ESP JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 690 of 1803

SECURED ACCESS METHOD

The Secured Access method applies to all vehicles.

This method requires the use of a DRBIIItscan tool.

This method will also require that you have access to

the unique four-digit PIN code that was assigned to

the original SKIM. The PIN codemustbe used to

enter the Secured Access Mode in the SKIM. This

PIN number may be obtained from the vehicle owner,

from the original vehicle invoice, or from the

DaimlerChrysler Customer Center. Refer to the

appropriate diagnostic information for the proper

Secured Access method programming procedures.

CUSTOMER LEARN METHOD

The Customer Learn feature is only available on

domestic vehicles, or those vehicles which have a

U.S. country code designator. This programming

method also requires access to at least two valid Sen-

try Keys. If two valid Sentry Keys are not available,

or if the vehicle does not have a U.S. country code

designator, the Secured Access Methodmustbe used

to program new or additional valid keys to the SKIM.

The Customer Learn programming method proce-

dures are as follows:

(1) Obtain the blank Sentry Key(s) that are to be

programmed as valid keys for the vehicle. Cut the

blank key(s) to match the ignition switch lock cylin-

der mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

On position.

(3) After the ignition switch has been in the On

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

the Off position. Replace the first valid Sentry Key in

the ignition switch lock cylinder with the second

valid Sentry Key and turn the ignition switch back to

the On position. The second valid Sentry Key must

be inserted in the lock cylinder within fifteen seconds

of removing the first valid key.

(4) About ten seconds after the completion of Step

3, the SKIS indicator in the instrument cluster will

start to flash and a single audible chime tone will

sound to indicate that the system has entered the

Customer Learn programming mode.

(5) Within sixty seconds of entering the Customer

Learn programming mode, turn the ignition switch to

the Off position, replace the valid Sentry Key with a

blank Sentry Key transponder, and turn the ignition

switch back to the On position.

(6)

About ten seconds after the completion of Step 5,

a single audible chime tone will sound and the SKIS

indicator will stop flashing, stay on solid for three sec-

onds, then turn off to indicate that the blank Sentry

Key has been successfully programmed. The SKIS will

immediately exit the Customer Learn programmingmode and the vehicle may now be started using the

newly programmed valid Sentry Key.

Each of these steps must be repeated and com-

pleted in their entirety for each additional Sentry

Key that is to be programmed. If the above steps are

not completed in the given sequence, or within the

allotted time, the SKIS will exit the Customer Learn

programming mode and the programming will be

unsuccessful. The SKIS will also automatically exit

the Customer Learn programming mode if it sees a

non-blank Sentry Key transponder when it should

see a blank, if it has already programmed eight (8)

valid Sentry Keys, or if the ignition switch is turned

to the Off position for more than about fifty seconds.

NOTE: If an attempt is made to start the vehicle

while in the Customer Learn mode (SKIS indicator

flashing), the SKIS will respond as though the vehi-

cle were being started with an invalid key. In other

words, the engine will stall after about two seconds

of operation. No faults will be set.

NOTE: Once a Sentry Key has been programmed as

a valid key to a vehicle, it cannot be programmed

as a valid key for use on any other vehicle.

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

Vehicles manufactured for North American mar-

kets that are equipped with the optional Vehicle

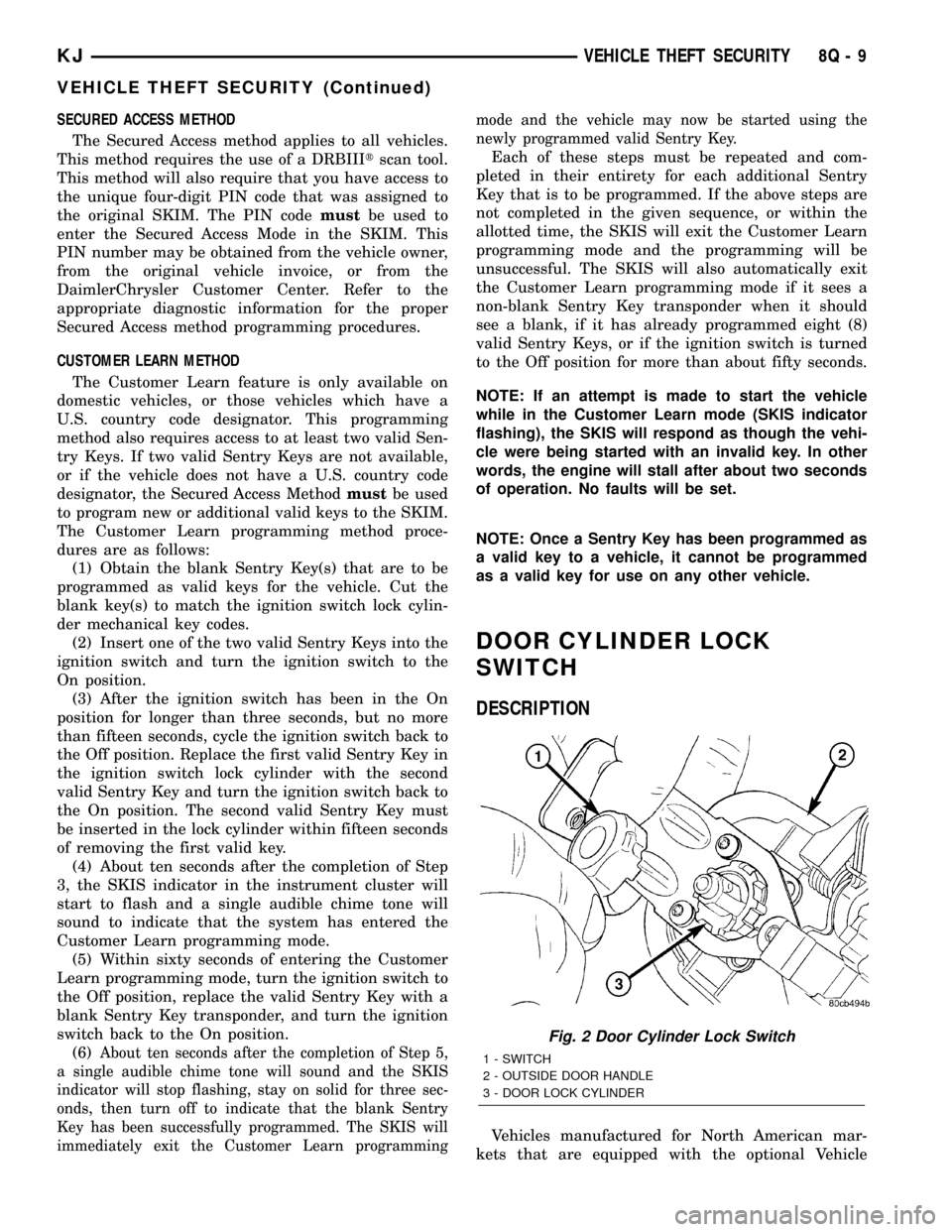

Fig. 2 Door Cylinder Lock Switch

1 - SWITCH

2 - OUTSIDE DOOR HANDLE

3 - DOOR LOCK CYLINDER

KJVEHICLE THEFT SECURITY 8Q - 9

VEHICLE THEFT SECURITY (Continued)

Page 699 of 1803

(2) Install and tighten the two screws that secure

the alarm siren module to the front extension of the

right front wheel house panel. Tighten the screws to

6 N´m (50 in. lbs.).

(3) Reconnect the headlamp and dash wire harness

connector for the alarm siren module to the module

connector receptacle.

