ABS JEEP WRANGLER 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: WRANGLER, Model: JEEP WRANGLER 2023Pages: 396, PDF Size: 25.15 MB

Page 246 of 396

244

SAFETY

SAFETY FEATURES

ANTI-LOCK BRAKE SYSTEM (ABS)

The ABS provides increased vehicle stability and brake

performance under most braking conditions. The system

automatically prevents wheel lock and enhances vehicle

control during braking.

The ABS performs a self-check cycle to ensure that the

ABS is working properly each time the vehicle is started

and driven. During this self-check, you may hear a slight

clicking sound as well as some related motor noises.

The ABS is activated during braking when the system

detects one or more wheels are beginning to lock. Road

conditions such as ice, snow, gravel, bumps, railroad

tracks, loose debris, or panic stops may increase the

likelihood of ABS activation(s).

You also may experience the following normal

characteristics when the ABS activates:

ABS motor noise or clicking sounds (you may continue

to hear for a short time after the stop)

Brake pedal pulsations

A slight drop of the brake pedal at the end of the stop

The ABS is designed to function with the Original

Equipment Manufacturer (OEM) tires. Modification may

result in degraded ABS performance.

Anti-Lock Brake System (ABS) Warning

Light

The yellow ABS Warning Light will turn on when the ignition

is placed in the ON/RUN mode and may stay on for as long

as four seconds.

If the ABS Warning Light remains on or comes on while

driving, it indicates that the anti-lock portion of the brake

system is not functioning and that service is required.

However, the conventional brake system will continue to

operate normally if the ABS Warning Light is on.

If the ABS Warning Light is on, the brake system should be

serviced as soon as possible to restore the benefits of

Anti-Lock Brakes. If the ABS Warning Light does not come

on when the ignition is placed in the ON/RUN mode, have

the light repaired as soon as possible.

REAR SEAT REMINDER ALERT (RSRA) —

I

F EQUIPPED

RSRA alerts you through a visual and auditory notification

of the possible presence of an object, passenger, or pet in

the rear seats if a rear door was opened up to 10 minutes

before the ignition was placed in the ON/RUN position.

RSRA does not directly detect objects, passengers, or pets

in the rear seats. When the previous conditions are met,

RSRA displays the message “Check Rear Seat” on the

instrument cluster display and sounds an auditory alert

upon the driver placing the ignition in the OFF position to

exit the vehicle.

WARNING!

The ABS contains sophisticated electronic equip -

ment that may be susceptible to interference caused

by improperly installed or high output radio transmit -

ting equipment. This interference can cause possible

loss of anti-lock braking capability. Installation of

such equipment should be performed by qualified

professionals.

Pumping of the Anti-Lock Brakes will diminish their

effectiveness and may lead to a collision. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

The ABS cannot prevent the natural laws of physics

from acting on the vehicle, nor can it increase

braking or steering efficiency beyond that afforded

by the condition of the vehicle brakes and tires or the

traction afforded.

The ABS cannot prevent collisions, including those

resulting from excessive speed in turns, following

another vehicle too closely, or hydroplaning.

The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner that could jeopardize the user’s safety or the

safety of others.

23_JL_OM_EN_USC_t.book Page 244

Page 247 of 396

SAFETY245

To enable or disable RSRA, see Úpage 184.

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

If applicable, refer to the “Hybrid Supplement” for

additional information.

Your vehicle is equipped with an advanced Electronic

Brake Control (EBC) system. This system includes

Anti-Lock Brake System (ABS), Brake Assist System (BAS),

Electronic Brake Force Distribution (EBD), Electronic Roll

Mitigation (ERM), Electronic Stability Control (ESC), Hill

Start Assist (HSA), and Traction Control System (TCS). These systems work together to enhance both vehicle

stability and control in various driving conditions.

Your vehicle may also be equipped with Hill Descent

Control (HDC), Rain Brake Support (RBS), Ready Alert

Braking (RAB), and Trailer Sway Control (TSC).

Brake System Warning Light

The red Brake System Warning Light will turn on when the

ignition is placed in the ON/RUN mode and may stay on for

as long as four seconds.

If the Brake System Warning Light remains on or comes on

while driving, it indicates that the brake system is not

functioning properly and that immediate service is

required. If the Brake System Warning Light does not

come on when the ignition is placed in the ON/RUN mode,

have the light repaired as soon as possible.

