Electrical JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1590 of 1803

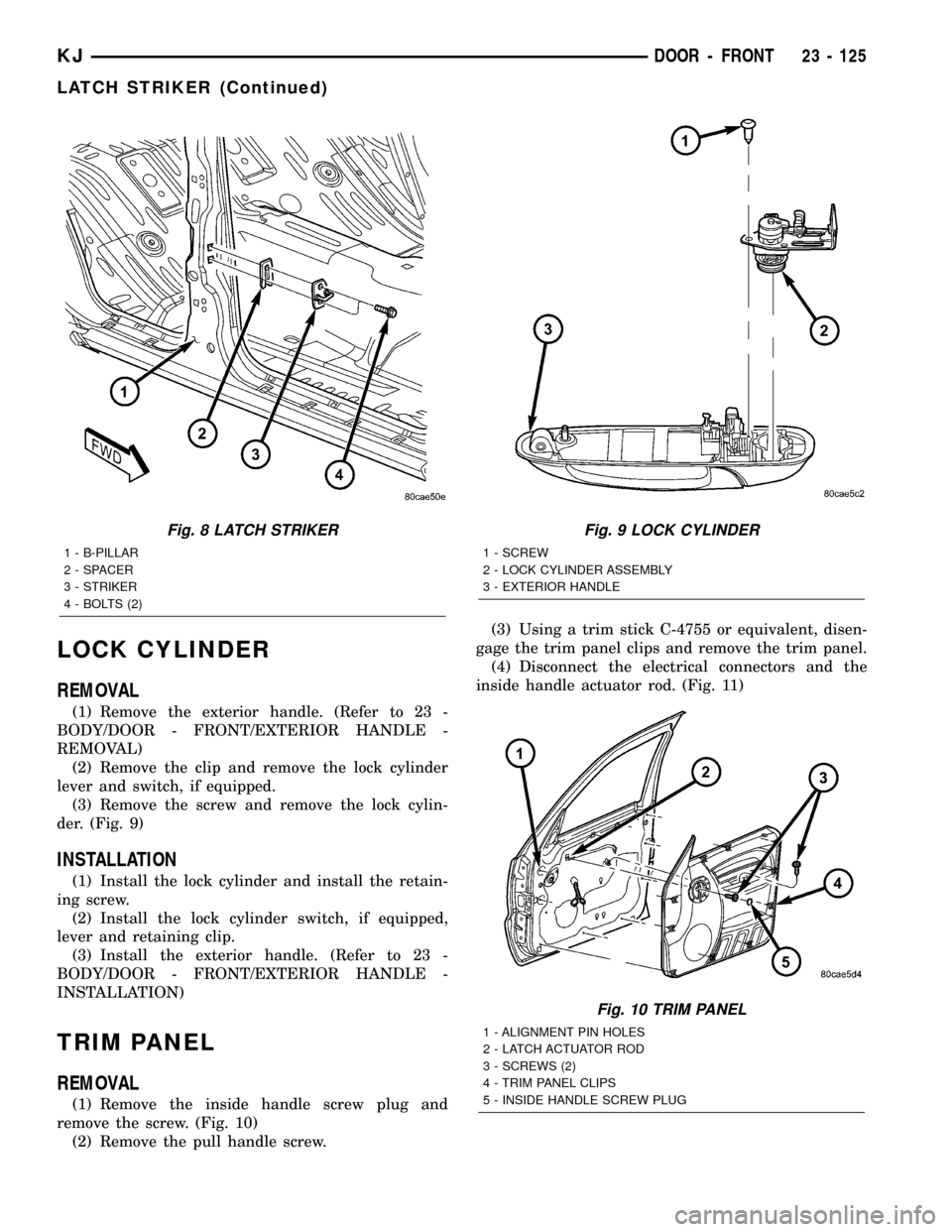

LOCK CYLINDER

REMOVAL

(1) Remove the exterior handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

REMOVAL)

(2) Remove the clip and remove the lock cylinder

lever and switch, if equipped.

(3) Remove the screw and remove the lock cylin-

der. (Fig. 9)

INSTALLATION

(1) Install the lock cylinder and install the retain-

ing screw.

(2) Install the lock cylinder switch, if equipped,

lever and retaining clip.

(3) Install the exterior handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

INSTALLATION)

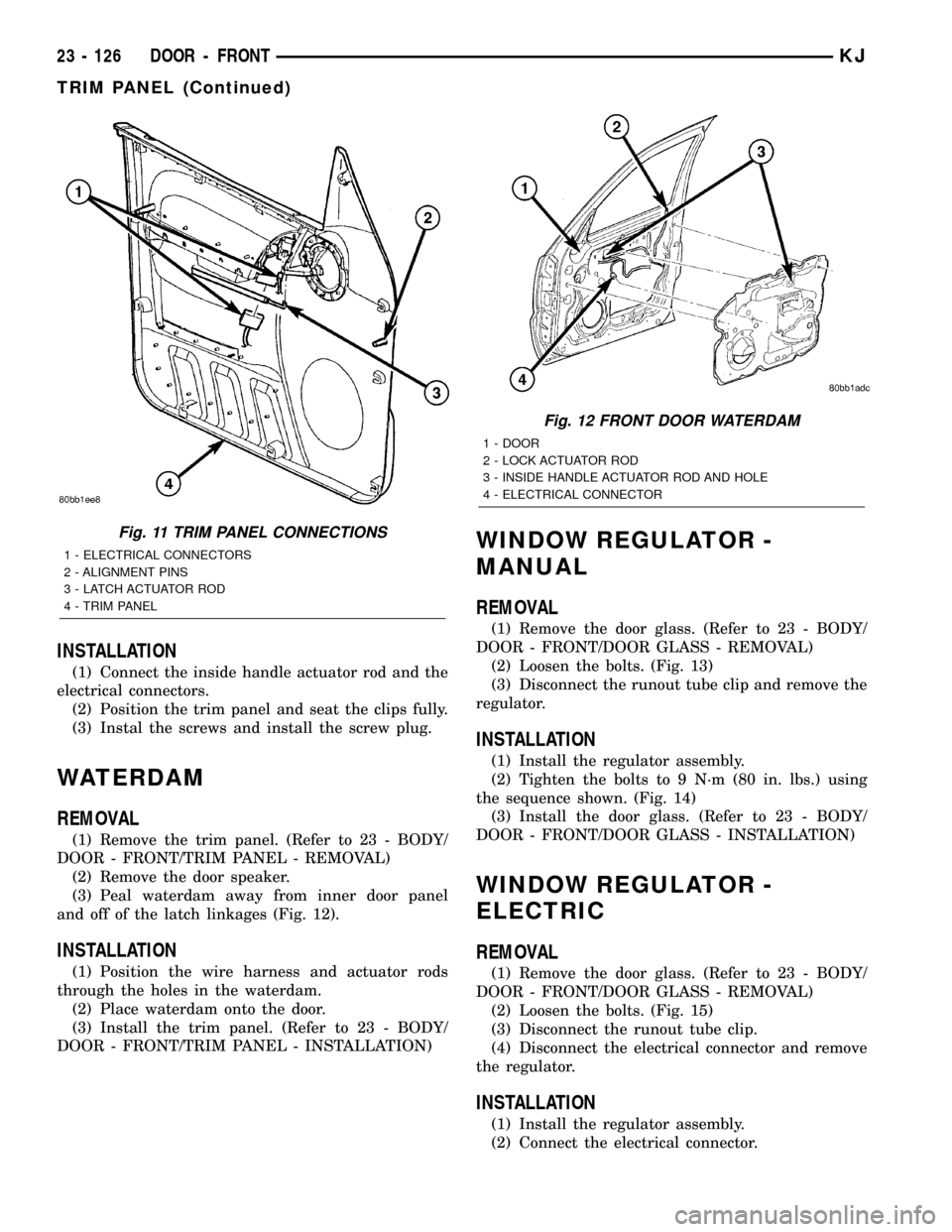

TRIM PANEL

REMOVAL

(1) Remove the inside handle screw plug and

remove the screw. (Fig. 10)

