warning light JEEP WRANGLER UNLIMITED 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: WRANGLER UNLIMITED, Model: JEEP WRANGLER UNLIMITED 2019Pages: 348, PDF Size: 6.5 MB

Page 163 of 348

NOTE:

• In order to ensure proper operation, the

Speed Control System has been designed

to shut down if multiple Speed Control

functions are operated at the same time. If

this occurs, the Speed Control System can

be reactivated by pushing the Speed Con-

trol on/off button and resetting the desired

vehicle set speed.

• Do not place the gear selector in neutral

when Speed Control is activated. Doing so

will disengage the system.

WARNING!

Speed Control can be dangerous where the

system cannot maintain a constant speed.

Your vehicle could go too fast for the con-

ditions, and you could lose control and

have an accident. Do not use Speed Con-

trol in heavy traffic or on roads that are

winding, icy, snow-covered or slippery.

To Activate

Push the on/off button to activate the Speed

Control. The cruise indicator light in the in-

strument cluster display will illuminate. Toturn the system off, push the on/off button a

second time. The cruise indicator light will

turn off. The system should be turned off

when not in use.

WARNING!

Leaving the Speed Control system on when

not in use is dangerous. You could acci-

dentally set the system or cause it to go

faster than you want. You could lose con-

trol and have an accident. Always leave the

system off when you are not using it.

To Set A Desired Speed

Turn the Speed Control on.

NOTE:

The vehicle should be traveling at a steady

speed and on level ground before pushing the

SET (+) or SET (-) button.

When the vehicle has reached the desired

speed, push the SET (+) or SET (-) button and

release. Release the accelerator and the ve-

hicle will operate at the selected speed.

To Vary The Speed Setting

To Increase Speed

When the Speed Control is set, you can in-

crease speed by pushing the SET(+)button.

The driver’s preferred units can be selected

through the instrument panel settings. Refer

to ”Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” in your Own-

er’s Manual for more information. The speed

increment shown is dependent on the chosen

speed unit of U.S. (mph) or Metric (km/h):

U.S. Speed (mph)

• Pushing the SET(+)button once will result

in a 1 mph increase in set speed. Each

subsequent tap of the button results in an

increase of 1 mph.

• If the button is continually pushed, the set

speed will continue to increase until the

button is released, then the new set speed

will be established.

161

Page 164 of 348

Metric Speed (km/h)

• Pushing the SET(+)button once will result

in a 1 km/h increase in set speed. Each

subsequent tap of the button results in an

increase of 1 km/h.

• If the button is continually pushed, the set

speed will continue to increase until the

button is released, then the new set speed

will be established.

To Decrease Speed

When the Speed Control is set, you can de-

crease speed by pushing the SET(-)button.

The driver’s preferred units can be selected

through the instrument panel settings. Refer

to ”Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” in your Own-

er’s Manual for more information. The speed

increment shown is dependent on the chosen

speed unit of U.S. (mph) or Metric (km/h):

U.S. Speed (mph)

• Pushing the SET(-)button once will result

in a 1 mph decrease in set speed. Each

subsequent tap of the button results in a

decrease of 1 mph.• If the button is continually pushed, the set

speed will continue to decrease until the

button is released, then the new set speed

will be established.

Metric Speed (km/h)

• Pushing the SET(-)button once will result

in a 1 km/h decrease in set speed. Each

subsequent tap of the button results in a

decrease of 1 km/h.

• If the button is continually pushed, the set

speed will continue to decrease until the

button is released, then the new set speed

will be established.

To Accelerate For Passing

Press the accelerator as you would normally.

When the pedal is released, the vehicle will

return to the set speed.

Using Speed Control On Hills

The transmission may downshift on hills to

maintain the vehicle set speed.

NOTE:

The Speed Control system maintains speed

up and down hills. A slight speed change on

moderate hills is normal.On steep hills, a greater speed loss or gain

may occur so it may be preferable to drive

without Speed Control.

