light JEEP LIBERTY 2008 KK / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: LIBERTY, Model: JEEP LIBERTY 2008 KK / 2.GPages: 493

Page 375 of 493

CAUTION!

If the trailer weighs more than 1,000 lbs (454 kg)

loaded, it should have its own brakes, and they

should be of adequate capacity. Failure to do this

could lead to accelerated brake lining wear, higher

brake pedal effort, and longer stopping distances.

WARNING!

Do not connect trailer brakes to your vehicle's hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

Towing Requirements Ð Trailer Lights & Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may includea4and7pin

wiring harness. Use a factory approved trailer harness

and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

STARTING AND OPERATING 375

5

Page 378 of 493

þUse speed control in flat terrain and with light loads to

maximize fuel efficiency.

Towing Tips Ð Cooling System

To reduce potential for engine and transmission over-

heating, take the following actions:

þCity Driving

When stopped for short periods of time, put transmission

in neutral and increase engine idle speed.

þHighway Driving

Reduce speed.

þAir Conditioning

Turn off temporarily.

þRefer to ªCooling Systemº under ªMaintenance Pro-

ceduresº in Section 7 of this manual for more informa-

tion.

RECREATIONAL TOWING (BEHIND

MOTORHOME, ETC.)

Towing ± 2WD Models

Recreational towing is not allowed.

CAUTION!

Towing with the rear wheels on the ground can result

in severe transmission damage.

Towing Ð 4WD Models

The transfer case must be shifted into Neutral (N) for

recreational towing. The Neutral (N) selection button is

located at the top of the 4WD Control Switch. Shifts into

and out of transfer case Neutral (N) can take place with

the selector switch in any mode position.

378 STARTING AND OPERATING

Page 380 of 493

3. Turn the ignition switch to the ON position.

4. Depress the brake pedal.

5. Shift the transmission to ªNº (Neutral) (automatic

transmission), or depress the clutch pedal (manual trans-

mission).

6. Use the point of a ballpoint pen or similar object to

depress the recessed transfer case Neutral (N) button for

4 seconds. After the shift is complete, and the Neutral (N)

light turns on, release the Neutral (N) button.

7. Start the engine.

8. Shift the automatic transmission into ªRº (Reverse).

9. Release the brake pedal for five seconds and ensure

that there is no vehicle movement.

10. Repeat Steps 8 and 9 with the transmission in ªDº

(Drive) (automatic transmission) or 1st gear (manual

transmission).11. Shut OFF the engine.

12. Turn the ignition switch to the unlocked OFF posi-

tion.

13. Shift the transmission into ªPº (Park) (automatic

transmission), or shift into 4th gear (manual transmis-

sion).

14. Attach the vehicle to a tow vehicle with a tow bar.

15. Disconnect the battery negative cable.

NOTE:

²Steps 1 through 5 are requirements for shifting the

transfer case. If these requirements are not met prior to

depressing the Neutral (N) selection button or while

the shift attempt is in process, then the Neutral (N)

indicator light will flash continuously until all require-

ments are met or until the Neutral (N) button is

released.

380 STARTING AND OPERATING

Page 381 of 493

²The ignition switch must be in the ON position for a

shift to take place and for the position indicator lights

to be operable. If the ignition switch is not in the ON

position, the shift will not take place and no position

indicator lights will be on or flashing.

²Flashing Neutral (N) position indicator light indicates

that shift requirements have not been met.

CAUTION!

Damage to the transmission may occur if the trans-

mission is shifted into ªPº (Park) with the transfer

case in Neutral (N) and the engine RUNNING. With

the transfer case in Neutral (N), ensure that the

engine is OFF prior to shifting the transmission into

ªPº (Park).

Shifting Out of Neutral (N)

Perform the following procedure to prepare your vehicle

for normal usage:

1. Bring the vehicle to a complete stop.

2. Reconnect the battery negative cable.

3. Place the ignition switch in the LOCK position (if it

has been moved or the engine has been started).

4. Turn the ignition switch to the ON position, but do not

start the engine.

5. Depress the brake pedal.

6. Shift the transmission into ªNº (Neutral) (automatic

transmission), or depress the clutch pedal (manual trans-

mission).

7. Use the point of a ballpoint pen or similar object to

depress the recessed transfer case Neutral (N) button.

