Body JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1349 of 1803

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect connector from inlet air tempera-

ture sensor.

(3) Disconnect air intake tube at throttle body and

remove upper air cleaner housing.

(4) Disconnect connector from throttle position

sensor (TPS).

(5) Disconnect connector from idle air control (IAC)

motor.

(6) Disconnect connector from MAP sensor.

(7) Remove vacuum lines for purge solenoid and

PCV valve at intake manifold.

(8) Remove vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at intake manifold fittings.

(9) Disconnect throttle, speed control (if equipped),

and transaxle control (if equipped) and cables from

throttle lever and bracket. (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/THROTTLE CONTROL

CABLE - REMOVAL)

(10) Perform fuel system pressure release proce-

durebefore attempting any repairs.(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE)

(11) Disconnect fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(12) Disconnect coolant temperature sensor/fuel

injector wire harness connector.

(13) Disconnect fuel injector harness.

(14) Remove intake manifold to cylinder head fas-

teners.

(15) Remove the manifold from engine.

CAUTION: Cover intake manifold openings to pre-

vent foreign material from entering engine.

(16) Inspect the manifold. (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSPECTION)

INSPECTION

(1) Check manifold surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (0.006 in. per foot) of manifold length.

(2) Inspect manifold for cracks or distortion.

Replace manifold if necessary.

INSTALLATION

(1) Clean manifold sealing surfaces.

(2) Install new manifold to cylinder head seals.

(3) Install manifold to head.

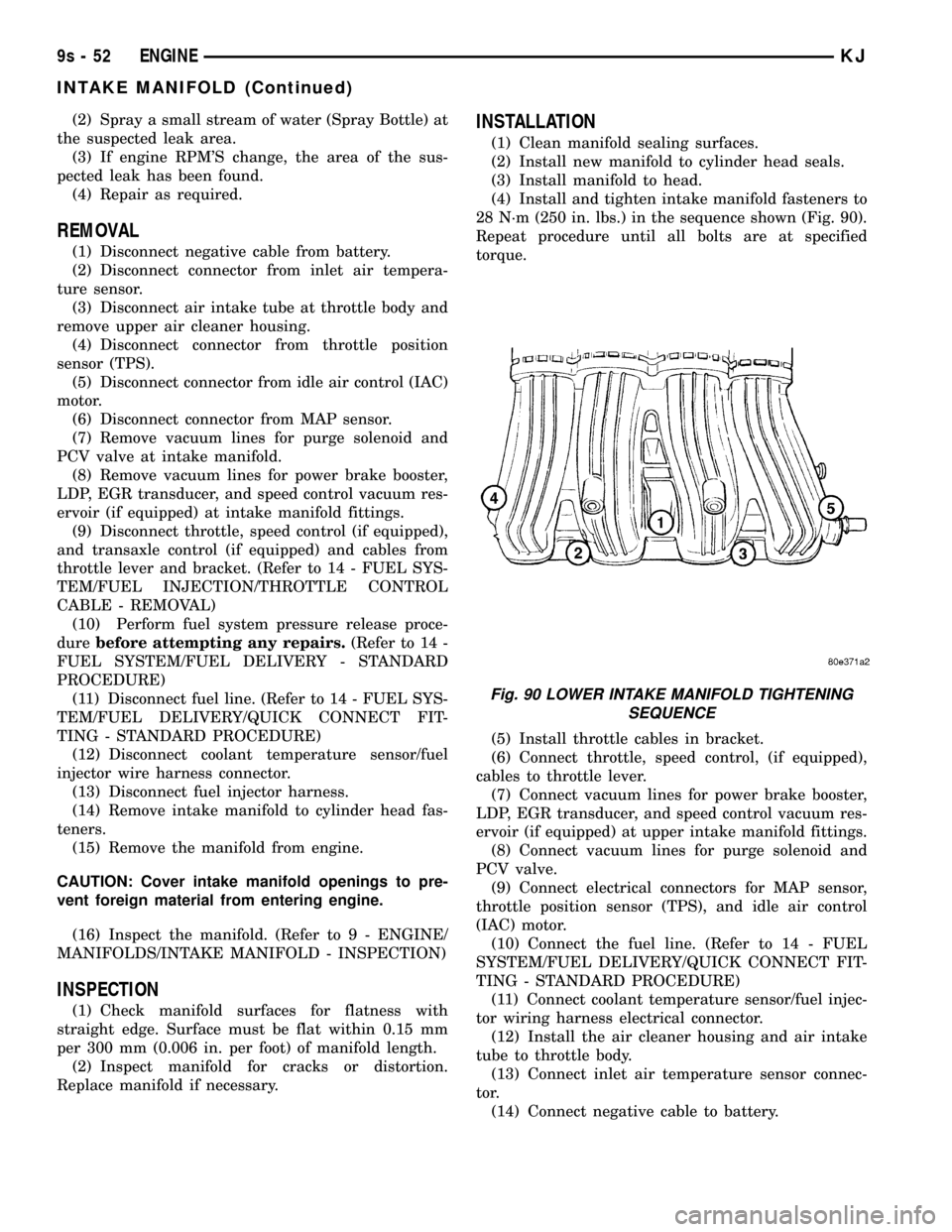

(4) Install and tighten intake manifold fasteners to

28 N´m (250 in. lbs.) in the sequence shown (Fig. 90).

Repeat procedure until all bolts are at specified

torque.

