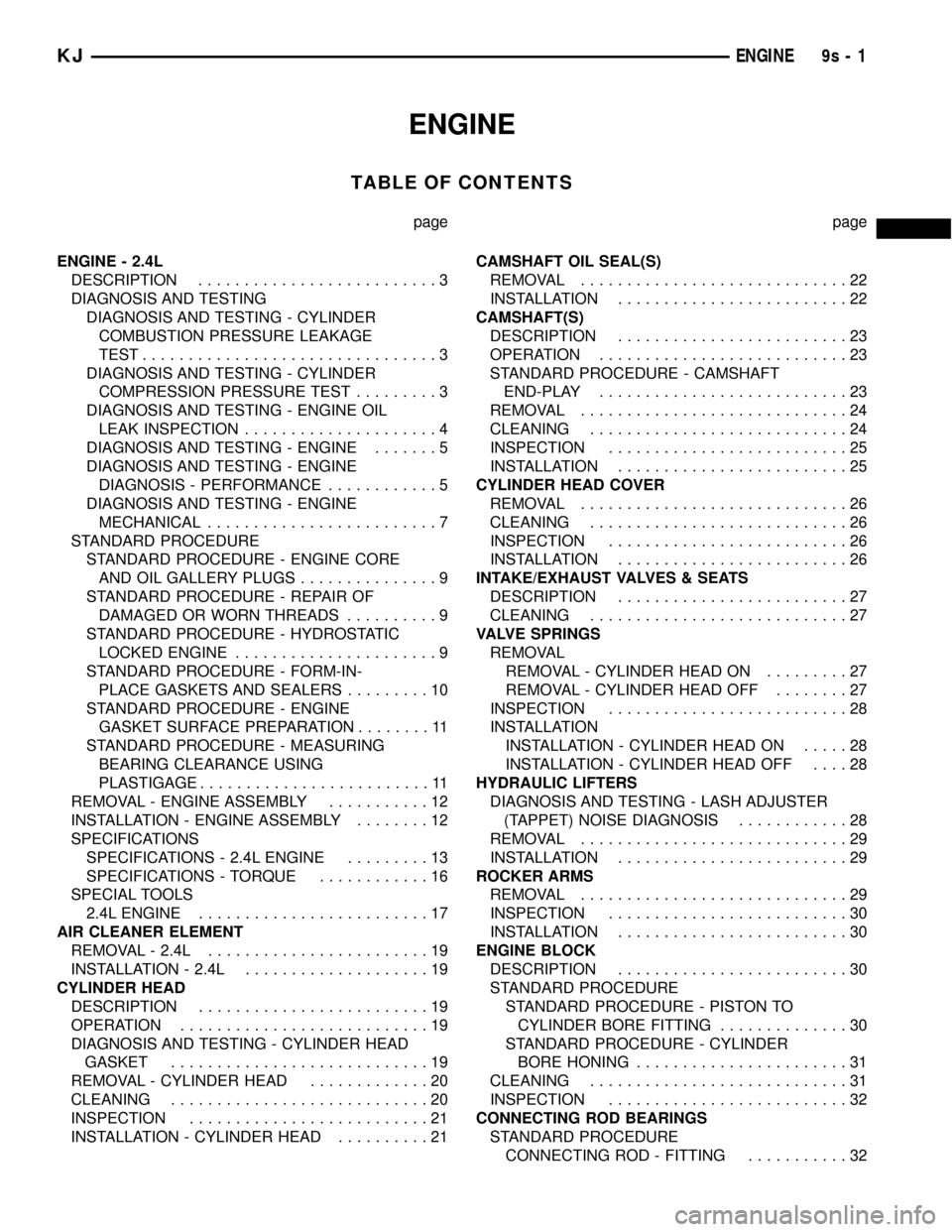

(1) Position the magnetic seal guide Special Tool

8349±2 (Fig. 49) onto the crankshaft rear face. Then

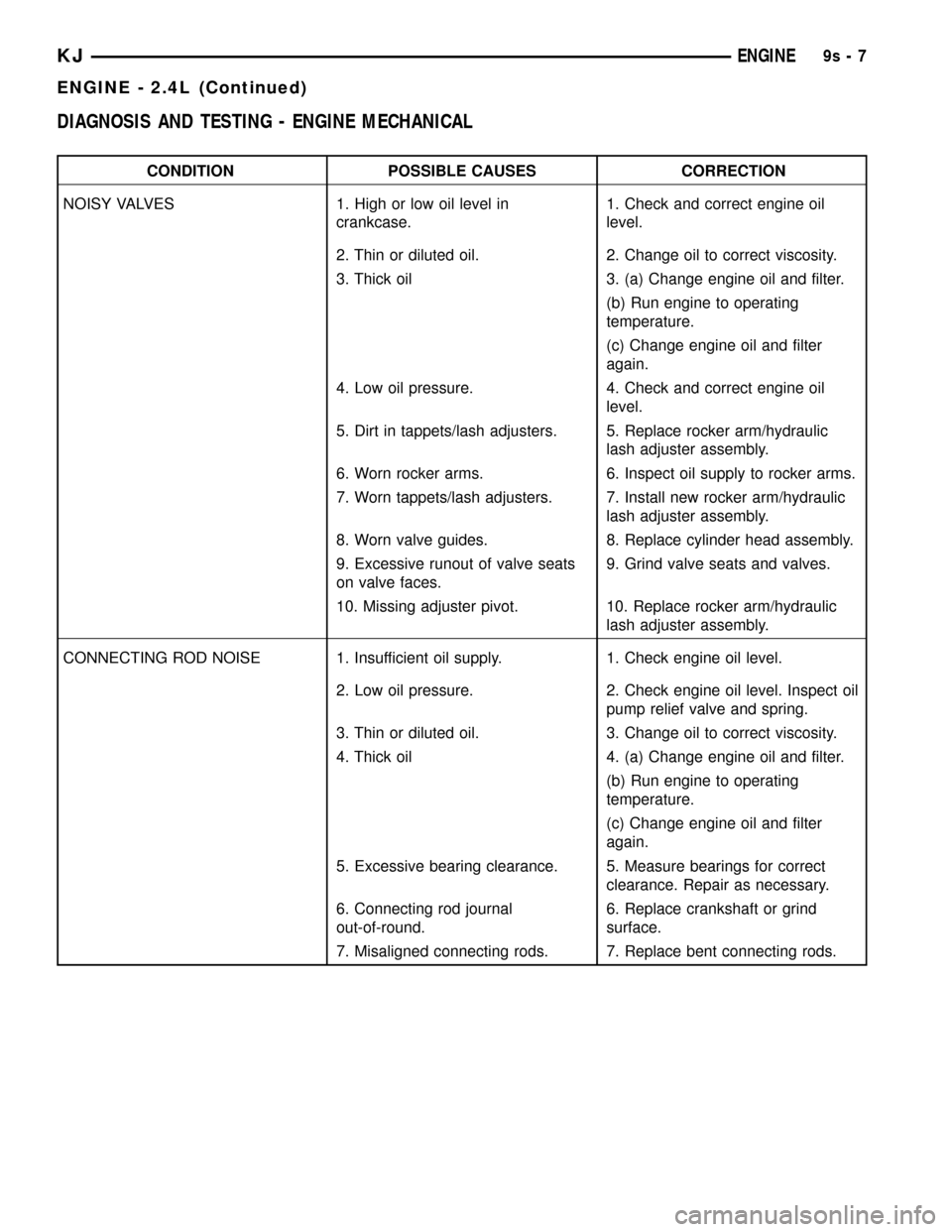

position the crankshaft rear oil seal onto the guide.(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 50),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

Fig. 48 Crankshaft Rear Oil Seal Removal

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8506

Fig. 49 Crankshaft Rear Oil Seal Guide Special Tool

8349±2 and Oil

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±2 GUIDE

Fig. 50 Crankshaft Rear Oil Seal Installation

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±1 INSTALLER

3 - SPECIAL TOOL C-4171 HANDLE

9 - 48 ENGINE - 3.7LKJ

Page 1298 of 1803

ENGINE

TABLE OF CONTENTS

page page

ENGINE - 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................3

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........3

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................4

DIAGNOSIS AND TESTING - ENGINE.......5

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............5

DIAGNOSIS AND TESTING - ENGINE

MECHANICAL.........................7

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS...............9

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS..........9

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE......................9

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........10

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE.........................11

REMOVAL - ENGINE ASSEMBLY...........12

INSTALLATION - ENGINE ASSEMBLY........12

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........13

SPECIFICATIONS - TORQUE............16

SPECIAL TOOLS

2.4L ENGINE.........................17

AIR CLEANER ELEMENT

REMOVAL - 2.4L........................19

INSTALLATION - 2.4L....................19

CYLINDER HEAD

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET............................19