Release the Neutral (N) button after the Neutral (N)

STARTING AND OPERATING 381

5

Page 382 of 493

indicator light turns off (approximately 1 second). After

the Neutral (N) button is released, the transfer case will

shift to the position identified by the selector switch.

8. Start the engine.

9. Shift the transmission into ªDº (Drive) (automatic

transmission) or into 1st gear and momentarily release

the clutch (manual transmission) to verify that the trans-

fer case has engaged.

10. Set the parking brake.

11. Shift the transmission into ªPº (Park) (automatic

transmission), or into ªNº (Neutral) (manual transmis-

sion).NOTE:

²Steps 1 through 6 are requirements for shifting the

transfer case. If these requirements not met prior to

depressing the Neutral (N) selection button or while

the shift attempt is in process, then all of the mode

position indicator lights will flash continuously until

all requirements are met or until the Neutral (N)

button is released.

²The ignition switch must be in the ON position for a

shift to take place and for the position indicator lights

to be operable. If the ignition switch in not in the ON

position, the shift will not take place and no position

indicator lights will be on or flashing.

²Flashing Neutral (N) position indicator light indicates

that shift requirements have not been met.

382 STARTING AND OPERATING

Page 389 of 493

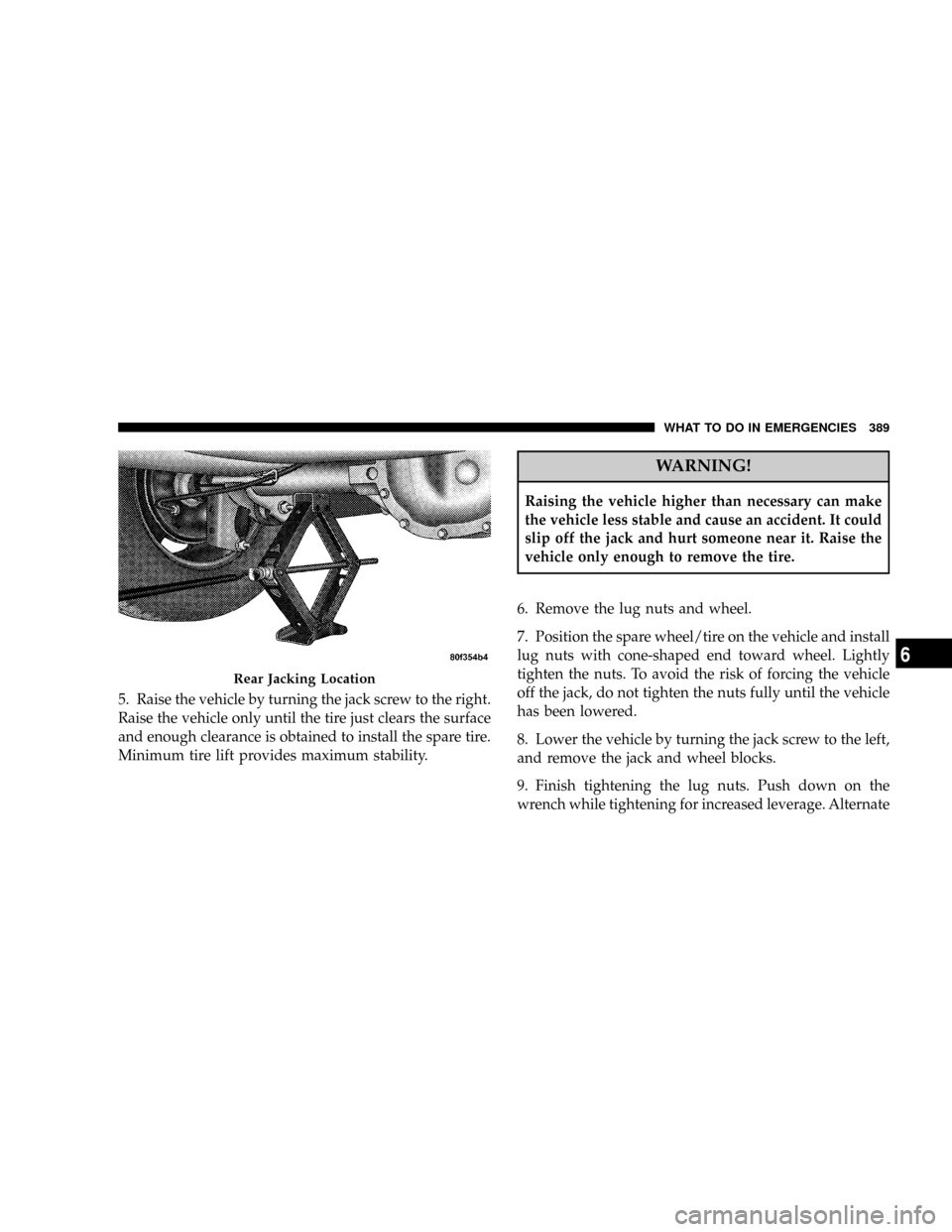

5. Raise the vehicle by turning the jack screw to the right.

Raise the vehicle only until the tire just clears the surface

and enough clearance is obtained to install the spare tire.

Minimum tire lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the vehicle and install

lug nuts with cone-shaped end toward wheel. Lightly

tighten the nuts. To avoid the risk of forcing the vehicle

off the jack, do not tighten the nuts fully until the vehicle

has been lowered.

8. Lower the vehicle by turning the jack screw to the left,

and remove the jack and wheel blocks.

9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

Rear Jacking Location

WHAT TO DO IN EMERGENCIES 389

6

Page 397 of 493

mReplacement Light Bulbs.................443

mBulb Replacement......................443

NHeadlight...........................443

NFront Turn Signal And Front Side Marker

Lights.............................444

NFront Fog Light......................445NRear Tail/Stop, Turn Signal, And Back-Up

Lights.............................445

mFluid Capacities........................447

mFluids, Lubricants, And Genuine Parts........448

NEngine.............................448

NChassis............................449

MAINTAINING YOUR VEHICLE 397

7

Page 399 of 493

ONBOARD DIAGNOSTIC SYSTEM Ð OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the ªMalfunction Indicator Light.º It will

also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your dealer for service as soon as

possible.CAUTION!

²Prolonged driving with the ªMalfunction Indica-

