engine JEEP RENEGADE 2023 Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: RENEGADE, Model: JEEP RENEGADE 2023Pages: 364, PDF Size: 18.65 MB

Page 278 of 364

276 IN CASE OF EMERGENCY

TIRE SERVICE KIT — IF EQUIPPED

TIRE SERVICE KIT STORAGE

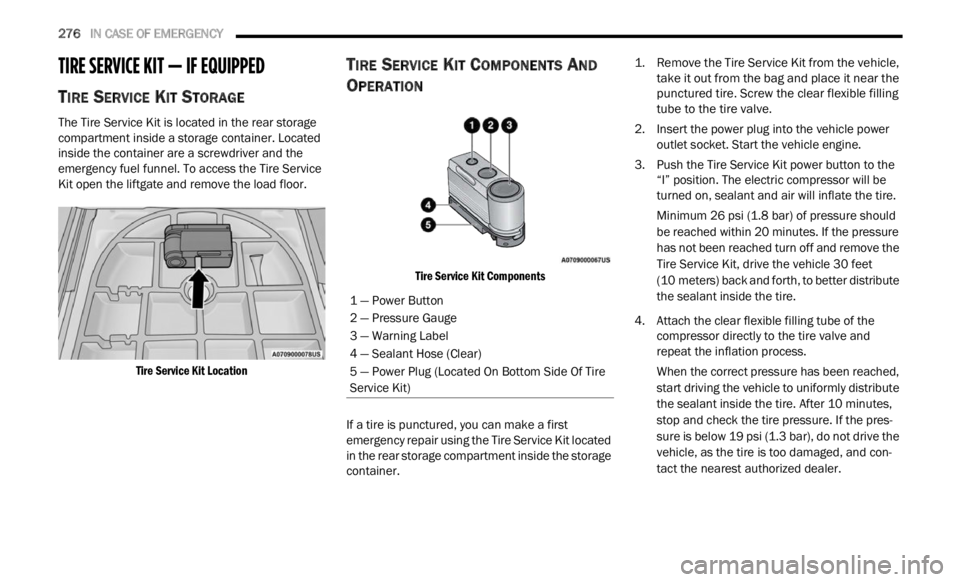

The Tire Service Kit is located in the rear storage

compartment inside a storage container. Located

inside the container are a screwdriver and the

emergency fuel funnel. To access the Tire Service

Kit open the liftgate and remove the load floor.

Tire Service Kit Location

TIRE SERVICE KIT COMPONENTS AND

O

PERATION

Tire Service Kit Components

If a tire is punctured, you can make a first

emerg e

ncy repair using the Tire Service Kit located

in the rear storage compartment inside the storage

container.

1. Remove the Tire Service Kit from the vehicle,

take

it out from the bag and place it near the

punctured tire. Screw the clear flexible filling

tube to the tire valve.

2. Insert the power plug into the vehicle power outlet

socket. Start the vehicle engine.

3. Push the Tire Service Kit power button to the “I” p

osition. The electric compressor will be

turned on, sealant and air will inflate the tire.

Minimum 26 psi (1.8 bar) of pressure should

be re a

ched within 20 minutes. If the pressure

has not

been reached turn off and remove the

Tire Service Kit, drive the vehicle 30 feet

(10 meters) back and forth, to better distribute

the se

alant inside the tire.

4. Attach the clear flexible filling tube of the compre

ssor directly to the tire valve and

repeat the inflation process.

When the correct pressure has been reached,

start

driving the vehicle to uniformly distribute

the sealant inside the tire. After 10 minutes,

stop an

d check the tire pressure. If the pres -

sure is below 19 psi (1.3 bar), do not drive the

vehicl

e, as the tire is too damaged, and con -

tact the nearest authorized dealer.

1 — Power Button

2 — Pressure Gauge

3 — Warning Label

4 — Sealant Hose (Clear)

5 — Power Plug (Located On Bottom Side Of Tire

Servic

e Kit)

Page 280 of 364

278 IN CASE OF EMERGENCY

REPLACING THE SEALANT

NOTE:

Replace the sealant canister prior to the expiration

date a

t an authorized dealer.