REMOVAL - CYLINDER HEAD.............20

CLEANING............................20

INSPECTION..........................21

INSTALLATION - CYLINDER HEAD..........21CAMSHAFT OIL SEAL(S)

REMOVAL.............................22

INSTALLATION.........................22

CAMSHAFT(S)

DESCRIPTION.........................23

OPERATION...........................23

STANDARD PROCEDURE - CAMSHAFT

END-PLAY...........................23

REMOVAL.............................24

CLEANING............................24

INSPECTION..........................25

INSTALLATION.........................25

CYLINDER HEAD COVER

REMOVAL.............................26

CLEANING............................26

INSPECTION..........................26

INSTALLATION.........................26

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................27

CLEANING............................27

VALVE SPRINGS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........27

REMOVAL - CYLINDER HEAD OFF........27

INSPECTION..........................28

INSTALLATION

INSTALLATION - CYLINDER HEAD ON.....28

INSTALLATION - CYLINDER HEAD OFF....28

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTING - LASH ADJUSTER

(TAPPET) NOISE DIAGNOSIS............28

REMOVAL.............................29

INSTALLATION.........................29

ROCKER ARMS

REMOVAL.............................29

INSPECTION..........................30

INSTALLATION.........................30

ENGINE BLOCK

DESCRIPTION.........................30

STANDARD PROCEDURE

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING..............30

STANDARD PROCEDURE - CYLINDER

BORE HONING.......................31

CLEANING............................31

INSPECTION..........................32

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING...........32

KJENGINE 9s - 1

Page 1304 of 1803

DIAGNOSIS AND TESTING - ENGINE MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

level.

5. Dirt in tappets/lash adjusters. 5. Replace rocker arm/hydraulic

lash adjuster assembly.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn tappets/lash adjusters. 7. Install new rocker arm/hydraulic

lash adjuster assembly.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

10. Missing adjuster pivot. 10. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

KJENGINE9s-7

ENGINE - 2.4L (Continued)

Page 1316 of 1803

AIR CLEANER ELEMENT

REMOVAL - 2.4L

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Disconnect air intake duct at side of element

cover.

(2) Pry up 2 spring clips from front of housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs

located on rear of housing, and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

INSTALLATION - 2.4L

(1) Install element into housing.

(2) Position housing cover into housing locating

tabs.

(3) Pry up spring clips and lock cover to housing.

(4) Connect air intake duct.

If any air filter, air resonator, air intake tubes or

air filter housing clamps had been loosened or

removed, tighten them to 5 N´m (40 in. lbs.) torque.

