water pump JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1659 of 1803

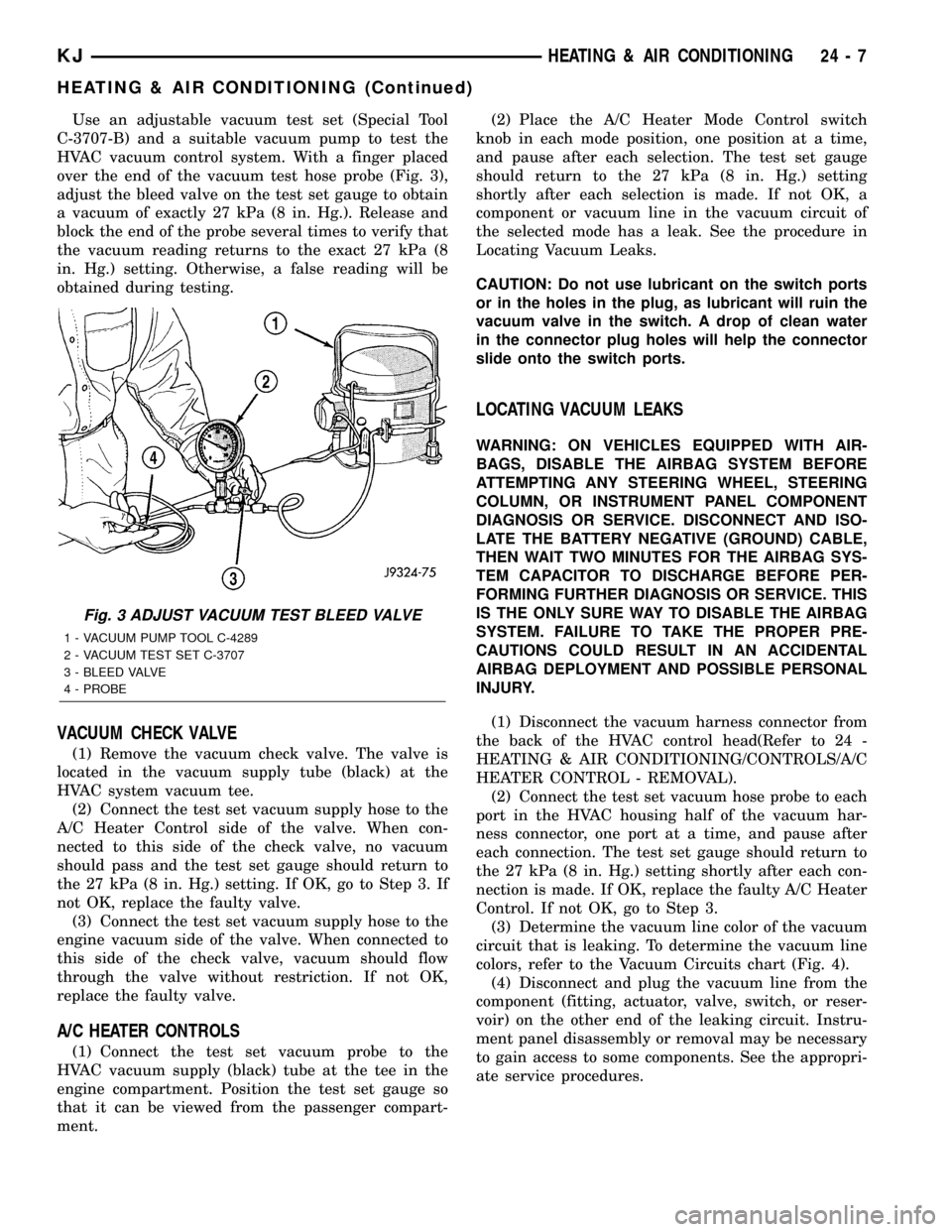

Use an adjustable vacuum test set (Special Tool

C-3707-B) and a suitable vacuum pump to test the

HVAC vacuum control system. With a finger placed

over the end of the vacuum test hose probe (Fig. 3),

adjust the bleed valve on the test set gauge to obtain

a vacuum of exactly 27 kPa (8 in. Hg.). Release and

block the end of the probe several times to verify that

the vacuum reading returns to the exact 27 kPa (8

in. Hg.) setting. Otherwise, a false reading will be

obtained during testing.

VACUUM CHECK VALVE

(1) Remove the vacuum check valve. The valve is

located in the vacuum supply tube (black) at the

HVAC system vacuum tee.

(2) Connect the test set vacuum supply hose to the

A/C Heater Control side of the valve. When con-

nected to this side of the check valve, no vacuum

should pass and the test set gauge should return to

the 27 kPa (8 in. Hg.) setting. If OK, go to Step 3. If

not OK, replace the faulty valve.

(3) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

A/C HEATER CONTROLS

(1) Connect the test set vacuum probe to the

HVAC vacuum supply (black) tube at the tee in the

engine compartment. Position the test set gauge so

that it can be viewed from the passenger compart-

ment.(2) Place the A/C Heater Mode Control switch

knob in each mode position, one position at a time,

and pause after each selection. The test set gauge

should return to the 27 kPa (8 in. Hg.) setting

shortly after each selection is made. If not OK, a

component or vacuum line in the vacuum circuit of

the selected mode has a leak. See the procedure in

Locating Vacuum Leaks.

CAUTION: Do not use lubricant on the switch ports

or in the holes in the plug, as lubricant will ruin the

vacuum valve in the switch. A drop of clean water

in the connector plug holes will help the connector

slide onto the switch ports.

LOCATING VACUUM LEAKS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect the vacuum harness connector from

the back of the HVAC control head(Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL).

(2) Connect the test set vacuum hose probe to each

port in the HVAC housing half of the vacuum har-

ness connector, one port at a time, and pause after

each connection. The test set gauge should return to

the 27 kPa (8 in. Hg.) setting shortly after each con-

nection is made. If OK, replace the faulty A/C Heater

Control. If not OK, go to Step 3.

(3) Determine the vacuum line color of the vacuum

circuit that is leaking. To determine the vacuum line

colors, refer to the Vacuum Circuits chart (Fig. 4).

(4) Disconnect and plug the vacuum line from the

component (fitting, actuator, valve, switch, or reser-

voir) on the other end of the leaking circuit. Instru-

ment panel disassembly or removal may be necessary

to gain access to some components. See the appropri-

ate service procedures.

Fig. 3 ADJUST VACUUM TEST BLEED VALVE

1 - VACUUM PUMP TOOL C-4289

2 - VACUUM TEST SET C-3707

3 - BLEED VALVE

4 - PROBE

KJHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 1711 of 1803

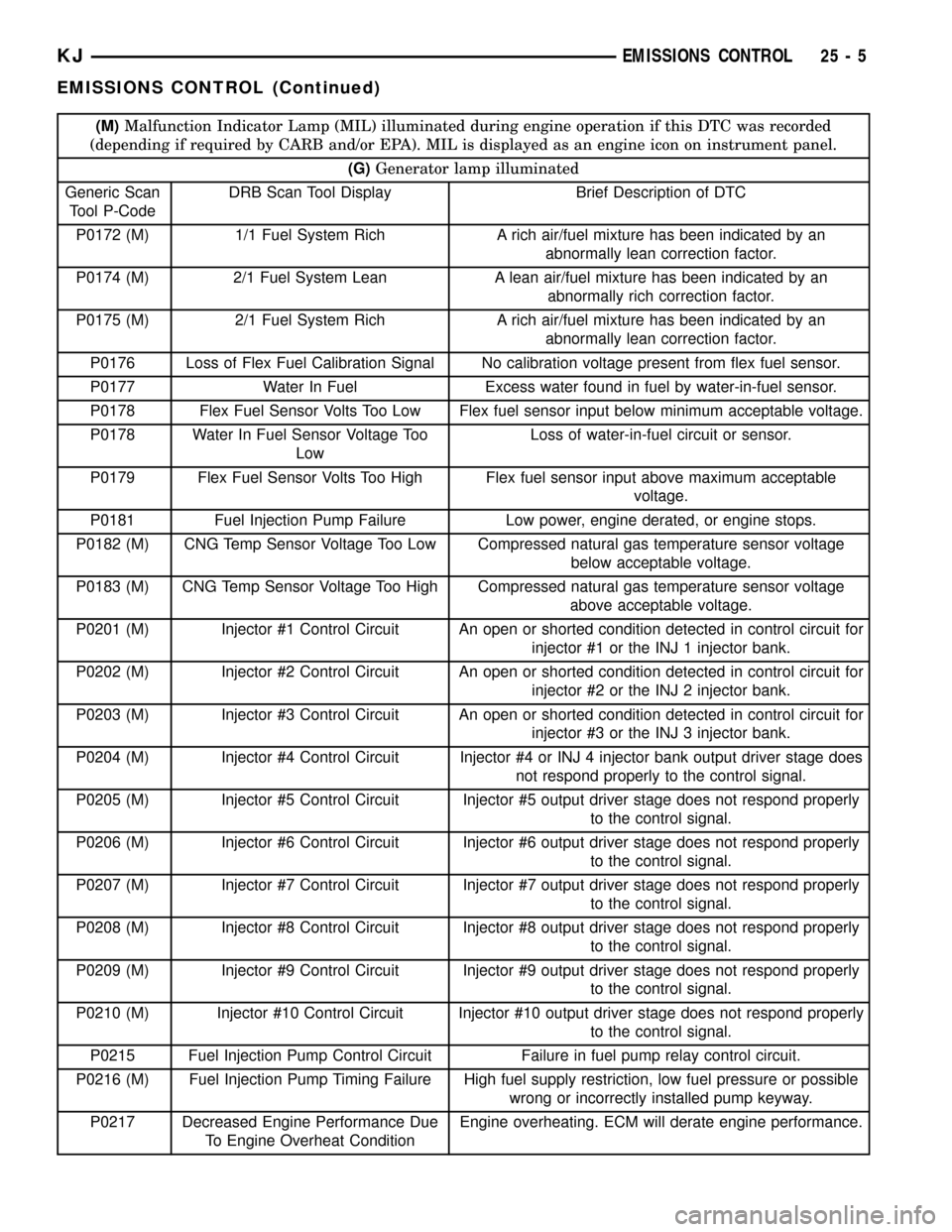

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0172 (M) 1/1 Fuel System Rich A rich air/fuel mixture has been indicated by an

abnormally lean correction factor.

