JEEP WRANGLER UNLIMITED 2020 Owner handbook (in English)

Manufacturer: JEEP, Model Year: 2020, Model line: WRANGLER UNLIMITED, Model: JEEP WRANGLER UNLIMITED 2020Pages: 330, PDF Size: 9.16 MB

Page 191 of 330

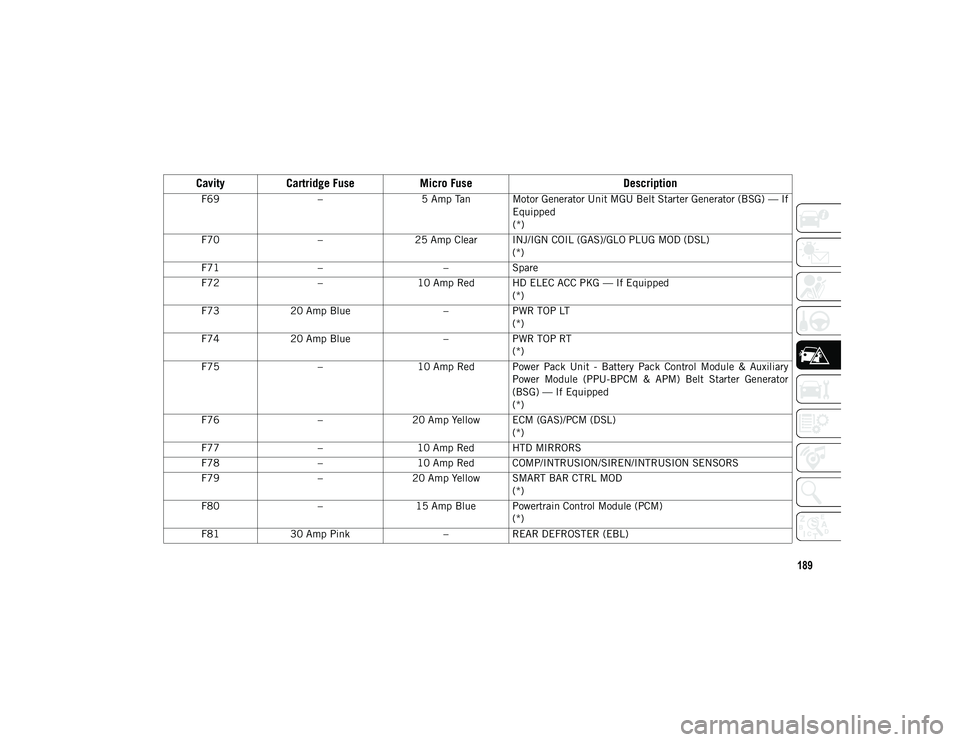

189

F69–5 Amp Tan Motor Generator Unit MGU Belt Starter Generator (BSG) — If

Equipped

(*)

F70 –25 Amp Clear INJ/IGN COIL (GAS)/GLO PLUG MOD (DSL)

(*)

F71 – –Spare

F72 –10 Amp Red HD ELEC ACC PKG — If Equipped

(*)

F73 20 Amp Blue –PWR TOP LT

(*)

F74 20 Amp Blue –PWR TOP RT

(*)

F75 –10 Amp Red Power Pack Unit - Battery Pack Control Module & Auxiliary

Power Module (PPU-BPCM & APM) Belt Starter Generator

(BSG) — If Equipped

(*)

F76 –20 Amp Yellow ECM (GAS)/PCM (DSL)

(*)

F77 –10 Amp Red HTD MIRRORS

F78 –10 Amp Red COMP/INTRUSION/SIREN/INTRUSION SENSORS

F79 –20 Amp Yellow SMART BAR CTRL MOD

(*)

F80 –15 Amp Blue Powertrain Control Module (PCM)

(*)

F81 30 Amp Pink –REAR DEFROSTER (EBL)

