sensor JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1321 of 1803

REMOVAL

(1) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Remove camshaft position sensor and camshaft

target magnet. (Refer to 8 - ELECTRICAL/IGNI-

TION CONTROL/CAMSHAFT POSITION SENSOR -

REMOVAL)

(3) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)(4) Remove camshaft sprockets and timing belt

rear cover. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - REMOVAL)

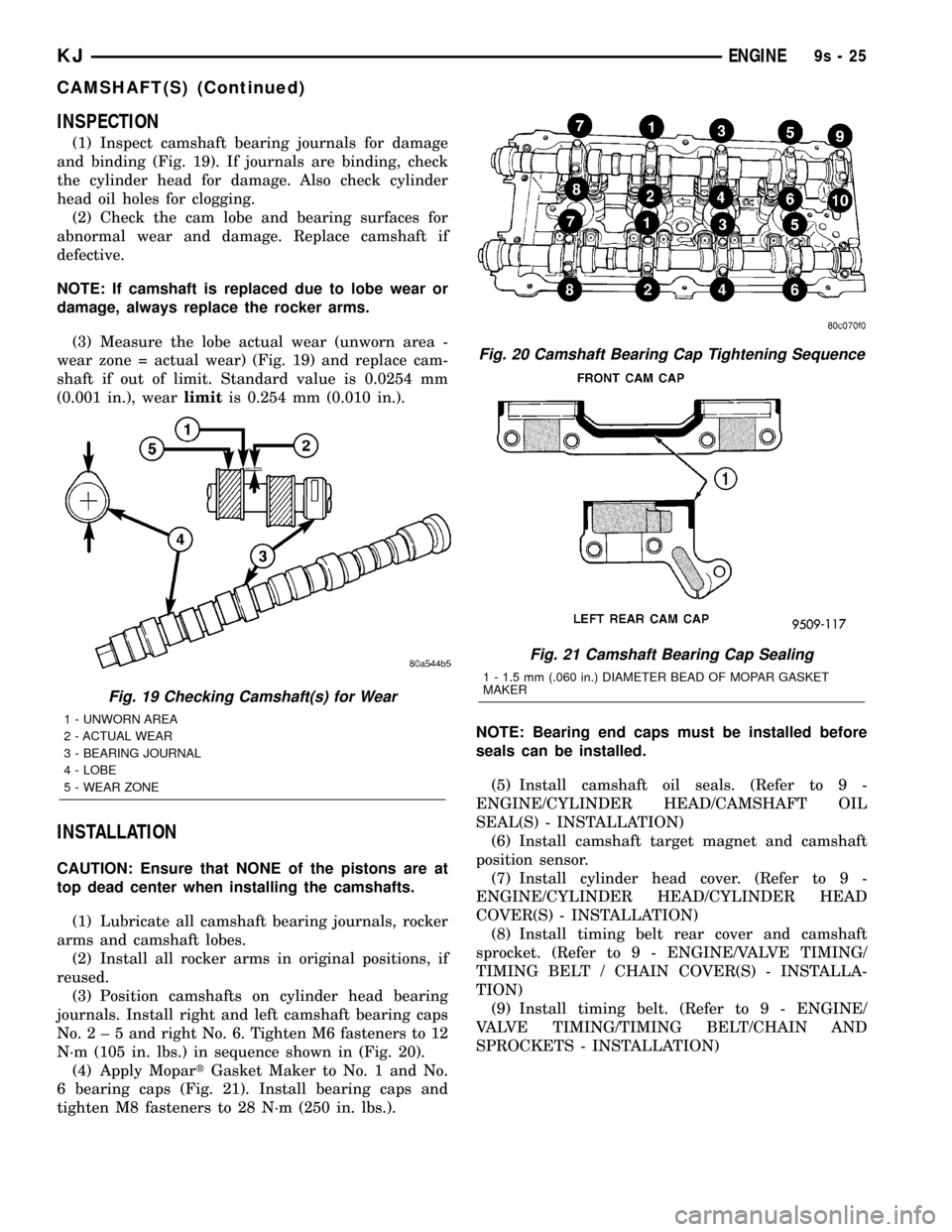

(5) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 17).

(6) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 18) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

(7) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

(8) Remove camshafts from cylinder head.

NOTE: If removing rocker arms, identify for reinstal-

lation in the original position.

CLEANING

Clean camshaft with a suitable solvent.