CYLINDER HEAD

DESCRIPTION

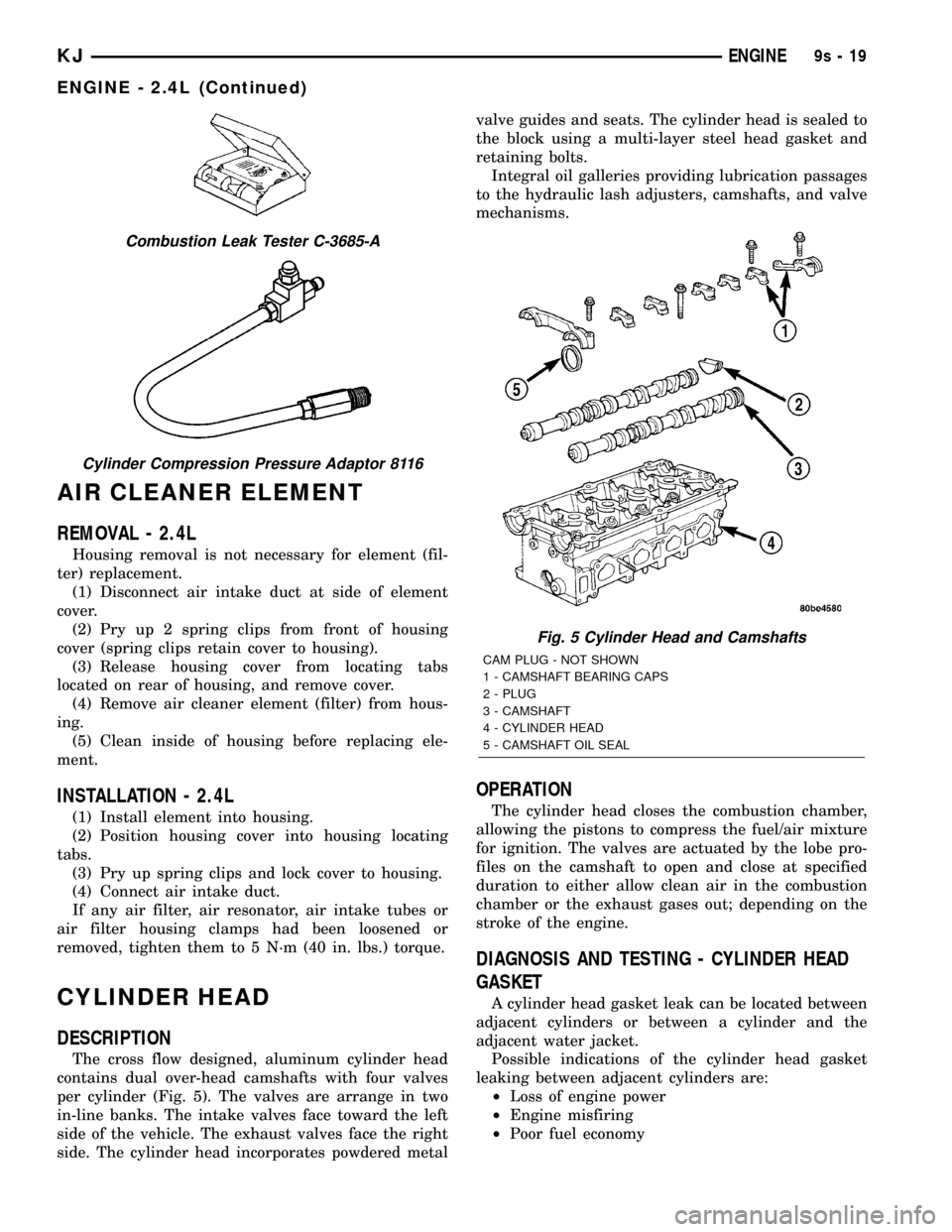

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 5). The valves are arrange in two

in-line banks. The intake valves face toward the left

side of the vehicle. The exhaust valves face the right

side. The cylinder head incorporates powdered metalvalve guides and seats. The cylinder head is sealed to

the block using a multi-layer steel head gasket and

retaining bolts.

Integral oil galleries providing lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Combustion Leak Tester C-3685-A

Cylinder Compression Pressure Adaptor 8116

Fig. 5 Cylinder Head and Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

KJENGINE9s-19

ENGINE - 2.4L (Continued)