(5) Install throttle cables in bracket.

(6) Connect throttle, speed control, (if equipped),

cables to throttle lever.

(7) Connect vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

(8) Connect vacuum lines for purge solenoid and

PCV valve.

(9) Connect electrical connectors for MAP sensor,

throttle position sensor (TPS), and idle air control

(IAC) motor.

(10) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(11) Connect coolant temperature sensor/fuel injec-

tor wiring harness electrical connector.

(12) Install the air cleaner housing and air intake

tube to throttle body.

(13) Connect inlet air temperature sensor connec-

tor.

(14) Connect negative cable to battery.

Fig. 90 LOWER INTAKE MANIFOLD TIGHTENING

SEQUENCE

9s - 52 ENGINEKJ

INTAKE MANIFOLD (Continued)

Page 1362 of 1803

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION..........................1

DIAGNOSIS AND TESTING - EXHAUST

SYSTEM.............................2

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER.....2

REMOVAL.............................2

INSPECTION...........................3

INSTALLATION..........................3CROSS-OVER PIPE

REMOVAL.............................3

INSTALLATION..........................3

HEAT SHIELDS

DESCRIPTION..........................4

MUFFLER

DESCRIPTION..........................4

REMOVAL.............................5

INSTALLATION..........................5

EXHAUST SYSTEM

DESCRIPTION

The basic exhaust system consists of an engine

exhaust manifold, exhaust down pipe, exhaust pipe,

exhaust heat shield(s), muffler and exhaust tailpipe

The exhaust system uses a single muffler.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. If the sys-

tem contacts any body panel, it will transfer objec-

tionable noises originating from the engine to the

body.

When inspecting an exhaust system, critically

inspect for cracked or loose joints, stripped screw or

bolt threads, corrosion damage and worn, cracked orbroken hangers. Replace all components that are

badly corroded or damaged. DO NOT attempt to

repair.

When replacement is required, use original equip-

ment parts (or equivalent). This will assure proper

alignment and provide acceptable exhaust noise lev-

els.

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

KJEXHAUST SYSTEM 11 - 1

Page 1363 of 1803

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts to specified

torque at leaking joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts.

7. Catalytic converter rusted or

blown out.7. Replace catalytic converter assy.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

CAUTION:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct thecause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen the nuts from the clamp that hold the

catalytic converter to the exhaust pipe flange connec-

tion.

11 - 2 EXHAUST SYSTEMKJ

EXHAUST SYSTEM (Continued)

