torque JEEP WAGONEER 2023 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WAGONEER, Model: JEEP WAGONEER 2023Pages: 396, PDF Size: 15.17 MB

Page 331 of 396

SERVICING AND MAINTENANCE329

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic

Transmission Fluid (ATF) is an engineered product and its

performance may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the

transmission. Avoid using transmission sealers as they

may adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required; therefore the

transmission has no dipstick. An authorized dealer can

check your transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immediately to

have the transmission fluid level checked. Operating the

vehicle with an improper fluid level can cause severe

transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the life

of the vehicle.

Routine fluid and filter changes are not required. However,

change the fluid and filter if the fluid becomes

contaminated (with water, etc.), or if the transmission is

disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer's specified transmission fluid

Úpage 377. It is important to maintain the transmission

fluid at the correct level using the recommended fluid.

NOTE:No chemical flushes should be used in any transmission;

only the approved lubricant should be used.

To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in an open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum-based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

WARNING!CAUTION!

Do not use chemical flushes in your transmission as the

chemicals can damage your transmission components.

Such damage is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an authorized

dealer immediately. Severe transmission damage may

occur. An authorized dealer has the proper tools to

adjust the fluid level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or torque

converter shudder.8

23_WS_OM_EN_USC_t.book Page 329

Page 332 of 396

330SERVICING AND MAINTENANCE

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the fluid

level.

Front Axle Fluid Level Check

The front axle oil level needs to be no lower than 1/8 inch

(3 mm) below the bottom of the fill hole.

The front axle fill and drain plugs should be tightened to

22 to 29 ft-lb (30 to 40 N·m).

Rear Axle Fluid Level Check

The rear axle oil level needs to be no lower than 1/8 inch

(3 mm) below the bottom of the fill hole.

The rear axle fill and drain plugs should be tightened to

22 to 29 ft-lb (30 to 40 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended fluid Úpage 377.

TRANSFER CASE

Fluid Level Check

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the transfer case assembly should

be inspected. If oil leakage is suspected inspect the fluid

level.

Adding Fluid

Add fluid at the filler hole, until it runs out of the hole, when

the vehicle is in a level position.

Drain

First remove fill plug, then remove drain plug.

Recommended tightening torque for drain and fill plugs is

15 to 25 ft-lb (20 to 34 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended fluid Úpage 377.

CAUTION!

Do not overtighten the plugs as it could damage them

and cause them to leak.

CAUTION!

Do not overtighten the plugs as it could damage them

and cause them to leak.CAUTION!

When installing plugs, do not overtighten. You could

damage them and cause them to leak.