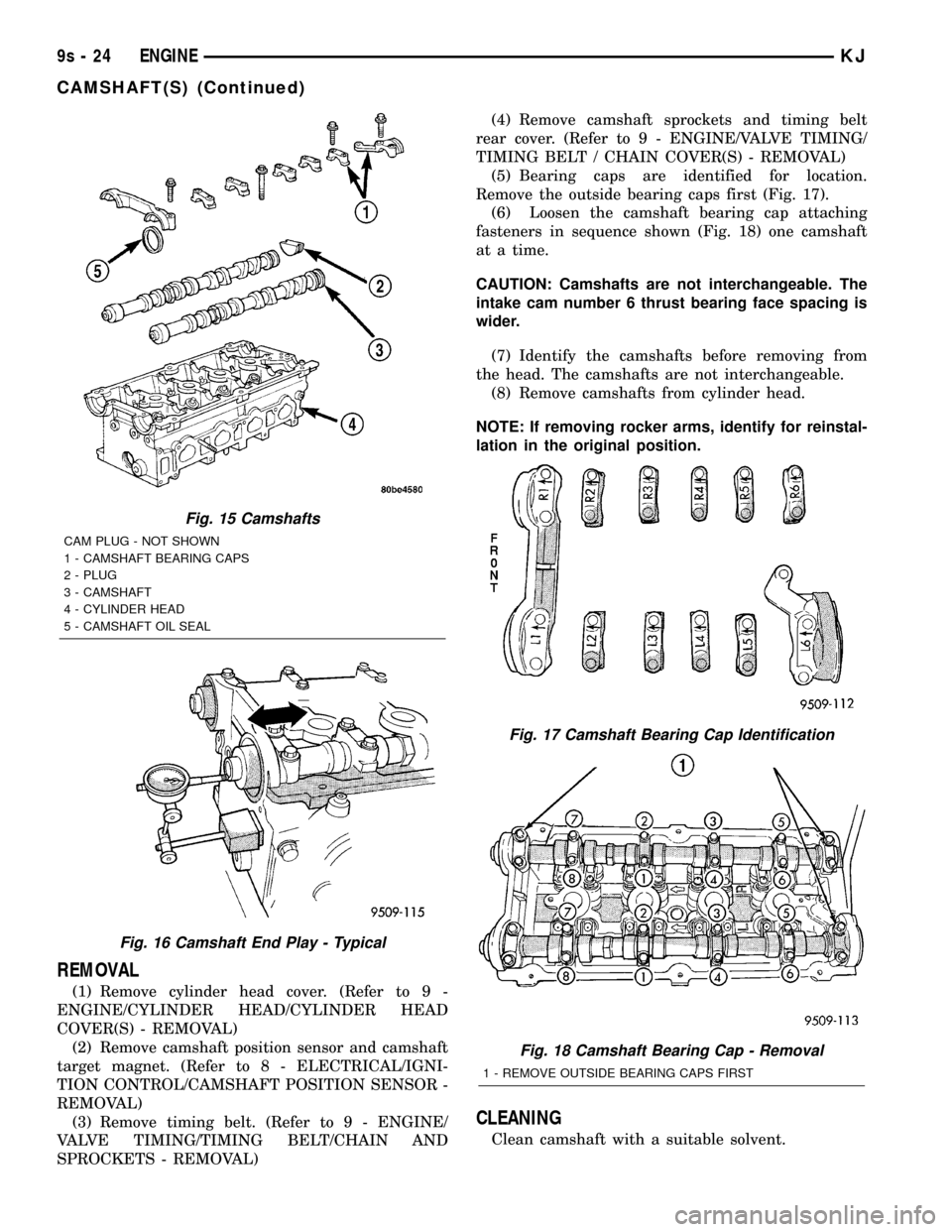

Fig. 15 Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

Fig. 16 Camshaft End Play - Typical

Fig. 17 Camshaft Bearing Cap Identification

Fig. 18 Camshaft Bearing Cap - Removal

1 - REMOVE OUTSIDE BEARING CAPS FIRST

9s - 24 ENGINEKJ

CAMSHAFT(S) (Continued)

Page 1322 of 1803

INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 19). If journals are binding, check

the cylinder head for damage. Also check cylinder

head oil holes for clogging.

(2) Check the cam lobe and bearing surfaces for

abnormal wear and damage. Replace camshaft if

defective.

NOTE: If camshaft is replaced due to lobe wear or

damage, always replace the rocker arms.

(3) Measure the lobe actual wear (unworn area -

wear zone = actual wear) (Fig. 19) and replace cam-

shaft if out of limit. Standard value is 0.0254 mm

(0.001 in.), wearlimitis 0.254 mm (0.010 in.).

INSTALLATION

CAUTION: Ensure that NONE of the pistons are at

top dead center when installing the camshafts.

(1) Lubricate all camshaft bearing journals, rocker

arms and camshaft lobes.

(2) Install all rocker arms in original positions, if

reused.

(3) Position camshafts on cylinder head bearing

journals. Install right and left camshaft bearing caps

No.2±5andright No. 6. Tighten M6 fasteners to 12

N´m (105 in. lbs.) in sequence shown in (Fig. 20).

(4) Apply MopartGasket Maker to No. 1 and No.

6 bearing caps (Fig. 21). Install bearing caps and

tighten M8 fasteners to 28 N´m (250 in. lbs.).NOTE: Bearing end caps must be installed before

seals can be installed.

(5) Install camshaft oil seals. (Refer to 9 -

ENGINE/CYLINDER HEAD/CAMSHAFT OIL

SEAL(S) - INSTALLATION)

(6) Install camshaft target magnet and camshaft

position sensor.

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and camshaft

sprocket. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 19 Checking Camshaft(s) for Wear

1 - UNWORN AREA

2 - ACTUAL WEAR

3 - BEARING JOURNAL

4 - LOBE

5 - WEAR ZONE

Fig. 20 Camshaft Bearing Cap Tightening Sequence

Fig. 21 Camshaft Bearing Cap Sealing

1 - 1.5 mm (.060 in.) DIAMETER BEAD OF MOPAR GASKET

MAKER

KJENGINE9s-25

CAMSHAFT(S) (Continued)

Page 1343 of 1803

LUBRICATION

DESCRIPTION

The lubrication system is a full-flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

OPERATION

Engine oil drawn up through the pickup tube and

is pressurized by the oil pump and routed through

the full-flow filter to the main oil gallery running the

length of the cylinder block. A diagonal hole in each

bulkhead feeds oil to each main bearing. Drilled pas-

sages within the crankshaft route oil from main bear-

ing journals to connecting rod journals. Balance shaft

lubrication is provided through an oil passage from

the number one main bearing cap through the bal-

ance shaft carrier support leg. This passage directly

supplies oil to the front bearings and internal

machined passages in the shafts that routes oil from

front to the rear shaft bearing journals. A vertical

hole at the number five bulkhead routes pressurized

oil through a restrictor (integral to the cylinder head

gasket) up past a cylinder head bolt to an oil gallery

running the length of the cylinder head. The cam-

shaft journals are partially slotted to allow a prede-

termined amount of pressurized oil to pass into the

bearing cap cavities. Lubrication of the camshaft

lobes are provided by small holes in the camshaft

bearing caps that are directed towards each lobe. Oil

returning to the pan from pressurized components

supplies lubrication to the valve stems. Cylinder

bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE CHECKING

(1) Disconnect and remove oil pressure switch.

(Refer to 9 - ENGINE/LUBRICATION/OIL PRES-

SURE SENSOR/SWITCH - REMOVAL)

(2) Install Special Tools C-3292 Gauge with 8406

Adaptor fitting.

(3) Start engine and record oil pressure. Refer to

Specifications for correct oil pressure requirements.

(Refer to 9 - ENGINE - SPECIFICATIONS)

CAUTION: If oil pressure is 0 at idle, do not perform

the 3000 RPM test

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

(5) After test is complete, remove test gauge and

fitting.