P0174 (M) 2/1 Fuel System Lean A lean air/fuel mixture has been indicated by an

abnormally rich correction factor.

P0175 (M) 2/1 Fuel System Rich A rich air/fuel mixture has been indicated by an

abnormally lean correction factor.

P0176 Loss of Flex Fuel Calibration Signal No calibration voltage present from flex fuel sensor.

P0177 Water In Fuel Excess water found in fuel by water-in-fuel sensor.

P0178 Flex Fuel Sensor Volts Too Low Flex fuel sensor input below minimum acceptable voltage.

P0178 Water In Fuel Sensor Voltage Too

LowLoss of water-in-fuel circuit or sensor.

P0179 Flex Fuel Sensor Volts Too High Flex fuel sensor input above maximum acceptable

voltage.

P0181 Fuel Injection Pump Failure Low power, engine derated, or engine stops.

P0182 (M) CNG Temp Sensor Voltage Too Low Compressed natural gas temperature sensor voltage

below acceptable voltage.

P0183 (M) CNG Temp Sensor Voltage Too High Compressed natural gas temperature sensor voltage

above acceptable voltage.

P0201 (M) Injector #1 Control Circuit An open or shorted condition detected in control circuit for

injector #1 or the INJ 1 injector bank.

P0202 (M) Injector #2 Control Circuit An open or shorted condition detected in control circuit for

injector #2 or the INJ 2 injector bank.

P0203 (M) Injector #3 Control Circuit An open or shorted condition detected in control circuit for

injector #3 or the INJ 3 injector bank.

P0204 (M) Injector #4 Control Circuit Injector #4 or INJ 4 injector bank output driver stage does

not respond properly to the control signal.

P0205 (M) Injector #5 Control Circuit Injector #5 output driver stage does not respond properly

to the control signal.

P0206 (M) Injector #6 Control Circuit Injector #6 output driver stage does not respond properly

to the control signal.

P0207 (M) Injector #7 Control Circuit Injector #7 output driver stage does not respond properly

to the control signal.

P0208 (M) Injector #8 Control Circuit Injector #8 output driver stage does not respond properly

to the control signal.

P0209 (M) Injector #9 Control Circuit Injector #9 output driver stage does not respond properly

to the control signal.

P0210 (M) Injector #10 Control Circuit Injector #10 output driver stage does not respond properly

to the control signal.

P0215 Fuel Injection Pump Control Circuit Failure in fuel pump relay control circuit.

P0216 (M) Fuel Injection Pump Timing Failure High fuel supply restriction, low fuel pressure or possible

wrong or incorrectly installed pump keyway.

P0217 Decreased Engine Performance Due

To Engine Overheat ConditionEngine overheating. ECM will derate engine performance.

KJEMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 1724 of 1803

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º

water. The cycle rate of pump strokes is quite rapid

as the system begins to pump up to this pressure. As

the pressure increases, the cycle rate starts to drop

off. If there is no leak in the system, the pump would

eventually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases dueto the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicated

by a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the Air Fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S sensor output. The programmed

memory acts as a self calibration tool that the engine

controller uses to compensate for variations in engine

specifications, sensor tolerances and engine fatigue

over the life span of the engine. By monitoring the

actual fuel-air ratio with the O2S sensor (short term)

and multiplying that with the program long-term

(adaptive) memory and comparing that to the limit,

it can be determined whether it will pass an emis-

sions test. If a malfunction occurs such that the PCM

cannot maintain the optimum A/F ratio, then the

MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

25 - 18 EMISSIONS CONTROLKJ

EMISSIONS CONTROL (Continued)

Page 1734 of 1803

The pump contains a 3 port solenoid, a pump that

contains a switch, a spring loaded canister vent valve

seal, 2 check valves and a spring/diaphragm.

OPERATION

Immediately after a cold start, engine temperature

between 40ÉF and 86ÉF, the 3 port solenoid is briefly

energized. This initializes the pump by drawing air

into the pump cavity and also closes the vent seal.

During non-test test conditions, the vent seal is held

open by the pump diaphragm assembly which pushes

it open at the full travel position. The vent seal will

remain closed while the pump is cycling. This is due

to the operation of the 3 port solenoid which prevents

the diaphragm assembly from reaching full travel.

After the brief initialization period, the solenoid is

de-energized, allowing atmospheric pressure to enter

the pump cavity. This permits the spring to drive the

diaphragm which forces air out of the pump cavity

and into the vent system. When the solenoid is ener-

gized and de-energized, the cycle is repeated creating

flow in typical diaphragm pump fashion. The pump

is controlled in 2 modes:

PUMP MODE:The pump is cycled at a fixed rate

to achieve a rapid pressure build in order to shorten

the overall test time.

TEST MODE:The solenoid is energized with a

fixed duration pulse. Subsequent fixed pulses occur

when the diaphragm reaches the switch closure

point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5 inches

of water.

When the pump starts, the cycle rate is quite high.

As the system becomes pressurized pump rate drops.

If there is no leak the pump will quit. If there is a

leak, the test is terminated at the end of the test

mode.

If there is no leak, the purge monitor is run. If the

cycle rate increases due to the flow through the

purge system, the test is passed and the diagnostic is

complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

REMOVAL

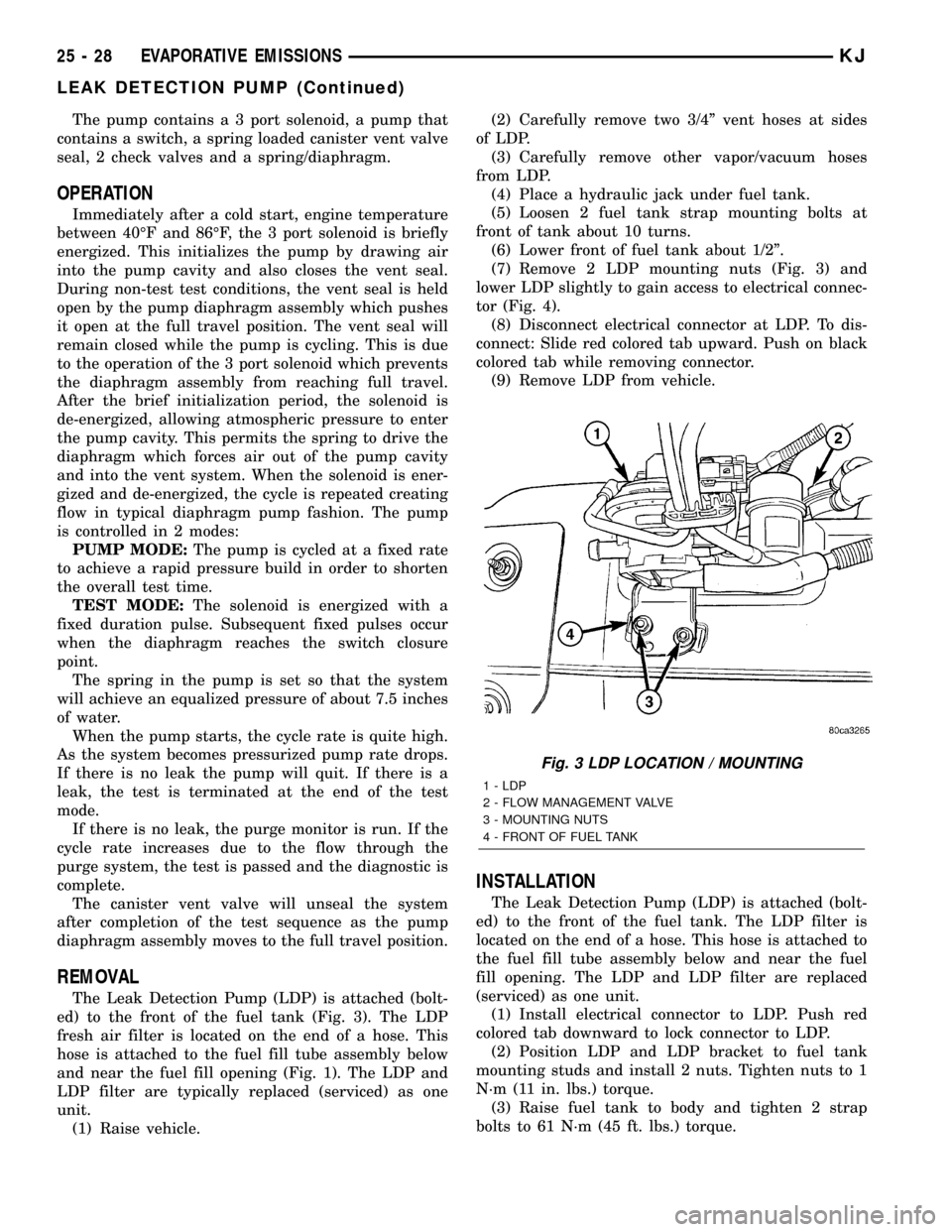

The Leak Detection Pump (LDP) is attached (bolt-

ed) to the front of the fuel tank (Fig. 3). The LDP

fresh air filter is located on the end of a hose. This

hose is attached to the fuel fill tube assembly below

and near the fuel fill opening (Fig. 1). The LDP and

LDP filter are typically replaced (serviced) as one

unit.

(1) Raise vehicle.(2) Carefully remove two 3/4º vent hoses at sides

of LDP.

(3) Carefully remove other vapor/vacuum hoses

from LDP.

(4) Place a hydraulic jack under fuel tank.

(5) Loosen 2 fuel tank strap mounting bolts at

front of tank about 10 turns.

(6) Lower front of fuel tank about 1/2º.

(7) Remove 2 LDP mounting nuts (Fig. 3) and

lower LDP slightly to gain access to electrical connec-

tor (Fig. 4).