(4) Reconnect the battery negative cable.

NOTE: If the alarm siren module has been replaced

with a new unit, the new unit MUST be configured

in the Intrusion Transceiver Module (ITM) before the

Vehicle Theft Security System can operate as

designed. The use of a DRBIIITscan tool is required

to configure the alarm siren module settings in the

ITM. Refer to the appropriate diagnostic informa-

tion.

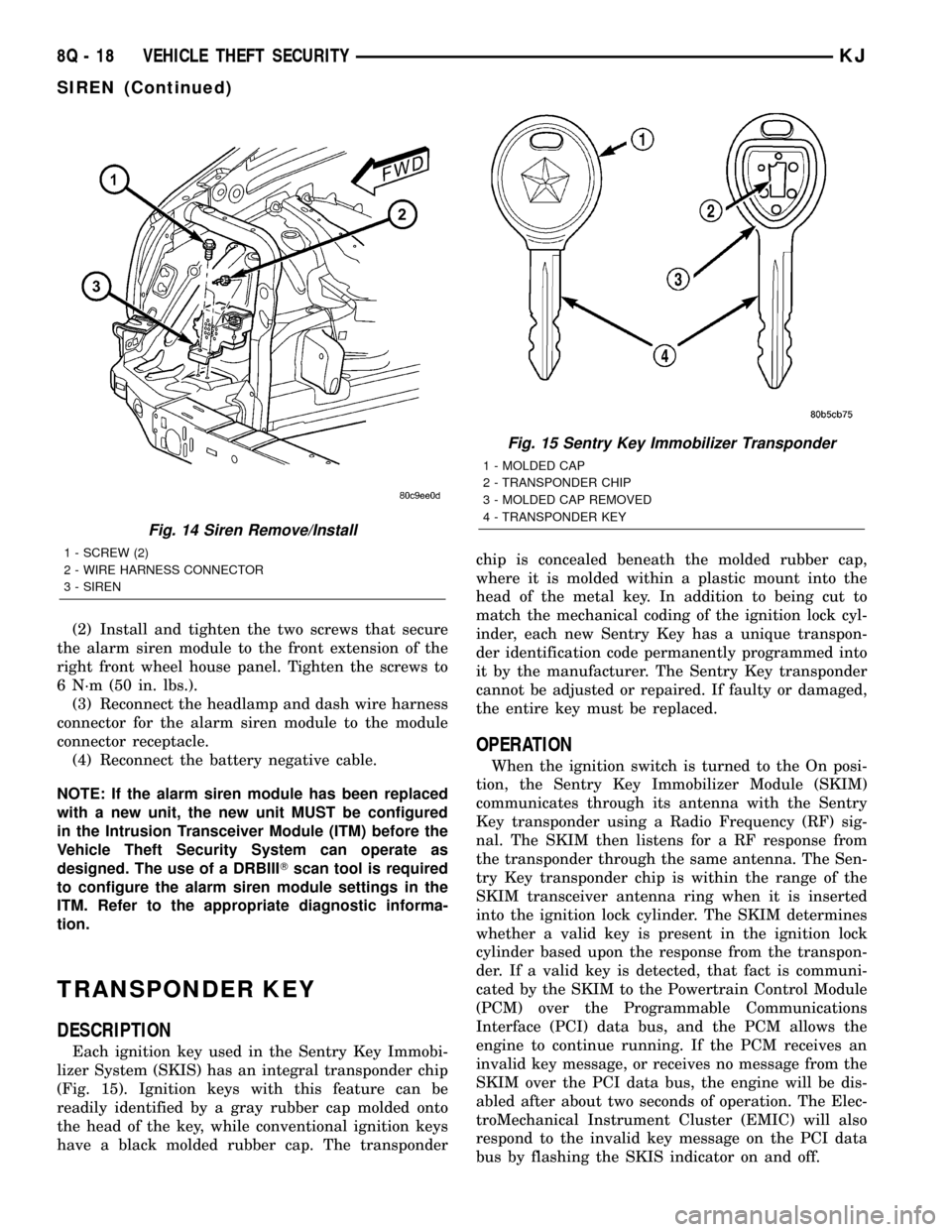

TRANSPONDER KEY

DESCRIPTION

Each ignition key used in the Sentry Key Immobi-

lizer System (SKIS) has an integral transponder chip

(Fig. 15). Ignition keys with this feature can be

readily identified by a gray rubber cap molded onto

the head of the key, while conventional ignition keys

have a black molded rubber cap. The transponderchip is concealed beneath the molded rubber cap,

where it is molded within a plastic mount into the

head of the metal key. In addition to being cut to

match the mechanical coding of the ignition lock cyl-

inder, each new Sentry Key has a unique transpon-

der identification code permanently programmed into

it by the manufacturer. The Sentry Key transponder

cannot be adjusted or repaired. If faulty or damaged,

the entire key must be replaced.

OPERATION

When the ignition switch is turned to the On posi-

tion, the Sentry Key Immobilizer Module (SKIM)

communicates through its antenna with the Sentry

Key transponder using a Radio Frequency (RF) sig-

nal. The SKIM then listens for a RF response from

the transponder through the same antenna. The Sen-

try Key transponder chip is within the range of the

SKIM transceiver antenna ring when it is inserted

into the ignition lock cylinder. The SKIM determines

whether a valid key is present in the ignition lock

cylinder based upon the response from the transpon-

der. If a valid key is detected, that fact is communi-

cated by the SKIM to the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus, and the PCM allows the

engine to continue running. If the PCM receives an

invalid key message, or receives no message from the

SKIM over the PCI data bus, the engine will be dis-

abled after about two seconds of operation. The Elec-

troMechanical Instrument Cluster (EMIC) will also

respond to the invalid key message on the PCI data

bus by flashing the SKIS indicator on and off.