tor Lightº on could cause further damage to the

emission control system. It could also affect fuel

economy and driveability. The vehicle must be

serviced before any emissions tests can be per-

formed.

²If the ªMalfunction Indicator Lightº is flashing

while the engine is running, severe catalytic con-

verter damage and power loss will soon occur.

Immediate service is required.

MAINTAINING YOUR VEHICLE 399

7

Page 400 of 493

Loose Fuel Filler Cap Message

If the vehicle diagnostic system determines that the fuel

filler cap in loose, improperly installed, or damaged, a

ªgASCAPº message will display in the instrument clus-

ter. Tighten the gas cap until a ªclickingº sound is heard.

This is an indication that the gas cap is properly tight-

ened. Press the trip odometer reset button to turn off the

message. If the problem persists, the message will appear

the next time the vehicle is started. This might indicate a

damaged cap. If the problem is detected twice in a row,

the system will turn on the Malfunction Indicator Light

(MIL). Resolving the problem will turn the MIL light off.

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass

an inspection of your vehicle's emissions control system.

Failure to pass could prevent vehicle registration.For states, which have an I/M (Inspection and

Maintenance) requirement, this check verifies the

following: the MIL (Malfunction Indicator Light)

is functioning and is not on when the engine is running,

and that the OBD (On Board Diagnostic) system is ready

for testing.

Normally, the OBD system will be ready. The OBD

system maynotbe ready if your vehicle was recently

serviced, if you recently had a dead battery, or a battery

replacement. If the OBD system should be determined

not ready for the I/M test, your vehicle may fail the test.

Your vehicle has a simple ignition key actuated test,

which you can use prior to going to the test station. To

check if your vehicle's OBD system is ready, you must do

the following:

1. Insert your ignition key into the ignition switch.

400 MAINTAINING YOUR VEHICLE

Page 423 of 493

²Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced

immediately! Eventual deterioration of the hose can

take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder - Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.Check the fluid level in the master cylinder when per-

forming underhood services.

Clean the top of the master cylinder area before removing

the cap. If necessary, add fluid to bring the fluid level up

to the requirements described on the brake fluid reser-

voir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Fluid level can be expected to fall as the brake pads wear.

Brake fluid level should be checked when pads are

replaced. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid. Re-

fer to ªFluids, Lubricants, and Genuine Partsº in this

section for the correct fluid type.

MAINTAINING YOUR VEHICLE 423

7