roof JEEP LIBERTY 2002 KJ / 1.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1466 of 1803

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................3

STANDARD PROCEDURE - HEAT STAKING . . 3

SPECIFICATIONS........................4

SPECIAL TOOLS

BODY...............................5BODY STRUCTURE.......................6

HOOD................................119

DOOR - FRONT........................121

DOORS - REAR........................128

SWING GATE..........................135

EXTERIOR............................140

INSTRUMENT PANEL....................147

INTERIOR.............................156

PAINT................................162

SEATS...............................164

STATIONARY GLASS....................172

SUNROOF.............................175

WEATHERSTRIP/SEALS..................185

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

²USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL±BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DaimlerChrysler Corporation uses many different

types of push-in fasteners to secure the interior and

exterior trim to the body. Most of these fasteners can

be reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

KJBODY 23 - 1

Page 1469 of 1803

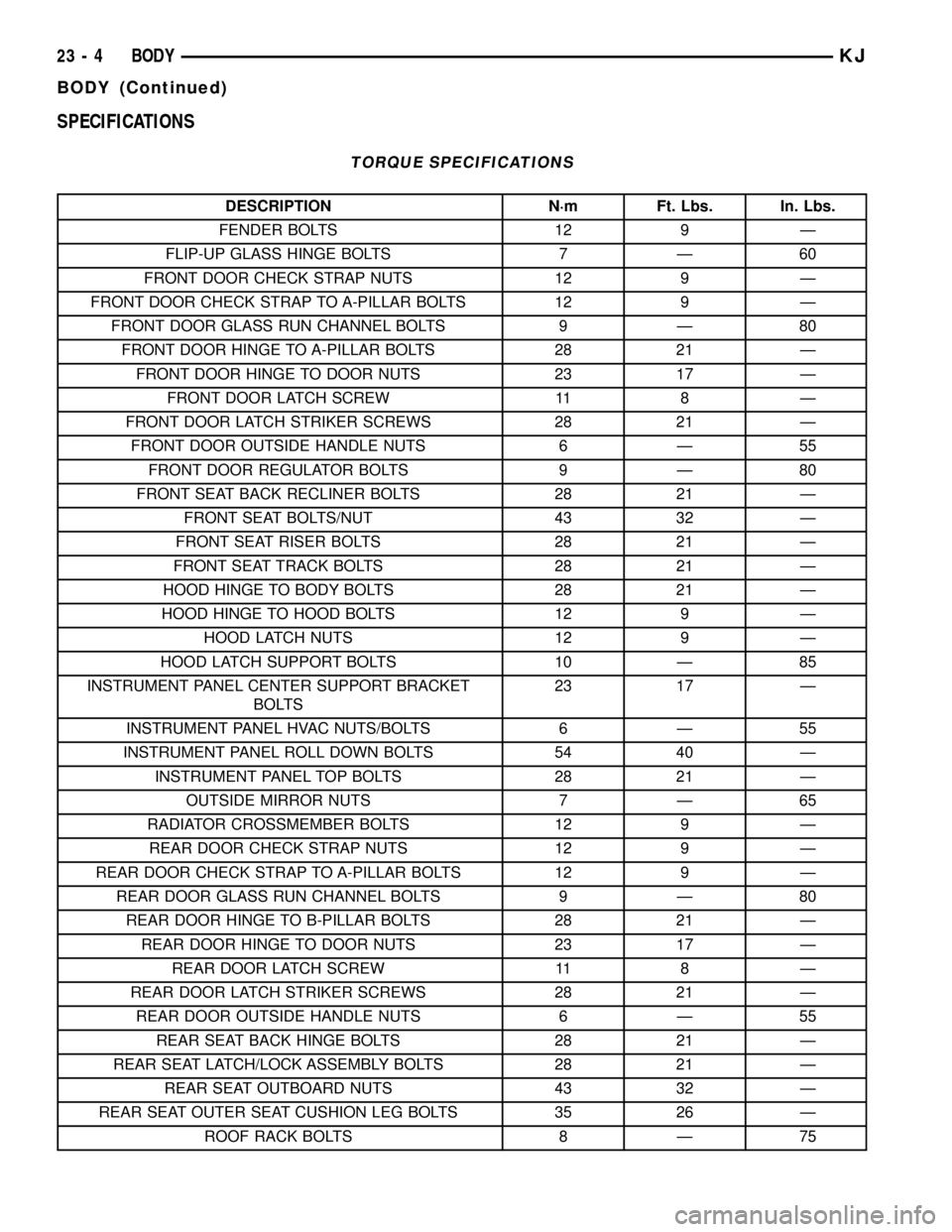

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

FENDER BOLTS 12 9 Ð

FLIP-UP GLASS HINGE BOLTS 7 Ð 60

FRONT DOOR CHECK STRAP NUTS 12 9 Ð

