length JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 706 of 1803

Following are paragraphs that briefly describe the

operation of each of the front wiper and washer sys-

tem operating modes.

CONTINUOUS WIPE MODE When the Low posi-

tion of the control knob on the right (wiper) control

stalk of the multi-function switch is selected, the

Body Control Module (BCM) energizes the wiper

on/off relay. This directs battery current through the

normally open contacts of the energized wiper on/off

relay and the normally closed contacts of the de-en-

ergized wiper high/low relay to the low speed brush

of the front wiper motor, causing the front wipers to

cycle at low speed. When the High position of the

control knob is selected, the BCM energizes both the

wiper on/off relay and the wiper high/low relay. This

directs battery current through the normally open

contacts of the energized wiper on/off relay and the

normally open contacts of the energized wiper high/

low relay to the high speed brush of the front wiper

motor, causing the front wipers to cycle at high

speed.

When the Off position of the control knob is

selected, the BCM de-energizes both the wiper on/off

and wiper high low relays, then one of two events

will occur. The event that occurs depends upon the

position of the wiper blades on the windshield at the

moment that the control knob Off position is selected.

If the wiper blades are in the down position on the

windshield when the Off position is selected, the

park switch that is integral to the front wiper motor

is closed to ground and the wiper motor ceases to

operate. If the wiper blades are not in the down posi-

tion on the windshield at the moment the Off posi-

tion is selected, the park switch is closed to battery

current from the fused ignition switch output (run-

acc) circuit of the front wiper motor. The park switch

directs this battery current to the low speed brush of

the wiper motor through the wiper park switch sense

circuit and the normally closed contacts of the de-en-

ergized wiper on/off and wiper high/low relays. This

causes the wiper motor to continue running at low

speed until the wiper blades are in the down position

on the windshield and the park switch is again

closed to ground.

INTERMITTENT WIPE MODE When the control

knob on the right (wiper) control stalk of the multi-

function switch is moved to one of the Delay interval

positions, the BCM electronic intermittent wipe logic

circuit responds by calculating the correct length of

time between wiper sweeps based upon the selected

delay interval input. The BCM monitors the chang-

ing state of the wiper motor park switch through a

hard wired front wiper park switch sense circuit

input. This input allows the BCM to determine the

proper intervals at which to energize and de-energize

the wiper on/off relay to operate the front wipermotor intermittently for one low speed cycle at a

time. The BCM logic is also programmed to provide

an immediate wipe cycle and begin a new delay

interval timing cycle each time a shorter delay inter-

val is selected, and to add the remaining delay tim-

ing interval to the new delay interval timing before

the next wipe cycle occurs each time a longer delay

interval is selected.

MIST WIPE MODE When the right (wiper) control

stalk of the multi-function switch is moved to the

momentary Mist position, the BCM energizes the

wiper on/off relay for as long as the Mist switch is

held closed, then de-energizes the relay when the

state of the Mist switch input changes to open. The

BCM can operate the front wiper motor in this mode

for only one low speed cycle at a time, or for an

indefinite number of sequential low speed cycles,

depending upon how long the Mist switch is held

closed.

WASH MODE When the right (wiper) control stalk

of the multi-function switch is moved to the momen-

tary front Wash position while the control knob is in

the Low or High positions, the circuitry within the

switch directs battery current and ground to the

washer pump/motor unit. This will cause the washer

pump/motor unit to be energized for as long as the

front Wash switch is held closed, and to de-energize

when the front Wash switch is released. When the

right (wiper) control stalk of the multi-function

switch is moved to the momentary front Wash posi-

tion while the control knob is in one of the Delay

interval positions, the front washer pump/motor oper-

ation is the same. However, the BCM energizes the

wiper on/off relay to override the selected delay inter-

val and operate the front wiper motor in a continu-

ous low speed mode for as long as the front Wash

switch is held closed, then de-energizes the relay and

reverts to the selected delay mode interval several

wipe cycles after the front Wash switch is released.

The BCM detects the front Wash switch state

through a hard wired washer pump driver circuit

input from the multi-function switch.

WIPE-AFTER-WASH MODE When the right

(wiper) control stalk of the multi-function switch is

moved to the momentary front Wash position while

the control knob is in the Off position, the BCM

detects that switch state through a hard wired

washer pump driver circuit input from the multi-

function switch. The BCM responds to this input by

energizing the wiper on/off relay for as long as the

Wash switch is held closed, then de-energizes the

relay several wipe cycles after the front Wash switch

is released. The BCM monitors the changing state of

the wiper motor park switch through a hard wired

front wiper park switch sense circuit input. This

input allows the BCM to count the number of wipe

KJFRONT WIPERS/WASHERS 8R - 5

FRONT WIPERS/WASHERS (Continued)

Page 710 of 1803

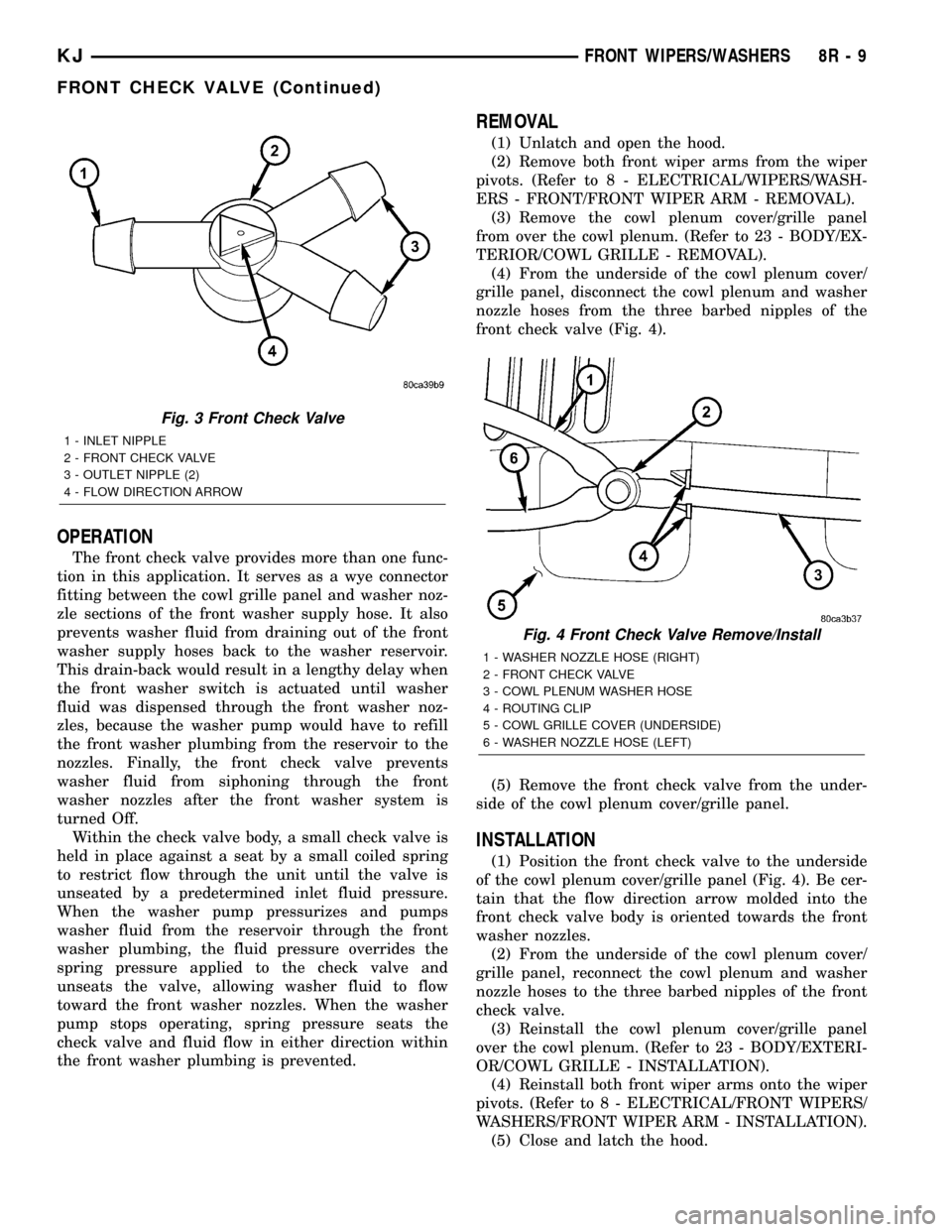

OPERATION

The front check valve provides more than one func-

tion in this application. It serves as a wye connector

fitting between the cowl grille panel and washer noz-

zle sections of the front washer supply hose. It also

prevents washer fluid from draining out of the front

washer supply hoses back to the washer reservoir.