Fig. 14 Siren Remove/Install

1 - SCREW (2)

2 - WIRE HARNESS CONNECTOR

3 - SIREN

Fig. 15 Sentry Key Immobilizer Transponder

1 - MOLDED CAP

2 - TRANSPONDER CHIP

3 - MOLDED CAP REMOVED

4 - TRANSPONDER KEY

8Q - 18 VEHICLE THEFT SECURITYKJ

SIREN (Continued)

Page 706 of 1803

Following are paragraphs that briefly describe the

operation of each of the front wiper and washer sys-

tem operating modes.

CONTINUOUS WIPE MODE When the Low posi-

tion of the control knob on the right (wiper) control

stalk of the multi-function switch is selected, the

Body Control Module (BCM) energizes the wiper

on/off relay. This directs battery current through the

normally open contacts of the energized wiper on/off

relay and the normally closed contacts of the de-en-

ergized wiper high/low relay to the low speed brush

of the front wiper motor, causing the front wipers to

cycle at low speed. When the High position of the

control knob is selected, the BCM energizes both the

wiper on/off relay and the wiper high/low relay. This

directs battery current through the normally open

contacts of the energized wiper on/off relay and the

normally open contacts of the energized wiper high/

low relay to the high speed brush of the front wiper

motor, causing the front wipers to cycle at high

speed.

When the Off position of the control knob is

selected, the BCM de-energizes both the wiper on/off

and wiper high low relays, then one of two events

will occur. The event that occurs depends upon the

position of the wiper blades on the windshield at the

moment that the control knob Off position is selected.

If the wiper blades are in the down position on the

windshield when the Off position is selected, the

park switch that is integral to the front wiper motor

is closed to ground and the wiper motor ceases to

operate. If the wiper blades are not in the down posi-

tion on the windshield at the moment the Off posi-

tion is selected, the park switch is closed to battery

current from the fused ignition switch output (run-

acc) circuit of the front wiper motor. The park switch

directs this battery current to the low speed brush of

the wiper motor through the wiper park switch sense

circuit and the normally closed contacts of the de-en-

ergized wiper on/off and wiper high/low relays. This

causes the wiper motor to continue running at low

speed until the wiper blades are in the down position

on the windshield and the park switch is again

closed to ground.

INTERMITTENT WIPE MODE When the control

knob on the right (wiper) control stalk of the multi-

function switch is moved to one of the Delay interval

positions, the BCM electronic intermittent wipe logic

circuit responds by calculating the correct length of

time between wiper sweeps based upon the selected

delay interval input. The BCM monitors the chang-

ing state of the wiper motor park switch through a

hard wired front wiper park switch sense circuit

input. This input allows the BCM to determine the

proper intervals at which to energize and de-energize

the wiper on/off relay to operate the front wipermotor intermittently for one low speed cycle at a

time. The BCM logic is also programmed to provide

an immediate wipe cycle and begin a new delay

interval timing cycle each time a shorter delay inter-

val is selected, and to add the remaining delay tim-

ing interval to the new delay interval timing before

the next wipe cycle occurs each time a longer delay

interval is selected.

MIST WIPE MODE When the right (wiper) control

stalk of the multi-function switch is moved to the

momentary Mist position, the BCM energizes the

wiper on/off relay for as long as the Mist switch is

held closed, then de-energizes the relay when the

state of the Mist switch input changes to open. The

BCM can operate the front wiper motor in this mode

for only one low speed cycle at a time, or for an

indefinite number of sequential low speed cycles,

depending upon how long the Mist switch is held

closed.

WASH MODE When the right (wiper) control stalk

of the multi-function switch is moved to the momen-

tary front Wash position while the control knob is in

the Low or High positions, the circuitry within the

switch directs battery current and ground to the

washer pump/motor unit. This will cause the washer

pump/motor unit to be energized for as long as the

front Wash switch is held closed, and to de-energize

when the front Wash switch is released. When the

right (wiper) control stalk of the multi-function

switch is moved to the momentary front Wash posi-

tion while the control knob is in one of the Delay

interval positions, the front washer pump/motor oper-

ation is the same. However, the BCM energizes the

wiper on/off relay to override the selected delay inter-

val and operate the front wiper motor in a continu-

ous low speed mode for as long as the front Wash

switch is held closed, then de-energizes the relay and

reverts to the selected delay mode interval several

wipe cycles after the front Wash switch is released.

The BCM detects the front Wash switch state

through a hard wired washer pump driver circuit

input from the multi-function switch.

WIPE-AFTER-WASH MODE When the right

(wiper) control stalk of the multi-function switch is

moved to the momentary front Wash position while

the control knob is in the Off position, the BCM

detects that switch state through a hard wired

washer pump driver circuit input from the multi-

function switch. The BCM responds to this input by

energizing the wiper on/off relay for as long as the

Wash switch is held closed, then de-energizes the

relay several wipe cycles after the front Wash switch

is released. The BCM monitors the changing state of

the wiper motor park switch through a hard wired

front wiper park switch sense circuit input. This

input allows the BCM to count the number of wipe

KJFRONT WIPERS/WASHERS 8R - 5

FRONT WIPERS/WASHERS (Continued)

