Electrical JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1424 of 1803

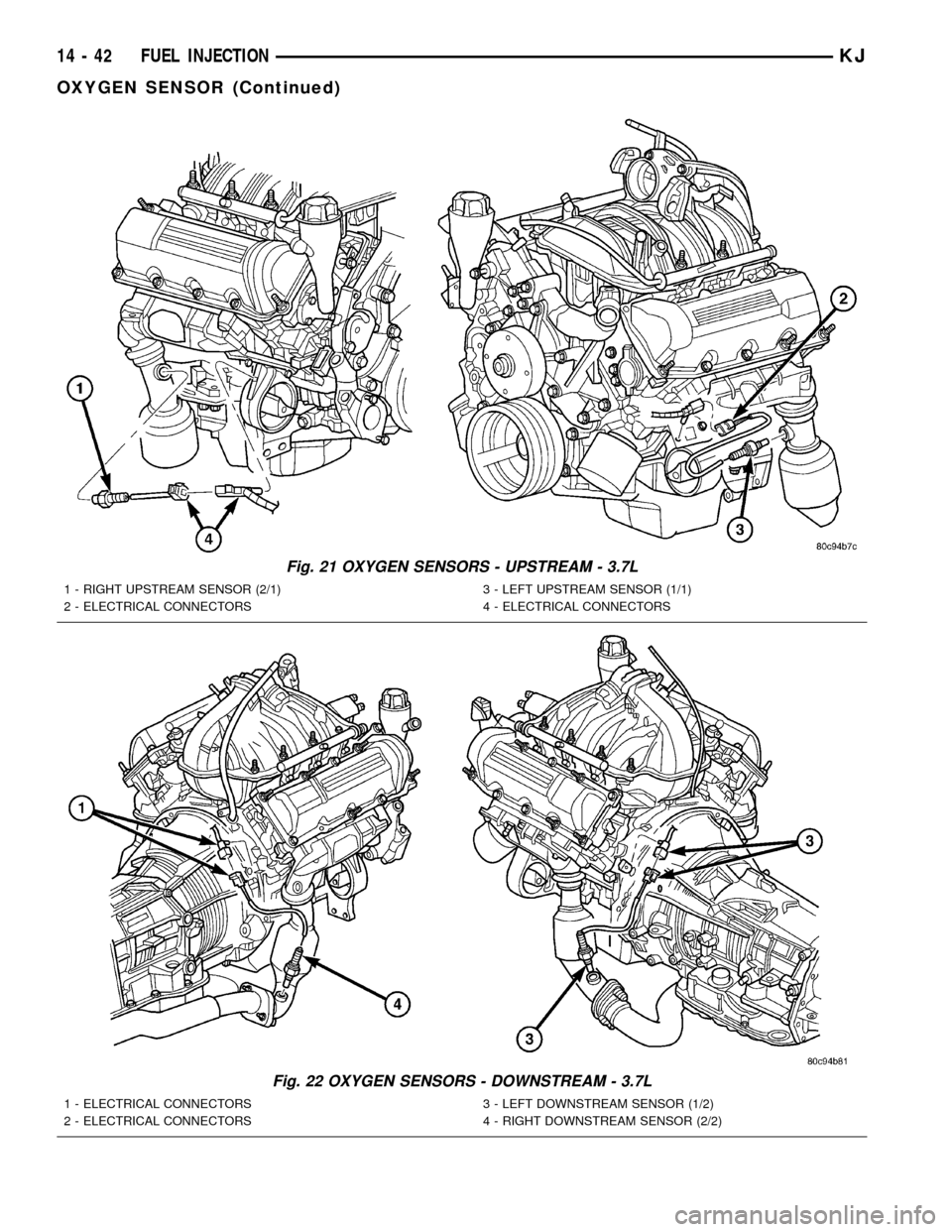

Fig. 21 OXYGEN SENSORS - UPSTREAM - 3.7L

1 - RIGHT UPSTREAM SENSOR (2/1)

2 - ELECTRICAL CONNECTORS3 - LEFT UPSTREAM SENSOR (1/1)