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s braking

capability during emergency braking maneuvers. The

system detects an emergency braking situation by sensing

the rate and amount of brake application and then applies

optimum pressure to the brakes. This can help reduce

braking distances. The BAS complements the Anti-Lock

Brake System (ABS). Applying the brakes very quickly

results in the best BAS assistance. To receive the benefit

of the system, you must apply continuous braking

pressure during the stopping sequence (do not “pump”

the brakes). Do not reduce brake pedal pressure unless

braking is no longer desired. Once the brake pedal is

released, the BAS is deactivated.

Electronic Brake Force Distribution (EBD)

EBD manages the distribution of the braking torque

between the front and rear axles by limiting braking

pressure to the rear axle. This is done to prevent overslip

of the rear wheels to avoid vehicle instability, and to

prevent the rear axle from entering ABS before the front

axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by monitoring

the driver’s steering wheel input and the speed of the

vehicle. When ERM determines that the rate of change of

the steering wheel angle and vehicle’s speed are

sufficient to potentially cause wheel lift, it then applies the

appropriate brake and may also reduce engine power to

lessen the chance that wheel lift will occur. ERM can only

reduce the chance of wheel lift occurring during severe or

evasive driving maneuvers; it cannot prevent wheel lift

due to other factors, such as road conditions, leaving the

roadway, or striking objects or other vehicles.

WARNING!

Before exiting a vehicle, always come to a complete

stop, then shift the automatic transmission into

PARK and apply the parking brake.

Always make sure the keyless ignition node is in the

OFF position, key fob is removed from the vehicle

and vehicle is locked.

Never leave children alone in a vehicle, or with

access to an unlocked vehicle. Leaving children in a

vehicle unattended is dangerous for a number of

reasons. A child or others could be seriously or fatally

injured. Children should be warned not to touch the

parking brake, brake pedal or the gear selector.

Do not leave children or animals inside parked vehi -

cles in hot weather. Interior heat buildup may cause

serious injury or death.

WARNING!

The Brake Assist System (BAS) cannot prevent the natu -

ral laws of physics from acting on the vehicle, nor can it

increase the traction afforded by prevailing road condi -

tions. BAS cannot prevent collisions, including those

resulting from excessive speed in turns, driving on very

slippery surfaces, or hydroplaning. The capabilities of a

BAS-equipped vehicle must never be exploited in a

reckless or dangerous manner, which could jeopardize

the user's safety or the safety of others.

6

23_JL_OM_EN_USC_t.book Page 245

Page 276 of 396

274SAFETY

The following requirements must be strictly followed:

Do not modify the front passenger seat assembly or

components in any way.

Do not use prior or future model year seat covers or

cushions not designated by FCA US LLC for the specific

model being repaired. Always use the correct seat

cover and cushion specified for the vehicle.

Do not replace the seat cover or cushion with an after -

market seat cover or cushion.

Do not add a secondary seat cover or mat.

At no time should any Supplemental Restraint System

(SRS) component or SRS related component or

fastener be modified or replaced with any part except

those which are approved by FCA US LLC.Knee Impact Bolsters

The knee impact bolsters help protect the knees of the

driver and front passenger, and position the front

occupants for improved interaction with the front air bags.

