eco JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1301 of 1803

(7) Crank engine until maximum pressure is

reached on gage. Record this pressure as #1 cylinder

pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

9s - 4 ENGINEKJ

ENGINE - 2.4L (Continued)

Page 1307 of 1803

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Alwaysinspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed-

plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gaskets

against leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

9s - 10 ENGINEKJ

ENGINE - 2.4L (Continued)

Page 1308 of 1803

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

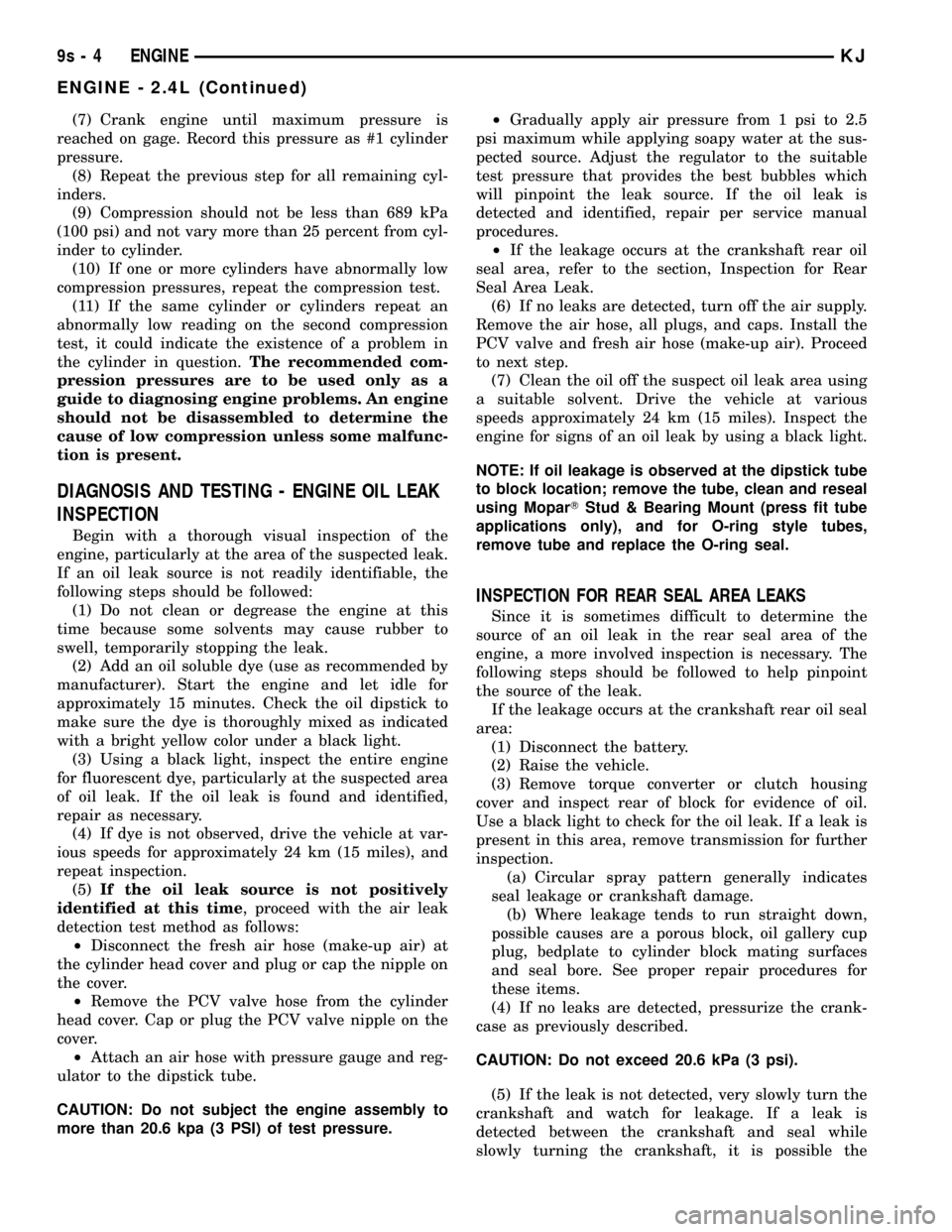

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 3)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 3)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 3)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

