engine JEEP RENEGADE 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: RENEGADE, Model: JEEP RENEGADE 2023Pages: 364, PDF Size: 18.65 MB

Page 303 of 364

SERVICING AND MAINTENANCE 301

damage. If HOAT and OAT coolant are mixed in

an emergency, have an authorized dealer drain,

flush, and refill with OAT coolant (conforming to

MS.90032) as soon as possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

engine coolant (antifreeze), and to ensure that

engine coolant will return to the radiator from the

coolant expansion bottle/recovery tank (if

equipped).

The cap should be inspected and cleaned if there

is an y

accumulation of foreign material on the

sealing surfaces.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is

a regulated substance requiring proper disposal.

Check with your local authorities to determine the

disposal rules for your community. To prevent

ingestion by animals or children, do not store

ethylene glycol-based coolant in open containers

or allow it to remain in puddles on the ground,

clean up any ground spills immediately. If ingested

by a child or pet, seek emergency assistance

immediately.

Coolant Level

The coolant expansion bottle provides a quick

visual method for determining that the coolant

level is adequate. With the engine off and cold, the

level of the coolant (antifreeze) in the bottle should

be between the “MAX” and “MIN” lines marked on

the bottle.

As long as the engine operating temperature is

satisf

actory, the coolant bottle need only be

checked once a month.

When additional coolant is needed to maintain the

proper

level, it should be added to the coolant

bottle. Do not overfill.

See an authorized dealer for service.

Cooling System Notes

NOTE:

When the vehicle is stopped after a few miles/kilo -

meters of operation, you may observe vapor

c oming

from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to

enter the radiator.

If an examination of your engine compartment

shows n

o evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro -

sion protection of your engine which contains

alumi n

um components.

WARNING!

Do not open hot engine cooling system. Never

add engine coolant (antifreeze) when the

engine is overheated. Do not loosen or

remove the cap to cool an overheated engine.

Heat causes pressure to build up in the

cooling system. To prevent scalding or injury,

do not remove the pressure cap while the

system is hot or under pressure.

Do not use a pressure cap other than the one

specified for your vehicle. Personal injury or

engine damage may result.

8

Page 304 of 364

302 SERVICING AND MAINTENANCE

(Continued)

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces-

sary, install ONLY the correct type thermostat.

O ther

designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Ú page 287.

Brake Master Cylinder

The fluid level in the master cylinder should be

checked when performing under hood services, or

immediately if the Brake Warning Light is on.

Be sure to clean the top of the master cylinder area

before

removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. Fluid level

can be expected to fall as the brake pads wear. The

brake fluid level should be checked when the pads

are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid

Ú page 345.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. Riding

the brakes may also reduce braking capacity in

an emergency.WARNING!

Use only manufacturer’s recommended brake

fluid

Ú page 345. Using the wrong type of

brake fluid can severely damage your brake

system

and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

CAUTION!

Use of improper brake fluids will affect overall

clutch system performance. Improper brake

fluids may damage the clutch system resulting in

loss of clutch function and the ability to shift the

transmission.

WARNING!

Page 305 of 364

SERVICING AND MAINTENANCE 303

(Continued)

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engine

ered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission. The

only exception to this policy is the use of special

dyes for diagnosing fluid leaks. Avoid using

transmission sealers as they may adversely affect

seals.

Fluid Level Check

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However

,

change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use the manufacturer specified transmission

fluid Ú page 345. It is important to maintain the

transmission fluid at the correct level using the

r ecomme

nded fluid.

NOTE:

No chemical flushes should be used in any trans -

mission; only the approved lubricant should be

u sed.

FUSES

General InformationCAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.CAUTION!

Using a transmission fluid other than the

manufacturer recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder Ú page 345.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