Tire Service Kit Expiration Date Location

JUMP STARTING

If your vehicle has a discharged battery it can be

jump started using a set of jumper cables and a

battery in another vehicle or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly so please follow the

procedures in this section carefully.

NOTE:

When using a portable battery booster pack follow

the m a

nufacturer’s operating instructions and

precautions.

PREPARATIONS FOR JUMP START

The battery in your vehicle is located in the front of

the engine compartment, behind the left headlight

assembly.

NOTE:

The positive (+) ba t tery post is covered with a

protective cap. Lift up on the cap to gain access to

the positive (+) battery post.

Positive (+) Battery Post

See below steps to prepare for jump starting:

1. Apply the Electric Park Brake, shift the auto m

atic transmission into PARK (P)

(manual transmission in NEUTRAL) and place

the ignition OFF.

2. Turn off the heater, radio, and all electrical acces

sories.

WARNING!

Store the sealant canister in its special compart -

ment, away from sources of heat. Failure to fol -

low this WARNING may result in sealant canister

r uptur

e and serious injury or death.

WARNING!

Do not attempt jump starting if the battery is fro -

zen. It could rupture or explode and cause per -

sonal injury.

CAUTION!

Do not use a portable battery booster pack or any

other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system may

occur.

Page 281 of 364

IN CASE OF EMERGENCY 279

3. If using another vehicle to jump start the

battery, park the vehicle within the jumper

cable’s reach, set the parking brake and make

sure the ignition is OFF.JUMP STARTING PROCEDURE

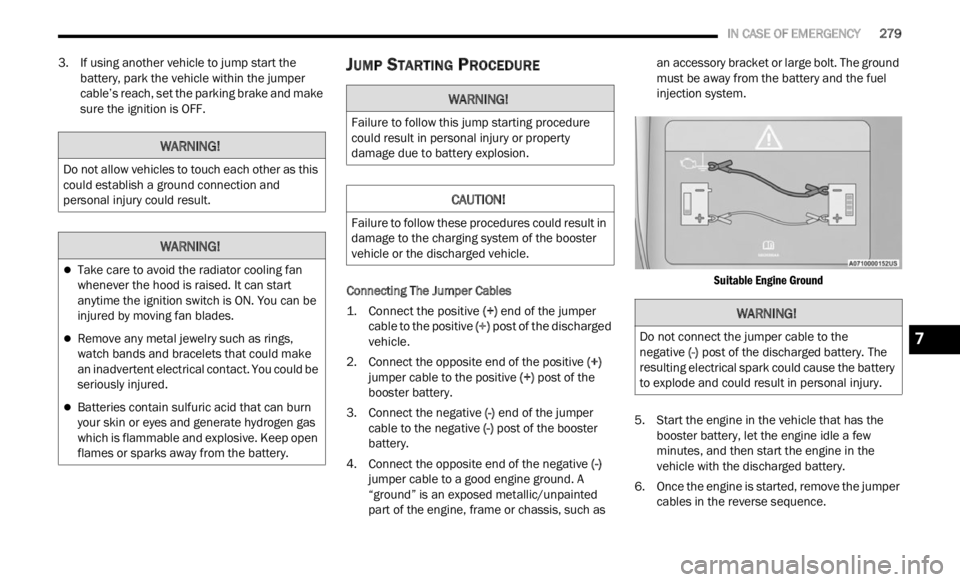

Connecting The Jumper Cables

1. Connect the positive

(+) en

d of the jumper

cable to the positive (+)

post of the discharged

vehicle.

2. Connect the opposite end of the positive (+)

ju m

per cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) en

d of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

ju m

per cable to a good engine ground. A

“ground” is an exposed metallic/unpainted

part of the engine, frame or chassis, such as an accessory bracket or large bolt. The ground

must be away from the battery and the fuel

injection system.

Suitable Engine Ground

5. S tart the engine in the vehicle that has the

booste r

battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, remove the jumper cable

s in the reverse sequence.

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and

personal injury could result.

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Batteries contain sulfuric acid that can burn

your skin or eyes and generate hydrogen gas

which is flammable and explosive. Keep open

flames or sparks away from the battery.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster

vehicle or the discharged vehicle.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery. The

res u

lting electrical spark could cause the battery

to explode and could result in personal injury.7

Page 282 of 364

280 IN CASE OF EMERGENCY

Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

en

d of the jumper

cable from the engine ground of the vehicle

with the discharged battery.