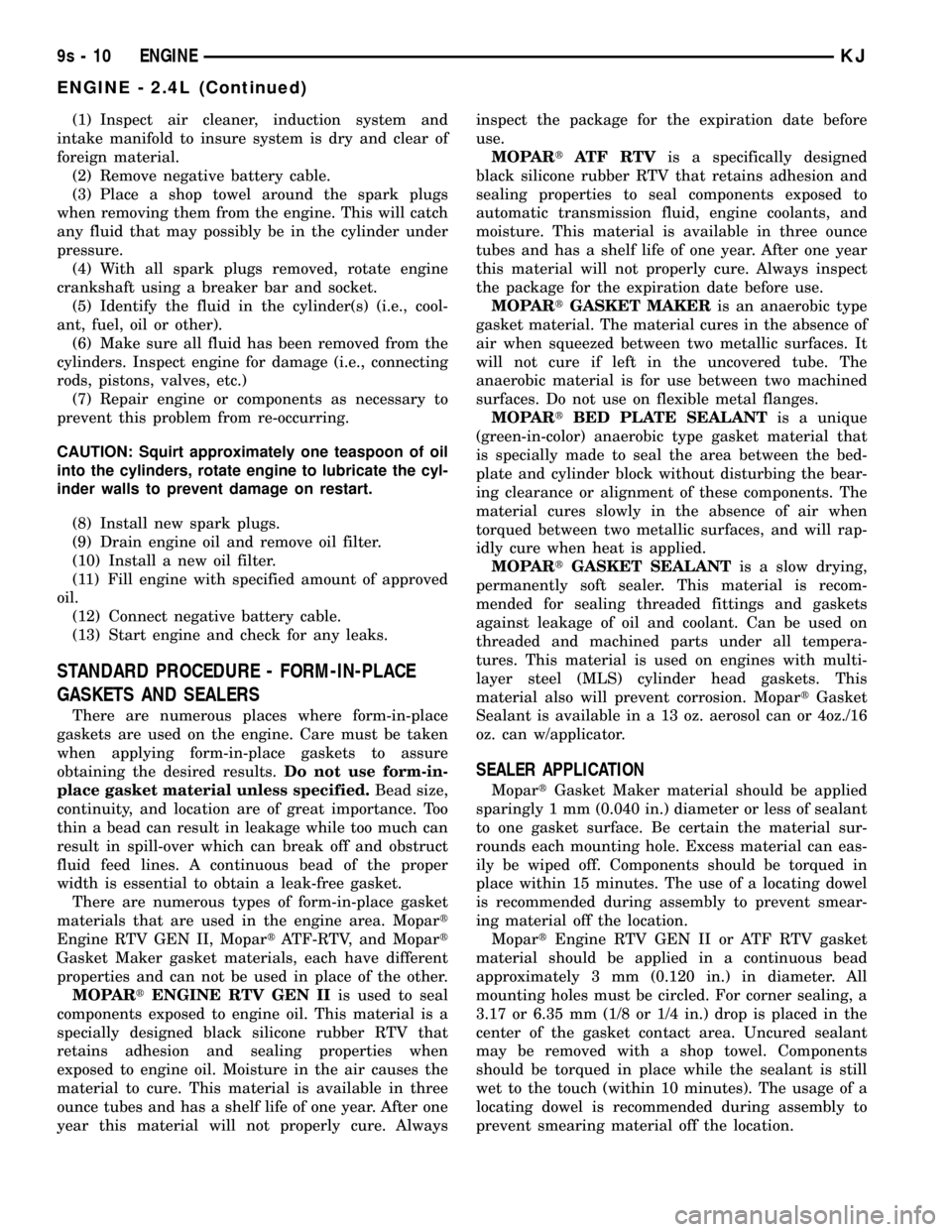

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 4). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metricscale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

Fig. 3 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 4 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

KJENGINE9s-11

ENGINE - 2.4L (Continued)

Page 1310 of 1803

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

(12) Install the exhaust pipe.

(13) Connect the oxygen sensors.

(14) Lower vehicle.

(15) Connect the knock sensors.

(16) Connect the engine to body ground straps.

(17) Install the power brake booster vacuum hose.

(18) Install the breather hoses.

(19) Install the PCV hose.

(20) Install the fuel rail.

(21) Install the coil over plugs.

(22) Reconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(23) Connect lower radiator hose.

(24) Connect upper radiator hose.

(25) Connect throttle and speed control cables.

(26) Install the heater hose assembly.

(27) Install coolant recovery bottle.

(28) Install the power steering pump.

(29) Install the generator.

(30) Install the A/C compressor.

(31) Install the drive belt.

(32) Install the fan shroud with the electric fan

assembly.

(33) Install the radiator core support bracket.

(34) Install the air cleaner assembly.

(35) Refill the engine cooling system.

(36) Install the hood.

(37) Check and fill engine oil.

(38) Connect the battery negative cable.