Supplemental Side Air Bags

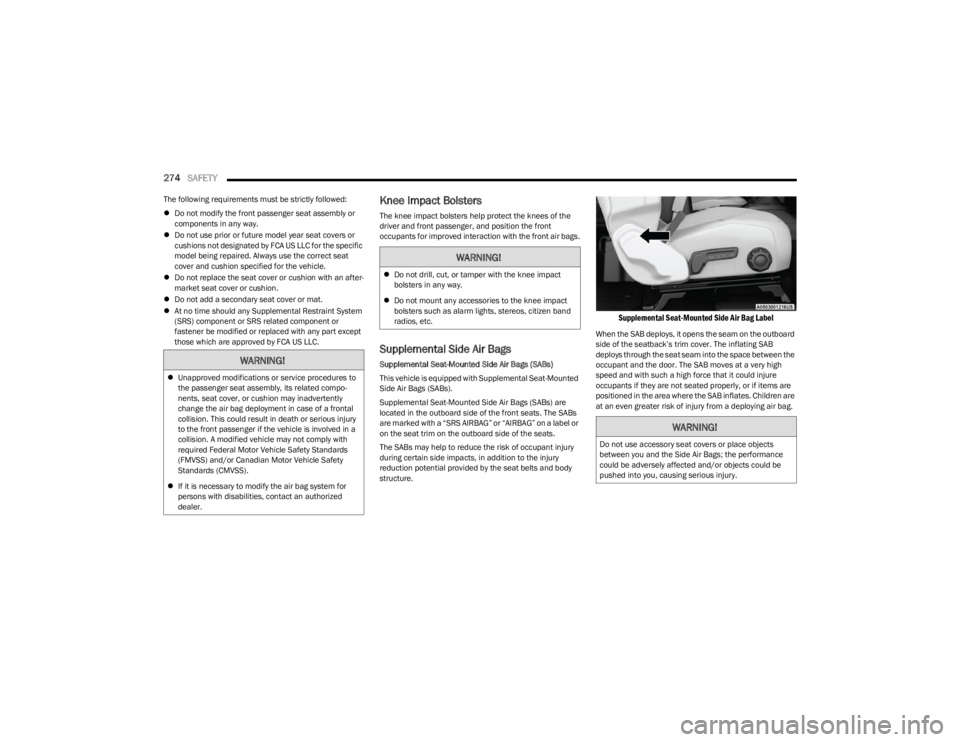

Supplemental Seat-Mounted Side Air Bags (SABs)

This vehicle is equipped with Supplemental Seat-Mounted

Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags (SABs) are

located in the outboard side of the front seats. The SABs

are marked with a “SRS AIRBAG” or “AIRBAG” on a label or

on the seat trim on the outboard side of the seats.

The SABs may help to reduce the risk of occupant injury

during certain side impacts, in addition to the injury

reduction potential provided by the seat belts and body

structure.

Supplemental Seat-Mounted Side Air Bag Label

When the SAB deploys, it opens the seam on the outboard

side of the seatback’s trim cover. The inflating SAB

deploys through the seat seam into the space between the

occupant and the door. The SAB moves at a very high

speed and with such a high force that it could injure

occupants if they are not seated properly, or if items are

positioned in the area where the SAB inflates. Children are

at an even greater risk of injury from a deploying air bag.

WARNING!

Unapproved modifications or service procedures to

the passenger seat assembly, its related compo -

nents, seat cover, or cushion may inadvertently

change the air bag deployment in case of a frontal

collision. This could result in death or serious injury

to the front passenger if the vehicle is involved in a

collision. A modified vehicle may not comply with

required Federal Motor Vehicle Safety Standards

(FMVSS) and/or Canadian Motor Vehicle Safety

Standards (CMVSS).

If it is necessary to modify the air bag system for

persons with disabilities, contact an authorized

dealer.

WARNING!

Do not drill, cut, or tamper with the knee impact

bolsters in any way.

Do not mount any accessories to the knee impact

bolsters such as alarm lights, stereos, citizen band

radios, etc.

WARNING!

Do not use accessory seat covers or place objects

between you and the Side Air Bags; the performance

could be adversely affected and/or objects could be

pushed into you, causing serious injury.

23_JL_OM_EN_USC_t.book Page 274

Page 319 of 396

SERVICING AND MAINTENANCE317

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop. The best time to

check the engine oil level is about five minutes after a fully

warmed up engine is shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low end of

the range and MAX at the high end of the range.

Crosshatched zone marked with dimples at the MIN

and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

NOTE:Use care when filling under hood fluids such as engine oil,

washer fluid, antifreeze, etc., to minimize spillage onto the

top of the engine. Any excess fluid that is spilled onto the

top of the engine should be removed using compressed

air or an absorbent cloth.

Adding 1 qt (1 L) of oil when the reading is at the low end

of the dipstick range will raise the oil level to the high end

of the range marking.

ADDING WASHER FLUID

The fluid reservoir for the windshield washers and the rear

window washer (if equipped) is shared. The fluid reservoir

is located in the engine compartment. Be sure to check

the fluid level at regular intervals. Fill the reservoir with

windshield washer solvent only (not radiator antifreeze).

