JEEP WRANGLER 2020 Owner handbook (in English)

Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER, Model: JEEP WRANGLER 2020Pages: 276, PDF Size: 4.47 MB

Page 151 of 276

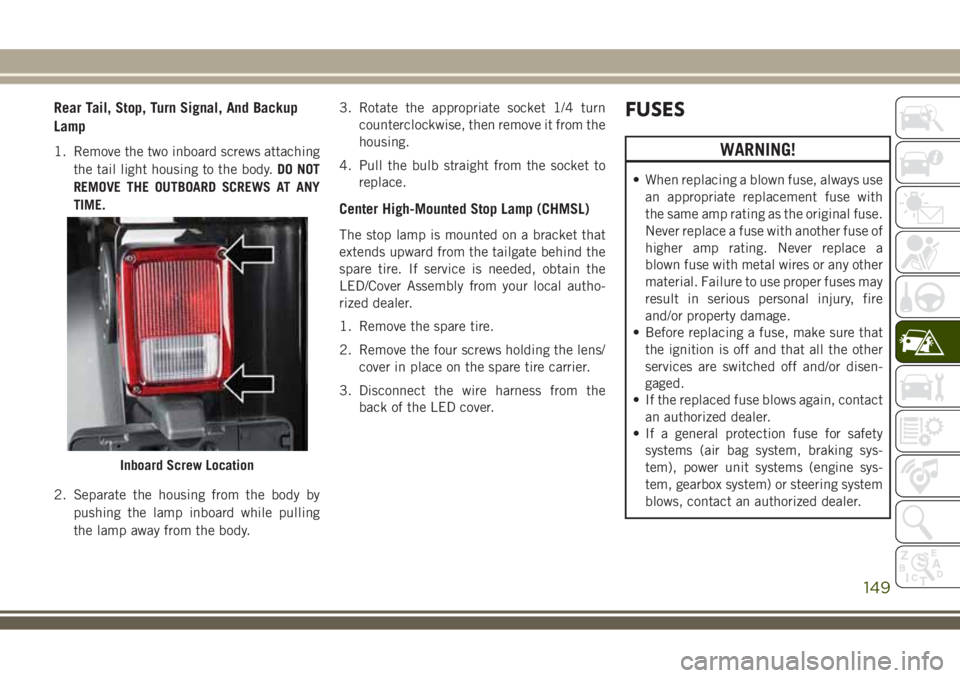

Rear Tail, Stop, Turn Signal, And Backup

Lamp

1. Remove the two inboard screws attaching

the tail light housing to the body.DO NOT

REMOVE THE OUTBOARD SCREWS AT ANY

TIME.

2. Separate the housing from the body by

pushing the lamp inboard while pulling

the lamp away from the body.3. Rotate the appropriate socket 1/4 turn

counterclockwise, then remove it from the

housing.

4. Pull the bulb straight from the socket to

replace.

Center High-Mounted Stop Lamp (CHMSL)

The stop lamp is mounted on a bracket that

extends upward from the tailgate behind the

spare tire. If service is needed, obtain the

LED/Cover Assembly from your local autho-

rized dealer.

1. Remove the spare tire.

2. Remove the four screws holding the lens/

cover in place on the spare tire carrier.

3. Disconnect the wire harness from the

back of the LED cover.

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Failure to use proper fuses may

result in serious personal injury, fire

and/or property damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, gearbox system) or steering system

blows, contact an authorized dealer.