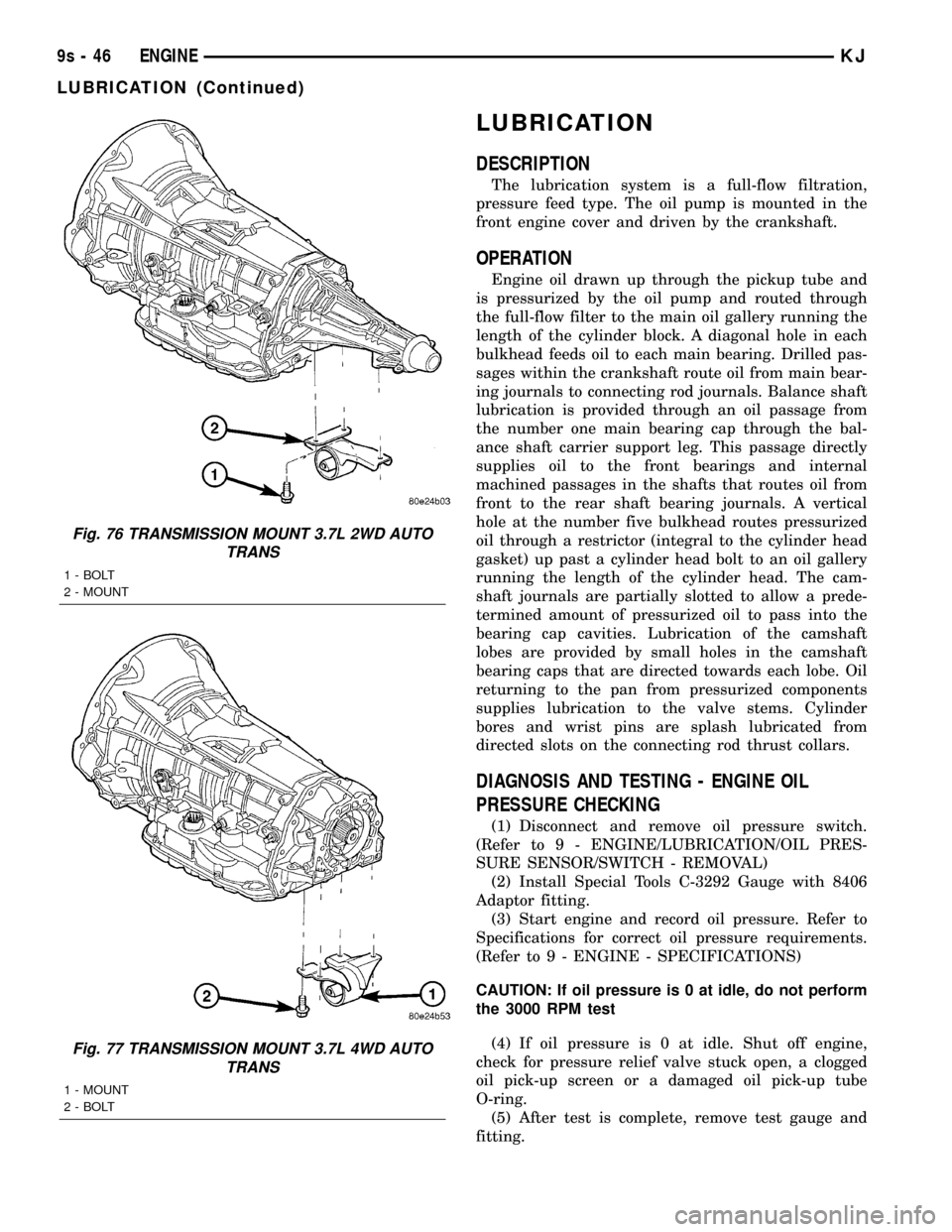

Fig. 76 TRANSMISSION MOUNT 3.7L 2WD AUTO

TRANS

1 - BOLT

2 - MOUNT

Fig. 77 TRANSMISSION MOUNT 3.7L 4WD AUTO

TRANS

1 - MOUNT

2 - BOLT

9s - 46 ENGINEKJ

LUBRICATION (Continued)

Page 1344 of 1803

(6) Install oil pressure switch and connector. (Refer

to 9 - ENGINE/LUBRICATION/OIL PRESSURE

SENSOR/SWITCH - INSTALLATION)