Page 716 of 1803

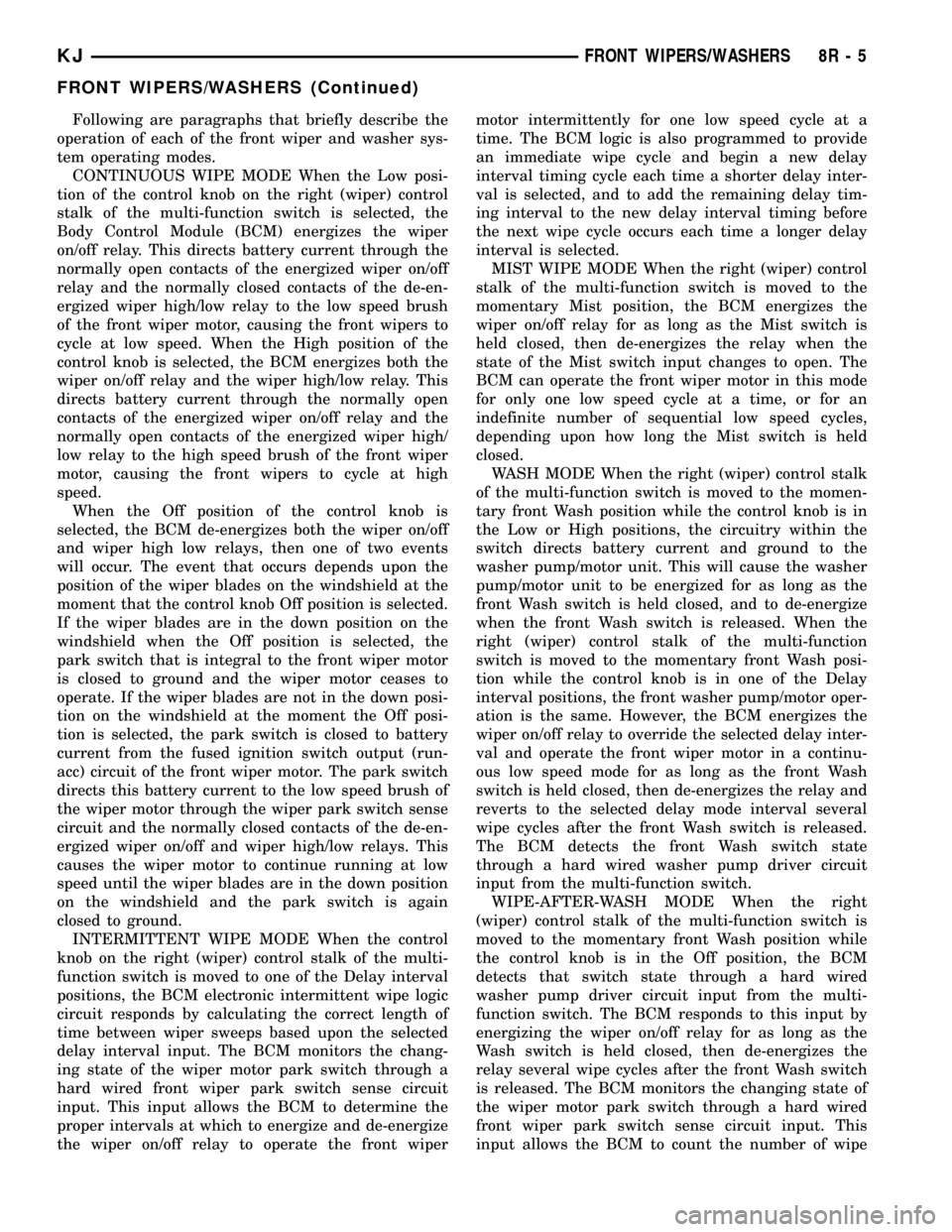

FRONT WIPER MODULE

DESCRIPTION

The front wiper module bracket is secured with

two nuts below the wiper motor through rubber insu-

lators to two weld studs on the bottom of the cowl

plenum panel beneath the cowl plenum cover/grille

panel (Fig. 14). Two screws secure the top of the

module bracket to the cowl plenum panel through

rubber insulators located on the outboard end of each

pivot bracket. The ends of the wiper pivot shafts that

protrude through dedicated openings in the cowl ple-

num cover/grille panel to drive the wiper arms and

blades are the only visible components of the front

wiper module. The front wiper module consists of the

following major components:

²Bracket- The front wiper module bracket con-

sists of a long tubular steel main member that has a

die cast pivot bracket formation near each end where

the two wiper pivots are secured. A stamped steel

mounting plate for the wiper motor is secured with

welds near the center of the main member. A short

stamped steel tab that extends laterally from one

side of the mounting plate provides a mounting loca-

tion for the wiper motor pigtail wire connector.

²Crank Arm- The front wiper motor crank arm

is a stamped steel unit with a slotted hole on thedriven end that is secured to the wiper motor output

shaft with a nut, and has a ball stud secured to the

drive end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the wiper pivot

lever arms. The right side drive link has a plastic

socket-type bushing on each end. The left side drive

link has a plastic socket-type bushing on one end,

and a plastic sleeve-type bushing on the other end.

The socket-type bushing on one end of each drive

link is snap-fit over the ball stud on the lever arm of

its respective pivot. The left side drive link sleeve-

type bushing end is then fit over the motor crank

arm ball stud, and the other socket-type bushing of

the right side drive link is snap-fit over the exposed

end of the wiper motor crank arm ball stud.

²Motor- The front wiper motor is secured with

three screws to the motor mounting plate near the

center of the wiper module bracket. The wiper motor

output shaft passes through a hole in the module

bracket, where a nut secures the wiper motor crank

arm to the motor output shaft. The two-speed perma-

nent magnet wiper motor features an integral trans-

mission, an internal park switch, and an internal

automatic resetting circuit breaker. A molded plastic

shield covers the top of the motor.

²Pivots- The two front wiper pivots are secured

within the die cast pivot brackets on the outboard

ends of the wiper module main member. The lever

arms that extend from the center of the pivot shafts

each have a ball stud on their end. The upper end of

each pivot shaft where the wiper arms will be fas-

tened each is tapered and serrated with a threaded

stud formation at the tip. The lower ends of the pivot

shafts are installed through lubricated bushings in

the pivot brackets and are secured with snap rings. A

molded plastic shield covers each pivot shaft where it

enters the pivot bracket.

The front wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire front wiper module unit must be

replaced.

OPERATION

The front wiper module operation is controlled by

the battery current inputs received by the wiper

motor from the wiper on/off and wiper high/low

relays. The wiper motor speed is controlled by cur-

rent flow to either the low speed or the high speed

set of brushes. The park switch is a single pole, sin-

gle throw, momentary switch within the wiper motor

that is mechanically actuated by the wiper motor

transmission components. The park switch alter-

nately closes the wiper park switch sense circuit to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

Fig. 14 Front Wiper Module

1 - PIVOT BRACKET (2)

2 - MOTOR COVER

3 - MOTOR BRACKET

4 - LINKAGE BUSHING (4)

5 - DRIVE LINK (2)

6 - PIVOT SHAFT (2)

7 - INSULATOR (4)

8 - PIVOT CRANK ARM (2)