Inboard Screw Location

149

Page 152 of 276

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

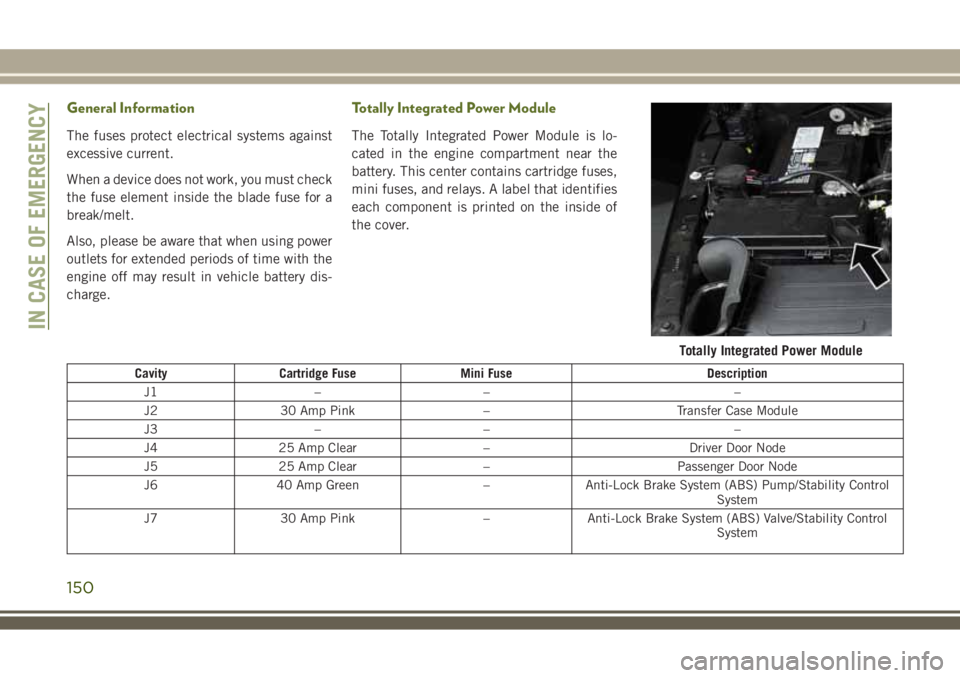

Totally Integrated Power Module

The Totally Integrated Power Module is lo-

cated in the engine compartment near the

battery. This center contains cartridge fuses,

mini fuses, and relays. A label that identifies

each component is printed on the inside of

the cover.

