Light JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1398 of 1803

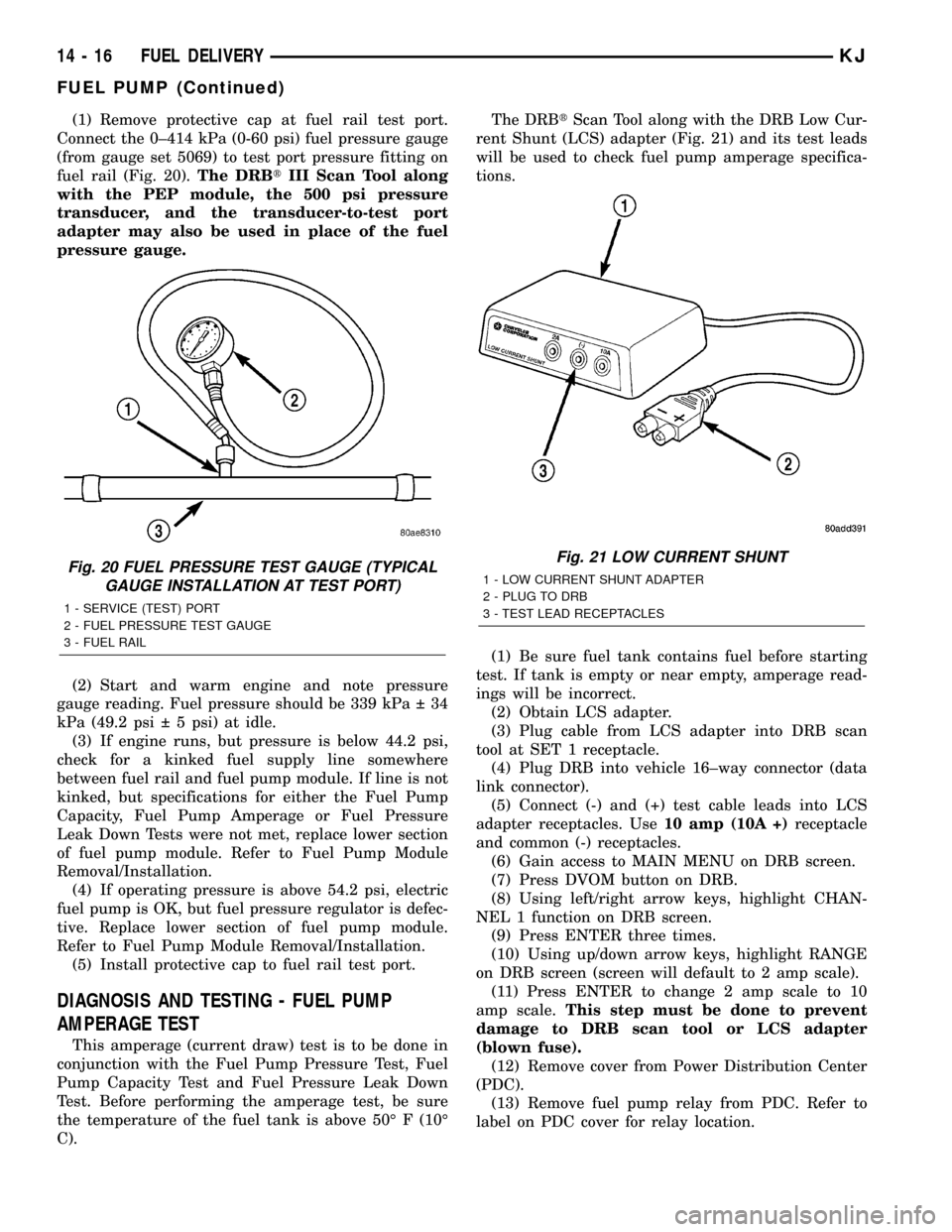

(1) Remove protective cap at fuel rail test port.

Connect the 0±414 kPa (0-60 psi) fuel pressure gauge

(from gauge set 5069) to test port pressure fitting on

fuel rail (Fig. 20).The DRBtIII Scan Tool along

with the PEP module, the 500 psi pressure

transducer, and the transducer-to-test port

adapter may also be used in place of the fuel

pressure gauge.

(2) Start and warm engine and note pressure

gauge reading. Fuel pressure should be 339 kPa 34

kPa (49.2 psi 5 psi) at idle.

(3) If engine runs, but pressure is below 44.2 psi,

check for a kinked fuel supply line somewhere

between fuel rail and fuel pump module. If line is not

kinked, but specifications for either the Fuel Pump

Capacity, Fuel Pump Amperage or Fuel Pressure

Leak Down Tests were not met, replace lower section

of fuel pump module. Refer to Fuel Pump Module

Removal/Installation.

(4) If operating pressure is above 54.2 psi, electric

fuel pump is OK, but fuel pressure regulator is defec-

tive. Replace lower section of fuel pump module.

Refer to Fuel Pump Module Removal/Installation.

(5) Install protective cap to fuel rail test port.

