JEEP PATRIOT 2013 1.G Manual PDF

Manufacturer: JEEP, Model Year: 2013, Model line: PATRIOT, Model: JEEP PATRIOT 2013 1.GPages: 108, PDF Size: 3.17 MB

Page 71 of 108

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving, werecommend you drive to the nearest service center and have the vehicle serviced

immediately.

- Electronic Throttle Control (ETC) Indicator Light

• This light informs you of a problem with the Electronic Throttle Control (ETC)system.

• If a problem is detected, the light will come on while the engine is running. Cycle the ignition when the vehicle has completely stopped and the shift lever is placed

in the PARK position; the light should turn off.

• If the light remains lit with the engine running, your vehicle will usually be drivable; however, see an authorized service center immediately. If the light is

flashing when the engine is running, immediate service is required and you may

experience reduced performance, an elevated/rough idle or engine stall and your

vehicle may require towing.

- Air Bag Warning Light

• If the light is not on during starting, stays on, or turns on while driving, have thevehicle serviced by an authorized service center immediately.

- 4WD System Fault Indicator Light

• When lit solid: There is a 4WD system fault. The 4WD performance will be at areduced level. We recommend you do not operate the vehicle. Have the vehicle

serviced immediately.

• When blinking: The 4WD system is temporarily disabled due to overload condition.

- Transmission Temperature Warning Light

• This light indicates that there is excessive transmission fluid temperature thatmight occur with severe usage such as trailer towing. If this light turns on, you will

experience reduced vehicle performance until the automatic transmission cools

down. If the overheating continues, stop the vehicle and run the engine at idle,

with the transmission in NEUTRAL, until the light turns off. Once the light turns

off, you may continue to drive normally.

Fuel Cap/Loose Gas Cap Message

• If a “gas cap” message (shown as gASCAP) appears, tighten the gas cap until a“clicking” sound is heard.

• Press the odometer reset button, located below the tachometer, to turn the message off.

• If the message continues to appear for more than three days after tightening the gas cap, see your authorized service center.

WHAT TO DO IN EMERGENCIES

69

Page 72 of 108

Oil Change Indicator

Message

• If an “oil change” message (shown as CHANgE OIL) appears and a single chimesounds, it is time for your next required oil change.

Resetting The Light After Servicing

• Turn the ignition switch to the ON/RUN position (do not start engine).

• Fully depress the accelerator pedal three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

IF YOUR ENGINE OVERHEATS

• In any of the following situations, you can reduce the potential for overheating by taking the appropriate action.

• On the highways — slow down.

• In city traffic — while stopped, place the transmission in NEUTRAL, but do not increase engine idle speed.

NOTE:

There are steps that you can take to slow down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine cooling system and turning the A/C off can help remove this heat.

• You can also turn the temperature control to maximum heat, the mode control to floor and the blower control to high. This allows the heater core to act as a

supplement to the radiator and aids in removing heat from the engine cooling

system.

CAUTION!

Driving with a hot cooling system could damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops back into the normal range. If the

pointer remains on HOT (H), and you hear continuous chimes, turn the engine off

immediately, and call for service.

WARNING!

You or others can be badly burned by hot engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam coming from under the hood, do not open

the hood until the radiator has had time to cool. Never try to open a cooling system

pressure cap when the radiator or coolant bottle is hot.

WHAT TO DO IN EMERGENCIES

70

Page 73 of 108

AUTOMATIC TRANSMISSION OVERHEATING

• During sustained high speed driving or trailer towing up long grades on hot days,the automatic transmission oil may become too hot.

• When the transmission overheat warning light

turns on, you will experience

reduced performance until the automatic transmission cools down. Once the

transmission has cooled down and the light turns off, you may continue to drive

normally. If the high speed is maintained, the overheating will continue to occur.

• If the overheating continues, it may become necessary to stop the vehicle and run the engine at idle with the transmission in NEUTRAL until the light turns off.

JACKING AND TIRE CHANGING

Jack Location

• The jack and jack-handle are stowed under the load floor in the cargo area.

Spare Tire Stowage

• The compact spare tire is stowed un-der the rear load floor in the cargo area.

Spare Tire Removal

• Lift up the load floor cover and removethe hold down.

Preparations For Jacking

1. Park the vehicle on a firm level sur-

face, avoiding ice or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever in PARK (automatic transmission) or REVERSE (manual transmission).

5. Turn OFF the ignition.

WHAT TO DO IN EMERGENCIES

71

Page 74 of 108

Block both the front and rear of the wheel

diagonally opposite the jacking position.

For example, if changing the right front

tire, block the left rear wheel.

NOTE:

Passengers should not remain in the

vehicle while the vehicle is being jacked.

Jacking Instructions

NOTE:

Refer to “Tires — General Information” in

“Starting And Operating” in the Owner's

Manual on the DVD for further informa-

tion about the spare tire, it's use, and

operation.