WARNING!

Speed Control can be dangerous where the

system cannot maintain a constant speed.

Your vehicle could go too fast for the con-

ditions, and you could lose control and

have an accident. Do not use Speed Con-

trol in heavy traffic or on roads that are

winding, icy, snow-covered or slippery.

To Resume Speed

To resume a previously set speed, push the

RES button and release. Resume can be used

at any speed above 20 mph (32 km/h).

To Deactivate

A soft tap on the brake pedal, pushing the

CANC (cancel) button, or normal brake pres-

sure while slowing the vehicle will deactivate

the speed control without erasing the set

speed from memory.

STARTING AND OPERATING

162

Page 168 of 348

CAUTION!

• To avoid vehicle damage, ParkView

should only be used as a parking aid.

The ParkView camera is unable to view

every obstacle or object in your drive

path.

• To avoid vehicle damage, the vehicle

must be driven slowly when using

ParkView to be able to stop in time when

an obstacle is seen. It is recommended

that the driver look frequently over his/

her shoulder when using ParkView.

NOTE:

If snow, ice, mud, or any foreign substance

builds up on the camera lens, clean the lens,

rinse with water, and dry with a soft cloth. Do

not cover the lens.

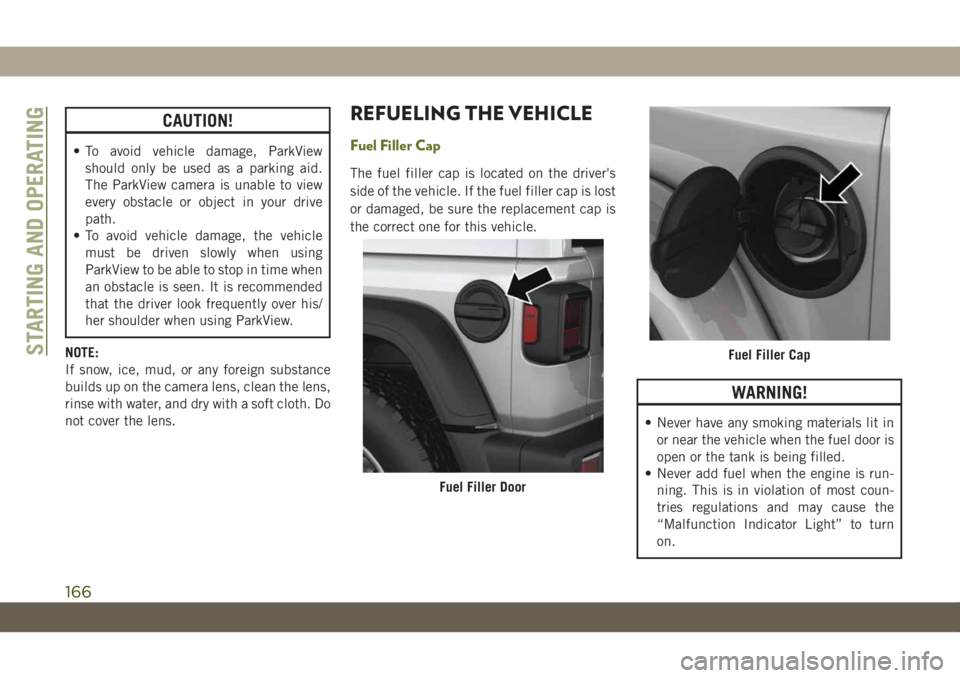

REFUELING THE VEHICLE

Fuel Filler Cap

The fuel filler cap is located on the driver's

side of the vehicle. If the fuel filler cap is lost

or damaged, be sure the replacement cap is

the correct one for this vehicle.

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

Fuel Filler Door

Fuel Filler CapSTARTING AND OPERATING

166

Page 169 of 348

WARNING!