DIAGNOSIS AND TESTING - FUEL PUMP

AMPERAGE TEST

This amperage (current draw) test is to be done in

conjunction with the Fuel Pump Pressure Test, Fuel

Pump Capacity Test and Fuel Pressure Leak Down

Test. Before performing the amperage test, be sure

the temperature of the fuel tank is above 50É F (10É

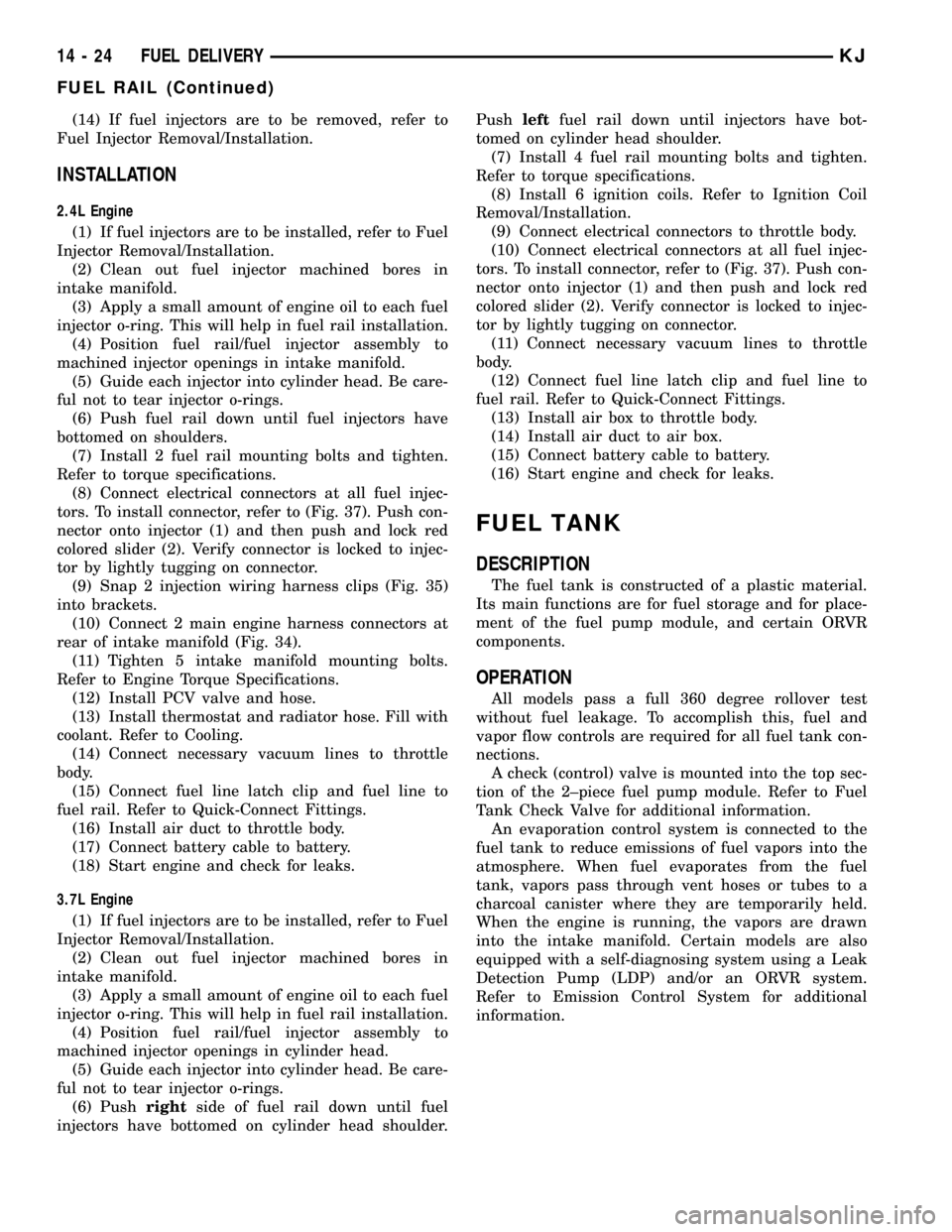

C).The DRBtScan Tool along with the DRB Low Cur-

rent Shunt (LCS) adapter (Fig. 21) and its test leads

will be used to check fuel pump amperage specifica-

tions.

(1) Be sure fuel tank contains fuel before starting

test. If tank is empty or near empty, amperage read-

ings will be incorrect.

(2) Obtain LCS adapter.

(3) Plug cable from LCS adapter into DRB scan

tool at SET 1 receptacle.

(4) Plug DRB into vehicle 16±way connector (data

link connector).

(5) Connect (-) and (+) test cable leads into LCS

adapter receptacles. Use10 amp (10A +)receptacle

and common (-) receptacles.

(6) Gain access to MAIN MENU on DRB screen.

(7) Press DVOM button on DRB.

(8) Using left/right arrow keys, highlight CHAN-

NEL 1 function on DRB screen.

(9) Press ENTER three times.

(10) Using up/down arrow keys, highlight RANGE

on DRB screen (screen will default to 2 amp scale).

(11) Press ENTER to change 2 amp scale to 10

amp scale.This step must be done to prevent

damage to DRB scan tool or LCS adapter

(blown fuse).

(12) Remove cover from Power Distribution Center

(PDC).

(13) Remove fuel pump relay from PDC. Refer to

label on PDC cover for relay location.