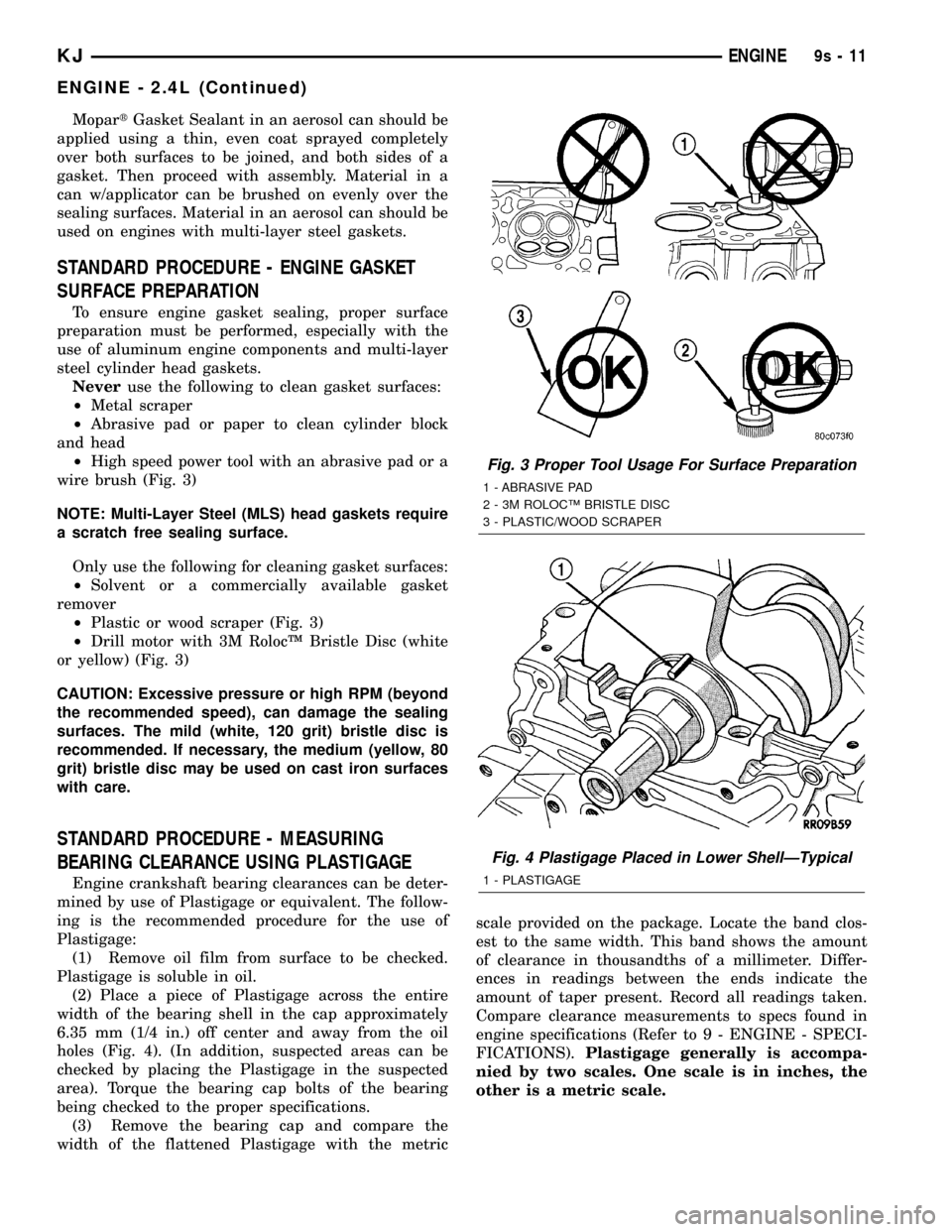

(39) Start the engine and check for leaks.SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE

DESCRIPTION SPECIFICATION

General Specification

Type In-Line OHV, DOHC

Number of Cylinders 4

Displacement 2.4 Liters

(148 cu. in.)

Bore 87.5 mm

(3.445 in.)

Stroke 101.0 mm

(3.976 in.)

Compression Ratio 9.4:1

Firing Order 1-3-4-2

Compression Pressure 690 kPa (Minimum)

(100 psi Minimum)

Max. Variation Between

Cylinders25%

Cylinder Block

Cylinder Bore Diameter 87.4924±87.5076 mm

(3.4446±3.4452 in.)

Out-of-Round (Max.) 0.051 mm

(0.002 in.)

Taper (Max.) 0.051 mm

(0.002 in.)

Pistons

Piston Diameter 87.463±87.481 mm

(3.4434±3.4441 in.)

Clearance @ 14 mm

(9/16 in.) from bottom of

skirt0.024±0.057 mm

(0.0009±0.0022 in.)

Weight 346±356 grams

(12.20±12.56 oz.)

Land Clearance

(Diametrical)0.614±0.664 mm

(0.024±0.026 in.)

Piston Length 66.25 mm

(2.608 in.)

Piston Ring Groove

Depth No. 14.640±4.784 mm

(0.182±0.188 in.)

Piston Ring Groove

Depth No. 24.575±4.719 mm

(0.180±0.185 in.)

KJENGINE9s-13

ENGINE - 2.4L (Continued)

Page 1316 of 1803

AIR CLEANER ELEMENT

REMOVAL - 2.4L

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Disconnect air intake duct at side of element

cover.

(2) Pry up 2 spring clips from front of housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs

located on rear of housing, and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

INSTALLATION - 2.4L

(1) Install element into housing.

(2) Position housing cover into housing locating

tabs.

(3) Pry up spring clips and lock cover to housing.

(4) Connect air intake duct.

If any air filter, air resonator, air intake tubes or

air filter housing clamps had been loosened or

removed, tighten them to 5 N´m (40 in. lbs.) torque.