1. Remove the scissors jack and lugwrench from the spare wheel as an

assembly. Turn the jack screw to

the left to loosen the lug wrench

and remove the wrench from the jack

assembly.

2. Loosen, but do not remove, the wheel nuts by turning them to the left one turn while the wheel is still on the ground.

NOTE: • There are front and rear jacking locations on each side of the body. The frontlocations are outlined by two triangular cutouts, the rear locations by two

rectangular cutouts.

WHAT TO DO IN EMERGENCIES

72

Page 75 of 108

• For vehicles equipped with plastictrim, the plastic has been cut away

to expose the jacking locations in

the body.

• Do not raise the vehicle until you are sure the jack is securely engaged.

3. Turn the jack screw to the left until the jack can be placed under the jacking

location. Once the jack is positioned,

turn the jack screw to the right until

the jack head is properly engaged with

the lift area closest to the wheel to be

changed.

4. Using the swivel wrench raise the ve- hicle by turning the jack screw to the

right. Raise the vehicle only until the

tire just clears the surface and enough

clearance is obtained to install the

spare tire. Minimum tire lift provides

maximum stability.

5. Remove the wheel nuts and pull the wheel and wheel covers, where appli-

cable, off the hub. Install the spare

wheel and wheel nuts with the cone

shaped end of the nuts toward the

wheel. Lightly tighten the nuts.

NOTE:

The wheel cover is held on the wheel by

the wheel nuts. When reinstalling the

original wheel, properly align the wheel

cover to the valve stem, place the wheel

cover onto the wheel, then install the

wheel nuts.

6. Lower the vehicle by turning the jack screw to the left.

7.

Finish tightening the nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten

the lug nuts in a star pattern until each

nut has been tightened twice. The

correct wheel nut torque is 100 ft lbs

(135 N·m). If you doubt that you have tightened the nuts correctly, have them

checked with a torque wrench by your authorized dealer or service station.

WHAT TO DO IN EMERGENCIES

73

Page 76 of 108

8. Remove the wheel blocks and lower the jack until it is free. Reassemble the lugwrench to the jack assembly and stow it in the spare tire area. Secure the

assembly using the means provided.