(8) Disconnect electrical connector at LDP. To dis-

connect: Slide red colored tab upward. Push on black

colored tab while removing connector.

(9) Remove LDP from vehicle.

INSTALLATION

The Leak Detection Pump (LDP) is attached (bolt-

ed) to the front of the fuel tank. The LDP filter is

located on the end of a hose. This hose is attached to

the fuel fill tube assembly below and near the fuel

fill opening. The LDP and LDP filter are replaced

(serviced) as one unit.

(1) Install electrical connector to LDP. Push red

colored tab downward to lock connector to LDP.

(2) Position LDP and LDP bracket to fuel tank

mounting studs and install 2 nuts. Tighten nuts to 1

N´m (11 in. lbs.) torque.

(3) Raise fuel tank to body and tighten 2 strap

bolts to 61 N´m (45 ft. lbs.) torque.

Fig. 3 LDP LOCATION / MOUNTING

1 - LDP

2 - FLOW MANAGEMENT VALVE

3 - MOUNTING NUTS

4 - FRONT OF FUEL TANK

25 - 28 EVAPORATIVE EMISSIONSKJ

LEAK DETECTION PUMP (Continued)

Page 1746 of 1803

COVER - REMOVAL, COWL TRIM.......23-157

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-152

COVER - REMOVAL, STRUCTURAL........9-55

COVER(S) - DESCRIPTION, CYLINDER

HEAD...............................9-25

COVER(S) - INSTALLATION, CYLINDER

HEAD...........................9-26,9-34

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN........................9-76

COVER(S) - REMOVAL, CYLINDER HEAD . . 9-25,

9-34

COVER(S) - REMOVAL, TIMING BELT /

CHAIN..............................9-74

COWL GRILLE - INSTALLATION........23-140

COWL GRILLE - REMOVAL............23-140

COWL TRIM COVER - INSTALLATION....23-157

COWL TRIM COVER - REMOVAL.......23-157

COWL WEATHERSTRIP - INSTALLATION . 23-185

COWL WEATHERSTRIP - REMOVAL.....23-185

COWL/PLENUM SEAL - INSTALLATION . . . 23-187

COWL/PLENUM SEAL - REMOVAL......23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

INSTALLATION......................23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

REMOVAL.........................23-187

CRADLE CROSSMEMBER -

INSTALLATION, ENGINE................13-6

CRADLE CROSSMEMBER - REMOVAL,

ENGINE.............................13-6

CRANKSHAFT - DESCRIPTION...........9-42

CRANKSHAFT - INSPECTION.............9-43

CRANKSHAFT - INSTALLATION...........9-43

CRANKSHAFT - REMOVAL..............9-43

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-47

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-46

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-48

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-48

CRANKSHAFT POSITION SENSOR -

DESCRIPTION.......................14-30

CRANKSHAFT POSITION SENSOR -

INSTALLATION.......................14-32

CRANKSHAFT POSITION SENSOR -

OPERATION.........................14-31

CRANKSHAFT POSITION SENSOR -

REMOVAL..........................14-31

CROSSMEMBER - INSTALLATION,

ENGINE CRADLE......................13-6

CROSSMEMBER - INSTALLATION,

RADIATOR.........................23-146

CROSSMEMBER - INSTALLATION, REAR . . . 13-7

CROSSMEMBER - REMOVAL, ENGINE

CRADLE.............................13-6

CROSSMEMBER - REMOVAL, RADIATOR . 23-146

CROSSMEMBER - REMOVAL, REAR.......13-7

CROSS-OVER PIPE - INSTALLATION.......11-3

CROSS-OVER PIPE - REMOVAL..........11-3

CRUISE INDICATOR - DESCRIPTION......8J-16

CRUISE INDICATOR - OPERATION.......8J-17

CURTAIN AIRBAG - DESCRIPTION, SIDE . . 8O-38

CURTAIN AIRBAG - INSTALLATION, SIDE . . 8O-41

CURTAIN AIRBAG - OPERATION, SIDE....8O-39

CURTAIN AIRBAG - REMOVAL, SIDE.....8O-40

CUSHION - FRONT - INSTALLATION,

SEAT .............................23-167

CUSHION - FRONT - INSTALLATION,

SEAT BACK........................23-167

CUSHION - FRONT - REMOVAL, SEAT . . . 23-167

CUSHION - FRONT - REMOVAL, SEAT

BACK.............................23-167

CUSHION - REAR - INSTALLATION, SEAT . 23-171

CUSHION - REAR - INSTALLATION, SEAT

BACK.............................23-170

CUSHION - REAR - REMOVAL, SEAT....23-171

CUSHION - REAR - REMOVAL, SEAT

BACK

.............................23-170

CUSHION COVER - FRONT -

INSTALLATION, SEAT

.................23-167

CUSHION COVER - FRONT - REMOVAL,

SEAT

.............................23-167

CUSHION SIDE SHIELDS -

INSTALLATION, SEAT

.................23-167

CUSHION SIDE SHIELDS - REMOVAL,

SEAT

.............................23-167CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-8

CV JOINT/BOOT-INNER - INSTALLATION . . . 3-17

CV JOINT/BOOT-INNER - REMOVAL.......3-15

CV JOINT/BOOT-OUTER - INSTALLATION . . . 3-13

CV JOINT/BOOT-OUTER - REMOVAL.......3-12

CYLINDER - DESCRIPTION, MASTER......5-24

CYLINDER - INSPECTION, MASTER........6-9

CYLINDER - INSTALLATION, FLIP-UP

GLASS SUPPORT...................23-139

CYLINDER - INSTALLATION, LOCK......23-125,

23-138

CYLINDER - INSTALLATION, LOCK.......19-11

CYLINDER - INSTALLATION, MASTER.....5-25

CYLINDER - INSTALLATION, SUPPORT . . . 23-120

CYLINDER - OPERATION, MASTER........5-24

CYLINDER - REMOVAL, FLIP-UP GLASS

SUPPORT.........................23-139

CYLINDER - REMOVAL, LOCK....23-125,23-137

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-25

CYLINDER - REMOVAL, SUPPORT......23-120

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-24

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-39

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING......9-8

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING...............9-8

CYLINDER FLUID LEVEL - STANDARD

PROCEDURES, MASTER................5-26

CYLINDER HEAD - DESCRIPTION.........9-30

CYLINDER HEAD COVER(S) -

DESCRIPTION........................9-25

CYLINDER HEAD COVER(S) -

INSTALLATION....................9-26,9-34

CYLINDER HEAD COVER(S) - REMOVAL . . . 9-25,

9-34

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING....................9-19,9-30

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8Q-9

CYLINDER LOCK SWITCH -

DESCRIPTION, TAILGATE...............8N-9

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR.................8Q-10

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, TAILGATE...............8N-9

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8Q-10

CYLINDER LOCK SWITCH -

INSTALLATION, TAILGATE..............8N-10

CYLINDER LOCK SWITCH - OPERATION,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - OPERATION,

TAILGATE...........................8N-9

CYLINDER LOCK SWITCH - REMOVAL,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - REMOVAL,

