torque JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 210 of 1803

CLUTCH DISC

REMOVAL

(1) Remove transmission.

(2) Mark position of pressure plate on flywheel

with paint or a scriber for assembly reference, if

clutch is not being replaced.

(3) Loosen pressure plate bolts evenly and in rota-

tion to relieve spring tension and avoid warping the

plate.

(4) Remove pressure plate bolts and pressure plate

and disc.

INSTALLATION

(1) Lightly scuff sand flywheel face with 180 grit

emery cloth, then clean with a wax and grease

remover.

(2) Lubricate pilot bearing with Mopar high tem-

perature bearing grease or equivalent.

(3) Check runout and operation ofnewclutch disc.

NOTE: Disc must slide freely on transmission input

shaft splines.

(4) With the disc on the input shaft, check face

runout with dial indicator. Check runout at disc hub

6 mm (1/4 in.) from outer edge of facing. Obtain

another clutch disc if runout exceed 0.5 mm (0.020

in.).

(5) Position clutch disc on flywheel with side

marked flywheel against the flywheel.

NOTE: If not marked, the flat side of disc hub goes

towards the flywheel on the 3.7L engine and

towards the transmission on 2.4L engine.

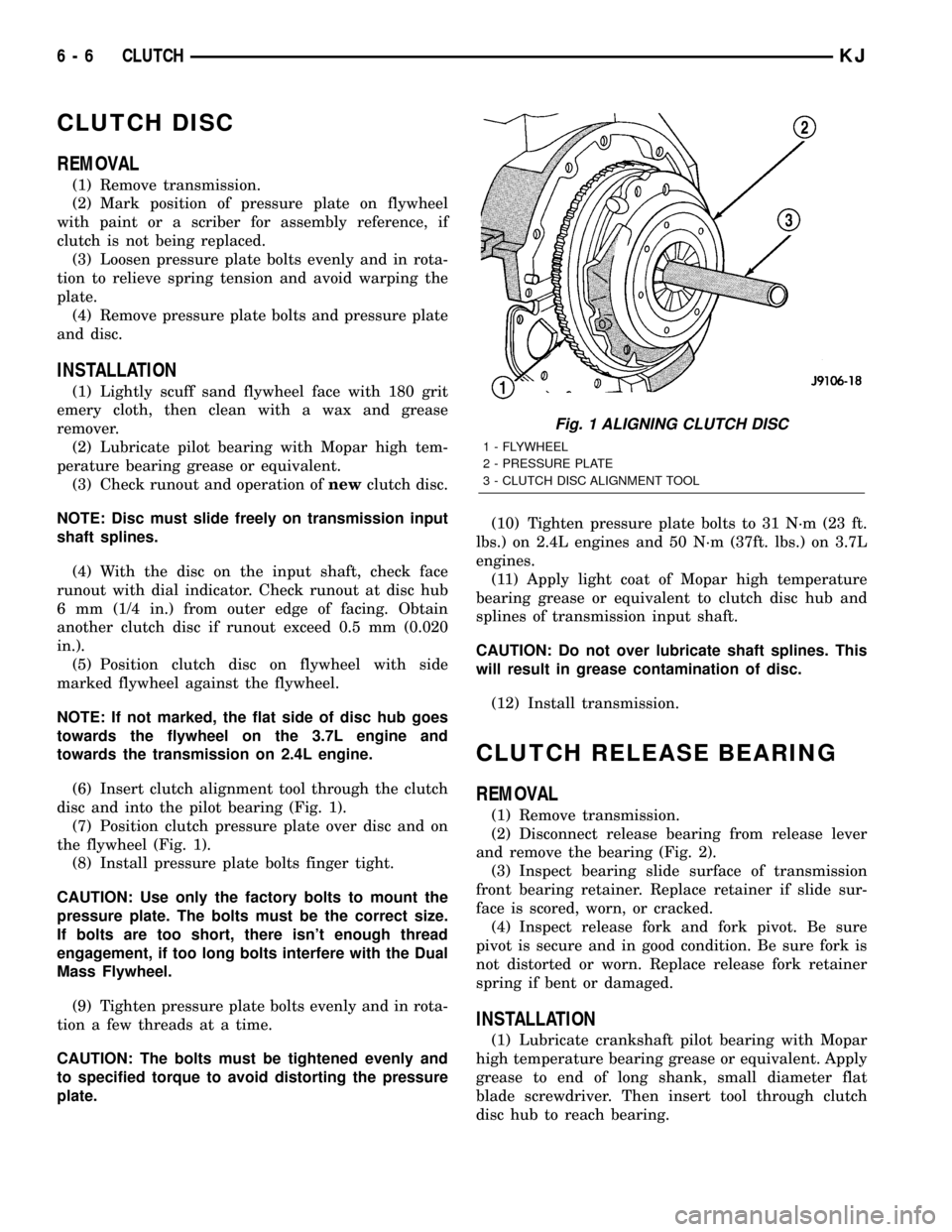

(6) Insert clutch alignment tool through the clutch

disc and into the pilot bearing (Fig. 1).

(7) Position clutch pressure plate over disc and on

the flywheel (Fig. 1).

(8) Install pressure plate bolts finger tight.

CAUTION: Use only the factory bolts to mount the

pressure plate. The bolts must be the correct size.

If bolts are too short, there isn't enough thread

engagement, if too long bolts interfere with the Dual

Mass Flywheel.

(9) Tighten pressure plate bolts evenly and in rota-

tion a few threads at a time.

CAUTION: The bolts must be tightened evenly and

to specified torque to avoid distorting the pressure

plate.(10) Tighten pressure plate bolts to 31 N´m (23 ft.

lbs.) on 2.4L engines and 50 N´m (37ft. lbs.) on 3.7L

engines.

(11) Apply light coat of Mopar high temperature

bearing grease or equivalent to clutch disc hub and

splines of transmission input shaft.

CAUTION: Do not over lubricate shaft splines. This

will result in grease contamination of disc.

(12) Install transmission.

CLUTCH RELEASE BEARING

REMOVAL

(1) Remove transmission.

(2) Disconnect release bearing from release lever

and remove the bearing (Fig. 2).

(3) Inspect bearing slide surface of transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(4) Inspect release fork and fork pivot. Be sure

pivot is secure and in good condition. Be sure fork is

not distorted or worn. Replace release fork retainer

spring if bent or damaged.

INSTALLATION

(1) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease or equivalent. Apply

grease to end of long shank, small diameter flat

blade screwdriver. Then insert tool through clutch

disc hub to reach bearing.

Fig. 1 ALIGNING CLUTCH DISC

1 - FLYWHEEL

2 - PRESSURE PLATE

3 - CLUTCH DISC ALIGNMENT TOOL

6 - 6 CLUTCHKJ

Page 212 of 1803

On a Dual Mass Flywheel the additional secondary

mass coupled to the transmission lowers the natural

frequency of the transmission rotating elements. This

decreases the transmission gear rattle. The damper

springs between the two flywheel masses replace the

clutch disc damper springs and assist in a smooth

transfer of torque to the transmission.