Cavity Cartridge Fuse Micro Fuse Description

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 189

Page 192 of 330

IN CASE OF EMERGENCY

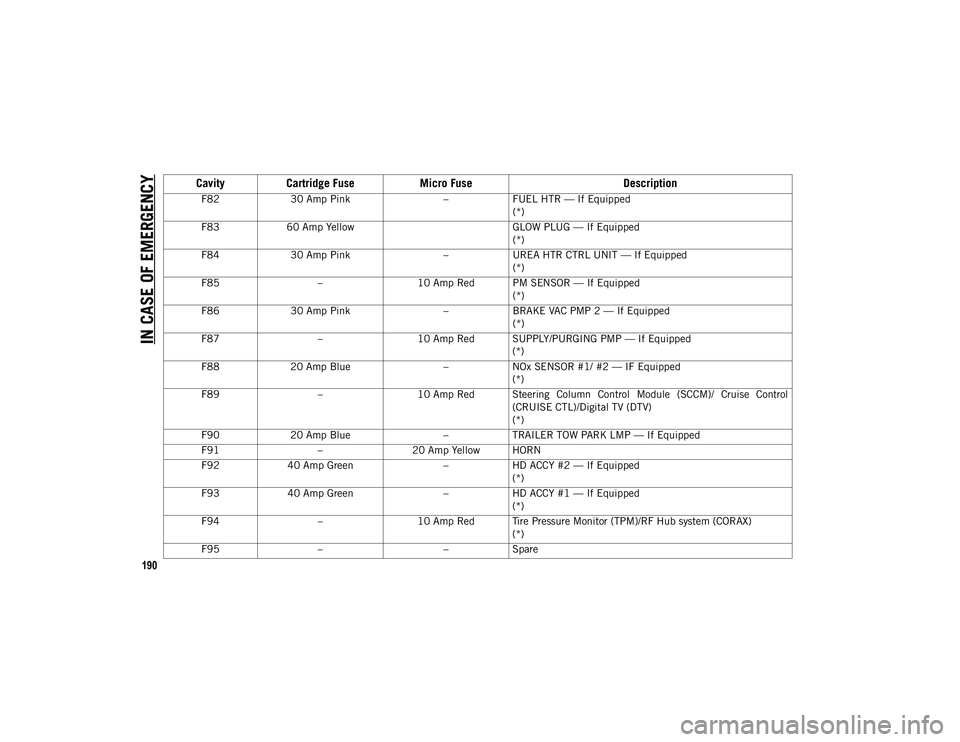

190

F8230 Amp Pink –FUEL HTR — If Equipped

(*)

F83 60 Amp Yellow GLOW PLUG — If Equipped

(*)

F84 30 Amp Pink –UREA HTR CTRL UNIT — If Equipped

(*)

F85 –10 Amp Red PM SENSOR — If Equipped

(*)

F86 30 Amp Pink –BRAKE VAC PMP 2 — If Equipped

(*)

F87 –10 Amp Red SUPPLY/PURGING PMP — If Equipped

(*)

F88 20 Amp Blue –NOx SENSOR #1/ #2 — IF Equipped

(*)

F89 –10 Amp Red Steering Column Control Module (SCCM)/ Cruise Control

(CRUISE CTL)/Digital TV (DTV)

(*)

F90 20 Amp Blue –TRAILER TOW PARK LMP — If Equipped

F91 –20 Amp Yellow HORN

F92 40 Amp Green –HD ACCY #2 — If Equipped

(*)

F93 40 Amp Green –HD ACCY #1 — If Equipped

(*)

F94 –10 Amp Red Tire Pressure Monitor (TPM)/RF Hub system (CORAX)

(*)