TAILGATE..........................8N-10

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER . . 5-21,5-24

CYLINDERS - ASSEMBLY, WHEEL.........5-29

CYLINDERS - CLEANING, WHEEL.........5-28

CYLINDERS - DISASSEMBLY, WHEEL......5-28

CYLINDERS - INSPECTION, WHEEL.......5-29

CYLINDERS - INSTALLATION, WHEEL

.....5-29

CYLINDERS - REMOVAL, WHEEL

.........5-28

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR

.........9-9

DAMPER - INSTALLATION, VIBRATION

.....9-55

DAMPER - REMOVAL, VIBRATION

........9-54

DATA LINK CONNECTOR - DESCRIPTION

. . 8E-10

DATA LINK CONNECTOR - OPERATION

....8E-10

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20

DAYTIME RUNNING LAMP RELAY -

REMOVAL

..........................8L-21

DECOUPLER - DIAGNOSIS AND

TESTING, GENERATOR

................8F-27

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR

........................8F-26DECOUPLER PULLEY - INSTALLATION,

GENERATOR........................8F-30

DECOUPLER PULLEY - OPERATION,

GENERATOR........................8F-27

DECOUPLER PULLEY - REMOVAL,

GENERATOR........................8F-27

DEFINITION - DESCRIPTION, TRIP.......25-19

DEFLECTOR - INSTALLATION, WIND.....23-180

DEFLECTOR - REMOVAL, WIND........23-180

DEFOGGER - DESCRIPTION, REAR

WINDOW............................8G-3

DEFOGGER - OPERATION, REAR

WINDOW............................8G-3

DEFOGGER FUNCTION - DIAGNOSIS AND

TESTING, REAR HVAC CONTROL

ASSEMBLY WINDOW..................8G-9

DEFOGGER GRID - DESCRIPTION, REAR

WINDOW............................8G-5

DEFOGGER GRID - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-5

DEFOGGER GRID - OPERATION, REAR

WINDOW............................8G-5

DEFOGGER RELAY - DESCRIPTION,

REAR WINDOW.......................8G-6

DEFOGGER RELAY - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-6

DEFOGGER RELAY - INSTALLATION,

REAR WINDOW.......................8G-7

DEFOGGER RELAY - OPERATION, REAR

WINDOW............................8G-6

DEFOGGER RELAY - REMOVAL, REAR

WINDOW............................8G-7

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-8

DEFOGGER SWITCH - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-8

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-8

DEFOGGER SYSTEM - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-4

DEFROST DOO - INSTALLATION, FLOOR . . 24-37

DEFROST DOOR - REMOVAL...........24-35

DEFROST DOOR - REMOVAL, FLOOR.....24-36

DEFROST DOOR ACTUATOR -

INSTALLATION, FLOOR................24-25

DEFROST DOOR ACTUATOR - REMOVAL,

FLOOR.............................24-24

DEFROST DUCT/DEMISTER ADAPTOR -

REMOVAL..........................24-32

DEFROST/DEMISTER DUCT -

INSTALLATION.......................24-32

DELIVERY - DESCRIPTION, FUEL.........14-2

DELIVERY - OPERATION, FUEL...........14-3

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-2

DEMISTER OUTLETS - DESCRIPTION.....24-29

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-6

DETECTION PUMP - DESCRIPTION, LEAK . 25-27

DETECTION PUMP - INSTALLATION,

LEAK..............................25-28

DETECTION PUMP - OPERATION, LEAK . . . 25-28

DETECTION PUMP - REMOVAL, LEAK....25-28

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-6

DIAGNOSIS, DIAGNOSIS AND TESTING -

WATER DRAINAGE AND WIND NOISE . . . 23-176

DIAGNOSTIC PROCEDURES, DIAGNOSIS

AND TESTING......................23-176

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-2

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-3

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21-100

DIESEL - TORQUE, EXCEPT.............8F-23

DIFFERENTIAL - ASSEMBLY

........3-105,3-41

DIFFERENTIAL - DISASSEMBLY

.....3-105,3-41

DIFFERENTIAL - INSTALLATION

. 3-105,3-42,3-73

DIFFERENTIAL - REMOVAL

.....3-104,3-40,3-71

DIFFERENTIAL - TRAC-LOK - ASSEMBLY

. . 3-109,

3-77

KJINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 1747 of 1803

DIFFERENTIAL - TRAC-LOK - CLEANING . . 3-109,

3-77

DIFFERENTIAL - TRAC-LOK -

DISASSEMBLY...................3-107,3-75

DIFFERENTIAL - TRAC-LOK -

INSPECTION....................3-109,3-77

DIFFERENTIAL CASE BEARINGS -

INSTALLATION...............3-110,3-44,3-79

DIFFERENTIAL CASE BEARINGS -

REMOVAL..................3-110,3-43,3-79

DIMENSIONS - SPECIFICATIONS, FRAME . . . 13-3

DIMENSIONS - SPECIFICATIONS,

OPENING..........................23-111

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DIODE REPLACEMENT - STANDARD

PROCEDURE.........................24-9

DISASSEMBLY - POWER DISTRIBUTION

CENTER DISASSEMBLY.............8W-97-7

DISASSEMBLY, 4C RETAINER/BULKHEAD . 21-122

DISASSEMBLY, DIAGNOSIS AND

TESTING...........................21-83

DISASSEMBLY, DIFFERENTIAL......3-105,3-41

DISASSEMBLY, DIFFERENTIAL -

TRAC-LOK......................3-107,3-75

DISASSEMBLY, DISASSEMBLY - POWER

DISTRIBUTION CENTER.............8W-97-7

DISASSEMBLY, DISC BRAKE CALIPERS....5-14

DISASSEMBLY, HVAC HOUSING.........24-34

DISASSEMBLY, INPUT CLUTCH

ASSEMBLY.........................21-135

DISASSEMBLY, INSTRUMENT CLUSTER....8J-9

DISASSEMBLY, LOW/REVERSE CLUTCH . . 21-145

DISASSEMBLY, MANUAL - NV1500........21-4

DISASSEMBLY, MANUAL - NV3550.......21-35

DISASSEMBLY, OIL PUMP...............9-65

DISASSEMBLY, OIL PUMP.............21-149

DISASSEMBLY, PLANETARY GEARTRAIN . 21-159

DISASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-8

DISASSEMBLY, TRANSFER CASE -

NV231............................21-182

DISASSEMBLY, TRANSFER CASE -

NV242............................21-218

DISASSEMBLY, VALVE BODY...........21-173

DISASSEMBLY, WHEEL CYLINDERS.......5-28

DISC - INSTALLATION, CLUTCH...........6-6

DISC - REMOVAL, CLUTCH...............6-6

DISC BRAKE CALIPER ADAPTER -

INSTALLATION........................5-18

DISC BRAKE CALIPER ADAPTER -

REMOVAL...........................5-18

DISC BRAKE CALIPERS - ASSEMBLY......5-16

DISC BRAKE CALIPERS - CLEANING......5-16

DISC BRAKE CALIPERS - DESCRIPTION....5-13

DISC BRAKE CALIPERS - DISASSEMBLY . . . 5-14

DISC BRAKE CALIPERS - INSPECTION.....5-16

DISC BRAKE CALIPERS - INSTALLATION . . . 5-17

DISC BRAKE CALIPERS - OPERATION.....5-14

DISC BRAKE CALIPERS - REMOVAL.......5-14

DISC BRAKE ROTOR - DIAGNOSIS AND

TESTING............................5-18

DISC BRAKE ROTOR - STANDARD

PROCEDURE.........................5-19

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - INSTALLATION, A/C . . . 24-47

DISCHARGE LINE - REMOVAL, A/C.......24-46

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-2

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION CENTER - DESCRIPTION,

POWER..........................8W-97-6

DISTRIBUTION CENTER - OPERATION,

POWER..........................8W-97-7

DISTRIBUTION CENTER - REMOVAL,

POWER..........................8W-97-7

DISTRIBUTION CENTER ASSEMBLY,

ASSEMBLY - POWER

..............8W-97-10

DISTRIBUTION CENTER DISASSEMBLY,

DISASSEMBLY - POWER

............8W-97-7

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER

...................8W-97-2

DOO - INSTALLATION, FLOOR -

DEFROST

...........................24-37

DOOR - INSTALLATION

.........23-122,23-129DOOR - INSTALLATION, BLEND.........24-35

DOOR - INSTALLATION, PANEL..........24-36

DOOR - INSTALLATION, PASSENGER

AIRBAG............................8O-30

DOOR - INSTALLATION, RECIRC.........24-37

DOOR - REMOVAL.............23-122,23-129

DOOR - REMOVAL, BLEND.............24-35

DOOR - REMOVAL, DEFROST...........24-35

DOOR - REMOVAL, FLOOR - DEFROST....24-36

DOOR - REMOVAL, PASSENGER AIRBAG . . 8O-29

DOOR - REMOVAL, RECIRC............24-37

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-20

DOOR ACTUATOR - INSTALLATION,

FLOOR - DEFROST...................24-25

DOOR ACTUATOR - INSTALLATION,

PANEL.............................24-25

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-26

DOOR ACTUATOR - REMOVAL, BLEND....24-20

DOOR ACTUATOR - REMOVAL, FLOOR -

DEFROST...........................24-24

DOOR ACTUATOR - REMOVAL, PANEL....24-24

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-26

DOOR AJAR INDICATOR - DESCRIPTION . . 8J-17

DOOR AJAR INDICATOR - OPERATION....8J-17

DOOR AJAR SWITCH - DESCRIPTION....8L-77

DOOR AJAR SWITCH - OPERATION........8L-77

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION........................8Q-9

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS AND TESTING.............8Q-10

DOOR CYLINDER LOCK SWITCH -

INSTALLATION......................8Q-10

DOOR CYLINDER LOCK SWITCH -

OPERATION.........................8Q-10

DOOR CYLINDER LOCK SWITCH -

REMOVAL..........................8Q-10

DOOR GLASS - INSTALLATION . . 23-122,23-129,

23-172

DOOR GLASS - REMOVAL......23-122,23-129,

23-172

DOOR LOCK / UNLOCK SWITCH -

INSTALLATION.......................8N-5

DOOR LOCK / UNLOCK SWITCH -

REMOVAL...........................8N-4

DOOR LOCK MOTOR - DESCRIPTION......8N-5

DOOR LOCK MOTOR - DIAGNOSIS AND

TESTING............................8N-5

DOOR LOCK MOTOR - OPERATION.......8N-5

DOOR LOCK RELAY - DESCRIPTION......8N-6

DOOR LOCK RELAY - DIAGNOSIS AND

TESTING............................8N-6

DOOR LOCK RELAY - INSTALLATION......8N-7

DOOR LOCK RELAY - OPERATION........8N-6

DOOR LOCK RELAY - REMOVAL.........8N-6

DOOR LOCK/UNLOCK SWITCH -

DIAGNOSIS AND TESTING..............8N-4

DOOR LOWER WEATHERSTRIP -

INSTALLATION......................23-186

DOOR LOWER WEATHERSTRIP -

REMOVAL.........................23-186

DOOR OUTER BELT MOLDING -

INSTALLATION, FRONT...............23-186

DOOR OUTER BELT MOLDING -

INSTALLATION, REAR................23-186

DOOR OUTER BELT MOLDING -

REMOVAL, FRONT...................23-186

DOOR OUTER BELT MOLDING -

REMOVAL, REAR....................23-186

DOOR PRIMARY WEATHERSTRIP -

INSTALLATION......................23-185

DOOR PRIMARY WEATHERSTRIP -

REMOVAL.........................23-185

DOOR SCUFF PLATE - INSTALLATION,

REAR.............................23-160

DOOR SCUFF PLATE - REMOVAL, REAR . . 23-160

DOOR SILL SCUFF PLATE -

INSTALLATION......................23-157

DOOR SILL SCUFF PLATE - REMOVAL

. . . 23-157

DOOR/HOUSING - INSTALLATION, FUEL

FILL

..............................23-141

DOOR/HOUSING - REMOVAL, FUEL FILL

. 23-141

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE

.................5-8

DRAIN AND FILL - STANDARD

PROCEDURE, FLUID

...........21-208,21-246DRAIN TUBE - INSTALLATION..........23-181

DRAIN TUBE - REMOVAL.............23-180

DRAINAGE AND WIND NOISE

DIAGNOSIS, DIAGNOSIS AND TESTING

- WATER ..........................23-176

DRAINING COOLING SYSTEM 3.7L

ENGINE - STANDARD PROCEDURE........7-12

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-14

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN........................7-28