Never replace a blown fuse with metal wires or

any other material. Failure to use proper fuses

may result in serious personal injury, fire and/

or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

8

Page 306 of 364

304 SERVICING AND MAINTENANCE

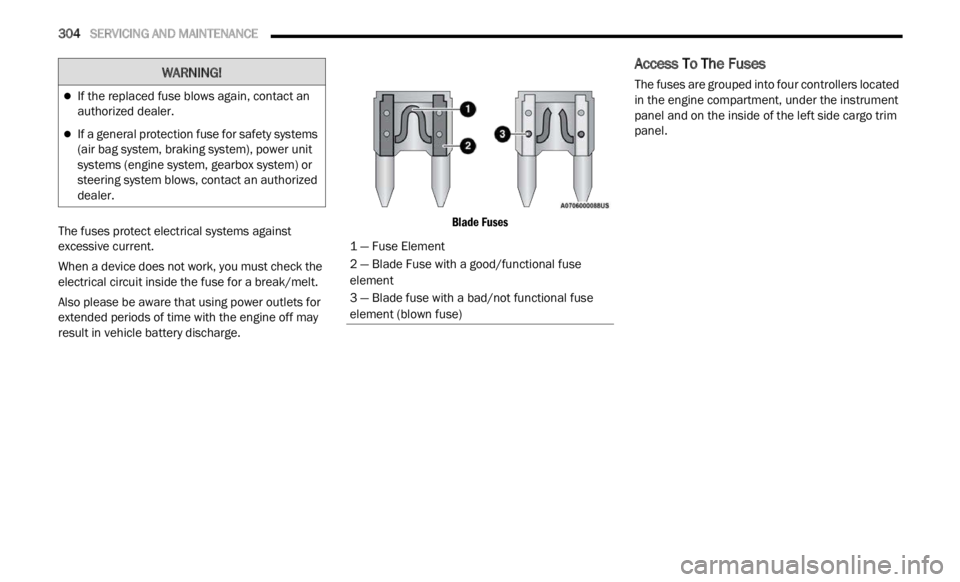

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check the

electr

ical circuit inside the fuse for a break/melt.

Also please be aware that using power outlets for

extend

ed periods of time with the engine off may

result in vehicle battery discharge.

Blade Fuses

Access To The Fuses

The fuses are grouped into four controllers located

in the engine compartment, under the instrument

panel and on the inside of the left side cargo trim

panel.If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, gearbox system) or

steering system blows, contact an authorized

dealer.

WARNING!

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

Page 307 of 364

SERVICING AND MAINTENANCE 305

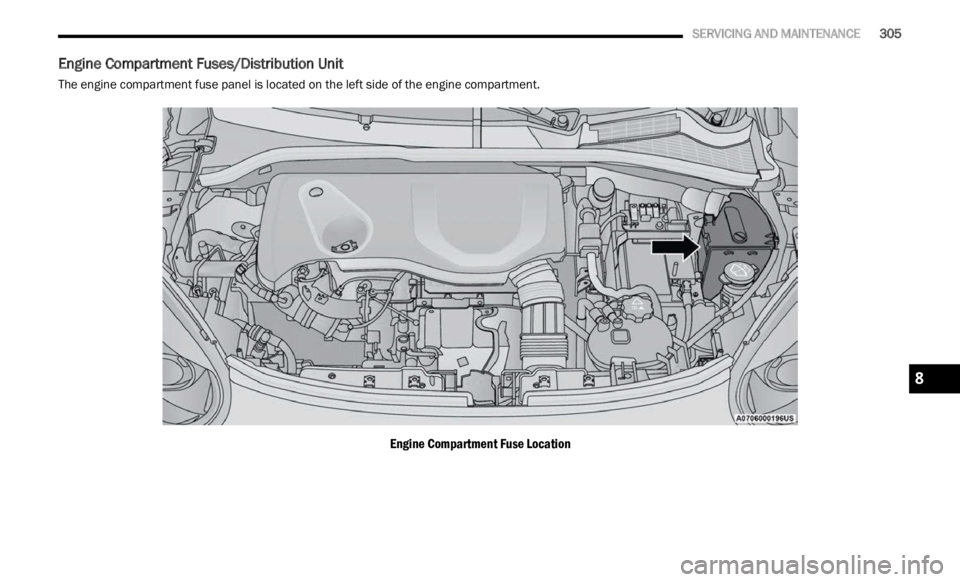

Engine Compartment Fuses/Distribution Unit

The engine compartment fuse panel is located on the left side of the engine compartment.