Page 1364 of 1803

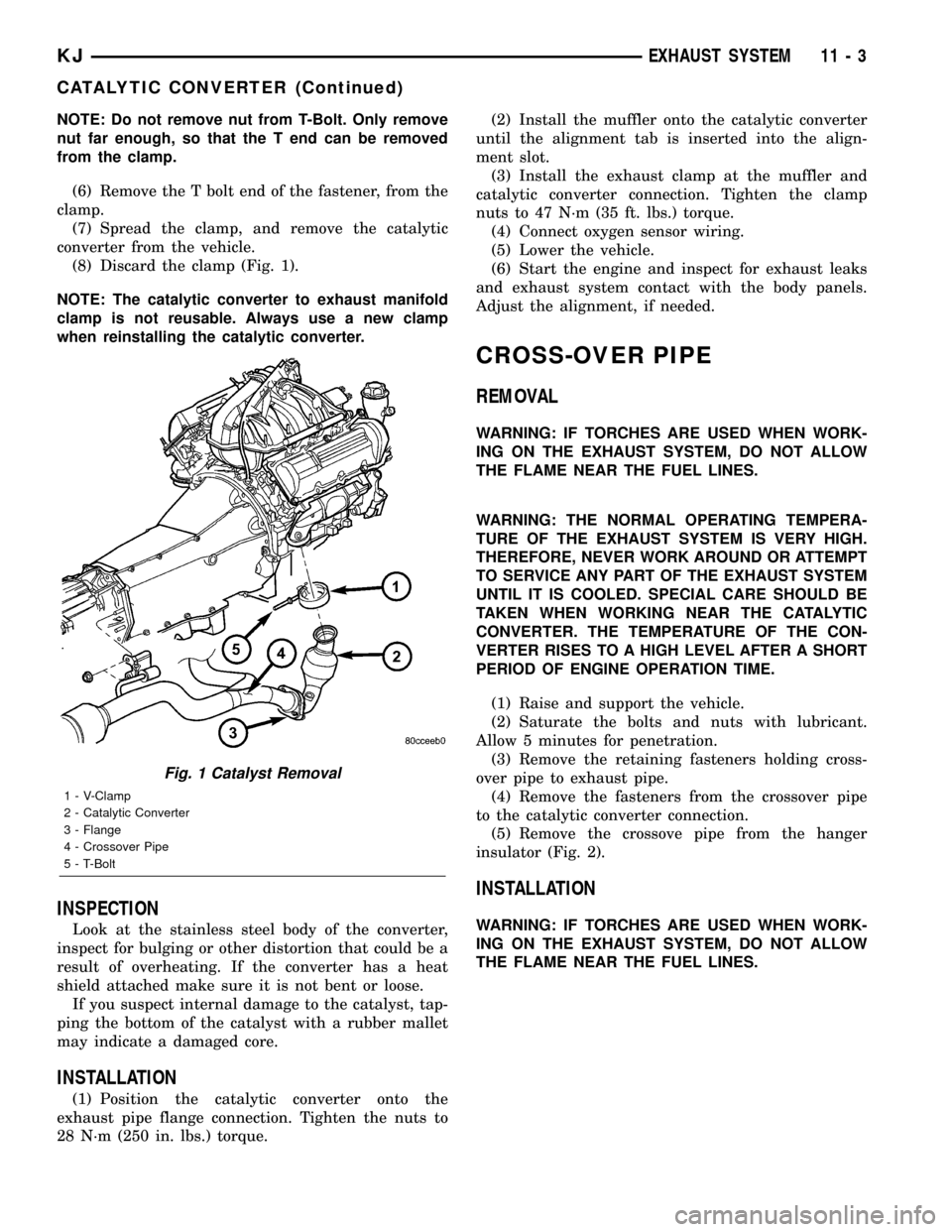

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(6) Remove the T bolt end of the fastener, from the

clamp.

(7) Spread the clamp, and remove the catalytic

converter from the vehicle.

(8) Discard the clamp (Fig. 1).

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Position the catalytic converter onto the

exhaust pipe flange connection. Tighten the nuts to

28 N´m (250 in. lbs.) torque.(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install the exhaust clamp at the muffler and

catalytic converter connection. Tighten the clamp

nuts to 47 N´m (35 ft. lbs.) torque.

(4) Connect oxygen sensor wiring.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

CROSS-OVER PIPE

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with lubricant.

Allow 5 minutes for penetration.

(3) Remove the retaining fasteners holding cross-

over pipe to exhaust pipe.

(4) Remove the fasteners from the crossover pipe

to the catalytic converter connection.

(5) Remove the crossove pipe from the hanger

insulator (Fig. 2).

INSTALLATION

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

Fig. 1 Catalyst Removal

1 - V-Clamp

2 - Catalytic Converter

3 - Flange

4 - Crossover Pipe

5 - T-Bolt

KJEXHAUST SYSTEM 11 - 3

CATALYTIC CONVERTER (Continued)

Page 1368 of 1803

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION..........................1

DIAGNOSIS AND TESTING - EXHAUST

SYSTEM.............................2

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER.....2

REMOVAL.............................2

INSPECTION...........................3

INSTALLATION..........................3CROSS-OVER PIPE

REMOVAL.............................4

INSTALLATION..........................4

HEAT SHIELDS

DESCRIPTION..........................4

MUFFLER

DESCRIPTION..........................4

REMOVAL.............................4

INSTALLATION..........................5

EXHAUST SYSTEM

DESCRIPTION

The basic exhaust system consists of an engine

exhaust manifold, exhaust down pipe, exhaust pipe,

exhaust heat shield(s), muffler and exhaust tailpipe

The exhaust system uses a single muffler.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. If the sys-

tem contacts any body panel, it will transfer objec-

tionable noises originating from the engine to the

body.

When inspecting an exhaust system, critically

inspect for cracked or loose joints, stripped screw or

bolt threads, corrosion damage and worn, cracked orbroken hangers. Replace all components that are

badly corroded or damaged. DO NOT attempt to

repair.

When replacement is required, use original equip-

ment parts (or equivalent). This will assure proper

alignment and provide acceptable exhaust noise lev-

els.

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

KJEXHAUST SYSTEM 11s - 1

Page 1369 of 1803

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts to specified

torque at leaking joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts.

7. Catalytic converter rusted or

blown out.7. Replace catalytic converter assy.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

CAUTION:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct thecause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen and remove the nuts from the clamp

that hold the catalytic converter to the exhaust pipe

flange connection.

11s - 2 EXHAUST SYSTEMKJ

EXHAUST SYSTEM (Continued)