2. Disconnect the opposite end of the negative (-)

ju m

per cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) en

d of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

ju m

per cable from the positive (+) post of the

vehicle with the discharged battery, and

reinstall the protective cap.

If frequent jump starting is required to start your

vehicl

e you should have the battery and charging

system inspected at an authorized dealer.

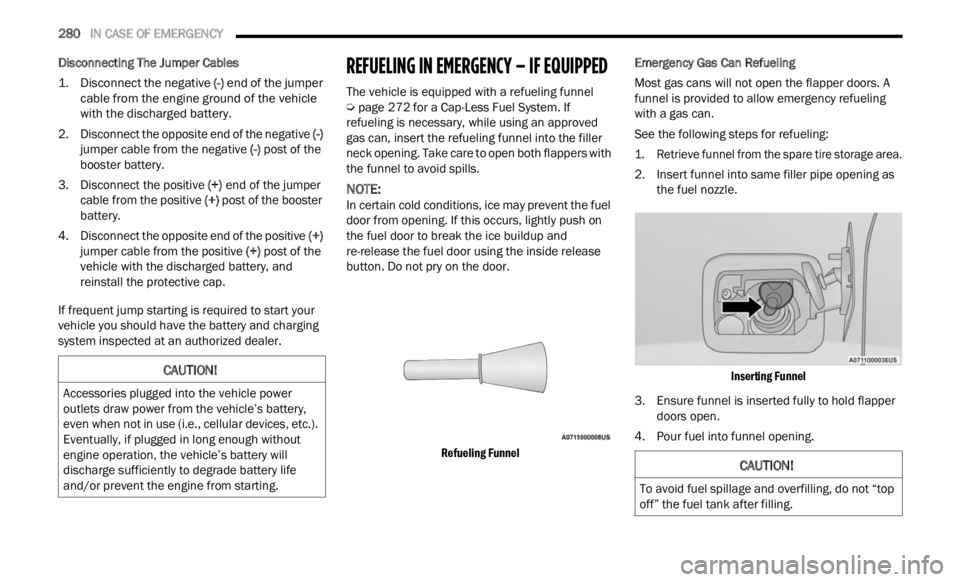

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle is equipped with a refueling funnel

Ú page 272 for a Cap-Less Fuel System. If

refueling is necessary, while using an approved

g as ca

n, insert the refueling funnel into the filler

neck opening. Take care to open both flappers with

the funnel to avoid spills.

NOTE:

In certain cold conditions, ice may prevent the fuel

door fr om

opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door using the inside release

button. Do not pry on the door.

Refueling Funnel

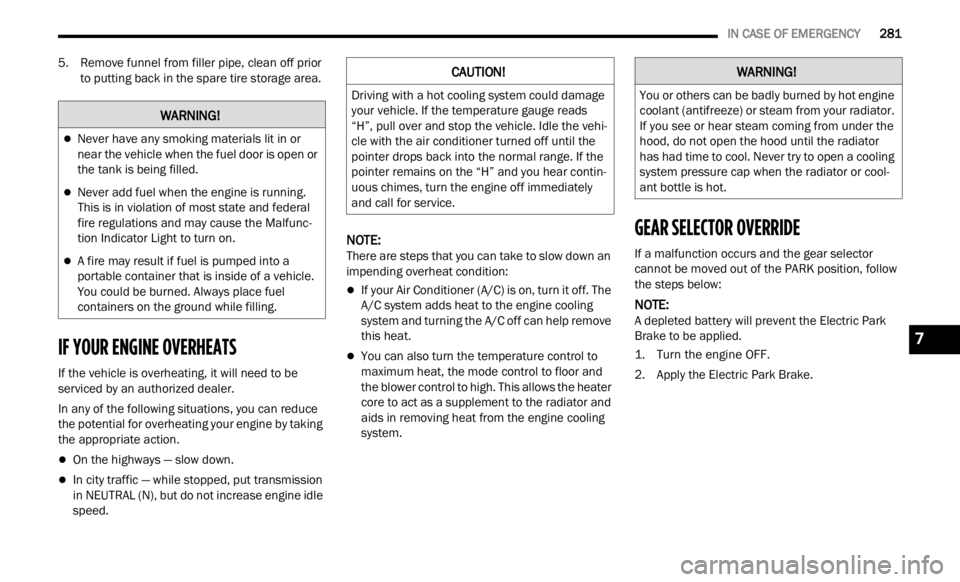

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

f

unne l

is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from the spare tire storage area.