OIL

STANDARD PROCEDURE

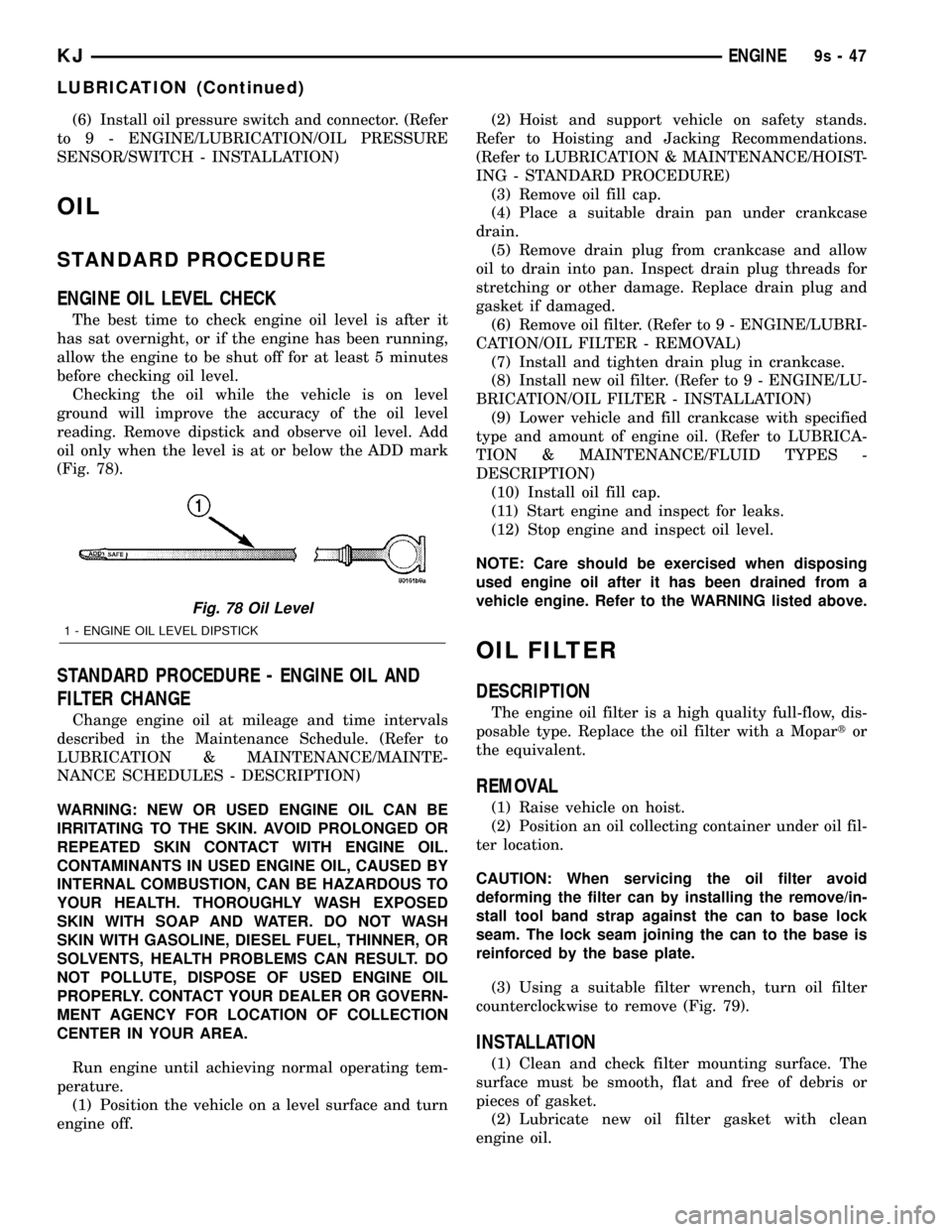

ENGINE OIL LEVEL CHECK

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick and observe oil level. Add

oil only when the level is at or below the ADD mark

(Fig. 78).

STANDARD PROCEDURE - ENGINE OIL AND

FILTER CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. (Refer to

LUBRICATION & MAINTENANCE/MAINTE-

NANCE SCHEDULES - DESCRIPTION)

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.(2) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Remove oil filter. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL)

(7) Install and tighten drain plug in crankcase.

(8) Install new oil filter. (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION)

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

OIL FILTER

DESCRIPTION

The engine oil filter is a high quality full-flow, dis-

posable type. Replace the oil filter with a Mopartor

the equivalent.

REMOVAL

(1) Raise vehicle on hoist.

(2) Position an oil collecting container under oil fil-

ter location.

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can to base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

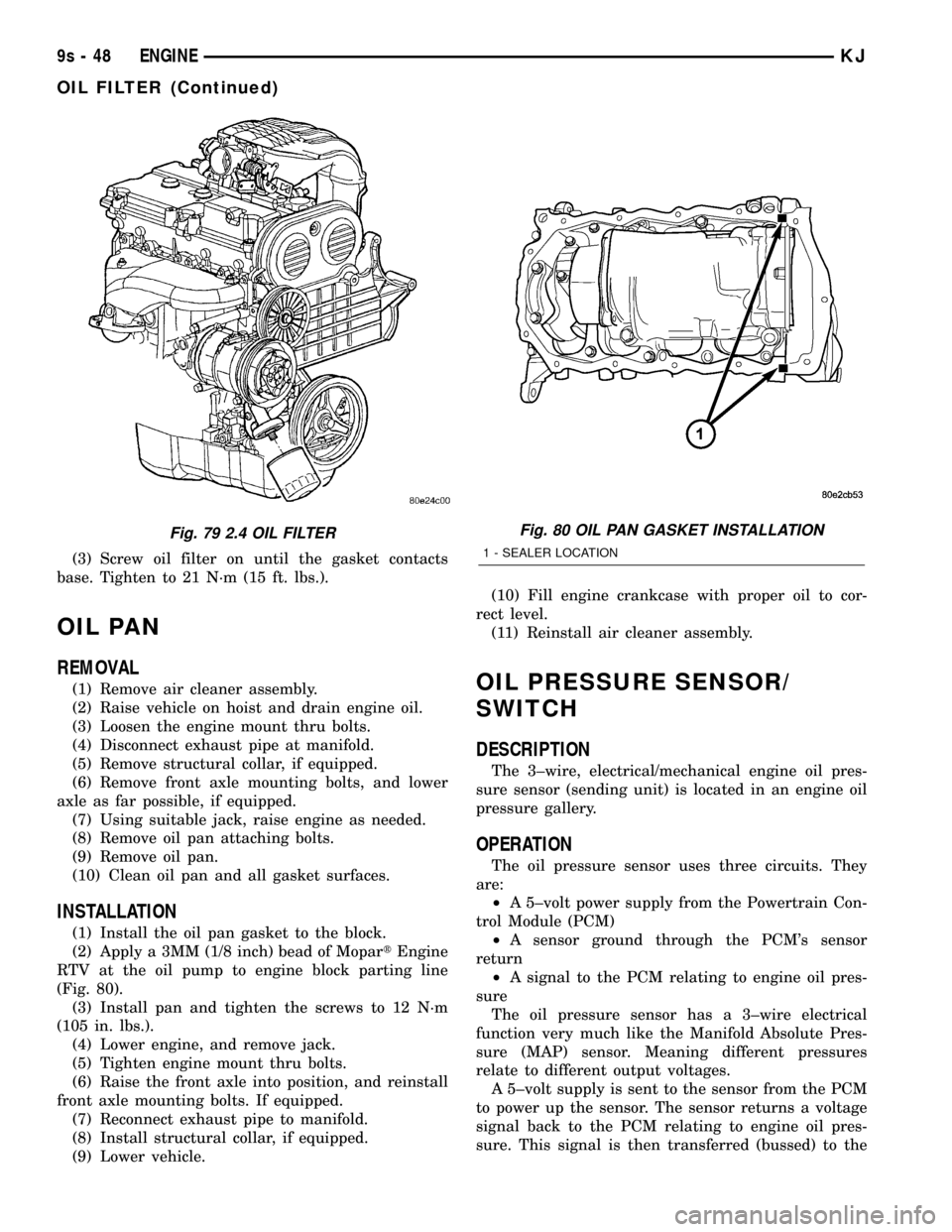

(3) Using a suitable filter wrench, turn oil filter

counterclockwise to remove (Fig. 79).