Page 1370 of 1803

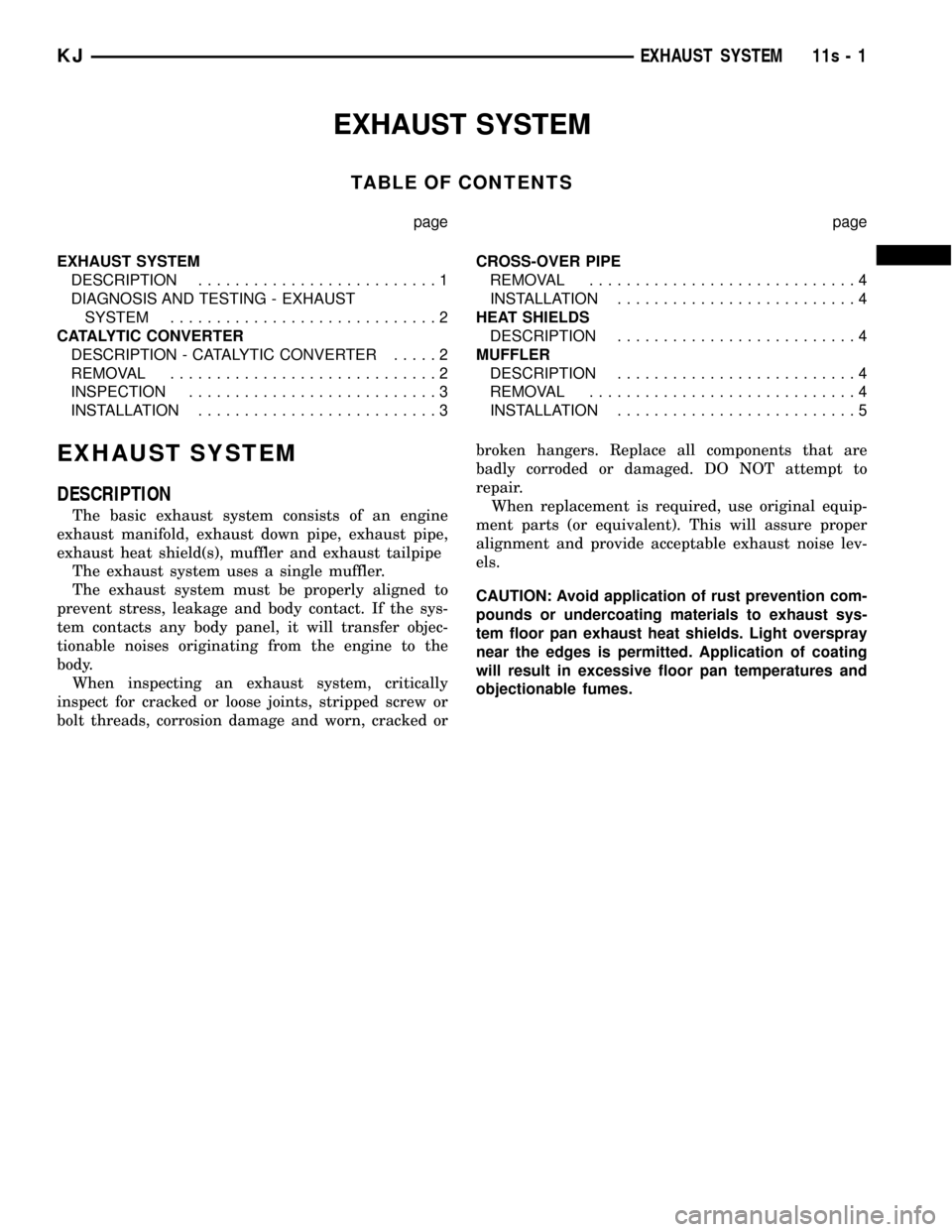

2.4L ENGINES

(1) Disconnect the oxygen sensors.

(2) Remove the two bolts and flanged nuts at the

manifold (Fig. 1).

(3) Lower the catalyst assembly and slide out of

the mount at the transmission (if equipped).

(4) Remove the catalyst assembly from the vehicle.