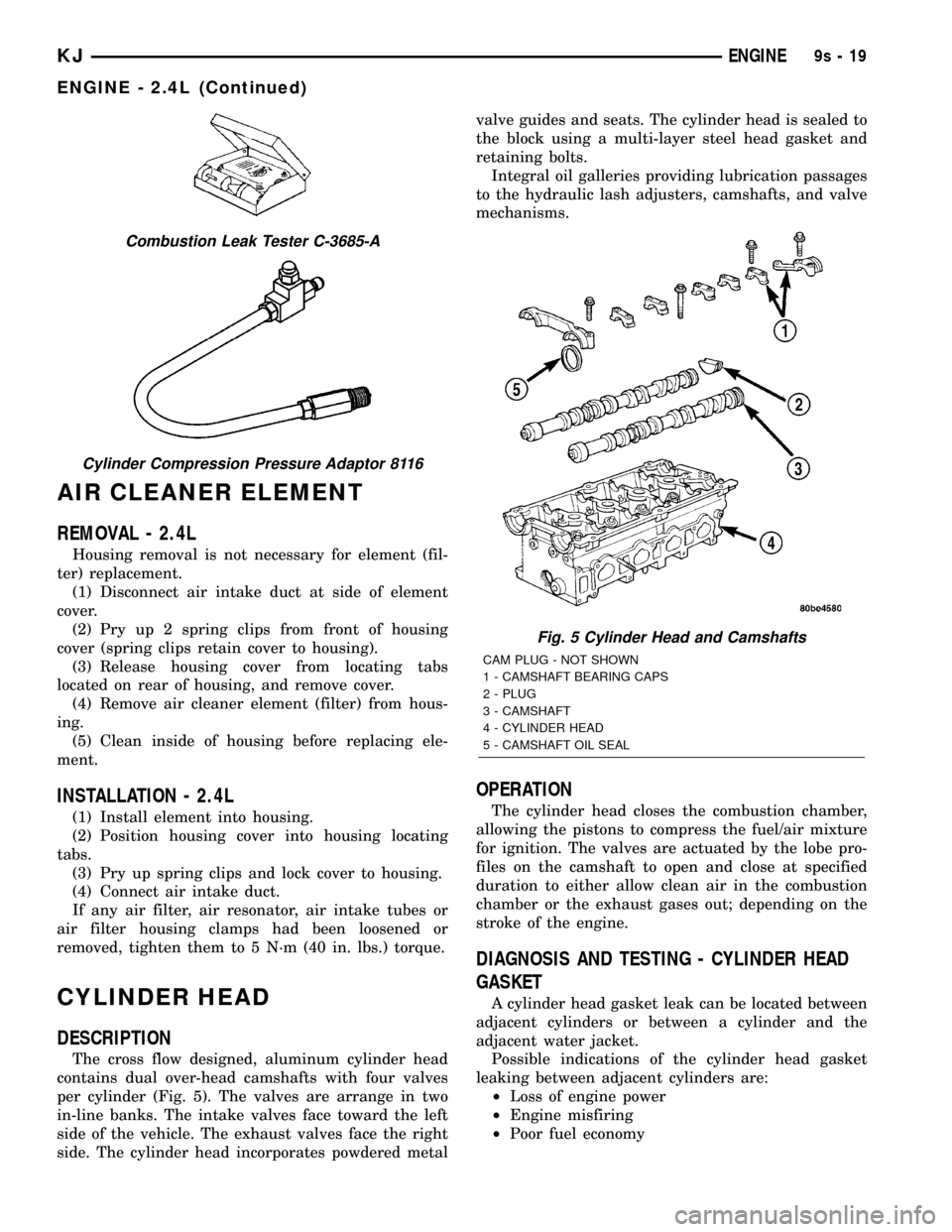

CYLINDER HEAD

DESCRIPTION

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 5). The valves are arrange in two

in-line banks. The intake valves face toward the left

side of the vehicle. The exhaust valves face the right

side. The cylinder head incorporates powdered metalvalve guides and seats. The cylinder head is sealed to

the block using a multi-layer steel head gasket and

retaining bolts.

Integral oil galleries providing lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Combustion Leak Tester C-3685-A

Cylinder Compression Pressure Adaptor 8116

Fig. 5 Cylinder Head and Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

KJENGINE9s-19

ENGINE - 2.4L (Continued)

Page 1318 of 1803

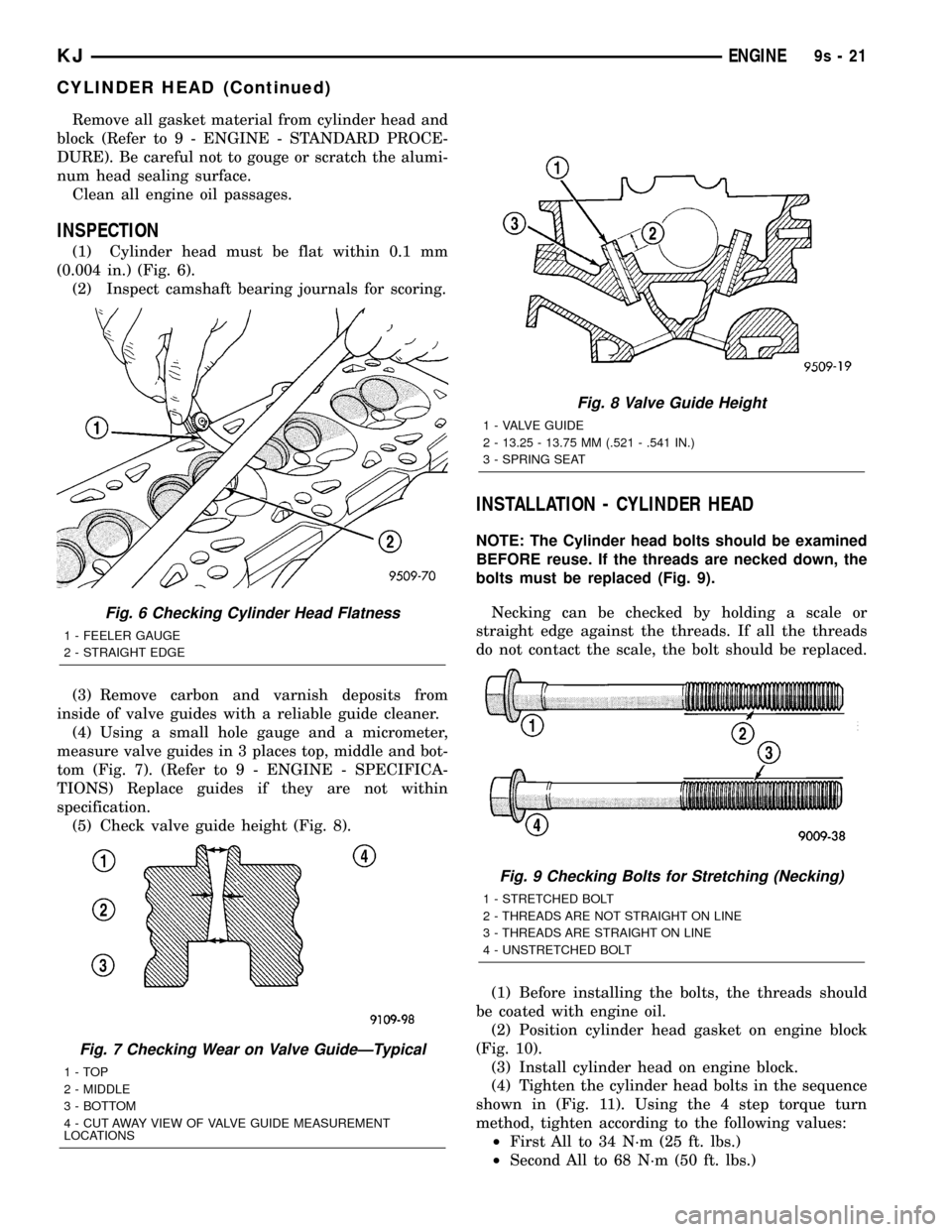

Remove all gasket material from cylinder head and

block (Refer to 9 - ENGINE - STANDARD PROCE-

DURE). Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

INSPECTION

(1) Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 6).