2. Ins

ert funnel into same filler pipe opening as

the f

uel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors op

en.

4. Pour fuel into funnel opening.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

Page 283 of 364

IN CASE OF EMERGENCY 281

5. Remove funnel from filler pipe, clean off prior

to putting back in the spare tire storage area.

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

In any of the following situations, you can reduce

the pot

ential for overheating your engine by taking

the appropriate action.

On the highways — slow down.

In city traffic — while stopped, put transmission

in NEUTRAL (N), but do not increase engine idle

speed.

NOTE:

There are steps that you can take to slow down an

impen d

ing overheat condition:

If your Air Conditioner (A/C) is on, turn it off. The

A/C system adds heat to the engine cooling

system and turning the A/C off can help remove

this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the heater

core to act as a supplement to the radiator and

aids in removing heat from the engine cooling

system.

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position, follow

the steps below:

NOTE:

A depleted battery will prevent the Electric Park

Brake

to be applied.

1. Turn the engine OFF.

2. App

ly the Electric Park Brake.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If the temperature gauge reads

“H”, pull over and stop the vehicle. Idle the vehi -

cle with the air conditioner turned off until the

pointe r

drops back into the normal range. If the

pointer remains on the “H” and you hear contin -

uous chimes, turn the engine off immediately

and c a

ll for service.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator.

If you see or hear steam coming from under the

hood, do not open the hood until the radiator

has had time to cool. Never try to open a cooling

system pressure cap when the radiator or cool -

ant bottle is hot.

7

Page 284 of 364

282 IN CASE OF EMERGENCY

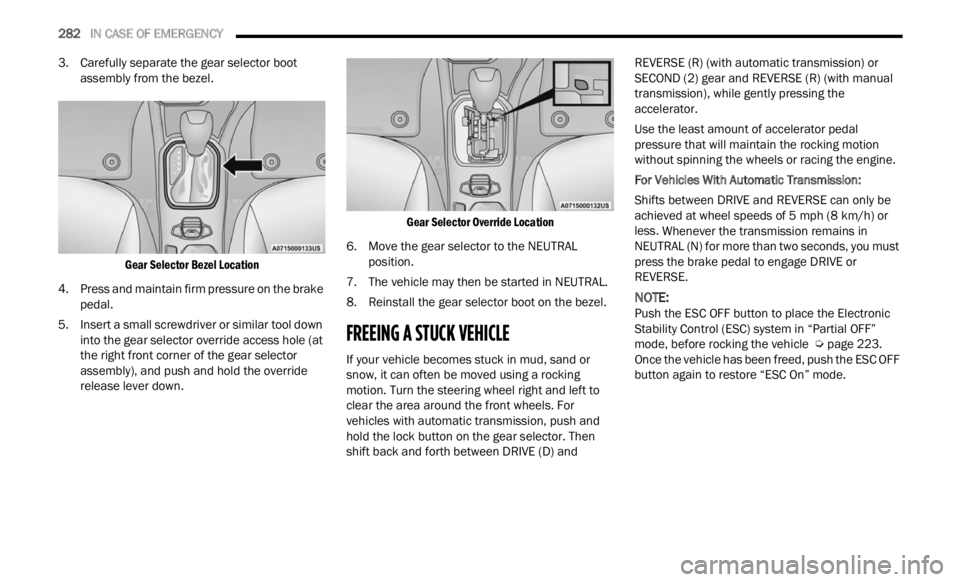

3. Carefully separate the gear selector boot

assembly from the bezel.

Gear Selector Bezel Location

4. Press and maintain firm pressure on the brake peda l

.

5. Insert a small screwdriver or similar tool down into t

he gear selector override access hole (at

the right front corner of the gear selector

assembly), and push and hold the override

release lever down.