FRONT DOOR CHECK STRAP TO A-PILLAR BOLTS 12 9 Ð

FRONT DOOR GLASS RUN CHANNEL BOLTS 9 Ð 80

FRONT DOOR HINGE TO A-PILLAR BOLTS 28 21 Ð

FRONT DOOR HINGE TO DOOR NUTS 23 17 Ð

FRONT DOOR LATCH SCREW 11 8 Ð

FRONT DOOR LATCH STRIKER SCREWS 28 21 Ð

FRONT DOOR OUTSIDE HANDLE NUTS 6 Ð 55

FRONT DOOR REGULATOR BOLTS 9 Ð 80

FRONT SEAT BACK RECLINER BOLTS 28 21 Ð

FRONT SEAT BOLTS/NUT 43 32 Ð

FRONT SEAT RISER BOLTS 28 21 Ð

FRONT SEAT TRACK BOLTS 28 21 Ð

HOOD HINGE TO BODY BOLTS 28 21 Ð

HOOD HINGE TO HOOD BOLTS 12 9 Ð

HOOD LATCH NUTS 12 9 Ð

HOOD LATCH SUPPORT BOLTS 10 Ð 85

INSTRUMENT PANEL CENTER SUPPORT BRACKET

BOLTS23 17 Ð

INSTRUMENT PANEL HVAC NUTS/BOLTS 6 Ð 55

INSTRUMENT PANEL ROLL DOWN BOLTS 54 40 Ð

INSTRUMENT PANEL TOP BOLTS 28 21 Ð

OUTSIDE MIRROR NUTS 7 Ð 65

RADIATOR CROSSMEMBER BOLTS 12 9 Ð

REAR DOOR CHECK STRAP NUTS 12 9 Ð

REAR DOOR CHECK STRAP TO A-PILLAR BOLTS 12 9 Ð

REAR DOOR GLASS RUN CHANNEL BOLTS 9 Ð 80

REAR DOOR HINGE TO B-PILLAR BOLTS 28 21 Ð

REAR DOOR HINGE TO DOOR NUTS 23 17 Ð

REAR DOOR LATCH SCREW 11 8 Ð

REAR DOOR LATCH STRIKER SCREWS 28 21 Ð

REAR DOOR OUTSIDE HANDLE NUTS 6 Ð 55

REAR SEAT BACK HINGE BOLTS 28 21 Ð

REAR SEAT LATCH/LOCK ASSEMBLY BOLTS 28 21 Ð

REAR SEAT OUTBOARD NUTS 43 32 Ð

REAR SEAT OUTER SEAT CUSHION LEG BOLTS 35 26 Ð

ROOF RACK BOLTS 8 Ð 75

23 - 4 BODYKJ

BODY (Continued)

Page 1476 of 1803

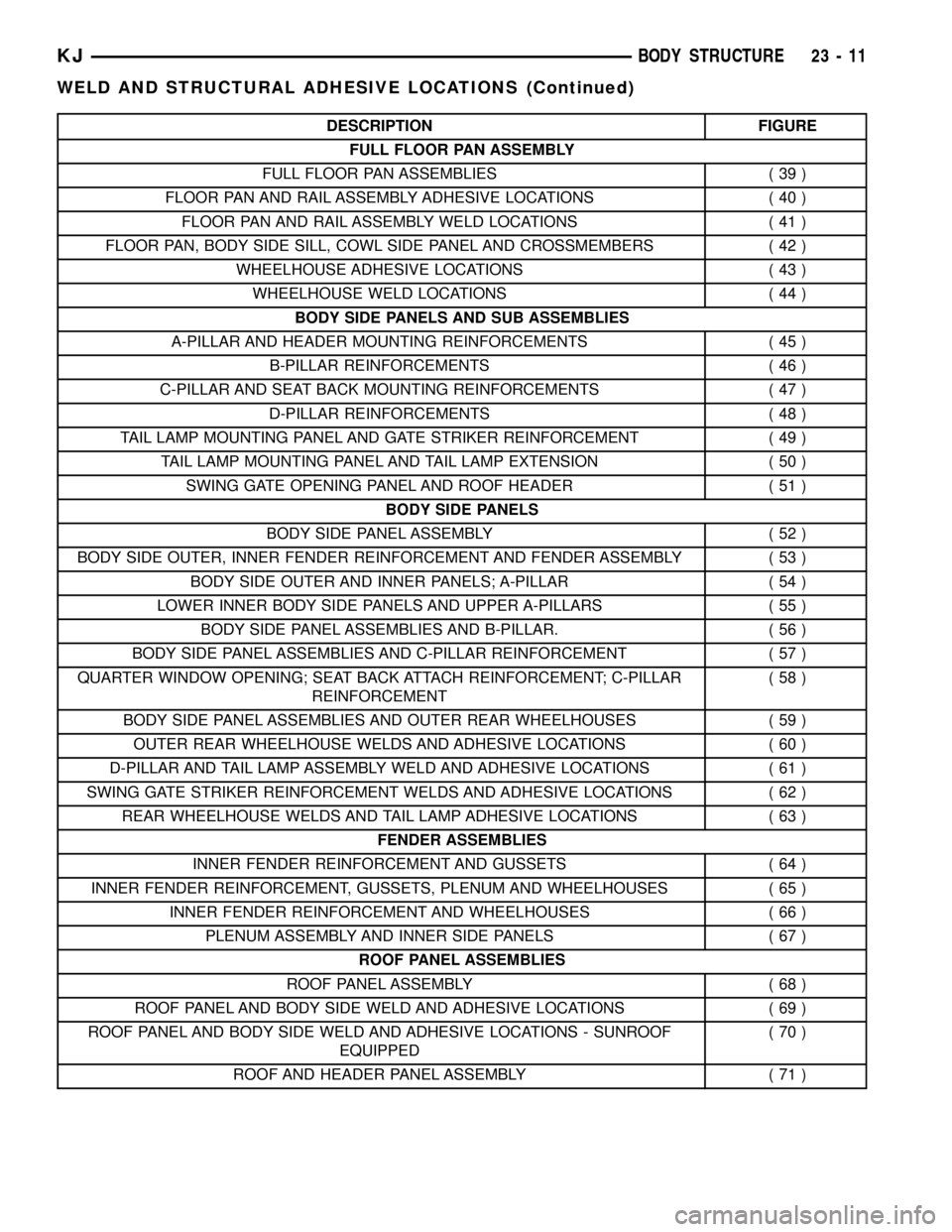

DESCRIPTION FIGURE

FULL FLOOR PAN ASSEMBLY

FULL FLOOR PAN ASSEMBLIES ( 39 )