(2) Remove the pull handle screw.(3) Using a trim stick C-4755 or equivalent, disen-

gage the trim panel clips and remove the trim panel.

(4) Disconnect the electrical connectors and the

inside handle actuator rod. (Fig. 11)

Fig. 8 LATCH STRIKER

1 - B-PILLAR

2 - SPACER

3 - STRIKER

4 - BOLTS (2)

Fig. 9 LOCK CYLINDER

1 - SCREW

2 - LOCK CYLINDER ASSEMBLY

3 - EXTERIOR HANDLE

Fig. 10 TRIM PANEL

1 - ALIGNMENT PIN HOLES

2 - LATCH ACTUATOR ROD

3 - SCREWS (2)

4 - TRIM PANEL CLIPS

5 - INSIDE HANDLE SCREW PLUG

KJDOOR - FRONT 23 - 125

LATCH STRIKER (Continued)

Page 1591 of 1803

INSTALLATION

(1) Connect the inside handle actuator rod and the

electrical connectors.

(2) Position the trim panel and seat the clips fully.

(3) Instal the screws and install the screw plug.

WATERDAM

REMOVAL

(1) Remove the trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the door speaker.

(3) Peal waterdam away from inner door panel

and off of the latch linkages (Fig. 12).

INSTALLATION

(1) Position the wire harness and actuator rods

through the holes in the waterdam.

(2) Place waterdam onto the door.

(3) Install the trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

WINDOW REGULATOR -

MANUAL

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Loosen the bolts. (Fig. 13)

(3) Disconnect the runout tube clip and remove the

regulator.

INSTALLATION

(1) Install the regulator assembly.

(2) Tighten the bolts to 9 N´m (80 in. lbs.) using

the sequence shown. (Fig. 14)

(3) Install the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - INSTALLATION)

WINDOW REGULATOR -

ELECTRIC

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Loosen the bolts. (Fig. 15)

(3) Disconnect the runout tube clip.

(4) Disconnect the electrical connector and remove

the regulator.

INSTALLATION

(1) Install the regulator assembly.

(2) Connect the electrical connector.

Fig. 11 TRIM PANEL CONNECTIONS

1 - ELECTRICAL CONNECTORS

2 - ALIGNMENT PINS

3 - LATCH ACTUATOR ROD

4 - TRIM PANEL

Fig. 12 FRONT DOOR WATERDAM

1 - DOOR

2 - LOCK ACTUATOR ROD

3 - INSIDE HANDLE ACTUATOR ROD AND HOLE

4 - ELECTRICAL CONNECTOR

23 - 126 DOOR - FRONTKJ

TRIM PANEL (Continued)

Page 1594 of 1803

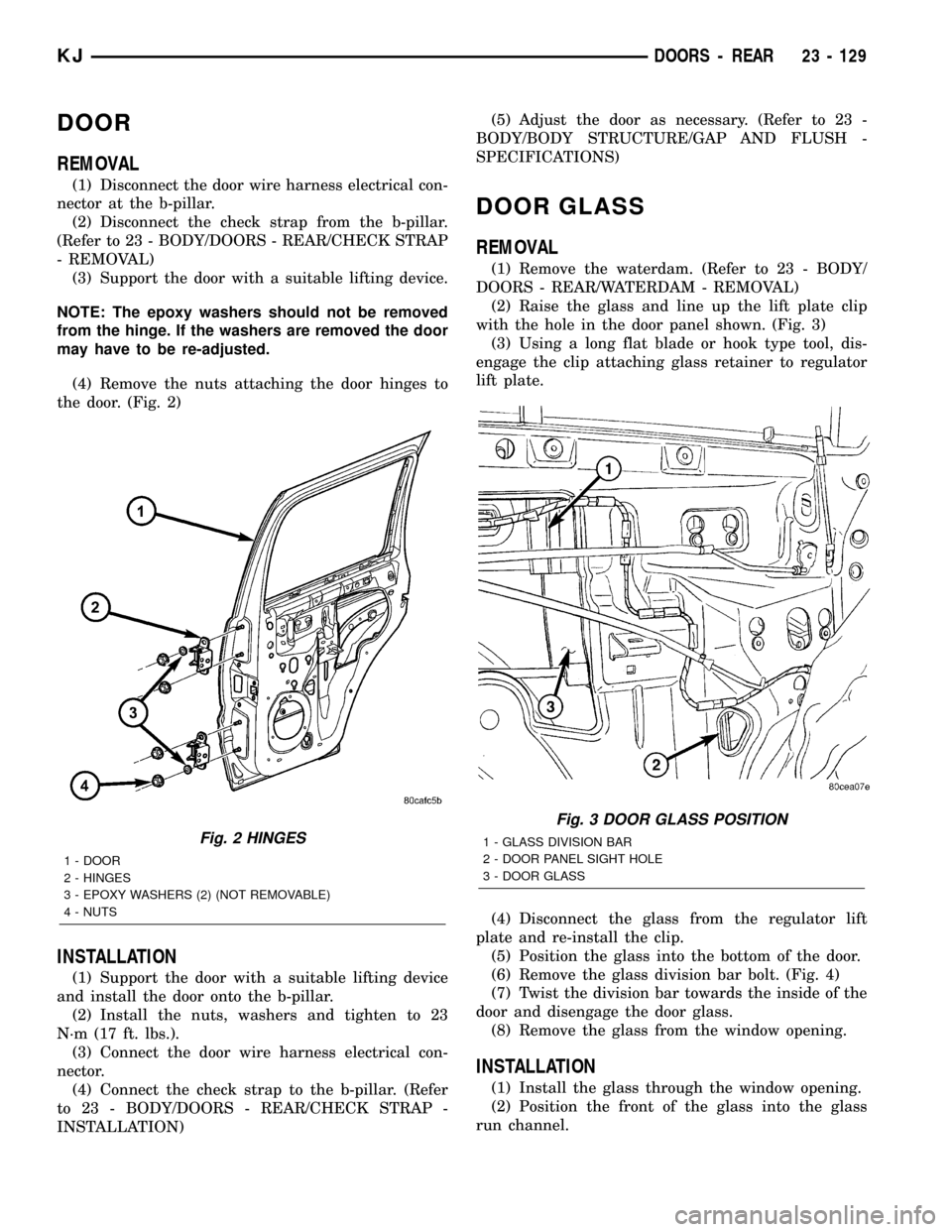

DOOR

REMOVAL

(1) Disconnect the door wire harness electrical con-

nector at the b-pillar.