F95 – –Spare

Cavity Cartridge Fuse Micro Fuse Description

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 190

Page 193 of 330

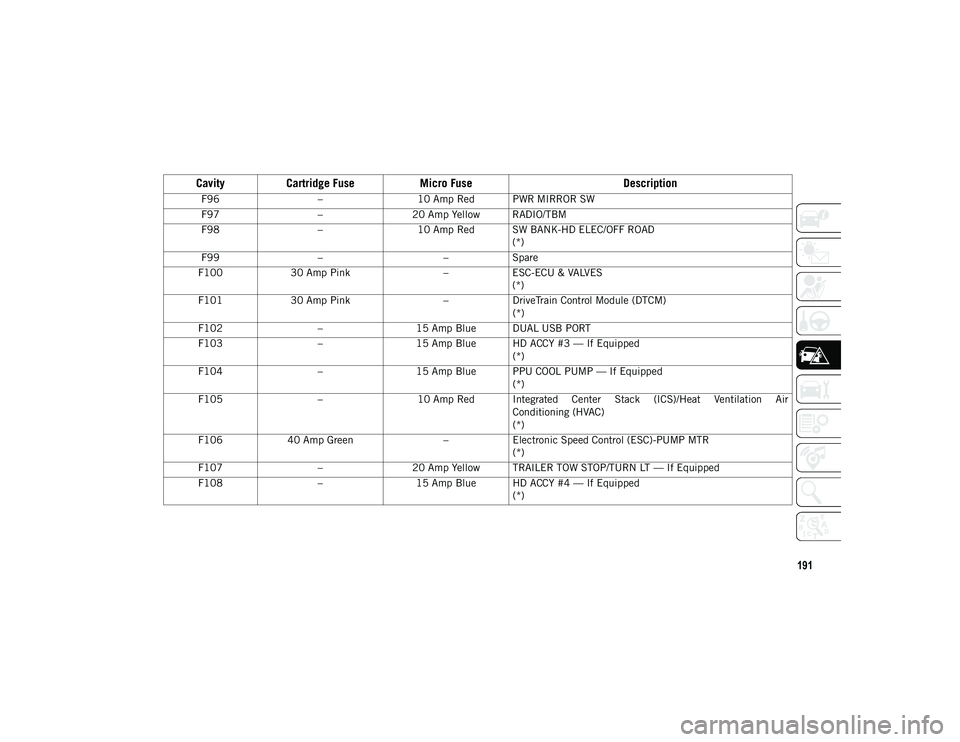

191

F96–10 Amp Red PWR MIRROR SW

F97 –20 Amp Yellow RADIO/TBM

F98 –10 Amp Red SW BANK-HD ELEC/OFF ROAD

(*)

F99 – –Spare

F100 30 Amp Pink –ESC-ECU & VALVES

(*)

F101 30 Amp Pink –DriveTrain Control Module (DTCM)

(*)

F102 –15 Amp Blue DUAL USB PORT

F103 –15 Amp Blue HD ACCY #3 — If Equipped

(*)

F104 –15 Amp Blue PPU COOL PUMP — If Equipped

(*)

F105 –10 Amp Red Integrated Center Stack (ICS)/Heat Ventilation Air

Conditioning (HVAC)

(*)

F106 40 Amp Green –Electronic Speed Control (ESC)-PUMP MTR

(*)

F107 –20 Amp Yellow TRAILER TOW STOP/TURN LT — If Equipped

F108 –15 Amp Blue HD ACCY #4 — If Equipped

(*)