INSTALLATION

(1) Clean and check filter mounting surface. The

surface must be smooth, flat and free of debris or

pieces of gasket.

(2) Lubricate new oil filter gasket with clean

engine oil.

Fig. 78 Oil Level

1 - ENGINE OIL LEVEL DIPSTICK

KJENGINE9s-47

LUBRICATION (Continued)

Page 1345 of 1803

(3) Screw oil filter on until the gasket contacts

base. Tighten to 21 N´m (15 ft. lbs.).

OIL PAN

REMOVAL

(1) Remove air cleaner assembly.

(2) Raise vehicle on hoist and drain engine oil.

(3) Loosen the engine mount thru bolts.

(4) Disconnect exhaust pipe at manifold.

(5) Remove structural collar, if equipped.

(6) Remove front axle mounting bolts, and lower

axle as far possible, if equipped.

(7) Using suitable jack, raise engine as needed.

(8) Remove oil pan attaching bolts.

(9) Remove oil pan.

(10) Clean oil pan and all gasket surfaces.

INSTALLATION

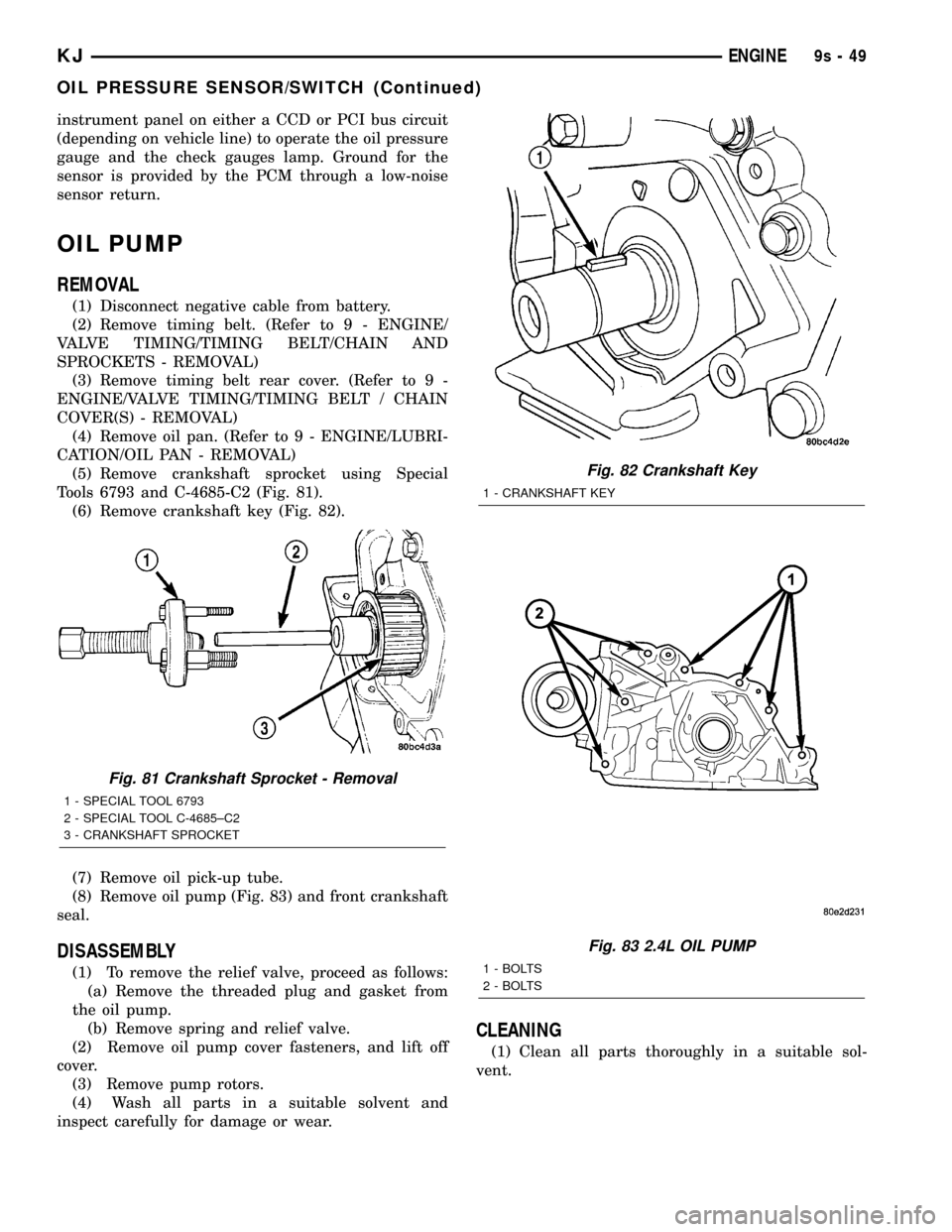

(1) Install the oil pan gasket to the block.

(2) Apply a 3MM (1/8 inch) bead of MopartEngine

RTV at the oil pump to engine block parting line

(Fig. 80).

(3) Install pan and tighten the screws to 12 N´m

(105 in. lbs.).

(4) Lower engine, and remove jack.

(5) Tighten engine mount thru bolts.

(6) Raise the front axle into position, and reinstall

front axle mounting bolts. If equipped.

(7) Reconnect exhaust pipe to manifold.

(8) Install structural collar, if equipped.

(9) Lower vehicle.(10) Fill engine crankcase with proper oil to cor-

rect level.

(11) Reinstall air cleaner assembly.

OIL PRESSURE SENSOR/

SWITCH

DESCRIPTION

The 3±wire, electrical/mechanical engine oil pres-

sure sensor (sending unit) is located in an engine oil

pressure gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to the

Fig. 79 2.4 OIL FILTERFig. 80 OIL PAN GASKET INSTALLATION

1 - SEALER LOCATION

9s - 48 ENGINEKJ

OIL FILTER (Continued)

Page 1346 of 1803

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(4) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(5) Remove crankshaft sprocket using Special

Tools 6793 and C-4685-C2 (Fig. 81).

(6) Remove crankshaft key (Fig. 82).

(7) Remove oil pick-up tube.

