Electrical JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1440 of 1803

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the left side of the

steering column, opposite the ignition lock cylinder.

It closes a path to ground for the instrument cluster

chime warning circuitry when the ignition key is

inserted in the ignition lock cylinder and the driver

door jamb switch is closed (driver door is open). The

key-in ignition switch opens the ground path when

the key is removed from the ignition lock cylinder.

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced. (Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - KEY-IN IGNITION

SWITCH

For circuit descriptions and diagrams, Refer to the

appropriate sections on the individual components.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the steering column shrouds. Unplug

the key-in ignition switch wire harness connector

from the ignition switch.

(2) Check for continuity between the key-in switch

sense circuit and the left front door jamb switch

sense circuit terminals of the key-in ignition switch.

There should be continuity with the key in the igni-

tion lock cylinder, and no continuity with the key

removed from the ignition lock cylinder. If OK, go to

Step 3. If not OK, replace the faulty ignition switch

assembly.

(3) Check for continuity between the left front door

jamb switch sense circuit cavity of the key-in ignition

switch wire harness connector and a good ground.

There should be continuity with the driver door open,

and no continuity with the driver door closed. If OK,

see the diagnosis for Instrument Cluster in this

group. If not OK, repair the circuit to the driver door

jamb switch as required.

LOCK CYLINDER

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) If equipped with an automatic transmission,

place shifter in PARK position.

(2) Remove the lower shroud cover.

(3) Remove the remote keyless entry (R.K.E.) mod-

ule.

(4) Remove the halo ring around the lock cylinder.

(5) Rotate key to ON position.

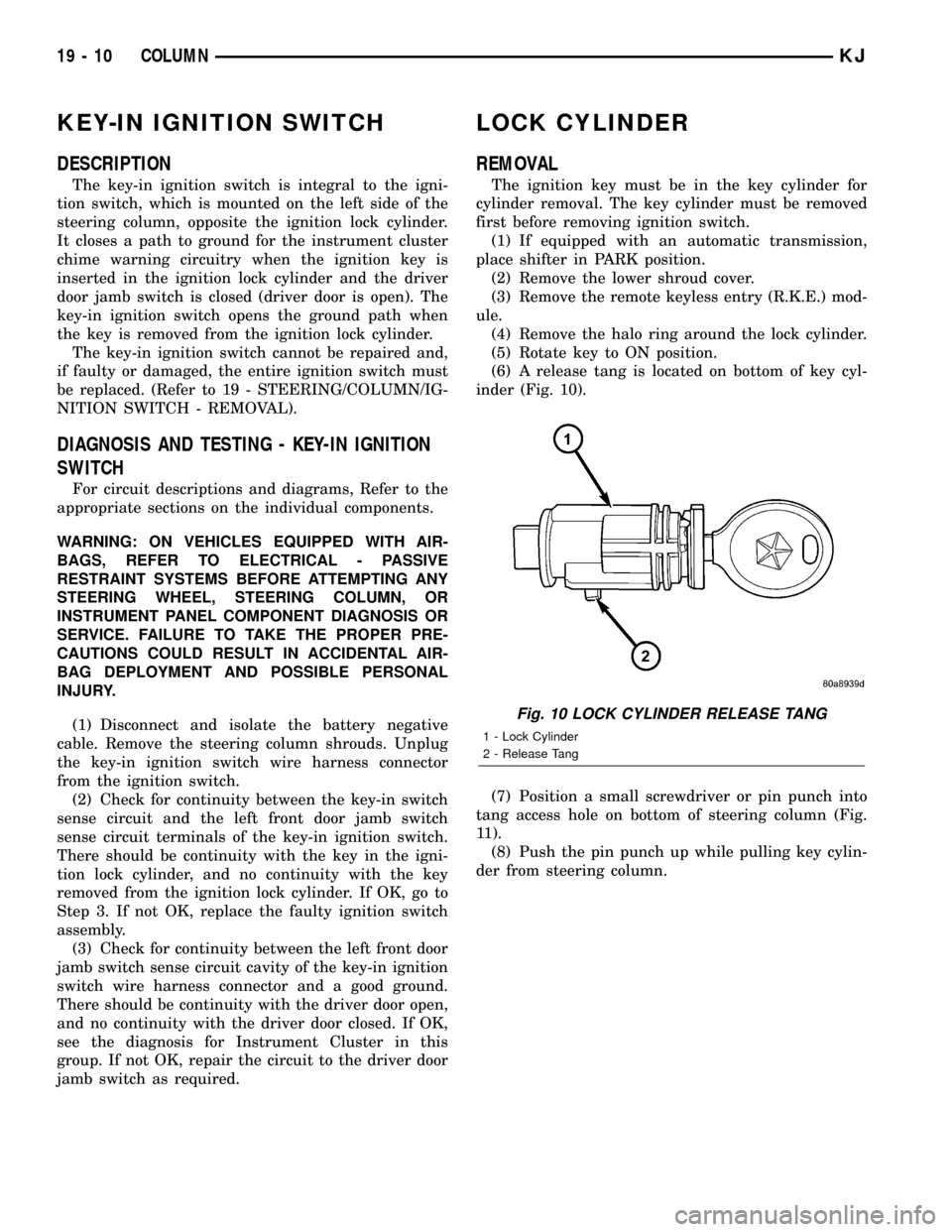

(6) A release tang is located on bottom of key cyl-

inder (Fig. 10).

(7) Position a small screwdriver or pin punch into

tang access hole on bottom of steering column (Fig.

11).

(8) Push the pin punch up while pulling key cylin-

der from steering column.