Engine Compartment Fuse Location

8

Page 308 of 364

306 SERVICING AND MAINTENANCE

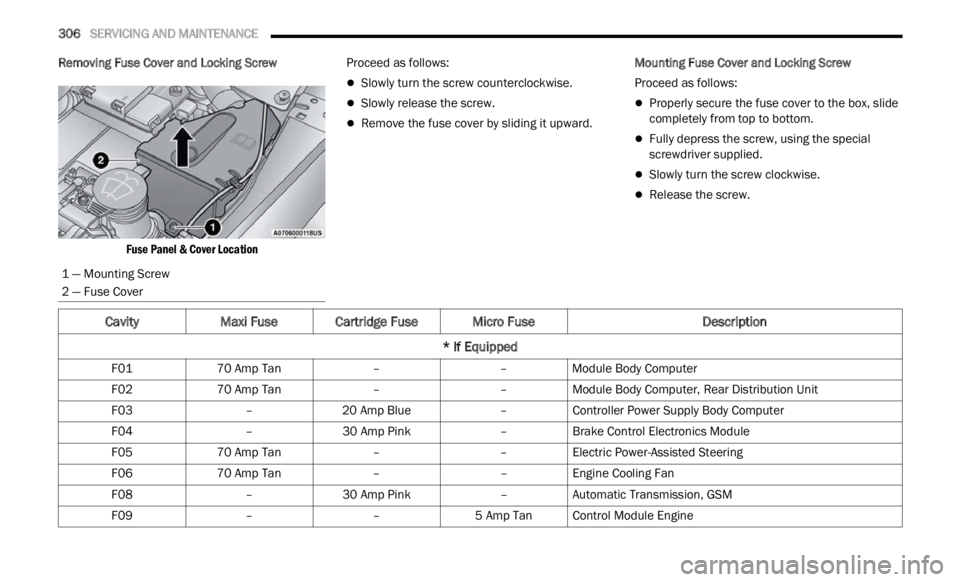

Removing Fuse Cover and Locking Screw

Fuse Panel & Cover Location

Proceed as follows:

Slowly turn the screw counterclockwise.

Slowly release the screw.

Remove the fuse cover by sliding it upward.

Mounting Fuse Cover and Locking Screw

Proceed as follows:

Properly secure the fuse cover to the box, slide

completely from top to bottom.

Fully depress the screw, using the special

screwdriver supplied.

Slowly turn the screw clockwise.

Release the screw.