(8) Remove oil pump (Fig. 83) and front crankshaft

seal.

DISASSEMBLY

(1) To remove the relief valve, proceed as follows:

(a) Remove the threaded plug and gasket from

the oil pump.

(b) Remove spring and relief valve.

(2) Remove oil pump cover fasteners, and lift off

cover.

(3) Remove pump rotors.

(4) Wash all parts in a suitable solvent and

inspect carefully for damage or wear.

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

Fig. 81 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - SPECIAL TOOL C-4685±C2

3 - CRANKSHAFT SPROCKET

Fig. 82 Crankshaft Key

1 - CRANKSHAFT KEY

Fig. 83 2.4L OIL PUMP

1 - BOLTS

2 - BOLTS

KJENGINE9s-49

OIL PRESSURE SENSOR/SWITCH (Continued)

Page 1349 of 1803

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect connector from inlet air tempera-

ture sensor.

(3) Disconnect air intake tube at throttle body and

remove upper air cleaner housing.

(4) Disconnect connector from throttle position

sensor (TPS).

(5) Disconnect connector from idle air control (IAC)

motor.

(6) Disconnect connector from MAP sensor.

(7) Remove vacuum lines for purge solenoid and

PCV valve at intake manifold.

(8) Remove vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at intake manifold fittings.

(9) Disconnect throttle, speed control (if equipped),

and transaxle control (if equipped) and cables from

throttle lever and bracket. (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/THROTTLE CONTROL

CABLE - REMOVAL)

(10) Perform fuel system pressure release proce-

durebefore attempting any repairs.(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE)

(11) Disconnect fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(12) Disconnect coolant temperature sensor/fuel

injector wire harness connector.

(13) Disconnect fuel injector harness.

(14) Remove intake manifold to cylinder head fas-

teners.

(15) Remove the manifold from engine.

CAUTION: Cover intake manifold openings to pre-

vent foreign material from entering engine.

(16) Inspect the manifold. (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSPECTION)

INSPECTION

(1) Check manifold surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (0.006 in. per foot) of manifold length.

(2) Inspect manifold for cracks or distortion.

Replace manifold if necessary.

INSTALLATION

(1) Clean manifold sealing surfaces.

(2) Install new manifold to cylinder head seals.

(3) Install manifold to head.

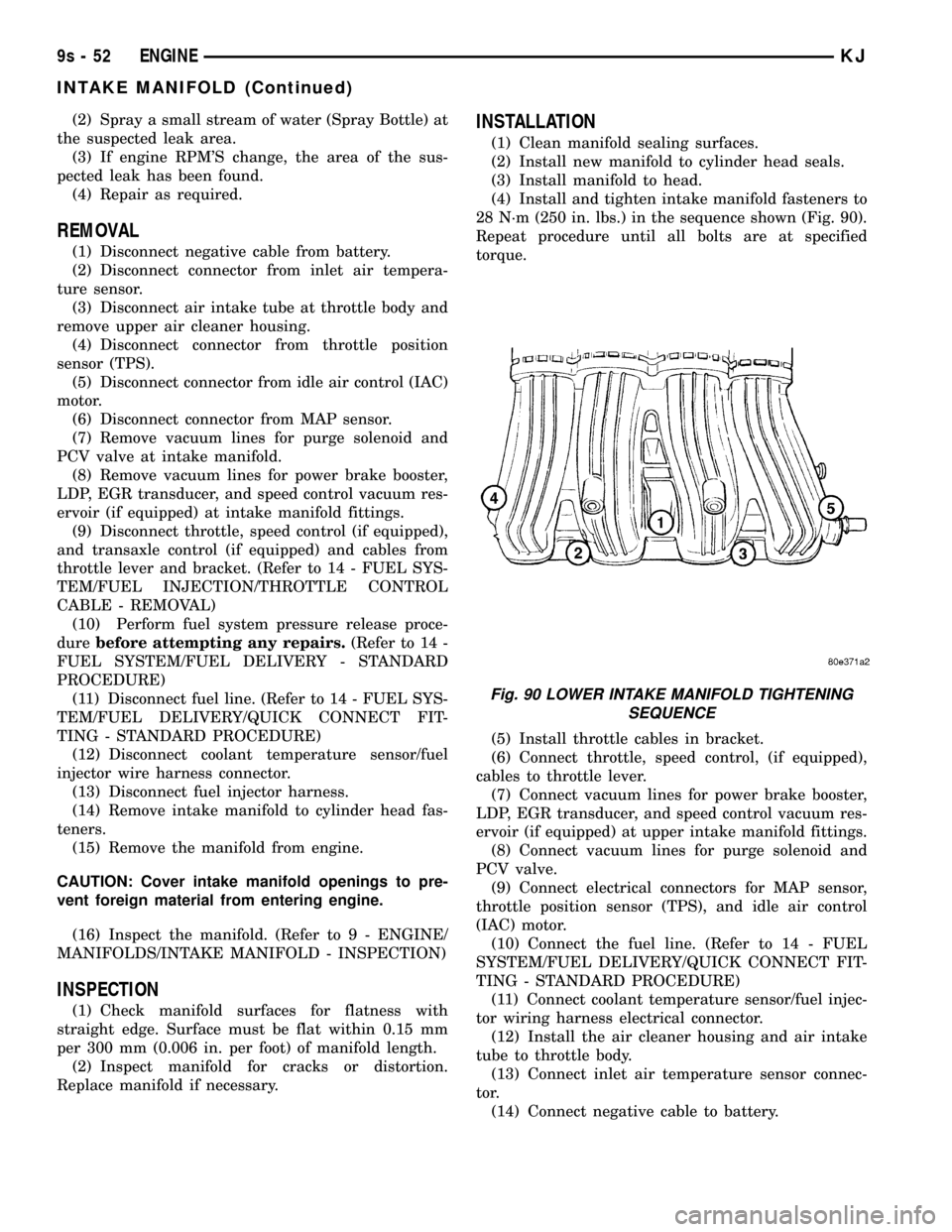

(4) Install and tighten intake manifold fasteners to

28 N´m (250 in. lbs.) in the sequence shown (Fig. 90).

Repeat procedure until all bolts are at specified

torque.

(5) Install throttle cables in bracket.

(6) Connect throttle, speed control, (if equipped),

cables to throttle lever.