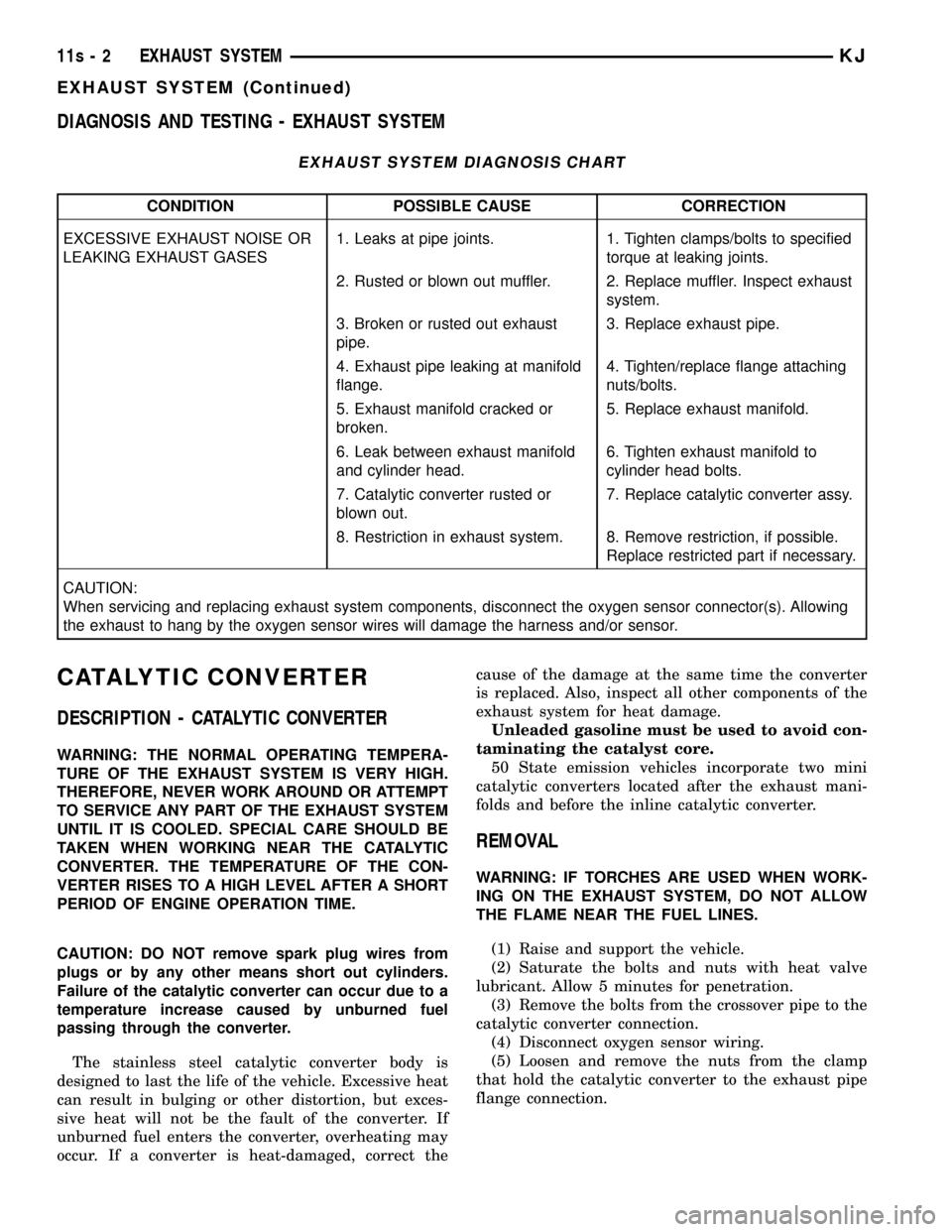

3.7L ENGINES

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(1) Remove the T bolt end of the fastener, from the

clamp.

(2) Spread the clamp, and remove the catalytic

converter from the vehicle.

(3) Discard the clamp (Fig. 2).

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Position the catalytic converter onto the

exhaust pipe flange connection. Tighten the nuts to

28 N´m (250 in. lbs.) torque.

(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install the exhaust clamp at the muffler and

catalytic converter connection. Tighten the clamp

nuts to 47 N´m (35 ft. lbs.) torque.

(4) Connect oxygen sensor wiring.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

Fig. 1 2.4L CATALYST ASSEMBLY - 4x4

1- FLANGED NUT

2- CATALYST ASSEMBLY

3- BOLT

4- HANGER

5- NUT

Fig. 2 Catalyst Removal

1 - V-Clamp

2 - Catalytic Converter

3 - Flange

4 - Crossover Pipe

5 - T-Bolt

KJEXHAUST SYSTEM 11s - 3

CATALYTIC CONVERTER (Continued)