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

• Damage to the fuel system or emission

control system could result from using

an improper fuel filler cap. A poorly

fitting cap could let impurities into the

fuel system. Also, a poorly fitting after-

market cap can cause the “Malfunction

Indicator Light (MIL)” to illuminate, due

to fuel vapors escaping from the system.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.NOTE:

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.

• Tighten the fuel filler cap about 1/4 turn

until you hear one click. This is an indica-

tion that the cap is properly tightened.

• If the fuel filler cap is not tightened prop-

erly, the MIL will come on. Be sure the cap

is tightened every time the vehicle is

refueled.

Loose Fuel Filler Cap Message

After fuel has been added, the vehicle diag-

nostic system can determine if the fuel filler

cap is possibly loose, improperly installed, or

damaged. If the system detects a malfunc-

tion, the “gASCAP” message will display in

the odometer display. Tighten the gas cap

until a "clicking" sound is heard. This is an

indication that the gas cap is properly tight-

ened. Push the odometer reset button to turn

the message off. If the problem persists, the

message will appear the next time the vehicle

is started. This might indicate a damagedcap. If the problem is detected twice in a row,

the system will turn on the MIL. Resolving the

problem will turn the MIL off.

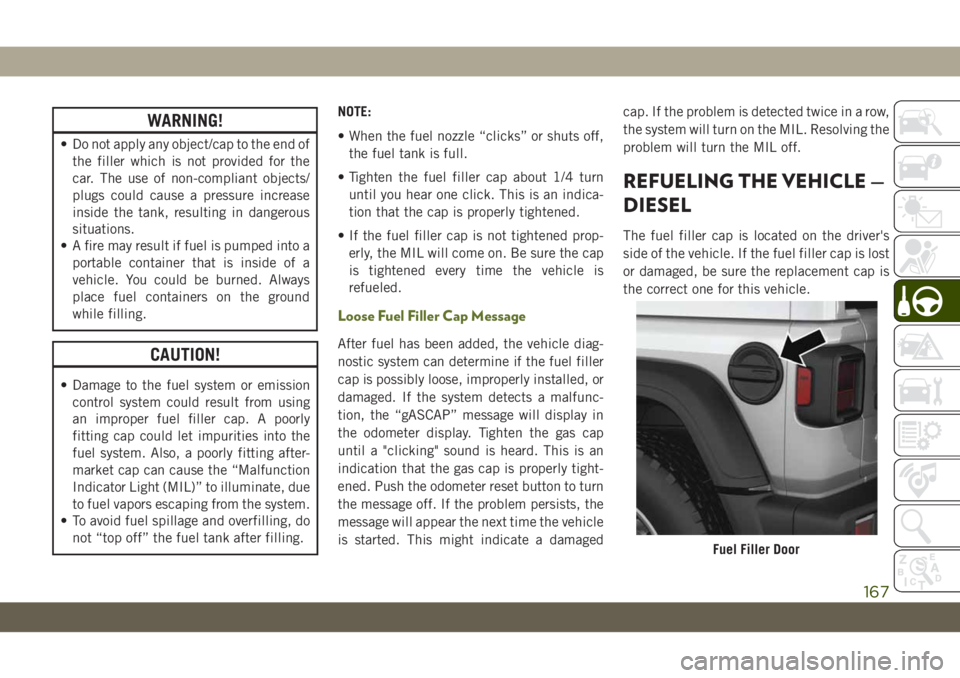

REFUELING THE VEHICLE —

DIESEL

The fuel filler cap is located on the driver's

side of the vehicle. If the fuel filler cap is lost

or damaged, be sure the replacement cap is

the correct one for this vehicle.

Fuel Filler Door

167

Page 170 of 348

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

WARNING!

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

• Damage to the fuel system or emission

control system could result from using

an improper fuel filler cap. A poorly

fitting cap could let impurities into the

fuel system. Also, a poorly fitting after-

market cap can cause the “Malfunction

Indicator Light (MIL)” to illuminate, due

to fuel vapors escaping from the system.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.NOTE:

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.