4 - ELECTRICAL CONNECTORS

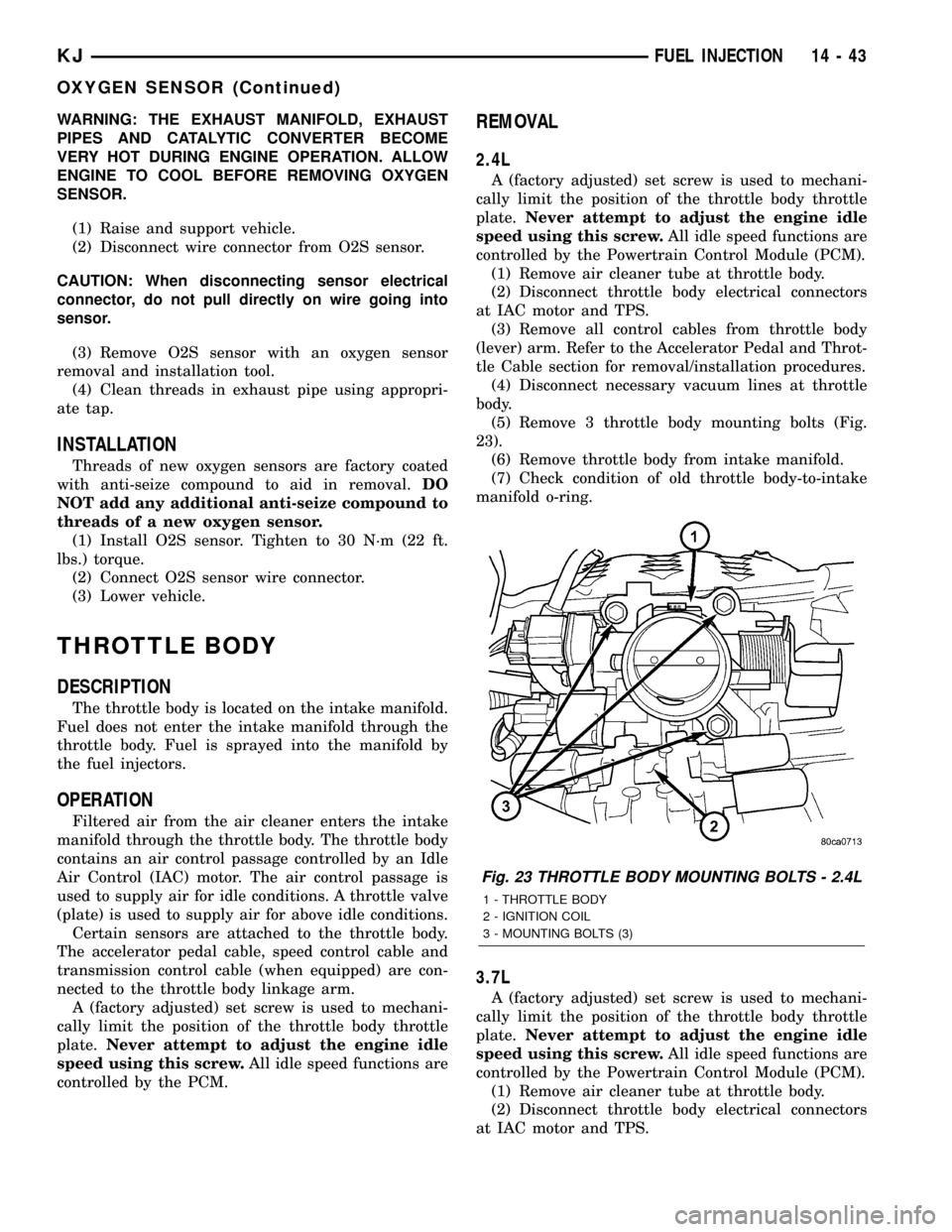

Fig. 22 OXYGEN SENSORS - DOWNSTREAM - 3.7L

1 - ELECTRICAL CONNECTORS

2 - ELECTRICAL CONNECTORS3 - LEFT DOWNSTREAM SENSOR (1/2)

4 - RIGHT DOWNSTREAM SENSOR (2/2)

14 - 42 FUEL INJECTIONKJ

OXYGEN SENSOR (Continued)

Page 1425 of 1803

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support vehicle.

(2) Disconnect wire connector from O2S sensor.

CAUTION: When disconnecting sensor electrical

connector, do not pull directly on wire going into

sensor.

(3) Remove O2S sensor with an oxygen sensor

removal and installation tool.

(4) Clean threads in exhaust pipe using appropri-

ate tap.

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

threads of a new oxygen sensor.

(1) Install O2S sensor. Tighten to 30 N´m (22 ft.

lbs.) torque.

(2) Connect O2S sensor wire connector.

(3) Lower vehicle.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

2.4L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

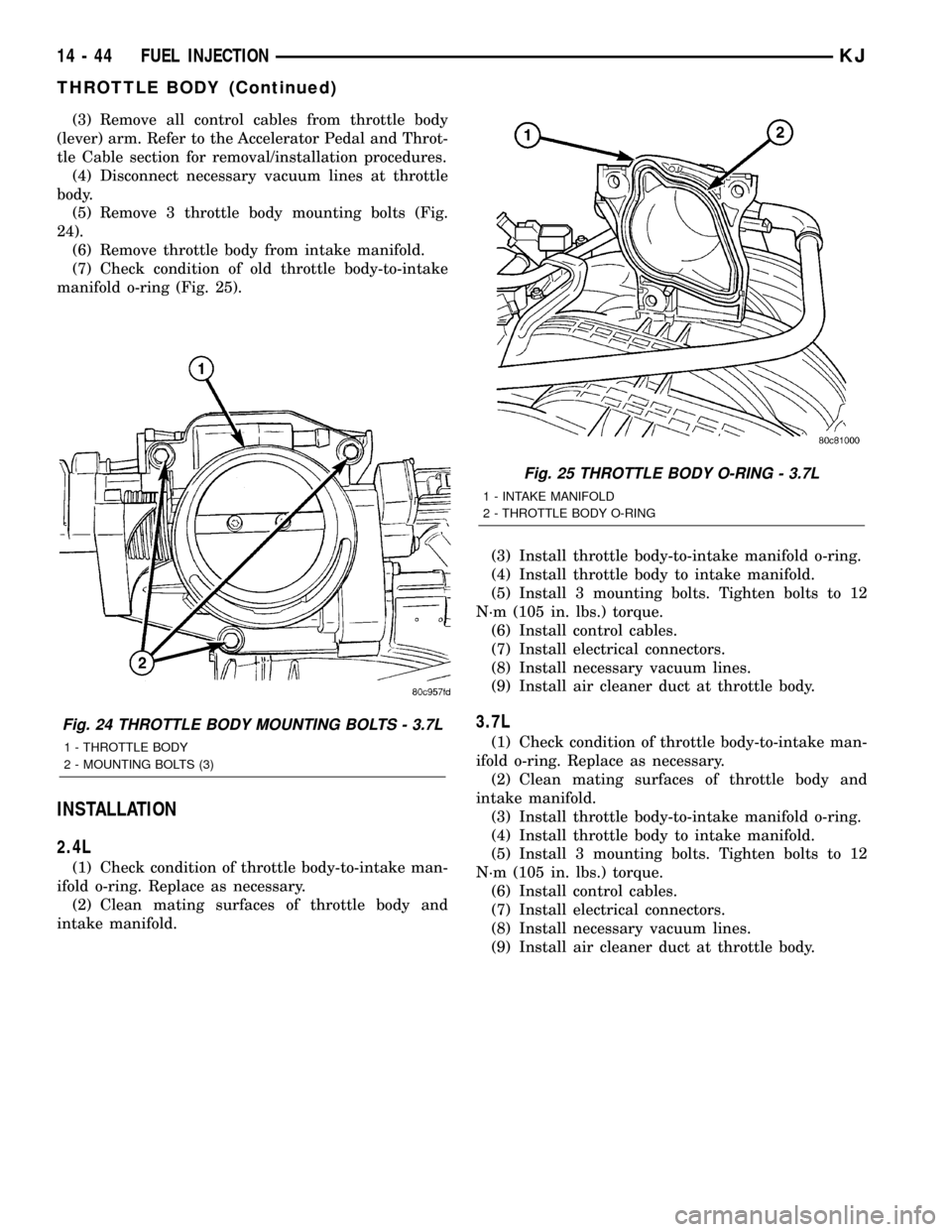

(5) Remove 3 throttle body mounting bolts (Fig.

23).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring.

3.7L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.

Fig. 23 THROTTLE BODY MOUNTING BOLTS - 2.4L

1 - THROTTLE BODY

2 - IGNITION COIL

3 - MOUNTING BOLTS (3)

KJFUEL INJECTION 14 - 43

OXYGEN SENSOR (Continued)

Page 1426 of 1803

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

(5) Remove 3 throttle body mounting bolts (Fig.