FLOOR PAN AND RAIL ASSEMBLY ADHESIVE LOCATIONS ( 40 )

FLOOR PAN AND RAIL ASSEMBLY WELD LOCATIONS ( 41 )

FLOOR PAN, BODY SIDE SILL, COWL SIDE PANEL AND CROSSMEMBERS ( 42 )

WHEELHOUSE ADHESIVE LOCATIONS ( 43 )

WHEELHOUSE WELD LOCATIONS ( 44 )

BODY SIDE PANELS AND SUB ASSEMBLIES

A-PILLAR AND HEADER MOUNTING REINFORCEMENTS ( 45 )

B-PILLAR REINFORCEMENTS ( 46 )

C-PILLAR AND SEAT BACK MOUNTING REINFORCEMENTS ( 47 )

D-PILLAR REINFORCEMENTS ( 48 )

TAIL LAMP MOUNTING PANEL AND GATE STRIKER REINFORCEMENT ( 49 )

TAIL LAMP MOUNTING PANEL AND TAIL LAMP EXTENSION ( 50 )

SWING GATE OPENING PANEL AND ROOF HEADER ( 51 )

BODY SIDE PANELS

BODY SIDE PANEL ASSEMBLY ( 52 )

BODY SIDE OUTER, INNER FENDER REINFORCEMENT AND FENDER ASSEMBLY ( 53 )

BODY SIDE OUTER AND INNER PANELS; A-PILLAR ( 54 )

LOWER INNER BODY SIDE PANELS AND UPPER A-PILLARS ( 55 )

BODY SIDE PANEL ASSEMBLIES AND B-PILLAR. ( 56 )

BODY SIDE PANEL ASSEMBLIES AND C-PILLAR REINFORCEMENT ( 57 )

QUARTER WINDOW OPENING; SEAT BACK ATTACH REINFORCEMENT; C-PILLAR

REINFORCEMENT(58)

BODY SIDE PANEL ASSEMBLIES AND OUTER REAR WHEELHOUSES ( 59 )

OUTER REAR WHEELHOUSE WELDS AND ADHESIVE LOCATIONS ( 60 )

D-PILLAR AND TAIL LAMP ASSEMBLY WELD AND ADHESIVE LOCATIONS ( 61 )

SWING GATE STRIKER REINFORCEMENT WELDS AND ADHESIVE LOCATIONS ( 62 )

REAR WHEELHOUSE WELDS AND TAIL LAMP ADHESIVE LOCATIONS ( 63 )

FENDER ASSEMBLIES

INNER FENDER REINFORCEMENT AND GUSSETS ( 64 )

INNER FENDER REINFORCEMENT, GUSSETS, PLENUM AND WHEELHOUSES ( 65 )

INNER FENDER REINFORCEMENT AND WHEELHOUSES ( 66 )

PLENUM ASSEMBLY AND INNER SIDE PANELS ( 67 )