Page 1374 of 1803

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

FRONT FASCIA

REMOVAL.............................1

INSTALLATION..........................2

REAR FASCIA

REMOVAL.............................2

INSTALLATION..........................2

REAR FASCIA SUPPORT

REMOVAL.............................3

INSTALLATION..........................3

FRAME

SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 3

SPECIFICATIONS - TORQUE.............6

FRONT SKID PLATE

REMOVAL.............................6

INSTALLATION..........................6

ENGINE CRADLE CROSSMEMBER

REMOVAL.............................6

INSTALLATION..........................6TRANSFER CASE SKID PLATE

REMOVAL.............................7

INSTALLATION..........................7

REAR CROSSMEMBER

REMOVAL.............................7

INSTALLATION..........................7

FRONT TOW HOOK

REMOVAL.............................8

INSTALLATION..........................8

REAR TOW HOOK

REMOVAL.............................8

INSTALLATION..........................8

TRAILER HITCH

REMOVAL.............................9

INSTALLATION..........................9

FUEL TANK SKID PLATE

REMOVAL.............................9

INSTALLATION..........................9

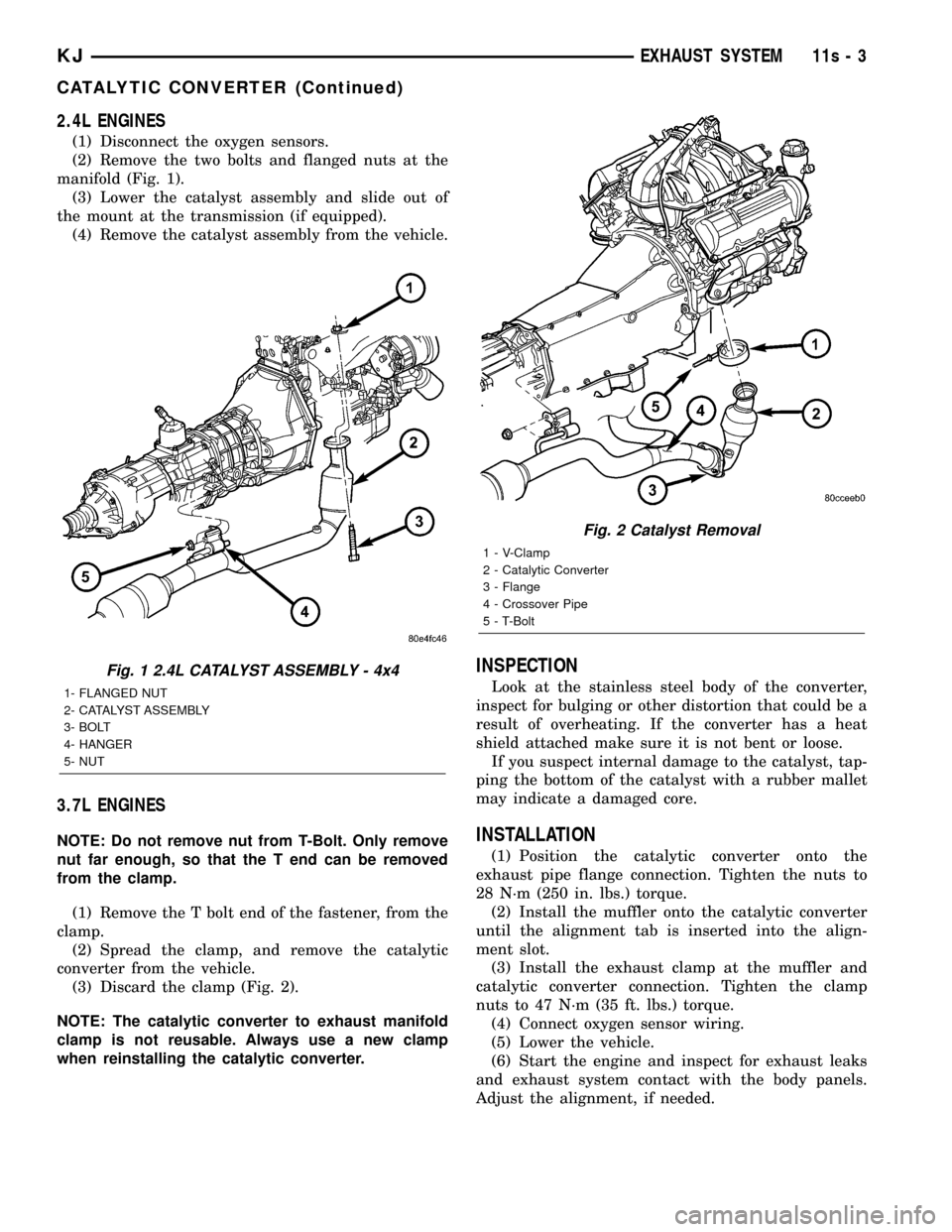

FRONT FASCIA

REMOVAL

(1) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(2) Raise and support vehicle.

(3) Remove the front wheel opening flare moldings.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL

OPENING FLARE MOLDINGS - REMOVAL)

(4) Remove the four screws through the lower air

dam (Fig. 1).

(5) Disconnect the electrical connectors:

²Fascia to grille opening reinforcement. (Fig. 1)

²Side repeater lights, both sides, if equipped.

(Fig. 2)

(6) Remove the six push pins from the grill sup-

port.

(7) Remove the rivets attaching the air dam to the

wheelhouse splash shield.

(8) Release the support tabs beneath the head-

lamps.