1 — Mounting Screw

2 — Fuse Cover

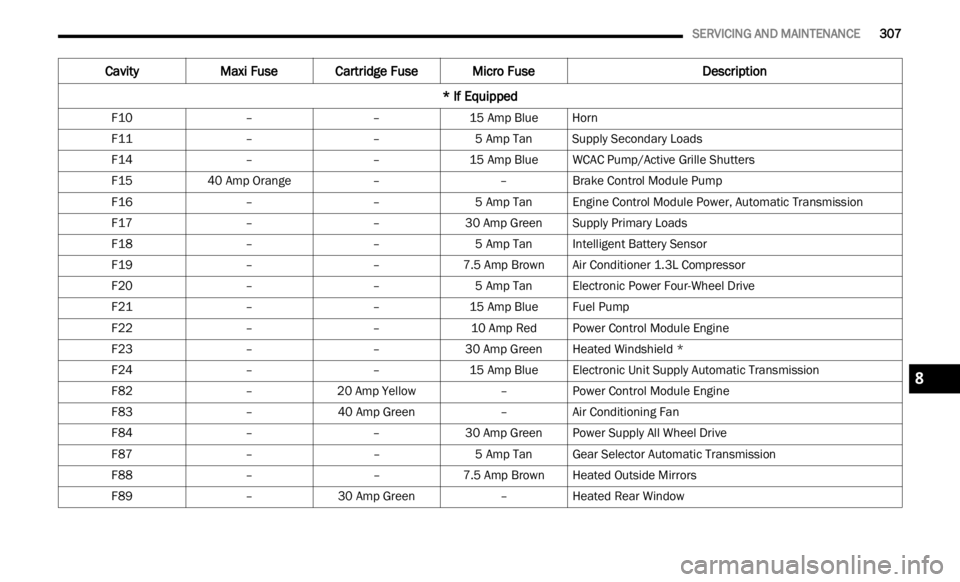

CavityMaxi Fuse Cartridge Fuse Micro Fuse Description

* If Equipped

F01 70 Amp Tan ––Module Body Computer

F02 70 Amp Tan ––Module Body Computer, Rear Distribution Unit

F03 –20 Amp Blue –Controller Power Supply Body Computer

F04 –30 Amp Pink –Brake Control Electronics Module

F05 70 Amp Tan ––Electric Power-Assisted Steering

F06 70 Amp Tan ––Engine Cooling Fan

F08 –30 Amp Pink –Automatic Transmission, GSM

F09 ––5 Amp TanControl Module Engine

Page 309 of 364

SERVICING AND MAINTENANCE 307

F10 ––15 Amp Blue Horn

F11 ––5 Amp TanSupply Secondary Loads

F14 ––15 Amp Blue WCAC Pump/Active Grille Shutters

F15 40 Amp Orange ––Brake Control Module Pump

F16 ––5 Amp TanEngine Control Module Power, Automatic Transmission

F17 ––30 Amp Green Supply Primary Loads

F18 ––5 Amp TanIntelligent Battery Sensor

F19 ––7.5 Amp Brown Air Conditioner 1.3L Compressor

F20 ––5 Amp TanElectronic Power Four-Wheel Drive

F21 ––15 Amp Blue Fuel Pump

F22 ––10 Amp Red Power Control Module Engine

F23 ––30 Amp Green Heated Windshield *

F24 ––15 Amp Blue Electronic Unit Supply Automatic Transmission

F82 –20 Amp Yellow –Power Control Module Engine

F83 –40 Amp Green –Air Conditioning Fan

F84 ––30 Amp Green Power Supply All Wheel Drive

F87 ––5 Amp TanGear Selector Automatic Transmission

F88 ––7.5 Amp Brown Heated Outside Mirrors

F89 –30 Amp Green –Heated Rear Window

Cavity Maxi Fuse Cartridge Fuse Micro Fuse Description

* If Equipped

8

Page 315 of 364

SERVICING AND MAINTENANCE 313

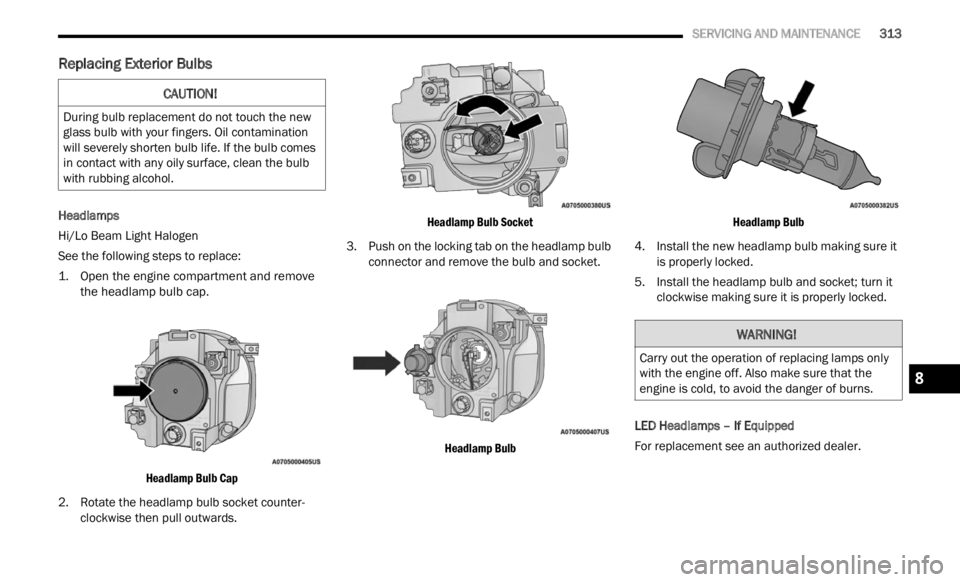

Replacing Exterior Bulbs

Headlamps

Hi/Lo Beam Light Halogen

See the following steps to replace:

1. O

pen the engine compartment and remove

the he a

dlamp bulb cap.

Headlamp Bulb Cap

2. Rotate the headlamp bulb socket counter -

clock w

ise then pull outwards.

Headlamp Bulb Socket

3. P ush on the locking tab on the headlamp bulb

conne c

tor and remove the bulb and socket.

Headlamp Bulb Headlamp Bulb

4. Install the new headlamp bulb making sure it is pr operly locked.

5. Install the headlamp bulb and socket; turn it clockw

ise making sure it is properly locked.

LED Headlamps – If Equipped

For replacement see an authorized dealer.

CAUTION!

During bulb replacement do not touch the new

glass bulb with your fingers. Oil contamination

will severely shorten bulb life. If the bulb comes

in contact with any oily surface, clean the bulb

with rubbing alcohol.

WARNING!

Carry out the operation of replacing lamps only

with the engine off. Also make sure that the

engine is cold, to avoid the danger of burns.

8

Page 317 of 364

SERVICING AND MAINTENANCE 315

4. Rotate the bulb counterclockwise, and then

replace the bulb.

5. Insert the new bulb in the socket, making sure the b

ulb is locked into place.

6. Reconnect the electrical connector.

7. R ein

stall the access door.

LE D

F

r

ont Fog Lamps – If Equipped

For replacement see an authorized dealer.