(2) Disconnect the check strap from the b-pillar.

(Refer to 23 - BODY/DOORS - REAR/CHECK STRAP

- REMOVAL)

(3) Support the door with a suitable lifting device.

NOTE: The epoxy washers should not be removed

from the hinge. If the washers are removed the door

may have to be re-adjusted.

(4) Remove the nuts attaching the door hinges to

the door. (Fig. 2)

INSTALLATION

(1) Support the door with a suitable lifting device

and install the door onto the b-pillar.

(2) Install the nuts, washers and tighten to 23

N´m (17 ft. lbs.).

(3) Connect the door wire harness electrical con-

nector.

(4) Connect the check strap to the b-pillar. (Refer

to 23 - BODY/DOORS - REAR/CHECK STRAP -

INSTALLATION)(5) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

DOOR GLASS

REMOVAL

(1) Remove the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - REMOVAL)

(2) Raise the glass and line up the lift plate clip

with the hole in the door panel shown. (Fig. 3)

(3) Using a long flat blade or hook type tool, dis-

engage the clip attaching glass retainer to regulator

lift plate.

(4) Disconnect the glass from the regulator lift

plate and re-install the clip.

(5) Position the glass into the bottom of the door.

(6) Remove the glass division bar bolt. (Fig. 4)

(7) Twist the division bar towards the inside of the

door and disengage the door glass.

(8) Remove the glass from the window opening.

INSTALLATION

(1) Install the glass through the window opening.

(2) Position the front of the glass into the glass

run channel.

Fig. 2 HINGES

1 - DOOR

2 - HINGES

3 - EPOXY WASHERS (2) (NOT REMOVABLE)

4 - NUTS

Fig. 3 DOOR GLASS POSITION

1 - GLASS DIVISION BAR

2 - DOOR PANEL SIGHT HOLE

3 - DOOR GLASS

KJDOORS - REAR 23 - 129

Page 1596 of 1803

HINGE

REMOVAL

(1) Remove the door. (Refer to 23 - BODY/DOORS

- REAR/DOOR - REMOVAL)

(2) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(3) Remove the two door hinge bolts from the

inside of the b-pillar.

(4) Remove the exterior bolts attaching the door

hinges to the b-pillar.

INSTALLATION

(1) Install the hinges.

(2) Install the exterior bolts and tighten to 28 N´m

(21 ft. lbs.).

(3) Install the two inner hinge bolts and tighten to

28 N´m (21 ft. lbs.).

(4) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

(5) Install the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION)

(6) Install the door. (Refer to 23 - BODY/DOORS -

REAR/DOOR - INSTALLATION)

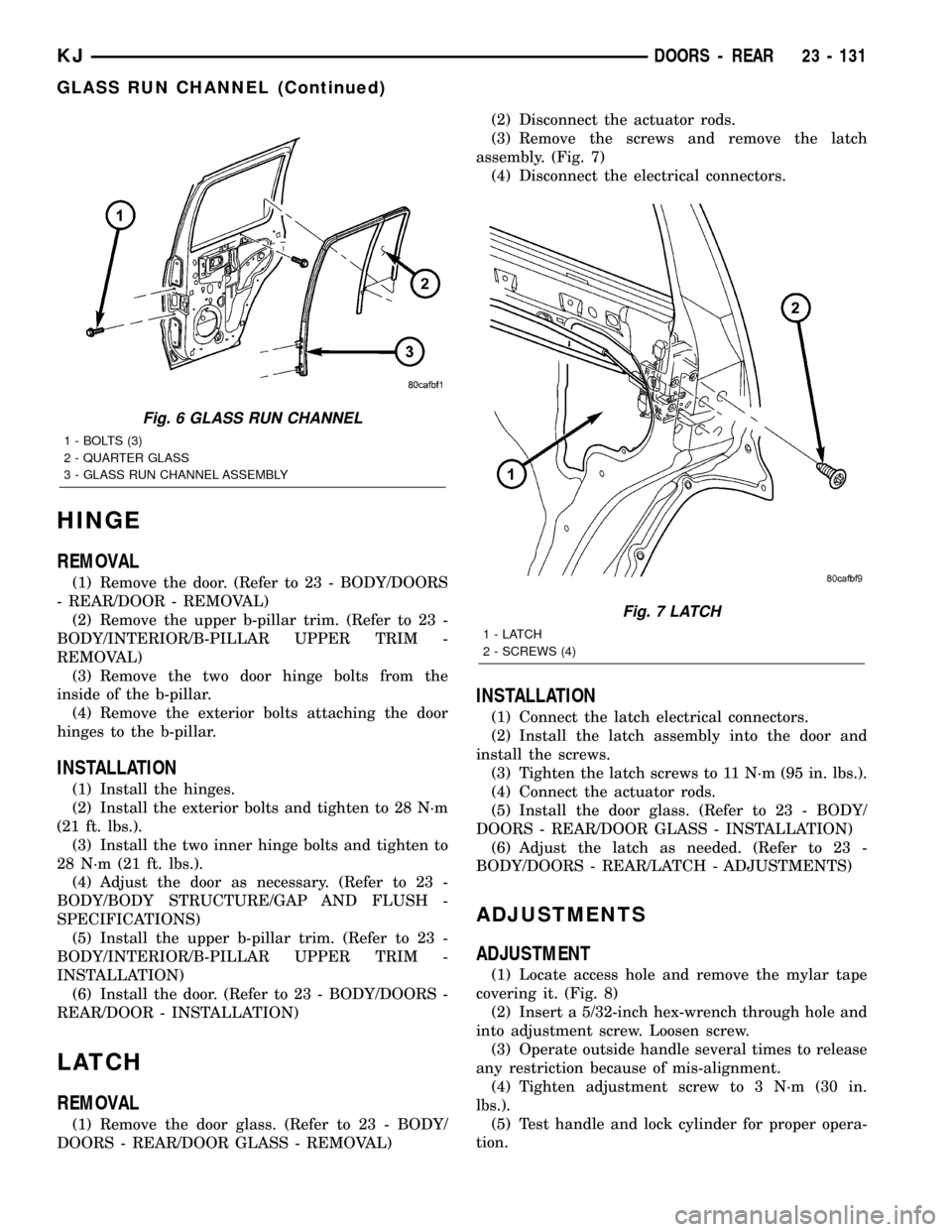

LATCH

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - REMOVAL)(2) Disconnect the actuator rods.

(3) Remove the screws and remove the latch

assembly. (Fig. 7)

(4) Disconnect the electrical connectors.

INSTALLATION

(1) Connect the latch electrical connectors.

(2) Install the latch assembly into the door and

install the screws.

(3) Tighten the latch screws to 11 N´m (95 in. lbs.).

(4) Connect the actuator rods.