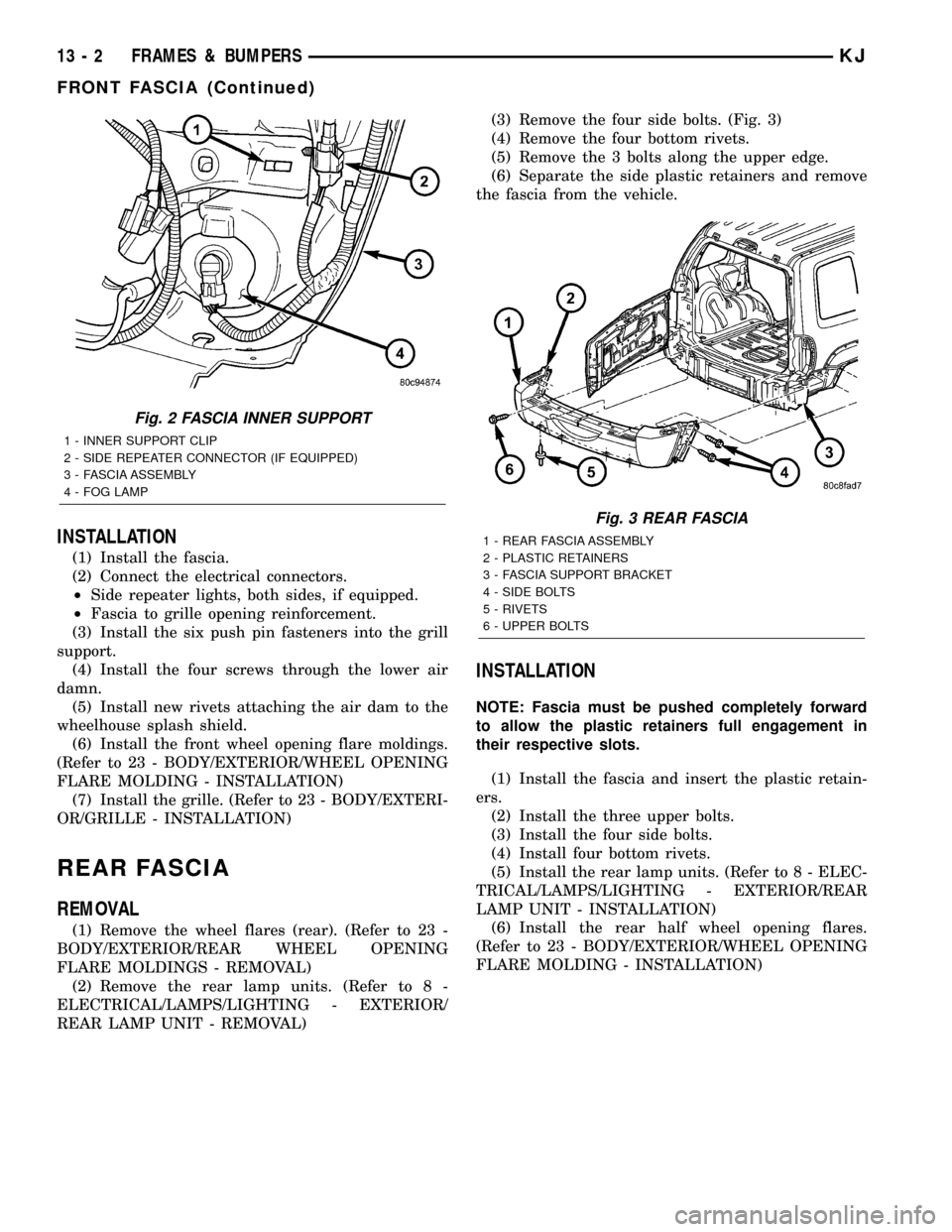

(9) Release the inner support clips from within the

fascia between the lights (Fig. 2).

(10) Remove the fascia.

Fig. 1 FRONT FASCIA

1 - ELECTRICAL CONNECTOR

2 - PUSH PINS

3 - FRONT FASCIA ASSEMBLY

4 - LOWER SCREWS

5 - PLASTIC RIVETS (2)

6 - INNER SUPPORT CLIPS

7 - SUPPORT TABS

KJFRAMES & BUMPERS 13 - 1

Page 1375 of 1803

INSTALLATION

(1) Install the fascia.

(2) Connect the electrical connectors.

²Side repeater lights, both sides, if equipped.

²Fascia to grille opening reinforcement.

(3) Install the six push pin fasteners into the grill

support.

(4) Install the four screws through the lower air

damn.

(5) Install new rivets attaching the air dam to the

wheelhouse splash shield.

(6) Install the front wheel opening flare moldings.

(Refer to 23 - BODY/EXTERIOR/WHEEL OPENING

FLARE MOLDING - INSTALLATION)

(7) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

REAR FASCIA

REMOVAL

(1) Remove the wheel flares (rear). (Refer to 23 -

BODY/EXTERIOR/REAR WHEEL OPENING

FLARE MOLDINGS - REMOVAL)

(2) Remove the rear lamp units. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

REAR LAMP UNIT - REMOVAL)(3) Remove the four side bolts. (Fig. 3)

(4) Remove the four bottom rivets.

(5) Remove the 3 bolts along the upper edge.

(6) Separate the side plastic retainers and remove

the fascia from the vehicle.

INSTALLATION

NOTE: Fascia must be pushed completely forward

to allow the plastic retainers full engagement in

their respective slots.

(1) Install the fascia and insert the plastic retain-

ers.

(2) Install the three upper bolts.

(3) Install the four side bolts.

(4) Install four bottom rivets.

(5) Install the rear lamp units. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/REAR

LAMP UNIT - INSTALLATION)

(6) Install the rear half wheel opening flares.

(Refer to 23 - BODY/EXTERIOR/WHEEL OPENING

FLARE MOLDING - INSTALLATION)

Fig. 2 FASCIA INNER SUPPORT

1 - INNER SUPPORT CLIP

2 - SIDE REPEATER CONNECTOR (IF EQUIPPED)

3 - FASCIA ASSEMBLY

4 - FOG LAMP

Fig. 3 REAR FASCIA

1 - REAR FASCIA ASSEMBLY

2 - PLASTIC RETAINERS

3 - FASCIA SUPPORT BRACKET

4 - SIDE BOLTS

5 - RIVETS

6 - UPPER BOLTS

13 - 2 FRAMES & BUMPERSKJ

FRONT FASCIA (Continued)