Fig. 10 LOCK CYLINDER RELEASE TANG

1 - Lock Cylinder

2 - Release Tang

19 - 10 COLUMNKJ

Page 1442 of 1803

STEERING WHEEL

REMOVAL

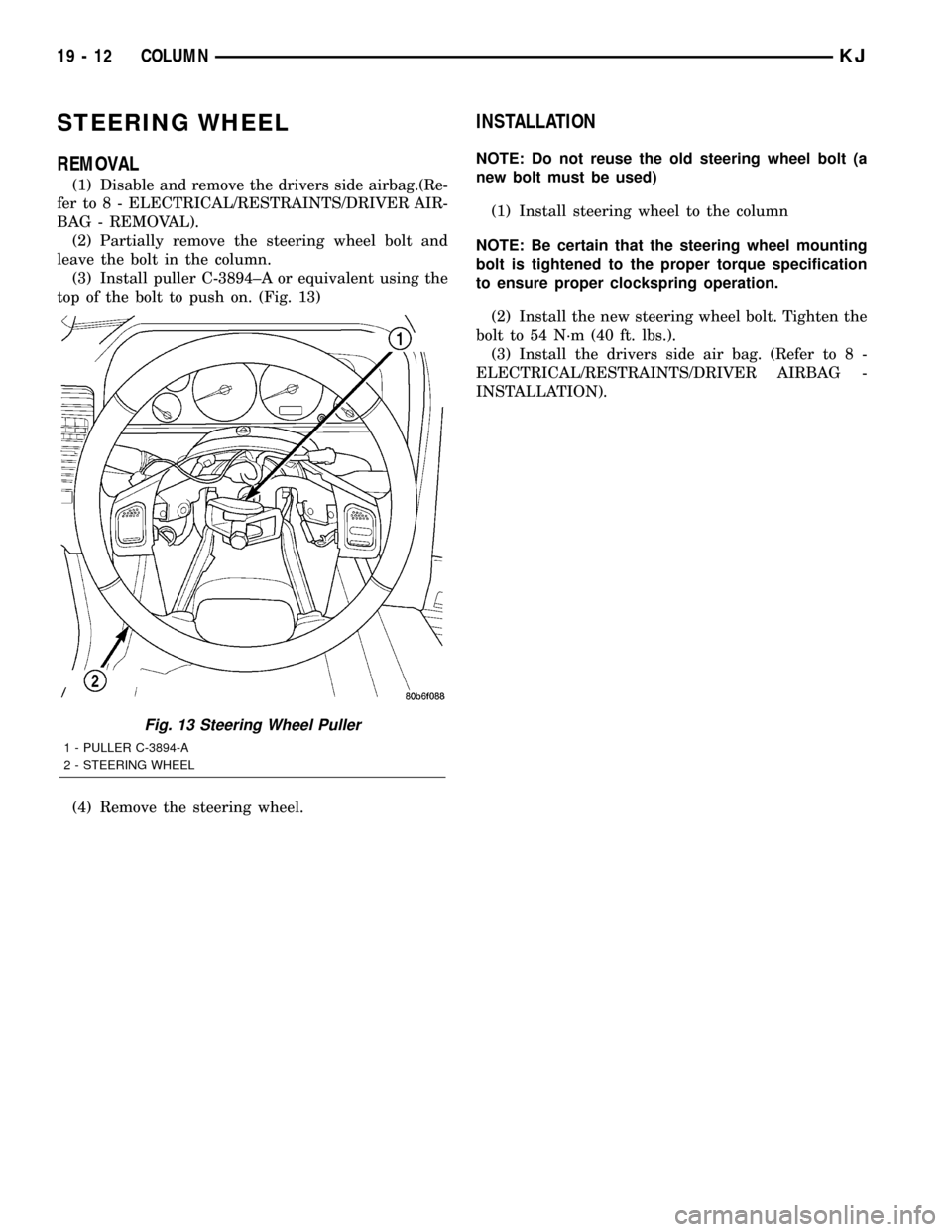

(1) Disable and remove the drivers side airbag.(Re-

fer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIR-

BAG - REMOVAL).

(2) Partially remove the steering wheel bolt and

leave the bolt in the column.

(3) Install puller C-3894±A or equivalent using the

top of the bolt to push on. (Fig. 13)

(4) Remove the steering wheel.

INSTALLATION

NOTE: Do not reuse the old steering wheel bolt (a

new bolt must be used)

(1) Install steering wheel to the column

NOTE: Be certain that the steering wheel mounting

bolt is tightened to the proper torque specification

to ensure proper clockspring operation.

(2) Install the new steering wheel bolt. Tighten the

bolt to 54 N´m (40 ft. lbs.).

(3) Install the drivers side air bag. (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

INSTALLATION).

Fig. 13 Steering Wheel Puller

1 - PULLER C-3894-A

2 - STEERING WHEEL

19 - 12 COLUMNKJ

Page 1451 of 1803

HOSES

REMOVAL

REMOVAL - PRESSURE HOSE

(1) Siphon the power steering fluid from the reser-

voir.

(2) Remove the radiator crossmember (Refer to 23

- BODY/EXTERIOR/RADIATOR CROSSMEMBER -

REMOVAL).

(3) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

(4) Remove the fan shroud.

(5) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(6) Remove the pressure hose at the pump.

(7) Disconnect the pressure switch electrical con-

nector from the pressure hose.

(8) Remove the pressure hose from the gear.

(9) Remove the pressure hose mounting bracket

bolts from behind the headlamp assembly. (Fig. 6)

(10) Remove the pressure hose from the vehicle

and transfer power steering pressure switch if neces-

sary.

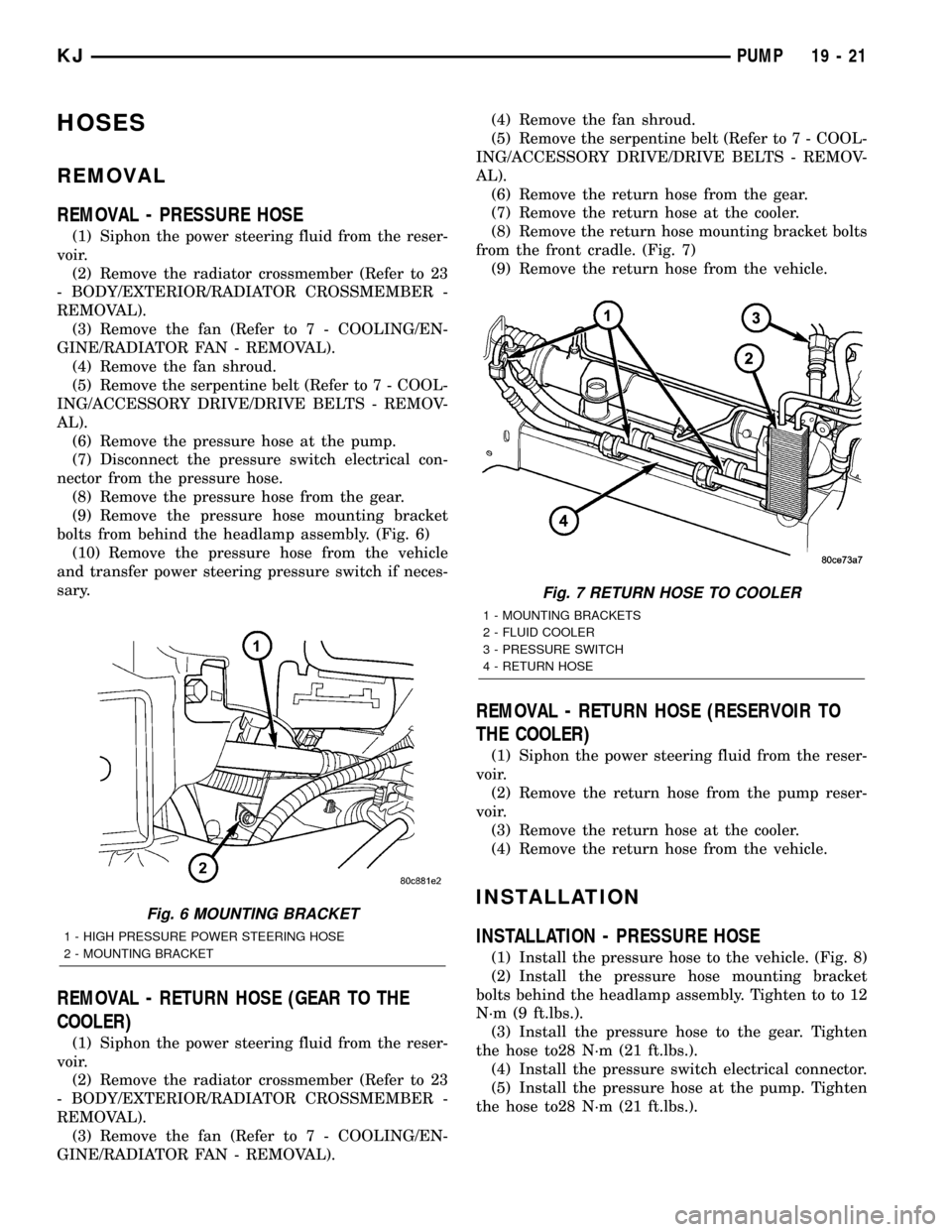

REMOVAL - RETURN HOSE (GEAR TO THE

COOLER)

(1) Siphon the power steering fluid from the reser-

voir.