Page 1324 of 1803

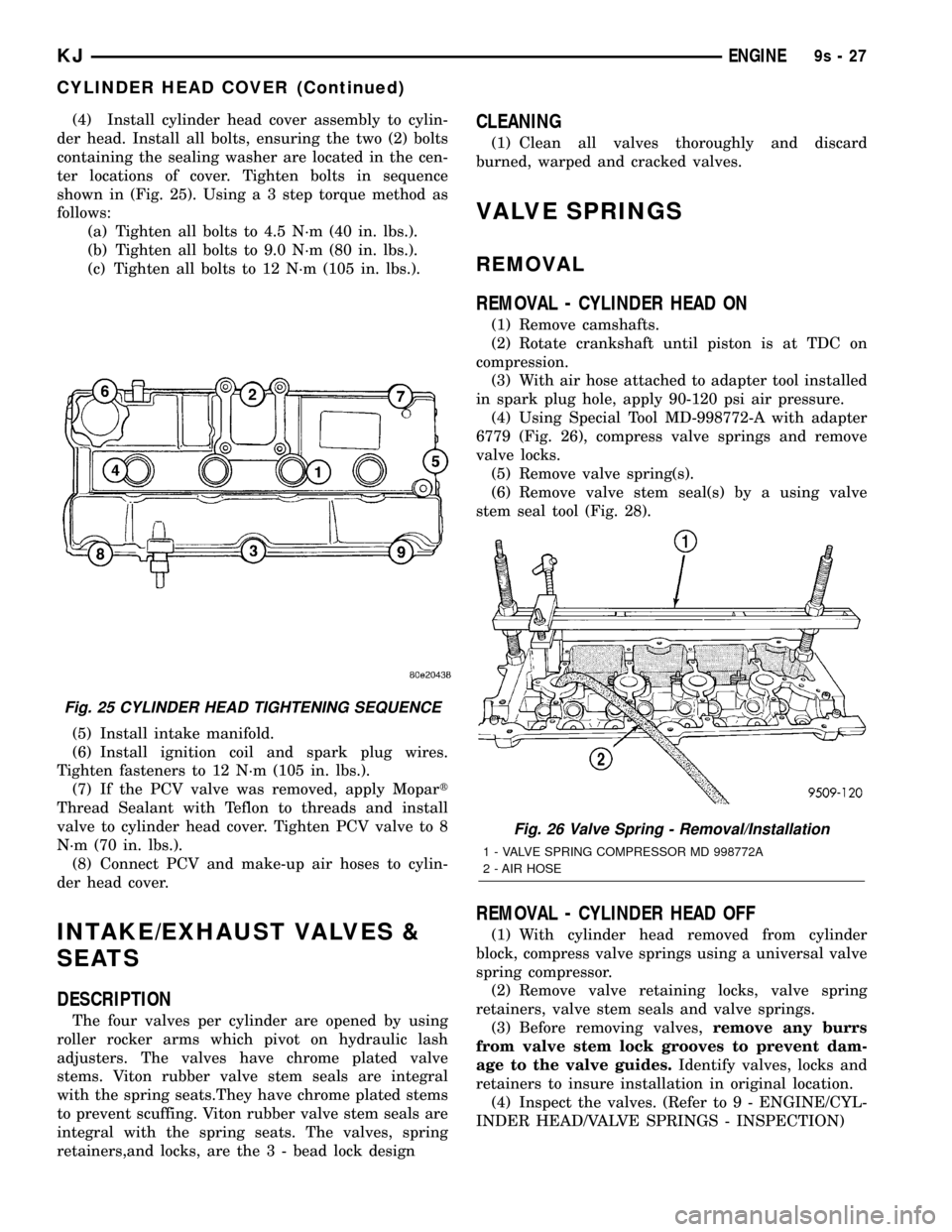

(4) Install cylinder head cover assembly to cylin-

der head. Install all bolts, ensuring the two (2) bolts

containing the sealing washer are located in the cen-

ter locations of cover. Tighten bolts in sequence

shown in (Fig. 25). Using a 3 step torque method as

follows:

(a) Tighten all bolts to 4.5 N´m (40 in. lbs.).

(b) Tighten all bolts to 9.0 N´m (80 in. lbs.).

(c) Tighten all bolts to 12 N´m (105 in. lbs.).

(5) Install intake manifold.

(6) Install ignition coil and spark plug wires.

Tighten fasteners to 12 N´m (105 in. lbs.).

(7) If the PCV valve was removed, apply Mopart

Thread Sealant with Teflon to threads and install

valve to cylinder head cover. Tighten PCV valve to 8

N´m (70 in. lbs.).

(8) Connect PCV and make-up air hoses to cylin-

der head cover.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The four valves per cylinder are opened by using