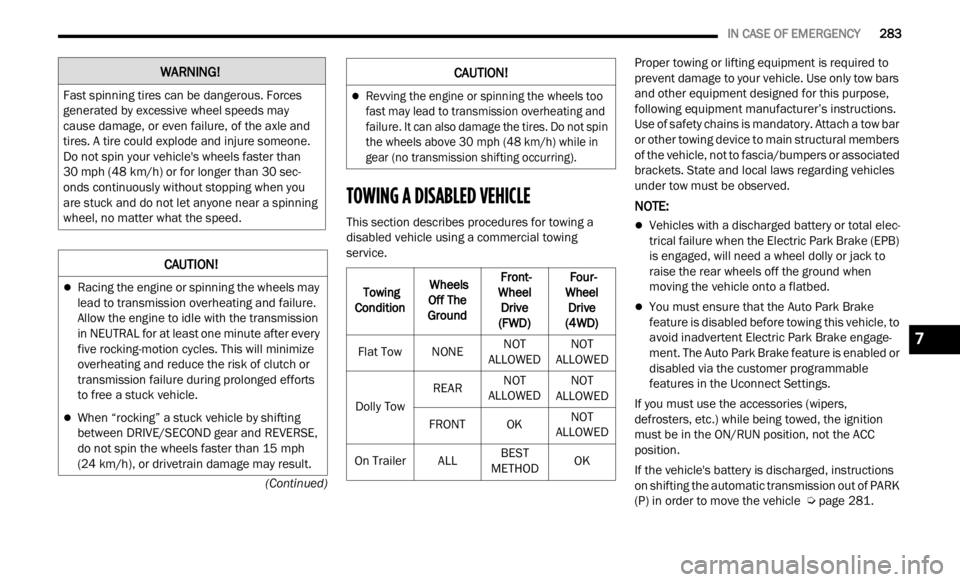

Gear Selector Override Location

6. Move the gear selector to the NEUTRAL posit i

on.

7. The vehicle may then be started in NEUTRAL.

8. R ein

stall the gear selector boot on the bezel.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. For

vehicles with automatic transmission, push and

hold the lock button on the gear selector. Then

shift back and forth between DRIVE (D) and REVERSE (R) (with automatic transmission) or

SECOND (2) gear and REVERSE (R) (with manual

transmission), while gently pressing the

accelerator.

Use the least amount of accelerator pedal

pressu

re that will maintain the rocking motion

without spinning the wheels or racing the engine.

For Vehicles With Automatic Transmission:

Shifts between DRIVE and REVERSE can only be

a chiev

ed at wheel speeds of 5 mph (8 km/h) or

less.

Whenever the transmission remains in

NEUTRAL (N) for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE.

NOTE:

Push the ESC OFF button to place the Electronic

Stabi l

ity Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 223.

Once the vehicle has been freed, push the ESC OFF

button

again to restore “ESC On” mode.

Page 285 of 364

IN CASE OF EMERGENCY 283

(Continued)

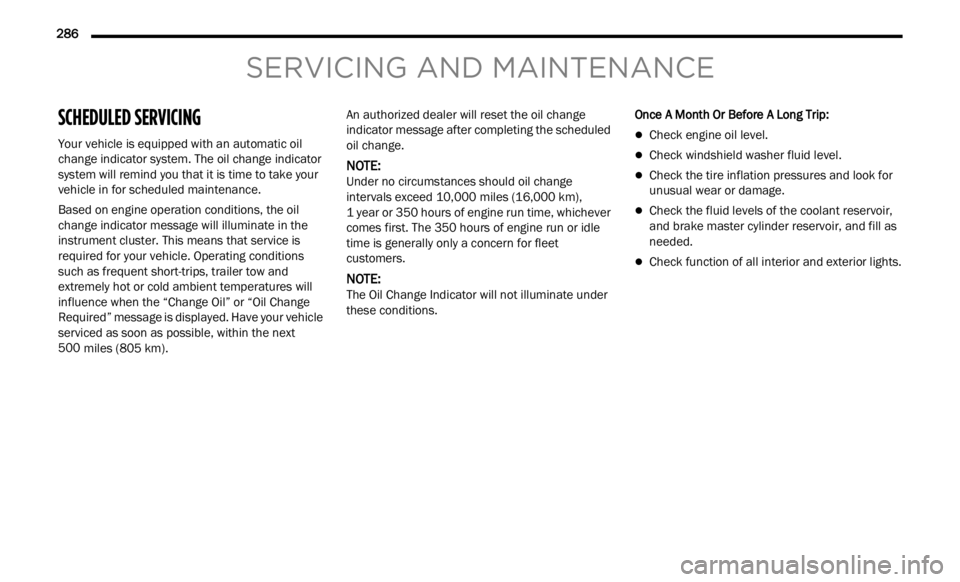

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service. Proper towing or lifting equipment is required to