DRIVE BELT - DIAGNOSIS AND TESTING,

SERPENTINE.........................7-15

DRIVE MOTOR - INSTALLATION........23-182

DRIVE MOTOR - REMOVAL............23-182

DRIVER AIRBAG - DESCRIPTION........8O-17

DRIVER AIRBAG - INSTALLATION.......8O-20

DRIVER AIRBAG - OPERATION..........8O-18

DRIVER AIRBAG - REMOVAL...........8O-19

DRIVER SEAT HEATER SWITCH -

DESCRIPTION.......................8G-11

DRIVER SEAT HEATER SWITCH -

INSTALLATION......................8G-13

DRIVER SEAT HEATER SWITCH -

OPERATION.........................8G-12

DRIVER SEAT HEATER SWITCH -

REMOVAL..........................8G-13

DRIVER SIDE BEZELS - INSTALLATION,

INSTRUMENT PANEL.................23-154

DRIVER SIDE BEZELS - REMOVAL,

INSTRUMENT PANEL.................23-153

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE...........8W-01-10

DRUM - DIAGNOSIS AND TESTING,

BRAKE..............................5-27

DRUM BRAKE - ADJUSTMENT, REAR......5-12

DRUM BRAKE - DESCRIPTION, REAR.....5-10

DRUM BRAKE - OPERATION, REAR.......5-11

DRUM BRAKE SHOES - INSTALLATION....5-11

DRUM BRAKE SHOES - REMOVAL........5-11

DRUM MACHINING - STANDARD

PROCEDURES, BRAKE.................5-27

DUCT - INSTALLATION, DEFROST/

DEMISTER..........................24-32

DUCT - INSTALLATION, FLOOR..........24-32

DUCT - INSTALLATION, FLOOR CONSOLE . 24-31

DUCT - REMOVAL, FLOOR.............24-32

DUCT - REMOVAL, FLOOR CONSOLE.....24-31

DUCT/DEMISTER ADAPTOR - REMOVAL,

DEFROST...........................24-32

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING............21-125

ELECTRIC - DESCRIPTION, RADIATOR

FAN ................................7-26

ELECTRIC - INSTALLATION, RADIATOR

FAN ................................7-27

ELECTRIC - INSTALLATION, WINDOW

REGULATOR.................23-126,23-134

ELECTRIC - OPERATION, RADIATOR FAN . . . 7-26

ELECTRIC - REMOVAL, RADIATOR FAN....7-26

ELECTRIC - REMOVAL, WINDOW

REGULATOR.................23-126,23-134

ELECTRICAL - DESCRIPTION............5-34

ELECTRICAL - OPERATION..............5-34

ELECTRICAL TESTER - STANDARD

PROCEDURE, USING MIDTRONICS.......8F-15

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT . 8G-13

ELEMENT - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-13

ELEMENT - OPERATION, HEATED SEAT . . . 8G-13

EMISSION CONTROL INFORMATION

(VECI) LABEL - DESCRIPTION,

VEHICLE..........................Intro.-8

EMISSION CONTROL SYSTEM -

DESCRIPTION........................25-1

END - INSTALLATION, TIE ROD.........19-16

END - REMOVAL, TIE ROD.............19-16

END CAP - INSTALLATION, INSTRUMENT

PANEL

............................23-153

END CAP - REMOVAL, INSTRUMENT

PANEL

............................23-153

END REMOVAL TOOL, SPECIAL TOOLS -

OUTER TIE ROD

.....................19-15

ENGINE - 3.7L - DESCRIPTION

............9-3

ENGINE - DESCRIPTION, 3.7L

............7-21

8 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1752 of 1803

HVAC CONTROL ASSEMBLY WINDOW

DEFOGGER FUNCTION - DIAGNOSIS

AND TESTING, REAR..................8G-9

HVAC HOUSING - ASSEMBLY...........24-34

HVAC HOUSING - DISASSEMBLY........24-34

HVAC HOUSING - INSTALLATION........24-34

HVAC HOUSING - REMOVAL............24-33

HYDRAULIC LASH ADJUSTER -

DIAGNOSIS AND TESTING..........9-19,9-30

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING.............21-79

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS....................21-100

HYDROMETER TEST - STANDARD

PROCEDURE........................8F-11

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-1

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-8

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-35

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-36

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-35

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-36

IDLER SHAFT - INSTALLATION...........9-77

IDLER SHAFT - REMOVAL...............9-77

IGNITION CIRCUIT SENSE -

DESCRIPTION.........................8E-13

IGNITION CIRCUIT SENSE - OPERATION . . 8E-15

IGNITION COIL - DESCRIPTION...........8I-9

IGNITION COIL - INSTALLATION.........8I-10

IGNITION COIL - OPERATION.............8I-9

IGNITION COIL - REMOVAL.............8I-10

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-16

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-16

IGNITION COIL CAPACITOR - OPERATION . . 8I-16

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-16

IGNITION COIL RESISTANCE, 2.4L.........8I-2

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-3

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION CONTROL - OPERATION.........8I-1

IGNITION SWITCH - DESCRIPTION........19-8

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-10

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-8

IGNITION SWITCH - DIAGNOSIS AND

TESTING, KEY-IN.....................19-10

IGNITION SWITCH INSTALLATION,

INSTALLATION........................19-9

IGNITION SWITCH REMOVAL, REMOVAL . . . 19-9

IGNITION SYSTEM - TORQUE............8I-3

IGNITION TIMING - SPECIFICATIONS......8I-2

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-14

ILLUMINATION BULB - INSTALLATION,

COMPASS MINI-TRIP

.................8L-75

ILLUMINATION BULB - INSTALLATION,

HEATER-A/C CONTROL

................8L-78

ILLUMINATION BULB - INSTALLATION,

TRANSMISSION RANGE INDICATOR

......8L-83

ILLUMINATION BULB - REMOVAL,

COMPASS MINI-TRIP

.................8L-74

ILLUMINATION BULB - REMOVAL,

HEATER-A/C CONTROL

................8L-78

ILLUMINATION BULB - REMOVAL,

TRANSMISSION RANGE INDICATOR

......8L-82

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY

........................8E-15

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY

........................8E-18

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY

........................8E-16

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY

........................8E-17

IMPACT AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE

..................8O-43

IMPACT AIRBAG CONTROL MODULE -

INSTALLATION, SIDE

.................8O-45

IMPACT AIRBAG CONTROL MODULE -

OPERATION, SIDE

....................8O-43IMPACT AIRBAG CONTROL MODULE -

REMOVAL, SIDE.....................8O-44

IMPACT SENSOR - DESCRIPTION,

FRONT.............................8O-21

IMPACT SENSOR - INSTALLATION,

FRONT.............................8O-22

IMPACT SENSOR - OPERATION, FRONT . . . 8O-21

IMPACT SENSOR - REMOVAL, FRONT....8O-22

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF............21-125

INDICATOR - DESCRIPTION, ABS........8J-11

INDICATOR - DESCRIPTION, AIRBAG.....8J-12

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-13

INDICATOR - DESCRIPTION, CHARGING . . . 8J-15

INDICATOR - DESCRIPTION, COOLANT

LOW...............................8J-15

INDICATOR - DESCRIPTION, CRUISE.....8J-16

INDICATOR - DESCRIPTION, DOOR AJAR . . 8J-17

INDICATOR - DESCRIPTION, FOUR LOW

MODE.............................8J-29

INDICATOR - DESCRIPTION, FRONT FOG

LAMP..............................8J-19

INDICATOR - DESCRIPTION, FULL TIME . . . 8J-29

INDICATOR - DESCRIPTION, GATE AJAR . . 8J-20

INDICATOR - DESCRIPTION, GLASS

AJAR..............................8J-21

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-22

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-22

INDICATOR - DESCRIPTION, LOW OIL

PRESSURE..........................8J-23

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-26

INDICATOR - DESCRIPTION, PART TIME . . 8J-29

INDICATOR - DESCRIPTION, REAR FOG

LAMP..............................8J-27

INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SECURITY . . . 8J-28

INDICATOR - DESCRIPTION, SKIS........8J-31

INDICATOR - DESCRIPTION, TRANS

TEMP..............................8J-33

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-34

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-35

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-37

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-14

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID......................8J-36

INDICATOR - OPERATION, ABS..........8J-11

INDICATOR - OPERATION, AIRBAG.......8J-12

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-13

INDICATOR - OPERATION, CHARGING....8J-15

INDICATOR - OPERATION, COOLANT

LOW...............................8J-16

INDICATOR - OPERATION, CRUISE.......8J-17

INDICATOR - OPERATION, DOOR AJAR . . . 8J-17

INDICATOR - OPERATION, FOUR LOW

MODE.............................8J-30

INDICATOR - OPERATION, FRONT FOG

LAMP..............................8J-19

INDICATOR - OPERATION, FULL TIME....8J-30

INDICATOR - OPERATION, GATE AJAR....8J-20

INDICATOR - OPERATION, GLASS AJAR . . . 8J-21

INDICATOR - OPERATION, HIGH BEAM

....8J-22

INDICATOR - OPERATION, LOW FUEL

.....8J-22

INDICATOR - OPERATION, LOW OIL

PRESSURE

..........................8J-23

INDICATOR - OPERATION, OVERDRIVE

OFF

...............................8J-26

INDICATOR - OPERATION, PART TIME

....8J-29

INDICATOR - OPERATION, REAR FOG

LAMP

..............................8J-27

INDICATOR - OPERATION, SEATBELT

.....8J-28

INDICATOR - OPERATION, SECURITY

.....8J-28

INDICATOR - OPERATION, SKIS

.........8J-31

INDICATOR - OPERATION, TRANS TEMP

. . 8J-34

INDICATOR - OPERATION, TURN SIGNAL

. . 8J-34

INDICATOR - OPERATION, WAIT-TO-

START

.............................8J-35

INDICATOR - OPERATION, WASHER

FLUID

..............................8J-36INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-37

INDICATOR ILLUMINATION BULB -

INSTALLATION, TRANSMISSION

RANGE.............................8L-83

INDICATOR ILLUMINATION BULB -

REMOVAL, TRANSMISSION RANGE......8L-82

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-24

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-24

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-10

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-8

INFLATION - DIAGNOSIS AND TESTING,

TIRE................................22-7

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-18

INITIALIZATION - STANDARD

PROCEDURE, SKIS....................8Q-8

INJECTION - DESCRIPTION, FUEL........14-29

INJECTOR - DESCRIPTION, FUEL........14-33

INJECTOR - DIAGNOSIS AND TESTING,

FUEL..............................14-33

INJECTOR - OPERATION, FUEL..........14-33

INLET FILTER - INSTALLATION..........14-28

INLET FILTER - REMOVAL..............14-28

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-4

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-138

INPUT CLUTCH ASSEMBLY -

DESCRIPTION......................21-133

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY......................21-135