This drain-back would result in a lengthy delay when

the front washer switch is actuated until washer

fluid was dispensed through the front washer noz-

zles, because the washer pump would have to refill

the front washer plumbing from the reservoir to the

nozzles. Finally, the front check valve prevents

washer fluid from siphoning through the front

washer nozzles after the front washer system is

turned Off.

Within the check valve body, a small check valve is

held in place against a seat by a small coiled spring

to restrict flow through the unit until the valve is

unseated by a predetermined inlet fluid pressure.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the front

washer plumbing, the fluid pressure overrides the

spring pressure applied to the check valve and

unseats the valve, allowing washer fluid to flow

toward the front washer nozzles. When the washer

pump stops operating, spring pressure seats the

check valve and fluid flow in either direction within

the front washer plumbing is prevented.

REMOVAL

(1) Unlatch and open the hood.

(2) Remove both front wiper arms from the wiper

pivots. (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS - FRONT/FRONT WIPER ARM - REMOVAL).

(3) Remove the cowl plenum cover/grille panel

from over the cowl plenum. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - REMOVAL).

(4) From the underside of the cowl plenum cover/

grille panel, disconnect the cowl plenum and washer

nozzle hoses from the three barbed nipples of the

front check valve (Fig. 4).

(5) Remove the front check valve from the under-

side of the cowl plenum cover/grille panel.

INSTALLATION

(1) Position the front check valve to the underside

of the cowl plenum cover/grille panel (Fig. 4). Be cer-

tain that the flow direction arrow molded into the

front check valve body is oriented towards the front

washer nozzles.

(2) From the underside of the cowl plenum cover/

grille panel, reconnect the cowl plenum and washer

nozzle hoses to the three barbed nipples of the front

check valve.

(3) Reinstall the cowl plenum cover/grille panel

over the cowl plenum. (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

(4) Reinstall both front wiper arms onto the wiper

pivots. (Refer to 8 - ELECTRICAL/FRONT WIPERS/

WASHERS/FRONT WIPER ARM - INSTALLATION).

(5) Close and latch the hood.

Fig. 3 Front Check Valve

1 - INLET NIPPLE

2 - FRONT CHECK VALVE

3 - OUTLET NIPPLE (2)

4 - FLOW DIRECTION ARROW

Fig. 4 Front Check Valve Remove/Install

1 - WASHER NOZZLE HOSE (RIGHT)

2 - FRONT CHECK VALVE

3 - COWL PLENUM WASHER HOSE

4 - ROUTING CLIP

5 - COWL GRILLE COVER (UNDERSIDE)

6 - WASHER NOZZLE HOSE (LEFT)

KJFRONT WIPERS/WASHERS 8R - 9

FRONT CHECK VALVE (Continued)

Page 711 of 1803

FRONT WASHER HOSES/

TUBES

DESCRIPTION

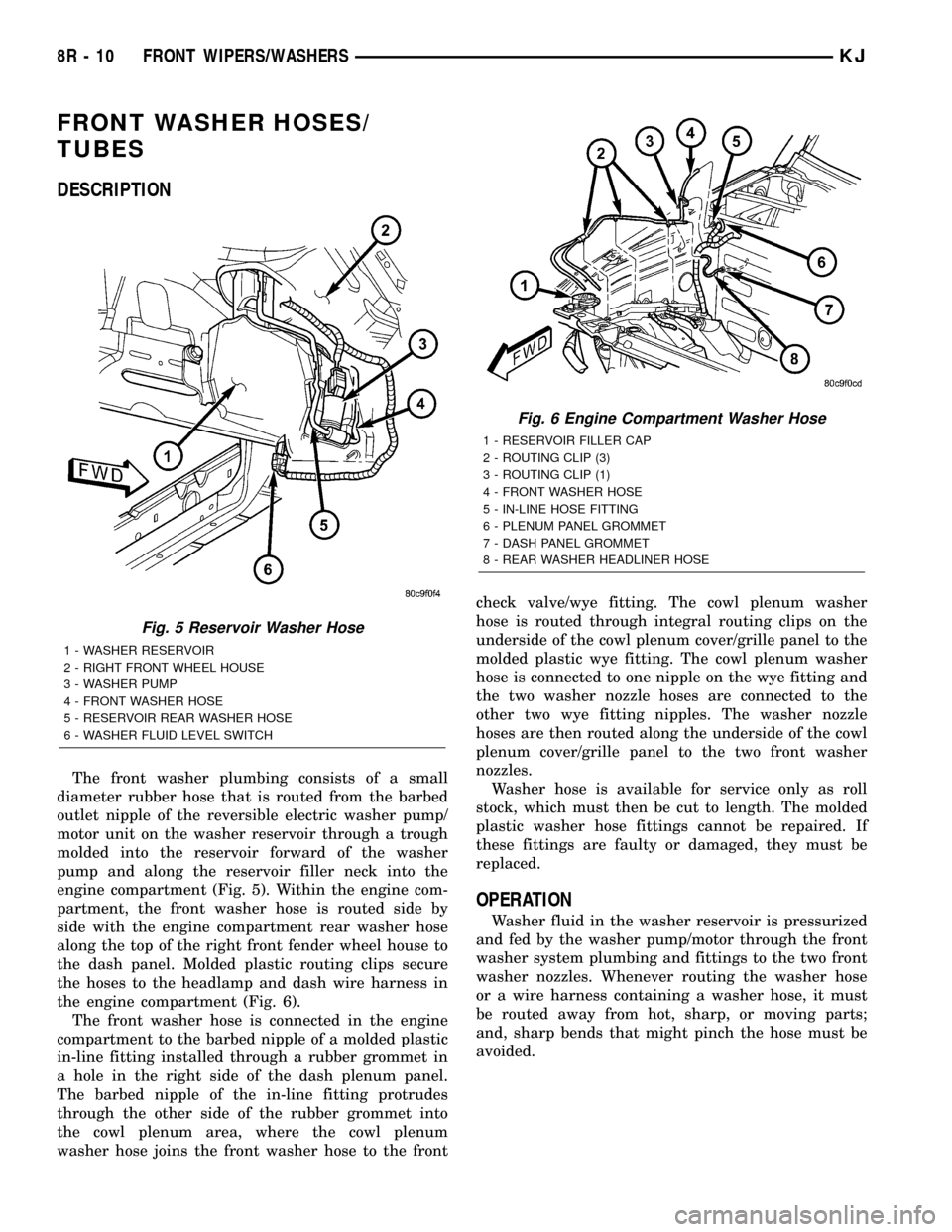

The front washer plumbing consists of a small

diameter rubber hose that is routed from the barbed

outlet nipple of the reversible electric washer pump/

motor unit on the washer reservoir through a trough

molded into the reservoir forward of the washer

pump and along the reservoir filler neck into the

engine compartment (Fig. 5). Within the engine com-

partment, the front washer hose is routed side by

side with the engine compartment rear washer hose

along the top of the right front fender wheel house to

the dash panel. Molded plastic routing clips secure

the hoses to the headlamp and dash wire harness in

the engine compartment (Fig. 6).