(5) Install the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - INSTALLATION)

(6) Adjust the latch as needed. (Refer to 23 -

BODY/DOORS - REAR/LATCH - ADJUSTMENTS)

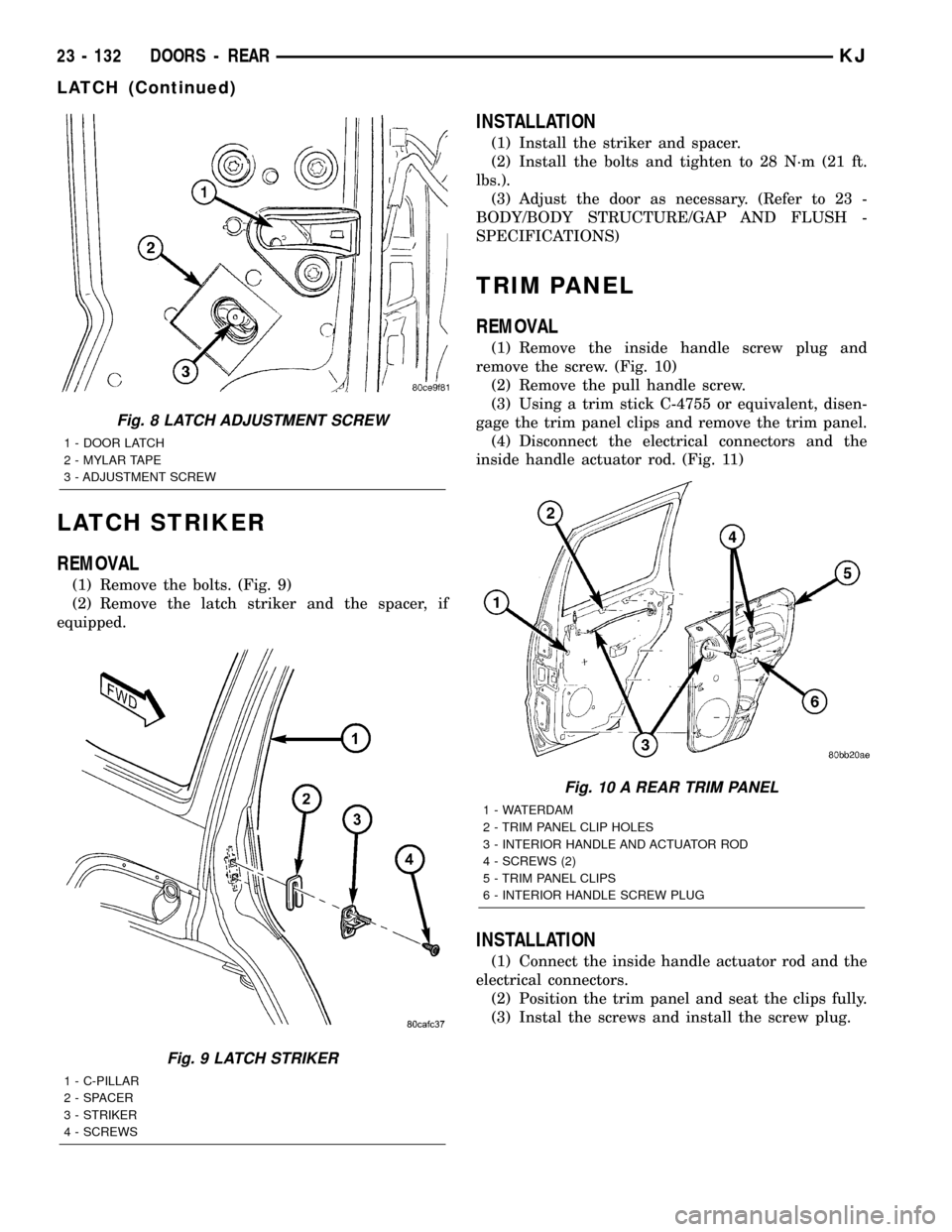

ADJUSTMENTS

ADJUSTMENT

(1) Locate access hole and remove the mylar tape

covering it. (Fig. 8)

(2) Insert a 5/32-inch hex-wrench through hole and

into adjustment screw. Loosen screw.

(3) Operate outside handle several times to release

any restriction because of mis-alignment.

(4) Tighten adjustment screw to 3 N´m (30 in.

lbs.).

(5) Test handle and lock cylinder for proper opera-

tion.

Fig. 6 GLASS RUN CHANNEL

1 - BOLTS (3)

2 - QUARTER GLASS

3 - GLASS RUN CHANNEL ASSEMBLY

Fig. 7 LATCH

1-LATCH

2 - SCREWS (4)

KJDOORS - REAR 23 - 131

GLASS RUN CHANNEL (Continued)

Page 1597 of 1803

LATCH STRIKER

REMOVAL

(1) Remove the bolts. (Fig. 9)

(2) Remove the latch striker and the spacer, if

equipped.

INSTALLATION

(1) Install the striker and spacer.

(2) Install the bolts and tighten to 28 N´m (21 ft.

lbs.).

(3) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

TRIM PANEL

REMOVAL

(1) Remove the inside handle screw plug and

remove the screw. (Fig. 10)

(2) Remove the pull handle screw.

(3) Using a trim stick C-4755 or equivalent, disen-

gage the trim panel clips and remove the trim panel.

(4) Disconnect the electrical connectors and the

inside handle actuator rod. (Fig. 11)

INSTALLATION

(1) Connect the inside handle actuator rod and the

electrical connectors.

(2) Position the trim panel and seat the clips fully.

(3) Instal the screws and install the screw plug.

Fig. 8 LATCH ADJUSTMENT SCREW

1 - DOOR LATCH

2 - MYLAR TAPE

3 - ADJUSTMENT SCREW

Fig. 9 LATCH STRIKER

1 - C-PILLAR

2 - SPACER

3 - STRIKER

4 - SCREWS

Fig. 10 A REAR TRIM PANEL

1 - WATERDAM

2 - TRIM PANEL CLIP HOLES

3 - INTERIOR HANDLE AND ACTUATOR ROD

4 - SCREWS (2)

5 - TRIM PANEL CLIPS

6 - INTERIOR HANDLE SCREW PLUG

23 - 132 DOORS - REARKJ

LATCH (Continued)