24).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring (Fig. 25).

INSTALLATION

2.4L

(1) Check condition of throttle body-to-intake man-

ifold o-ring. Replace as necessary.

(2) Clean mating surfaces of throttle body and

intake manifold.(3) Install throttle body-to-intake manifold o-ring.

(4) Install throttle body to intake manifold.

(5) Install 3 mounting bolts. Tighten bolts to 12

N´m (105 in. lbs.) torque.

(6) Install control cables.

(7) Install electrical connectors.

(8) Install necessary vacuum lines.

(9) Install air cleaner duct at throttle body.

3.7L

(1) Check condition of throttle body-to-intake man-

ifold o-ring. Replace as necessary.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body-to-intake manifold o-ring.

(4) Install throttle body to intake manifold.

(5) Install 3 mounting bolts. Tighten bolts to 12

N´m (105 in. lbs.) torque.

(6) Install control cables.

(7) Install electrical connectors.

(8) Install necessary vacuum lines.

(9) Install air cleaner duct at throttle body.

Fig. 24 THROTTLE BODY MOUNTING BOLTS - 3.7L

1 - THROTTLE BODY

2 - MOUNTING BOLTS (3)

Fig. 25 THROTTLE BODY O-RING - 3.7L

1 - INTAKE MANIFOLD

2 - THROTTLE BODY O-RING

14 - 44 FUEL INJECTIONKJ

THROTTLE BODY (Continued)

Page 1429 of 1803

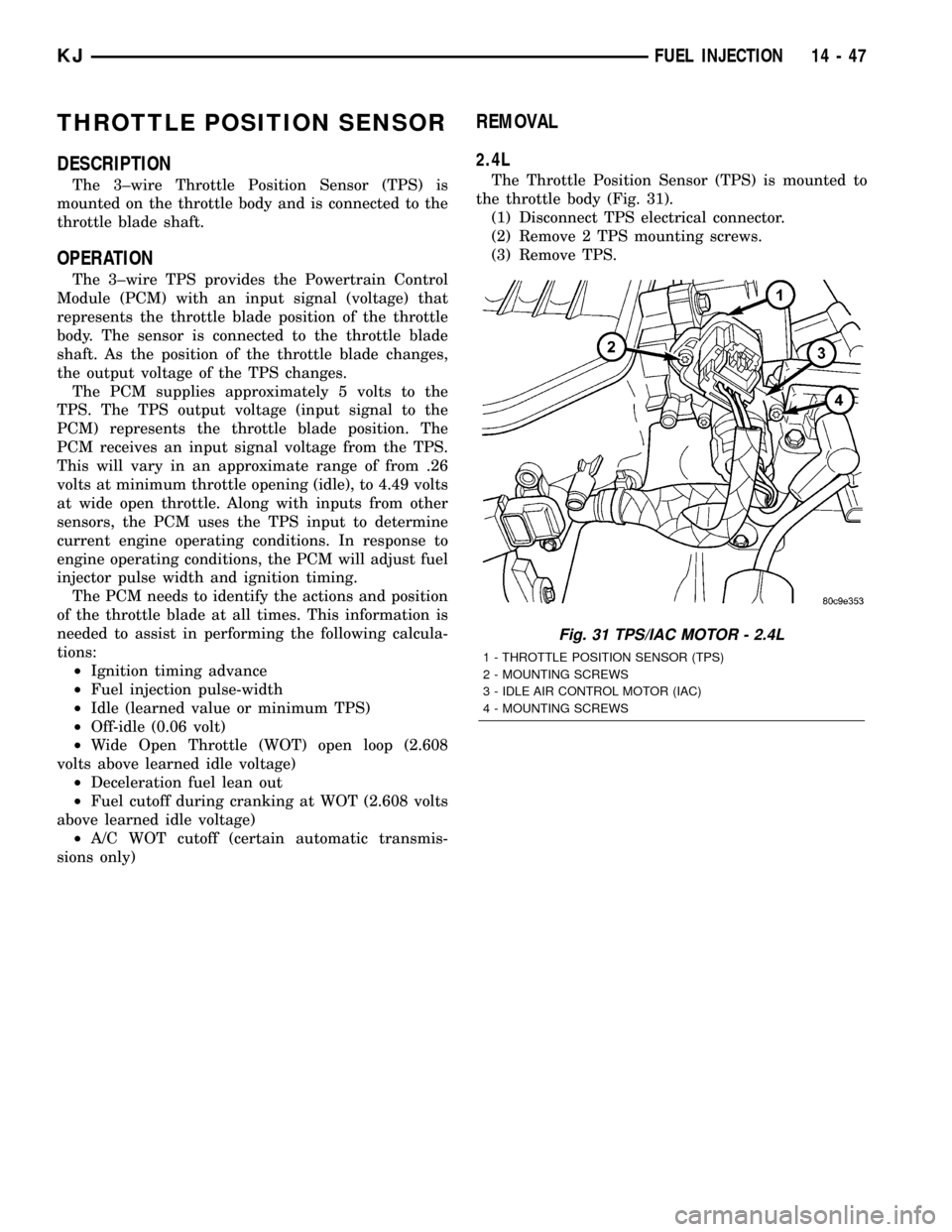

THROTTLE POSITION SENSOR

DESCRIPTION

The 3±wire Throttle Position Sensor (TPS) is

mounted on the throttle body and is connected to the

throttle blade shaft.

OPERATION

The 3±wire TPS provides the Powertrain Control

Module (PCM) with an input signal (voltage) that

represents the throttle blade position of the throttle

body. The sensor is connected to the throttle blade

shaft. As the position of the throttle blade changes,

the output voltage of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from .26

volts at minimum throttle opening (idle), to 4.49 volts

at wide open throttle. Along with inputs from other

sensors, the PCM uses the TPS input to determine

current engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.

The PCM needs to identify the actions and position

of the throttle blade at all times. This information is

needed to assist in performing the following calcula-

tions:

²Ignition timing advance

²Fuel injection pulse-width

²Idle (learned value or minimum TPS)

²Off-idle (0.06 volt)

²Wide Open Throttle (WOT) open loop (2.608

volts above learned idle voltage)

²Deceleration fuel lean out

²Fuel cutoff during cranking at WOT (2.608 volts

above learned idle voltage)

²A/C WOT cutoff (certain automatic transmis-

sions only)

REMOVAL

2.4L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 31).

(1) Disconnect TPS electrical connector.

(2) Remove 2 TPS mounting screws.