The front washer hose is connected in the engine

compartment to the barbed nipple of a molded plastic

in-line fitting installed through a rubber grommet in

a hole in the right side of the dash plenum panel.

The barbed nipple of the in-line fitting protrudes

through the other side of the rubber grommet into

the cowl plenum area, where the cowl plenum

washer hose joins the front washer hose to the frontcheck valve/wye fitting. The cowl plenum washer

hose is routed through integral routing clips on the

underside of the cowl plenum cover/grille panel to the

molded plastic wye fitting. The cowl plenum washer

hose is connected to one nipple on the wye fitting and

the two washer nozzle hoses are connected to the

other two wye fitting nipples. The washer nozzle

hoses are then routed along the underside of the cowl

plenum cover/grille panel to the two front washer

nozzles.

Washer hose is available for service only as roll

stock, which must then be cut to length. The molded

plastic washer hose fittings cannot be repaired. If

these fittings are faulty or damaged, they must be

replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the front

washer system plumbing and fittings to the two front

washer nozzles. Whenever routing the washer hose

or a wire harness containing a washer hose, it must

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

Fig. 5 Reservoir Washer Hose

1 - WASHER RESERVOIR

2 - RIGHT FRONT WHEEL HOUSE

3 - WASHER PUMP

4 - FRONT WASHER HOSE

5 - RESERVOIR REAR WASHER HOSE

6 - WASHER FLUID LEVEL SWITCH

Fig. 6 Engine Compartment Washer Hose

1 - RESERVOIR FILLER CAP

2 - ROUTING CLIP (3)

3 - ROUTING CLIP (1)

4 - FRONT WASHER HOSE

5 - IN-LINE HOSE FITTING

6 - PLENUM PANEL GROMMET

7 - DASH PANEL GROMMET

8 - REAR WASHER HEADLINER HOSE

8R - 10 FRONT WIPERS/WASHERSKJ

Page 714 of 1803

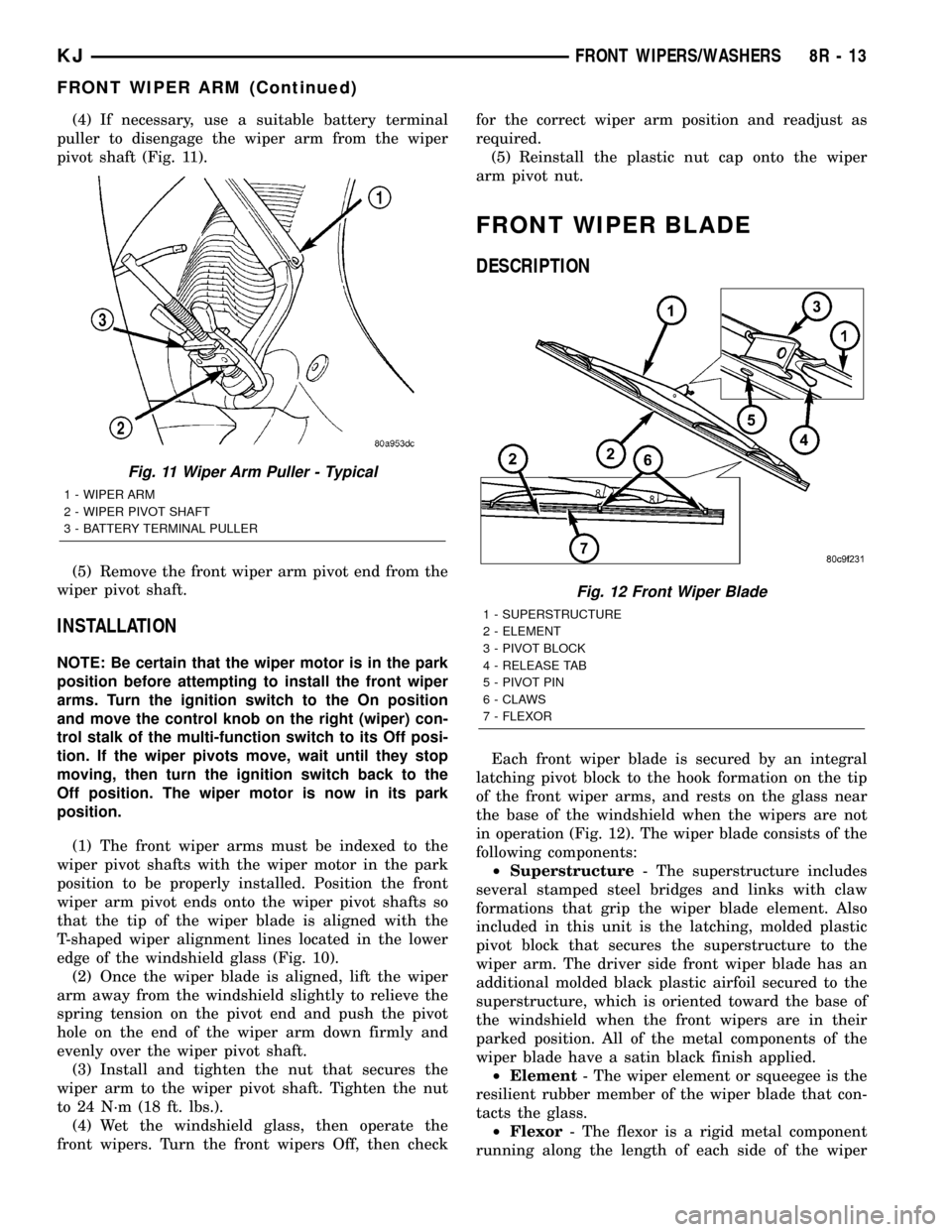

(4) If necessary, use a suitable battery terminal

puller to disengage the wiper arm from the wiper

pivot shaft (Fig. 11).

(5) Remove the front wiper arm pivot end from the

wiper pivot shaft.

INSTALLATION

NOTE: Be certain that the wiper motor is in the park

position before attempting to install the front wiper

arms. Turn the ignition switch to the On position

and move the control knob on the right (wiper) con-

trol stalk of the multi-function switch to its Off posi-

tion. If the wiper pivots move, wait until they stop

moving, then turn the ignition switch back to the

Off position. The wiper motor is now in its park

position.

(1) The front wiper arms must be indexed to the

wiper pivot shafts with the wiper motor in the park

position to be properly installed. Position the front

wiper arm pivot ends onto the wiper pivot shafts so

that the tip of the wiper blade is aligned with the

T-shaped wiper alignment lines located in the lower

edge of the windshield glass (Fig. 10).

(2) Once the wiper blade is aligned, lift the wiper

arm away from the windshield slightly to relieve the

spring tension on the pivot end and push the pivot

hole on the end of the wiper arm down firmly and

evenly over the wiper pivot shaft.

(3) Install and tighten the nut that secures the

wiper arm to the wiper pivot shaft. Tighten the nut

to 24 N´m (18 ft. lbs.).

(4) Wet the windshield glass, then operate the

front wipers. Turn the front wipers Off, then checkfor the correct wiper arm position and readjust as

required.

(5) Reinstall the plastic nut cap onto the wiper

arm pivot nut.