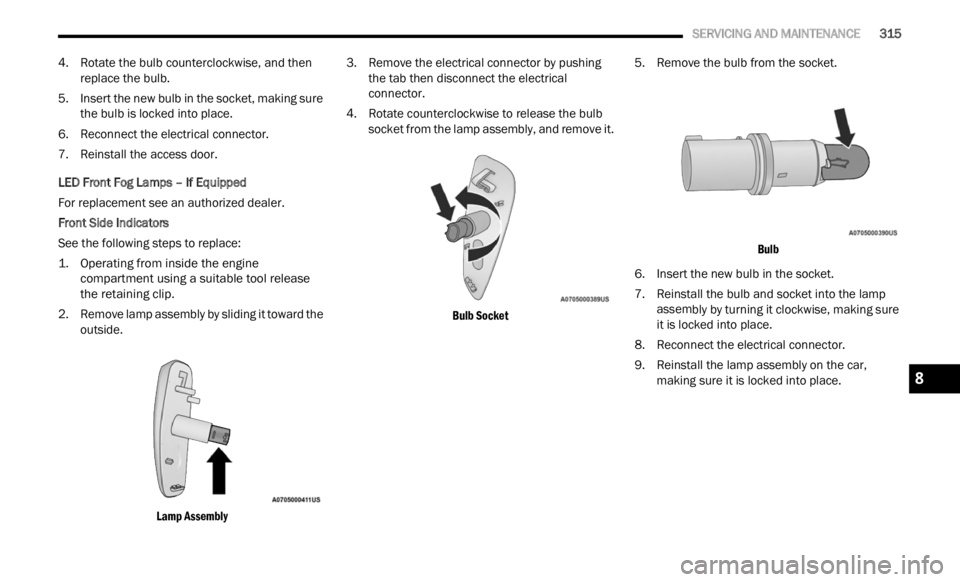

Front Side Indicators

See the following steps to replace:

1. O perating from inside the engine

comp a

rtment using a suitable tool release

the retaining clip.

2. Remove lamp assembly by sliding it toward the outsi d

e.

Lamp Assembly

3. Remove the electrical connector by pushing

the t

ab then disconnect the electrical

connector.

4. Rotate counterclockwise to release the bulb socke t

from the lamp assembly, and remove it.

Bulb Socket

5. Remove the bulb from the socket.

Bulb

6 .

Insert the new bulb in the socket.

7. Rei

nstall the bulb and socket into the lamp

asse m

bly by turning it clockwise, making sure

it is locked into place.

8. Reconnect the electrical connector.

9. R ein

stall the lamp assembly on the car,

m a

ki

n

g sure it is locked into place.8

Page 343 of 364

341

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is stamped on a plate located on the left

front corner of the instrument panel cover, which is

visible from outside the car through the

windshield.

Vehicle Identification Number (VIN)

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose

normal capability, the remaining system will still

function. However, there will be some loss of

overall braking effectiveness. You may notice

increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repea t

ed brake applications with the engine OFF)

the brakes will still function. However, the effort

required to brake the vehicle will be much greater

than that required with the power system

operating.

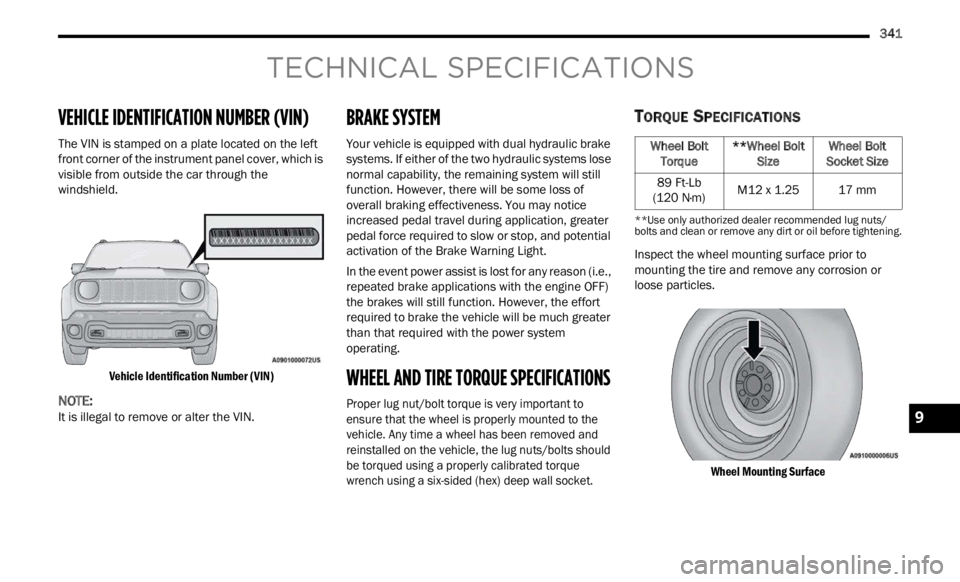

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts should

be torqued using a properly calibrated torque

wrench using a six-sided (hex) deep wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Wheel Bolt Torque**Wheel Bolt Size Wheel Bolt

Socket Size

89 Ft-Lb

(120 N·

m) M12 x 1.25

17 mm

9