(3) Remove TPS.

Fig. 31 TPS/IAC MOTOR - 2.4L

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

KJFUEL INJECTION 14 - 47

Page 1430 of 1803

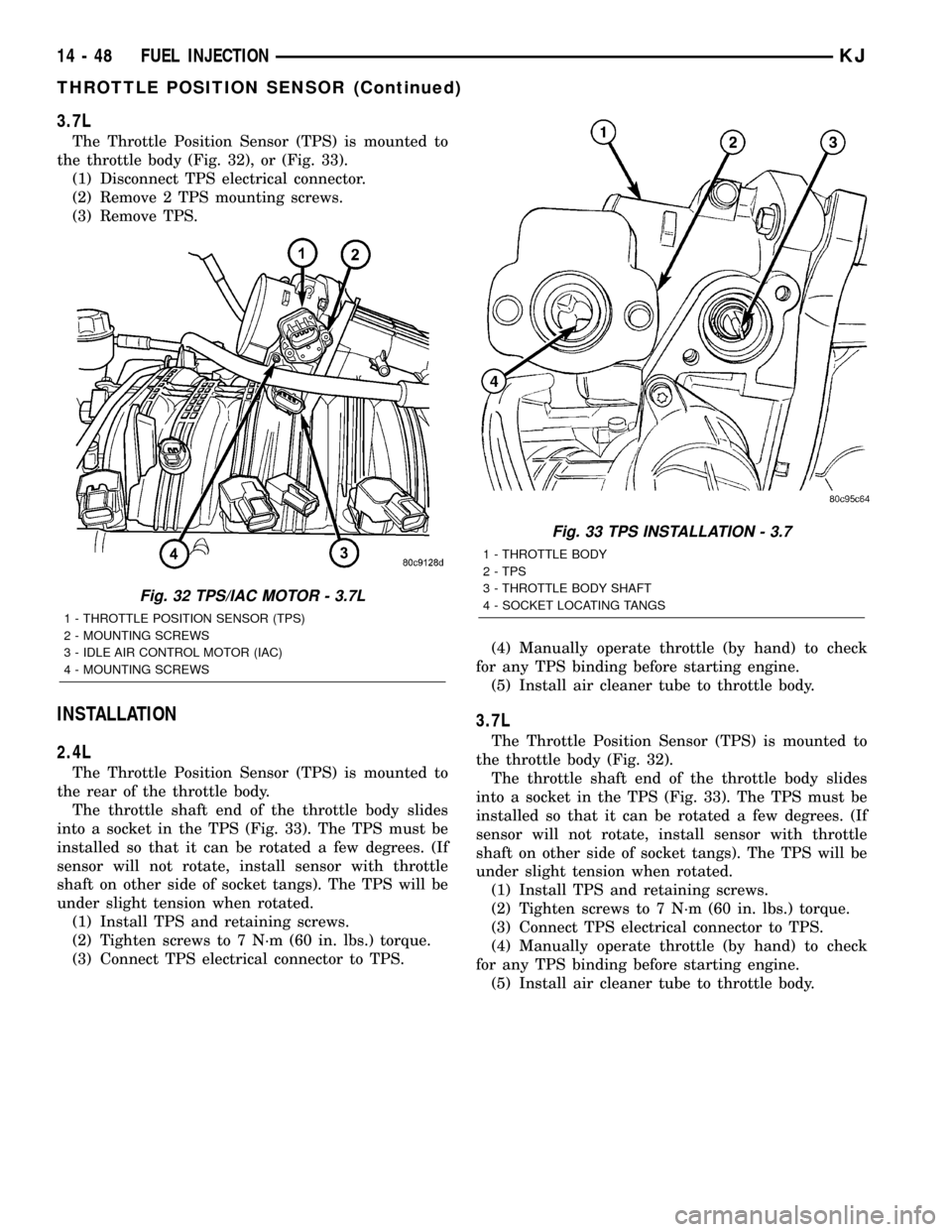

3.7L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 32), or (Fig. 33).

(1) Disconnect TPS electrical connector.

(2) Remove 2 TPS mounting screws.

(3) Remove TPS.