preve

n

t damage to your vehicle. Use only tow bars

and other equipment designed for this purpose,

following equipment manufacturer’s instructions.

Use of safety chains is mandatory. Attach a tow bar

or other towing device to main structural members

of the vehicle, not to fascia/bumpers or associated

brackets. State and local laws regarding vehicles

under tow must be observed.

NOTE:

Vehicles with a discharged battery or total elec -

trical failure when the Electric Park Brake (EPB)

is en g

aged, will need a wheel dolly or jack to

raise the rear wheels off the ground when

moving the vehicle onto a flatbed.

You must ensure that the Auto Park Brake

feature is disabled before towing this vehicle, to

avoid inadvertent Electric Park Brake engage -

ment. The Auto Park Brake feature is enabled or

disab l

ed via the customer programmable

features in the Uconnect Settings.

If you must use the accessories (wipers,

defros t

ers, etc.) while being towed, the ignition

must be in the ON/RUN position, not the ACC

position.

If the vehicle's battery is discharged, instructions

on shif

ting the automatic transmission out of PARK

(P) in order to move the vehicle Ú page 281.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle and

tires. A tire could explode and injure someone.

Do not spin your vehicle's wheels faster than

30

mph (48 km/h) or for longer than 30 sec-

onds c on

tinuously without stopping when you

are stuck and do not let anyone near a spinning

wheel, no matter what the speed.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of clutch or

transmission failure during prolonged efforts

to free a stuck vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE/SECOND gear and REVERSE,

do not spin the wheels faster than 15 mph

(24 km/

h), or drivetrain damage may result.

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not spin

the wheels above 30 mph (48 km/h) while in

gear (

no transmission shifting occurring).

Towing

Condit i

on Wheels

Off T h

e

Ground Front-

Wheel

D

rive

(FWD) Four-

Wheel D

rive

(4WD)

Flat Tow NONENOT

ALLOWED N

O

T

ALLOWED

Dol

ly Tow REAR

NOT

ALLOWED N

O

T

ALLOWED

FR

ONT OK NOT

ALLOWED

O n

Trailer ALLBEST

METHOD O

K

CAUTION!

7

Page 288 of 364

286

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change

indicator message will illuminate in the

instrument cluster. This means that service is

required for your vehicle. Operating conditions

such as frequent short-trips, trailer tow and

extremely hot or cold ambient temperatures will

influence when the “Change Oil” or “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km). An authorized dealer will reset the oil change

indica

tor message after completing the scheduled

oil change.

NOTE:

Under no circumstances should oil change

inter v

als exceed 10,000 miles (16,000 km),

1 year or 350 hours of engine run time, whichever

c omes f

irst. The 350 hours of engine run or idle

time is generally only a concern for fleet

customers.

NOTE:

The Oil Change Indicator will not illuminate under

these

conditions. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check the tire inflation pressures and look for

unusual wear or damage.

Check the fluid levels of the coolant reservoir,

and brake master cylinder reservoir, and fill as

needed.

Check function of all interior and exterior lights.