Fig. 20 FUEL PRESSURE TEST GAUGE (TYPICAL

GAUGE INSTALLATION AT TEST PORT)

1 - SERVICE (TEST) PORT

2 - FUEL PRESSURE TEST GAUGE

3 - FUEL RAIL

Fig. 21 LOW CURRENT SHUNT

1 - LOW CURRENT SHUNT ADAPTER

2 - PLUG TO DRB

3 - TEST LEAD RECEPTACLES

14 - 16 FUEL DELIVERYKJ

FUEL PUMP (Continued)

Page 1406 of 1803

(14) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

INSTALLATION

2.4L Engine

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Push fuel rail down until fuel injectors have

bottomed on shoulders.

(7) Install 2 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 37). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(9) Snap 2 injection wiring harness clips (Fig. 35)

into brackets.

(10) Connect 2 main engine harness connectors at

rear of intake manifold (Fig. 34).

(11) Tighten 5 intake manifold mounting bolts.

Refer to Engine Torque Specifications.

(12) Install PCV valve and hose.

(13) Install thermostat and radiator hose. Fill with

coolant. Refer to Cooling.

(14) Connect necessary vacuum lines to throttle

body.

(15) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(16) Install air duct to throttle body.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

3.7L Engine

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 37). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(13) Install air box to throttle body.

(14) Install air duct to air box.

(15) Connect battery cable to battery.

(16) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and certain ORVR

components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.

A check (control) valve is mounted into the top sec-

tion of the 2±piece fuel pump module. Refer to Fuel

Tank Check Valve for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an ORVR system.

Refer to Emission Control System for additional

information.

14 - 24 FUEL DELIVERYKJ

FUEL RAIL (Continued)

Page 1414 of 1803

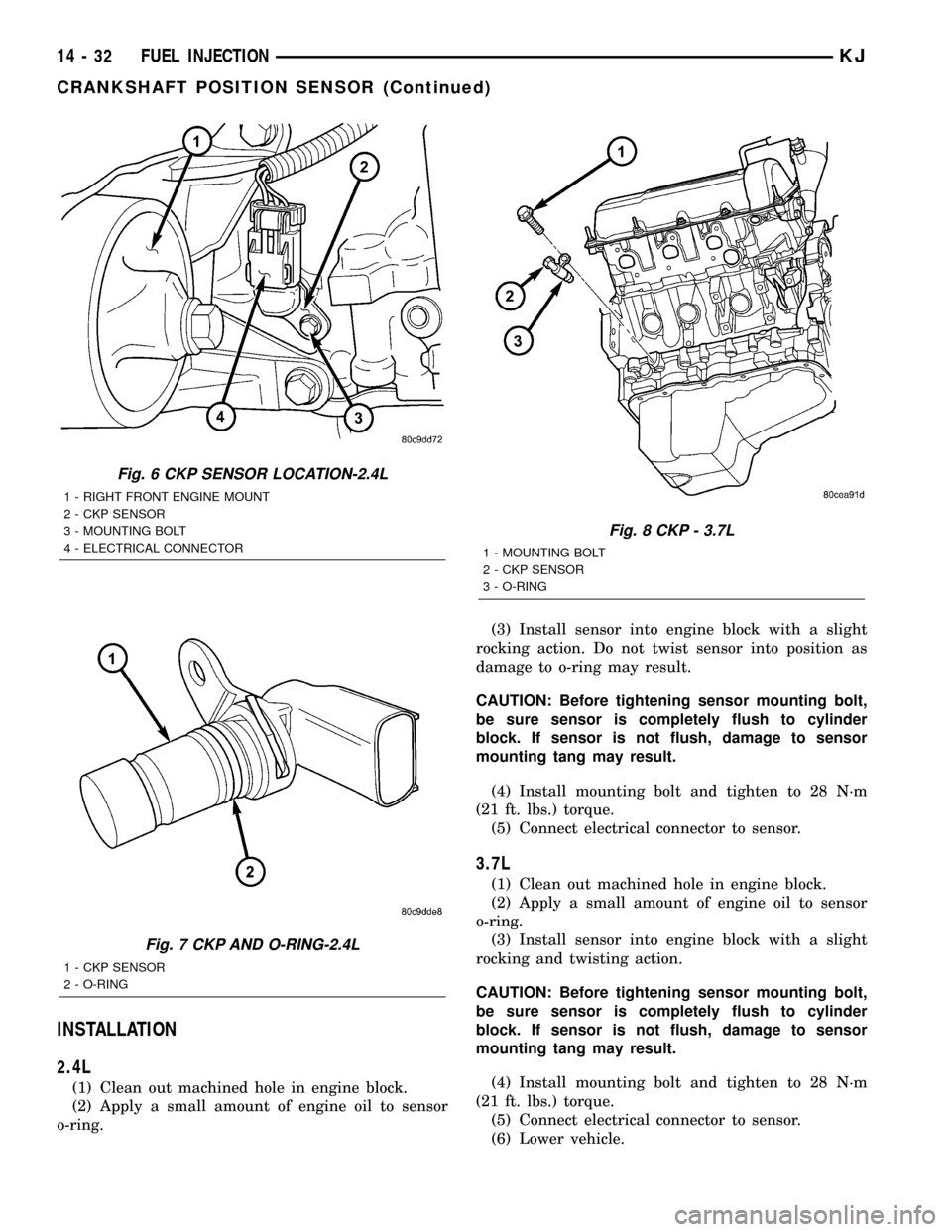

INSTALLATION

2.4L

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.(3) Install sensor into engine block with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