(2) Remove the radiator crossmember (Refer to 23

- BODY/EXTERIOR/RADIATOR CROSSMEMBER -

REMOVAL).

(3) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).(4) Remove the fan shroud.

(5) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(6) Remove the return hose from the gear.

(7) Remove the return hose at the cooler.

(8) Remove the return hose mounting bracket bolts

from the front cradle. (Fig. 7)

(9) Remove the return hose from the vehicle.

REMOVAL - RETURN HOSE (RESERVOIR TO

THE COOLER)

(1) Siphon the power steering fluid from the reser-

voir.

(2) Remove the return hose from the pump reser-

voir.

(3) Remove the return hose at the cooler.

(4) Remove the return hose from the vehicle.

INSTALLATION

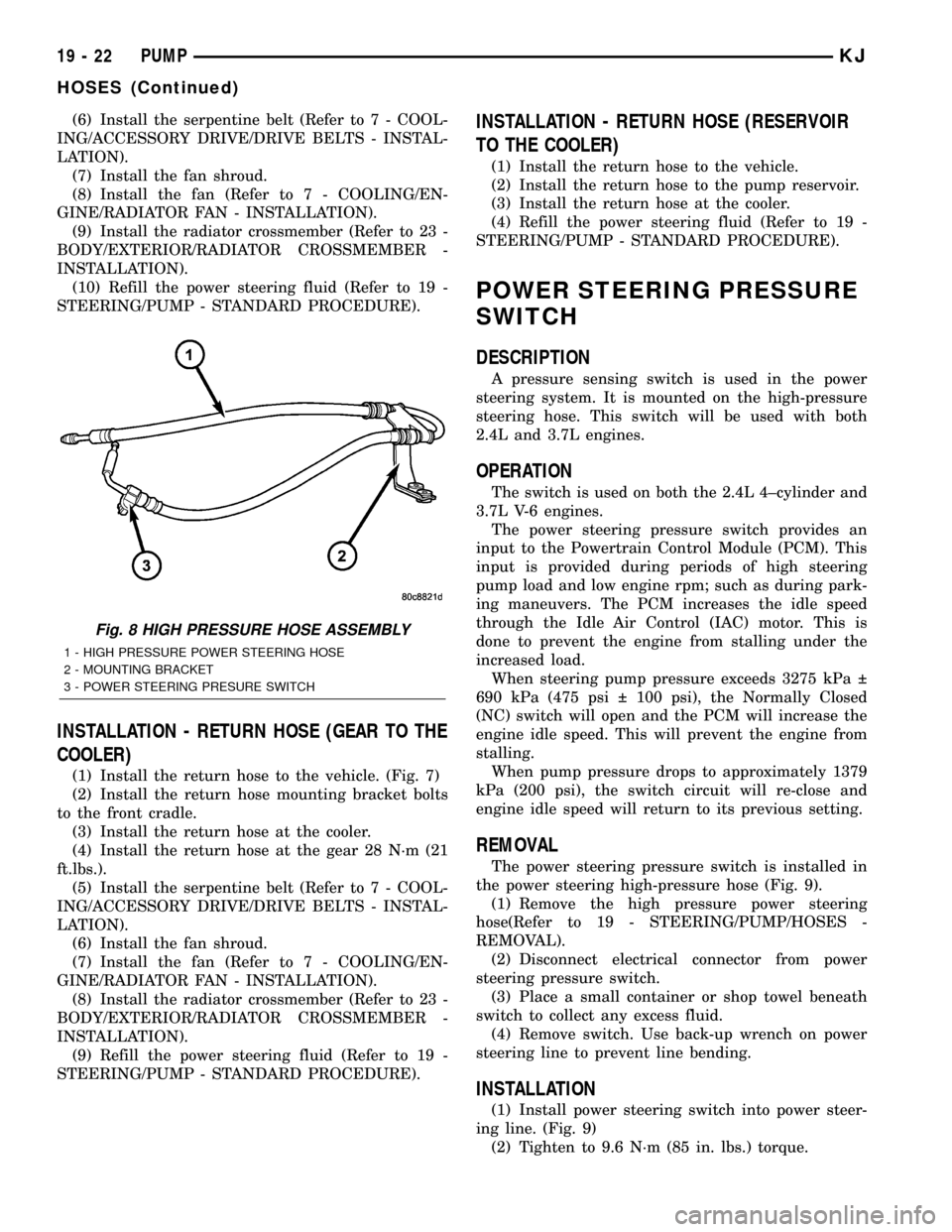

INSTALLATION - PRESSURE HOSE

(1) Install the pressure hose to the vehicle. (Fig. 8)

(2) Install the pressure hose mounting bracket

bolts behind the headlamp assembly. Tighten to to 12

N´m (9 ft.lbs.).

(3) Install the pressure hose to the gear. Tighten

the hose to28 N´m (21 ft.lbs.).

(4) Install the pressure switch electrical connector.

(5) Install the pressure hose at the pump. Tighten

the hose to28 N´m (21 ft.lbs.).

Fig. 6 MOUNTING BRACKET

1 - HIGH PRESSURE POWER STEERING HOSE

2 - MOUNTING BRACKET

Fig. 7 RETURN HOSE TO COOLER

1 - MOUNTING BRACKETS

2 - FLUID COOLER

3 - PRESSURE SWITCH

4 - RETURN HOSE

KJPUMP 19 - 21

Page 1452 of 1803

(6) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(7) Install the fan shroud.

(8) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(9) Install the radiator crossmember (Refer to 23 -

BODY/EXTERIOR/RADIATOR CROSSMEMBER -

INSTALLATION).

(10) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE (GEAR TO THE

COOLER)

(1) Install the return hose to the vehicle. (Fig. 7)

(2) Install the return hose mounting bracket bolts

to the front cradle.

(3) Install the return hose at the cooler.

(4) Install the return hose at the gear 28 N´m (21

ft.lbs.).

(5) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Install the fan shroud.

(7) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(8) Install the radiator crossmember (Refer to 23 -

BODY/EXTERIOR/RADIATOR CROSSMEMBER -

INSTALLATION).