When refilling the washer fluid reservoir, take some

washer fluid and apply it to a cloth or towel and wipe clean

the wiper blades; this will help blade performance.

To prevent freeze-up of your windshield washer system in

cold weather, select a solution or mixture that meets or

exceeds the temperature range of your climate. This rating

information can be found on most washer fluid containers.

NOTE:Use care when filling under hood fluids such as engine oil,

washer fluid, antifreeze, etc., to minimize spillage onto the

top of the engine. Any excess fluid that is spilled onto the

top of the engine should be removed using compressed

air or an absorbent cloth.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free battery.

You will never have to add water, and periodic

maintenance is not required.

CAUTION!

Overfilling or underfilling the crankcase will cause

aeration or loss of oil pressure. This could damage your

engine.

WARNING!

Commercial windshield washer solvents are flammable.

They could ignite and burn you. Care must be exercised

when filling or working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and can burn

or even blind you. Do not allow battery fluid to

contact your eyes, skin, or clothing. Do not lean over

a battery when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately with large

amounts of water

Úpage 298.

Battery gas is flammable and explosive. Keep flame

or sparks away from the battery. Do not use a

booster battery or any other booster source with an

output greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands after

handling.

Vehicles with the Stop/Start system will be equipped

with two batteries. Both the main and the supple -

mental batteries must be disconnected to

completely de-energize the 12 Volt electrical system.

Serious injury or death could result if you do not

disconnect both batteries. To learn how to properly

disconnect, see an authorized dealer.

8

23_JL_OM_EN_USC_t.book Page 317

Page 327 of 396

SERVICING AND MAINTENANCE325

Refrigerant Recovery And Recycling —

R–1234yf

R–1234yf Air Conditioning Refrigerant is a Hydrofluo -

roolefin (HFO) that is endorsed by the Environmental

Protection Agency and is an ozone-friendly substance with

a low global-warming potential. The manufacturer

recommends that air conditioning service be performed by

an authorized dealer using recovery and recycling

equipment.

NOTE:Use only the manufacturer approved A/C system PAG

compressor oil, and refrigerants.

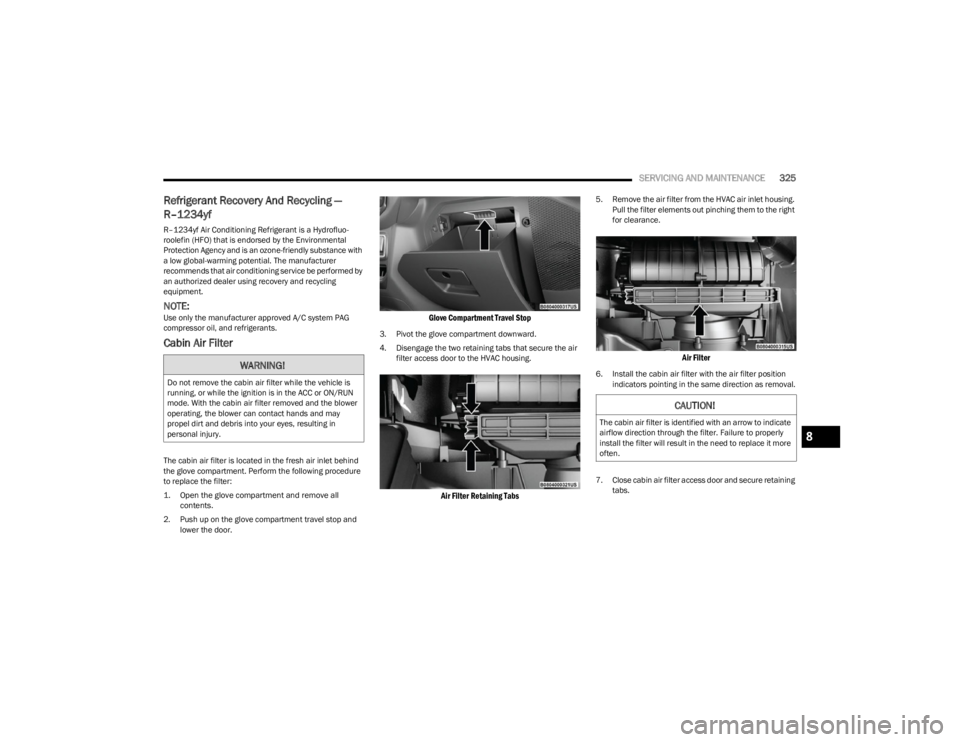

Cabin Air Filter

The cabin air filter is located in the fresh air inlet behind

the glove compartment. Perform the following procedure

to replace the filter:

1. Open the glove compartment and remove all contents.

2. Push up on the glove compartment travel stop and lower the door.

Glove Compartment Travel Stop

3. Pivot the glove compartment downward.

4. Disengage the two retaining tabs that secure the air filter access door to the HVAC housing.

Air Filter Retaining Tabs

5. Remove the air filter from the HVAC air inlet housing. Pull the filter elements out pinching them to the right

for clearance.

Air Filter

6. Install the cabin air filter with the air filter position indicators pointing in the same direction as removal.

7. Close cabin air filter access door and secure retaining tabs.WARNING!

Do not remove the cabin air filter while the vehicle is

running, or while the ignition is in the ACC or ON/RUN

mode. With the cabin air filter removed and the blower

operating, the blower can contact hands and may

propel dirt and debris into your eyes, resulting in

personal injury.

CAUTION!

The cabin air filter is identified with an arrow to indicate

airflow direction through the filter. Failure to properly

install the filter will result in the need to replace it more

often.

8

23_JL_OM_EN_USC_t.book Page 325

Page 332 of 396

330SERVICING AND MAINTENANCE

NOTE:

It is the owner's responsibility to maintain the proper

level of protection against freezing according to the

temperatures occurring in the area where the vehicle is

operated.

Use care when filling under hood fluids such as engine

oil, washer fluid, antifreeze, etc., to minimize spillage

onto the top of the engine. Any excess fluid that is

spilled onto the top of the engine should be removed

using compressed air or an absorbent cloth.

Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could

lead to severe internal engine damage. If any coolant is

needed to be added to the system, please contact an

authorized dealer.

Mixing engine coolant types is not recommended and

can result in cooling system damage. If HOAT and OAT

coolant are mixed in an emergency, have an authorized

dealer drain, flush, and refill with OAT coolant

(conforming to MS.90032) as soon as possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of engine

coolant (antifreeze), and to ensure that engine coolant will

return to the radiator from the coolant expansion bottle/

recovery tank if so equipped.

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) OAT or

HOAT, is a regulated substance requiring proper disposal.

Check with your local authorities to determine the disposal

rules for your community. To prevent ingestion by animals

or children, do not store ethylene glycol-based coolant in

open containers or allow it to remain in puddles on the

ground, clean up any ground spills immediately. If

ingested, seek emergency assistance immediately.

Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With the

engine OFF and cold, the level of the engine coolant

(antifreeze) in the bottle should be between the ranges

indicated on the bottle. The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant freeze point or

replacing coolant. Advise your service attendant of this. As

long as the engine operating temperature is satisfactory,

the coolant bottle need only be checked once a month.

When additional engine coolant is needed to maintain the

proper level, only OAT coolant that meets the

requirements of the manufacturer Material Standard

MS.90032 should be added to the coolant bottle. Do not

overfill.

Engine Coolant Level — 2.0L

WARNING!

Do not open hot engine cooling system. Never add

engine coolant (antifreeze) when the engine is over -

heated. Do not loosen or remove the cap to cool an

overheated engine. Heat causes pressure to build up

in the cooling system. To prevent scalding or injury,

do not remove the pressure cap while the system is

hot or under pressure.

Do not use a pressure cap other than the one speci -

fied for your vehicle. Personal injury or engine

damage may result.

WARNING!

Do not open hot engine cooling system. Never add

engine coolant (antifreeze) when the engine is over -

heated. Do not loosen or remove the cap to cool an

overheated engine. Heat causes pressure to build up

in the cooling system. To prevent scalding or injury,

do not remove the pressure cap while the system is

hot or under pressure.

Do not use a pressure cap other than the one speci -

fied for your vehicle. Personal injury or engine

damage may result.

23_JL_OM_EN_USC_t.book Page 330

Page 334 of 396

332SERVICING AND MAINTENANCE

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the fluid

level.

Fluid Level Check

Lubricant should be approximately 1/8 inch (3 mm) below

the bottom edge of the oil fill hole.