• Tighten the fuel filler cap about 1/4 turn

until you hear one click. This is an indica-

tion that the cap is properly tightened.

• If the fuel filler cap is not tightened prop-

erly, the MIL will come on. Be sure the cap

is tightened every time the vehicle is

refueled.

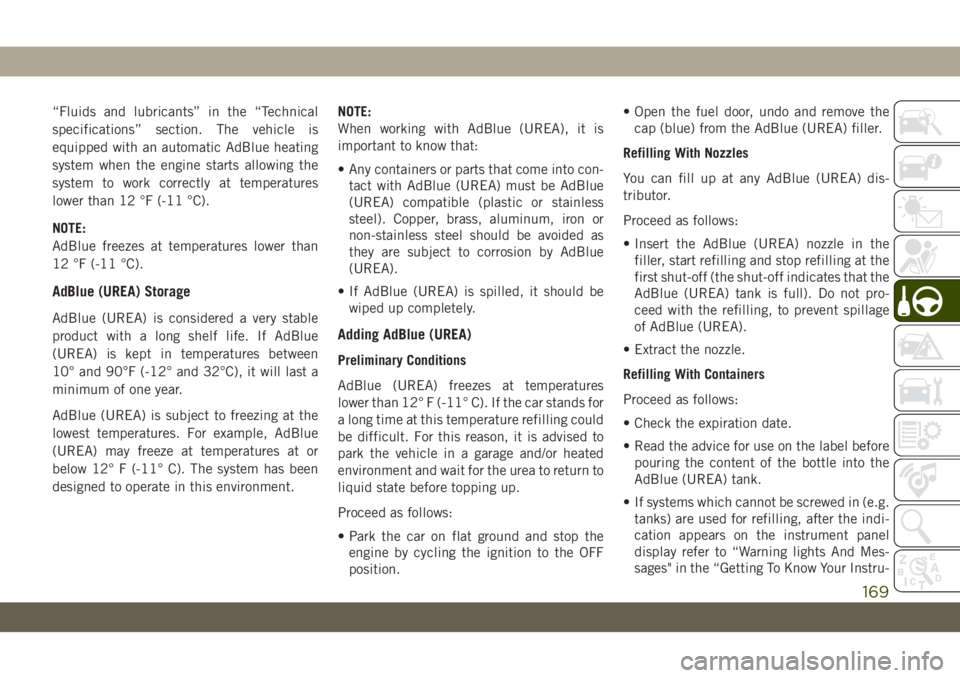

Adblue (UREA) — If Equipped

The vehicle is equipped with an UREA injec-

tion system and Selective Catalytic Reduc-

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same, they

ensure fuel-efficiency, handling, torque and

power. For messages and system warnings,

refer to the "Warning Lights And Messages" in

the "Getting To Know Your Instrument Panel"