(9) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE (RESERVOIR

TO THE COOLER)

(1) Install the return hose to the vehicle.

(2) Install the return hose to the pump reservoir.

(3) Install the return hose at the cooler.

(4) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

POWER STEERING PRESSURE

SWITCH

DESCRIPTION

A pressure sensing switch is used in the power

steering system. It is mounted on the high-pressure

steering hose. This switch will be used with both

2.4L and 3.7L engines.

OPERATION

The switch is used on both the 2.4L 4±cylinder and

3.7L V-6 engines.

The power steering pressure switch provides an

input to the Powertrain Control Module (PCM). This

input is provided during periods of high steering

pump load and low engine rpm; such as during park-

ing maneuvers. The PCM increases the idle speed

through the Idle Air Control (IAC) motor. This is

done to prevent the engine from stalling under the

increased load.

When steering pump pressure exceeds 3275 kPa

690 kPa (475 psi 100 psi), the Normally Closed

(NC) switch will open and the PCM will increase the

engine idle speed. This will prevent the engine from

stalling.

When pump pressure drops to approximately 1379

kPa (200 psi), the switch circuit will re-close and

engine idle speed will return to its previous setting.

REMOVAL

The power steering pressure switch is installed in

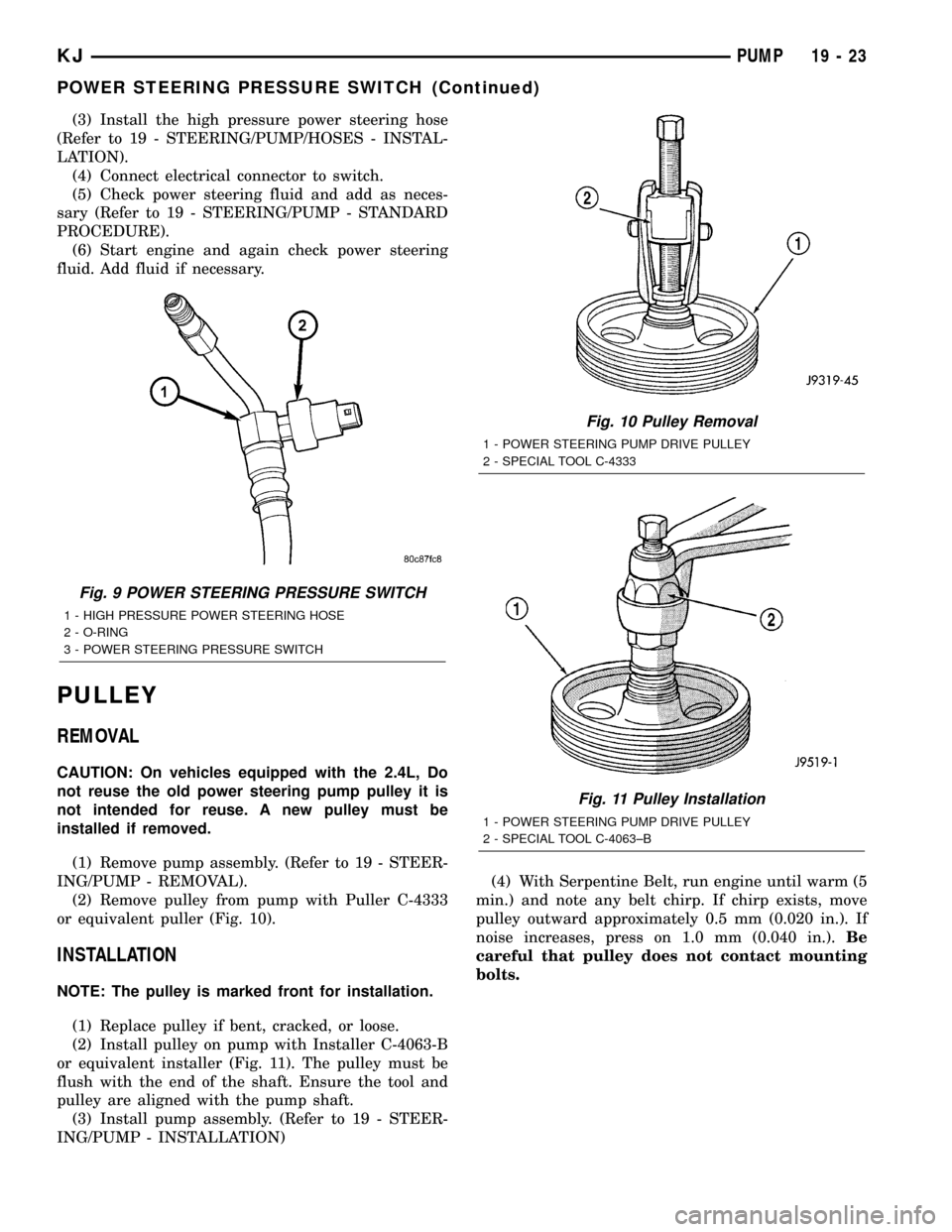

the power steering high-pressure hose (Fig. 9).

(1) Remove the high pressure power steering

hose(Refer to 19 - STEERING/PUMP/HOSES -

REMOVAL).

(2) Disconnect electrical connector from power

steering pressure switch.

(3) Place a small container or shop towel beneath

switch to collect any excess fluid.

(4) Remove switch. Use back-up wrench on power

steering line to prevent line bending.

INSTALLATION

(1) Install power steering switch into power steer-

ing line. (Fig. 9)

(2) Tighten to 9.6 N´m (85 in. lbs.) torque.

Fig. 8 HIGH PRESSURE HOSE ASSEMBLY

1 - HIGH PRESSURE POWER STEERING HOSE

2 - MOUNTING BRACKET

3 - POWER STEERING PRESURE SWITCH

19 - 22 PUMPKJ

HOSES (Continued)

Page 1453 of 1803

(3) Install the high pressure power steering hose

(Refer to 19 - STEERING/PUMP/HOSES - INSTAL-

LATION).

(4) Connect electrical connector to switch.

(5) Check power steering fluid and add as neces-

sary (Refer to 19 - STEERING/PUMP - STANDARD

PROCEDURE).

(6) Start engine and again check power steering

fluid. Add fluid if necessary.