INSTALLATION

2.4L

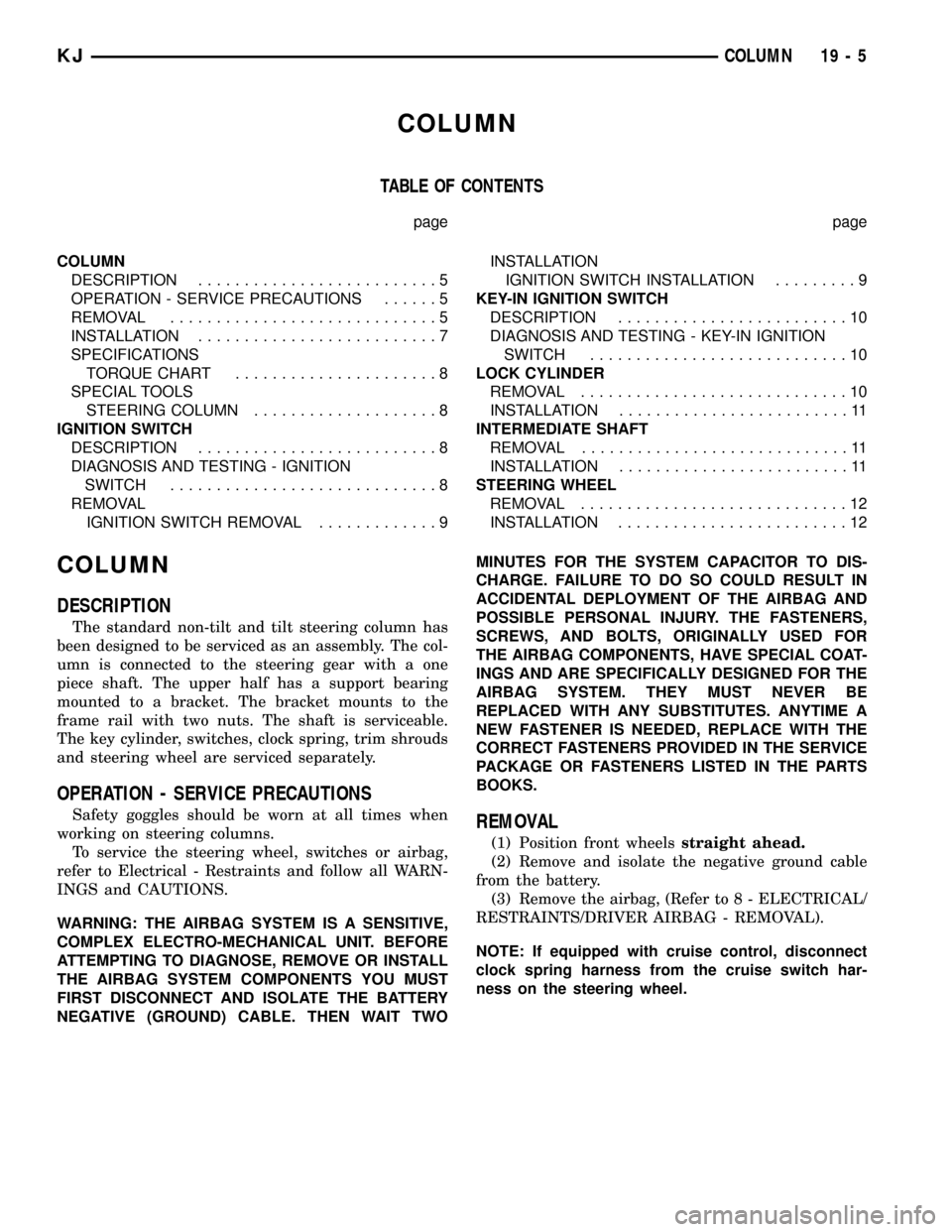

The Throttle Position Sensor (TPS) is mounted to

the rear of the throttle body.

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 33). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

3.7L

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 32).

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 33). The TPS must be

installed so that it can be rotated a few degrees. (If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs). The TPS will be

under slight tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

Fig. 32 TPS/IAC MOTOR - 3.7L

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

Fig. 33 TPS INSTALLATION - 3.7

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

14 - 48 FUEL INJECTIONKJ

THROTTLE POSITION SENSOR (Continued)

Page 1435 of 1803

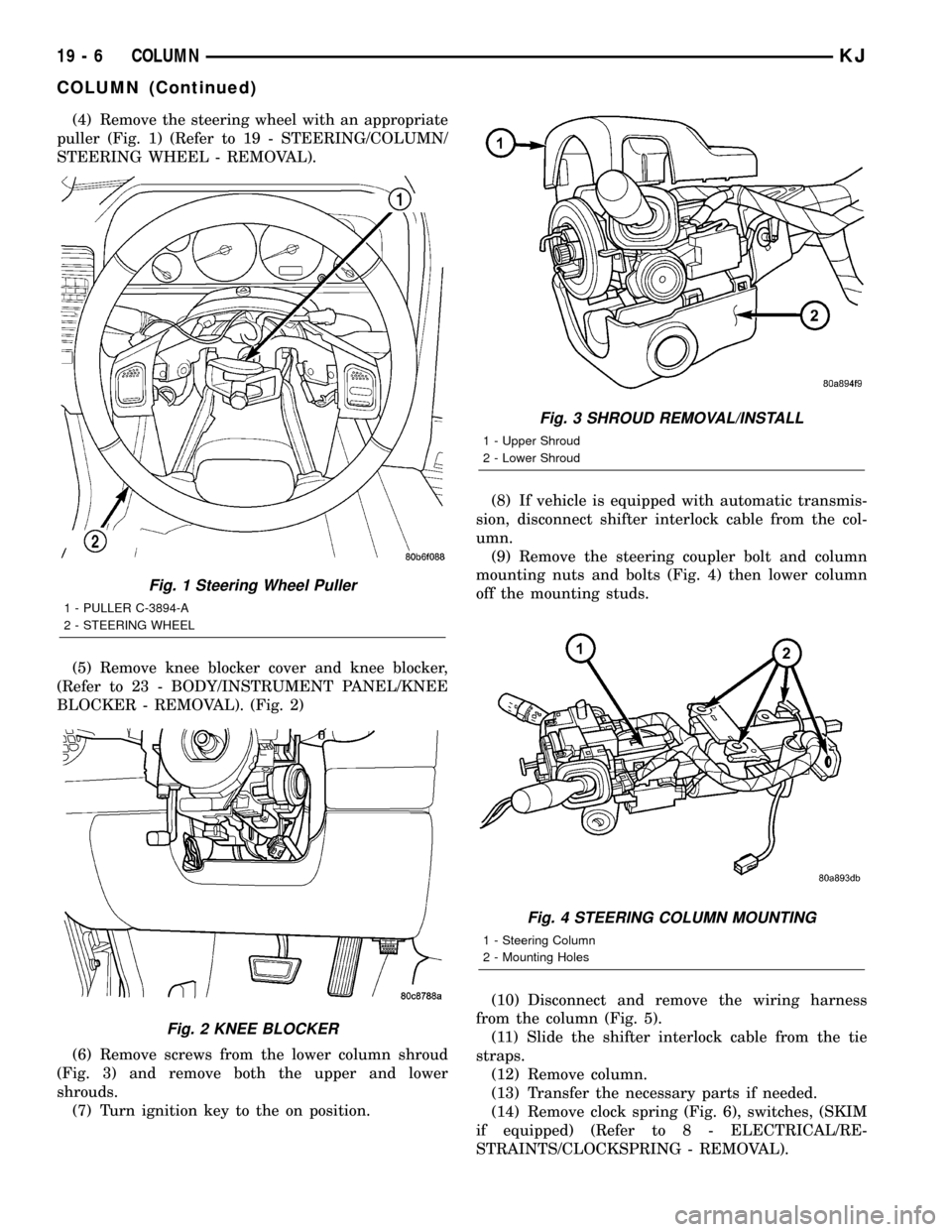

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION..........................5

OPERATION - SERVICE PRECAUTIONS......5

REMOVAL.............................5

INSTALLATION..........................7

SPECIFICATIONS

TORQUE CHART......................8

SPECIAL TOOLS

STEERING COLUMN....................8

IGNITION SWITCH

DESCRIPTION..........................8

DIAGNOSIS AND TESTING - IGNITION

SWITCH.............................8

REMOVAL

IGNITION SWITCH REMOVAL.............9INSTALLATION

IGNITION SWITCH INSTALLATION.........9

KEY-IN IGNITION SWITCH

DESCRIPTION.........................10

DIAGNOSIS AND TESTING - KEY-IN IGNITION

SWITCH............................10

LOCK CYLINDER

REMOVAL.............................10

INSTALLATION.........................11

INTERMEDIATE SHAFT

REMOVAL.............................11

INSTALLATION.........................11

STEERING WHEEL

REMOVAL.............................12

INSTALLATION.........................12

COLUMN

DESCRIPTION

The standard non-tilt and tilt steering column has

been designed to be serviced as an assembly. The col-

umn is connected to the steering gear with a one

piece shaft. The upper half has a support bearing

mounted to a bracket. The bracket mounts to the

frame rail with two nuts. The shaft is serviceable.