9. Place the deflated (flat) tire in the cargo area, have the tire repaired or replaced as

soon as possible.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

Road Tire Installation

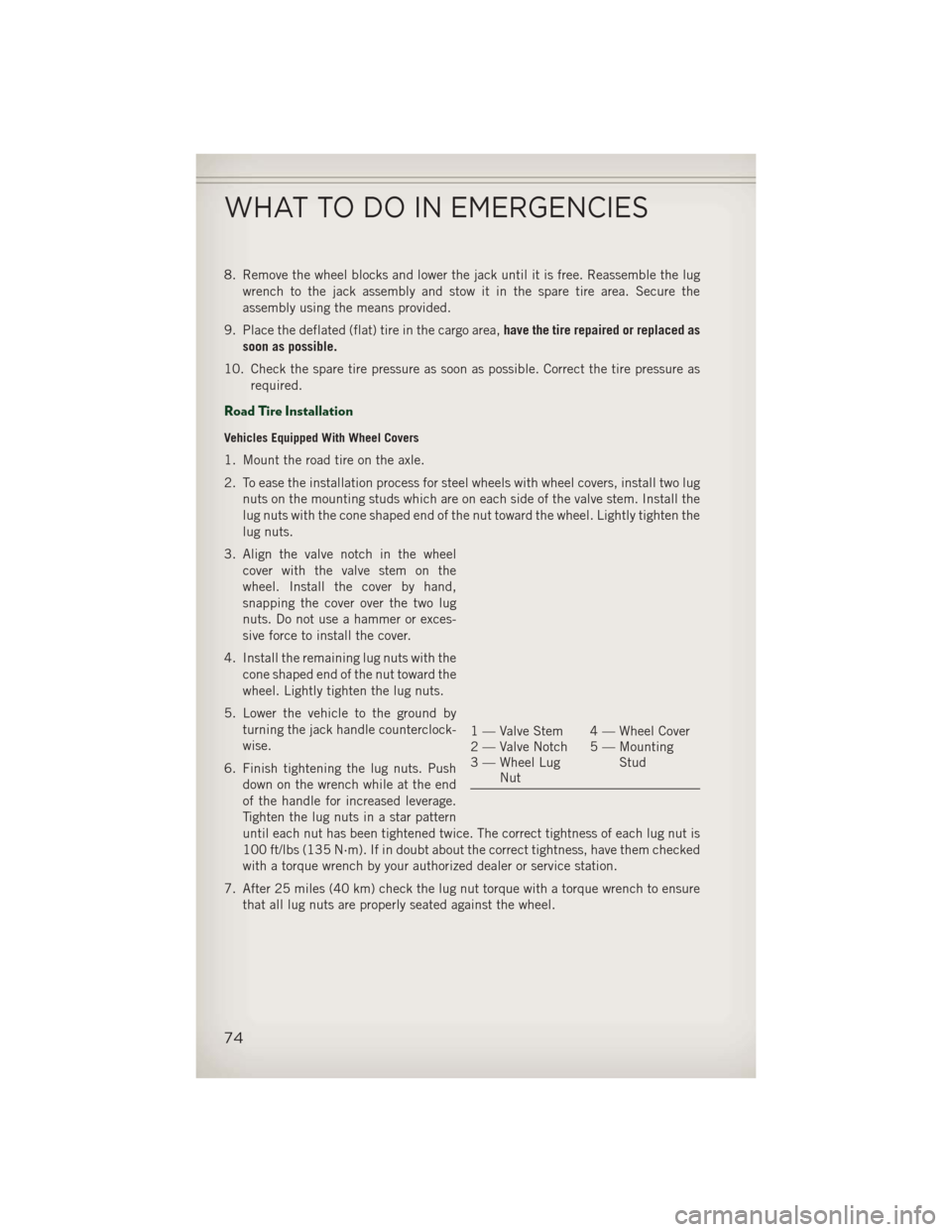

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lugnuts on the mounting studs which are on each side of the valve stem. Install the

lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

3. Align the valve notch in the wheel cover with the valve stem on the

wheel. Install the cover by hand,

snapping the cover over the two lug

nuts. Do not use a hammer or exces-

sive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by turning the jack handle counterclock-

wise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end

of the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened twice. The correct tightness of each lug nut is

100 ft/lbs (135 N·m). If in doubt about the correct tightness, have them checked

with a torque wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug

Nut

WHAT TO DO IN EMERGENCIES

74

Page 77 of 108

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward thewheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

CAUTION!

• Do not attempt to raise the vehicle by jacking on locations other than thoseindicated in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

75

Page 78 of 108

WARNING!

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off thejack and fall on you. You could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get under a raised vehicle, take

it to a service center where it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack

should not be used to lift the vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or slippery areas.

• Do not attempt to change a tire on the side of the vehicle close to moving

traffic, pull far enough off the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadwayas possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK;

a manual transmission in REVERSE.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during

a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

• Raising the vehicle higher than necessary can make the vehicle less stable. It

could slip off the jack and hurt someone near it. Raise the vehicle only enough

to remove the tire.

• To avoid possible personal injury, handle the wheel covers with care to avoid

contact with any sharp edges.

• A loose tire or jack thrown forward in a collision or hard stop could injure the

occupants in the vehicle. Have the deflated (flat) tire repaired or replaced

immediately.

• To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts

fully until the vehicle is lowered to the ground. Failure to follow this warning

may result in personal injury.

JUMP-STARTING PROCEDURES

• If your vehicle has a discharged battery it can be jump-started using a set of

jumper cables and a battery in another vehicle or by using a portable battery

booster pack. Jump-starting can be dangerous if done improperly so please follow

the procedures in this section carefully.

WHAT TO DO IN EMERGENCIES

76

Page 79 of 108

NOTE:

When using a portable battery booster pack follow the manufacturer’s operating

instructions and precautions.

Preparations For Jump-Start

• The battery in your vehicle is located in the front of the engine compartment belowthe air intake duct. To access the battery remove the air intake duct by turning the

two finger screws, located on the radiator support.

1. Set the parking brake, shift the automatic transmission into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electrical accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

WHAT TO DO IN EMERGENCIES

77

Page 80 of 108

Jump-Starting Procedure

NOTE:

Remove Air Intake before proceeding with this Jump-Starting procedure.

1. Connect the positive(+)end of the jumper cable to the positive (+)post of the

discharged vehicle.

2. Connect the opposite end of the positive (+)jumper cable to the positive (+)post

of the booster battery.

3. Connect the negative end (-)of the jumper cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged vehicle’s engine) away from the battery and

the fuel injection system.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

Once the engine is started, remove the jumper cables in the reverse sequence:

6. Disconnect the negative (-)jumper cable from the engine ground of the vehicle

with the discharged battery.

7. Disconnect the negative end (-)of the jumper cable from the negative (-)post of

the booster battery.

8. Disconnect the opposite end of the positive (+)jumper cable from the positive (+)

post of the booster battery.

9. Disconnect the positive (+)end of the jumper cable from the positive (+)post of

the discharged vehicle.

10. Reinstall the air intake duct.

If frequent jump-starting is required to start your vehicle you should have the battery

and charging system inspected at your authorized dealer.

CAUTION!

• Accessories that can be plugged into the vehicle power outlets draw power from the vehicle’s battery, even when not in use (i.e., cellular phones, etc.).

Eventually, if plugged in long enough, the vehicle’s battery will discharge

sufficiently to degrade battery life and/or prevent the engine from starting.

• Do not use a portable battery booster pack or any other booster source with a

system voltage greater than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

• Failure to follow these procedures could result in damage to the charging

system of the booster vehicle or the discharged vehicle.

WHAT TO DO IN EMERGENCIES

78