PULLEY

REMOVAL

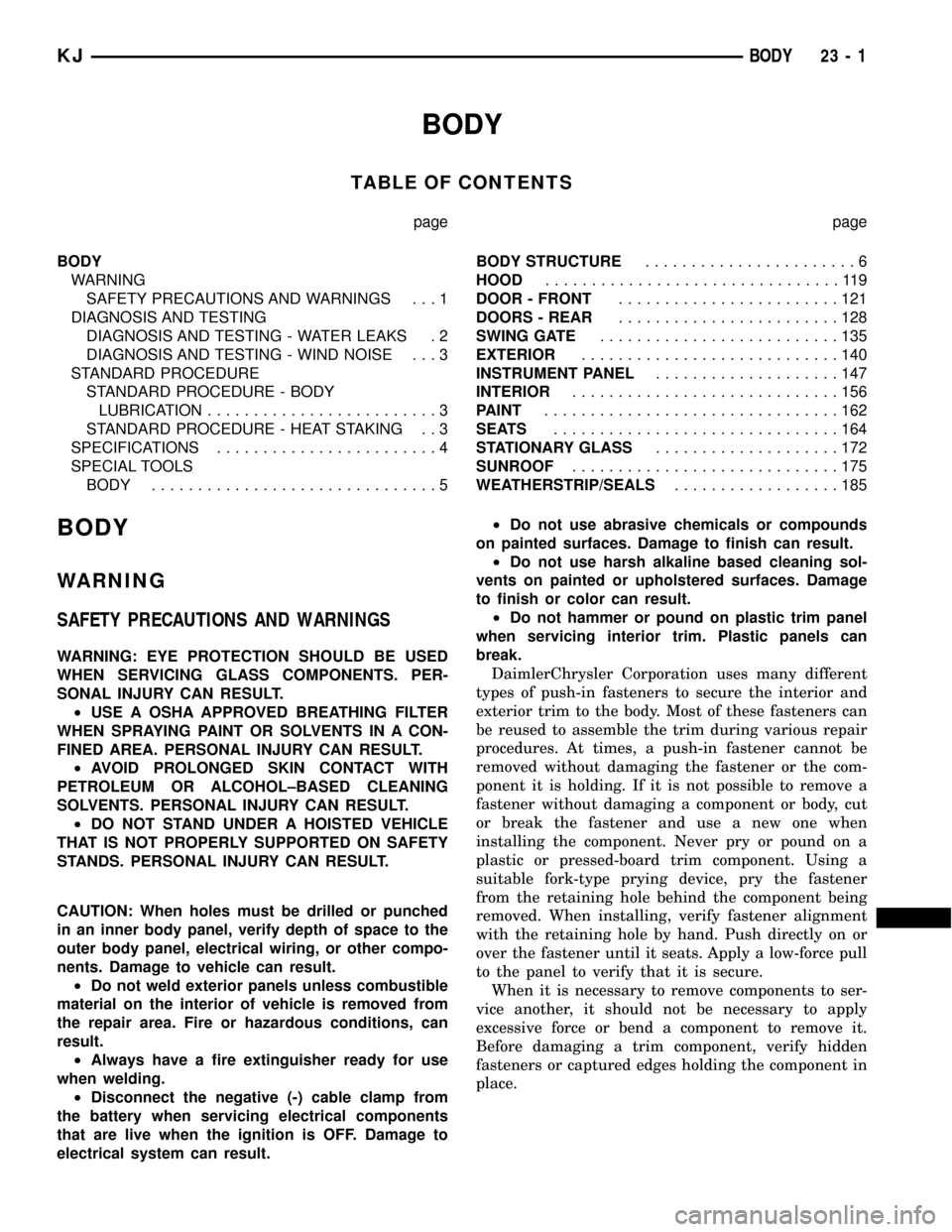

CAUTION: On vehicles equipped with the 2.4L, Do

not reuse the old power steering pump pulley it is

not intended for reuse. A new pulley must be

installed if removed.

(1) Remove pump assembly. (Refer to 19 - STEER-

ING/PUMP - REMOVAL).

(2) Remove pulley from pump with Puller C-4333

or equivalent puller (Fig. 10).

INSTALLATION

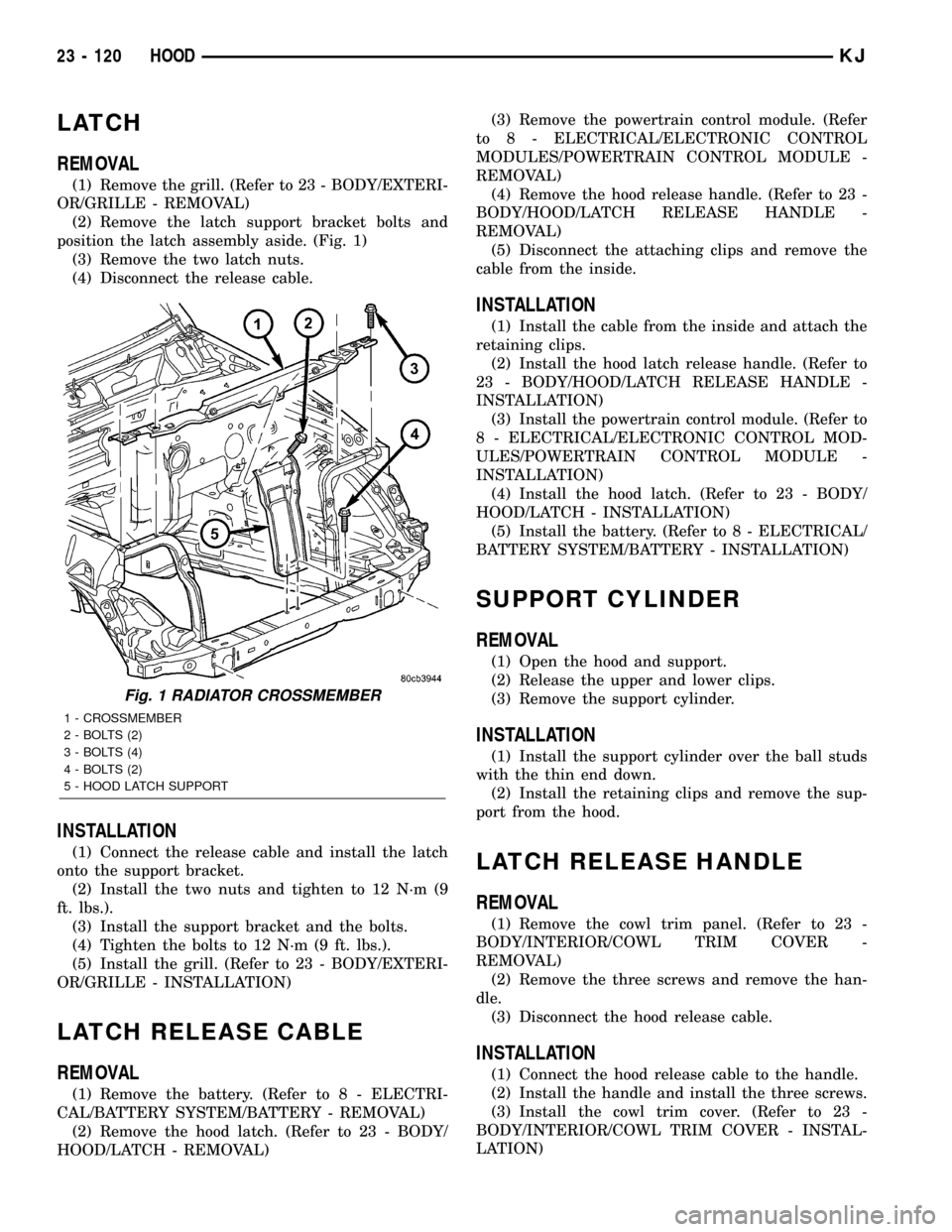

NOTE: The pulley is marked front for installation.