FRONT WIPER BLADE

DESCRIPTION

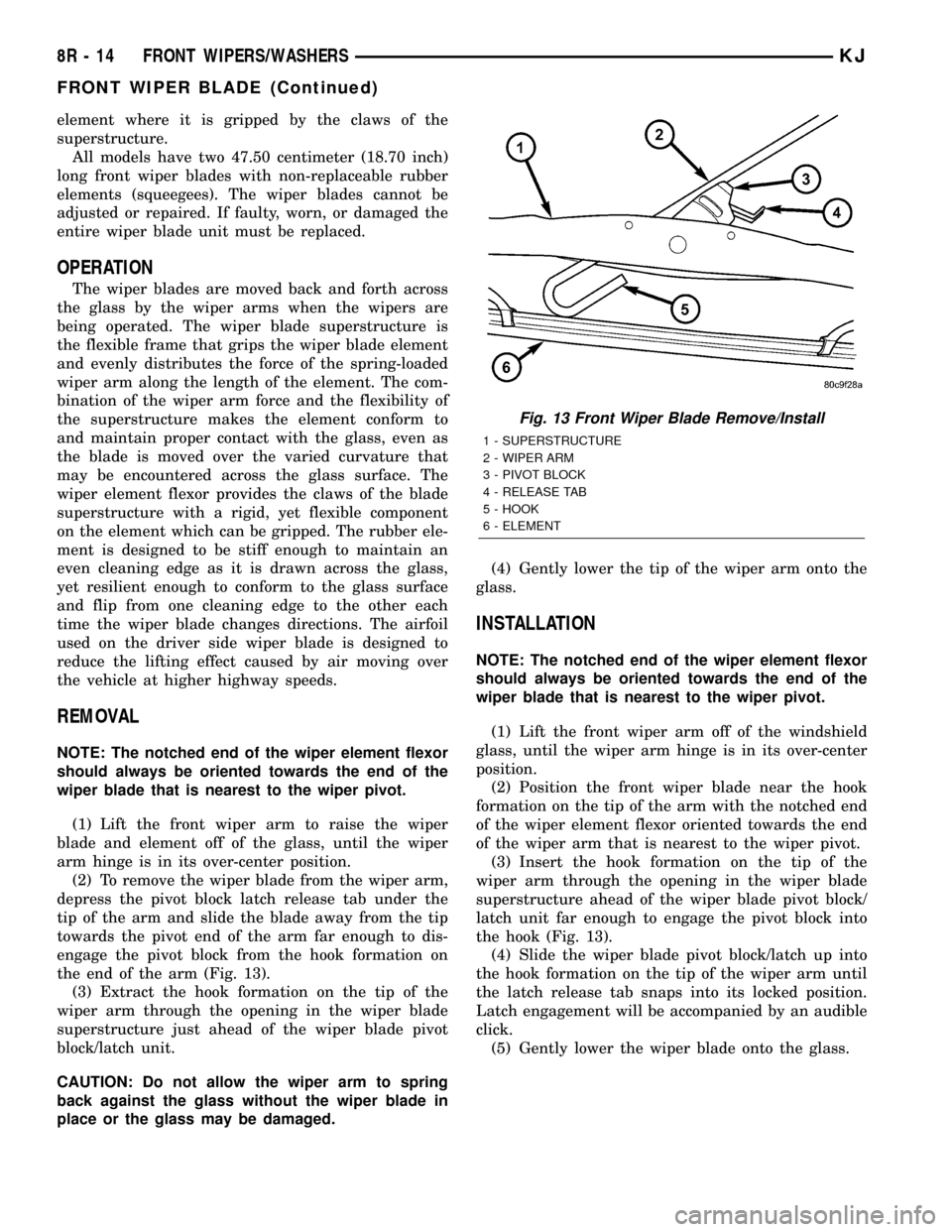

Each front wiper blade is secured by an integral

latching pivot block to the hook formation on the tip

of the front wiper arms, and rests on the glass near

the base of the windshield when the wipers are not

in operation (Fig. 12). The wiper blade consists of the

following components:

²Superstructure- The superstructure includes

several stamped steel bridges and links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. The driver side front wiper blade has an

additional molded black plastic airfoil secured to the

superstructure, which is oriented toward the base of

the windshield when the front wipers are in their

parked position. All of the metal components of the

wiper blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.

²Flexor- The flexor is a rigid metal component

running along the length of each side of the wiper

Fig. 11 Wiper Arm Puller - Typical

1 - WIPER ARM

2 - WIPER PIVOT SHAFT

3 - BATTERY TERMINAL PULLER

Fig. 12 Front Wiper Blade

1 - SUPERSTRUCTURE

2 - ELEMENT

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - PIVOT PIN

6 - CLAWS

7 - FLEXOR

KJFRONT WIPERS/WASHERS 8R - 13

FRONT WIPER ARM (Continued)

Page 715 of 1803

element where it is gripped by the claws of the

superstructure.

All models have two 47.50 centimeter (18.70 inch)

long front wiper blades with non-replaceable rubber

elements (squeegees). The wiper blades cannot be

adjusted or repaired. If faulty, worn, or damaged the

entire wiper blade unit must be replaced.

OPERATION

The wiper blades are moved back and forth across

the glass by the wiper arms when the wipers are

being operated. The wiper blade superstructure is

the flexible frame that grips the wiper blade element

and evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature that

may be encountered across the glass surface. The

wiper element flexor provides the claws of the blade

superstructure with a rigid, yet flexible component

on the element which can be gripped. The rubber ele-

ment is designed to be stiff enough to maintain an

even cleaning edge as it is drawn across the glass,

yet resilient enough to conform to the glass surface

and flip from one cleaning edge to the other each

time the wiper blade changes directions. The airfoil

used on the driver side wiper blade is designed to

reduce the lifting effect caused by air moving over

the vehicle at higher highway speeds.

REMOVAL

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the front wiper arm to raise the wiper

blade and element off of the glass, until the wiper

arm hinge is in its over-center position.

(2) To remove the wiper blade from the wiper arm,

depress the pivot block latch release tab under the

tip of the arm and slide the blade away from the tip

towards the pivot end of the arm far enough to dis-

engage the pivot block from the hook formation on

the end of the arm (Fig. 13).

(3) Extract the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure just ahead of the wiper blade pivot

block/latch unit.

CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.(4) Gently lower the tip of the wiper arm onto the

glass.

INSTALLATION

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the front wiper arm off of the windshield

glass, until the wiper arm hinge is in its over-center

position.

(2) Position the front wiper blade near the hook

formation on the tip of the arm with the notched end

of the wiper element flexor oriented towards the end

of the wiper arm that is nearest to the wiper pivot.

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block into

the hook (Fig. 13).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

Fig. 13 Front Wiper Blade Remove/Install

1 - SUPERSTRUCTURE

2 - WIPER ARM

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - HOOK

6 - ELEMENT

8R - 14 FRONT WIPERS/WASHERSKJ

FRONT WIPER BLADE (Continued)

Page 735 of 1803

REAR WASHER SYSTEM

The washer system components should be

inspected periodically, not just when washer perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Check for ice or other foreign material in the

washer reservoir. If contaminated, clean and flush

the washer system. (Refer to 8 - ELECTRICAL/

REAR WIPERS/WASHERS - CLEANING).

(2) Inspect the washer plumbing for pinched, leak-

ing, deteriorated, or incorrectly routed hoses and

damaged or disconnected hose fittings. Replace dam-

aged or deteriorated hoses and hose fittings. Leaking

washer hoses can sometimes be repaired by cutting

the hose at the leak and splicing it back together

using an in-line connector fitting. Similarly, sections

of deteriorated hose can be cut out and replaced by

splicing in new sections of hose using in-line connec-

tor fittings. Whenever routing a washer hose or a

wire harness containing a washer hose, it must be

routed away from hot, sharp, or moving parts. Also,

sharp bends that might pinch the washer hose must

be avoided.