(2) Inspect camshaft bearing journals for scoring.

(3) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(4) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 7). (Refer to 9 - ENGINE - SPECIFICA-

TIONS) Replace guides if they are not within

specification.

(5) Check valve guide height (Fig. 8).

INSTALLATION - CYLINDER HEAD

NOTE: The Cylinder head bolts should be examined

BEFORE reuse. If the threads are necked down, the

bolts must be replaced (Fig. 9).

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale, the bolt should be replaced.

(1) Before installing the bolts, the threads should

be coated with engine oil.

(2) Position cylinder head gasket on engine block

(Fig. 10).

(3) Install cylinder head on engine block.

(4) Tighten the cylinder head bolts in the sequence

shown in (Fig. 11). Using the 4 step torque turn

method, tighten according to the following values:

²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

Fig. 6 Checking Cylinder Head Flatness

1 - FEELER GAUGE

2 - STRAIGHT EDGE

Fig. 7 Checking Wear on Valve GuideÐTypical

1-TOP

2 - MIDDLE

3 - BOTTOM

4 - CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 8 Valve Guide Height

1 - VALVE GUIDE

2 - 13.25 - 13.75 MM (.521 - .541 IN.)

3 - SPRING SEAT

Fig. 9 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

KJENGINE9s-21

CYLINDER HEAD (Continued)

Page 1320 of 1803

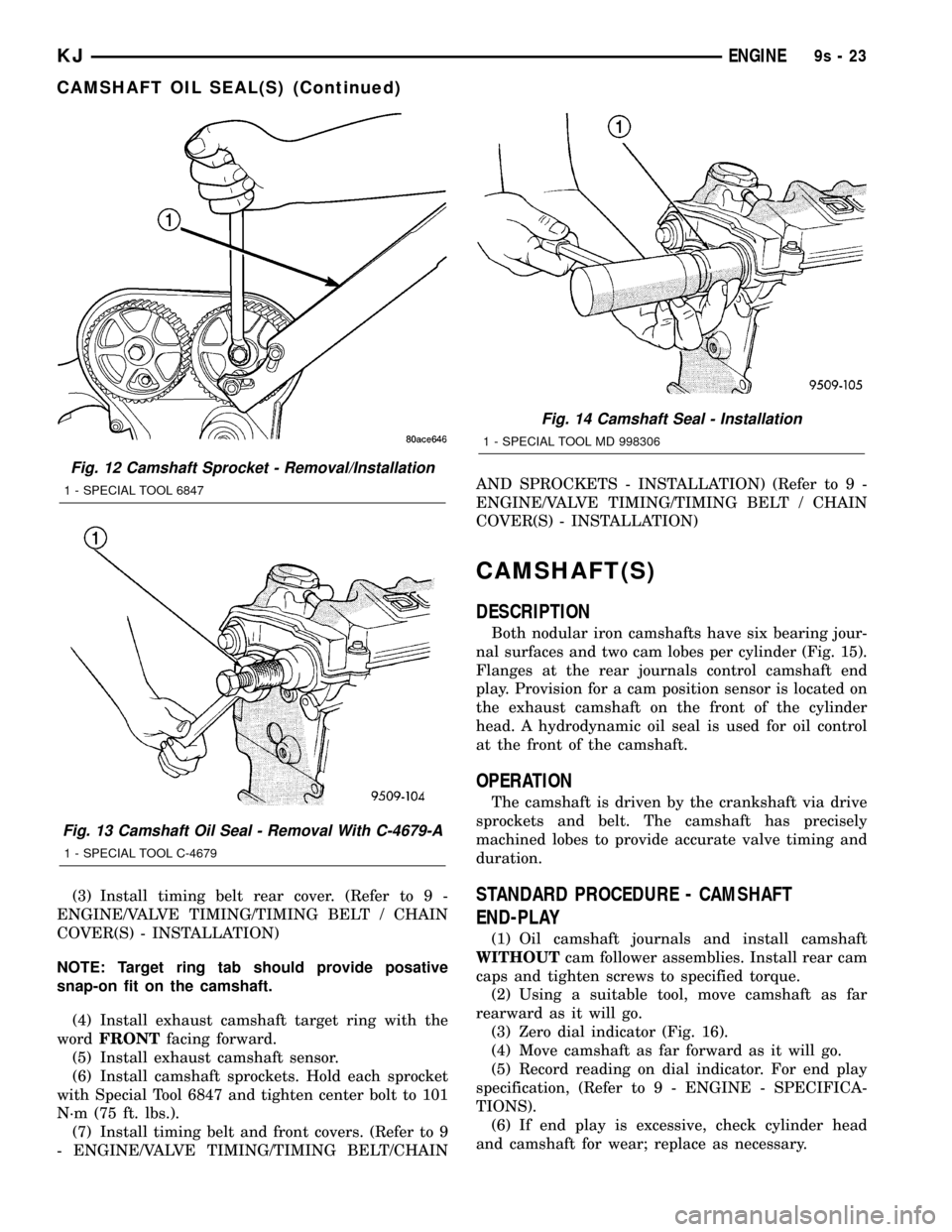

(3) Install timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

NOTE: Target ring tab should provide posative

snap-on fit on the camshaft.