(1) Replace pulley if bent, cracked, or loose.

(2) Install pulley on pump with Installer C-4063-B

or equivalent installer (Fig. 11). The pulley must be

flush with the end of the shaft. Ensure the tool and

pulley are aligned with the pump shaft.

(3) Install pump assembly. (Refer to 19 - STEER-

ING/PUMP - INSTALLATION)(4) With Serpentine Belt, run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.

Fig. 9 POWER STEERING PRESSURE SWITCH

1 - HIGH PRESSURE POWER STEERING HOSE

2 - O-RING

3 - POWER STEERING PRESSURE SWITCH

Fig. 10 Pulley Removal

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4333

Fig. 11 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4063±B

KJPUMP 19 - 23

POWER STEERING PRESSURE SWITCH (Continued)

Page 1466 of 1803

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................3

STANDARD PROCEDURE - HEAT STAKING . . 3

SPECIFICATIONS........................4

SPECIAL TOOLS

BODY...............................5BODY STRUCTURE.......................6

HOOD................................119

DOOR - FRONT........................121

DOORS - REAR........................128

SWING GATE..........................135

EXTERIOR............................140

INSTRUMENT PANEL....................147

INTERIOR.............................156

PAINT................................162

SEATS...............................164

STATIONARY GLASS....................172

SUNROOF.............................175

WEATHERSTRIP/SEALS..................185

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

²USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL±BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DaimlerChrysler Corporation uses many different

types of push-in fasteners to secure the interior and

exterior trim to the body. Most of these fasteners can

be reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

KJBODY 23 - 1

Page 1585 of 1803

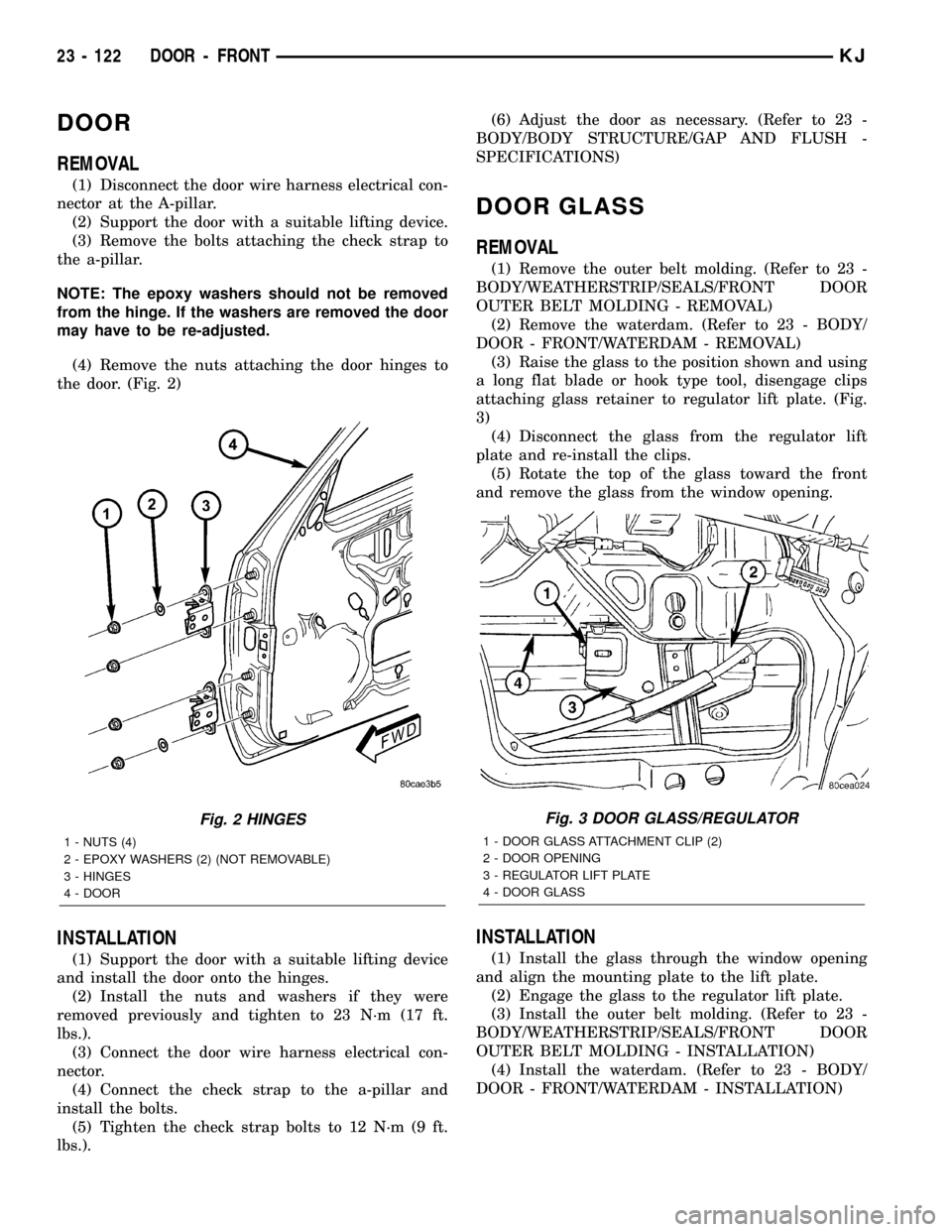

LATCH

REMOVAL

(1) Remove the grill. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - REMOVAL)

(2) Remove the latch support bracket bolts and

position the latch assembly aside. (Fig. 1)

(3) Remove the two latch nuts.

(4) Disconnect the release cable.

INSTALLATION

(1) Connect the release cable and install the latch

onto the support bracket.

(2) Install the two nuts and tighten to 12 N´m (9

ft. lbs.).

(3) Install the support bracket and the bolts.

(4) Tighten the bolts to 12 N´m (9 ft. lbs.).

(5) Install the grill. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

LATCH RELEASE CABLE

REMOVAL

(1) Remove the battery. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL)

(2) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)(3) Remove the powertrain control module. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

REMOVAL)

(4) Remove the hood release handle. (Refer to 23 -

BODY/HOOD/LATCH RELEASE HANDLE -

REMOVAL)

(5) Disconnect the attaching clips and remove the

cable from the inside.

INSTALLATION

(1) Install the cable from the inside and attach the

retaining clips.

(2) Install the hood latch release handle. (Refer to

23 - BODY/HOOD/LATCH RELEASE HANDLE -

INSTALLATION)

(3) Install the powertrain control module. (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

INSTALLATION)

(4) Install the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - INSTALLATION)

(5) Install the battery. (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION)

SUPPORT CYLINDER

REMOVAL

(1) Open the hood and support.

(2) Release the upper and lower clips.

(3) Remove the support cylinder.

INSTALLATION

(1) Install the support cylinder over the ball studs

with the thin end down.

(2) Install the retaining clips and remove the sup-

port from the hood.