CavityCartridge Fuse Micro Fuse Description

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 191

Page 194 of 330

IN CASE OF EMERGENCY

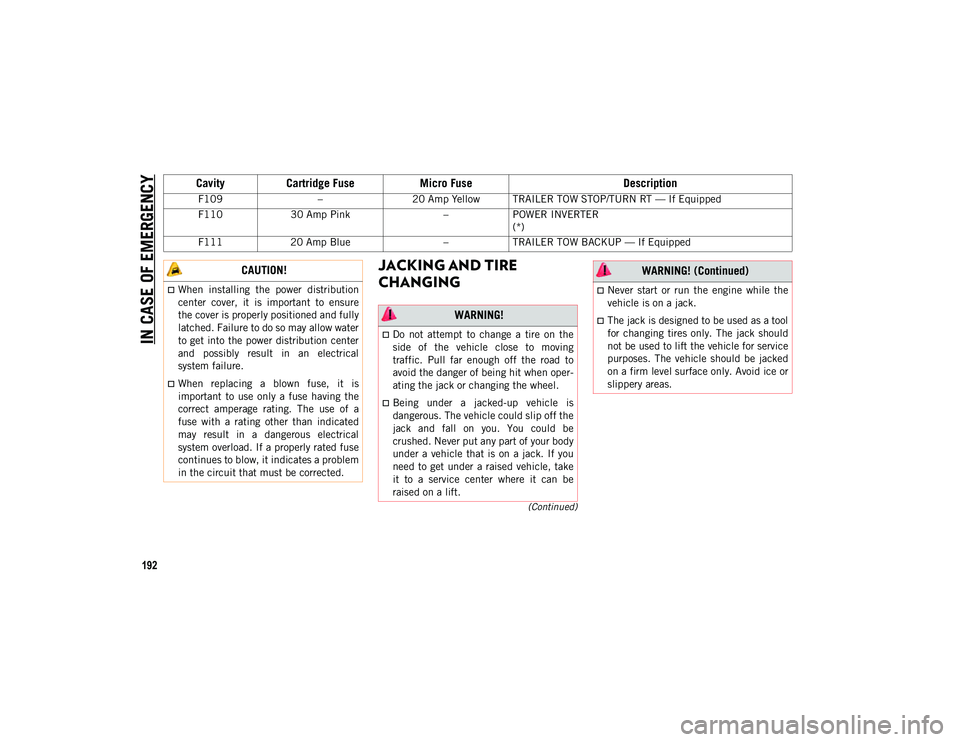

192

(Continued)

JACKING AND TIRE

CHANGING

F109–20 Amp Yellow TRAILER TOW STOP/TURN RT — If Equipped

F110 30 Amp Pink –POWER INVERTER

(*)

F111 20 Amp Blue –TRAILER TOW BACKUP — If Equipped

Cavity Cartridge Fuse Micro Fuse Description

CAUTION!

When installing the power distribution

center cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the power distribution center

and possibly result in an electrical

system failure.

When replacing a blown fuse, it is

important to use only a fuse having the

correct amperage rating. The use of a

fuse with a rating other than indicated

may result in a dangerous electrical

system overload. If a properly rated fuse

continues to blow, it indicates a problem

in the circuit that must be corrected.

WARNING!

Do not attempt to change a tire on the

side of the vehicle close to moving

traffic. Pull far enough off the road to

avoid the danger of being hit when oper-

ating the jack or changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

WARNING! (Continued)