(4) Install exhaust camshaft target ring with the

wordFRONTfacing forward.

(5) Install exhaust camshaft sensor.

(6) Install camshaft sprockets. Hold each sprocket

with Special Tool 6847 and tighten center bolt to 101

N´m (75 ft. lbs.).

(7) Install timing belt and front covers. (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT/CHAINAND SPROCKETS - INSTALLATION) (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

CAMSHAFT(S)

DESCRIPTION

Both nodular iron camshafts have six bearing jour-

nal surfaces and two cam lobes per cylinder (Fig. 15).

Flanges at the rear journals control camshaft end

play. Provision for a cam position sensor is located on

the exhaust camshaft on the front of the cylinder

head. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

OPERATION

The camshaft is driven by the crankshaft via drive

sprockets and belt. The camshaft has precisely

machined lobes to provide accurate valve timing and

duration.

STANDARD PROCEDURE - CAMSHAFT

END-PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTcam follower assemblies. Install rear cam

caps and tighten screws to specified torque.

(2) Using a suitable tool, move camshaft as far

rearward as it will go.

(3) Zero dial indicator (Fig. 16).

(4) Move camshaft as far forward as it will go.

(5) Record reading on dial indicator. For end play

specification, (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

(6) If end play is excessive, check cylinder head

and camshaft for wear; replace as necessary.

Fig. 12 Camshaft Sprocket - Removal/Installation

1 - SPECIAL TOOL 6847

Fig. 13 Camshaft Oil Seal - Removal With C-4679-A

1 - SPECIAL TOOL C-4679

Fig. 14 Camshaft Seal - Installation

1 - SPECIAL TOOL MD 998306

KJENGINE9s-23

CAMSHAFT OIL SEAL(S) (Continued)

Page 1325 of 1803

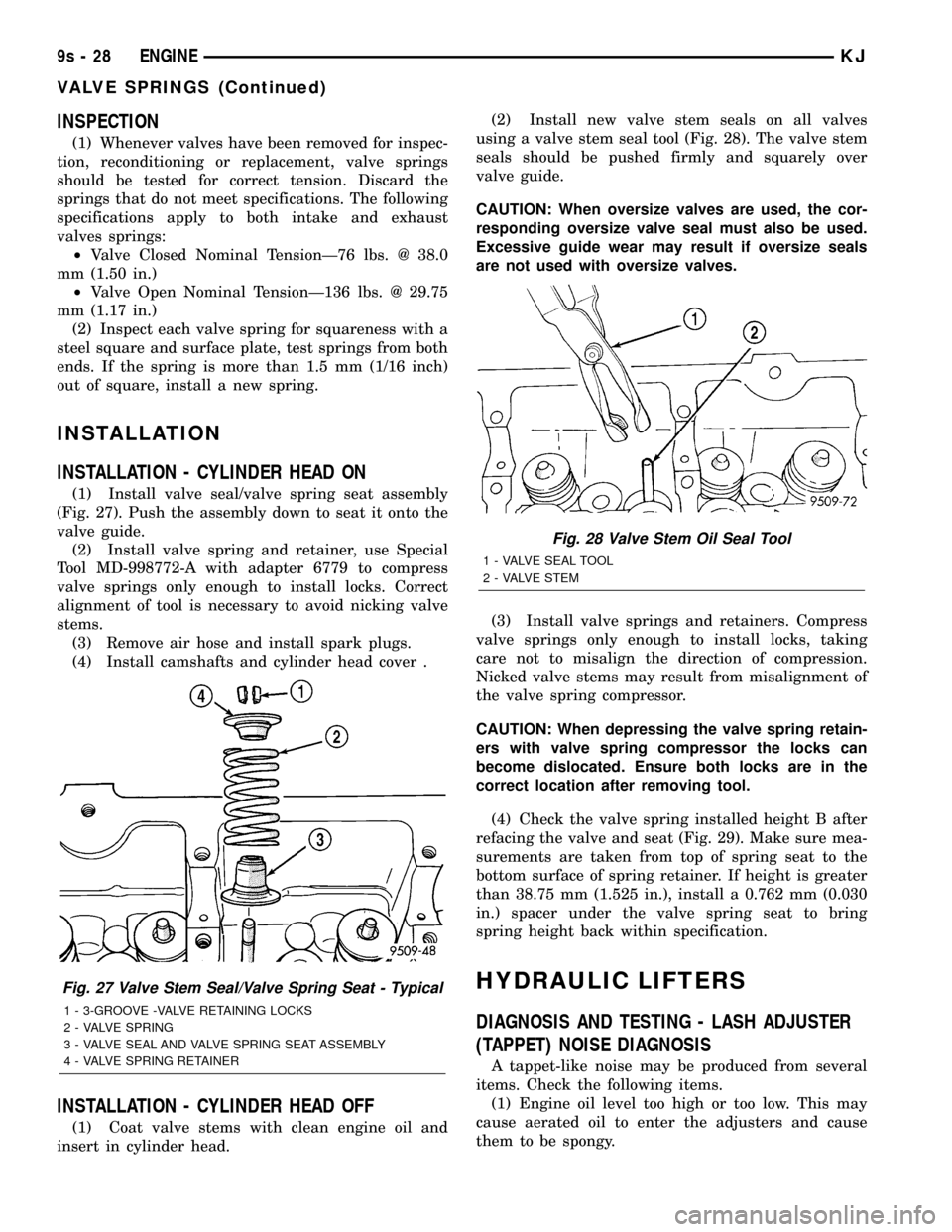

INSPECTION

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested for correct tension. Discard the

springs that do not meet specifications. The following

specifications apply to both intake and exhaust

valves springs:

²Valve Closed Nominal TensionÐ76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

INSTALLATION

INSTALLATION - CYLINDER HEAD ON

(1) Install valve seal/valve spring seat assembly

(Fig. 27). Push the assembly down to seat it onto the

valve guide.