The key cylinder, switches, clock spring, trim shrouds

and steering wheel are serviced separately.

OPERATION - SERVICE PRECAUTIONS

Safety goggles should be worn at all times when

working on steering columns.

To service the steering wheel, switches or airbag,

refer to Electrical - Restraints and follow all WARN-

INGS and CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWOMINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.REMOVAL

(1) Position front wheelsstraight ahead.

(2) Remove and isolate the negative ground cable

from the battery.

(3) Remove the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

NOTE: If equipped with cruise control, disconnect

clock spring harness from the cruise switch har-

ness on the steering wheel.

KJCOLUMN 19 - 5

Page 1436 of 1803

(4) Remove the steering wheel with an appropriate

puller (Fig. 1) (Refer to 19 - STEERING/COLUMN/

STEERING WHEEL - REMOVAL).

(5) Remove knee blocker cover and knee blocker,

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL). (Fig. 2)

(6) Remove screws from the lower column shroud

(Fig. 3) and remove both the upper and lower

shrouds.

(7) Turn ignition key to the on position.(8) If vehicle is equipped with automatic transmis-

sion, disconnect shifter interlock cable from the col-

umn.

(9) Remove the steering coupler bolt and column

mounting nuts and bolts (Fig. 4) then lower column

off the mounting studs.

(10) Disconnect and remove the wiring harness

from the column (Fig. 5).

(11) Slide the shifter interlock cable from the tie

straps.

(12) Remove column.

(13) Transfer the necessary parts if needed.

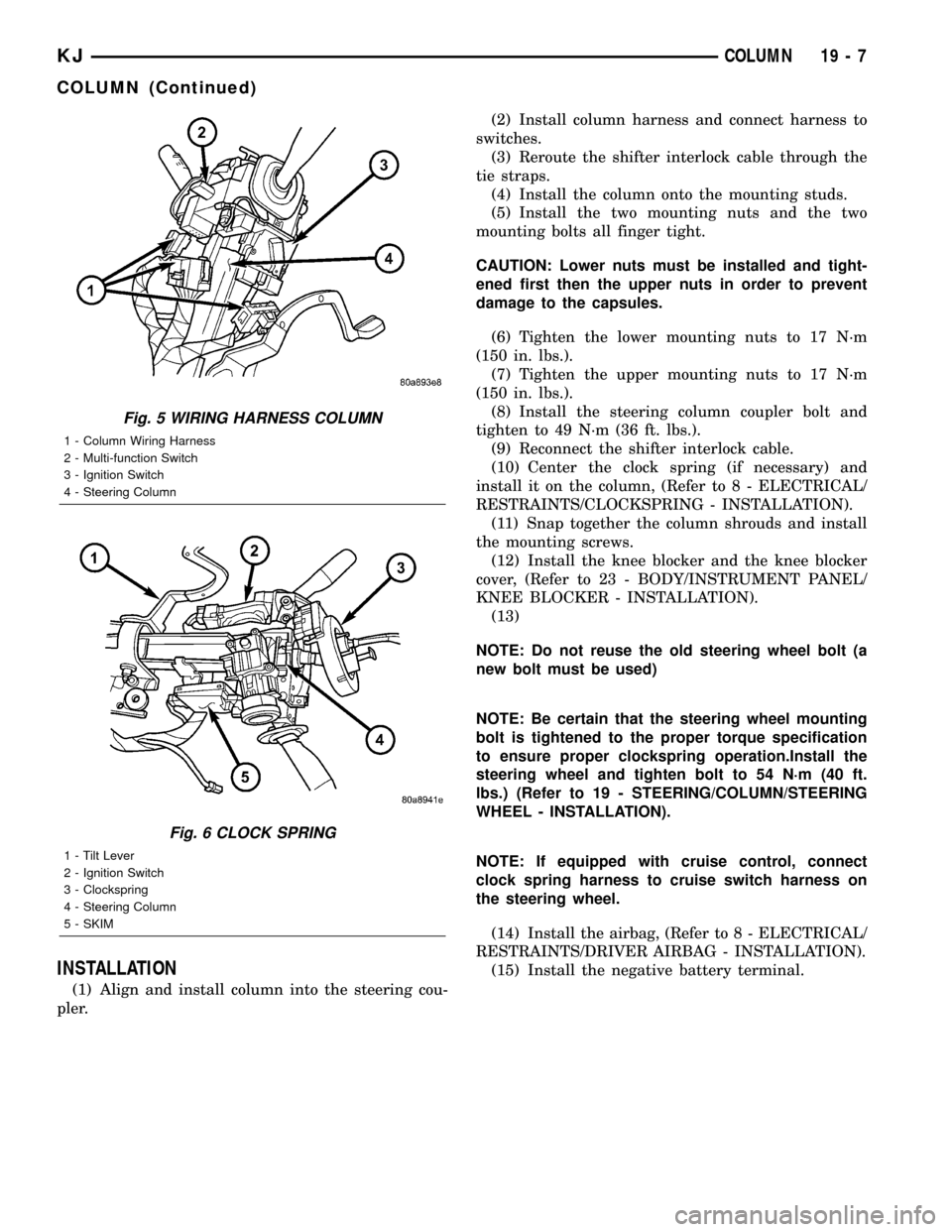

(14) Remove clock spring (Fig. 6), switches, (SKIM

if equipped) (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - REMOVAL).

Fig. 1 Steering Wheel Puller

1 - PULLER C-3894-A

2 - STEERING WHEEL

Fig. 2 KNEE BLOCKER

Fig. 3 SHROUD REMOVAL/INSTALL

1 - Upper Shroud

2 - Lower Shroud

Fig. 4 STEERING COLUMN MOUNTING

1 - Steering Column

2 - Mounting Holes

19 - 6 COLUMNKJ

COLUMN (Continued)

Page 1437 of 1803

INSTALLATION

(1) Align and install column into the steering cou-

pler.(2) Install column harness and connect harness to

switches.

(3) Reroute the shifter interlock cable through the

tie straps.

(4) Install the column onto the mounting studs.

(5) Install the two mounting nuts and the two

mounting bolts all finger tight.