23_WS_OM_EN_USC_t.book Page 330

Page 373 of 396

371

TECHNICAL SPECIFICATIONS

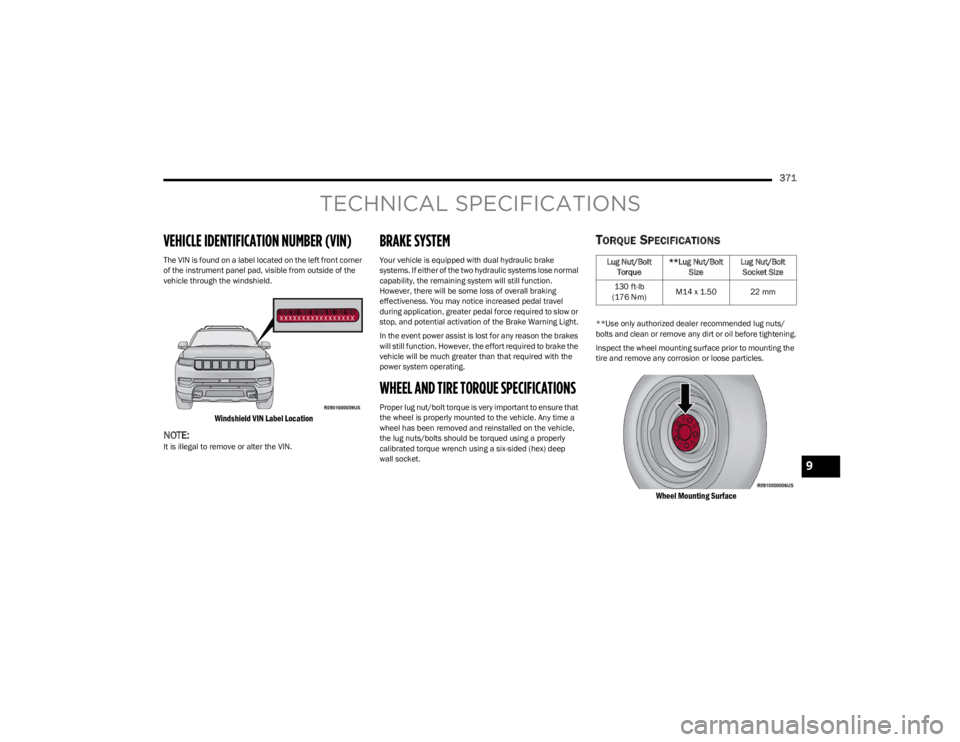

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on a label located on the left front corner

of the instrument panel pad, visible from outside of the

vehicle through the windshield.

Windshield VIN Label Location

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose normal

capability, the remaining system will still function.

However, there will be some loss of overall braking

effectiveness. You may notice increased pedal travel

during application, greater pedal force required to slow or

stop, and potential activation of the Brake Warning Light.

In the event power assist is lost for any reason the brakes

will still function. However, the effort required to brake the

vehicle will be much greater than that required with the

power system operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle,

the lug nuts/bolts should be torqued using a properly

calibrated torque wrench using a six-sided (hex) deep

wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

Lug Nut/Bolt Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

130 ft-lb

(176 N·m) M14 x 1.50 22 mm

9

23_WS_OM_EN_USC_t.book Page 371

Page 374 of 396

372TECHNICAL SPECIFICATIONS

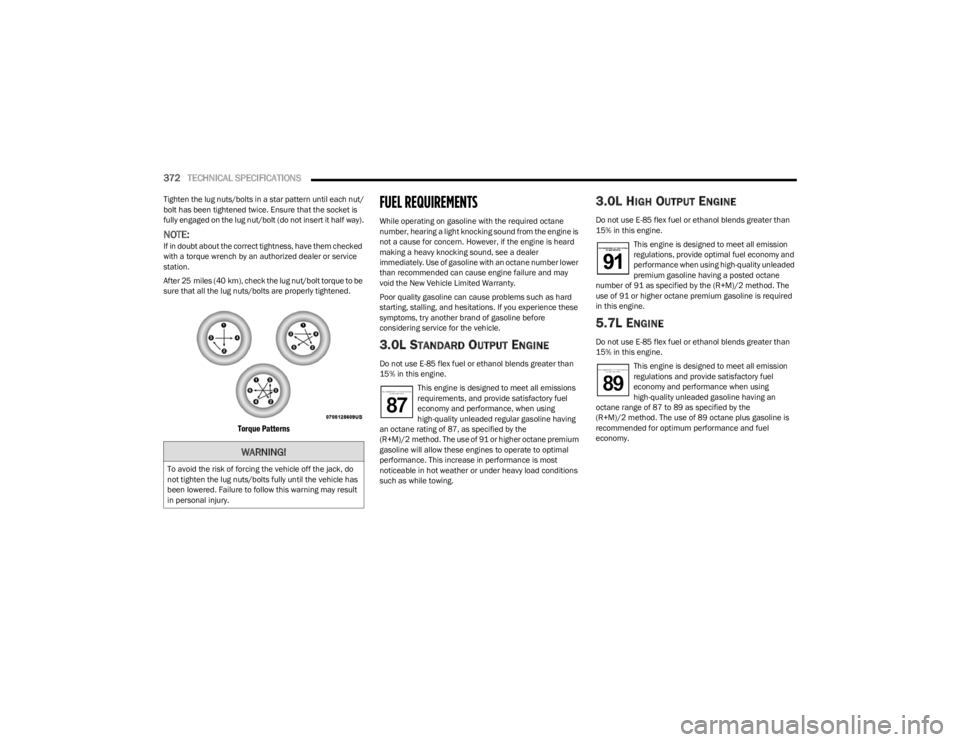

Tighten the lug nuts/bolts in a star pattern until each nut/

bolt has been tightened twice. Ensure that the socket is

fully engaged on the lug nut/bolt (do not insert it half way).

NOTE:If in doubt about the correct tightness, have them checked

with a torque wrench by an authorized dealer or service

station.