LATCH RELEASE HANDLE

REMOVAL

(1) Remove the cowl trim panel. (Refer to 23 -

BODY/INTERIOR/COWL TRIM COVER -

REMOVAL)

(2) Remove the three screws and remove the han-

dle.

(3) Disconnect the hood release cable.

INSTALLATION

(1) Connect the hood release cable to the handle.

(2) Install the handle and install the three screws.

(3) Install the cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM COVER - INSTAL-

LATION)

Fig. 1 RADIATOR CROSSMEMBER

1 - CROSSMEMBER

2 - BOLTS (2)

3 - BOLTS (4)

4 - BOLTS (2)

5 - HOOD LATCH SUPPORT

23 - 120 HOODKJ

Page 1587 of 1803

DOOR

REMOVAL

(1) Disconnect the door wire harness electrical con-

nector at the A-pillar.

(2) Support the door with a suitable lifting device.

(3) Remove the bolts attaching the check strap to

the a-pillar.

NOTE: The epoxy washers should not be removed

from the hinge. If the washers are removed the door

may have to be re-adjusted.

(4) Remove the nuts attaching the door hinges to

the door. (Fig. 2)

INSTALLATION

(1) Support the door with a suitable lifting device

and install the door onto the hinges.

(2) Install the nuts and washers if they were

removed previously and tighten to 23 N´m (17 ft.

lbs.).

(3) Connect the door wire harness electrical con-

nector.

(4) Connect the check strap to the a-pillar and

install the bolts.

(5) Tighten the check strap bolts to 12 N´m (9 ft.

lbs.).(6) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

DOOR GLASS

REMOVAL

(1) Remove the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - REMOVAL)

(2) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)

(3) Raise the glass to the position shown and using

a long flat blade or hook type tool, disengage clips

attaching glass retainer to regulator lift plate. (Fig.

3)

(4) Disconnect the glass from the regulator lift

plate and re-install the clips.

(5) Rotate the top of the glass toward the front

and remove the glass from the window opening.

INSTALLATION

(1) Install the glass through the window opening

and align the mounting plate to the lift plate.

(2) Engage the glass to the regulator lift plate.

(3) Install the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - INSTALLATION)

(4) Install the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION)

Fig. 2 HINGES

1 - NUTS (4)

2 - EPOXY WASHERS (2) (NOT REMOVABLE)

3 - HINGES

4 - DOOR

Fig. 3 DOOR GLASS/REGULATOR

1 - DOOR GLASS ATTACHMENT CLIP (2)

2 - DOOR OPENING

3 - REGULATOR LIFT PLATE

4 - DOOR GLASS

23 - 122 DOOR - FRONTKJ

Page 1588 of 1803

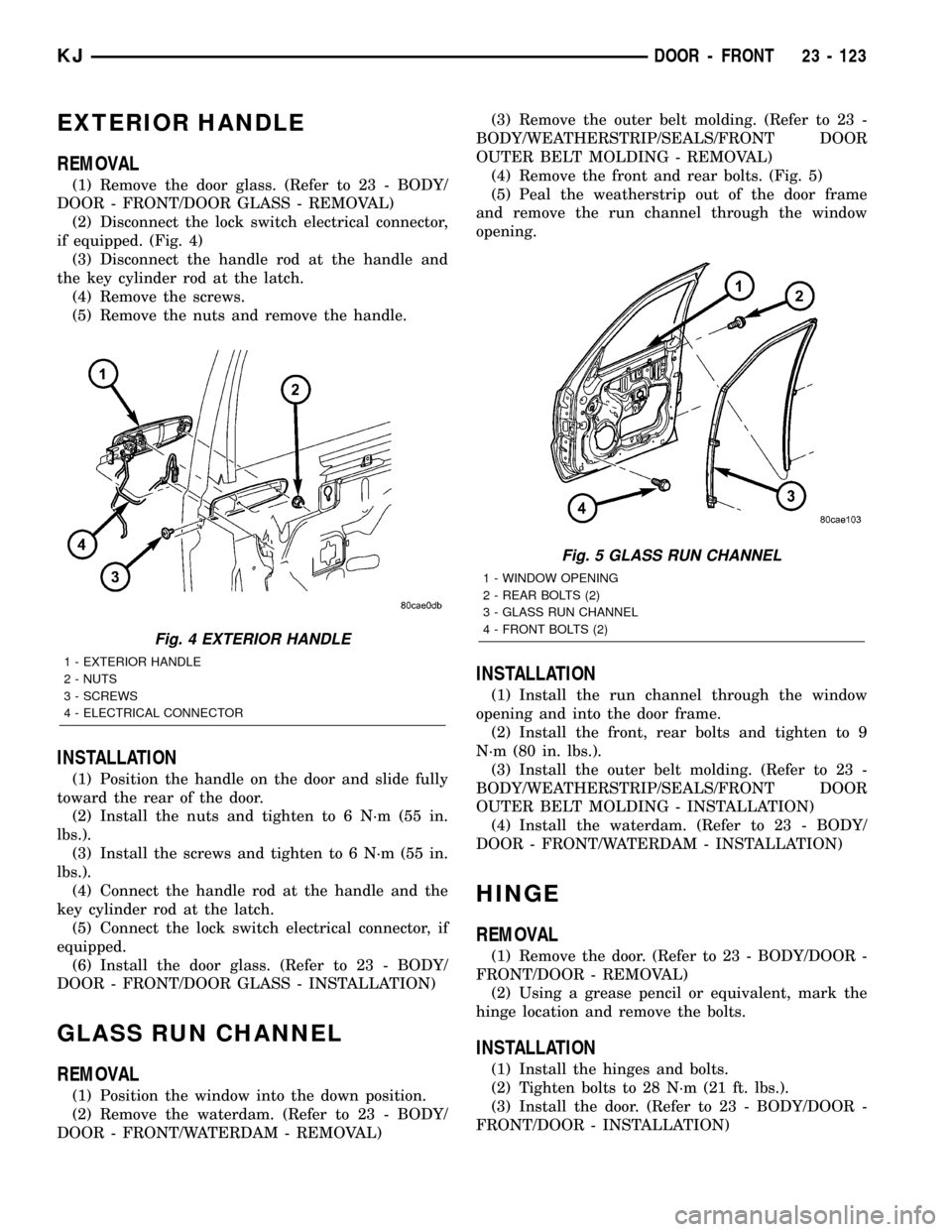

EXTERIOR HANDLE

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Disconnect the lock switch electrical connector,

if equipped. (Fig. 4)

(3) Disconnect the handle rod at the handle and

the key cylinder rod at the latch.

(4) Remove the screws.

(5) Remove the nuts and remove the handle.

INSTALLATION

(1) Position the handle on the door and slide fully

toward the rear of the door.

(2) Install the nuts and tighten to 6 N´m (55 in.

lbs.).

(3) Install the screws and tighten to 6 N´m (55 in.

lbs.).

(4) Connect the handle rod at the handle and the

key cylinder rod at the latch.

(5) Connect the lock switch electrical connector, if

equipped.

(6) Install the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - INSTALLATION)

GLASS RUN CHANNEL

REMOVAL

(1) Position the window into the down position.