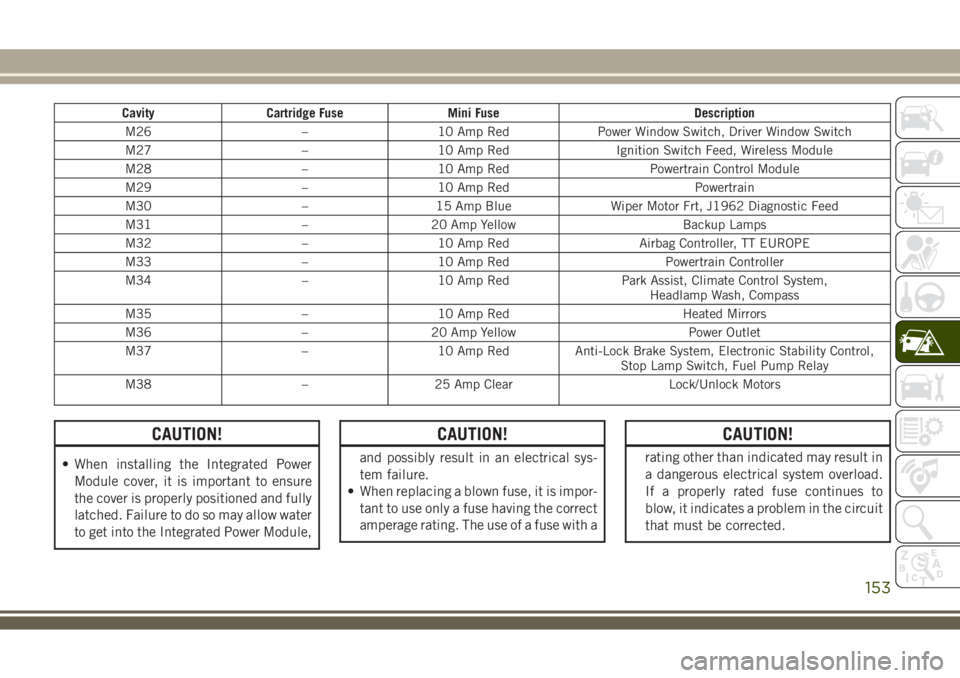

Cavity Cartridge Fuse Mini Fuse Description

J1 – – –

J2 30 Amp Pink – Transfer Case Module

J3 – – –

J4 25 Amp Clear – Driver Door Node

J5 25 Amp Clear – Passenger Door Node

J6 40 Amp Green – Anti-Lock Brake System (ABS) Pump/Stability Control

System

J7 30 Amp Pink – Anti-Lock Brake System (ABS) Valve/Stability Control

System

Totally Integrated Power Module

IN CASE OF EMERGENCY

150

Page 153 of 276

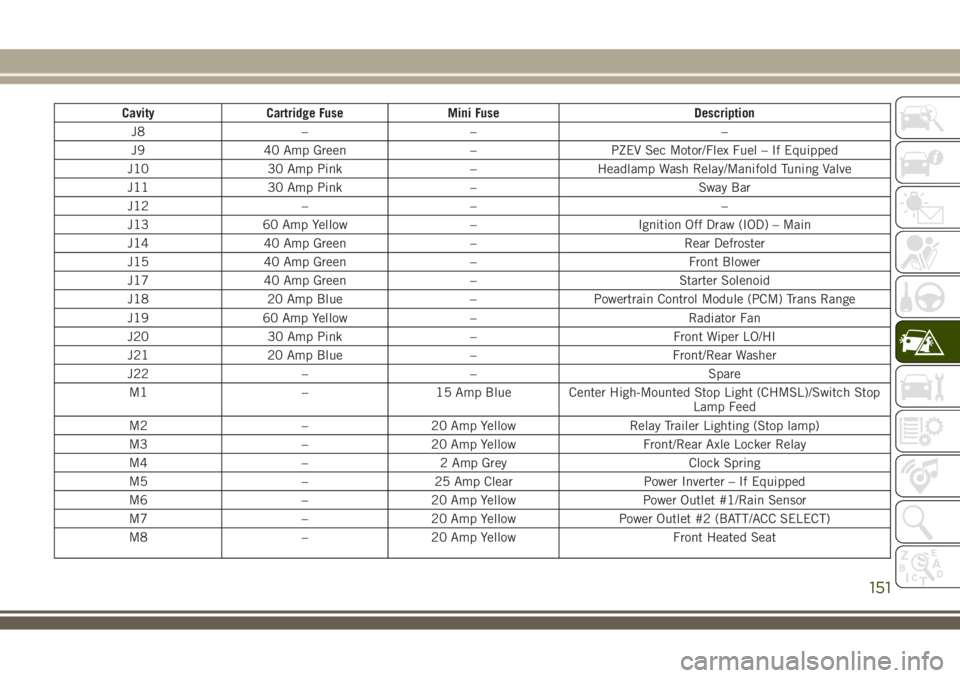

Cavity Cartridge Fuse Mini Fuse Description

J8 – – –

J9 40 Amp Green – PZEV Sec Motor/Flex Fuel – If Equipped

J10 30 Amp Pink – Headlamp Wash Relay/Manifold Tuning Valve

J11 30 Amp Pink – Sway Bar

J12 – – –

J13 60 Amp Yellow – Ignition Off Draw (IOD) – Main

J14 40 Amp Green – Rear Defroster

J15 40 Amp Green – Front Blower

J17 40 Amp Green – Starter Solenoid

J18 20 Amp Blue – Powertrain Control Module (PCM) Trans Range

J19 60 Amp Yellow – Radiator Fan

J20 30 Amp Pink – Front Wiper LO/HI

J21 20 Amp Blue – Front/Rear Washer

J22 – – Spare

M1 – 15 Amp Blue Center High-Mounted Stop Light (CHMSL)/Switch Stop

Lamp Feed

M2 – 20 Amp Yellow Relay Trailer Lighting (Stop lamp)

M3 – 20 Amp Yellow Front/Rear Axle Locker Relay

M4 – 2 Amp Grey Clock Spring

M5 – 25 Amp Clear Power Inverter – If Equipped

M6 – 20 Amp Yellow Power Outlet #1/Rain Sensor

M7 – 20 Amp Yellow Power Outlet #2 (BATT/ACC SELECT)