section. AdBlue (UREA) is a very stable prod-

uct with a long shelf life. Stored at tempera-

tures LOWER than 90 °F (32 °C), it has a

shelf life of at least one year. For more infor-

mation on the AdBlue liquid type, see the

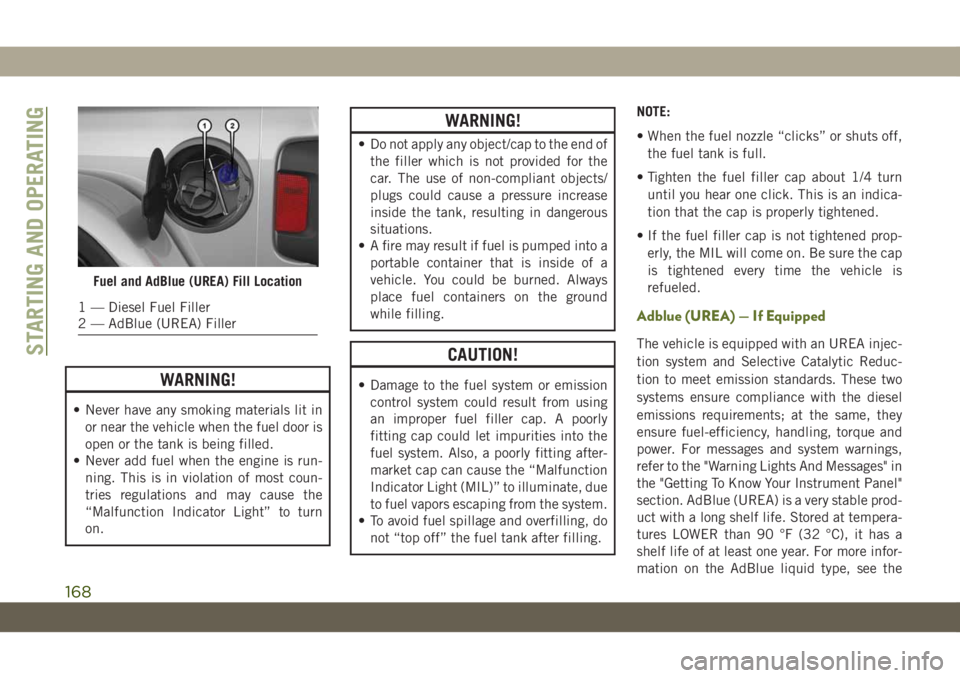

Fuel and AdBlue (UREA) Fill Location

1 — Diesel Fuel Filler

2 — AdBlue (UREA) Filler

STARTING AND OPERATING

168

Page 171 of 348

“Fluids and lubricants” in the “Technical

specifications” section. The vehicle is

equipped with an automatic AdBlue heating

system when the engine starts allowing the

system to work correctly at temperatures

lower than 12 °F (-11 °C).

NOTE:

AdBlue freezes at temperatures lower than

12 °F (-11 °C).

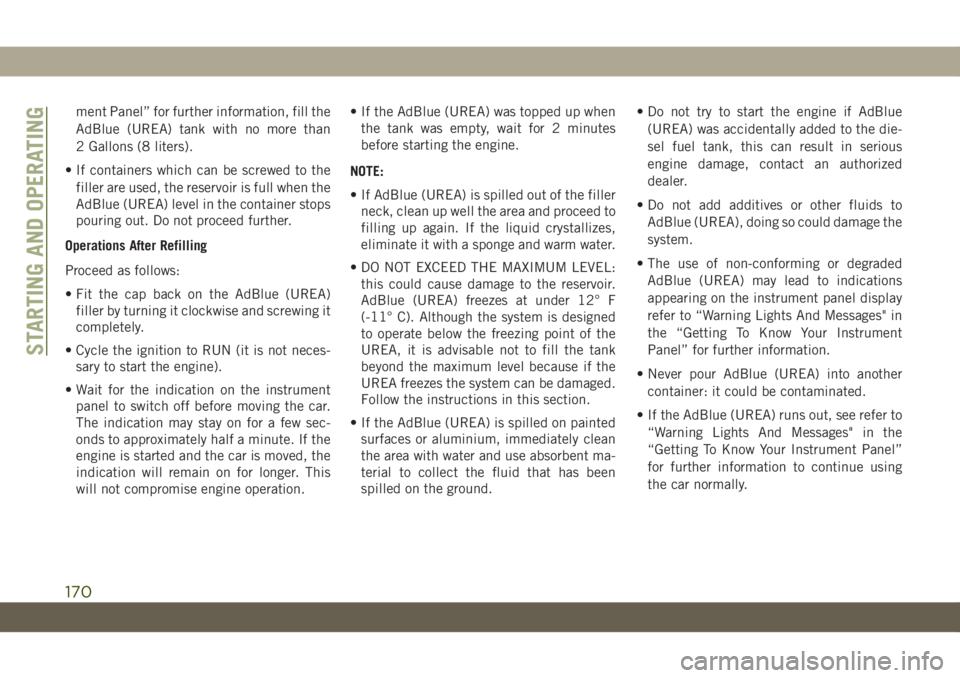

AdBlue (UREA) Storage

AdBlue (UREA) is considered a very stable

product with a long shelf life. If AdBlue

(UREA) is kept in temperatures between

10° and 90°F (-12° and 32°C), it will last a

minimum of one year.