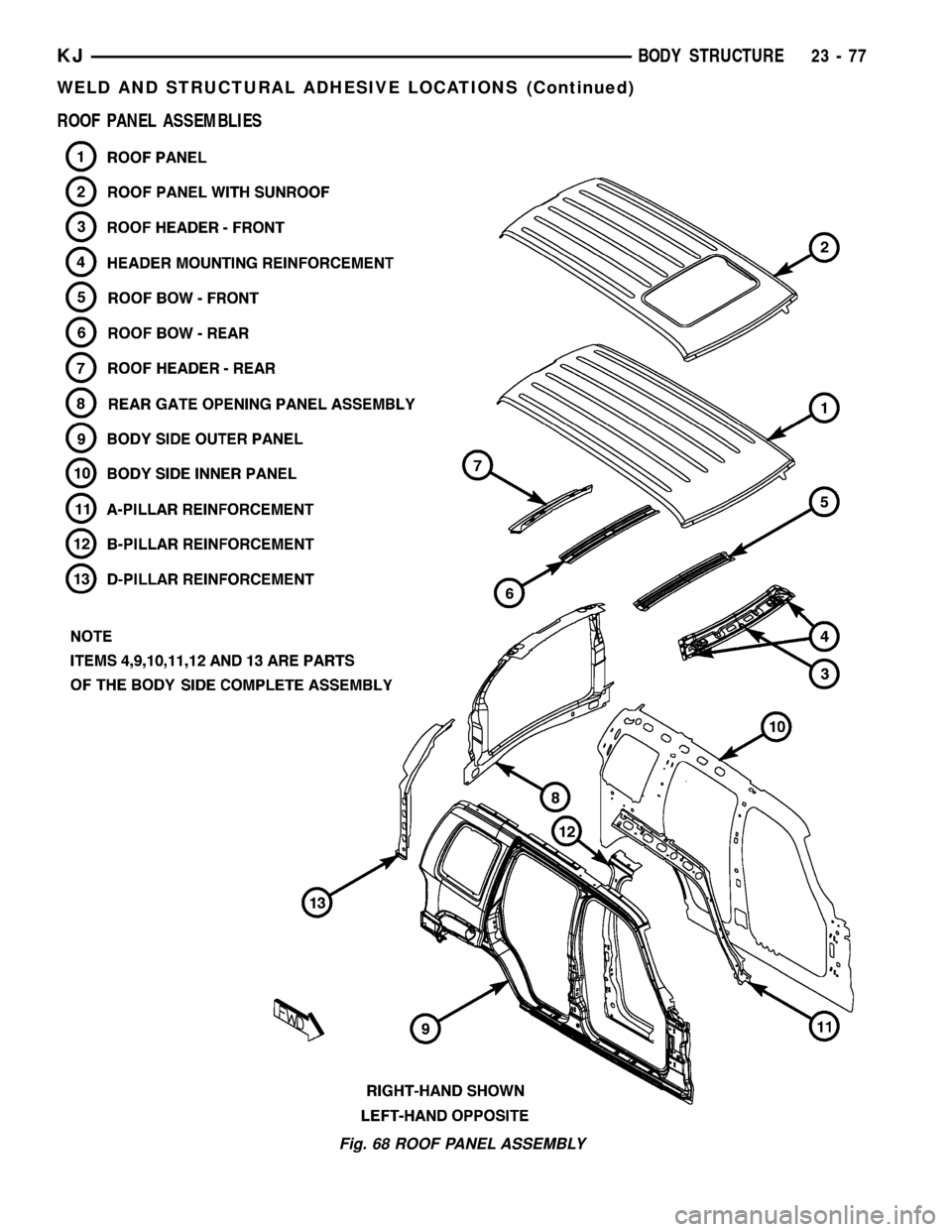

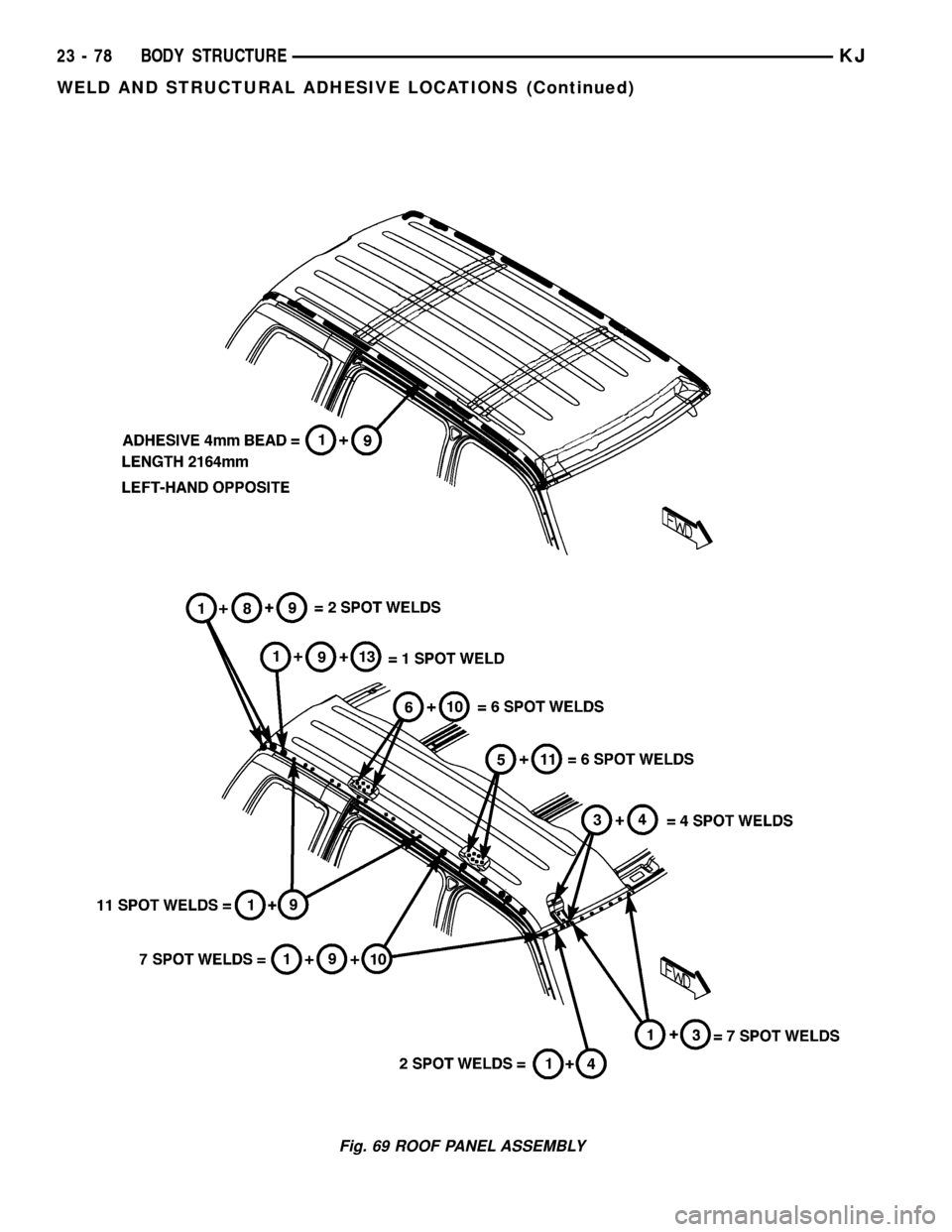

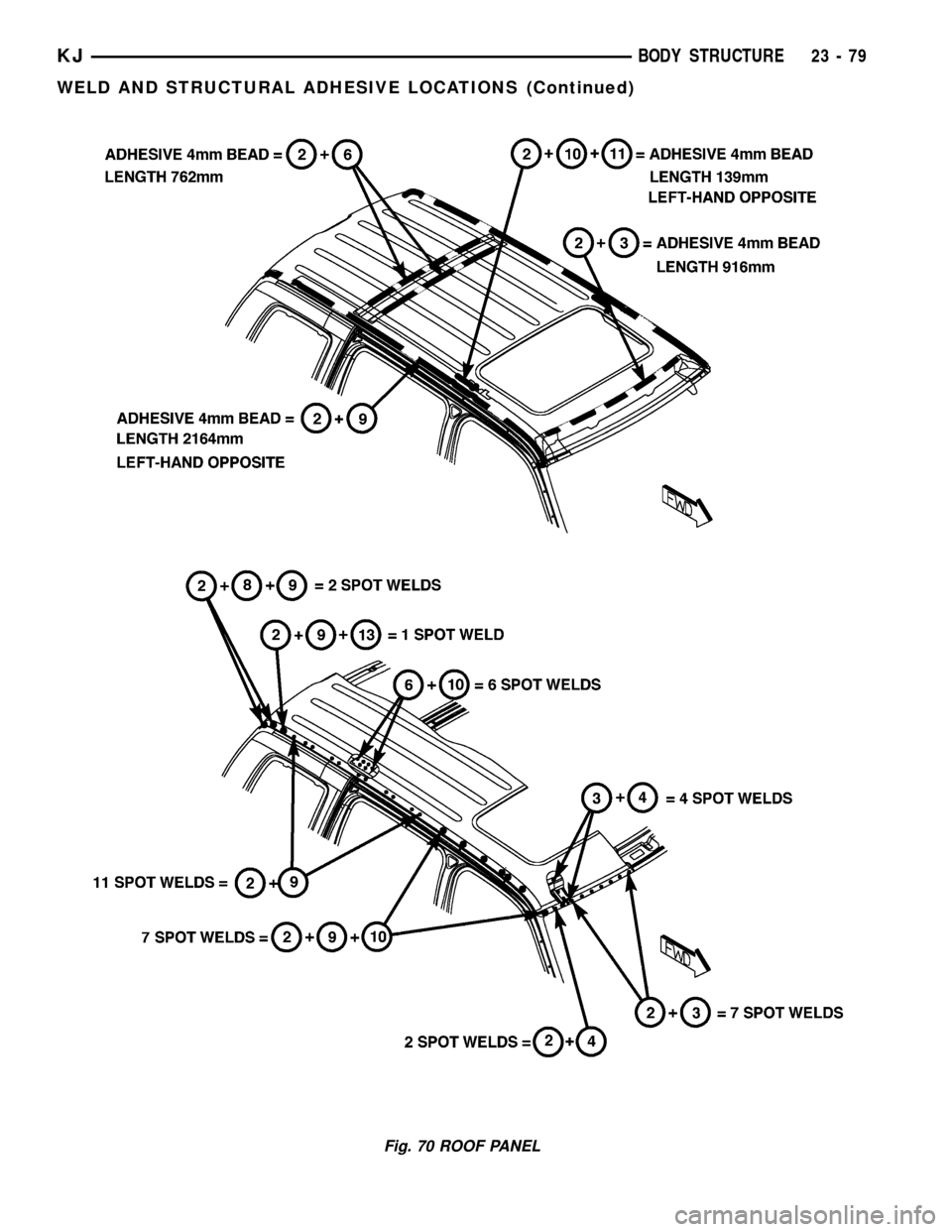

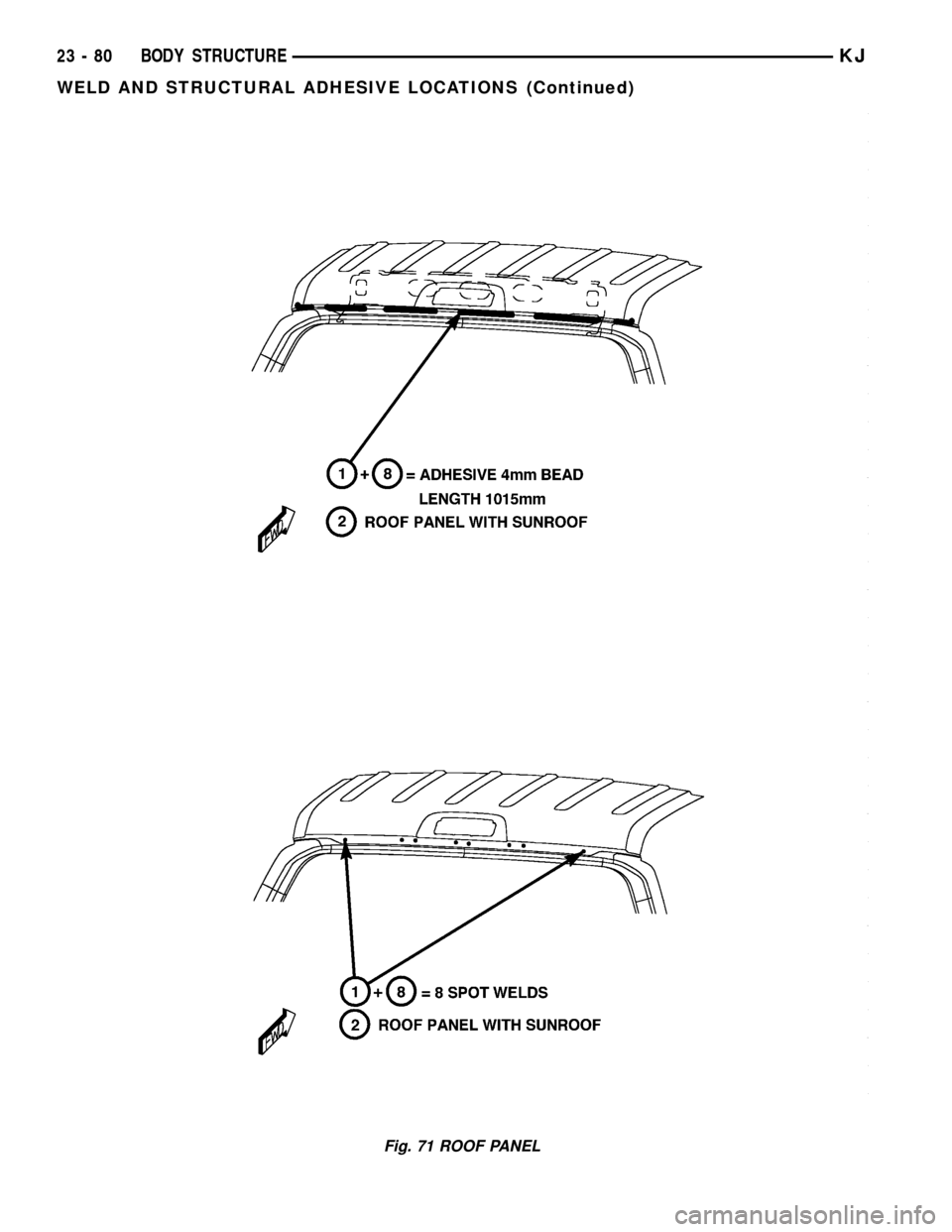

ROOF PANEL ASSEMBLIES

ROOF PANEL ASSEMBLY ( 68 )