M8 – 20 Amp Yellow Front Heated Seat

151

Page 154 of 276

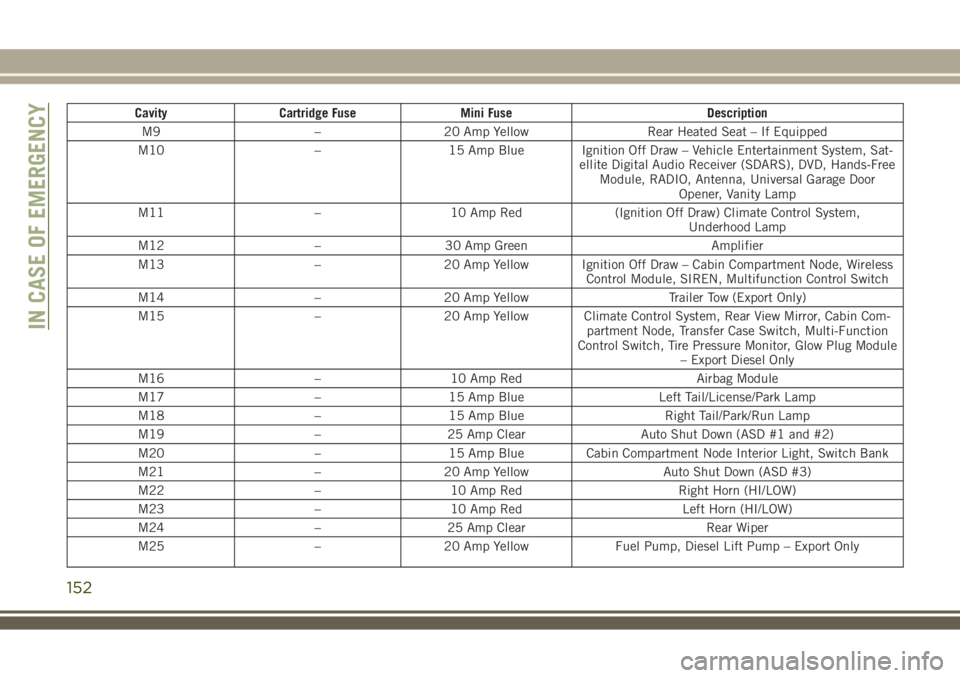

Cavity Cartridge Fuse Mini Fuse Description

M9 – 20 Amp Yellow Rear Heated Seat – If Equipped

M10 – 15 Amp Blue Ignition Off Draw – Vehicle Entertainment System, Sat-

ellite Digital Audio Receiver (SDARS), DVD, Hands-Free

Module, RADIO, Antenna, Universal Garage Door

Opener, Vanity Lamp

M11 – 10 Amp Red (Ignition Off Draw) Climate Control System,

Underhood Lamp

M12 – 30 Amp Green Amplifier

M13 – 20 Amp Yellow Ignition Off Draw – Cabin Compartment Node, Wireless

Control Module, SIREN, Multifunction Control Switch

M14 – 20 Amp Yellow Trailer Tow (Export Only)

M15 – 20 Amp Yellow Climate Control System, Rear View Mirror, Cabin Com-

partment Node, Transfer Case Switch, Multi-Function

Control Switch, Tire Pressure Monitor, Glow Plug Module

– Export Diesel Only

M16 – 10 Amp Red Airbag Module

M17 – 15 Amp Blue Left Tail/License/Park Lamp

M18 – 15 Amp Blue Right Tail/Park/Run Lamp

M19 – 25 Amp Clear Auto Shut Down (ASD #1 and #2)

M20 – 15 Amp Blue Cabin Compartment Node Interior Light, Switch Bank

M21 – 20 Amp Yellow Auto Shut Down (ASD #3)

M22 – 10 Amp Red Right Horn (HI/LOW)

M23 – 10 Amp Red Left Horn (HI/LOW)