CAUTION: The Dual Mass Flywheel is serviced as

an assembly only and should never be taken apart.

DIAGNOSIS AND TESTING - FLYWHEEL

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on a stud installed in place of one of the fly-

wheel bolts.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock

removal isnot recommended.Replace the flywheel

if scoring is severe and deeper than 0.076 mm (0.003

in.). Excessive stock removal can result in flywheel

cracking or warpage after installation; it can also

weaken the flywheel and interfere with proper clutch

release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

PILOT BEARING

REMOVAL

(1) Remove the transmission.

(2) Remove pressure plate and clutch disc.

(3) Remove pilot bearing with an internal (blind

hole) puller.

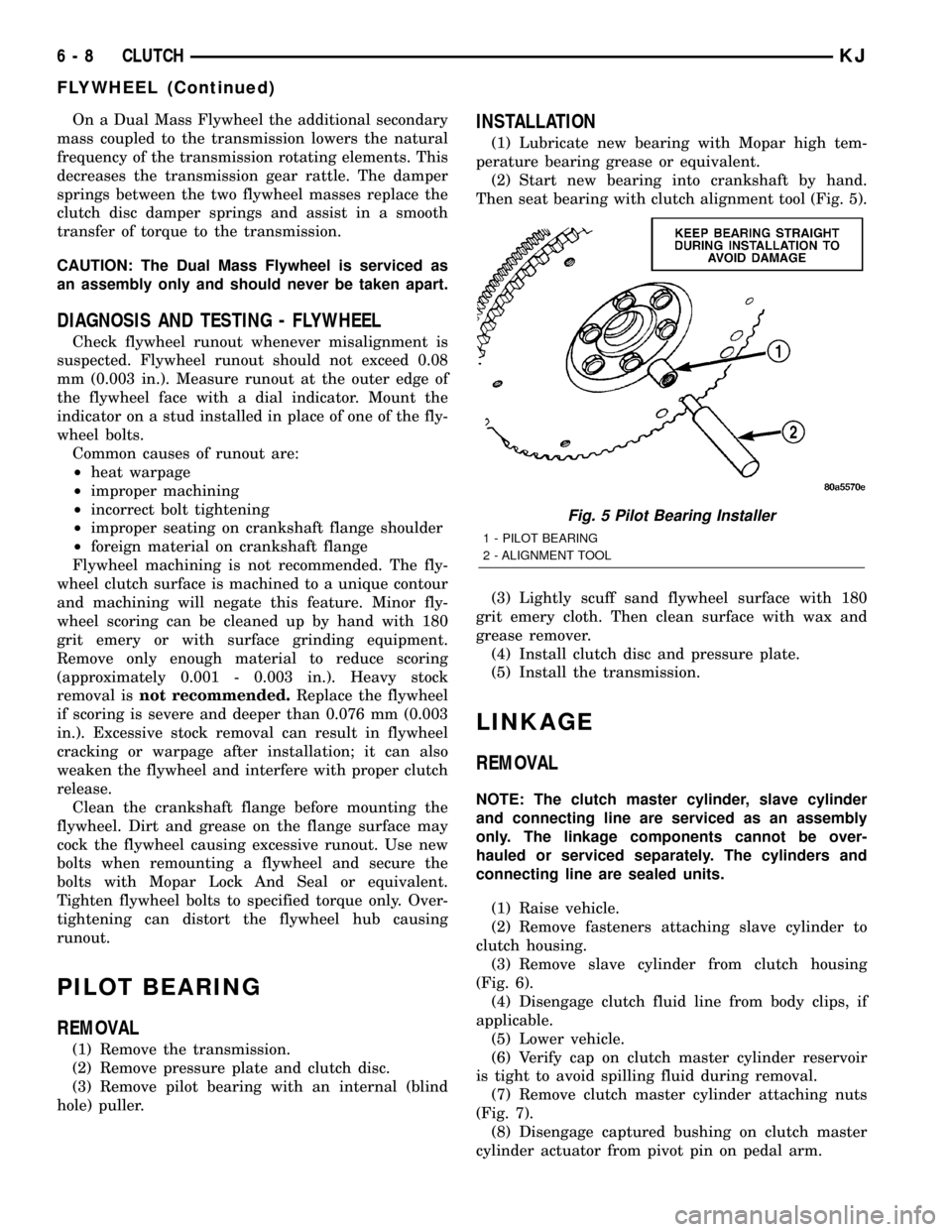

INSTALLATION

(1) Lubricate new bearing with Mopar high tem-

perature bearing grease or equivalent.

(2) Start new bearing into crankshaft by hand.

Then seat bearing with clutch alignment tool (Fig. 5).

(3) Lightly scuff sand flywheel surface with 180

grit emery cloth. Then clean surface with wax and

grease remover.

(4) Install clutch disc and pressure plate.

(5) Install the transmission.

LINKAGE

REMOVAL

NOTE: The clutch master cylinder, slave cylinder

and connecting line are serviced as an assembly

only. The linkage components cannot be over-

hauled or serviced separately. The cylinders and

connecting line are sealed units.

(1) Raise vehicle.

(2) Remove fasteners attaching slave cylinder to

clutch housing.

(3) Remove slave cylinder from clutch housing

(Fig. 6).

(4) Disengage clutch fluid line from body clips, if

applicable.

(5) Lower vehicle.

(6) Verify cap on clutch master cylinder reservoir

is tight to avoid spilling fluid during removal.

(7) Remove clutch master cylinder attaching nuts

(Fig. 7).

(8) Disengage captured bushing on clutch master

cylinder actuator from pivot pin on pedal arm.