3.7L

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

Fig. 6 CKP SENSOR LOCATION-2.4L

1 - RIGHT FRONT ENGINE MOUNT

2 - CKP SENSOR

3 - MOUNTING BOLT

4 - ELECTRICAL CONNECTOR

Fig. 7 CKP AND O-RING-2.4L

1 - CKP SENSOR

2 - O-RING

Fig. 8 CKP - 3.7L

1 - MOUNTING BOLT

2 - CKP SENSOR

3 - O-RING

14 - 32 FUEL INJECTIONKJ

CRANKSHAFT POSITION SENSOR (Continued)

Page 1417 of 1803

IDLE AIR CONTROL MOTOR

DESCRIPTION

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. Fromthis point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

KJFUEL INJECTION 14 - 35

Page 1430 of 1803

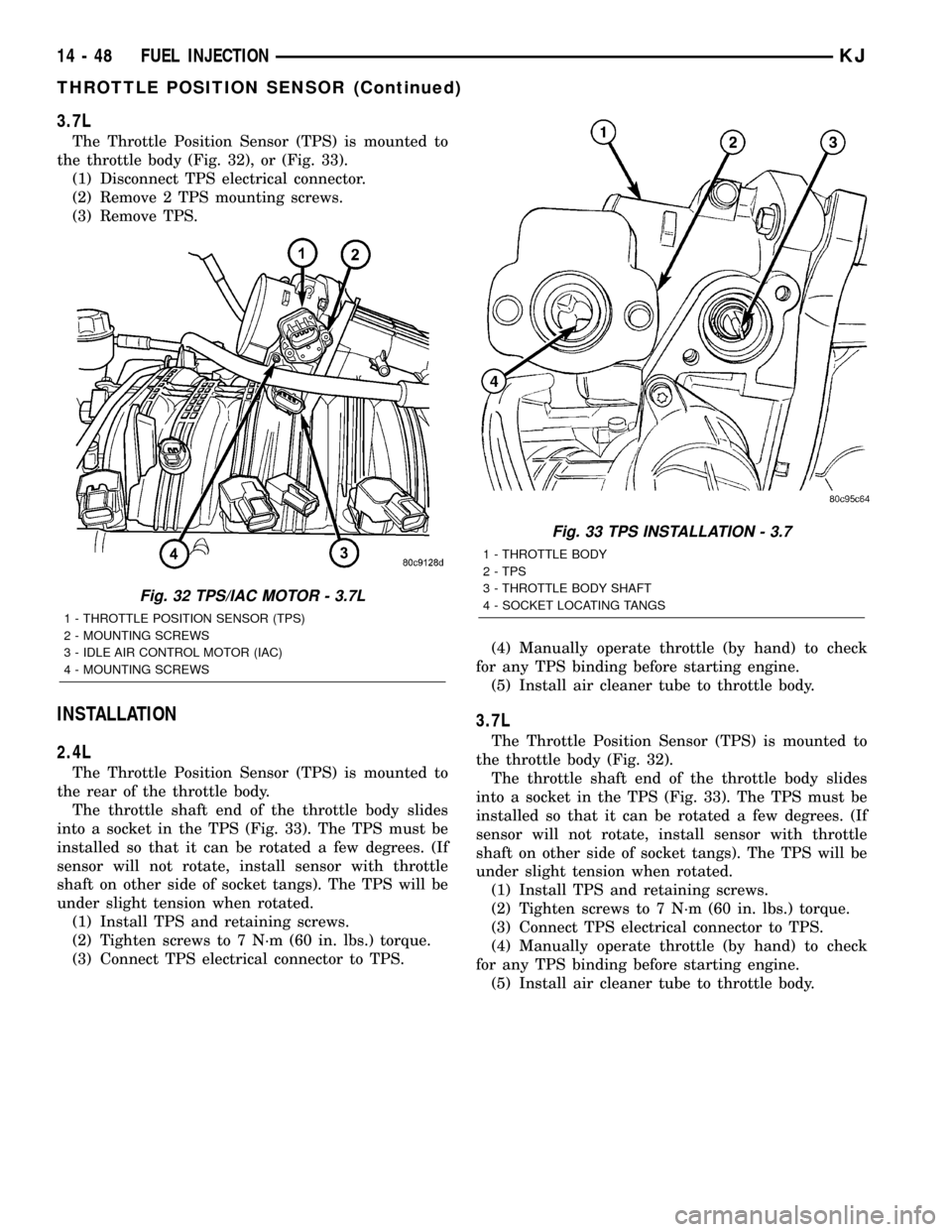

3.7L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 32), or (Fig. 33).

(1) Disconnect TPS electrical connector.

(2) Remove 2 TPS mounting screws.

(3) Remove TPS.

INSTALLATION

2.4L

The Throttle Position Sensor (TPS) is mounted to

the rear of the throttle body.

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 33). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

3.7L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 32).