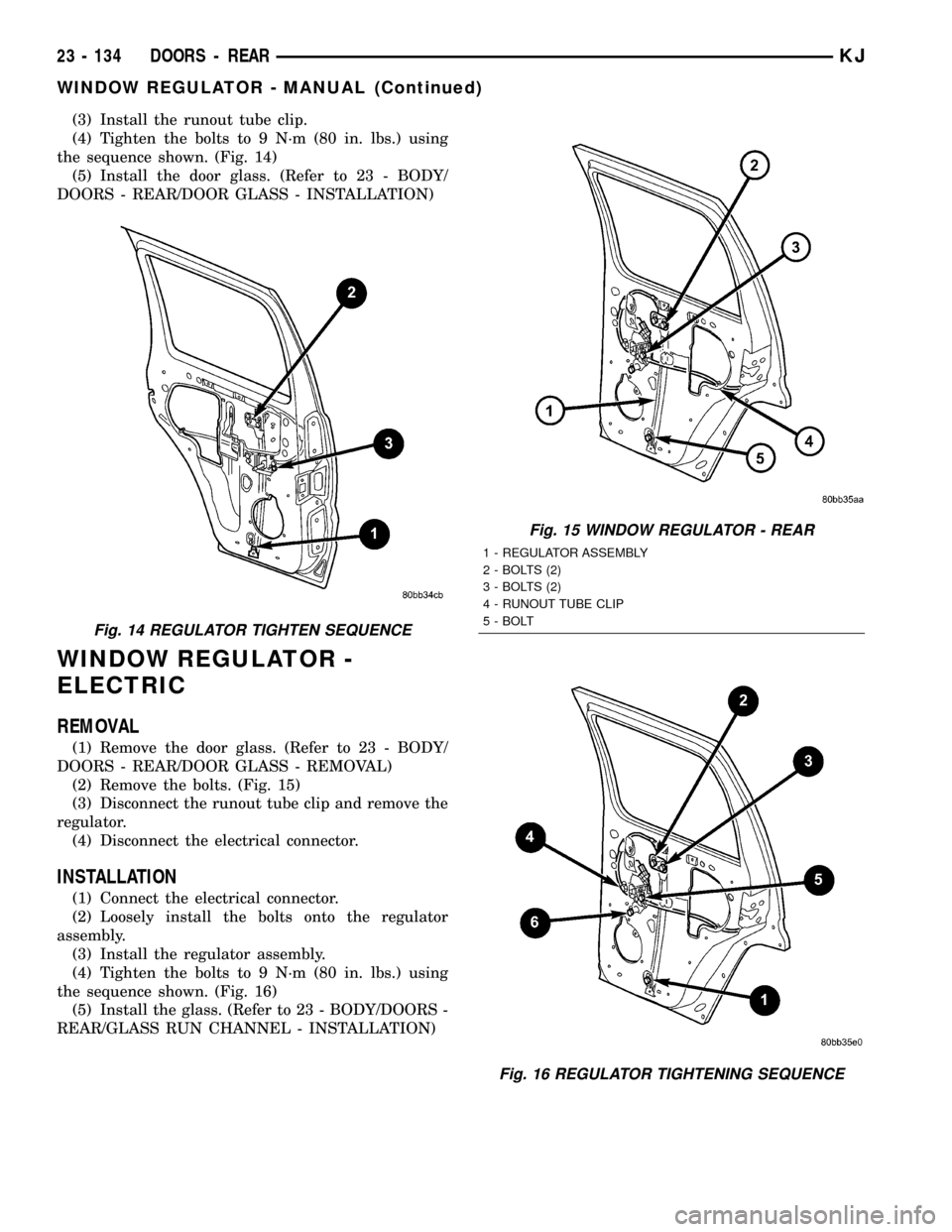

Page 1599 of 1803

(3) Install the runout tube clip.

(4) Tighten the bolts to 9 N´m (80 in. lbs.) using

the sequence shown. (Fig. 14)

(5) Install the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - INSTALLATION)

WINDOW REGULATOR -

ELECTRIC

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - REMOVAL)

(2) Remove the bolts. (Fig. 15)

(3) Disconnect the runout tube clip and remove the

regulator.

(4) Disconnect the electrical connector.

INSTALLATION

(1) Connect the electrical connector.

(2) Loosely install the bolts onto the regulator

assembly.

(3) Install the regulator assembly.

(4) Tighten the bolts to 9 N´m (80 in. lbs.) using

the sequence shown. (Fig. 16)

(5) Install the glass. (Refer to 23 - BODY/DOORS -

REAR/GLASS RUN CHANNEL - INSTALLATION)

Fig. 14 REGULATOR TIGHTEN SEQUENCE

Fig. 15 WINDOW REGULATOR - REAR

1 - REGULATOR ASSEMBLY

2 - BOLTS (2)

3 - BOLTS (2)

4 - RUNOUT TUBE CLIP

5 - BOLT

Fig. 16 REGULATOR TIGHTENING SEQUENCE

23 - 134 DOORS - REARKJ

WINDOW REGULATOR - MANUAL (Continued)

Page 1601 of 1803

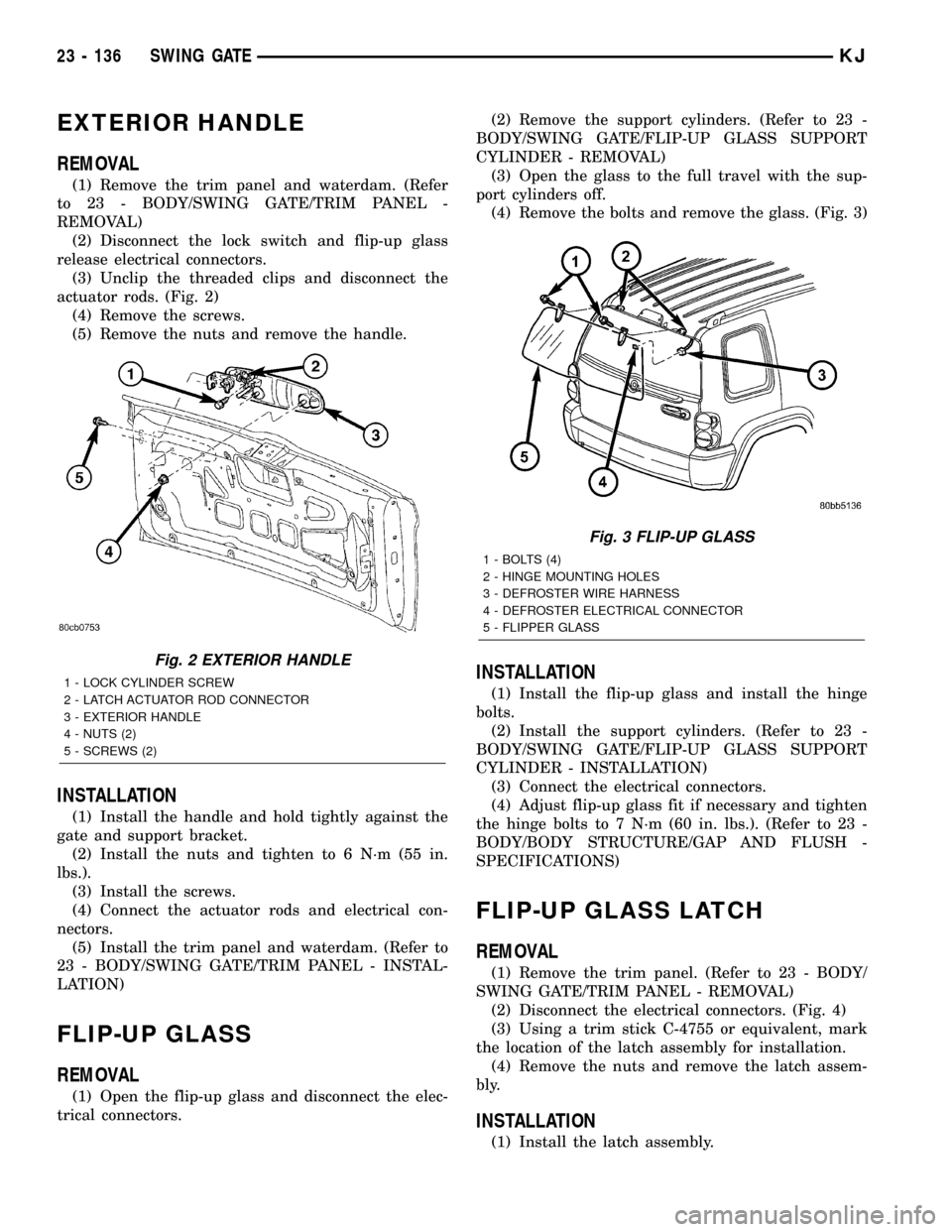

EXTERIOR HANDLE

REMOVAL

(1) Remove the trim panel and waterdam. (Refer

to 23 - BODY/SWING GATE/TRIM PANEL -

REMOVAL)