(7) Connect vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

(8) Connect vacuum lines for purge solenoid and

PCV valve.

(9) Connect electrical connectors for MAP sensor,

throttle position sensor (TPS), and idle air control

(IAC) motor.

(10) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(11) Connect coolant temperature sensor/fuel injec-

tor wiring harness electrical connector.

(12) Install the air cleaner housing and air intake

tube to throttle body.

(13) Connect inlet air temperature sensor connec-

tor.

(14) Connect negative cable to battery.

Fig. 90 LOWER INTAKE MANIFOLD TIGHTENING

SEQUENCE

9s - 52 ENGINEKJ

INTAKE MANIFOLD (Continued)

Page 1350 of 1803

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifold is made of Hi-Silicone Moly

nodular cast iron for strength and high tempera-

tures. The manifold attaches to the cylinder head.

OPERATION

The exhaust manifold collects the exhaust gasses

exiting the combustion chambers. Then it channels

the exhaust gasses to the exhaust pipe attached to

the manifold.

REMOVAL

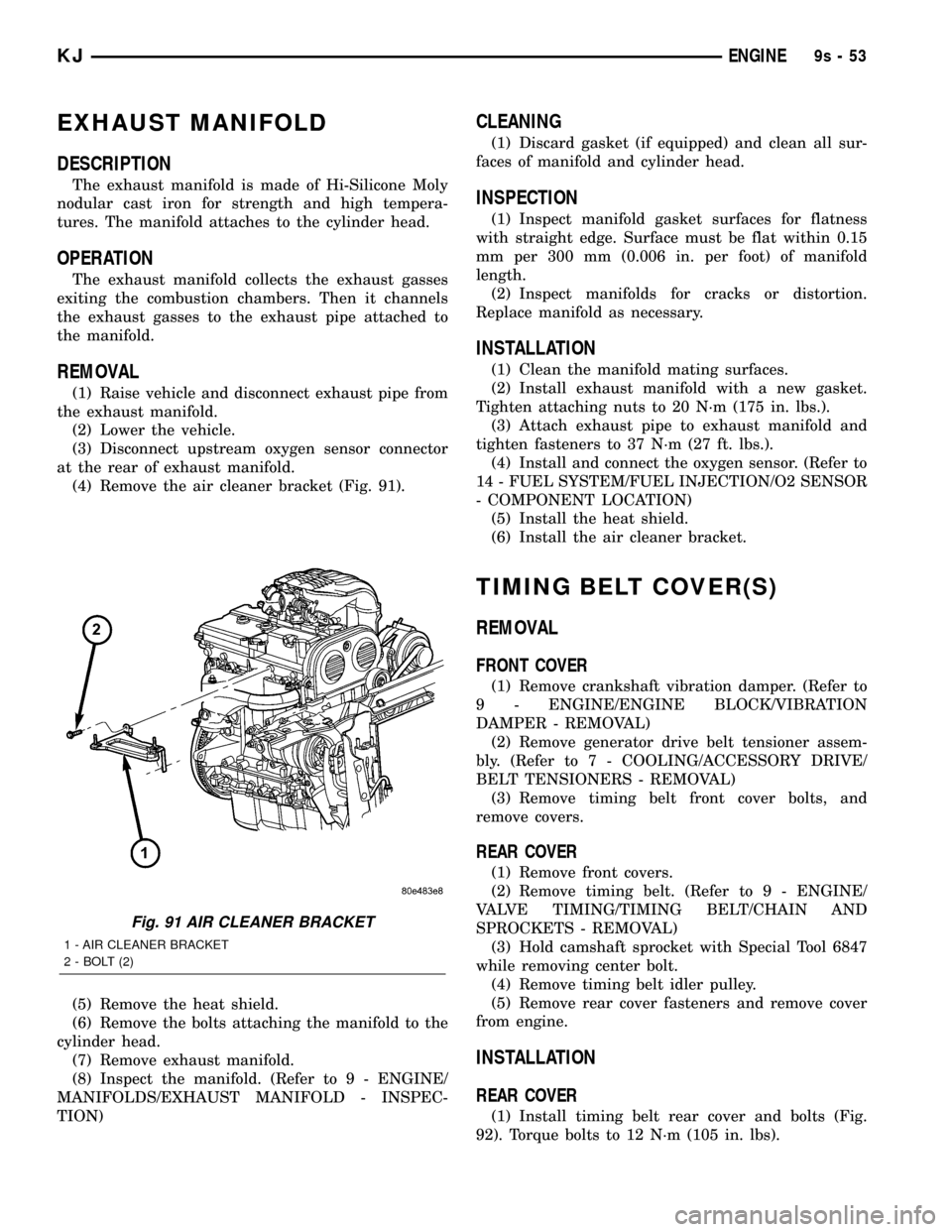

(1) Raise vehicle and disconnect exhaust pipe from

the exhaust manifold.

(2) Lower the vehicle.

(3) Disconnect upstream oxygen sensor connector

at the rear of exhaust manifold.

(4) Remove the air cleaner bracket (Fig. 91).

(5) Remove the heat shield.

(6) Remove the bolts attaching the manifold to the

cylinder head.

(7) Remove exhaust manifold.

(8) Inspect the manifold. (Refer to 9 - ENGINE/

MANIFOLDS/EXHAUST MANIFOLD - INSPEC-

TION)

CLEANING

(1) Discard gasket (if equipped) and clean all sur-

faces of manifold and cylinder head.

INSPECTION

(1) Inspect manifold gasket surfaces for flatness

with straight edge. Surface must be flat within 0.15

mm per 300 mm (0.006 in. per foot) of manifold

length.

(2) Inspect manifolds for cracks or distortion.

Replace manifold as necessary.

INSTALLATION

(1) Clean the manifold mating surfaces.

(2) Install exhaust manifold with a new gasket.

Tighten attaching nuts to 20 N´m (175 in. lbs.).

(3) Attach exhaust pipe to exhaust manifold and

tighten fasteners to 37 N´m (27 ft. lbs.).

(4) Install and connect the oxygen sensor. (Refer to

14 - FUEL SYSTEM/FUEL INJECTION/O2 SENSOR

- COMPONENT LOCATION)

(5) Install the heat shield.