Fig. 5 Pilot Bearing Installer

1 - PILOT BEARING

2 - ALIGNMENT TOOL

6 - 8 CLUTCHKJ

FLYWHEEL (Continued)

Page 214 of 1803

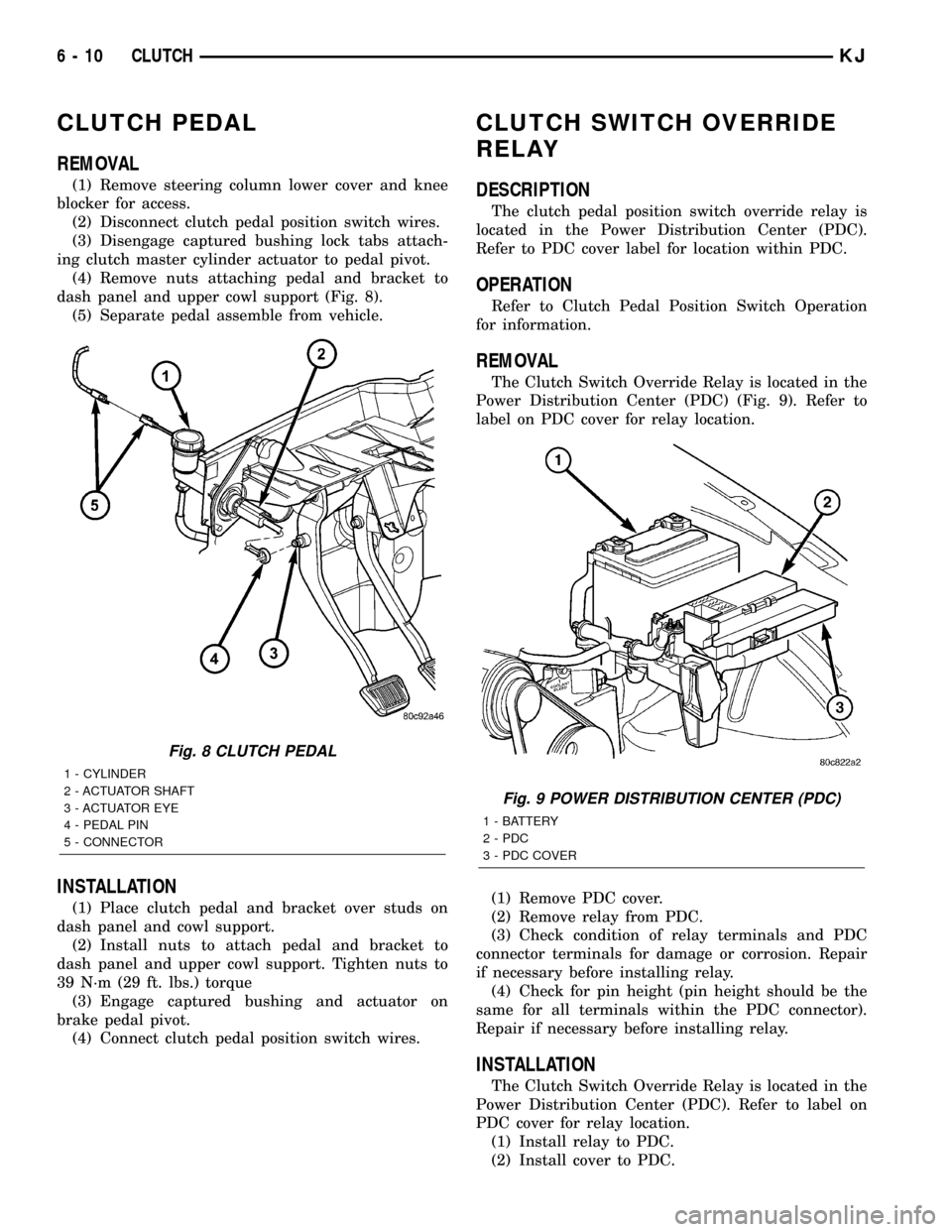

CLUTCH PEDAL

REMOVAL

(1) Remove steering column lower cover and knee

blocker for access.

(2) Disconnect clutch pedal position switch wires.

(3) Disengage captured bushing lock tabs attach-

ing clutch master cylinder actuator to pedal pivot.

(4) Remove nuts attaching pedal and bracket to

dash panel and upper cowl support (Fig. 8).

(5) Separate pedal assemble from vehicle.

INSTALLATION

(1) Place clutch pedal and bracket over studs on

dash panel and cowl support.

(2) Install nuts to attach pedal and bracket to

dash panel and upper cowl support. Tighten nuts to

39 N´m (29 ft. lbs.) torque

(3) Engage captured bushing and actuator on

brake pedal pivot.

(4) Connect clutch pedal position switch wires.

CLUTCH SWITCH OVERRIDE

RELAY

DESCRIPTION

The clutch pedal position switch override relay is

located in the Power Distribution Center (PDC).

Refer to PDC cover label for location within PDC.

OPERATION

Refer to Clutch Pedal Position Switch Operation

for information.

REMOVAL

The Clutch Switch Override Relay is located in the

Power Distribution Center (PDC) (Fig. 9). Refer to

label on PDC cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The Clutch Switch Override Relay is located in the

Power Distribution Center (PDC). Refer to label on

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

Fig. 8 CLUTCH PEDAL

1 - CYLINDER

2 - ACTUATOR SHAFT

3 - ACTUATOR EYE

4 - PEDAL PIN

5 - CONNECTOR

Fig. 9 POWER DISTRIBUTION CENTER (PDC)

1 - BATTERY

2 - PDC

3 - PDC COVER

6 - 10 CLUTCHKJ

Page 216 of 1803

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 3.7L

ENGINE..............................1

DESCRIPTION - COOLING SYSTEM

ROUTING 3.7L ENGINE..................2

DESCRIPTION - HOSE CLAMPS...........2

OPERATION

OPERATION - COOLING SYSTEM.........2

OPERATION - HOSE CLAMPS............3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTICS (OBD)...................3

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS.............................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAKS.......................4DIAGNOSIS AND TESTING - COOLING

SYSTEM DIAGNOSIS CHART.............6

STANDARD PROCEDURE

STANDARD PROCEDURE - DRAINING

COOLING SYSTEM 3.7L ENGINE.........12

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 3.7L ENGINE.........12

STANDARD PROCEDURE - COOLING

SYSTEM - REVERSE FLUSHING..........12

SPECIFICATIONS

TORQUE............................13

SPECIAL TOOLS

COOLING...........................14

ACCESSORY DRIVE......................15

ENGINE...............................19

TRANSMISSION.........................32

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 3.7L

ENGINE

The cooling system consists of the following items:

²Electric cooling fan - Standard.

²Electric cooling fan and mechanical thermal vis-

cous fan with low disengaged - Heavy duty cooling

only²Radiator

²Hot bottle pressure cap

²Thermostat

²Coolant reserve/overflow system

²Radiator in-tank transmission oil cooler (if

equipped with an automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

KJCOOLING 7 - 1

Page 228 of 1803

(Mopar Radiator Kleen or equivalent) before flushing.

This will soften scale and other deposits and aid the

flushing operation.

CAUTION: Be sure instructions on the container are

followed.

REVERSE FLUSHING RADIATOR

Disconnect the radiator hoses from the radiator fit-

tings. Attach a section of radiator hose to the radia-

tor bottom outlet fitting and insert the flushing gun.

Connect a water supply hose and air supply hose to

the flushing gun.

CAUTION: The cooling system normally operates at

97-to-110 kPa (14- to-16 psi) pressure. Exceeding

this pressure may damage the radiator or hoses.

Allow the radiator to fill with water. When radiator

is filled, apply air in short blasts allowing radiator to

refill between blasts. Continue this reverse flushing

until clean water flows out through rear of radiator

cooling tube passages. For more information, refer to

operating instructions supplied with flushing equip-

ment. Have radiator cleaned more extensively by a

radiator repair shop.