ROOF PANEL AND BODY SIDE WELD AND ADHESIVE LOCATIONS ( 69 )

ROOF PANEL AND BODY SIDE WELD AND ADHESIVE LOCATIONS - SUNROOF

EQUIPPED(70)

ROOF AND HEADER PANEL ASSEMBLY ( 71 )

KJBODY STRUCTURE 23 - 11

WELD AND STRUCTURAL ADHESIVE LOCATIONS (Continued)

Page 1477 of 1803

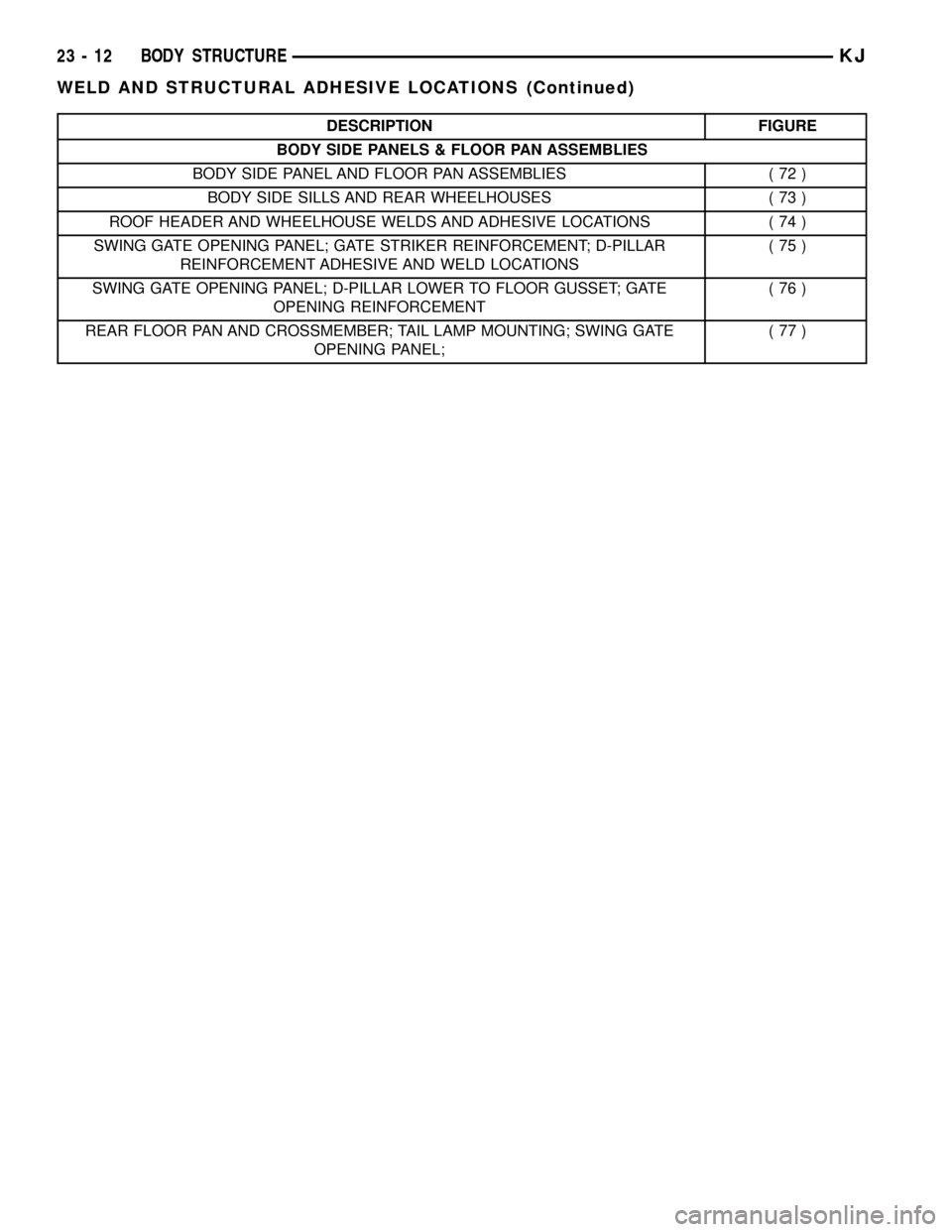

DESCRIPTION FIGURE

BODY SIDE PANELS & FLOOR PAN ASSEMBLIES

BODY SIDE PANEL AND FLOOR PAN ASSEMBLIES ( 72 )