(6) Install the air cleaner bracket.

TIMING BELT COVER(S)

REMOVAL

FRONT COVER

(1) Remove crankshaft vibration damper. (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(2) Remove generator drive belt tensioner assem-

bly. (Refer to 7 - COOLING/ACCESSORY DRIVE/

BELT TENSIONERS - REMOVAL)

(3) Remove timing belt front cover bolts, and

remove covers.

REAR COVER

(1) Remove front covers.

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Hold camshaft sprocket with Special Tool 6847

while removing center bolt.

(4) Remove timing belt idler pulley.

(5) Remove rear cover fasteners and remove cover

from engine.

INSTALLATION

REAR COVER

(1) Install timing belt rear cover and bolts (Fig.

92). Torque bolts to 12 N´m (105 in. lbs).

Fig. 91 AIR CLEANER BRACKET

1 - AIR CLEANER BRACKET

2 - BOLT (2)

KJENGINE9s-53

Page 1363 of 1803

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts to specified

torque at leaking joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts.

7. Catalytic converter rusted or

blown out.7. Replace catalytic converter assy.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

CAUTION:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct thecause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen the nuts from the clamp that hold the

catalytic converter to the exhaust pipe flange connec-

tion.

11 - 2 EXHAUST SYSTEMKJ

EXHAUST SYSTEM (Continued)

Page 1364 of 1803

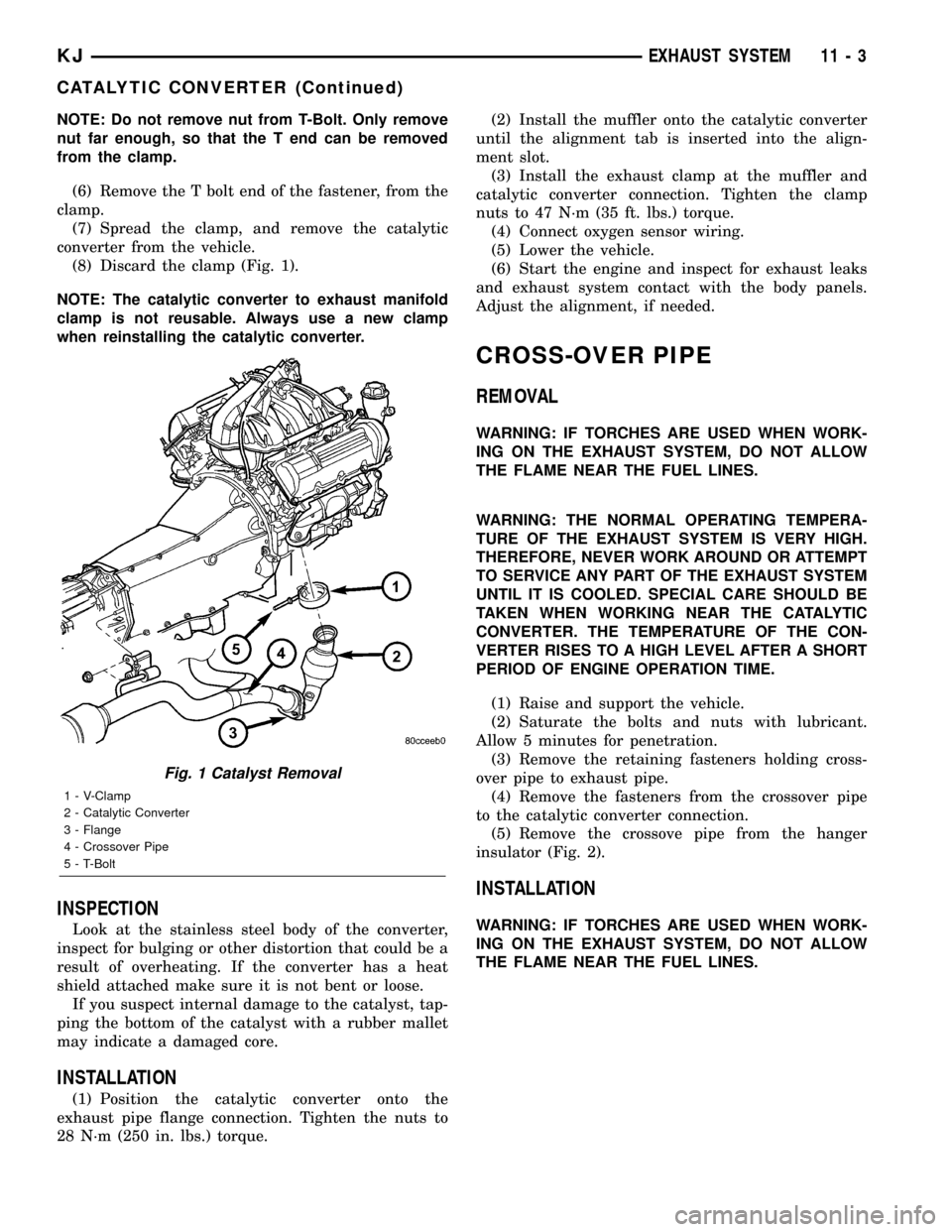

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(6) Remove the T bolt end of the fastener, from the

clamp.

(7) Spread the clamp, and remove the catalytic

converter from the vehicle.

(8) Discard the clamp (Fig. 1).

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Position the catalytic converter onto the

exhaust pipe flange connection. Tighten the nuts to

28 N´m (250 in. lbs.) torque.(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install the exhaust clamp at the muffler and

catalytic converter connection. Tighten the clamp

nuts to 47 N´m (35 ft. lbs.) torque.

(4) Connect oxygen sensor wiring.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

CROSS-OVER PIPE

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with lubricant.

Allow 5 minutes for penetration.

(3) Remove the retaining fasteners holding cross-

over pipe to exhaust pipe.

(4) Remove the fasteners from the crossover pipe

to the catalytic converter connection.

(5) Remove the crossove pipe from the hanger

insulator (Fig. 2).

INSTALLATION

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

Fig. 1 Catalyst Removal

1 - V-Clamp

2 - Catalytic Converter

3 - Flange

4 - Crossover Pipe

5 - T-Bolt

KJEXHAUST SYSTEM 11 - 3

CATALYTIC CONVERTER (Continued)