REAR CHECK VALVE

DESCRIPTION

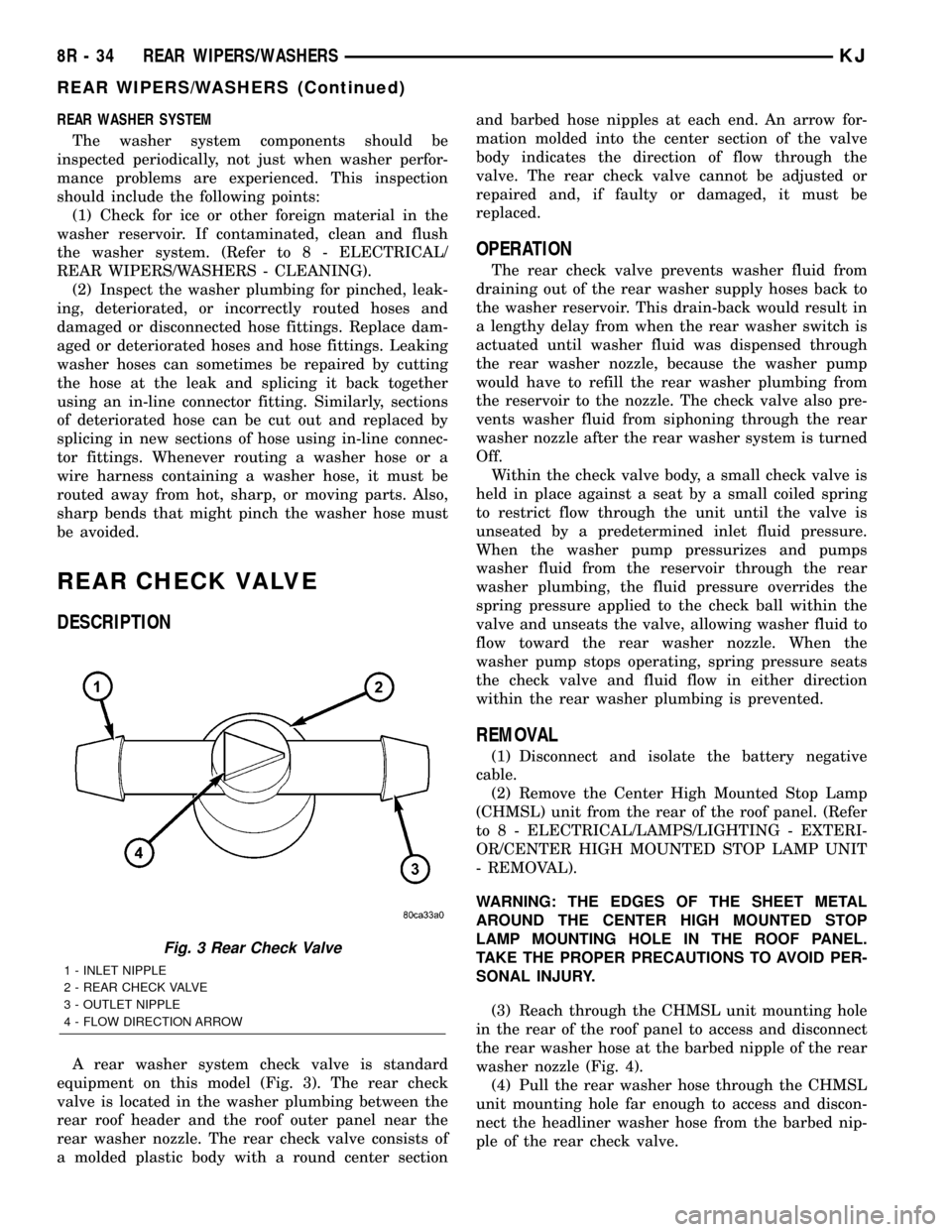

A rear washer system check valve is standard

equipment on this model (Fig. 3). The rear check

valve is located in the washer plumbing between the

rear roof header and the roof outer panel near the

rear washer nozzle. The rear check valve consists of

a molded plastic body with a round center sectionand barbed hose nipples at each end. An arrow for-

mation molded into the center section of the valve

body indicates the direction of flow through the

valve. The rear check valve cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The rear check valve prevents washer fluid from

draining out of the rear washer supply hoses back to

the washer reservoir. This drain-back would result in

a lengthy delay from when the rear washer switch is

actuated until washer fluid was dispensed through

the rear washer nozzle, because the washer pump

would have to refill the rear washer plumbing from

the reservoir to the nozzle. The check valve also pre-

vents washer fluid from siphoning through the rear

washer nozzle after the rear washer system is turned

Off.

Within the check valve body, a small check valve is

held in place against a seat by a small coiled spring

to restrict flow through the unit until the valve is

unseated by a predetermined inlet fluid pressure.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the rear

washer plumbing, the fluid pressure overrides the

spring pressure applied to the check ball within the

valve and unseats the valve, allowing washer fluid to

flow toward the rear washer nozzle. When the

washer pump stops operating, spring pressure seats

the check valve and fluid flow in either direction

within the rear washer plumbing is prevented.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Center High Mounted Stop Lamp

(CHMSL) unit from the rear of the roof panel. (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/CENTER HIGH MOUNTED STOP LAMP UNIT

- REMOVAL).

WARNING: THE EDGES OF THE SHEET METAL

AROUND THE CENTER HIGH MOUNTED STOP

LAMP MOUNTING HOLE IN THE ROOF PANEL.

TAKE THE PROPER PRECAUTIONS TO AVOID PER-

SONAL INJURY.

(3) Reach through the CHMSL unit mounting hole

in the rear of the roof panel to access and disconnect

the rear washer hose at the barbed nipple of the rear

washer nozzle (Fig. 4).

(4) Pull the rear washer hose through the CHMSL

unit mounting hole far enough to access and discon-

nect the headliner washer hose from the barbed nip-

ple of the rear check valve.

Fig. 3 Rear Check Valve

1 - INLET NIPPLE

2 - REAR CHECK VALVE

3 - OUTLET NIPPLE

4 - FLOW DIRECTION ARROW

8R - 34 REAR WIPERS/WASHERSKJ

REAR WIPERS/WASHERS (Continued)

Page 737 of 1803

headliner hose is glued to top of the headliner and

routed along the right roof side rail to the rear of the

vehicle. At the rear of the vehicle, the headliner hose

passes through a hole at the rear portion of the roof

rear inner header panel and is connected to the rear

check valve. From the rear check valve, there is a

short section of hose that connects the rear check

valve to the rear washer nozzle.

Washer hose is available for service only as roll

stock, which must then be cut to length. The head-

liner washer hose is integral to the headliner unit

and, if faulty or damaged, the headliner unit must be

replaced. However, the headliner hose is marked

with a white cut line on the A-pillar where the hose

should be cut and spliced with a plastic in-line con-

nector fitting to facilitate headliner removal without

the need to remove the instrument panel. (Refer to

23 - BODY/INTERIOR/HEADLINER - REMOVAL

AND INSTALLATION). The molded plastic washer

hose fittings cannot be repaired. If these fittings are

faulty or damaged, they must be replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the rear

washer system plumbing and fittings to the rear

washer nozzle located on the roof panel above the

rear flip-up glass opening. Whenever routing the

washer hose or a wire harness containing a washer

hose, it must be routed away from hot, sharp, or

moving parts; and, sharp bends that might pinch the

hose must be avoided.