CAUTION: Lower nuts must be installed and tight-

ened first then the upper nuts in order to prevent

damage to the capsules.

(6) Tighten the lower mounting nuts to 17 N´m

(150 in. lbs.).

(7) Tighten the upper mounting nuts to 17 N´m

(150 in. lbs.).

(8) Install the steering column coupler bolt and

tighten to 49 N´m (36 ft. lbs.).

(9) Reconnect the shifter interlock cable.

(10) Center the clock spring (if necessary) and

install it on the column, (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - INSTALLATION).

(11) Snap together the column shrouds and install

the mounting screws.

(12) Install the knee blocker and the knee blocker

cover, (Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - INSTALLATION).

(13)

NOTE: Do not reuse the old steering wheel bolt (a

new bolt must be used)

NOTE: Be certain that the steering wheel mounting

bolt is tightened to the proper torque specification

to ensure proper clockspring operation.Install the

steering wheel and tighten bolt to 54 N´m (40 ft.

lbs.) (Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - INSTALLATION).

NOTE: If equipped with cruise control, connect

clock spring harness to cruise switch harness on

the steering wheel.

(14) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(15) Install the negative battery terminal.

Fig. 5 WIRING HARNESS COLUMN

1 - Column Wiring Harness

2 - Multi-function Switch

3 - Ignition Switch

4 - Steering Column

Fig. 6 CLOCK SPRING

1 - Tilt Lever

2 - Ignition Switch

3 - Clockspring

4 - Steering Column

5 - SKIM

KJCOLUMN 19 - 7

COLUMN (Continued)

Page 1438 of 1803

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Tilt Steering Column

Steering Wheel Bolt54 40 Ð

Tilt Steering Column

Mounting Bolts17 Ð 150

Tilt Steering Column

Coupler Bolt49 36 Ð

Non-Tilt Steering Column

Steering Wheel Bolt54 40 Ð

Non-Tilt Steering Column

Mounting Bolts17 Ð 150

Non-Tilt Steering Column

Coupler Bolt49 36 Ð

Ignition Switch Screws 2 Ð 17

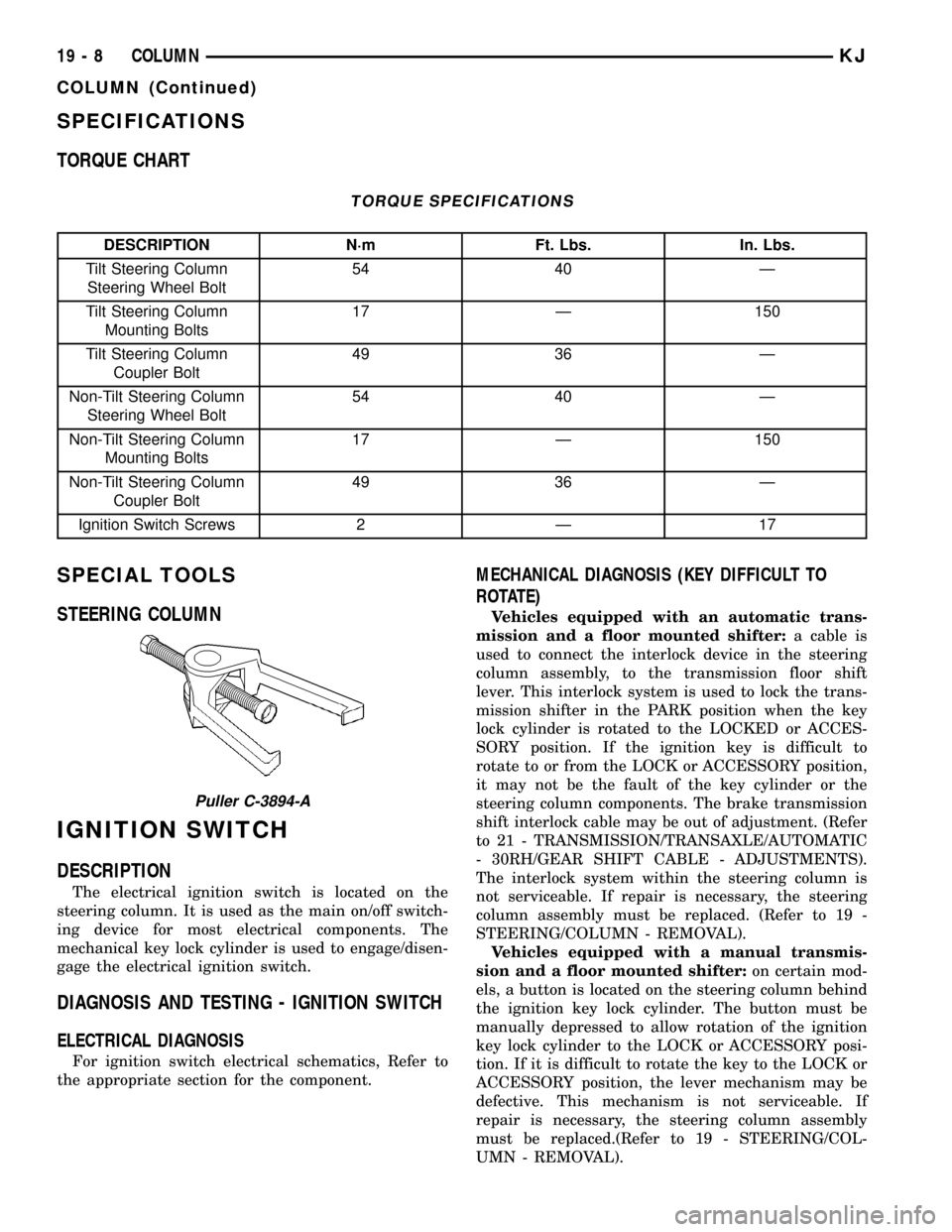

SPECIAL TOOLS

STEERING COLUMN

IGNITION SWITCH

DESCRIPTION

The electrical ignition switch is located on the

steering column. It is used as the main on/off switch-

ing device for most electrical components. The

mechanical key lock cylinder is used to engage/disen-

gage the electrical ignition switch.

DIAGNOSIS AND TESTING - IGNITION SWITCH

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, Refer to

the appropriate section for the component.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

Vehicles equipped with an automatic trans-

mission and a floor mounted shifter:a cable is

used to connect the interlock device in the steering

column assembly, to the transmission floor shift

lever. This interlock system is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is rotated to the LOCKED or ACCES-

SORY position. If the ignition key is difficult to

rotate to or from the LOCK or ACCESSORY position,

it may not be the fault of the key cylinder or the

steering column components. The brake transmission

shift interlock cable may be out of adjustment. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 30RH/GEAR SHIFT CABLE - ADJUSTMENTS).