REVERSE FLUSHING ENGINE

Drain the cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE). Remove the thermostat

housing and thermostat. Install the thermostat hous-

ing. Disconnect the radiator upper hose from the

radiator and attach the flushing gun to the hose. Dis-

connect the radiator lower hose from the water

pump. Attach a lead away hose to the water pump

inlet fitting.

CAUTION: Be sure that the heater control valve is

closed (heat off). This is done to prevent coolant

flow with scale and other deposits from entering

the heater core.

Connect the water supply hose and air supply hose

to the flushing gun. Allow the engine to fill with

water. When the engine is filled, apply air in short

blasts, allowing the system to fill between air blasts.

Continue until clean water flows through the lead

away hose. For more information, refer to operating

instructions supplied with flushing equipment.

Remove the lead away hose, flushing gun, water

supply hose and air supply hose. Remove the thermo-

stat housing (Refer to 7 - COOLING/ENGINE/EN-

GINE COOLANT THERMOSTAT - REMOVAL).

Install the thermostat and housing with a replace-

ment gasket (Refer to 7 - COOLING/ENGINE/EN-

GINE COOLANT THERMOSTAT -INSTALLATION). Connect the radiator hoses. Refill

the cooling system with the correct antifreeze/water

mixture (Refer to 7 - COOLING - STANDARD PRO-

CEDURE).

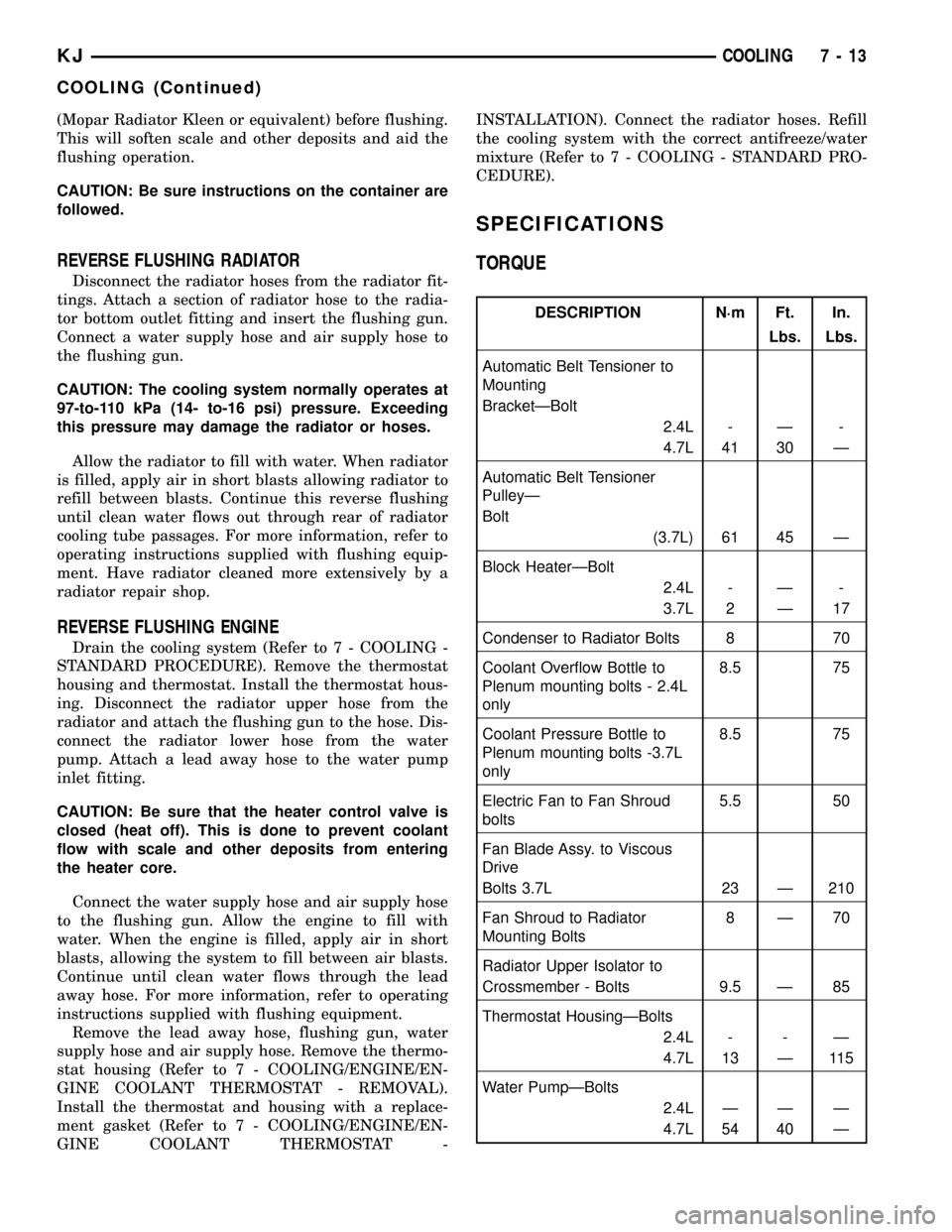

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Automatic Belt Tensioner to

Mounting

BracketÐBolt

2.4L - Ð -

4.7L 41 30 Ð

Automatic Belt Tensioner

PulleyÐ

Bolt

(3.7L) 61 45 Ð

Block HeaterÐBolt

2.4L - Ð -

3.7L 2 Ð 17

Condenser to Radiator Bolts 8 70

Coolant Overflow Bottle to

Plenum mounting bolts - 2.4L

only8.5 75

Coolant Pressure Bottle to

Plenum mounting bolts -3.7L

only8.5 75

Electric Fan to Fan Shroud

bolts5.5 50

Fan Blade Assy. to Viscous

Drive

Bolts 3.7L 23 Ð 210

Fan Shroud to Radiator

Mounting Bolts8Ð70

Radiator Upper Isolator to

Crossmember - Bolts 9.5 Ð 85

Thermostat HousingÐBolts

2.4L - - Ð

4.7L 13 Ð 115

Water PumpÐBolts

2.4L Ð Ð Ð

4.7L 54 40 Ð

KJCOOLING 7 - 13

COOLING (Continued)

Page 232 of 1803

CONDITION POSSIBLE CAUSES CORRECTION

BELT BROKEN (NOTE: IDENTIFY

AND CORRECT PROBLEM

BEFORE NEW BELT IS

INSTALLED)1. Excessive tension. 1. Replace belt and automatic belt

tensioner.

2. Incorrect belt. 2. Replace belt.

3. Tensile member damaged during

belt installation.3. Replace belt.

4. Severe misalignment. 4. Check and replace.

5. Bracket, pulley, or bearing failure. 5. Replace defective component

and belt.