(2) Disconnect the lock switch and flip-up glass

release electrical connectors.

(3) Unclip the threaded clips and disconnect the

actuator rods. (Fig. 2)

(4) Remove the screws.

(5) Remove the nuts and remove the handle.

INSTALLATION

(1) Install the handle and hold tightly against the

gate and support bracket.

(2) Install the nuts and tighten to 6 N´m (55 in.

lbs.).

(3) Install the screws.

(4) Connect the actuator rods and electrical con-

nectors.

(5) Install the trim panel and waterdam. (Refer to

23 - BODY/SWING GATE/TRIM PANEL - INSTAL-

LATION)

FLIP-UP GLASS

REMOVAL

(1) Open the flip-up glass and disconnect the elec-

trical connectors.(2) Remove the support cylinders. (Refer to 23 -

BODY/SWING GATE/FLIP-UP GLASS SUPPORT

CYLINDER - REMOVAL)

(3) Open the glass to the full travel with the sup-

port cylinders off.

(4) Remove the bolts and remove the glass. (Fig. 3)

INSTALLATION

(1) Install the flip-up glass and install the hinge

bolts.

(2) Install the support cylinders. (Refer to 23 -

BODY/SWING GATE/FLIP-UP GLASS SUPPORT

CYLINDER - INSTALLATION)

(3) Connect the electrical connectors.

(4) Adjust flip-up glass fit if necessary and tighten

the hinge bolts to 7 N´m (60 in. lbs.). (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

FLIP-UP GLASS LATCH

REMOVAL

(1) Remove the trim panel. (Refer to 23 - BODY/

SWING GATE/TRIM PANEL - REMOVAL)

(2) Disconnect the electrical connectors. (Fig. 4)

(3) Using a trim stick C-4755 or equivalent, mark

the location of the latch assembly for installation.

(4) Remove the nuts and remove the latch assem-

bly.

INSTALLATION

(1) Install the latch assembly.

Fig. 2 EXTERIOR HANDLE

1 - LOCK CYLINDER SCREW

2 - LATCH ACTUATOR ROD CONNECTOR

3 - EXTERIOR HANDLE

4 - NUTS (2)

5 - SCREWS (2)

Fig. 3 FLIP-UP GLASS

1 - BOLTS (4)

2 - HINGE MOUNTING HOLES

3 - DEFROSTER WIRE HARNESS

4 - DEFROSTER ELECTRICAL CONNECTOR

5 - FLIPPER GLASS

23 - 136 SWING GATEKJ

Page 1602 of 1803

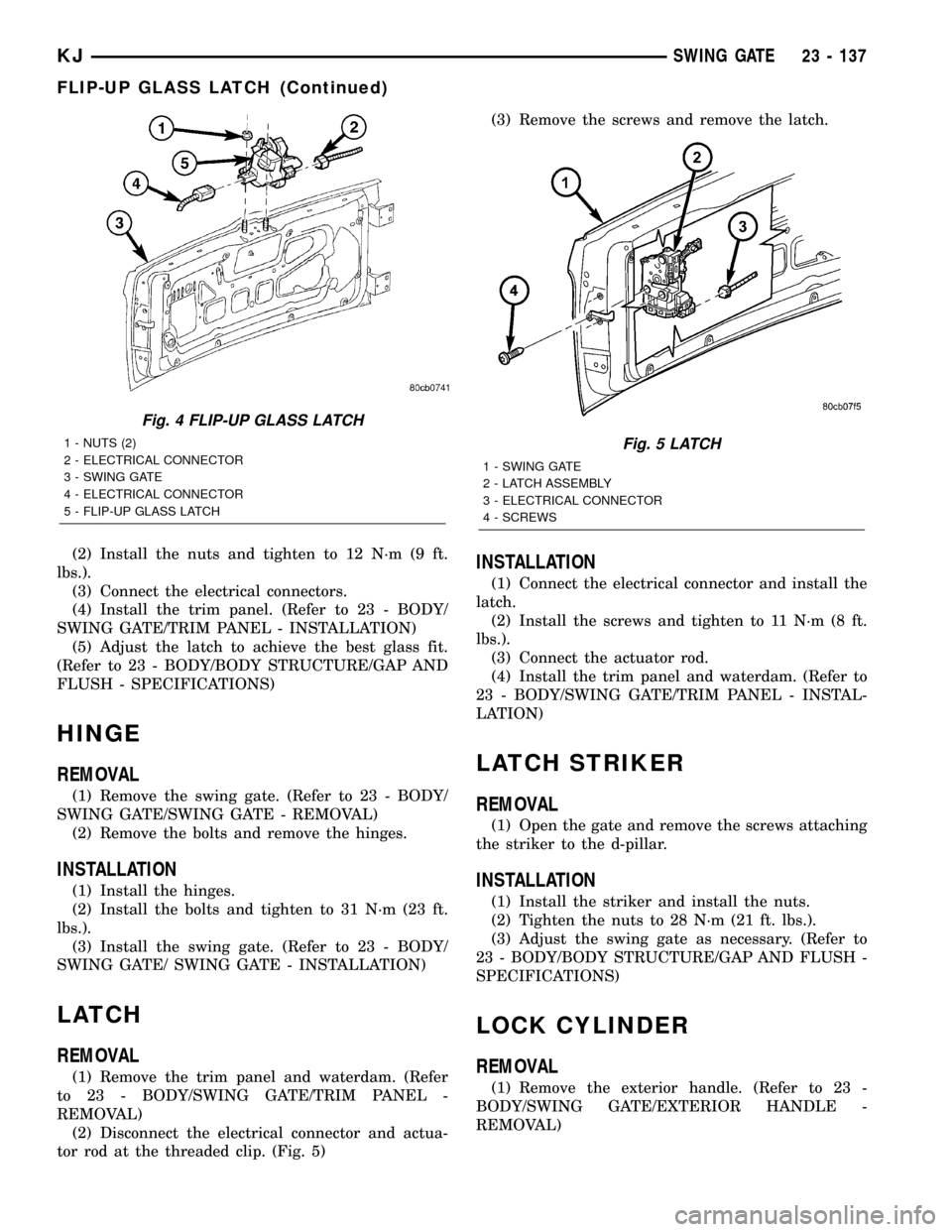

(2) Install the nuts and tighten to 12 N´m (9 ft.

lbs.).