Page 1387 of 1803

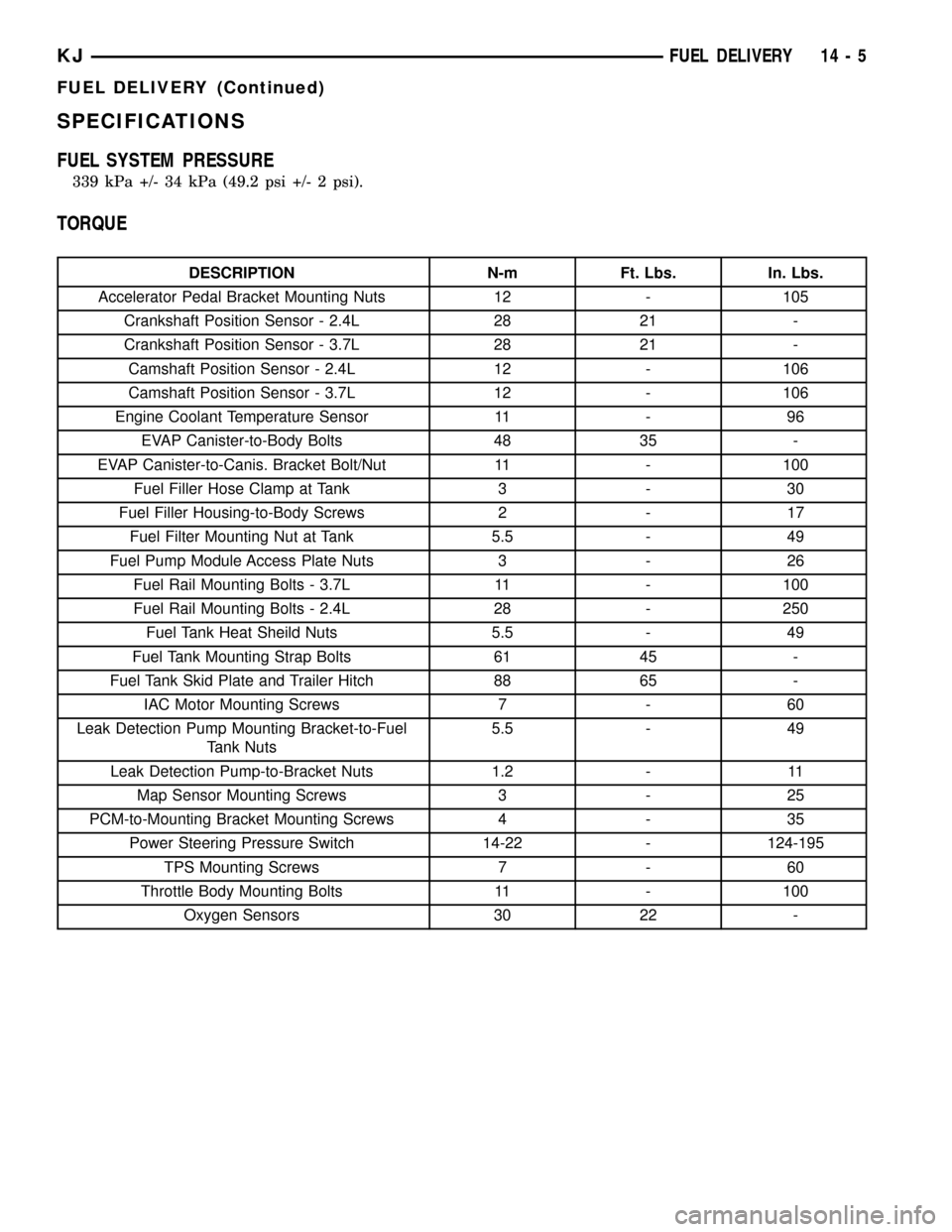

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa +/- 34 kPa (49.2 psi +/- 2 psi).

TORQUE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting Nuts 12 - 105

Crankshaft Position Sensor - 2.4L 28 21 -

Crankshaft Position Sensor - 3.7L 28 21 -

Camshaft Position Sensor - 2.4L 12 - 106

Camshaft Position Sensor - 3.7L 12 - 106

Engine Coolant Temperature Sensor 11 - 96

EVAP Canister-to-Body Bolts 48 35 -

EVAP Canister-to-Canis. Bracket Bolt/Nut 11 - 100

Fuel Filler Hose Clamp at Tank 3 - 30

Fuel Filler Housing-to-Body Screws 2 - 17

Fuel Filter Mounting Nut at Tank 5.5 - 49

Fuel Pump Module Access Plate Nuts 3 - 26

Fuel Rail Mounting Bolts - 3.7L 11 - 100

Fuel Rail Mounting Bolts - 2.4L 28 - 250

Fuel Tank Heat Sheild Nuts 5.5 - 49

Fuel Tank Mounting Strap Bolts 61 45 -

Fuel Tank Skid Plate and Trailer Hitch 88 65 -

IAC Motor Mounting Screws 7 - 60

Leak Detection Pump Mounting Bracket-to-Fuel

Tank Nuts5.5 - 49

Leak Detection Pump-to-Bracket Nuts 1.2 - 11

Map Sensor Mounting Screws 3 - 25

PCM-to-Mounting Bracket Mounting Screws 4 - 35

Power Steering Pressure Switch 14-22 - 124-195

TPS Mounting Screws 7 - 60

Throttle Body Mounting Bolts 11 - 100

Oxygen Sensors 30 22 -

KJFUEL DELIVERY 14 - 5

FUEL DELIVERY (Continued)