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 33). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

Fig. 32 TPS/IAC MOTOR - 3.7L

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

Fig. 33 TPS INSTALLATION - 3.7

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

14 - 48 FUEL INJECTIONKJ

THROTTLE POSITION SENSOR (Continued)

Page 1448 of 1803

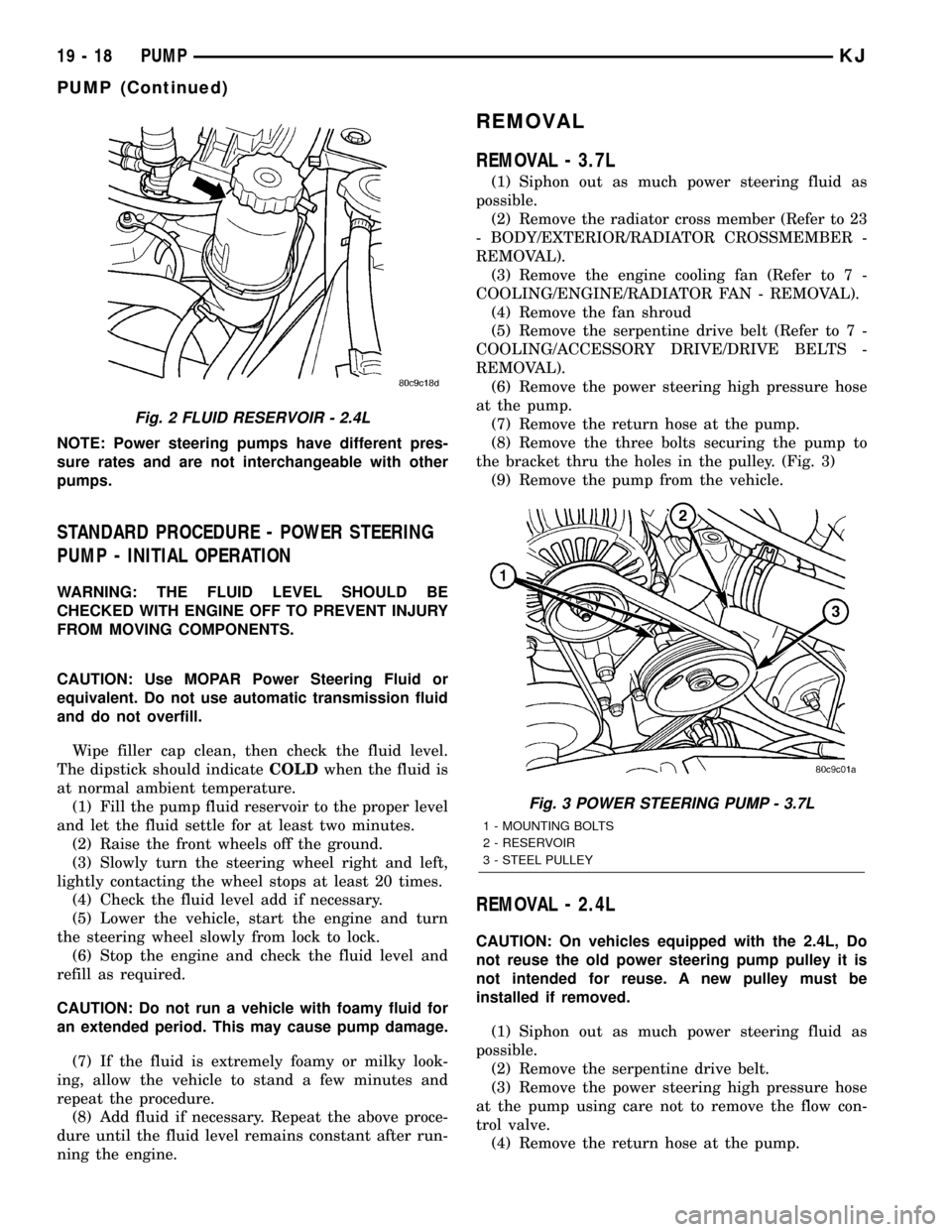

NOTE: Power steering pumps have different pres-

sure rates and are not interchangeable with other

pumps.

STANDARD PROCEDURE - POWER STEERING

PUMP - INITIAL OPERATION

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Raise the front wheels off the ground.

(3) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(4) Check the fluid level add if necessary.

(5) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(6) Stop the engine and check the fluid level and

refill as required.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

(7) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

(8) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

REMOVAL

REMOVAL - 3.7L

(1) Siphon out as much power steering fluid as

possible.

(2) Remove the radiator cross member (Refer to 23

- BODY/EXTERIOR/RADIATOR CROSSMEMBER -

REMOVAL).

(3) Remove the engine cooling fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(4) Remove the fan shroud

(5) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove the power steering high pressure hose

at the pump.

(7) Remove the return hose at the pump.

(8) Remove the three bolts securing the pump to

the bracket thru the holes in the pulley. (Fig. 3)

(9) Remove the pump from the vehicle.

REMOVAL - 2.4L

CAUTION: On vehicles equipped with the 2.4L, Do

not reuse the old power steering pump pulley it is

not intended for reuse. A new pulley must be

installed if removed.

(1) Siphon out as much power steering fluid as

possible.

(2) Remove the serpentine drive belt.

(3) Remove the power steering high pressure hose

at the pump using care not to remove the flow con-

trol valve.

(4) Remove the return hose at the pump.