(3) Connect the electrical connectors.

(4) Install the trim panel. (Refer to 23 - BODY/

SWING GATE/TRIM PANEL - INSTALLATION)

(5) Adjust the latch to achieve the best glass fit.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

HINGE

REMOVAL

(1) Remove the swing gate. (Refer to 23 - BODY/

SWING GATE/SWING GATE - REMOVAL)

(2) Remove the bolts and remove the hinges.

INSTALLATION

(1) Install the hinges.

(2) Install the bolts and tighten to 31 N´m (23 ft.

lbs.).

(3) Install the swing gate. (Refer to 23 - BODY/

SWING GATE/ SWING GATE - INSTALLATION)

LATCH

REMOVAL

(1) Remove the trim panel and waterdam. (Refer

to 23 - BODY/SWING GATE/TRIM PANEL -

REMOVAL)

(2) Disconnect the electrical connector and actua-

tor rod at the threaded clip. (Fig. 5)(3) Remove the screws and remove the latch.

INSTALLATION

(1) Connect the electrical connector and install the

latch.

(2) Install the screws and tighten to 11 N´m (8 ft.

lbs.).

(3) Connect the actuator rod.

(4) Install the trim panel and waterdam. (Refer to

23 - BODY/SWING GATE/TRIM PANEL - INSTAL-

LATION)

LATCH STRIKER

REMOVAL

(1) Open the gate and remove the screws attaching

the striker to the d-pillar.

INSTALLATION

(1) Install the striker and install the nuts.

(2) Tighten the nuts to 28 N´m (21 ft. lbs.).

(3) Adjust the swing gate as necessary. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

LOCK CYLINDER

REMOVAL

(1) Remove the exterior handle. (Refer to 23 -

BODY/SWING GATE/EXTERIOR HANDLE -

REMOVAL)

Fig. 4 FLIP-UP GLASS LATCH

1 - NUTS (2)

2 - ELECTRICAL CONNECTOR

3 - SWING GATE

4 - ELECTRICAL CONNECTOR

5 - FLIP-UP GLASS LATCHFig. 5 LATCH

1 - SWING GATE

2 - LATCH ASSEMBLY

3 - ELECTRICAL CONNECTOR

4 - SCREWS

KJSWING GATE 23 - 137

FLIP-UP GLASS LATCH (Continued)

Page 1603 of 1803

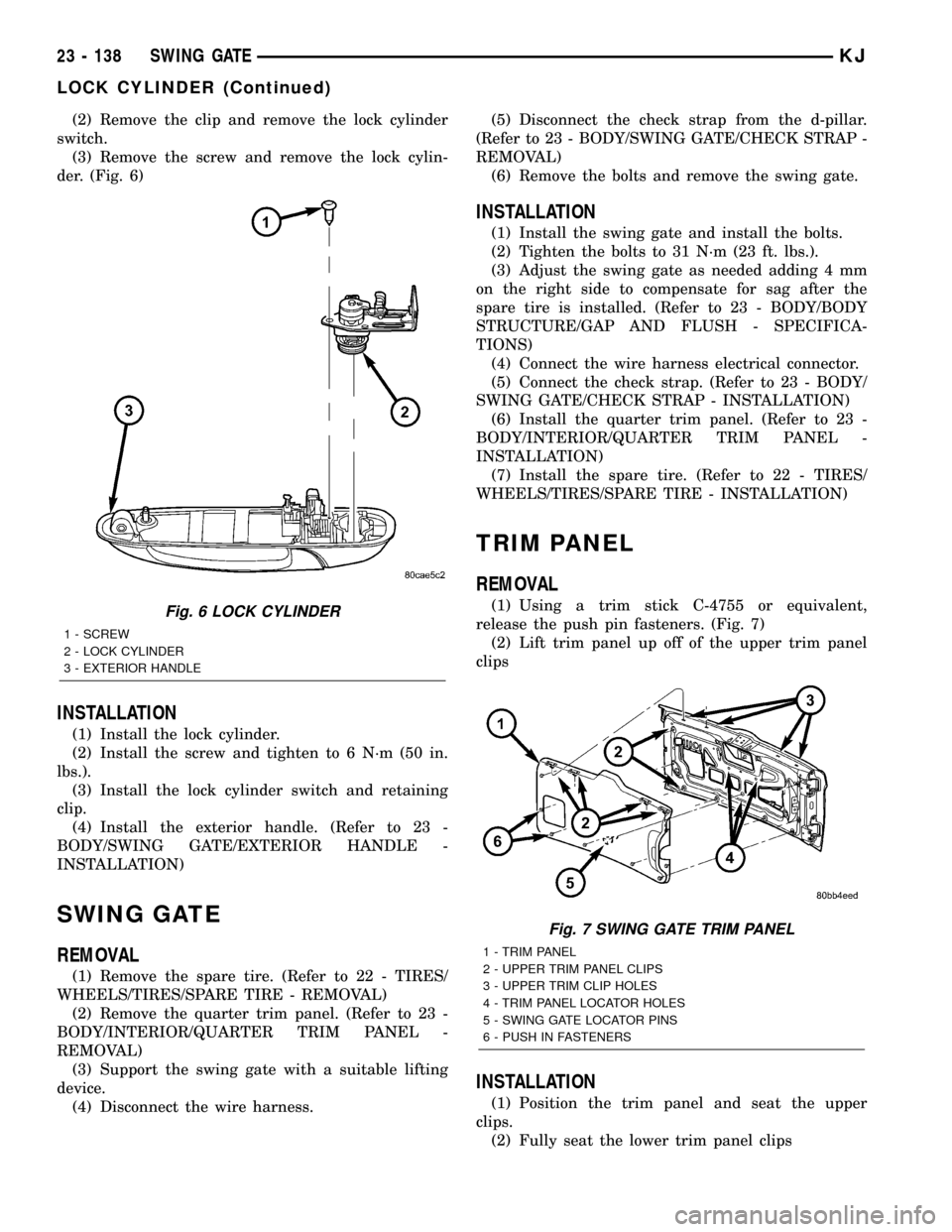

(2) Remove the clip and remove the lock cylinder

switch.

(3) Remove the screw and remove the lock cylin-

der. (Fig. 6)

INSTALLATION

(1) Install the lock cylinder.

(2) Install the screw and tighten to 6 N´m (50 in.

lbs.).

(3) Install the lock cylinder switch and retaining

clip.

(4) Install the exterior handle. (Refer to 23 -

BODY/SWING GATE/EXTERIOR HANDLE -

INSTALLATION)

SWING GATE

REMOVAL

(1) Remove the spare tire. (Refer to 22 - TIRES/

WHEELS/TIRES/SPARE TIRE - REMOVAL)

(2) Remove the quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(3) Support the swing gate with a suitable lifting

device.

(4) Disconnect the wire harness.(5) Disconnect the check strap from the d-pillar.