AdBlue (UREA) is subject to freezing at the

lowest temperatures. For example, AdBlue

(UREA) may freeze at temperatures at or

below 12° F (-11° C). The system has been

designed to operate in this environment.NOTE:

When working with AdBlue (UREA), it is

important to know that:

• Any containers or parts that come into con-

tact with AdBlue (UREA) must be AdBlue

(UREA) compatible (plastic or stainless

steel). Copper, brass, aluminum, iron or

non-stainless steel should be avoided as

they are subject to corrosion by AdBlue

(UREA).

• If AdBlue (UREA) is spilled, it should be

wiped up completely.

Adding AdBlue (UREA)

Preliminary Conditions

AdBlue (UREA) freezes at temperatures

lower than 12° F (-11° C). If the car stands for

a long time at this temperature refilling could

be difficult. For this reason, it is advised to

park the vehicle in a garage and/or heated

environment and wait for the urea to return to

liquid state before topping up.

Proceed as follows:

• Park the car on flat ground and stop the

engine by cycling the ignition to the OFF

position.• Open the fuel door, undo and remove the

cap (blue) from the AdBlue (UREA) filler.

Refilling With Nozzles

You can fill up at any AdBlue (UREA) dis-

tributor.

Proceed as follows:

• Insert the AdBlue (UREA) nozzle in the

filler, start refilling and stop refilling at the

first shut-off (the shut-off indicates that the

AdBlue (UREA) tank is full). Do not pro-

ceed with the refilling, to prevent spillage

of AdBlue (UREA).

• Extract the nozzle.

Refilling With Containers

Proceed as follows:

• Check the expiration date.

• Read the advice for use on the label before

pouring the content of the bottle into the

AdBlue (UREA) tank.

• If systems which cannot be screwed in (e.g.

tanks) are used for refilling, after the indi-

cation appears on the instrument panel

display refer to “Warning lights And Mes-

sages" in the “Getting To Know Your Instru-

169

Page 172 of 348

ment Panel” for further information, fill the

AdBlue (UREA) tank with no more than

2 Gallons (8 liters).

• If containers which can be screwed to the

filler are used, the reservoir is full when the

AdBlue (UREA) level in the container stops

pouring out. Do not proceed further.

Operations After Refilling

Proceed as follows:

• Fit the cap back on the AdBlue (UREA)

filler by turning it clockwise and screwing it

completely.

• Cycle the ignition to RUN (it is not neces-

sary to start the engine).

• Wait for the indication on the instrument

panel to switch off before moving the car.

The indication may stay on for a few sec-

onds to approximately half a minute. If the

engine is started and the car is moved, the

indication will remain on for longer. This

will not compromise engine operation.• If the AdBlue (UREA) was topped up when

the tank was empty, wait for 2 minutes

before starting the engine.

NOTE:

• If AdBlue (UREA) is spilled out of the filler

neck, clean up well the area and proceed to

filling up again. If the liquid crystallizes,

eliminate it with a sponge and warm water.

• DO NOT EXCEED THE MAXIMUM LEVEL:

this could cause damage to the reservoir.

AdBlue (UREA) freezes at under 12° F

(-11° C). Although the system is designed

to operate below the freezing point of the

UREA, it is advisable not to fill the tank

beyond the maximum level because if the

UREA freezes the system can be damaged.

Follow the instructions in this section.