Fig. 2 FLUID RESERVOIR - 2.4L

Fig. 3 POWER STEERING PUMP - 3.7L

1 - MOUNTING BOLTS

2 - RESERVOIR

3 - STEEL PULLEY

19 - 18 PUMPKJ

PUMP (Continued)

Page 1462 of 1803

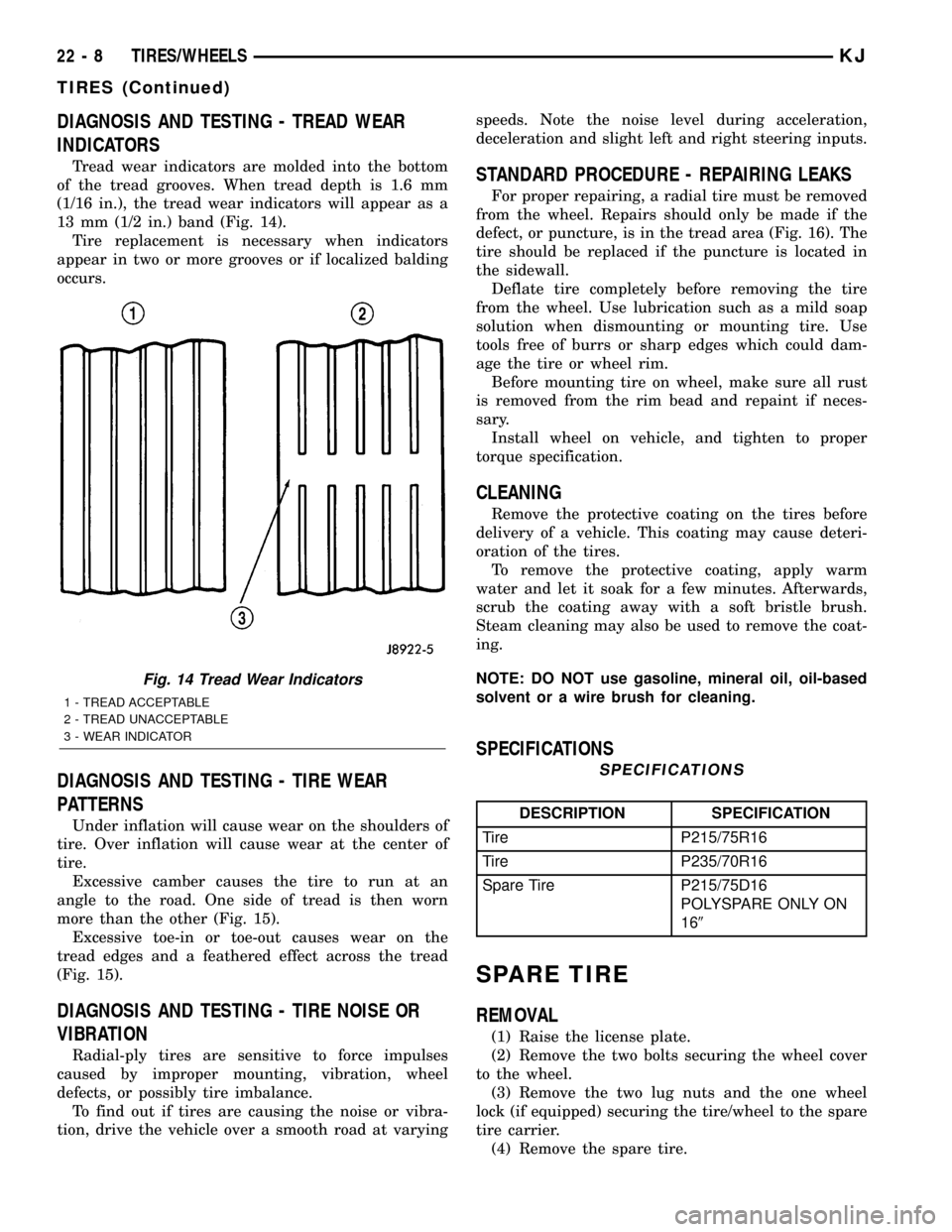

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 14).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 15).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 15).

DIAGNOSIS AND TESTING - TIRE NOISE OR

VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varyingspeeds. Note the noise level during acceleration,

deceleration and slight left and right steering inputs.

STANDARD PROCEDURE - REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 16). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and tighten to proper

torque specification.

CLEANING

Remove the protective coating on the tires before

delivery of a vehicle. This coating may cause deteri-

oration of the tires.

To remove the protective coating, apply warm

water and let it soak for a few minutes. Afterwards,

scrub the coating away with a soft bristle brush.

Steam cleaning may also be used to remove the coat-

ing.

NOTE: DO NOT use gasoline, mineral oil, oil-based

solvent or a wire brush for cleaning.

SPECIFICATIONS

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Tire P215/75R16

Tire P235/70R16

Spare Tire P215/75D16

POLYSPARE ONLY ON

169

SPARE TIRE

REMOVAL

(1) Raise the license plate.

(2) Remove the two bolts securing the wheel cover

to the wheel.

(3) Remove the two lug nuts and the one wheel

lock (if equipped) securing the tire/wheel to the spare

tire carrier.

(4) Remove the spare tire.

Fig. 14 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

22 - 8 TIRES/WHEELSKJ

TIRES (Continued)

Page 1467 of 1803

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 2 BODYKJ

BODY (Continued)

Page 1607 of 1803

(2) Install the three screws.

(3) Install the fuel cap.