NOTE:Make sure that the vehicle is level and supported by the

axles.

Adding Fluid

Add lubricant only at the fill hole and only to the level

specified above.

Selection Of Lubricant

Use only manufacturer recommended fluid Úpage 376.

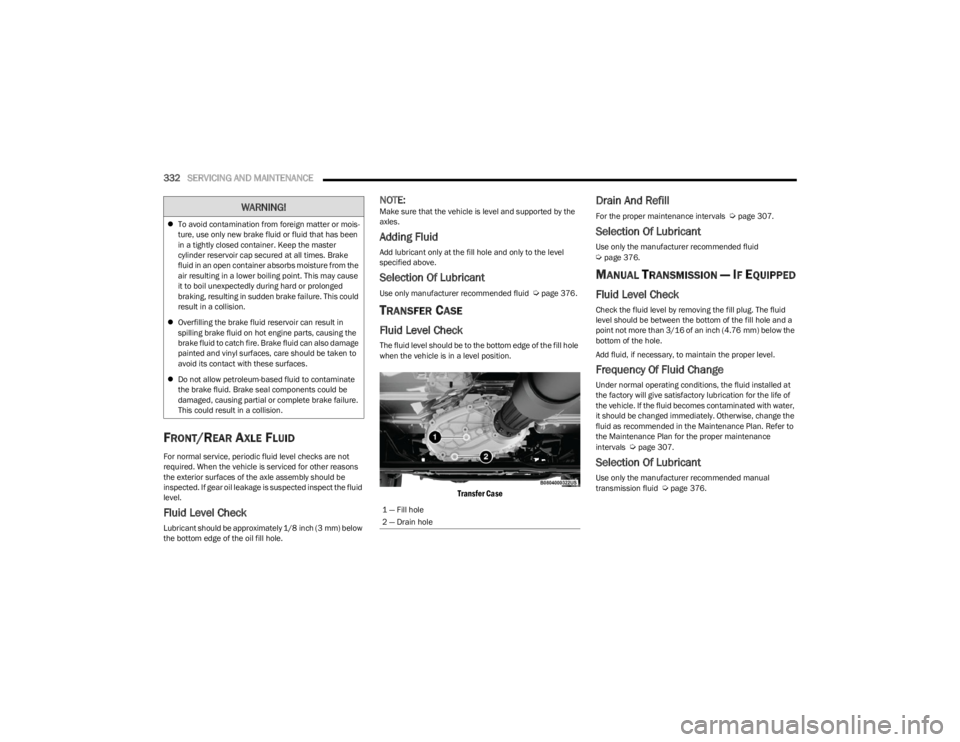

TRANSFER CASE

Fluid Level Check

The fluid level should be to the bottom edge of the fill hole

when the vehicle is in a level position.

Transfer Case

Drain And Refill

For the proper maintenance intervals Úpage 307.

Selection Of Lubricant

Use only the manufacturer recommended fluid Úpage 376.

MANUAL TRANSMISSION — IF EQUIPPED

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more than 3/16 of an inch (4.76 mm) below the

bottom of the hole.

Add fluid, if necessary, to maintain the proper level.

Frequency Of Fluid Change

Under normal operating conditions, the fluid installed at

the factory will give satisfactory lubrication for the life of

the vehicle. If the fluid becomes contaminated with water,

it should be changed immediately. Otherwise, change the

fluid as recommended in the Maintenance Plan. Refer to

the Maintenance Plan for the proper maintenance

intervals

Úpage 307.

Selection Of Lubricant

Use only the manufacturer recommended manual

transmission fluid Úpage 376.

To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in an open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum-based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

WARNING!