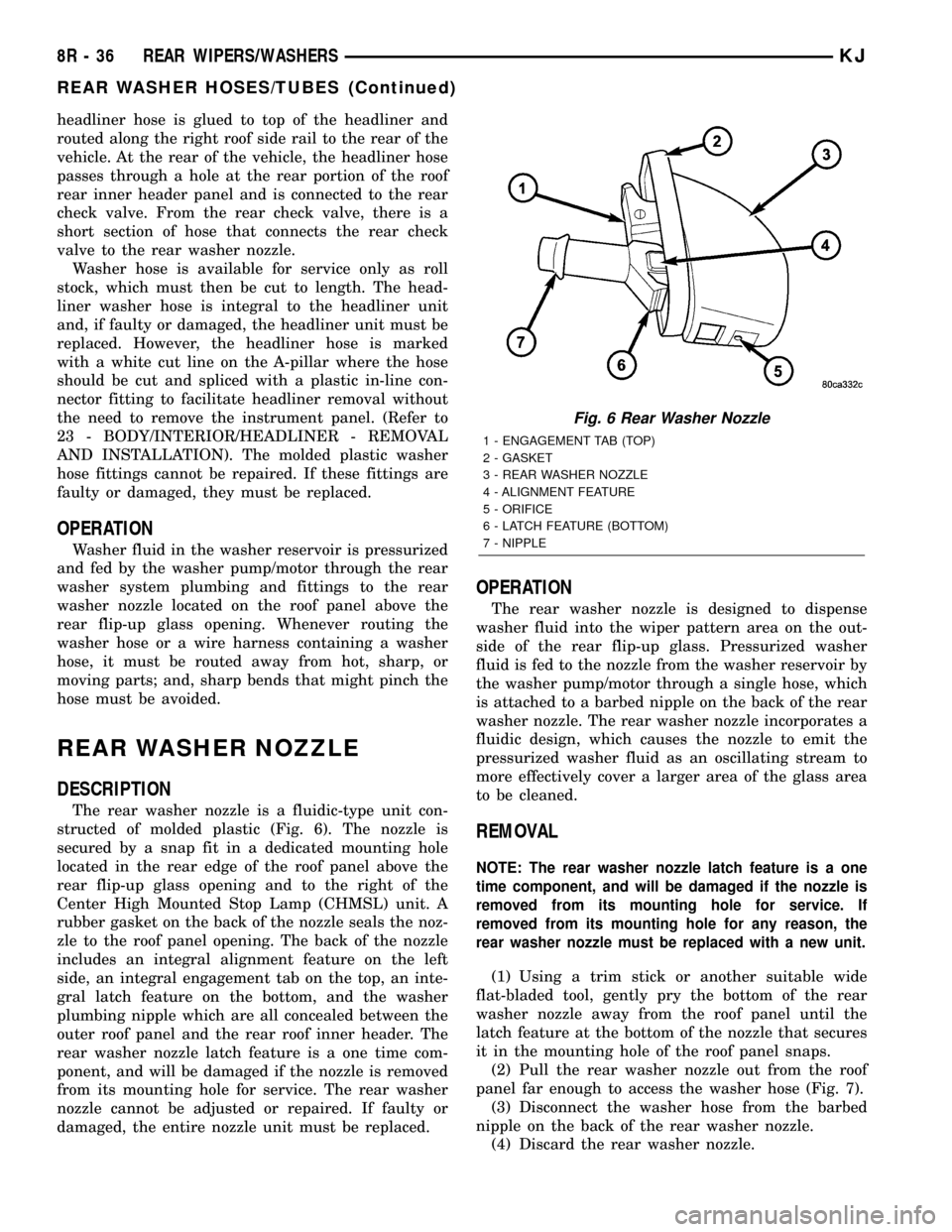

REAR WASHER NOZZLE

DESCRIPTION

The rear washer nozzle is a fluidic-type unit con-

structed of molded plastic (Fig. 6). The nozzle is

secured by a snap fit in a dedicated mounting hole

located in the rear edge of the roof panel above the

rear flip-up glass opening and to the right of the

Center High Mounted Stop Lamp (CHMSL) unit. A

rubber gasket on the back of the nozzle seals the noz-

zle to the roof panel opening. The back of the nozzle

includes an integral alignment feature on the left

side, an integral engagement tab on the top, an inte-

gral latch feature on the bottom, and the washer

plumbing nipple which are all concealed between the

outer roof panel and the rear roof inner header. The

rear washer nozzle latch feature is a one time com-

ponent, and will be damaged if the nozzle is removed

from its mounting hole for service. The rear washer

nozzle cannot be adjusted or repaired. If faulty or

damaged, the entire nozzle unit must be replaced.

OPERATION

The rear washer nozzle is designed to dispense

washer fluid into the wiper pattern area on the out-

side of the rear flip-up glass. Pressurized washer

fluid is fed to the nozzle from the washer reservoir by

the washer pump/motor through a single hose, which

is attached to a barbed nipple on the back of the rear

washer nozzle. The rear washer nozzle incorporates a

fluidic design, which causes the nozzle to emit the

pressurized washer fluid as an oscillating stream to

more effectively cover a larger area of the glass area

to be cleaned.

REMOVAL

NOTE: The rear washer nozzle latch feature is a one

time component, and will be damaged if the nozzle is

removed from its mounting hole for service. If

removed from its mounting hole for any reason, the

rear washer nozzle must be replaced with a new unit.

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the bottom of the rear

washer nozzle away from the roof panel until the

latch feature at the bottom of the nozzle that secures

it in the mounting hole of the roof panel snaps.

(2) Pull the rear washer nozzle out from the roof

panel far enough to access the washer hose (Fig. 7).

(3) Disconnect the washer hose from the barbed

nipple on the back of the rear washer nozzle.

(4) Discard the rear washer nozzle.

Fig. 6 Rear Washer Nozzle

1 - ENGAGEMENT TAB (TOP)

2 - GASKET

3 - REAR WASHER NOZZLE

4 - ALIGNMENT FEATURE

5 - ORIFICE

6 - LATCH FEATURE (BOTTOM)

7 - NIPPLE

8R - 36 REAR WIPERS/WASHERSKJ

REAR WASHER HOSES/TUBES (Continued)

Page 740 of 1803

(4) Install and tighten the nut that secures the

rear wiper arm to the rear wiper motor output shaft.

Tighten the nut to 18 N´m (13 ft. lbs.).

(5) Close the rear wiper arm pivot cover.

(6) Lift the rear wiper arm support away from the

park ramp, then place the wiper arm support in the

park ramp in the Park Position (Fig. 11).