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 192

Page 195 of 330

193

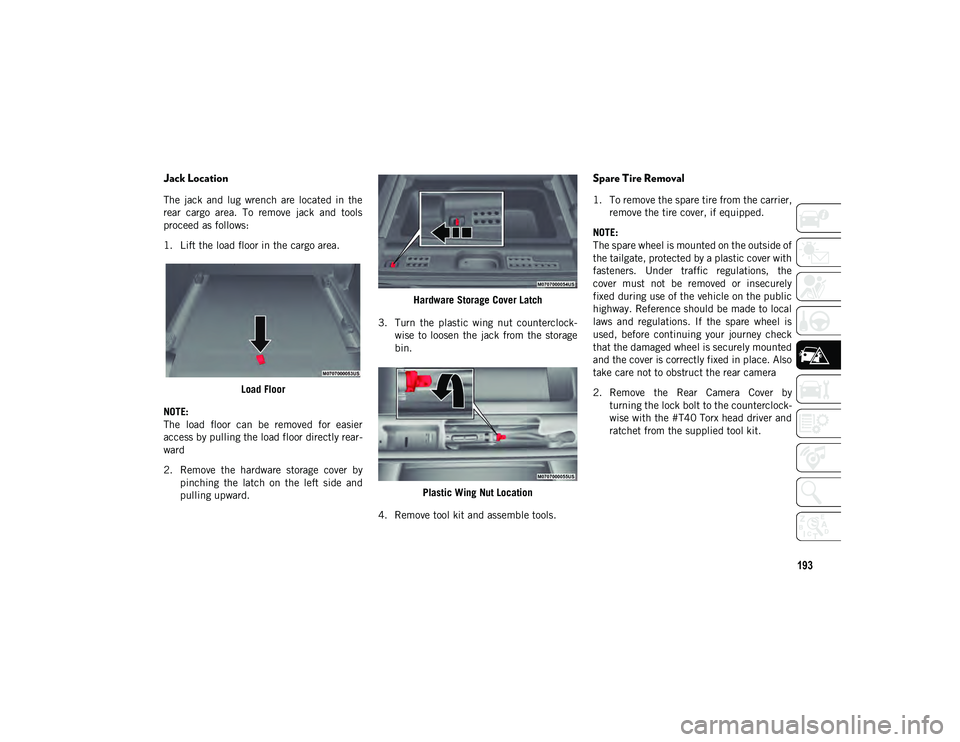

Jack Location

The jack and lug wrench are located in the

rear cargo area. To remove jack and tools

proceed as follows:

1. Lift the load floor in the cargo area.Load Floor

NOTE:

The load floor can be removed for easier

access by pulling the load floor directly rear -

ward

2. Remove the hardware storage cover by pinching the latch on the left side and

pulling upward. Hardware Storage Cover Latch

3. Turn the plastic wing nut counterclock -

wise to loosen the jack from the storage

bin.

Plastic Wing Nut Location

4. Remove tool kit and assemble tools.

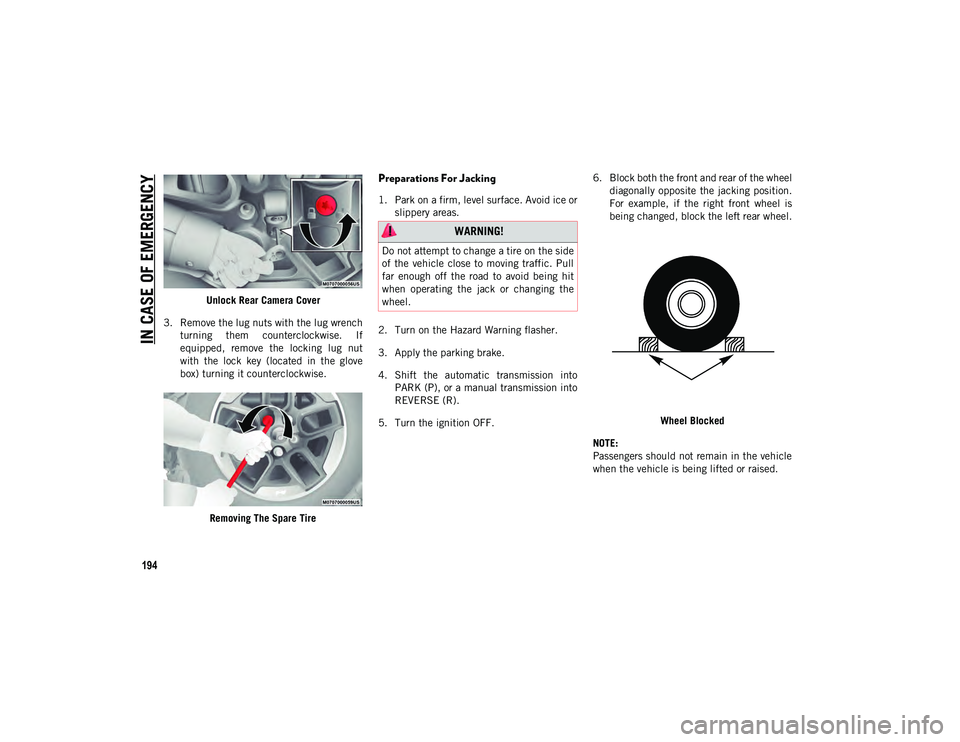

Spare Tire Removal

1. To remove the spare tire from the carrier, remove the tire cover, if equipped.

NOTE:

The spare wheel is mounted on the outside of

the tailgate, protected by a plastic cover with

fasteners. Under traffic regulations, the

cover must not be removed or insecurely

fixed during use of the vehicle on the public

highway. Reference should be made to local

laws and regulations. If the spare wheel is

used, before continuing your journey check

that the damaged wheel is securely mounted

and the cover is correctly fixed in place. Also

take care not to obstruct the rear camera

2. Remove the Rear Camera Cover by turning the lock bolt to the counterclock -

wise with the #T40 Torx head driver and

ratchet from the supplied tool kit.

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 193

Page 196 of 330

IN CASE OF EMERGENCY

194

Unlock Rear Camera Cover

3. Remove the lug nuts with the lug wrench turning them counterclockwise. If

equipped, remove the locking lug nut

with the lock key (located in the glove

box) turning it counterclockwise.

Removing The Spare Tire

Preparations For Jacking

1. Park on a firm, level surface. Avoid ice orslippery areas.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.

4. Shift the automatic transmission into PARK (P), or a manual transmission into

REVERSE (R).

5. Turn the ignition OFF. 6. Block both the front and rear of the wheel

diagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being lifted or raised.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 194

Page 197 of 330

195

(Continued)

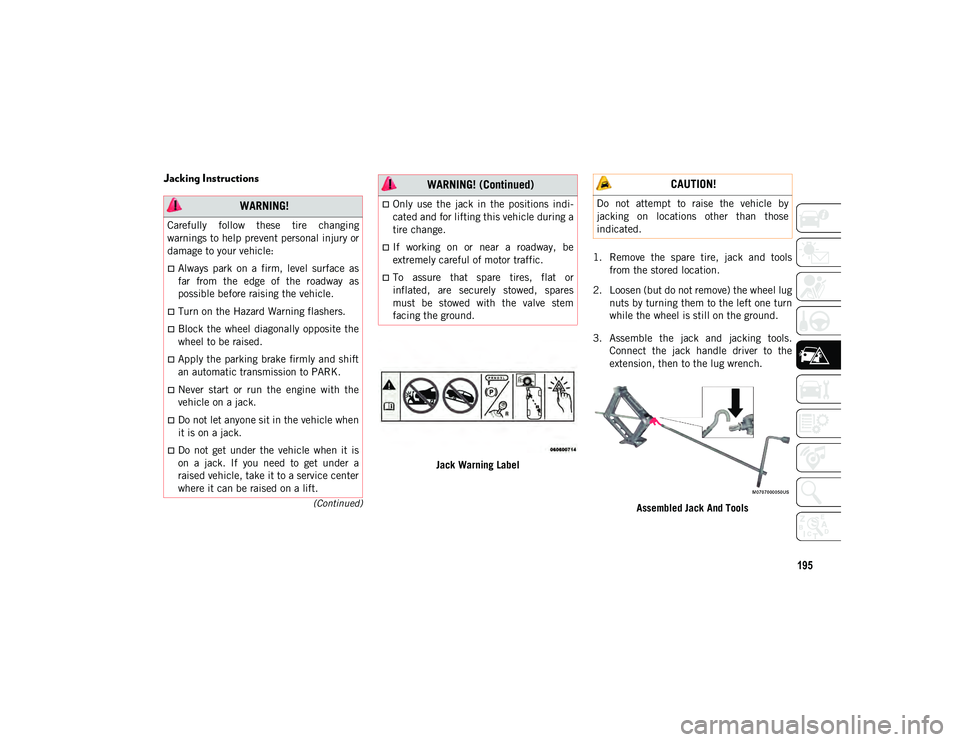

Jacking Instructions

Jack Warning Label1. Remove the spare tire, jack and tools

from the stored location.