GRILLE

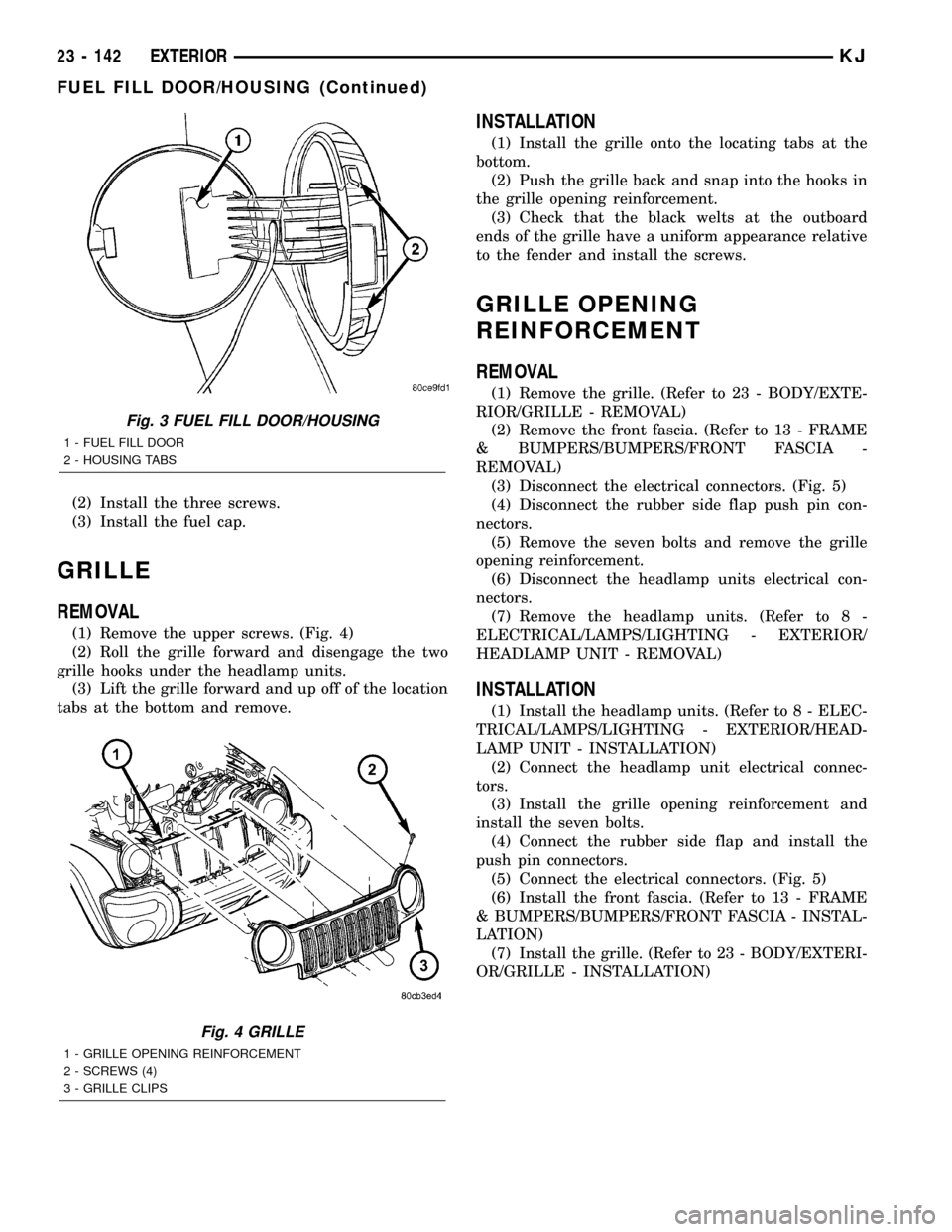

REMOVAL

(1) Remove the upper screws. (Fig. 4)

(2) Roll the grille forward and disengage the two

grille hooks under the headlamp units.

(3) Lift the grille forward and up off of the location

tabs at the bottom and remove.

INSTALLATION

(1) Install the grille onto the locating tabs at the

bottom.

(2) Push the grille back and snap into the hooks in

the grille opening reinforcement.

(3) Check that the black welts at the outboard

ends of the grille have a uniform appearance relative

to the fender and install the screws.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(2) Remove the front fascia. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT FASCIA -

REMOVAL)

(3) Disconnect the electrical connectors. (Fig. 5)

(4) Disconnect the rubber side flap push pin con-

nectors.

(5) Remove the seven bolts and remove the grille

opening reinforcement.

(6) Disconnect the headlamp units electrical con-

nectors.

(7) Remove the headlamp units. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

INSTALLATION

(1) Install the headlamp units. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(2) Connect the headlamp unit electrical connec-

tors.

(3) Install the grille opening reinforcement and

install the seven bolts.

(4) Connect the rubber side flap and install the

push pin connectors.

(5) Connect the electrical connectors. (Fig. 5)

(6) Install the front fascia. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT FASCIA - INSTAL-

LATION)

(7) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

Fig. 3 FUEL FILL DOOR/HOUSING

1 - FUEL FILL DOOR

2 - HOUSING TABS

Fig. 4 GRILLE

1 - GRILLE OPENING REINFORCEMENT

2 - SCREWS (4)

3 - GRILLE CLIPS

23 - 142 EXTERIORKJ

FUEL FILL DOOR/HOUSING (Continued)

Page 1614 of 1803

(1) Open the glove box.