9 - PIVOT COVER

10 - MOTOR CRANK ARM

11 - PIGTAIL WIRE CONNECTOR

KJFRONT WIPERS/WASHERS 8R - 15

Page 718 of 1803

WASHER FLUID LEVEL

SWITCH

DESCRIPTION

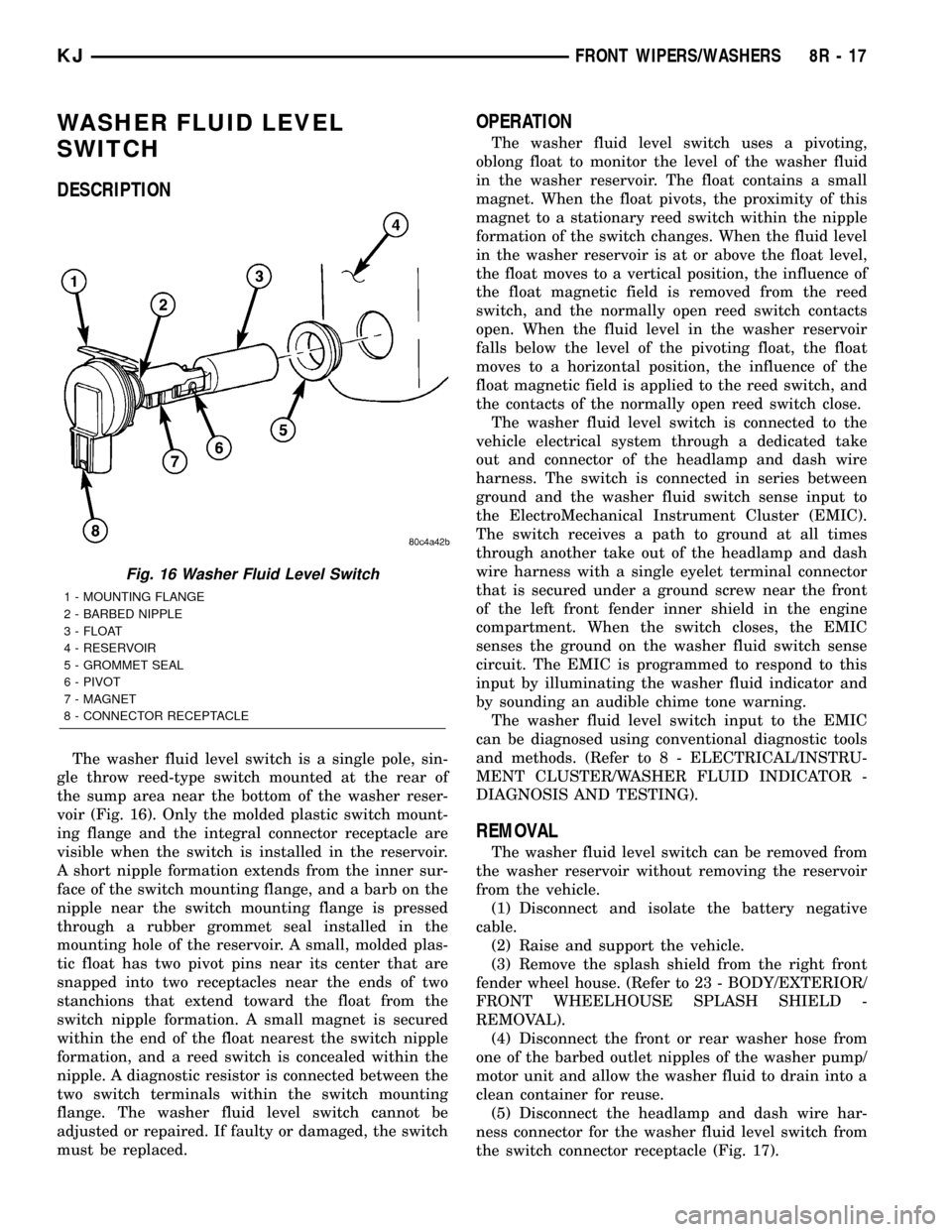

The washer fluid level switch is a single pole, sin-

gle throw reed-type switch mounted at the rear of

the sump area near the bottom of the washer reser-

voir (Fig. 16). Only the molded plastic switch mount-

ing flange and the integral connector receptacle are

visible when the switch is installed in the reservoir.

A short nipple formation extends from the inner sur-

face of the switch mounting flange, and a barb on the

nipple near the switch mounting flange is pressed

through a rubber grommet seal installed in the

mounting hole of the reservoir. A small, molded plas-

tic float has two pivot pins near its center that are

snapped into two receptacles near the ends of two

stanchions that extend toward the float from the

switch nipple formation. A small magnet is secured

within the end of the float nearest the switch nipple

formation, and a reed switch is concealed within the

nipple. A diagnostic resistor is connected between the

two switch terminals within the switch mounting

flange. The washer fluid level switch cannot be

adjusted or repaired. If faulty or damaged, the switch

must be replaced.

OPERATION

The washer fluid level switch uses a pivoting,

oblong float to monitor the level of the washer fluid

in the washer reservoir. The float contains a small

magnet. When the float pivots, the proximity of this

magnet to a stationary reed switch within the nipple

formation of the switch changes. When the fluid level

in the washer reservoir is at or above the float level,

the float moves to a vertical position, the influence of

the float magnetic field is removed from the reed

switch, and the normally open reed switch contacts

open. When the fluid level in the washer reservoir

falls below the level of the pivoting float, the float

moves to a horizontal position, the influence of the

float magnetic field is applied to the reed switch, and

the contacts of the normally open reed switch close.

The washer fluid level switch is connected to the

vehicle electrical system through a dedicated take

out and connector of the headlamp and dash wire

harness. The switch is connected in series between

ground and the washer fluid switch sense input to

the ElectroMechanical Instrument Cluster (EMIC).

The switch receives a path to ground at all times

through another take out of the headlamp and dash

wire harness with a single eyelet terminal connector

that is secured under a ground screw near the front

of the left front fender inner shield in the engine

compartment. When the switch closes, the EMIC

senses the ground on the washer fluid switch sense

circuit. The EMIC is programmed to respond to this

input by illuminating the washer fluid indicator and

by sounding an audible chime tone warning.

The washer fluid level switch input to the EMIC

can be diagnosed using conventional diagnostic tools

and methods. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER/WASHER FLUID INDICATOR -

DIAGNOSIS AND TESTING).

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Remove the splash shield from the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(4) Disconnect the front or rear washer hose from

one of the barbed outlet nipples of the washer pump/

motor unit and allow the washer fluid to drain into a

clean container for reuse.

(5) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the switch connector receptacle (Fig. 17).