(Refer to 23 - BODY/SWING GATE/CHECK STRAP -

REMOVAL)

(6) Remove the bolts and remove the swing gate.

INSTALLATION

(1) Install the swing gate and install the bolts.

(2) Tighten the bolts to 31 N´m (23 ft. lbs.).

(3) Adjust the swing gate as needed adding 4 mm

on the right side to compensate for sag after the

spare tire is installed. (Refer to 23 - BODY/BODY

STRUCTURE/GAP AND FLUSH - SPECIFICA-

TIONS)

(4) Connect the wire harness electrical connector.

(5) Connect the check strap. (Refer to 23 - BODY/

SWING GATE/CHECK STRAP - INSTALLATION)

(6) Install the quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION)

(7) Install the spare tire. (Refer to 22 - TIRES/

WHEELS/TIRES/SPARE TIRE - INSTALLATION)

TRIM PANEL

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

release the push pin fasteners. (Fig. 7)

(2) Lift trim panel up off of the upper trim panel

clips

INSTALLATION

(1) Position the trim panel and seat the upper

clips.

(2) Fully seat the lower trim panel clips

Fig. 6 LOCK CYLINDER

1 - SCREW

2 - LOCK CYLINDER

3 - EXTERIOR HANDLE

Fig. 7 SWING GATE TRIM PANEL

1 - TRIM PANEL

2 - UPPER TRIM PANEL CLIPS

3 - UPPER TRIM CLIP HOLES

4 - TRIM PANEL LOCATOR HOLES

5 - SWING GATE LOCATOR PINS

6 - PUSH IN FASTENERS

23 - 138 SWING GATEKJ

LOCK CYLINDER (Continued)

Page 1607 of 1803

(2) Install the three screws.

(3) Install the fuel cap.

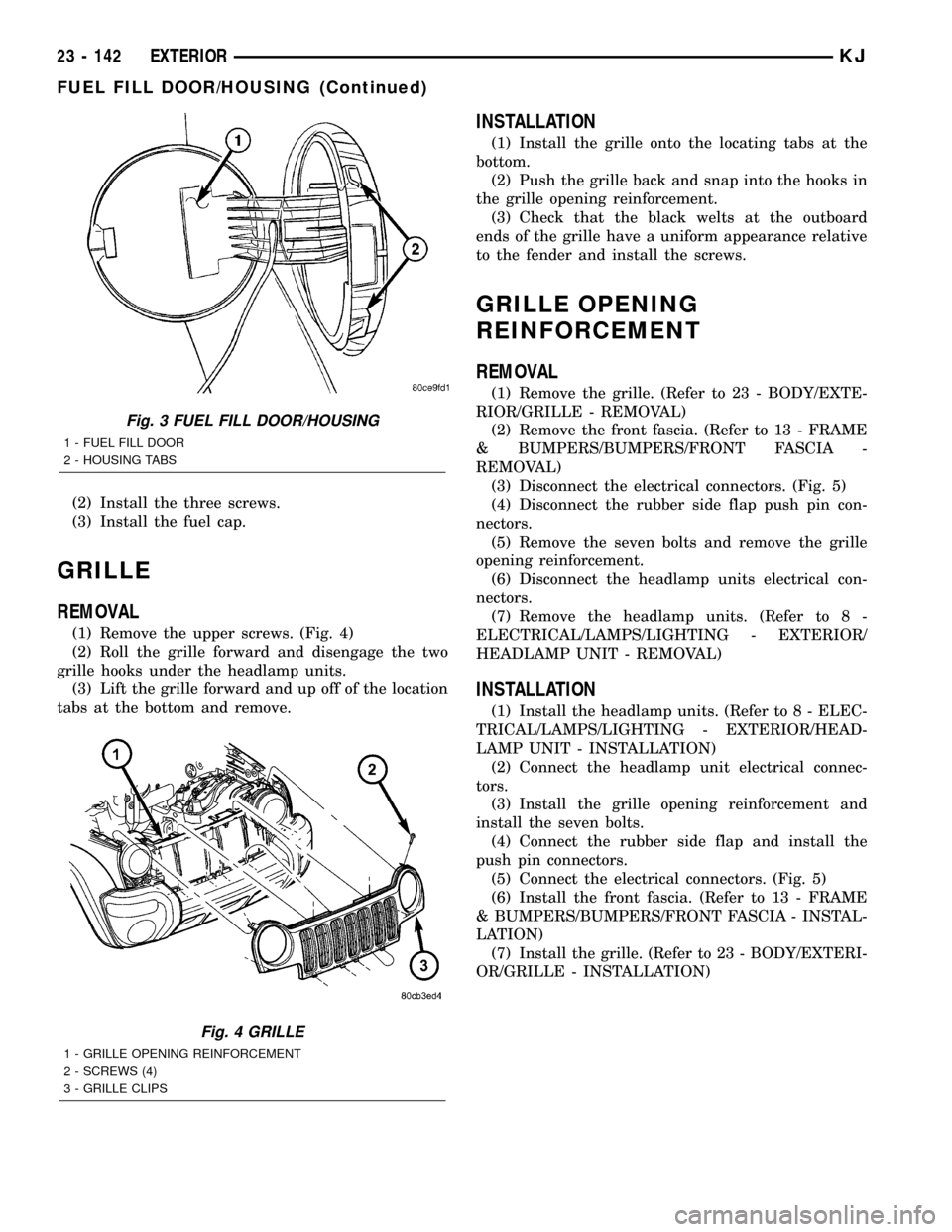

GRILLE

REMOVAL

(1) Remove the upper screws. (Fig. 4)

(2) Roll the grille forward and disengage the two

grille hooks under the headlamp units.

(3) Lift the grille forward and up off of the location

tabs at the bottom and remove.

INSTALLATION

(1) Install the grille onto the locating tabs at the

bottom.

(2) Push the grille back and snap into the hooks in

the grille opening reinforcement.

(3) Check that the black welts at the outboard

ends of the grille have a uniform appearance relative

to the fender and install the screws.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(2) Remove the front fascia. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT FASCIA -

REMOVAL)

(3) Disconnect the electrical connectors. (Fig. 5)

(4) Disconnect the rubber side flap push pin con-

nectors.

(5) Remove the seven bolts and remove the grille

opening reinforcement.

(6) Disconnect the headlamp units electrical con-

nectors.

(7) Remove the headlamp units. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

INSTALLATION

(1) Install the headlamp units. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(2) Connect the headlamp unit electrical connec-

tors.

(3) Install the grille opening reinforcement and

install the seven bolts.

(4) Connect the rubber side flap and install the

push pin connectors.

(5) Connect the electrical connectors. (Fig. 5)

(6) Install the front fascia. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT FASCIA - INSTAL-

LATION)

(7) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

Fig. 3 FUEL FILL DOOR/HOUSING

1 - FUEL FILL DOOR

2 - HOUSING TABS

Fig. 4 GRILLE

1 - GRILLE OPENING REINFORCEMENT

2 - SCREWS (4)

3 - GRILLE CLIPS

23 - 142 EXTERIORKJ

FUEL FILL DOOR/HOUSING (Continued)