INPUT CLUTCH ASSEMBLY - OPERATION . 21-135

INPUT SPEED SENSOR - DESCRIPTION . . 21-143

INPUT SPEED SENSOR - INSTALLATION . 21-143

INPUT SPEED SENSOR - OPERATION....21-143

INPUT SPEED SENSOR - REMOVAL.....21-143

INSTRUMENT CLUSTER - ASSEMBLY.....8J-10

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING........................8J-7

INSTRUMENT CLUSTER - DISASSEMBLY . . . 8J-9

INSTRUMENT CLUSTER - INSTALLATION . . 8J-11

INSTRUMENT CLUSTER - OPERATION.....8J-4

INSTRUMENT CLUSTER - REMOVAL......8J-9

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-8

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-7

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION......................23-151

INSTRUMENT PANEL ASSEMBLY -

REMOVAL.........................23-149

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION......................23-154

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL.........................23-154

INSTRUMENT PANEL DRIVER SIDE

BEZELS - INSTALLATION..............23-154

INSTRUMENT PANEL DRIVER SIDE

BEZELS - REMOVAL.................23-153

INSTRUMENT PANEL END CAP -

INSTALLATION

......................23-153

INSTRUMENT PANEL END CAP -

REMOVAL

.........................23-153

INSTRUMENT PANEL PASSENGER SIDE

BEZEL - INSTALLATION

...............23-154

INSTRUMENT PANEL PASSENGER SIDE

BEZEL - REMOVAL

..................23-154

INSTRUMENT PANEL TOP COVER -

INSTALLATION

......................23-153

INSTRUMENT PANEL TOP COVER -

REMOVAL

.........................23-152

INTAKE AIR TEMPERATURE SENSOR -

DESCRIPTION

.......................14-36

INTAKE AIR TEMPERATURE SENSOR -

INSTALLATION

.......................14-38

INTAKE AIR TEMPERATURE SENSOR -

OPERATION

.........................14-36

INTAKE AIR TEMPERATURE SENSOR -

REMOVAL

..........................14-37

INTAKE MANIFOLD - DESCRIPTION

.......9-68

INTAKE MANIFOLD - INSTALLATION

.......9-69

INTAKE MANIFOLD - REMOVAL

..........9-68

KJINDEX 13

Description Group-Page Description Group-Page Description Group-Page

Page 1754 of 1803

LATCH - ACCESS PANEL - REMOVAL....23-139

LATCH - INSTALLATION . . 23-120,23-124,23-131,

23-137

LATCH - INSTALLATION, FLIP-UP GLASS . 23-136

LATCH - INSTALLATION, FLOOR

CONSOLE LID......................23-158

LATCH - INSTALLATION, GLOVE BOX....23-148

LATCH / LOCK - INSTALLATION,

FOLDING REAR SEAT BACK...........23-170

LATCH / LOCK - REMOVAL, FOLDING

REAR SEAT BACK...................23-170

LATCH - REMOVAL......23-120,23-124,23-131,

23-137

LATCH - REMOVAL, FLIP-UP GLASS.....23-136

LATCH - REMOVAL, FLOOR CONSOLE

LID...............................23-158

LATCH - REMOVAL, GLOVE BOX........23-148

LATCH RELEASE CABLE - INSTALLATION . 23-120

LATCH RELEASE CABLE - REMOVAL....23-120

LATCH RELEASE HANDLE -

INSTALLATION......................23-120

LATCH RELEASE HANDLE - REMOVAL . . . 23-120

LATCH STRIKER - INSTALLATION......23-124,

23-132,23-137

LATCH STRIKER - INSTALLATION, GLOVE

BOX ..............................23-149

LATCH STRIKER - INSTALLATION, REAR

SEAT BACK........................23-171

LATCH STRIKER - REMOVAL....23-124,23-132,

23-137

LATCH STRIKER - REMOVAL, GLOVE

BOX ..............................23-148

LATCH STRIKER - REMOVAL, REAR

SEAT BACK........................23-170

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID...........21-80

LEAK - DIAGNOSIS AND TESTING,

ENGINE OIL..........................9-60

LEAK DETECTION PUMP - DESCRIPTION . . 25-27

LEAK DETECTION PUMP - INSTALLATION . 25-28

LEAK DETECTION PUMP - OPERATION....25-28

LEAK DETECTION PUMP - REMOVAL.....25-28

LEAK DOWN TEST - DIAGNOSIS AND

TESTING, FUEL PRESSURE..............14-3

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE.......9-8

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-4

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-68

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA.....................9-61

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-2

LEAKS - STANDARD PROCEDURE,

REPAIRING..........................22-8

LEARN - STANDARD PROCEDURE, TCM

QUICK.............................8E-21

LEFT POWER SEAT SWITCH -

DESCRIPTION.......................8N-16

LEFT POWER SEAT SWITCH -

DIAGNOSIS AND TESTING.............8N-17

LEFT POWER SEAT SWITCH -

INSTALLATION......................8N-18

LEFT POWER SEAT SWITCH -

OPERATION

.........................8N-17

LEFT POWER SEAT SWITCH - REMOVAL

. . 8N-18

LEFT SIDE - INSTALLATION

.........2-12,2-15

LEFT SIDE - REMOVAL

.............2-11,2-15

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID

........21-125

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL

...................24-54

LEVEL - STANDARD PROCEDURES,

MASTER CYLINDER FLUID

..............5-26

LEVEL CHECK - STANDARD

PROCEDURE, FLUID

.................21-126

LEVEL SENDING UNIT - DIAGNOSIS AND

TESTING, FUEL

.......................14-9

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL

...................14-9

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL

.................14-10

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL

.....................14-9

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL

......................14-9LEVEL SWITCH - DESCRIPTION,

WASHER FLUID.....................8R-17

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-18

LEVEL SWITCH - OPERATION, WASHER

FLUID.............................8R-17

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-17

LEVELING MOTOR - DESCRIPTION,

HEADLAMP.........................8L-35

LEVELING MOTOR - INSTALLATION,

HEADLAMP.........................8L-36

LEVELING MOTOR - OPERATION,

HEADLAMP.........................8L-36

LEVELING MOTOR - REMOVAL,

HEADLAMP.........................8L-36

LEVELING SWITCH - DESCRIPTION,

HEADLAMP.........................8L-37

LEVELING SWITCH - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-37

LEVELING SWITCH - INSTALLATION,

HEADLAMP.........................8L-38

LEVELING SWITCH - OPERATION,

HEADLAMP.........................8L-37

LEVELING SWITCH - REMOVAL,

HEADLAMP.........................8L-38

LEVER - INSTALLATION................5-31

LEVER - INSTALLATION, SHIFT . . . 21-214,21-249

LEVER - REMOVAL....................5-31

LEVER - REMOVAL, SHIFT......21-213,21-248

LHD - INSTALLATION...............8W-97-6

LHD - REMOVAL....................8W-97-5

LICENSE PLATE LAMP BULB -

INSTALLATION.......................8L-45

LICENSE PLATE LAMP BULB - REMOVAL . . 8L-44

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-46

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-45

LID LATCH - INSTALLATION, FLOOR

CONSOLE..........................23-158

LID LATCH - REMOVAL, FLOOR

CONSOLE..........................23-158

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIMITS - DESCRIPTION, HIGH AND LOW . . 25-20