• If the AdBlue (UREA) is spilled on painted

surfaces or aluminium, immediately clean

the area with water and use absorbent ma-

terial to collect the fluid that has been

spilled on the ground.• Do not try to start the engine if AdBlue

(UREA) was accidentally added to the die-

sel fuel tank, this can result in serious

engine damage, contact an authorized

dealer.

• Do not add additives or other fluids to

AdBlue (UREA), doing so could damage the

system.

• The use of non-conforming or degraded

AdBlue (UREA) may lead to indications

appearing on the instrument panel display

refer to “Warning Lights And Messages" in

the “Getting To Know Your Instrument

Panel” for further information.

• Never pour AdBlue (UREA) into another

container: it could be contaminated.

• If the AdBlue (UREA) runs out, see refer to

“Warning Lights And Messages" in the

“Getting To Know Your Instrument Panel”

for further information to continue using

the car normally.

STARTING AND OPERATING

170

Page 195 of 348

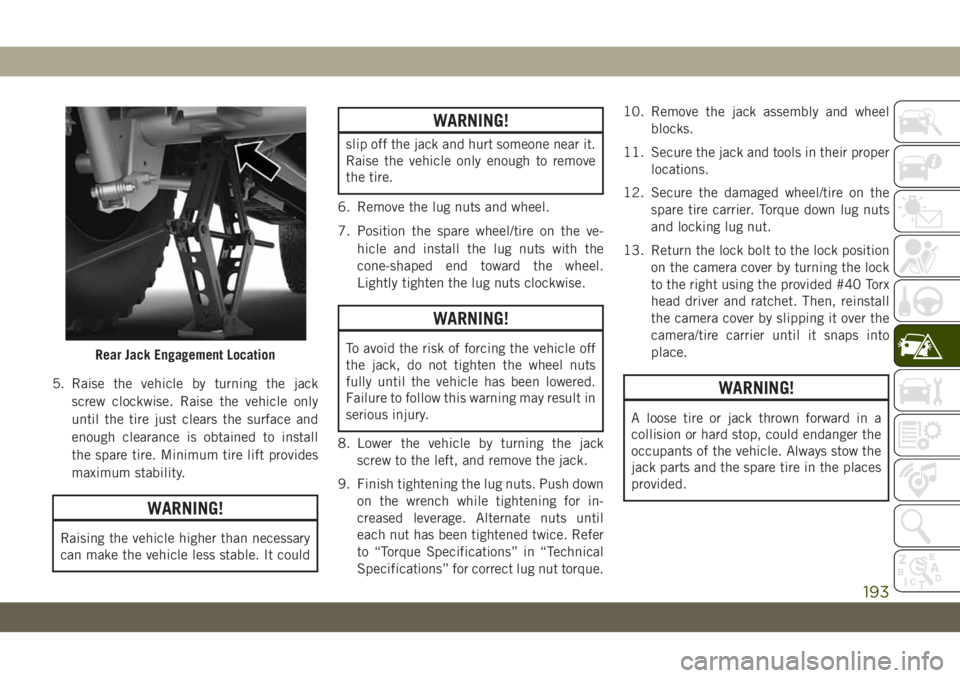

5. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the lug nuts clockwise.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

8. Lower the vehicle by turning the jack

screw to the left, and remove the jack.

9. Finish tightening the lug nuts. Push down

on the wrench while tightening for in-

creased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Torque Specifications” in “Technical

Specifications” for correct lug nut torque.10. Remove the jack assembly and wheel

blocks.

11. Secure the jack and tools in their proper

locations.

12. Secure the damaged wheel/tire on the

spare tire carrier. Torque down lug nuts

and locking lug nut.