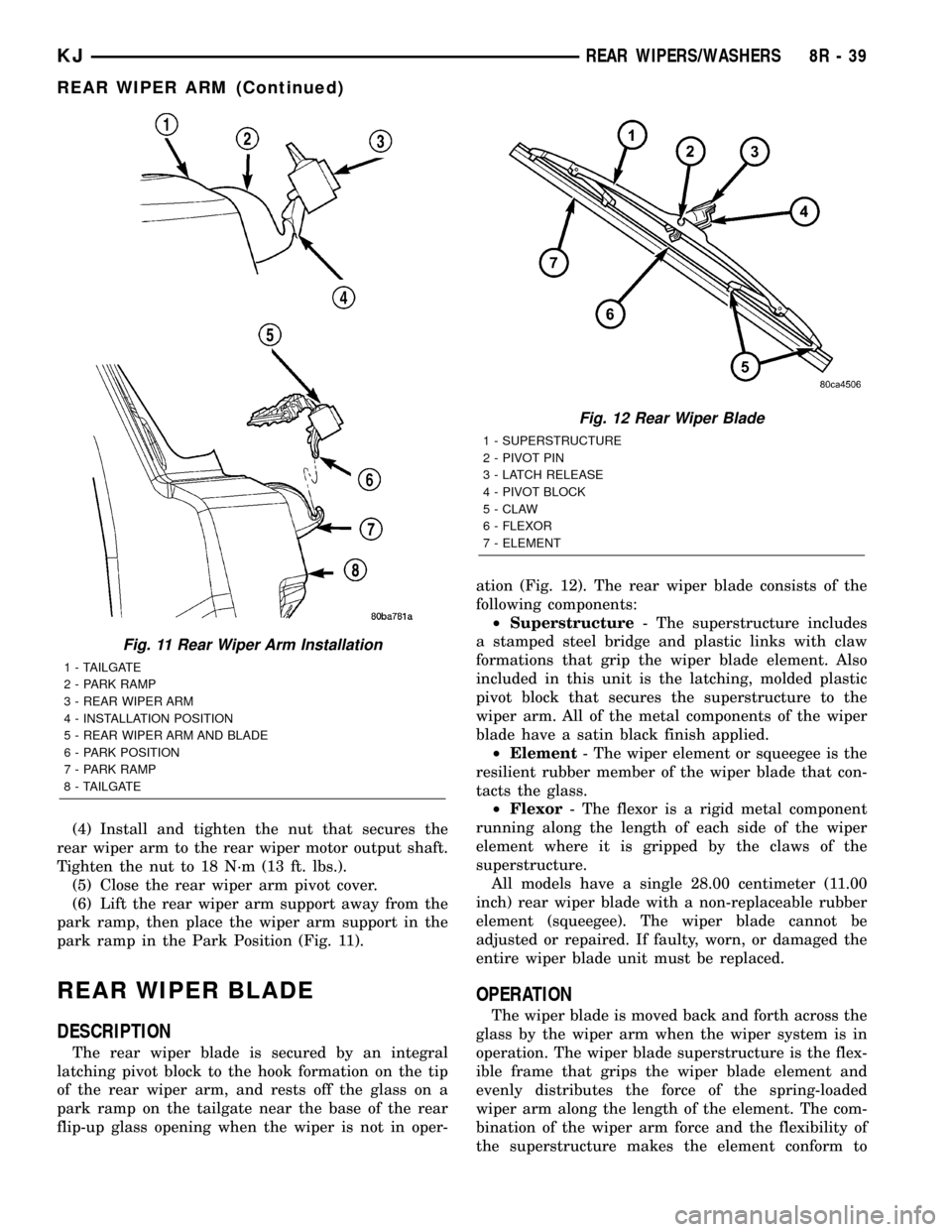

REAR WIPER BLADE

DESCRIPTION

The rear wiper blade is secured by an integral

latching pivot block to the hook formation on the tip

of the rear wiper arm, and rests off the glass on a

park ramp on the tailgate near the base of the rear

flip-up glass opening when the wiper is not in oper-ation (Fig. 12). The rear wiper blade consists of the

following components:

²Superstructure- The superstructure includes

a stamped steel bridge and plastic links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. All of the metal components of the wiper

blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.

²Flexor- The flexor is a rigid metal component

running along the length of each side of the wiper

element where it is gripped by the claws of the

superstructure.

All models have a single 28.00 centimeter (11.00

inch) rear wiper blade with a non-replaceable rubber

element (squeegee). The wiper blade cannot be

adjusted or repaired. If faulty, worn, or damaged the

entire wiper blade unit must be replaced.

OPERATION

The wiper blade is moved back and forth across the

glass by the wiper arm when the wiper system is in

operation. The wiper blade superstructure is the flex-

ible frame that grips the wiper blade element and

evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

Fig. 11 Rear Wiper Arm Installation

1 - TAILGATE

2 - PARK RAMP

3 - REAR WIPER ARM

4 - INSTALLATION POSITION

5 - REAR WIPER ARM AND BLADE

6 - PARK POSITION

7 - PARK RAMP

8 - TAILGATE

Fig. 12 Rear Wiper Blade

1 - SUPERSTRUCTURE

2 - PIVOT PIN

3 - LATCH RELEASE

4 - PIVOT BLOCK

5 - CLAW

6 - FLEXOR

7 - ELEMENT

KJREAR WIPERS/WASHERS 8R - 39

REAR WIPER ARM (Continued)

Page 760 of 1803

INSTALLATION

(1) Insert the removed terminal in the same cavity

on the repair connector.

(2) Repeat steps for each terminal in the connec-

tor, being sure that all wires are inserted into the

proper cavities. For additional connector pin-out

identification, refer to the wiring diagrams.

(3) When the connector is re-assembled, the sec-

ondary terminal lock must be placed in the locked

position to prevent terminal push out.

(4) Replace dress cover (if applicable).

(5) Connect connector to its mating half/compo-

nent.

(6) Connect battery and test all affected systems.

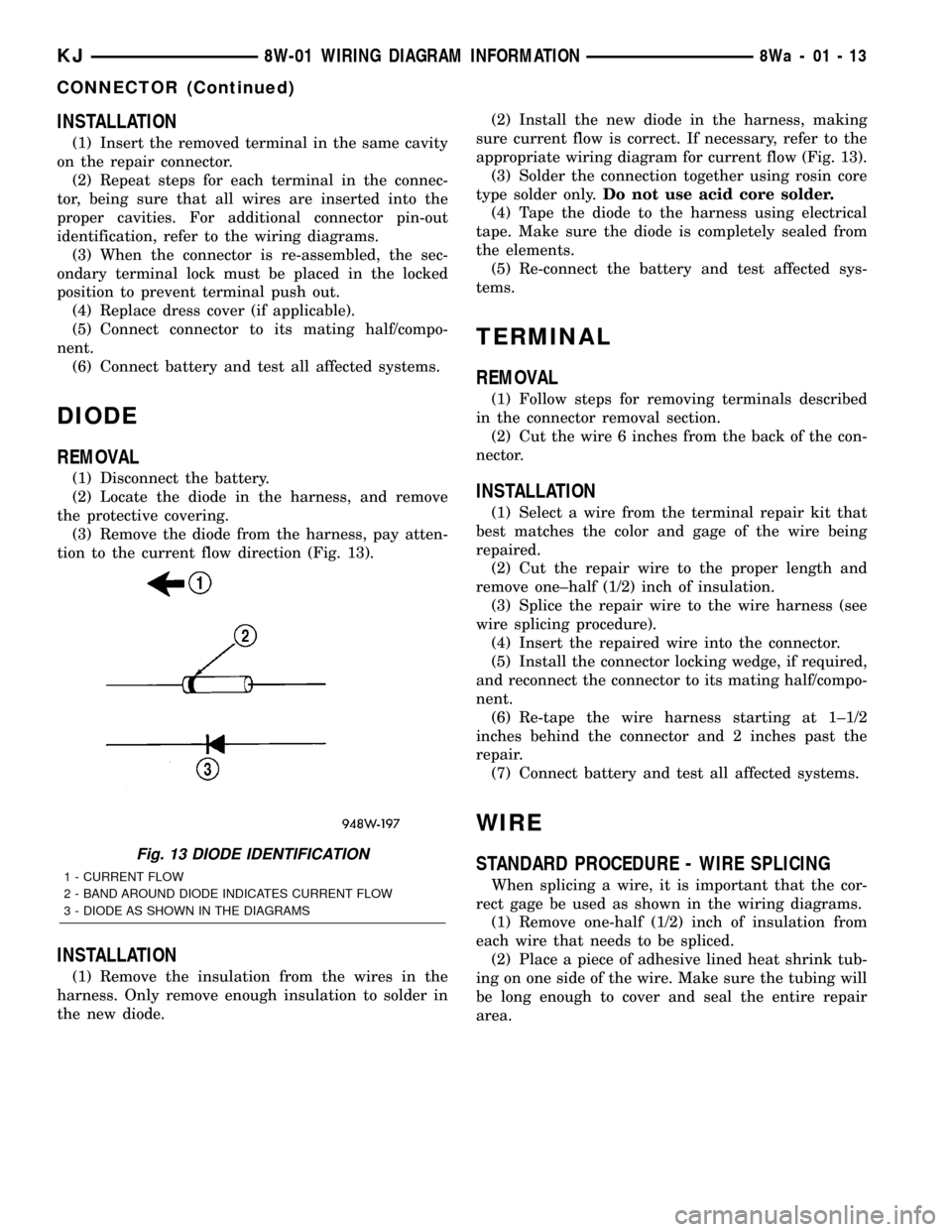

DIODE

REMOVAL

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 13).