NOISE (OBJECTIONABLE

SQUEAL, SQUEAK, OR RUMBLE

IS HEARD OR FELT WHILE

DRIVE BELT IS IN OPERATION)1. Belt slippage. 1. Replace belt or automatic belt

tensioner.

2. Bearing noise. 2. Locate and repair.

3. Belt misalignment. 3. Replace belt.

4. Belt-to-pulley mismatch. 4. Install correct belt.

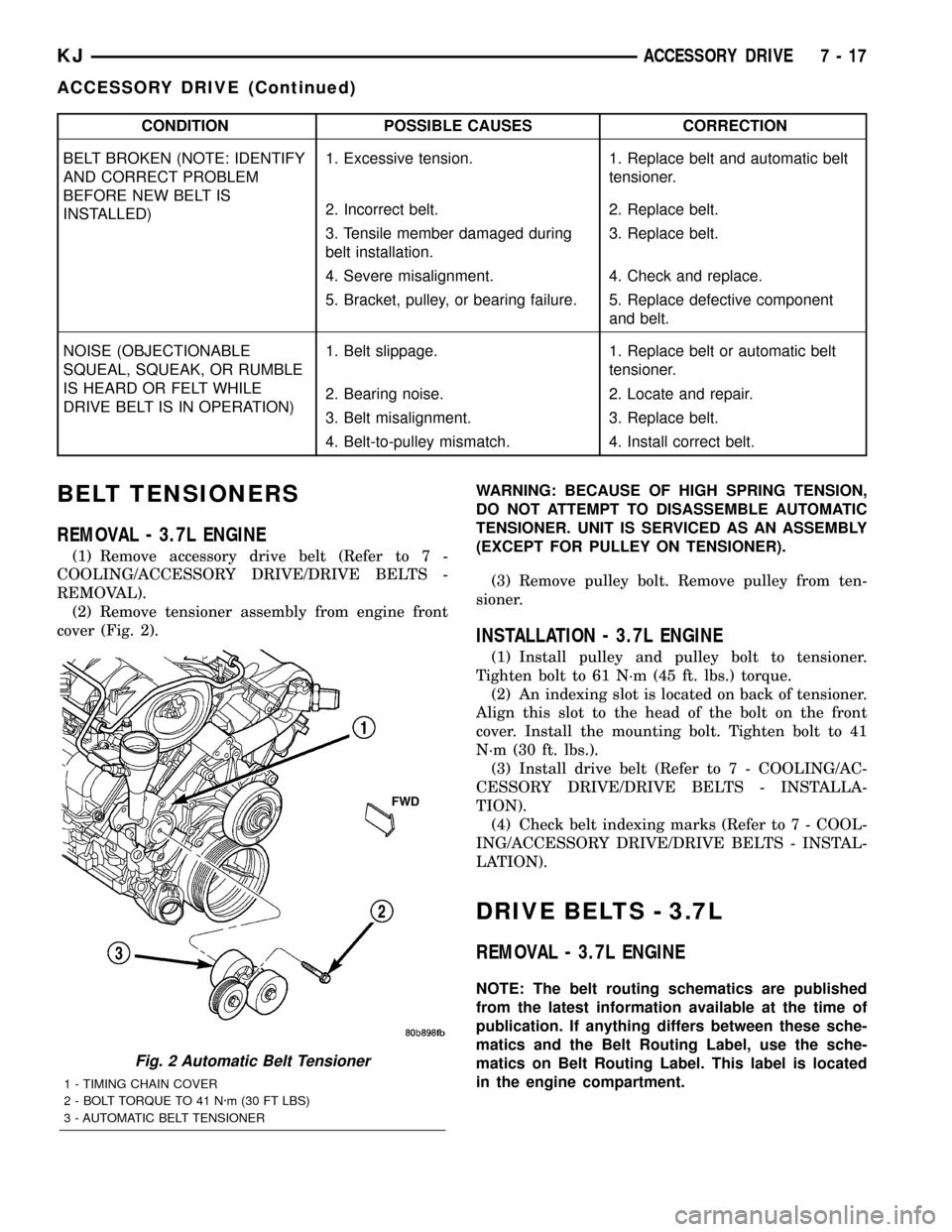

BELT TENSIONERS

REMOVAL - 3.7L ENGINE

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner assembly from engine front

cover (Fig. 2).WARNING: BECAUSE OF HIGH SPRING TENSION,

DO NOT ATTEMPT TO DISASSEMBLE AUTOMATIC

TENSIONER. UNIT IS SERVICED AS AN ASSEMBLY

(EXCEPT FOR PULLEY ON TENSIONER).

(3) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION - 3.7L ENGINE

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) An indexing slot is located on back of tensioner.

Align this slot to the head of the bolt on the front

cover. Install the mounting bolt. Tighten bolt to 41

N´m (30 ft. lbs.).

(3) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(4) Check belt indexing marks (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

DRIVE BELTS - 3.7L

REMOVAL - 3.7L ENGINE

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label. This label is located

in the engine compartment.

Fig. 2 Automatic Belt Tensioner

1 - TIMING CHAIN COVER

2 - BOLT TORQUE TO 41 N´m (30 FT LBS)

3 - AUTOMATIC BELT TENSIONER

KJACCESSORY DRIVE 7 - 17

ACCESSORY DRIVE (Continued)

Page 236 of 1803

INSTALLATION

(1) Apply thread sealant to sensor threads.

(2) Install sensor to engine.

(3) Tighten sensor to 11 N´m (8 ft. lbs.) torque.

(4) Replace any lost engine coolant.