Fig. 16 Washer Fluid Level Switch

1 - MOUNTING FLANGE

2 - BARBED NIPPLE

3 - FLOAT

4 - RESERVOIR

5 - GROMMET SEAL

6 - PIVOT

7 - MAGNET

8 - CONNECTOR RECEPTACLE

KJFRONT WIPERS/WASHERS 8R - 17

Page 754 of 1803

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

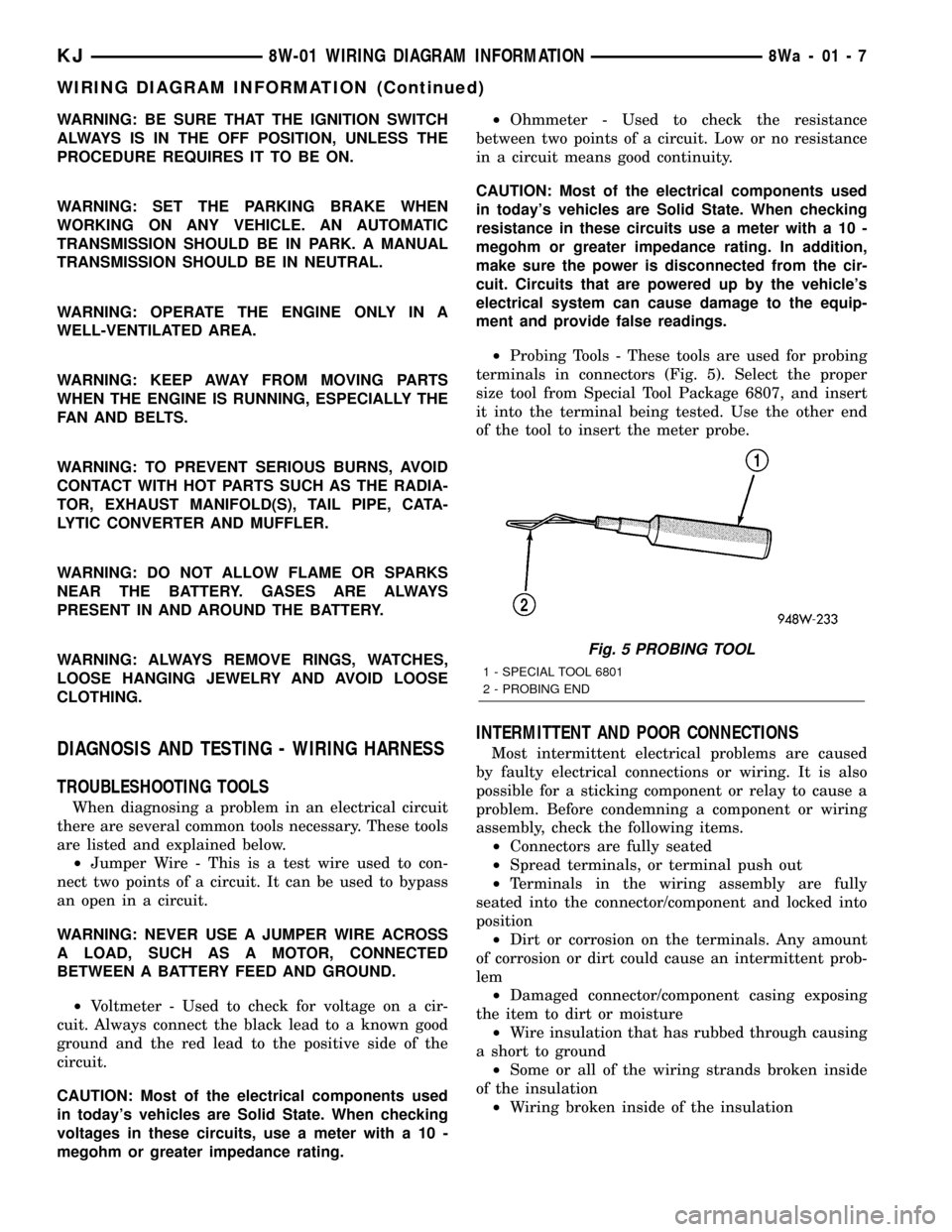

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 5). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly, check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²Terminals in the wiring assembly are fully

seated into the connector/component and locked into

position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt or moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation

²Wiring broken inside of the insulation

Fig. 5 PROBING TOOL

1 - SPECIAL TOOL 6801

2 - PROBING END

KJ8W-01 WIRING DIAGRAM INFORMATION8Wa-01-7

WIRING DIAGRAM INFORMATION (Continued)

Page 1224 of 1803

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

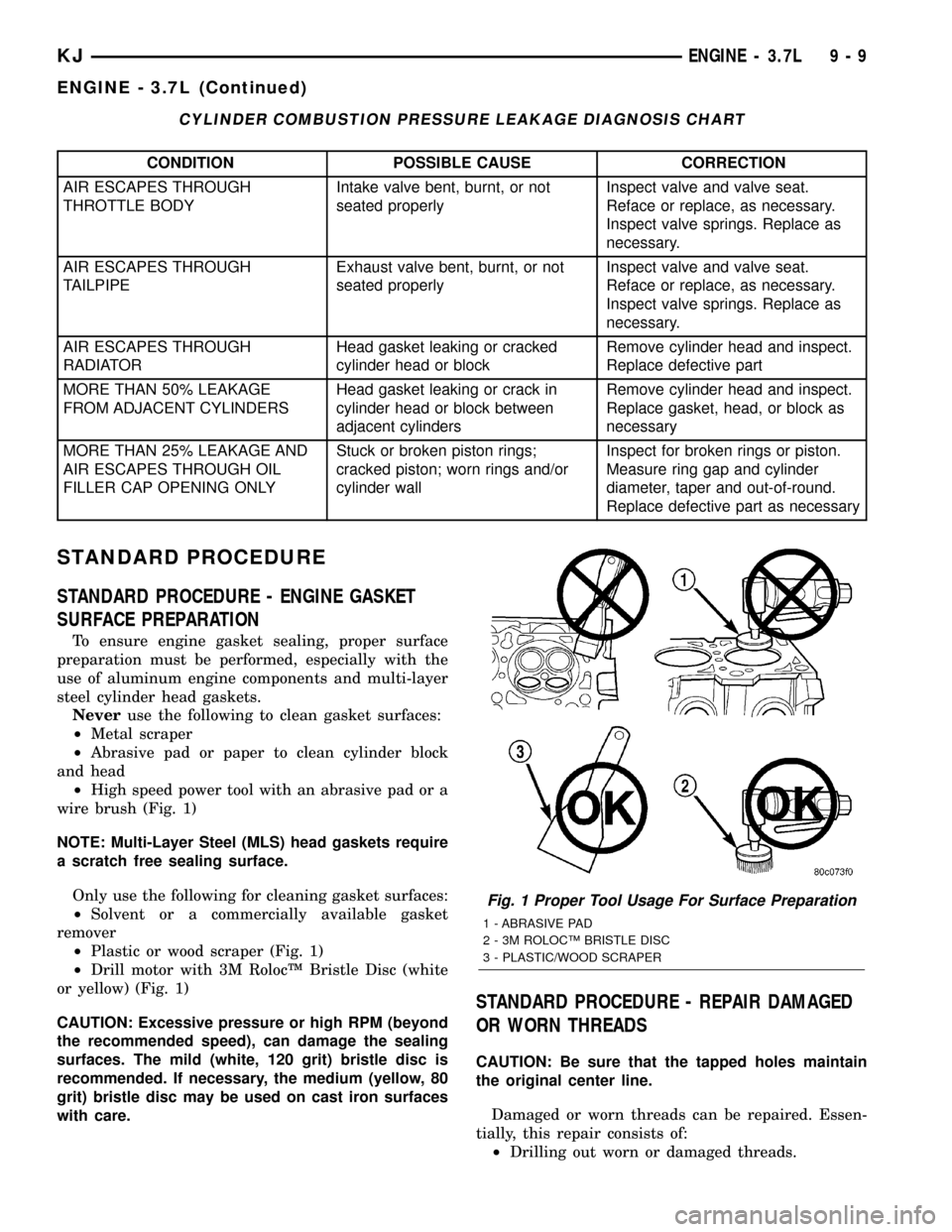

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 1)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 1)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 1)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