13. Return the lock bolt to the lock position

on the camera cover by turning the lock

to the right using the provided #40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

Rear Jack Engagement Location

193

Page 196 of 348

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut

has been tightened twice. For the correct

lug nut torque refer to “Torque Specifica-

tions” in “Technical Specifications”. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.5. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Declaration Of Conformance

1. The undersigned, FlexNGate, represent-

ing the manufacturer, herewith declares

that the machinery described below ful-

fills all relevant provisions of:

•The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

WranglerJL 1000 kg

MaxFGLF2

3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road, Totten-

ham, ON CANADA L0G 1W04. Manufacturers (2):

FlexNGate Querétaro Ventramex, S.A. de

C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico

5. Legal Person authorized to compile the

technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN 08960

6. References to harmonized standards:

PF-90065

7. Done at: Bradford, ON CANADA

8. Date: 10/02/2017FlexNGate Representative

IN CASE OF EMERGENCY

194

Page 214 of 348

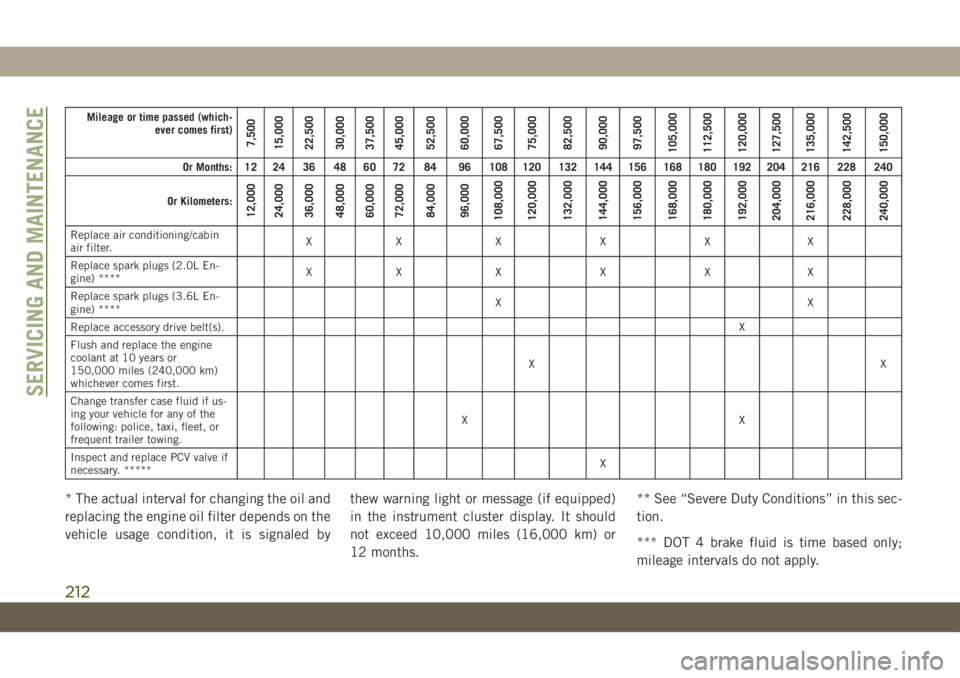

Mileage or time passed (which-

ever comes first)

7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Replace air conditioning/cabin

air filter.XX X X X X

Replace spark plugs (2.0L En-

gine) ****XX X X X X

Replace spark plugs (3.6L En-

gine) ****XX

Replace accessory drive belt(s).X

Flush and replace the engine

coolant at 10 years or

150,000 miles (240,000 km)

whichever comes first.XX

Change transfer case fluid if us-

ing your vehicle for any of the

following: police, taxi, fleet, or

frequent trailer towing.XX

Inspect and replace PCV valve if

necessary. *****X

* The actual interval for changing the oil and

replacing the engine oil filter depends on the

vehicle usage condition, it is signaled bythew warning light or message (if equipped)

in the instrument cluster display. It should

not exceed 10,000 miles (16,000 km) or

12 months.** See “Severe Duty Conditions” in this sec-

tion.

*** DOT 4 brake fluid is time based only;

mileage intervals do not apply.

SERVICING AND MAINTENANCE

212