ENGINE COOLANT

THERMOSTAT

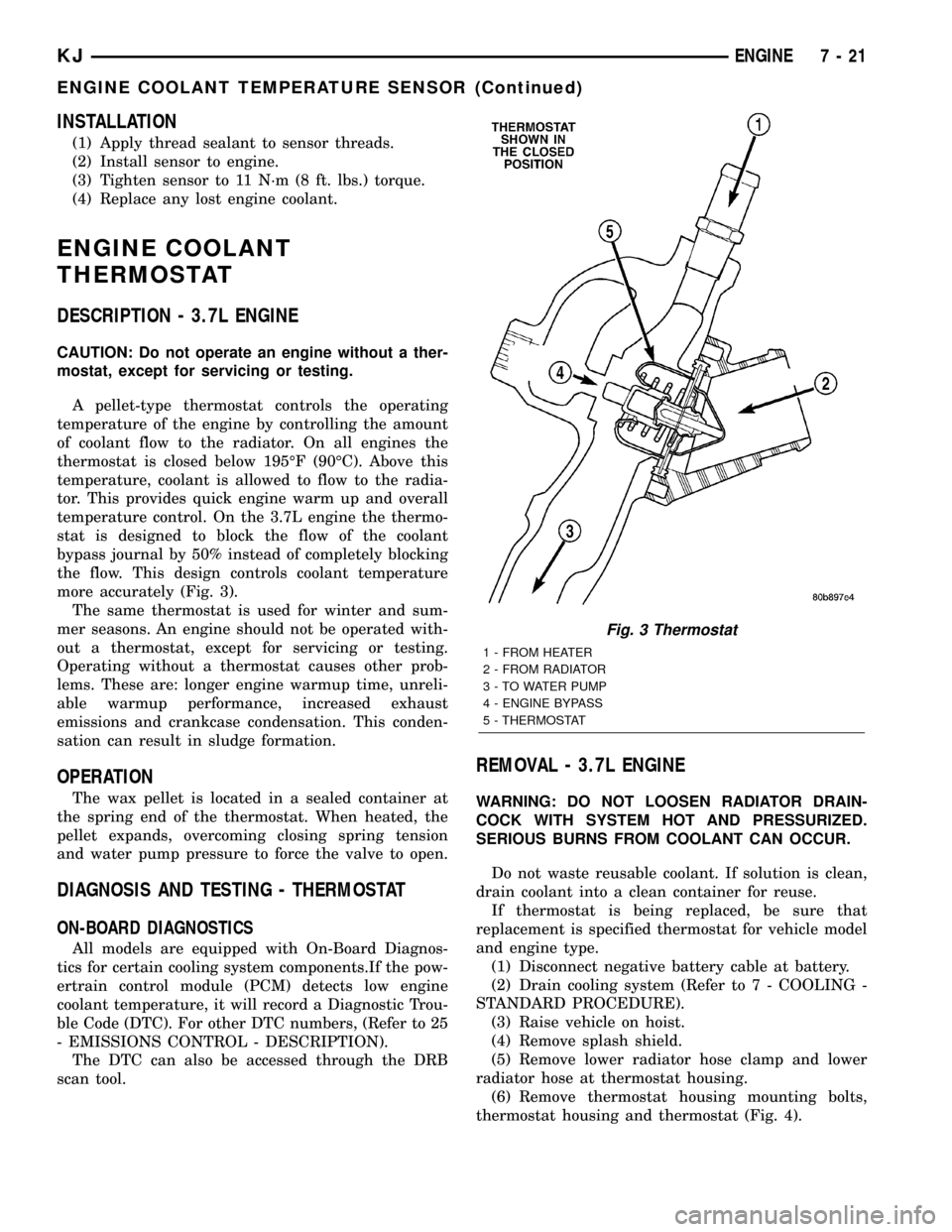

DESCRIPTION - 3.7L ENGINE

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L engine the thermo-

stat is designed to block the flow of the coolant

bypass journal by 50% instead of completely blocking

the flow. This design controls coolant temperature

more accurately (Fig. 3).

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTING - THERMOSTAT

ON-BOARD DIAGNOSTICS

All models are equipped with On-Board Diagnos-

tics for certain cooling system components.If the pow-

ertrain control module (PCM) detects low engine

coolant temperature, it will record a Diagnostic Trou-

ble Code (DTC). For other DTC numbers, (Refer to 25

- EMISSIONS CONTROL - DESCRIPTION).

The DTC can also be accessed through the DRB

scan tool.

REMOVAL - 3.7L ENGINE

WARNING: DO NOT LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND PRESSURIZED.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

If thermostat is being replaced, be sure that

replacement is specified thermostat for vehicle model

and engine type.

(1) Disconnect negative battery cable at battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Raise vehicle on hoist.

(4) Remove splash shield.

(5) Remove lower radiator hose clamp and lower

radiator hose at thermostat housing.

(6) Remove thermostat housing mounting bolts,

thermostat housing and thermostat (Fig. 4).

Fig. 3 Thermostat

1 - FROM HEATER

2 - FROM RADIATOR

3 - TO WATER PUMP

4 - ENGINE BYPASS

5 - THERMOSTAT

KJENGINE 7 - 21

ENGINE COOLANT TEMPERATURE SENSOR (Continued)