Fig. 1 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

KJENGINE - 3.7L 9 - 9

ENGINE - 3.7L (Continued)

Page 1237 of 1803

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, due to the design of the cylin-

der head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components (Fig. 8). (Refer

to 9 - ENGINE - STANDARD PROCEDURE)

INSTALLATION

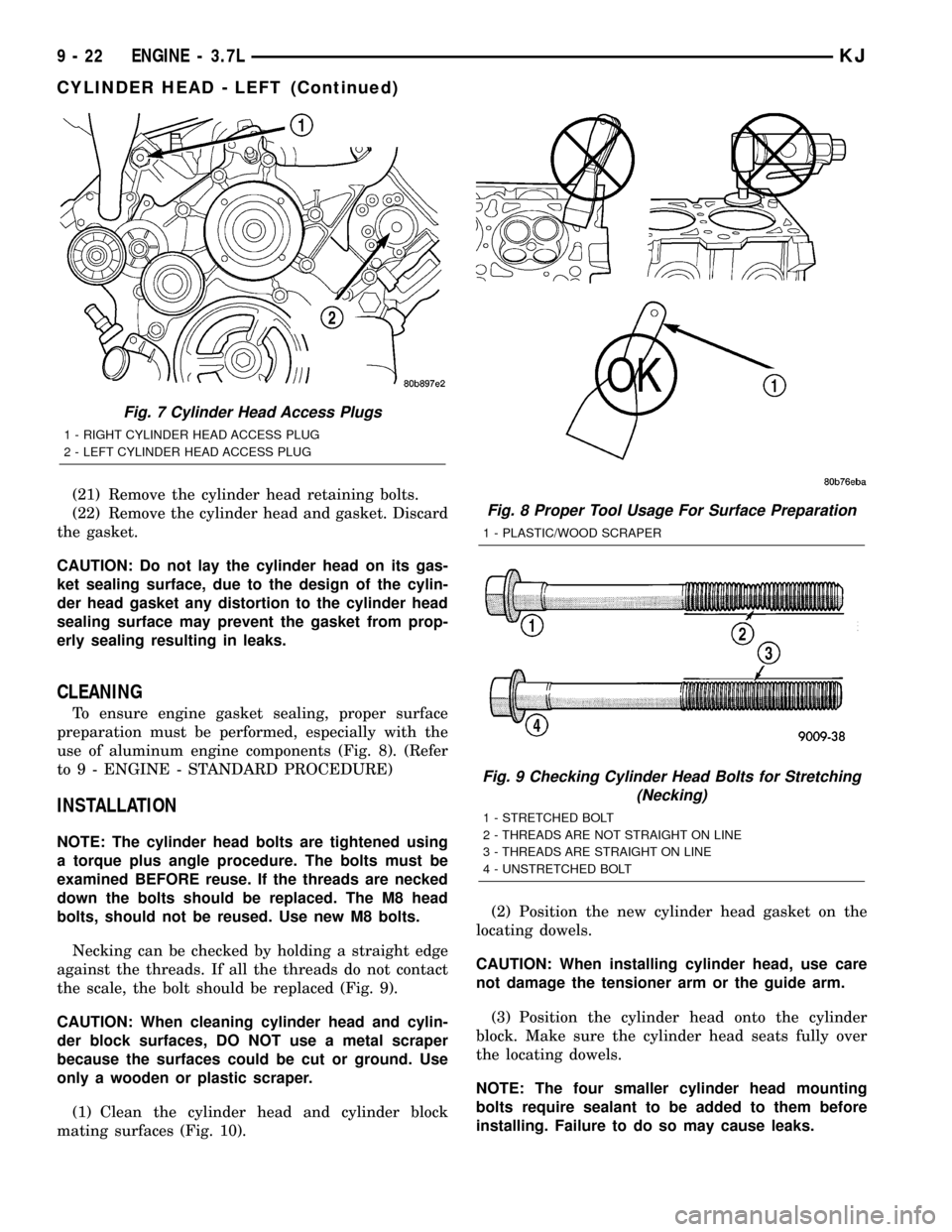

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced. The M8 head

bolts, should not be reused. Use new M8 bolts.

Necking can be checked by holding a straight edge

against the threads. If all the threads do not contact

the scale, the bolt should be replaced (Fig. 9).

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Fig. 10).(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

Fig. 7 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

Fig. 8 Proper Tool Usage For Surface Preparation

1 - PLASTIC/WOOD SCRAPER

Fig. 9 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

9 - 22 ENGINE - 3.7LKJ

CYLINDER HEAD - LEFT (Continued)