1 — Fill hole

2 — Drain hole

23_JL_OM_EN_USC_t.book Page 332

Page 348 of 396

346SERVICING AND MAINTENANCE

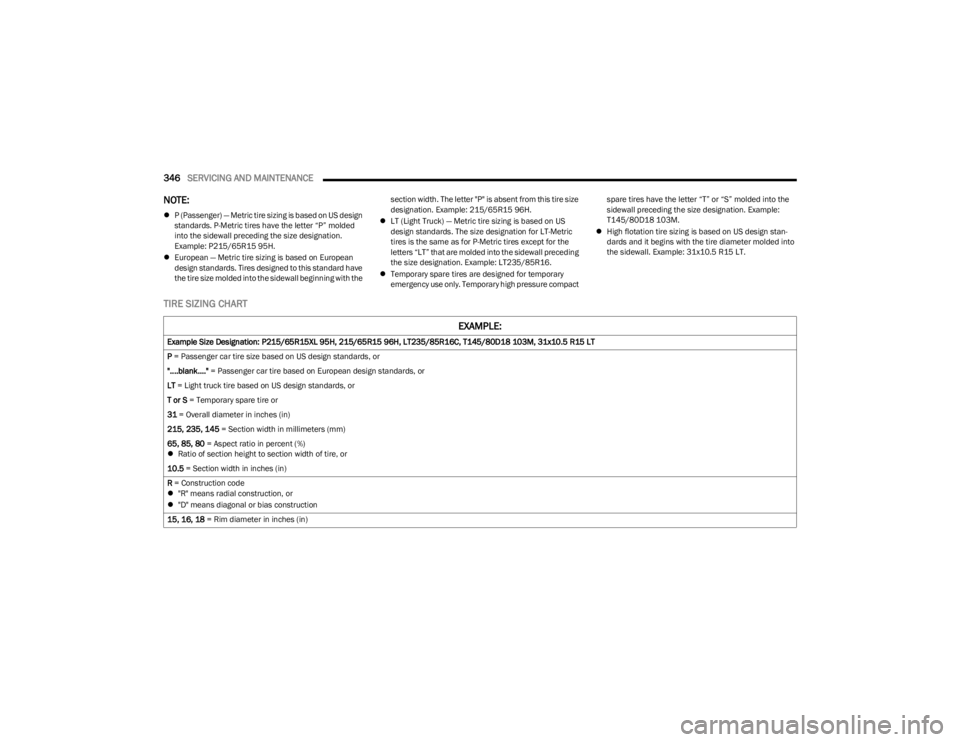

NOTE:

P (Passenger) — Metric tire sizing is based on US design

standards. P-Metric tires have the letter “P” molded

into the sidewall preceding the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with the section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on US

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters “LT” that are molded into the sidewall preceding

the size designation. Example: LT235/85R16.

Temporary spare tires are designed for temporary

emergency use only. Temporary high pressure compact spare tires have the letter “T” or “S” molded into the

sidewall preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US design stan -

dards and it begins with the tire diameter molded into

the sidewall. Example: 31x10.5 R15 LT.