Page 289 of 364

SERVICING AND MAINTENANCE 287

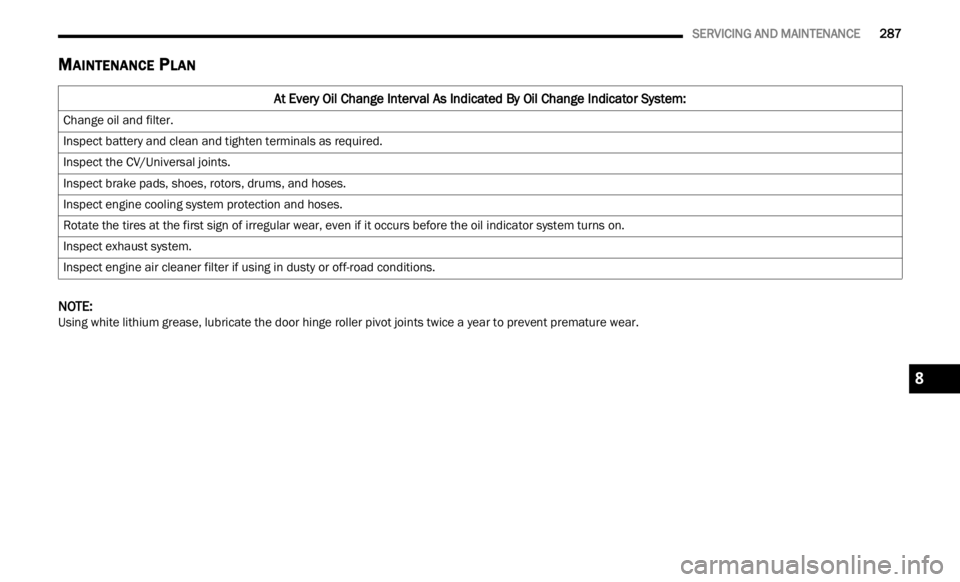

MAINTENANCE PLAN

NOTE:

Using white lithium grease, lubricate the door hinge roller pivot joints twice a year to prevent premature wear.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, and hoses.

Inspect engine cooling system protection and hoses.

Rotate the tires at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions.

8

Page 290 of 364

288 SERVICING AND MAINTENANCE

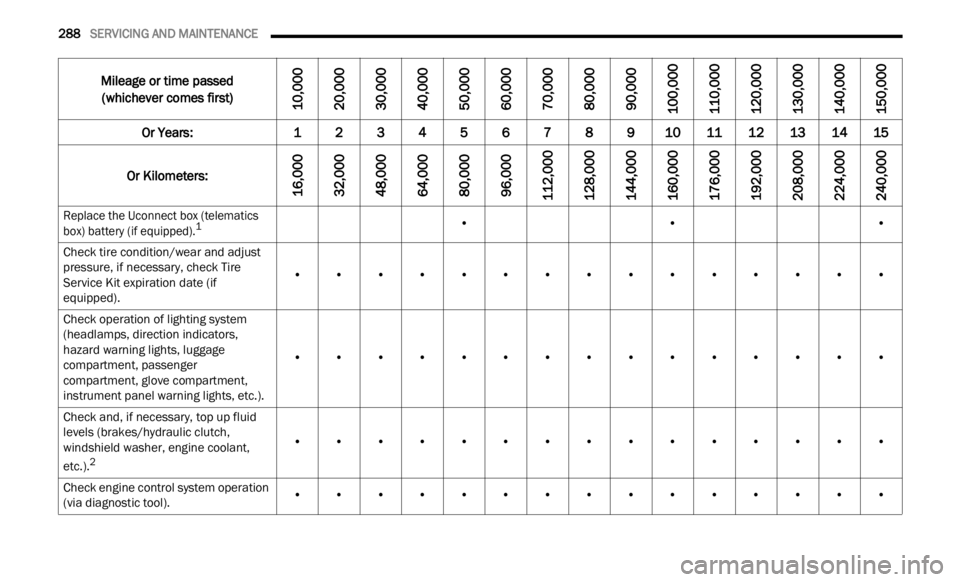

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 12345678910 1112131415

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Replace the Uconnect box (telematics

box) battery (if equipped).1

• ••

Check tire condition/wear and adjust

press u

re, if necessary, check Tire

Service Kit expiration date (if

equipped). •

••••••••••••••

Check operation of lighting system

(head l

amps, direction indicators,

hazard warning lights, luggage

compartment, passenger

compartment, glove compartment,

instrument panel warning lights, etc.). •

••••••••••••••

Check and, if necessary, top up fluid

l evel

s

(brakes/hydraulic clutch,

windshield washer, engine coolant,

etc.).

2

• ••••••••••••••

Check engine control system operation

(via d

iagnostic tool). •

••••••••••••••