INSTALLATION

(1) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.(2) Install the new diode in the harness, making

sure current flow is correct. If necessary, refer to the

appropriate wiring diagram for current flow (Fig. 13).

(3) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(4) Tape the diode to the harness using electrical

tape. Make sure the diode is completely sealed from

the elements.

(5) Re-connect the battery and test affected sys-

tems.

TERMINAL

REMOVAL

(1) Follow steps for removing terminals described

in the connector removal section.

(2) Cut the wire 6 inches from the back of the con-

nector.

INSTALLATION

(1) Select a wire from the terminal repair kit that

best matches the color and gage of the wire being

repaired.

(2) Cut the repair wire to the proper length and

remove one±half (1/2) inch of insulation.

(3) Splice the repair wire to the wire harness (see

wire splicing procedure).

(4) Insert the repaired wire into the connector.

(5) Install the connector locking wedge, if required,

and reconnect the connector to its mating half/compo-

nent.

(6) Re-tape the wire harness starting at 1±1/2

inches behind the connector and 2 inches past the

repair.

(7) Connect battery and test all affected systems.

WIRE

STANDARD PROCEDURE - WIRE SPLICING

When splicing a wire, it is important that the cor-

rect gage be used as shown in the wiring diagrams.

(1) Remove one-half (1/2) inch of insulation from

each wire that needs to be spliced.

(2) Place a piece of adhesive lined heat shrink tub-

ing on one side of the wire. Make sure the tubing will

be long enough to cover and seal the entire repair

area.

Fig. 13 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

KJ8W-01 WIRING DIAGRAM INFORMATION8Wa-01-13

CONNECTOR (Continued)

Page 1229 of 1803

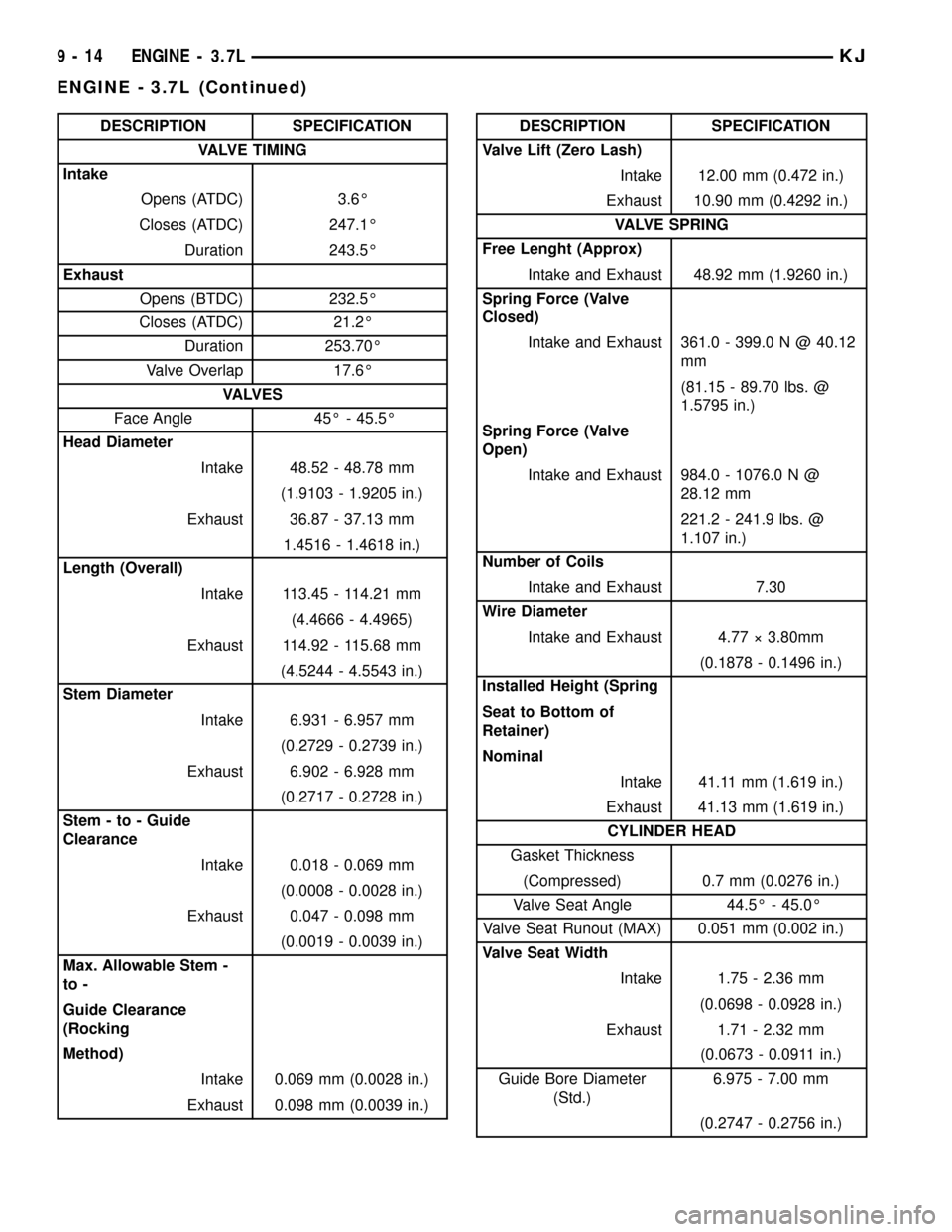

DESCRIPTION SPECIFICATION

VALVE TIMING

Intake

Opens (ATDC) 3.6É

Closes (ATDC) 247.1É

Duration 243.5É

Exhaust

Opens (BTDC) 232.5É

Closes (ATDC) 21.2É

Duration 253.70É

Valve Overlap 17.6É

VA LV E S

Face Angle 45É - 45.5É

Head Diameter

Intake 48.52 - 48.78 mm

(1.9103 - 1.9205 in.)

Exhaust 36.87 - 37.13 mm

1.4516 - 1.4618 in.)

Length (Overall)

Intake 113.45 - 114.21 mm

(4.4666 - 4.4965)

Exhaust 114.92 - 115.68 mm

(4.5244 - 4.5543 in.)

Stem Diameter

Intake 6.931 - 6.957 mm

(0.2729 - 0.2739 in.)

Exhaust 6.902 - 6.928 mm

(0.2717 - 0.2728 in.)

Stem - to - Guide

Clearance

Intake 0.018 - 0.069 mm

(0.0008 - 0.0028 in.)

Exhaust 0.047 - 0.098 mm

(0.0019 - 0.0039 in.)

Max. Allowable Stem -

to -

Guide Clearance

(Rocking

Method)

Intake 0.069 mm (0.0028 in.)

Exhaust 0.098 mm (0.0039 in.)DESCRIPTION SPECIFICATION

Valve Lift (Zero Lash)

Intake 12.00 mm (0.472 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Lenght (Approx)

Intake and Exhaust 48.92 mm (1.9260 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 361.0 - 399.0 N @ 40.12

mm

(81.15 - 89.70 lbs. @

1.5795 in.)

Spring Force (Valve

Open)

Intake and Exhaust 984.0 - 1076.0 N @

28.12 mm

221.2 - 241.9 lbs. @

1.107 in.)

Number of Coils

Intake and Exhaust 7.30

Wire Diameter

Intake and Exhaust 4.77 ý 3.80mm

(0.1878 - 0.1496 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 41.11 mm (1.619 in.)

Exhaust 41.13 mm (1.619 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) 0.7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)

9 - 14 ENGINE - 3.7LKJ

ENGINE - 3.7L (Continued)