BODY SIDE SILLS AND REAR WHEELHOUSES ( 73 )

ROOF HEADER AND WHEELHOUSE WELDS AND ADHESIVE LOCATIONS ( 74 )

SWING GATE OPENING PANEL; GATE STRIKER REINFORCEMENT; D-PILLAR

REINFORCEMENT ADHESIVE AND WELD LOCATIONS(75)

SWING GATE OPENING PANEL; D-PILLAR LOWER TO FLOOR GUSSET; GATE

OPENING REINFORCEMENT(76)

REAR FLOOR PAN AND CROSSMEMBER; TAIL LAMP MOUNTING; SWING GATE

OPENING PANEL;(77)

23 - 12 BODY STRUCTUREKJ

WELD AND STRUCTURAL ADHESIVE LOCATIONS (Continued)

Page 1542 of 1803

ROOF PANEL ASSEMBLIES

Fig. 68 ROOF PANEL ASSEMBLY

KJBODY STRUCTURE 23 - 77

WELD AND STRUCTURAL ADHESIVE LOCATIONS (Continued)

Page 1543 of 1803

Fig. 69 ROOF PANEL ASSEMBLY

23 - 78 BODY STRUCTUREKJ

WELD AND STRUCTURAL ADHESIVE LOCATIONS (Continued)

Page 1544 of 1803

Fig. 70 ROOF PANEL

KJBODY STRUCTURE 23 - 79

WELD AND STRUCTURAL ADHESIVE LOCATIONS (Continued)

Page 1545 of 1803

Fig. 71 ROOF PANEL

23 - 80 BODY STRUCTUREKJ

WELD AND STRUCTURAL ADHESIVE LOCATIONS (Continued)

Page 1552 of 1803

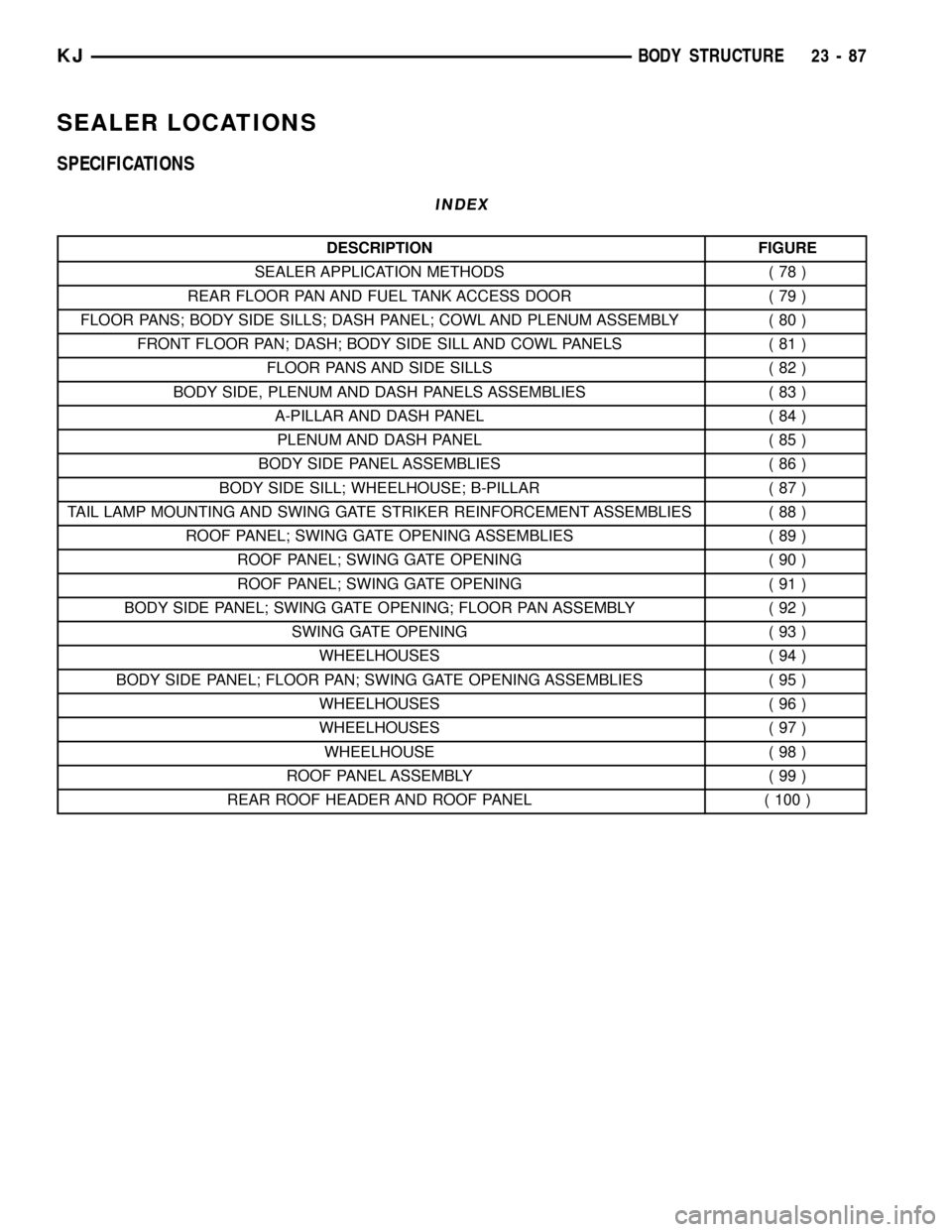

SEALER LOCATIONS

SPECIFICATIONS

INDEX

DESCRIPTION FIGURE

SEALER APPLICATION METHODS ( 78 )