After 25 miles (40 km), check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly tightened.

Torque Patterns

FUEL REQUIREMENTS

While operating on gasoline with the required octane

number, hearing a light knocking sound from the engine is

not a cause for concern. However, if the engine is heard

making a heavy knocking sound, see a dealer

immediately. Use of gasoline with an octane number lower

than recommended can cause engine failure and may

void the New Vehicle Limited Warranty.

Poor quality gasoline can cause problems such as hard

starting, stalling, and hesitations. If you experience these

symptoms, try another brand of gasoline before

considering service for the vehicle.

3.0L STANDARD OUTPUT ENGINE

Do not use E-85 flex fuel or ethanol blends greater than

15% in this engine.

This engine is designed to meet all emissions

requirements, and provide satisfactory fuel

economy and performance, when using

high-quality unleaded regular gasoline having

an octane rating of 87, as specified by the

(R+M)/2 method. The use of 91 or higher octane premium

gasoline will allow these engines to operate to optimal

performance. This increase in performance is most

noticeable in hot weather or under heavy load conditions

such as while towing.

3.0L HIGH OUTPUT ENGINE

Do not use E-85 flex fuel or ethanol blends greater than

15% in this engine.

This engine is designed to meet all emission

regulations, provide optimal fuel economy and

performance when using high-quality unleaded

premium gasoline having a posted octane

number of 91 as specified by the (R+M)/2 method. The

use of 91 or higher octane premium gasoline is required

in this engine.

5.7L ENGINE

Do not use E-85 flex fuel or ethanol blends greater than

15% in this engine.

This engine is designed to meet all emission

regulations and provide satisfactory fuel

economy and performance when using

high-quality unleaded gasoline having an

octane range of 87 to 89 as specified by the

(R+M)/2 method. The use of 89 octane plus gasoline is

recommended for optimum performance and fuel

economy.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts/bolts fully until the vehicle has

been lowered. Failure to follow this warning may result

in personal injury.

23_WS_OM_EN_USC_t.book Page 372

Page 392 of 396

390

Sun ScreensSecond Row Seats ..................................................... 76

Sun Visor..........................................................................51

Sunglasses Storage ........................................................73

Surroundview Camera ................................................. 175

Sway Control, Trailer .................................................... 247

Synthetic Engine Oil ..................................................... 319

System, Remote Starting ................................................22

TTelescoping Steering Column ........................................30

Temperature Control, Automatic (ATC) ..........................71

Third Party Apps ........................................................... 226

Third Row USB.................................................................78 Tie Down Hooks, Cargo...................................................89Tilt Steering Column ....................................................... 30

Tire And Loading Information Placard ........................ 354

Tire Markings................................................................ 349

Tire Safety Information ................................................ 349 Tires ................................................... 289

, 357, 361, 366

Aging (Life Of Tires) ................................................. 359

Air Pressure.............................................................. 357

Chains ...................................................................... 364

Changing .................................................................. 293

Compact Spare ........................................................ 361

General Information ...................................... 357

, 361

High Speed .............................................................. 358

Inflation Pressure ....................................................357 Life Of Tires .............................................................. 359

Load Capacity .......................................................... 354

Pressure Monitoring System (TPMS) ........... 114

, 252

Quality Grading ........................................................ 366

Radial ....................................................................... 358

Replacement ...........................................................360

Rotation....................................................................366 Safety ............................................................. 349

, 357

Sizes ......................................................................... 350

Snow Tires................................................................ 361 Spare Tires ........................................... 295

, 361, 362

Spinning ................................................................... 359

Trailer Towing .......................................................... 186

Tread Wear Indicators ............................................ 359

Wheel Nut Torque ................................................... 371

To Open Hood ................................................................. 85

Tongue Weight/Trailer Weight..................................... 185

Tow/Haul Mode ............................................................ 129

Towing ........................................................ 115

, 178, 306

Disabled Vehicle...................................................... 306

Guide........................................................................ 182

Recreational ............................................................ 190

Weight ...................................................................... 182

Towing Behind A Motorhome ...................................... 190

Traction Control ............................................................ 246

Traffic Sign Recognition System.................................. 146

Trailer Sway Control (TSC) ........................................... 247

23_WS_OM_EN_USC_t.book Page 390