Page 237 of 1803

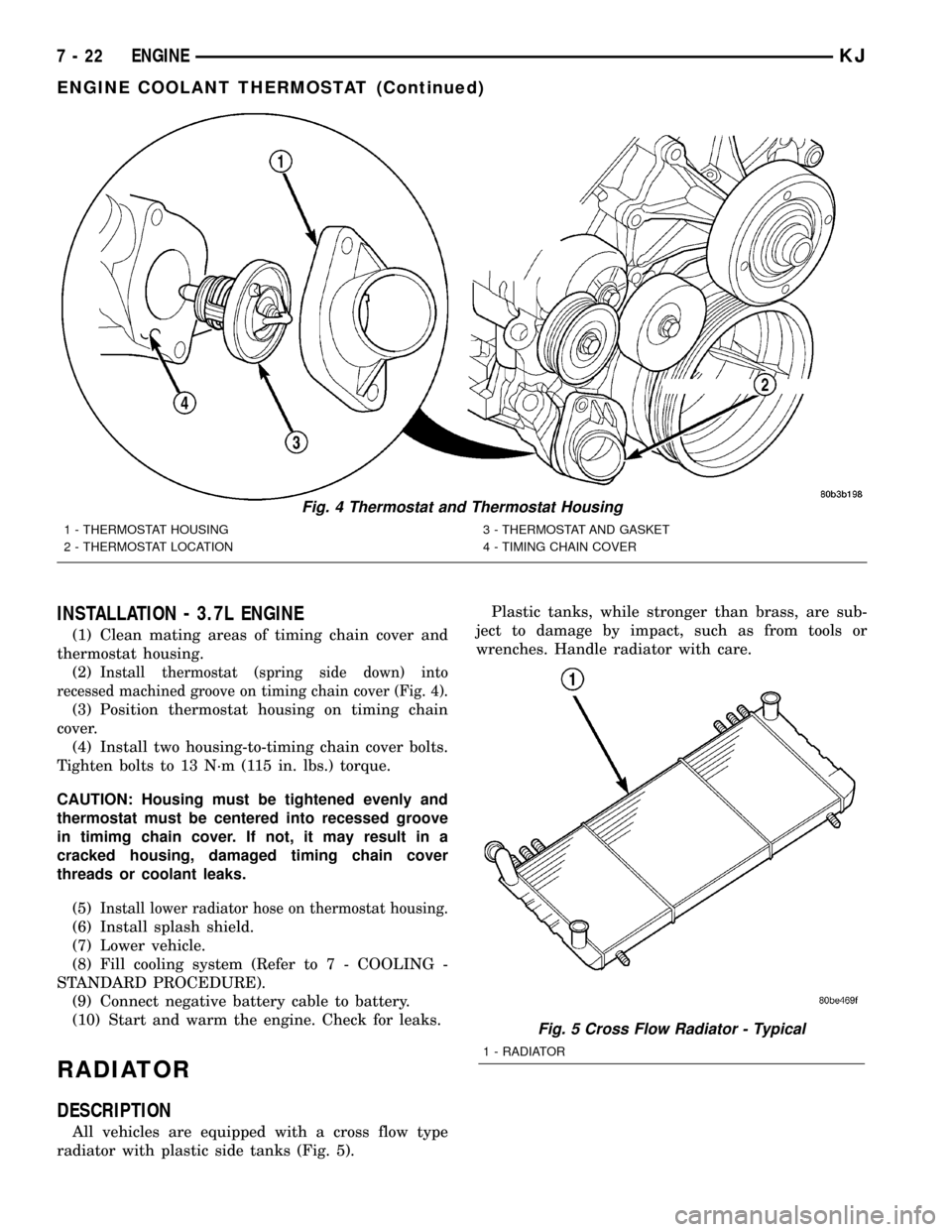

INSTALLATION - 3.7L ENGINE

(1) Clean mating areas of timing chain cover and

thermostat housing.

(2)

Install thermostat (spring side down) into

recessed machined groove on timing chain cover (Fig. 4).

(3) Position thermostat housing on timing chain

cover.

(4) Install two housing-to-timing chain cover bolts.

Tighten bolts to 13 N´m (115 in. lbs.) torque.

CAUTION: Housing must be tightened evenly and

thermostat must be centered into recessed groove

in timimg chain cover. If not, it may result in a

cracked housing, damaged timing chain cover

threads or coolant leaks.

(5)

Install lower radiator hose on thermostat housing.

(6) Install splash shield.

(7) Lower vehicle.

(8) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(9) Connect negative battery cable to battery.

(10) Start and warm the engine. Check for leaks.

RADIATOR

DESCRIPTION

All vehicles are equipped with a cross flow type

radiator with plastic side tanks (Fig. 5).Plastic tanks, while stronger than brass, are sub-

ject to damage by impact, such as from tools or

wrenches. Handle radiator with care.

Fig. 4 Thermostat and Thermostat Housing

1 - THERMOSTAT HOUSING

2 - THERMOSTAT LOCATION3 - THERMOSTAT AND GASKET

4 - TIMING CHAIN COVER

Fig. 5 Cross Flow Radiator - Typical

1 - RADIATOR

7 - 22 ENGINEKJ

ENGINE COOLANT THERMOSTAT (Continued)

Page 244 of 1803

CAUTION: Do not remove water pump pulley-to-wa-

ter pump bolts. This pulley is under belt tension.

(8) Remove four bolts securing fan blade assembly

to viscous fan drive.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (four bolts).

(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, loose

rivets or broken welds. Replace fan if any damage is

found.

INSTALLATION

(1) Assemble fan blade to viscous fan drive.

Tighten mounting bolts to 27 N´m (20 ft. lbs.) torque.

NOTE: The vicous fan and fan shroud must be

installed as an assembly.

(2) Gently lay vicous fan into fan shroud.

(3) Install the fan shroud to radiator mounting

bolts, torque bolts to (5.5N´M or 50 in´lbs).

(4) Thread the fan and fan drive onto the water

pump pulley, and tighten nut using special tool 6958

spanner wrench and 8346 adapters.

(5) Connect the electrical connector for the electric

fan.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

for correct belt routing.

WATER PUMP

DESCRIPTION

DESCRIPTION - WATER PUMP

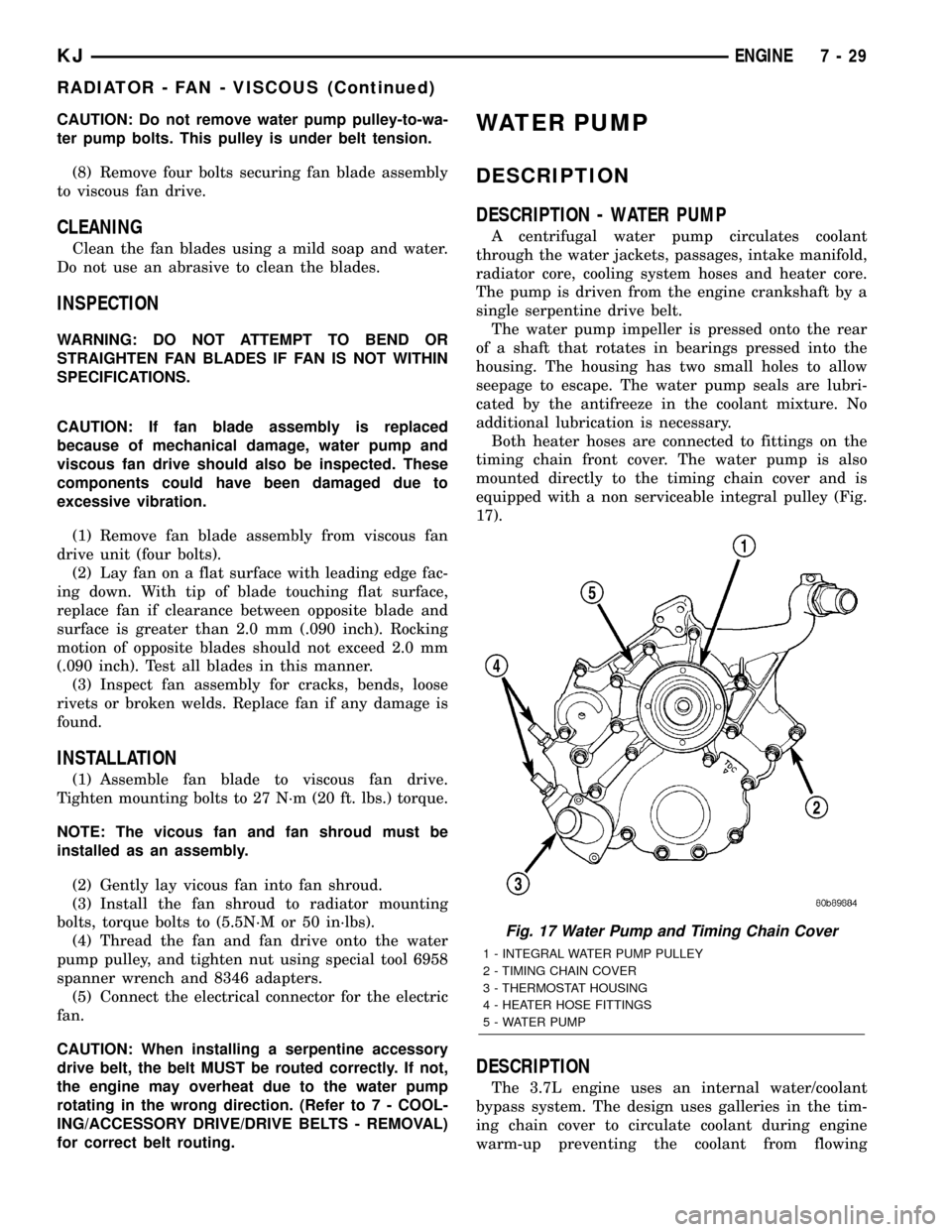

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary.