(2) Install valve spring and retainer, use Special

Tool MD-998772-A with adapter 6779 to compress

valve springs only enough to install locks. Correct

alignment of tool is necessary to avoid nicking valve

stems.

(3) Remove air hose and install spark plugs.

(4) Install camshafts and cylinder head cover .

INSTALLATION - CYLINDER HEAD OFF

(1) Coat valve stems with clean engine oil and

insert in cylinder head.(2) Install new valve stem seals on all valves

using a valve stem seal tool (Fig. 28). The valve stem

seals should be pushed firmly and squarely over

valve guide.

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with valve spring compressor the locks can

become dislocated. Ensure both locks are in the

correct location after removing tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 29). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a 0.762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTING - LASH ADJUSTER

(TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

Fig. 27 Valve Stem Seal/Valve Spring Seat - Typical

1 - 3-GROOVE -VALVE RETAINING LOCKS

2 - VALVE SPRING

3 - VALVE SEAL AND VALVE SPRING SEAT ASSEMBLY

4 - VALVE SPRING RETAINER

Fig. 28 Valve Stem Oil Seal Tool

1 - VALVE SEAL TOOL

2 - VALVE STEM

9s - 28 ENGINEKJ

VALVE SPRINGS (Continued)

Page 1328 of 1803

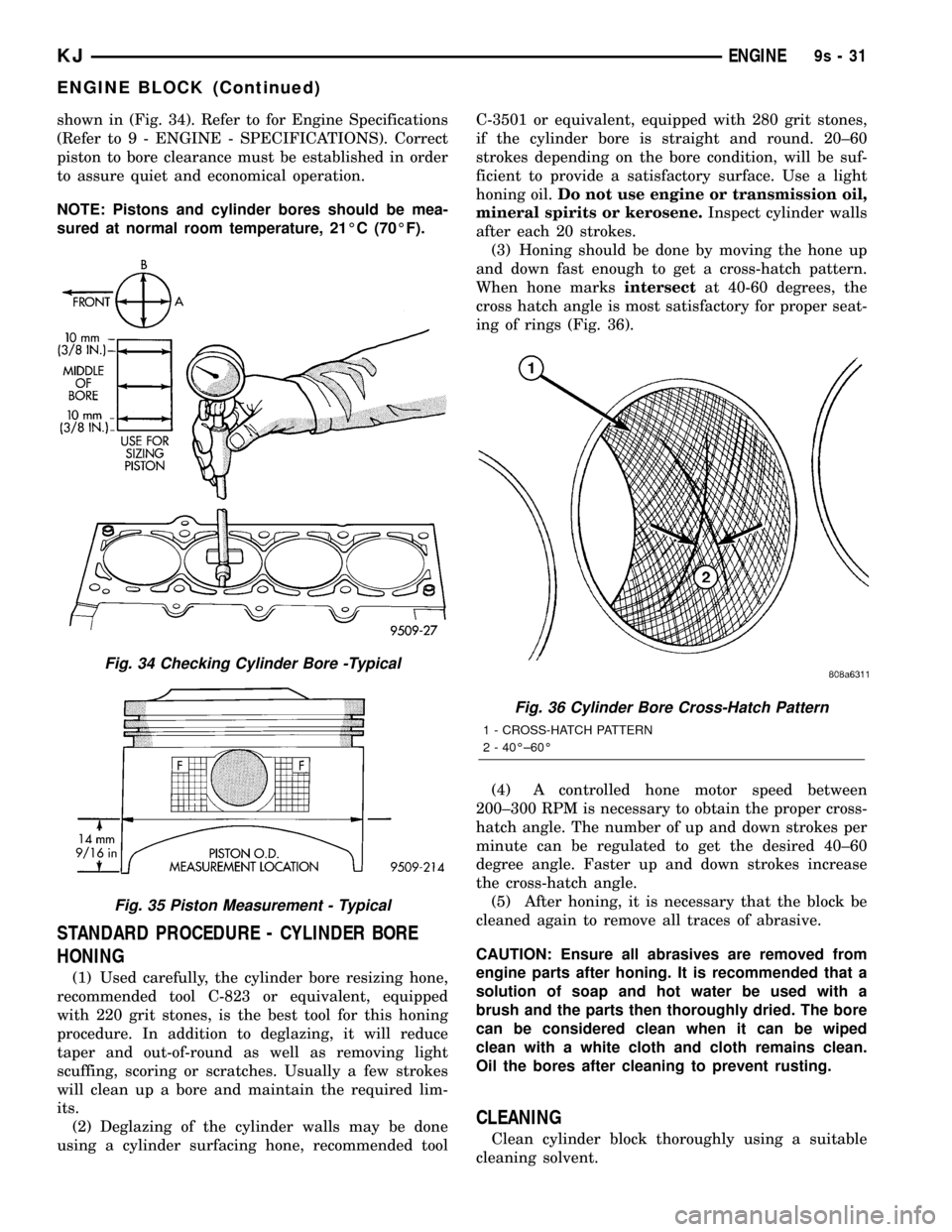

shown in (Fig. 34). Refer to for Engine Specifications

(Refer to 9 - ENGINE - SPECIFICATIONS). Correct

piston to bore clearance must be established in order

to assure quiet and economical operation.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21ÉC (70ÉF).