The interlock system within the steering column is

not serviceable. If repair is necessary, the steering

column assembly must be replaced. (Refer to 19 -

STEERING/COLUMN - REMOVAL).

Vehicles equipped with a manual transmis-

sion and a floor mounted shifter:on certain mod-

els, a button is located on the steering column behind

the ignition key lock cylinder. The button must be

manually depressed to allow rotation of the ignition

key lock cylinder to the LOCK or ACCESSORY posi-

tion. If it is difficult to rotate the key to the LOCK or

ACCESSORY position, the lever mechanism may be

defective. This mechanism is not serviceable. If

repair is necessary, the steering column assembly

must be replaced.(Refer to 19 - STEERING/COL-

UMN - REMOVAL).

Puller C-3894-A

19 - 8 COLUMNKJ

COLUMN (Continued)

Page 1439 of 1803

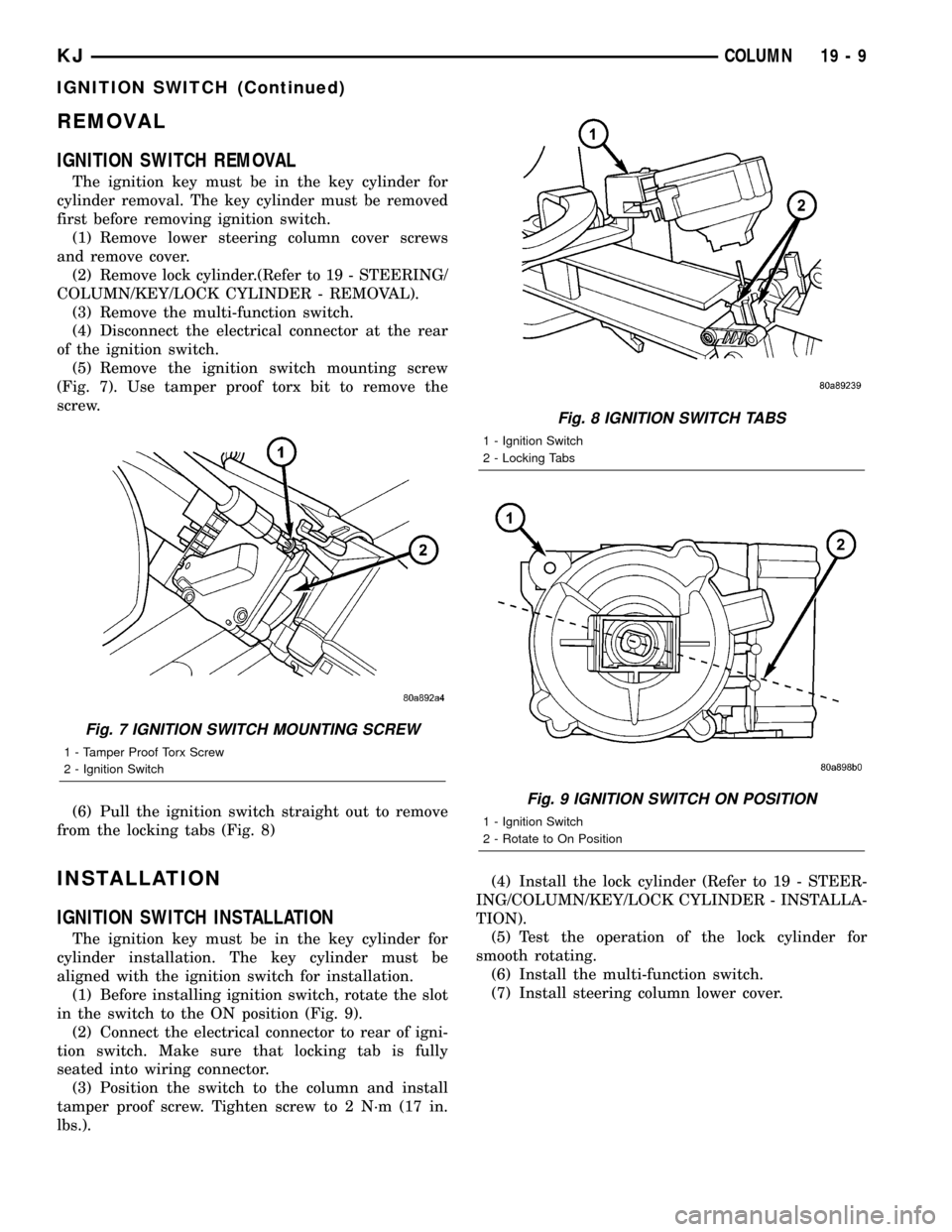

REMOVAL

IGNITION SWITCH REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Remove lower steering column cover screws

and remove cover.

(2) Remove lock cylinder.(Refer to 19 - STEERING/

COLUMN/KEY/LOCK CYLINDER - REMOVAL).

(3) Remove the multi-function switch.

(4) Disconnect the electrical connector at the rear

of the ignition switch.

(5) Remove the ignition switch mounting screw

(Fig. 7). Use tamper proof torx bit to remove the

screw.

(6) Pull the ignition switch straight out to remove

from the locking tabs (Fig. 8)

INSTALLATION

IGNITION SWITCH INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation. The key cylinder must be

aligned with the ignition switch for installation.

(1) Before installing ignition switch, rotate the slot

in the switch to the ON position (Fig. 9).

(2) Connect the electrical connector to rear of igni-

tion switch. Make sure that locking tab is fully

seated into wiring connector.

(3) Position the switch to the column and install

tamper proof screw. Tighten screw to 2 N´m (17 in.

lbs.).(4) Install the lock cylinder (Refer to 19 - STEER-

ING/COLUMN/KEY/LOCK CYLINDER - INSTALLA-

TION).

(5) Test the operation of the lock cylinder for

smooth rotating.

(6) Install the multi-function switch.

(7) Install steering column lower cover.

Fig. 7 IGNITION SWITCH MOUNTING SCREW

1 - Tamper Proof Torx Screw

2 - Ignition Switch

Fig. 8 IGNITION SWITCH TABS

1 - Ignition Switch

2 - Locking Tabs

Fig. 9 IGNITION SWITCH ON POSITION

1 - Ignition Switch

2 - Rotate to On Position

KJCOLUMN 19 - 9

IGNITION SWITCH (Continued)