Both heater hoses are connected to fittings on the

timing chain front cover. The water pump is also

mounted directly to the timing chain cover and is

equipped with a non serviceable integral pulley (Fig.

17).

DESCRIPTION

The 3.7L engine uses an internal water/coolant

bypass system. The design uses galleries in the tim-

ing chain cover to circulate coolant during engine

warm-up preventing the coolant from flowing

Fig. 17 Water Pump and Timing Chain Cover

1 - INTEGRAL WATER PUMP PULLEY

2 - TIMING CHAIN COVER

3 - THERMOSTAT HOUSING

4 - HEATER HOSE FITTINGS

5 - WATER PUMP

KJENGINE 7 - 29

RADIATOR - FAN - VISCOUS (Continued)

Page 246 of 1803

CAUTION: Do not pry water pump at timing chain

case/cover. The machined surfaces may be dam-

aged resulting in leaks.

(11) Remove water pump and gasket. Discard gas-

ket.

CLEANING

Clean the gasket mating surface. Use caution not

to damage the gasket sealing surface.

INSPECTION

Inspect the water pump assembly for cracks in the

housing, Water leaks from shaft seal, Loose or rough

turning bearing or Impeller rubbing either the pump

body or timing chain case/cover.

INSTALLATION

The water pump on 3.7L engines is bolted directly

to the engine timing chain case cover.

(1) Clean gasket mating surfaces.

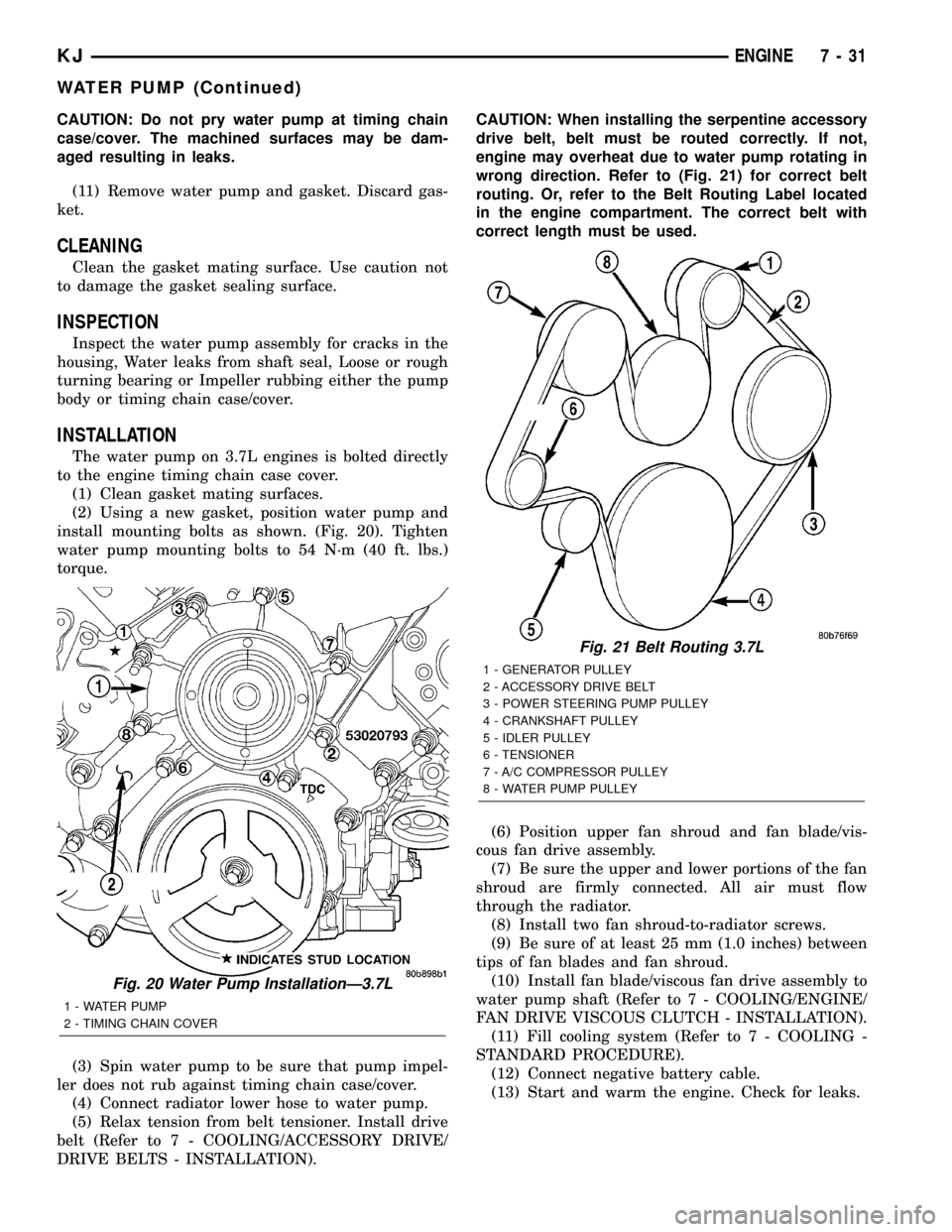

(2) Using a new gasket, position water pump and

install mounting bolts as shown. (Fig. 20). Tighten

water pump mounting bolts to 54 N´m (40 ft. lbs.)

torque.

(3) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(4) Connect radiator lower hose to water pump.

(5) Relax tension from belt tensioner. Install drive

belt (Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - INSTALLATION).CAUTION: When installing the serpentine accessory

drive belt, belt must be routed correctly. If not,

engine may overheat due to water pump rotating in

wrong direction. Refer to (Fig. 21) for correct belt

routing. Or, refer to the Belt Routing Label located

in the engine compartment. The correct belt with

correct length must be used.

(6) Position upper fan shroud and fan blade/vis-

cous fan drive assembly.

(7) Be sure the upper and lower portions of the fan

shroud are firmly connected. All air must flow

through the radiator.

(8) Install two fan shroud-to-radiator screws.

(9) Be sure of at least 25 mm (1.0 inches) between

tips of fan blades and fan shroud.

(10) Install fan blade/viscous fan drive assembly to

water pump shaft (Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH - INSTALLATION).

(11) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(12) Connect negative battery cable.

(13) Start and warm the engine. Check for leaks.

Fig. 20 Water Pump InstallationÐ3.7L

1 - WATER PUMP

2 - TIMING CHAIN COVER

Fig. 21 Belt Routing 3.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

KJENGINE 7 - 31

WATER PUMP (Continued)