(2) Remove the two striker screws and remove the

latch striker.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install the striker and install the two screws.

(2) Loosen the screws to adjust if necessary.

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

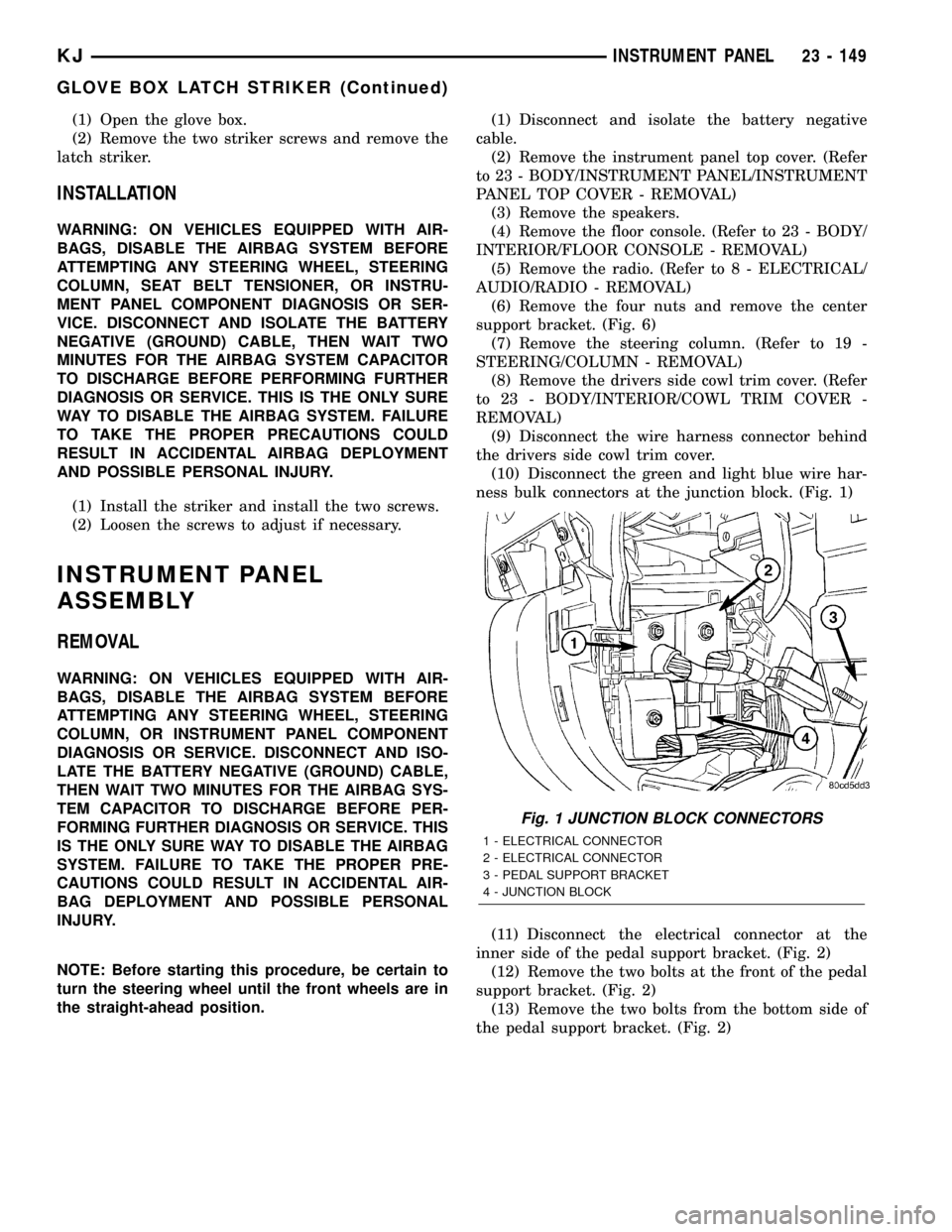

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - REMOVAL)

(3) Remove the speakers.

(4) Remove the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL)

(5) Remove the radio. (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - REMOVAL)

(6) Remove the four nuts and remove the center

support bracket. (Fig. 6)

(7) Remove the steering column. (Refer to 19 -

STEERING/COLUMN - REMOVAL)

(8) Remove the drivers side cowl trim cover. (Refer

to 23 - BODY/INTERIOR/COWL TRIM COVER -

REMOVAL)

(9) Disconnect the wire harness connector behind

the drivers side cowl trim cover.

(10) Disconnect the green and light blue wire har-

ness bulk connectors at the junction block. (Fig. 1)

(11) Disconnect the electrical connector at the

inner side of the pedal support bracket. (Fig. 2)

(12) Remove the two bolts at the front of the pedal

support bracket. (Fig. 2)

(13) Remove the two bolts from the bottom side of

the pedal support bracket. (Fig. 2)

Fig. 1 JUNCTION BLOCK CONNECTORS

1 - ELECTRICAL CONNECTOR

2 - ELECTRICAL CONNECTOR

3 - PEDAL SUPPORT BRACKET

4 - JUNCTION BLOCK

KJINSTRUMENT PANEL 23 - 149

GLOVE BOX LATCH STRIKER (Continued)