REAR FLOOR PAN AND FUEL TANK ACCESS DOOR ( 79 )

FLOOR PANS; BODY SIDE SILLS; DASH PANEL; COWL AND PLENUM ASSEMBLY ( 80 )

FRONT FLOOR PAN; DASH; BODY SIDE SILL AND COWL PANELS ( 81 )

FLOOR PANS AND SIDE SILLS ( 82 )

BODY SIDE, PLENUM AND DASH PANELS ASSEMBLIES ( 83 )

A-PILLAR AND DASH PANEL ( 84 )

PLENUM AND DASH PANEL ( 85 )

BODY SIDE PANEL ASSEMBLIES ( 86 )

BODY SIDE SILL; WHEELHOUSE; B-PILLAR ( 87 )

TAIL LAMP MOUNTING AND SWING GATE STRIKER REINFORCEMENT ASSEMBLIES ( 88 )

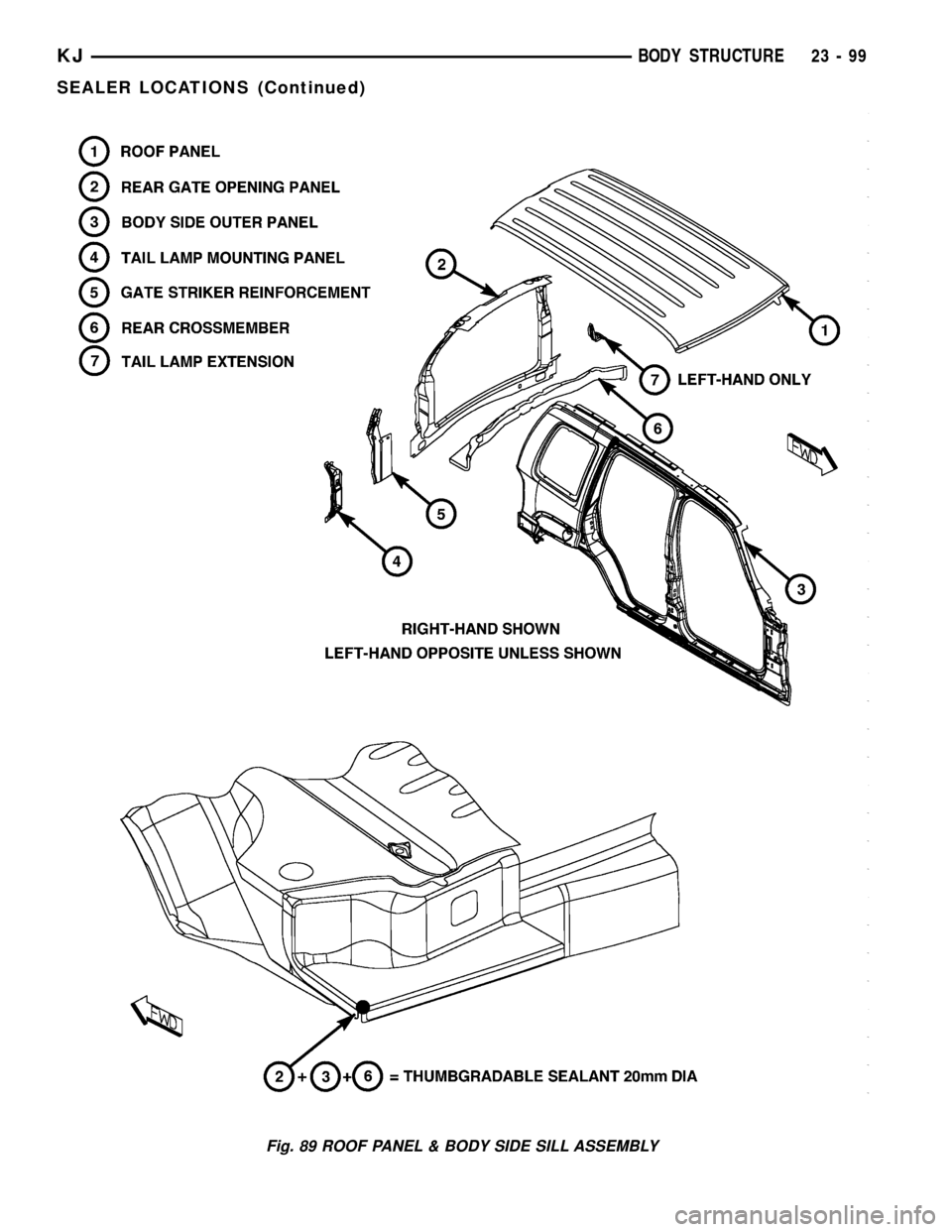

ROOF PANEL; SWING GATE OPENING ASSEMBLIES ( 89 )

ROOF PANEL; SWING GATE OPENING ( 90 )

ROOF PANEL; SWING GATE OPENING ( 91 )

BODY SIDE PANEL; SWING GATE OPENING; FLOOR PAN ASSEMBLY ( 92 )

SWING GATE OPENING ( 93 )

WHEELHOUSES ( 94 )

BODY SIDE PANEL; FLOOR PAN; SWING GATE OPENING ASSEMBLIES ( 95 )

WHEELHOUSES ( 96 )

WHEELHOUSES ( 97 )

WHEELHOUSE ( 98 )

ROOF PANEL ASSEMBLY ( 99 )

REAR ROOF HEADER AND ROOF PANEL ( 100 )

KJBODY STRUCTURE 23 - 87

Page 1564 of 1803

Fig. 89 ROOF PANEL & BODY SIDE SILL ASSEMBLY

KJBODY STRUCTURE 23 - 99

SEALER LOCATIONS (Continued)