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

23_JL_OM_EN_USC_t.book Page 346

Page 349 of 396

SERVICING AND MAINTENANCE347

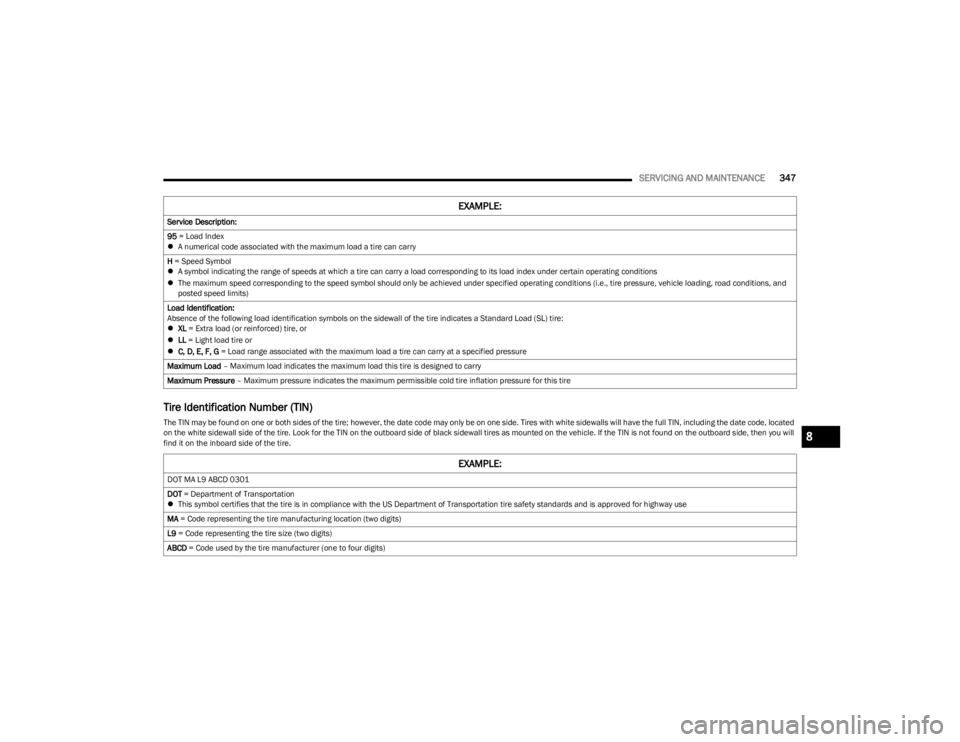

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls will have the full TIN, including the date code, located

on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as mounted on the vehicle. If the TIN is not found on the outboard side, then you will

find it on the inboard side of the tire.Service Description:

95

= Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and

posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

8

23_JL_OM_EN_USC_t.book Page 347

Page 381 of 396

CUSTOMER ASSISTANCE379

CUSTOMER ASSISTANCE FOR THE

H

EARING OR SPEECH IMPAIRED

(TDD/TTY)

To assist customers who have hearing difficulties, FCA US

LLC has installed special Telecommunication Devices for

the Deaf (TDD) equipment at its customer center. Any

hearing or speech impaired customer, who has access to

a TDD or a conventional teletypewriter (TTY) in the United

States, can communicate with the manufacturer by dialing

1-800-380-2479.

Canadian residents with hearing difficulties that require

assistance can use the special needs relay service offered

by Bell Canada. For TTY teletypewriter users, dial 711 and

for Voice callers, dial 1-800-855-0511 to connect with a

Bell Relay Service operator.

SERVICE CONTRACT

You may have purchased a service contract for a vehicle

to help protect you from the high cost of unexpected

repairs after FCA US LLC’s New Vehicle Limited Warranty

expires. The Mopar® Vehicle Protection plans are the

ONLY vehicle extended protection plans authorized,

endorsed and backed by FCA US LLC to provide additional

protection beyond your vehicle’s warranty. If you

purchased a Mopar® Vehicle Protection Plan, you will

receive Plan Provisions and an Owner Identification Card

in the mail within three weeks of the vehicle delivery date.

If you have any questions about the service contract, call

the manufacturer's Service Contract National Customer

Hotline at 1-800-521-9922 (Canadian residents, call

(800) 465-2001 English /(800) 387-9983 French). FCA US LLC is not responsible for any service contract you

may have purchased from another manufacturer. If you

require service after FCA US LLC’s New Vehicle Limited

Warranty expires, please refer to the contract documents,

and contact the person listed in those documents.

We appreciate that you have made a major investment

when you purchased the vehicle. An authorized dealer has

also made a major investment in facilities, tools, and

training to assure that you are absolutely delighted with

the ownership experience.

WARRANTY INFORMATION

See the Warranty Information for the terms and provisions

of FCA US LLC warranties applicable to this vehicle and

market. Refer to www.mopar.com/om for further

information.

See the Warranty Information for the terms and provisions

of FCA Canada Inc. warranties applicable to this vehicle

and market.

Use this QR code to access your digital

experience.

MOPAR® PARTS

Mopar® original equipment parts & accessories and

factory filled fluids are available from an authorized

dealer. They are recommended for your vehicle to keep it

operating at its best and maintain its original condition.

REPORTING SAFETY DEFECTS

IN THE 50 UNITED STATES AND

W

ASHINGTON, D.C.

If you believe that your vehicle has a

defect that could cause a crash or cause

injury or death, you should immediately

inform the National Highway Traffic

Safety Administration (NHTSA) in

addition to notifying FCA US LLC.

If NHTSA receives similar complaints, it

may open an investigation, and if it finds

that a safety defect exists in a group of

vehicles, it may order a recall and

WARNING!

Engine exhaust (internal combustion engines only),

some of its constituents, and certain vehicle

components contain, or emit, chemicals known to the

State of California to cause cancer and birth defects, or

other reproductive harm. In addition, certain fluids

contained in vehicles and certain products of

component wear contain, or emit, chemicals known to

the State of California to cause cancer and birth

defects, or other reproductive harm.

10

23_JL_OM_EN_USC_t.book Page 379