LINE - DESCRIPTION, REFRIGERANT.....24-38

LINE - INSTALLATION, A/C DISCHARGE . . . 24-47

LINE - INSTALLATION, A/C LIQUID.......24-47

LINE - INSTALLATION, A/C SUCTION.....24-49

LINE - REMOVAL, A/C DISCHARGE.......24-46

LINE - REMOVAL, A/C LIQUID...........24-47

LINE - REMOVAL, A/C SUCTION.........24-48

LINE AND HOSES - DIAGNOSIS AND

TESTING, BRAKE.......................5-8

LINE PRESSURE (LP) SENSOR -

DESCRIPTION......................21-144

LINE PRESSURE (LP) SENSOR -

INSTALLATION......................21-144

LINE PRESSURE (LP) SENSOR -

OPERATION........................21-144

LINE PRESSURE (LP) SENSOR -

REMOVAL.........................21-144

LINES - DESCRIPTION, BRAKE............5-8

LINES - DESCRIPTION, FUEL...........14-10

LINES - DESCRIPTION, VACUUM........25-33

LINK - INSTALLATION, STABILIZER.......2-14

LINK - REMOVAL, STABILIZER...........2-14

LINK CONNECTOR - DESCRIPTION, DATA . 8E-10

LINK CONNECTOR - OPERATION, DATA . . . 8E-10

LINKAGE - INSTALLATION................6-9

LINKAGE - REMOVAL...................6-8

LINKAGE - STANDARD PROCEDURE,

STEERING..........................19-16

LIQUID LINE - INSTALLATION, A/C.......24-47

LIQUID LINE - REMOVAL, A/C...........24-47

LOAD TEST - STANDARD PROCEDURE....8F-12

LOAD VALUE - DESCRIPTION

...........25-20

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL

......8W-01-9

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE

...................8W-91-1

LOCATIONS - DESCRIPTION, FLUID

FILL/CHECK

...........................0-4

LOCATIONS - SPECIFICATIONS, SEALER

. . 23-87LOCATIONS - SPECIFICATIONS, WELD

AND STRUCTURAL ADHESIVE...........23-9

LOCK - INSTALLATION, FOLDING REAR

SEAT BACK LATCH..................23-170

LOCK - REMOVAL, FOLDING REAR SEAT

BACK LATCH.......................23-170

LOCK / UNLOCK SWITCH -

INSTALLATION, DOOR.................8N-5

LOCK / UNLOCK SWITCH - REMOVAL,

DOOR..............................8N-4

LOCK CYLINDER - INSTALLATION......23-125,

23-138

LOCK CYLINDER - INSTALLATION.......19-11

LOCK CYLINDER - REMOVAL....23-125,23-137

LOCK CYLINDER - REMOVAL...........19-10

LOCK MOTOR - DESCRIPTION, DOOR.....8N-5

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR......................8N-5

LOCK MOTOR - OPERATION, DOOR.......8N-5

LOCK OUT - ADJUSTMENT..............5-30

LOCK RELAY - DESCRIPTION, DOOR......8N-6

LOCK RELAY - DIAGNOSIS AND

TESTING, DOOR......................8N-6

LOCK RELAY - INSTALLATION, DOOR.....8N-7

LOCK RELAY - OPERATION, DOOR........8N-6

LOCK RELAY - REMOVAL, DOOR.........8N-6

LOCK SWITCH - DESCRIPTION, DOOR

CYLINDER...........................8Q-9

LOCK SWITCH - DESCRIPTION,

TAILGATE CYLINDER...................8N-9

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR CYLINDER............8Q-10

LOCK SWITCH - DIAGNOSIS AND

TESTING, TAILGATE CYLINDER..........8N-9

LOCK SWITCH - INSTALLATION, DOOR

CYLINDER..........................8Q-10

LOCK SWITCH - INSTALLATION,

TAILGATE CYLINDER..................8N-10

LOCK SWITCH - OPERATION, DOOR

CYLINDER..........................8Q-10

LOCK SWITCH - OPERATION, TAILGATE

CYLINDER...........................8N-9

LOCK SWITCH - REMOVAL, DOOR

CYLINDER..........................8Q-10

LOCK SWITCH - REMOVAL, TAILGATE

CYLINDER..........................8N-10

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-3

LOCKS - OPERATION, POWER...........8N-3

LOCK/UNLOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR..................8N-4

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-38

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-37

LOW BEAM RELAY - DESCRIPTION,

HEADLAMP.........................8L-39

LOW BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP.................8L-40

LOW BEAM RELAY - INSTALLATION,

HEADLAMP.........................8L-41

LOW BEAM RELAY - OPERATION,

HEADLAMP.........................8L-39

LOW BEAM RELAY - REMOVAL,

HEADLAMP

.........................8L-40

LOW FUEL INDICATOR - DESCRIPTION

. . . 8J-22

LOW FUEL INDICATOR - OPERATION

.....8J-22

LOW INDICATOR - DESCRIPTION,

COOLANT

...........................8J-15

LOW INDICATOR - OPERATION,

COOLANT

...........................8J-16

LOW LIMITS - DESCRIPTION, HIGH

......25-20

LOW MODE INDICATOR - DESCRIPTION,

FOUR

..............................8J-29

LOW MODE INDICATOR - OPERATION,

FOUR

..............................8J-30

LOW OIL PRESSURE INDICATOR -

DESCRIPTION

.......................8J-23

LOW OIL PRESSURE INDICATOR -

OPERATION

.........................8J-23

LOW PRESSURE SWITCH -

DESCRIPTION, A/C

...................24-18

LOW PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C

...................24-19

LOW PRESSURE SWITCH -

INSTALLATION, A/C

...................24-19

KJINDEX 15

Description Group-Page Description Group-Page Description Group-Page

Page 1756 of 1803

MOTOR - OPERATION, IDLE AIR

CONTROL..........................14-35

MOTOR - OPERATION, REAR WIPER.....8R-41

MOTOR - REMOVAL, BLOWER..........24-30

MOTOR - REMOVAL, DRIVE...........23-182

MOTOR - REMOVAL, HEADLAMP

LEVELING..........................8L-36

MOTOR - REMOVAL, IDLE AIR CONTROL . . 14-36

MOTOR - REMOVAL, REAR WIPER......8R-42

MOTOR - REMOVAL, STARTER..........8F-39

MOTOR - REMOVAL, WINDOW..........8N-22

MOTOR, GAS POWERED - STARTER......8F-39

MOTOR RELAY - DESCRIPTION,

BLOWER...........................24-20

MOTOR RELAY - DESCRIPTION,

STARTER ...........................8F-41

MOTOR RELAY - DIAGNOSIS AND

TESTING, BLOWER...................24-21

MOTOR RELAY - INSTALLATION,

BLOWER...........................24-22

MOTOR RELAY - INSTALLATION,

STARTER ...........................8F-43

MOTOR RELAY - OPERATION, BLOWER . . . 24-20

MOTOR RELAY - OPERATION, STARTER . . . 8F-42

MOTOR RELAY - REMOVAL, BLOWER....24-21

MOTOR RELAY - REMOVAL, STARTER....8F-43

MOTOR RESISTOR - DESCRIPTION,

BLOWER...........................24-22

MOTOR RESISTOR - DIAGNOSIS AND

TESTING, BLOWER.....................24-22

MOTOR RESISTOR - INSTALLATION,

BLOWER...........................24-22

MOTOR RESISTOR - OPERATION,

BLOWER...........................24-22

MOTOR RESISTOR - REMOVAL,

BLOWER...........................24-22

MOTOR SWITCH - DESCRIPTION,

BLOWER...........................24-23

MOTOR SWITCH - DIAGNOSIS AND

TESTING, BLOWER...................24-23

MOTOR SWITCH - INSTALLATION,

BLOWER...........................24-23

MOTOR SWITCH - OPERATION, BLOWER . . 24-23

MOTOR SWITCH - REMOVAL, BLOWER . . . 24-23

MOUNT - INSTALLATION, FRONT.........9-57

MOUNT - INSTALLATION, REAR..........9-57

MOUNT - REMOVAL, FRONT.............9-56

MOUNT - REMOVAL, REAR..............9-57

MOUNTED STOP LAMP BULB -

INSTALLATION, CENTER HIGH..........8L-19

MOUNTED STOP LAMP BULB -

REMOVAL, CENTER HIGH..............8L-18

MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER HIGH..........8L-19

MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER HIGH..............8L-19

MOUNTING - STANDARD PROCEDURE,

MATCH .............................22-3

MOUNTING - STANDARD PROCEDURE,

WHEEL............................22-10

MOUNTING BRACKET - INSTALLATION,

PASSENGER AIRBAG.................8O-31

MOUNTING BRACKET - REMOVAL,

PASSENGER AIRBAG.................8O-31

MUFFLER - DESCRIPTION...............11-4

MUFFLER - INSTALLATION

..............11-5

MUFFLER - REMOVAL

..................11-5

MULTI-FUNCTION SWITCH -

DESCRIPTION

.......................8L-46

MULTI-FUNCTION SWITCH - DIAGNOSIS

AND TESTING

.......................8L-50

MULTI-FUNCTION SWITCH -

INSTALLATION

.......................8L-53

MULTI-FUNCTION SWITCH - OPERATION

. . 8L-48

MULTI-FUNCTION SWITCH - REMOVAL

. . . 8L-53

NAME PLATES - INSTALLATION,

EXTERIOR

.........................23-141

NAME PLATES - REMOVAL, EXTERIOR

. . . 23-140

NOISE - DIAGNOSIS AND TESTING, A/C

COMPRESSOR

.......................24-42

NOISE - DIAGNOSIS AND TESTING,

WIND

...............................23-3

NOISE DIAGNOSIS, DIAGNOSIS AND

TESTING - WATER DRAINAGE AND

WIND

.............................23-176

NOISE OR VIBRATION - DIAGNOSIS AND

TESTING, TIRE

.......................22-8NOISE SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO..................8A-9

NOISE SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO................8A-11