STANDARD PROCEDURE - CYLINDER BORE

HONING

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended toolC-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20±60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Use a light

honing oil.Do not use engine or transmission oil,

mineral spirits or kerosene.Inspect cylinder walls

after each 20 strokes.

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 40-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 36).

(4) A controlled hone motor speed between

200±300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40±60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

CLEANING

Clean cylinder block thoroughly using a suitable

cleaning solvent.

Fig. 34 Checking Cylinder Bore -Typical

Fig. 35 Piston Measurement - Typical

Fig. 36 Cylinder Bore Cross-Hatch Pattern

1 - CROSS-HATCH PATTERN

2 - 40ɱ60É

KJENGINE9s-31

ENGINE BLOCK (Continued)

Page 1338 of 1803

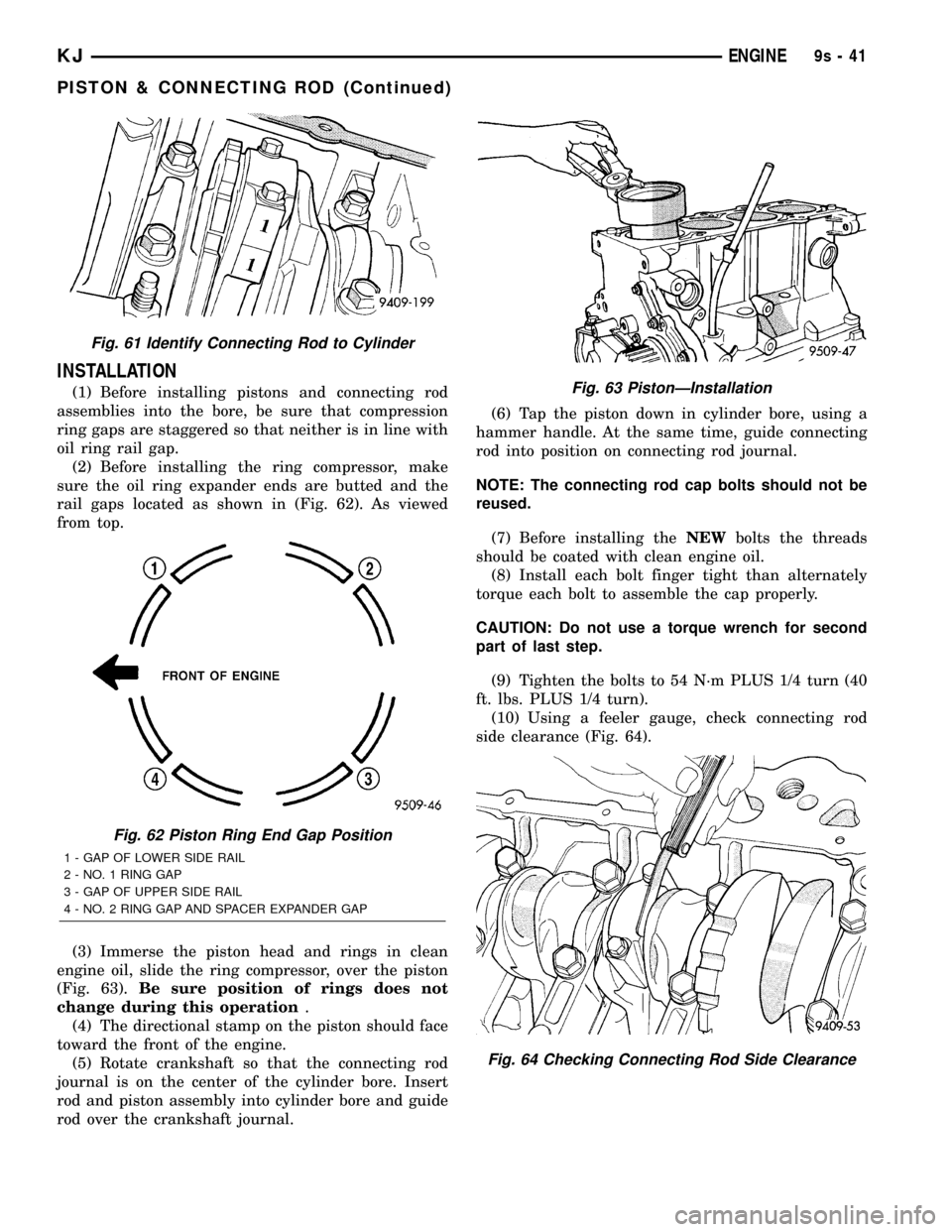

INSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 62). As viewed

from top.

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 63).Be sure position of rings does not

change during this operation.

(4) The directional stamp on the piston should face

toward the front of the engine.

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

NOTE: The connecting rod cap bolts should not be

reused.

(7) Before installing theNEWbolts the threads

should be coated with clean engine oil.

(8) Install each bolt finger tight than alternately

torque each bolt to assemble the cap properly.

CAUTION: Do not use a torque wrench for second

part of last step.

(9) Tighten the bolts to 54 N´m PLUS 1/4 turn (40

ft. lbs. PLUS 1/4 turn).

(10) Using a feeler gauge, check connecting rod

side clearance (Fig. 64).

Fig. 61 Identify Connecting Rod to Cylinder

Fig. 62 Piston Ring End Gap Position

1 - GAP OF LOWER SIDE RAIL

2 - NO. 1 RING GAP

3 - GAP OF UPPER SIDE RAIL

4 - NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 63 PistonÐInstallation

Fig. 64 Checking Connecting Rod Side Clearance

KJENGINE9s-41

PISTON & CONNECTING ROD (Continued)