(2) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)(3) Remove the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - REMOVAL)

(4) Remove the front and rear bolts. (Fig. 5)

(5) Peal the weatherstrip out of the door frame

and remove the run channel through the window

opening.

INSTALLATION

(1) Install the run channel through the window

opening and into the door frame.

(2) Install the front, rear bolts and tighten to 9

N´m (80 in. lbs.).

(3) Install the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - INSTALLATION)

(4) Install the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION)

HINGE

REMOVAL

(1) Remove the door. (Refer to 23 - BODY/DOOR -

FRONT/DOOR - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

hinge location and remove the bolts.

INSTALLATION

(1) Install the hinges and bolts.

(2) Tighten bolts to 28 N´m (21 ft. lbs.).

(3) Install the door. (Refer to 23 - BODY/DOOR -

FRONT/DOOR - INSTALLATION)

Fig. 4 EXTERIOR HANDLE

1 - EXTERIOR HANDLE

2 - NUTS

3 - SCREWS

4 - ELECTRICAL CONNECTOR

Fig. 5 GLASS RUN CHANNEL

1 - WINDOW OPENING

2 - REAR BOLTS (2)

3 - GLASS RUN CHANNEL

4 - FRONT BOLTS (2)

KJDOOR - FRONT 23 - 123

Page 1589 of 1803

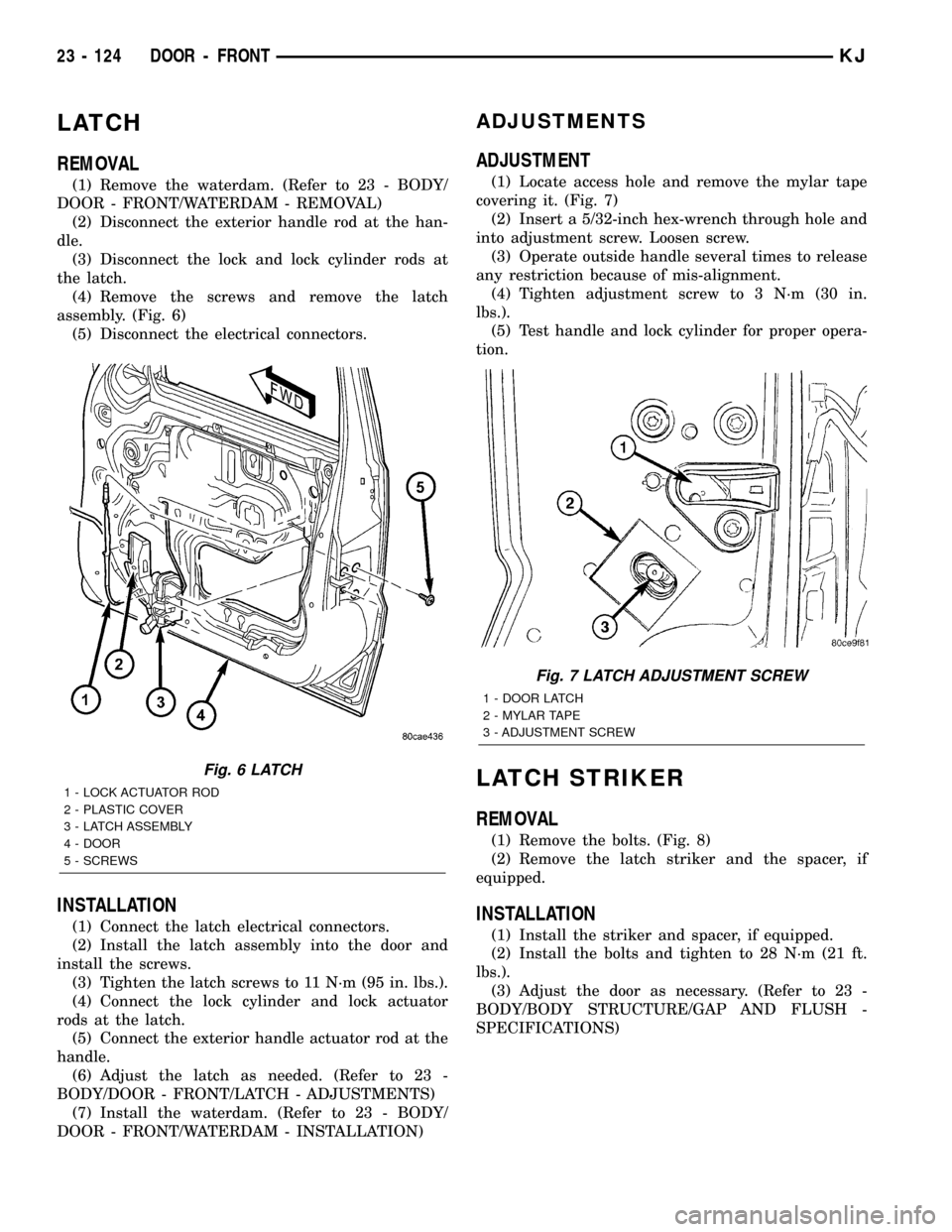

LATCH

REMOVAL

(1) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)

(2) Disconnect the exterior handle rod at the han-

dle.

(3) Disconnect the lock and lock cylinder rods at

the latch.

(4) Remove the screws and remove the latch

assembly. (Fig. 6)

(5) Disconnect the electrical connectors.

INSTALLATION

(1) Connect the latch electrical connectors.

(2) Install the latch assembly into the door and

install the screws.

(3) Tighten the latch screws to 11 N´m (95 in. lbs.).

(4) Connect the lock cylinder and lock actuator

rods at the latch.

(5) Connect the exterior handle actuator rod at the

handle.

(6) Adjust the latch as needed. (Refer to 23 -

BODY/DOOR - FRONT/LATCH - ADJUSTMENTS)

(7) Install the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION)

ADJUSTMENTS

ADJUSTMENT

(1) Locate access hole and remove the mylar tape

covering it. (Fig. 7)

(2) Insert a 5/32-inch hex-wrench through hole and

into adjustment screw. Loosen screw.

(3) Operate outside handle several times to release

any restriction because of mis-alignment.

(4) Tighten adjustment screw to 3 N´m (30 in.

lbs.).

(5) Test handle and lock cylinder for proper opera-

tion.

LATCH STRIKER

REMOVAL

(1) Remove the bolts. (Fig. 8)

(2) Remove the latch striker and the spacer, if

equipped.

INSTALLATION

(1) Install the striker and spacer, if equipped.

(2) Install the bolts and tighten to 28 N´m (21 ft.

lbs.).

(3) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

Fig. 6 LATCH

1 - LOCK ACTUATOR ROD

2 - PLASTIC COVER

3 - LATCH ASSEMBLY

4 - DOOR

5 - SCREWS

Fig. 7 LATCH ADJUSTMENT SCREW

1 - DOOR LATCH

2 - MYLAR TAPE

3 - ADJUSTMENT SCREW

23 - 124 DOOR - FRONTKJ