M24 – 25 Amp Clear Rear Wiper

M25 – 20 Amp Yellow Fuel Pump, Diesel Lift Pump – Export Only

IN CASE OF EMERGENCY

152

Page 155 of 276

Cavity Cartridge Fuse Mini Fuse Description

M26 – 10 Amp Red Power Window Switch, Driver Window Switch

M27 – 10 Amp Red Ignition Switch Feed, Wireless Module

M28 – 10 Amp Red Powertrain Control Module

M29 – 10 Amp Red Powertrain

M30 – 15 Amp Blue Wiper Motor Frt, J1962 Diagnostic Feed

M31 – 20 Amp Yellow Backup Lamps

M32 – 10 Amp Red Airbag Controller, TT EUROPE

M33 – 10 Amp Red Powertrain Controller

M34 – 10 Amp Red Park Assist, Climate Control System,

Headlamp Wash, Compass

M35 – 10 Amp Red Heated Mirrors

M36 – 20 Amp Yellow Power Outlet

M37 – 10 Amp Red Anti-Lock Brake System, Electronic Stability Control,

Stop Lamp Switch, Fuel Pump Relay

M38 – 25 Amp Clear Lock/Unlock Motors

CAUTION!

• When installing the Integrated Power

Module cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the Integrated Power Module,

CAUTION!

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with a

CAUTION!

rating other than indicated may result in

a dangerous electrical system overload.

If a properly rated fuse continues to

blow, it indicates a problem in the circuit

that must be corrected.

153

Page 156 of 276

JACKING AND TIRE

CHANGING

WARNING!

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

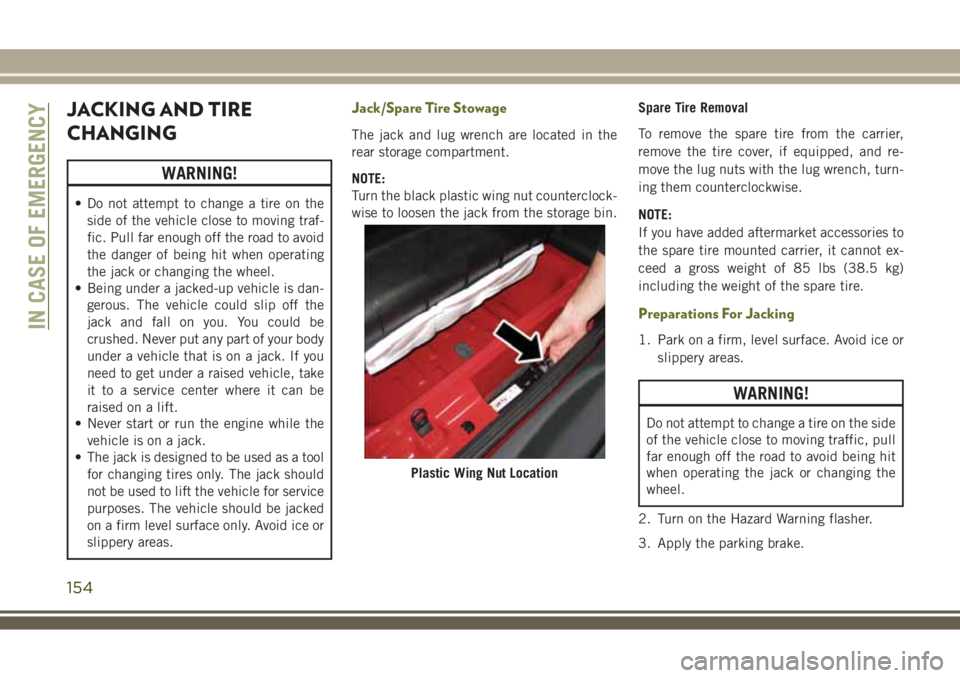

Jack/Spare Tire Stowage

The jack and lug wrench are located in the

rear storage compartment.

NOTE:

Turn the black plastic wing nut counterclock-

wise to loosen the jack from the storage bin.Spare Tire Removal

To remove the spare tire from the carrier,

remove the tire cover, if equipped, and re-

move the lug nuts with the lug wrench, turn-

ing them counterclockwise.

NOTE:

If you have added aftermarket accessories to

the spare tire mounted carrier, it cannot ex-

ceed a gross weight of 85 lbs (38.5 kg)

including the weight of the spare tire.

Preparations For Jacking

1. Park on a firm, level surface. Avoid ice or

slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic, pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.