roller rocker arms which pivot on hydraulic lash

adjusters. The valves have chrome plated valve

stems. Viton rubber valve stem seals are integral

with the spring seats.They have chrome plated stems

to prevent scuffing. Viton rubber valve stem seals are

integral with the spring seats. The valves, spring

retainers,and locks, are the 3 - bead lock design

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

VALVE SPRINGS

REMOVAL

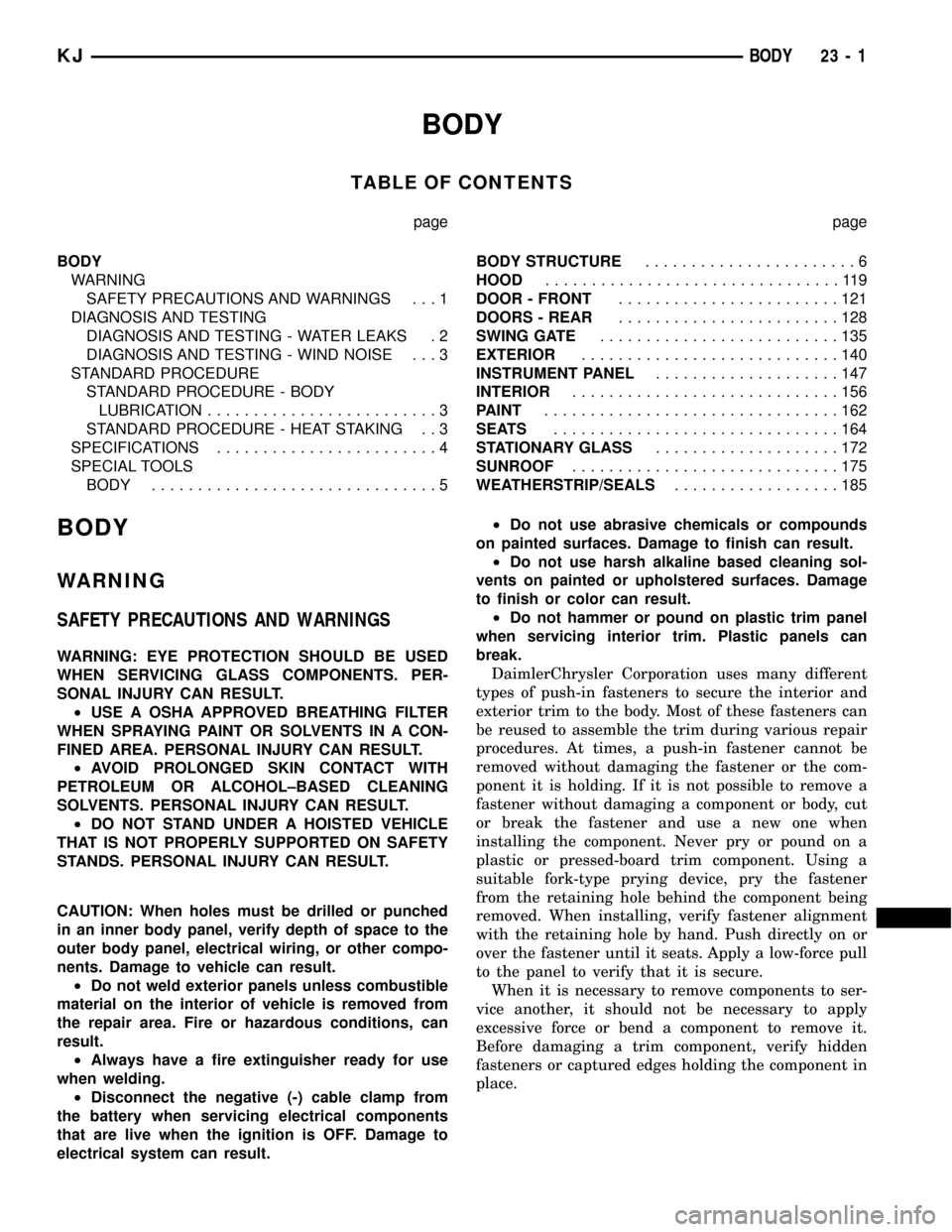

REMOVAL - CYLINDER HEAD ON

(1) Remove camshafts.

(2) Rotate crankshaft until piston is at TDC on

compression.

(3) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.

(4) Using Special Tool MD-998772-A with adapter

6779 (Fig. 26), compress valve springs and remove

valve locks.

(5) Remove valve spring(s).

(6) Remove valve stem seal(s) by a using valve

stem seal tool (Fig. 28).

REMOVAL - CYLINDER HEAD OFF

(1) With cylinder head removed from cylinder

block, compress valve springs using a universal valve

spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves, locks and

retainers to insure installation in original location.

(4) Inspect the valves. (Refer to 9 - ENGINE/CYL-

INDER HEAD/VALVE SPRINGS - INSPECTION)

Fig. 25 CYLINDER HEAD TIGHTENING SEQUENCE

Fig. 26 Valve Spring - Removal/Installation

1 - VALVE SPRING COMPRESSOR MD 998772A

2 - AIR HOSE

KJENGINE9s-27

CYLINDER HEAD COVER (Continued)

Page 1466 of 1803

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................3

STANDARD PROCEDURE - HEAT STAKING . . 3

SPECIFICATIONS........................4

SPECIAL TOOLS

BODY...............................5BODY STRUCTURE.......................6

HOOD................................119

DOOR - FRONT........................121

DOORS - REAR........................128

SWING GATE..........................135

EXTERIOR............................140

INSTRUMENT PANEL....................147

INTERIOR.............................156

PAINT................................162

SEATS...............................164

STATIONARY GLASS....................172

SUNROOF.............................175

WEATHERSTRIP/SEALS..................185

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

²USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL±BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DaimlerChrysler Corporation uses many different

types of push-in fasteners to secure the interior and

exterior trim to the body. Most of these fasteners can

be reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

KJBODY 23 - 1