Page 1246 of 1803

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

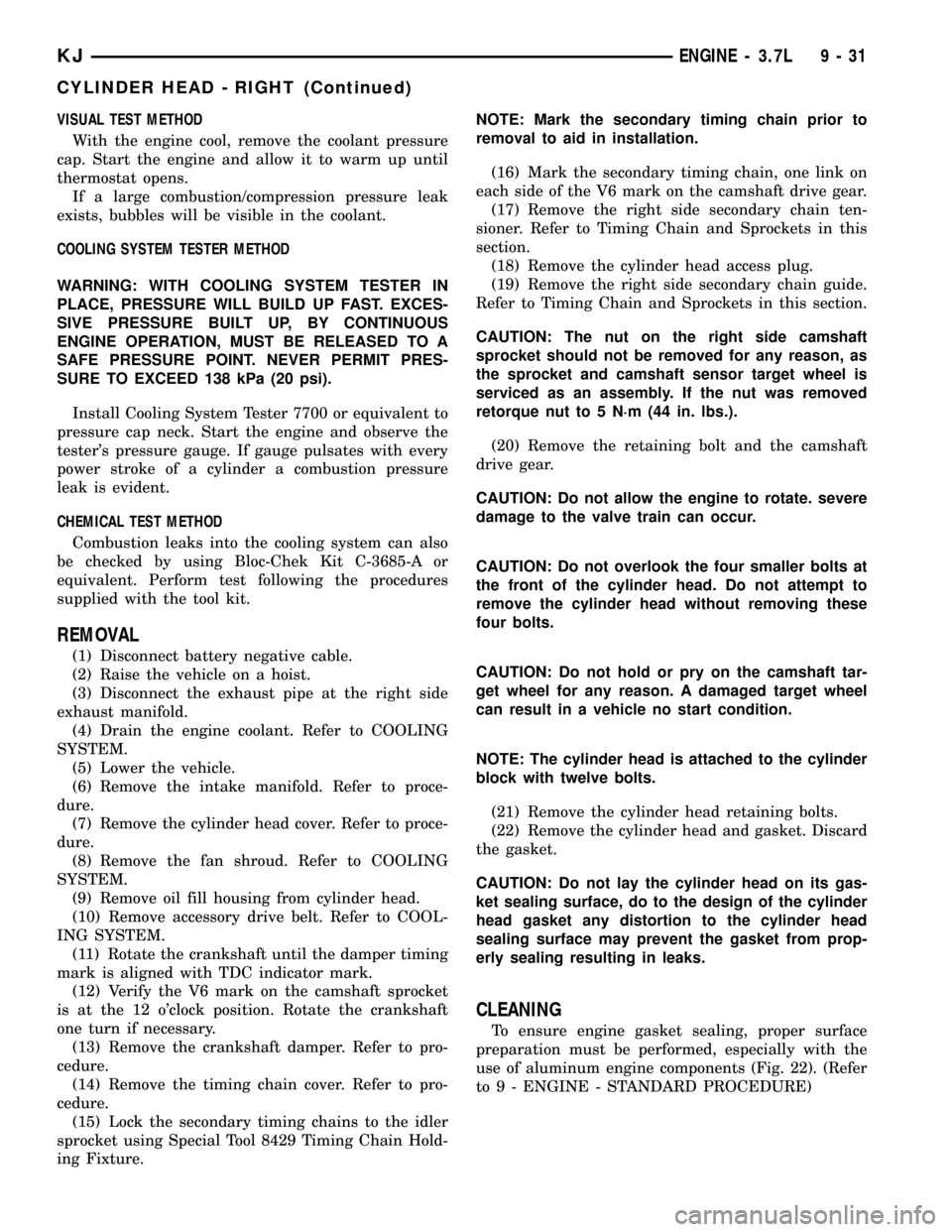

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant. Refer to COOLING

SYSTEM.

(5) Lower the vehicle.

(6) Remove the intake manifold. Refer to proce-

dure.

(7) Remove the cylinder head cover. Refer to proce-

dure.

(8) Remove the fan shroud. Refer to COOLING

SYSTEM.

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position. Rotate the crankshaft

one turn if necessary.

(13) Remove the crankshaft damper. Refer to pro-

cedure.

(14) Remove the timing chain cover. Refer to pro-

cedure.

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture.NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(17) Remove the right side secondary chain ten-

sioner. Refer to Timing Chain and Sprockets in this

section.

(18) Remove the cylinder head access plug.

(19) Remove the right side secondary chain guide.

Refer to Timing Chain and Sprockets in this section.

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components (Fig. 22). (Refer

to 9 - ENGINE - STANDARD PROCEDURE)

KJENGINE - 3.7L 9 - 31

CYLINDER HEAD - RIGHT (Continued)

Page 1260 of 1803

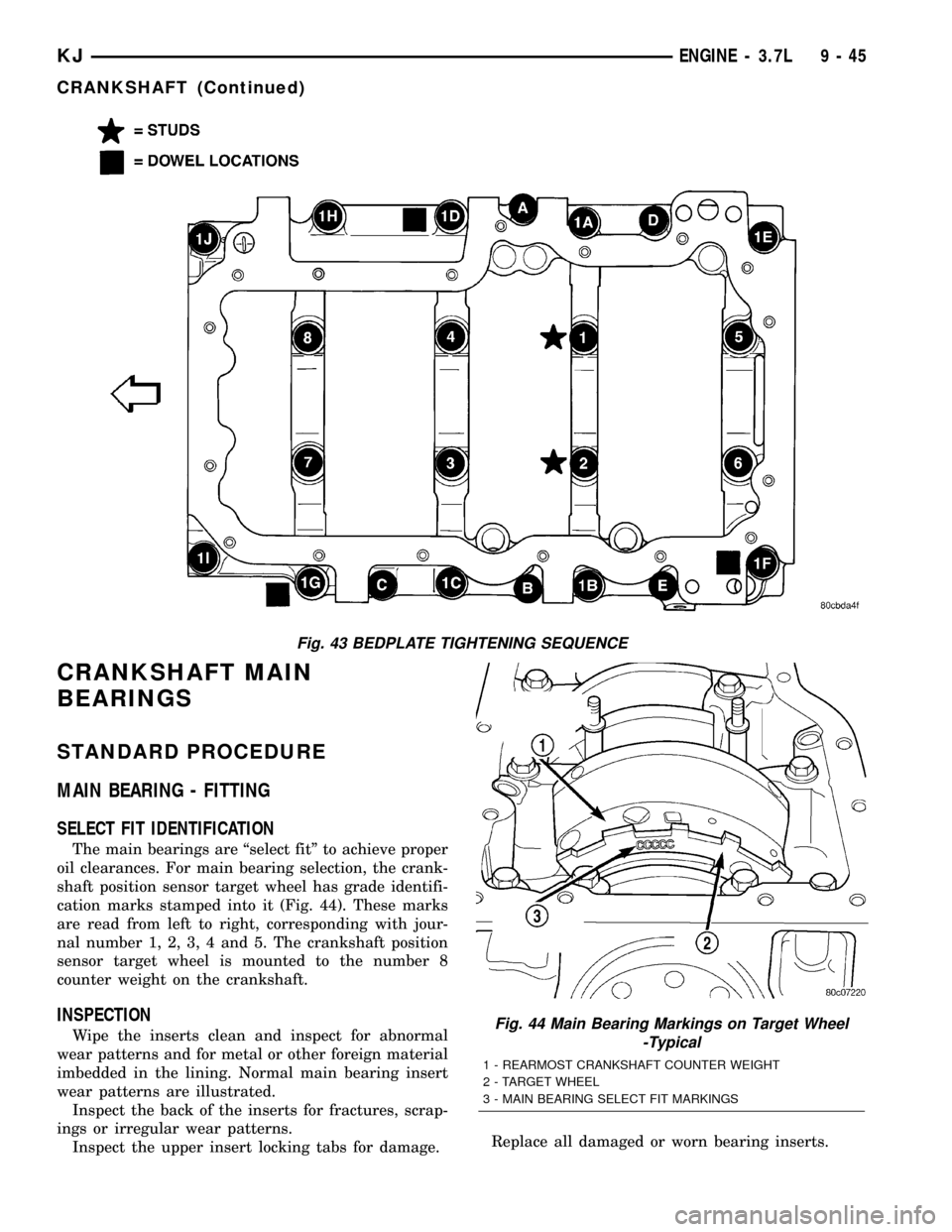

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE

MAIN BEARING - FITTING

SELECT FIT IDENTIFICATION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 44). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4 and 5. The crankshaft position

sensor target wheel is mounted to the number 8

counter weight on the crankshaft.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.Replace all damaged or worn bearing inserts.

Fig. 43 BEDPLATE TIGHTENING SEQUENCE

Fig. 44 Main Bearing Markings on Target Wheel

-Typical

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

KJENGINE - 3.7L 9 - 45

CRANKSHAFT (Continued)