Plastic Wing Nut Location

IN CASE OF EMERGENCY

154

Page 157 of 276

4. Shift the automatic transmission into

PARK, or a manual transmission into

REVERSE.

5. Turn the ignition to LOCK.

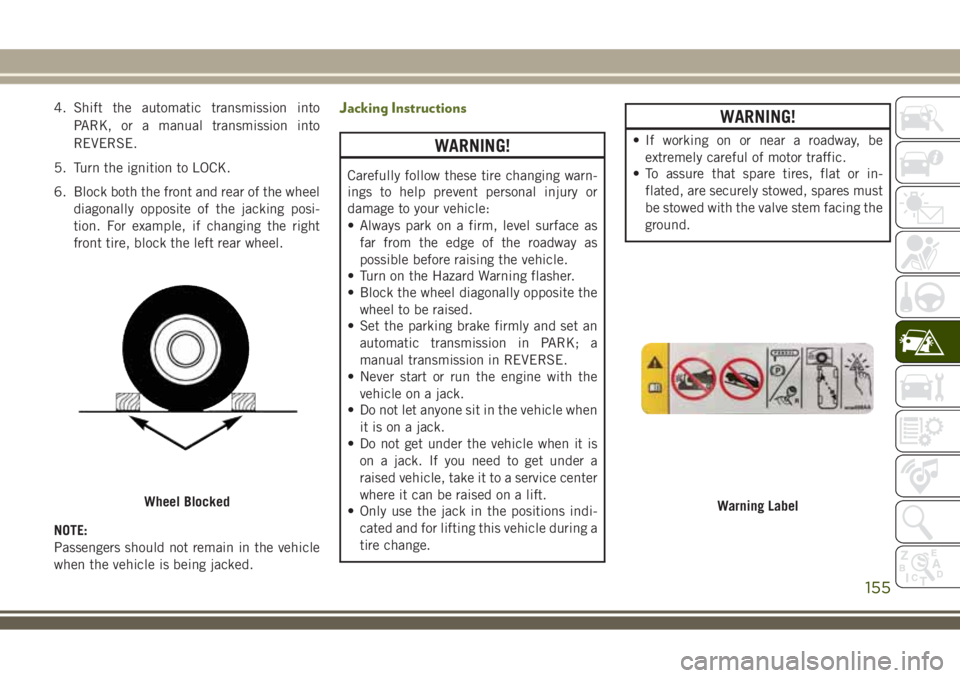

6. Block both the front and rear of the wheel

diagonally opposite of the jacking posi-

tion. For example, if changing the right

front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as

far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set an

automatic transmission in PARK; a

manual transmission in REVERSE.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, be

extremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

Wheel BlockedWarning Label

155

Page 158 of 276

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated.

1. Remove the spare tire, jack and tools from

the stored location.

2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left one turn

while the wheel is still on the ground.