NOISE SUPPRESSION GROUND STRAP -

OPERATION, RADIO..................8A-10

NOISE SUPPRESSION GROUND STRAP -

REMOVAL, RADIO....................8A-10

NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS - STANDARD

PROCEDURE, HANDLING...............8O-6

NON-MONITORED CIRCUITS -

DESCRIPTION.......................25-20

NOZZLE - DESCRIPTION, FRONT

WASHER...........................8R-11

NOZZLE - DESCRIPTION, REAR WASHER . 8R-36

NOZZLE - INSTALLATION, FRONT

WASHER...........................8R-11

NOZZLE - INSTALLATION, REAR

WASHER...........................8R-37

NOZZLE - OPERATION, FRONT WASHER . . 8R-11

NOZZLE - OPERATION, REAR WASHER . . . 8R-36

NOZZLE - REMOVAL, FRONT WASHER....8R-11

NOZZLE - REMOVAL, REAR WASHER....8R-36

NUMBER - DESCRIPTION, VEHICLE

IDENTIFICATION....................Intro.-8

NV1500 - ASSEMBLY, MANUAL.........21-13

NV1500 - CLEANING, MANUAL..........21-10

NV1500 - DESCRIPTION, MANUAL........21-1

NV1500 - DISASSEMBLY, MANUAL........21-4

NV1500 - INSPECTION, MANUAL..........21-11

NV1500 - INSTALLATION, EXTENSION

HOUSING SEAL......................21-32

NV1500 - INSTALLATION, MANUAL......21-29

NV1500 - MANUAL...................21-30

NV1500 - OPERATION, MANUAL..........21-1

NV1500 - REMOVAL, EXTENSION

HOUSING SEAL......................21-32

NV1500 - REMOVAL, MANUAL...........21-3

NV1500 - SPECIFICATIONS.............21-30

NV231 - ASSEMBLY, TRANSFER CASE . . . 21-194

NV231 - CLEANING, TRANSFER CASE . . . 21-190

NV231 - DESCRIPTION, TRANSFER CASE . . . 0-3

NV231 - DESCRIPTION, TRANSFER CASE . 21-178

NV231 - DIAGNOSIS AND TESTING,

TRANSFER CASE....................21-180

NV231 - DISASSEMBLY, TRANSFER

CASE.............................21-182

NV231 - INSPECTION, TRANSFER CASE . . 21-190

NV231 - INSTALLATION, TRANSFER

CASE.............................21-205

NV231 - OPERATION, TRANSFER CASE . . 21-179

NV231 - REMOVAL, TRANSFER CASE....21-181

NV231 - TRANSFER CASE.............21-206

NV242 - ASSEMBLY, TRANSFER CASE . . . 21-230

NV242 - CLEANING, TRANSFER CASE . . . 21-227

NV242 - DESCRIPTION, TRANSFER CASE . . . 0-3

NV242 - DESCRIPTION, TRANSFER CASE . 21-215

NV242 - DIAGNOSIS AND TESTING,

TRANSFER CASE....................21-216

NV242 - DISASSEMBLY, TRANSFER

CASE.............................21-218

NV242 - INSPECTION, TRANSFER CASE . . 21-228

NV242 - INSTALLATION, TRANSFER

CASE.............................21-243

NV242 - OPERATION, TRANSFER CASE . . 21-215

NV242 - REMOVAL, TRANSFER CASE....21-217

NV242 - TRANSFER CASE.............21-244

NV242 TRANSFER CASE,

SPECIFICATIONS....................21-244

NV3550 - ASSEMBLY, MANUAL.........21-48

NV3550 - CLEANING, MANUAL..........21-46

NV3550 - DESCRIPTION, MANUAL.......21-33

NV3550 - DISASSEMBLY, MANUAL.......21-35

NV3550 - INSPECTION, MANUAL........21-46

NV3550 - INSTALLATION, EXTENSION

HOUSING BUSHING...................21-74

NV3550 - INSTALLATION, EXTENSION

HOUSING SEAL......................21-74

NV3550 - INSTALLATION, MANUAL......21-70

NV3550 - MANUAL...................21-71

NV3550 - OPERATION, MANUAL

.........21-33

NV3550 - REMOVAL, EXTENSION

HOUSING BUSHING

...................21-73

NV3550 - REMOVAL, EXTENSION

HOUSING SEAL

......................21-74

NV3550 - REMOVAL, MANUAL

..........21-34

ODOMETER - DESCRIPTION

............8J-25ODOMETER - OPERATION..............8J-25

OFF INDICATOR - DESCRIPTION,

OVERDRIVE.........................8J-26

OFF INDICATOR - OPERATION,

OVERDRIVE.........................8J-26

OIL - DESCRIPTION, REFRIGERANT......24-53

OIL - OPERATION, REFRIGERANT........24-54

OIL - STANDARD PROCEDURE, ENGINE....9-61

OIL FILTER - INSTALLATION.............9-63

OIL FILTER - REMOVAL.................9-63

OIL GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE.............9-10

OIL LEAK - DIAGNOSIS AND TESTING,

ENGINE.............................9-60

OIL LEVEL - STANDARD PROCEDURE,

REFRIGERANT.......................24-54

OIL PAN - CLEANING..................9-63

OIL PAN - DESCRIPTION................9-63

OIL PAN - INSPECTION.................9-63

OIL PAN - INSTALLATION...............9-64

OIL PAN - REMOVAL...................9-63

OIL PRESSURE - DIAGNOSIS AND

TESTING, ENGINE.....................9-60

OIL PRESSURE INDICATOR -

DESCRIPTION, LOW..................8J-23

OIL PRESSURE INDICATOR -

OPERATION, LOW....................8J-23

OIL PRESSURE SENSOR/SWITCH -

DESCRIPTION........................9-65

OIL PRESSURE SENSOR/SWITCH -

INSTALLATION........................9-65

OIL PRESSURE SENSOR/SWITCH -

OPERATION..........................9-65

OIL PRESSURE SENSOR/SWITCH -

REMOVAL...........................9-65

OIL PUMP - ASSEMBLY................9-67

OIL PUMP - ASSEMBLY..............21-151

OIL PUMP - CLEANING...............21-150

OIL PUMP - DESCRIPTION............21-147

OIL PUMP - DISASSEMBLY.............9-65

OIL PUMP - DISASSEMBLY............21-149

OIL PUMP - INSPECTION...............9-66

OIL PUMP - INSPECTION.............21-150

OIL PUMP - INSTALLATION.............9-67

OIL PUMP - OPERATION..............21-147

OIL PUMP - REMOVAL.................9-65

OIL PUMP FRONT SEAL - INSTALLATION . 21-152

OIL PUMP FRONT SEAL - REMOVAL....21-152

OIL PUMP VOLUME CHECK - STANDARD

PROCEDURE.......................21-148

OIL SEAL - FRONT - INSTALLATION,

CRANKSHAFT........................9-47

OIL SEAL - FRONT - REMOVAL,

CRANKSHAFT........................9-46

OIL SEAL - REAR - INSTALLATION,

CRANKSHAFT........................9-48

OIL SEAL - REAR - REMOVAL,

CRANKSHAFT........................9-48

ON-BOARD DIAGNOSTICS (OBD) -

DIAGNOSIS AND TESTING...............7-3

ON/OFF RELAY - DESCRIPTION, WIPER . . . 8R-25

ON/OFF RELAY - DIAGNOSIS AND

TESTING, WIPER.....................8R-26

ON/OFF RELAY - INSTALLATION, WIPER . . 8R-26

ON/OFF RELAY - OPERATION, WIPER....8R-25

ON/OFF RELAY - REMOVAL, WIPER......8R-26

OPEN-CIRCUIT VOLTAGE TEST -

STANDARD PROCEDURE...............8F-12

OPENING DIMENSIONS -

SPECIFICATIONS....................23-111

OPENING FLARE MOLDINGS -

INSTALLATION, FRONT WHEEL.........23-145

OPENING FLARE MOLDINGS -

INSTALLATION, REAR WHEEL..........23-145

OPENING FLARE MOLDINGS -

REMOVAL, FRONT WHEEL............23-145

OPENING FLARE MOLDINGS -

REMOVAL, REAR WHEEL.............23-145

OPENING REINFORCEMENT -

INSTALLATION, GRILLE...............23-142

OPENING REINFORCEMENT - REMOVAL,

GRILLE

...........................23-142

OPENING TRIM LACE - INSTALLATION

. . . 23-180

OPENING TRIM LACE - REMOVAL

......23-180

OPENING WEATHERSTRIP -

INSTALLATION, SWING GATE

..........23-186

OPENING WEATHERSTRIP - REMOVAL,

SWING GATE

.......................23-186

KJINDEX 17

Description Group-Page Description Group-Page Description Group-Page

Page 1759 of 1803

PRIMARY WEATHERSTRIP - REMOVAL,

DOOR............................23-185

PROGRAMING - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-9

PROGRAMMING - STANDARD

PROCEDURE, PCM/SKIM................8E-1

PROGRAMMING - STANDARD

PROCEDURE, SENTRY KEY

TRANSPONDER.......................8Q-8

PROPELLER SHAFT - DIAGNOSIS AND

TESTING.............................3-1

PROPELLER SHAFT - FRONT -

INSTALLATION.........................3-6

PROPELLER SHAFT - FRONT - REMOVAL . . . 3-6

PROPELLER SHAFT - REAR -

INSTALLATION.........................3-7

PROPELLER SHAFT - REAR - REMOVAL....3-7

PROPELLER SHAFT ANGLE - STANDARD

PROCEDURES.........................3-3

PROPELLER SHAFT, SPECIFICATIONS.......3-6

PROPORTIONING VALVE - DIAGNOSIS

AND TESTING........................5-20

PULLEY - DESCRIPTION, GENERATOR

DECOUPLER........................8F-26

PULLEY - INSTALLATION..............19-23

PULLEY - INSTALLATION, GENERATOR

DECOUPLER........................8F-30

PULLEY - OPERATION, GENERATOR

DECOUPLER........................8F-27

PULLEY - REMOVAL..................19-23

PULLEY - REMOVAL, GENERATOR

DECOUPLER........................8F-27

PUMP - ASSEMBLY, OIL................9-67

PUMP - ASSEMBLY, OIL..............21-151

PUMP - CLEANING, OIL..............21-150

PUMP - DESCRIPTION................19-17

PUMP - DESCRIPTION, FUEL...........14-15

PUMP - DESCRIPTION, LEAK DETECTION . 25-27

PUMP - DESCRIPTION, OIL............21-147

PUMP - DESCRIPTION, WATER..........7-29

PUMP - DISASSEMBLY, OIL.............9-65

PUMP - DISASSEMBLY, OIL...........21-149

PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER

STEERING..........................19-18

PUMP - INSPECTION, OIL...............9-66

PUMP - INSPECTION, OIL.............21-150

PUMP - INSTALLATION, LEAK

DETECTION.........................25-28

PUMP - INSTALLATION, OIL.............9-67

PUMP - OPERATION..................19-17

PUMP - OPERATION, FUEL.............14-15

PUMP - OPERATION, LEAK DETECTION . . . 25-28

PUMP - OPERATION, OIL.............21-147

PUMP - OPERATION, WATER............7-30

PUMP - REMOVAL, LEAK DETECTION....25-28

PUMP - REMOVAL, OIL.................9-65

PUMP AMPERAGE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-16

PUMP CAPACITY TEST - DIAGNOSIS

AND TESTING, FUEL..................14-15

PUMP FRONT SEAL - INSTALLATION,

OIL...............................21-152

PUMP FRONT SEAL - REMOVAL, OIL....21-152

PUMP MODULE - DESCRIPTION, FUEL....14-18

PUMP MODULE - INSTALLATION, FUEL . . . 14-19

PUMP MODULE - OPERATION, FUEL.....14-18

PUMP MODULE - REMOVAL, FUEL.......14-18

PUMP PRESSURE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-15

PUMP RELAY - DESCRIPTION, FUEL.....14-34

PUMP RELAY - DIAGNOSIS AND

TESTING, FUEL......................14-34

PUMP RELAY - INSTALLATION, FUEL.....14-34

PUMP RELAY - OPERATION, FUEL.......14-34

PUMP RELAY - REMOVAL, FUEL........14-34

PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD AND FUEL...............8I-4

PUMP, SPECIAL TOOLS - POWER

STEERING..........................19-20

PUMP VOLUME CHECK - STANDARD

PROCEDURE, OIL...................21-148

PUMP/MOTOR - DESCRIPTION, WASHER

. 8R-18

PUMP/MOTOR - INSTALLATION,

WASHER