3. Assemble the jack and jacking tools. Con-

nect the jack handle driver to the exten-

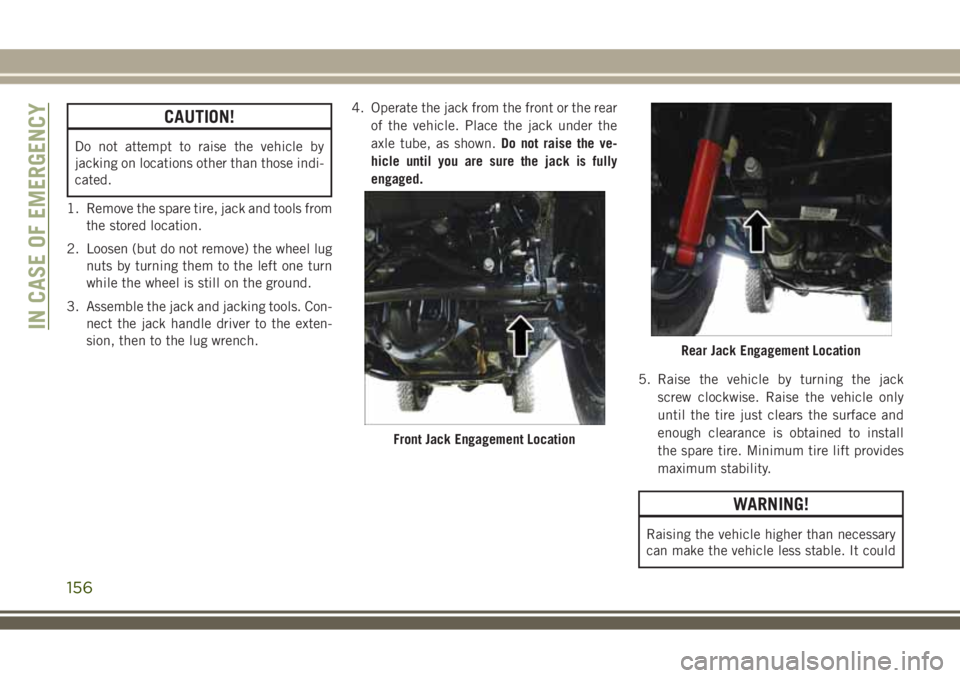

sion, then to the lug wrench.4. Operate the jack from the front or the rear

of the vehicle. Place the jack under the

axle tube, as shown.Do not raise the ve-

hicle until you are sure the jack is fully

engaged.

5. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

Front Jack Engagement Location

Rear Jack Engagement Location

IN CASE OF EMERGENCY

156

Page 159 of 276

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.9. Finish tightening the lug nuts. Push down

on the wrench while tightening for in-

creased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.

10. Remove the jack assembly and wheel

blocks.

11. Secure the tire, jack, and tools in their

proper locations.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

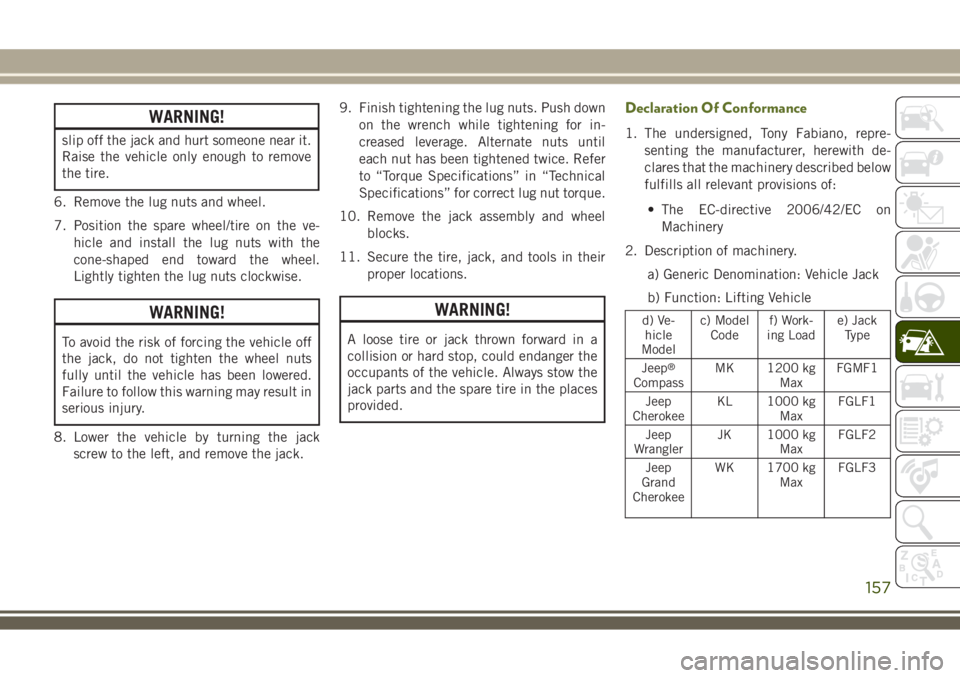

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described below

fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

157

Page 160 of 276

3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road,

Tottenham, ON CANADA L0G 1W0

4. Manufacturers (2):

FlexNGate Querétaro Ventramex,

S.A. de C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico5. Legal Person authorized to compile the

technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN 08960

6. References to harmonized standards:

PF-12074

7. Done at: Bradford, ON CANADA8. Date: 09/30/2015

IN CASE OF EMERGENCY

158