2. Loosen (but do not remove) the wheel lug nuts by turning them to the left one turn

while the wheel is still on the ground.

3. Assemble the jack and jacking tools. Connect the jack handle driver to the

extension, then to the lug wrench.

Assembled Jack And Tools

WARNING!

Carefully follow these tire changing

warnings to help prevent personal injury or

damage to your vehicle:

Always park on a firm, level surface as

far from the edge of the roadway as

possible before raising the vehicle.

Turn on the Hazard Warning flashers.

Block the wheel diagonally opposite the

wheel to be raised.

Apply the parking brake firmly and shift

an automatic transmission to PARK.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when

it is on a jack.

Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

Only use the jack in the positions indi -

cated and for lifting this vehicle during a

tire change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or

inflated, are securely stowed, spares

must be stowed with the valve stem

facing the ground.

WARNING! (Continued) CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated.

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 195

Page 198 of 330

IN CASE OF EMERGENCY

196

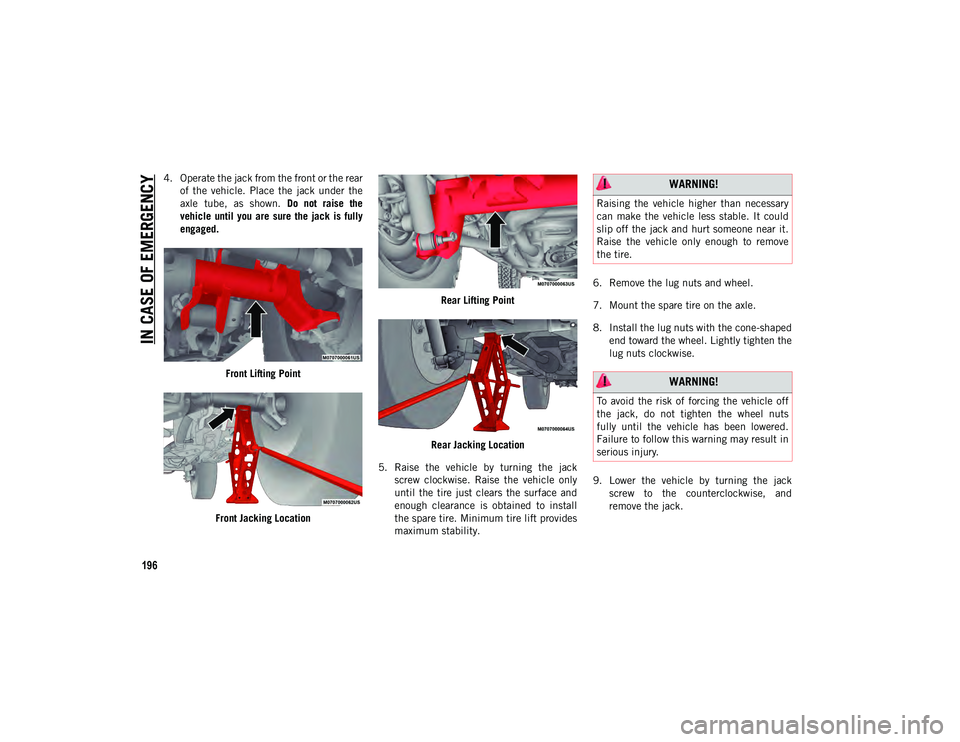

4. Operate the jack from the front or the rearof the vehicle. Place the jack under the

axle tube, as shown. Do not raise the

vehicle until you are sure the jack is fully

engaged.

Front Lifting Point

Front Jacking Location Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability. 6. Remove the lug nuts and wheel.

7. Mount the spare tire on the axle.

8. Install the lug nuts with the cone-shaped

end toward the wheel. Lightly tighten the

lug nuts clockwise.

9. Lower the vehicle by turning the jack screw to the counterclockwise, and

remove the jack. WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 196

Page 199 of 330

197

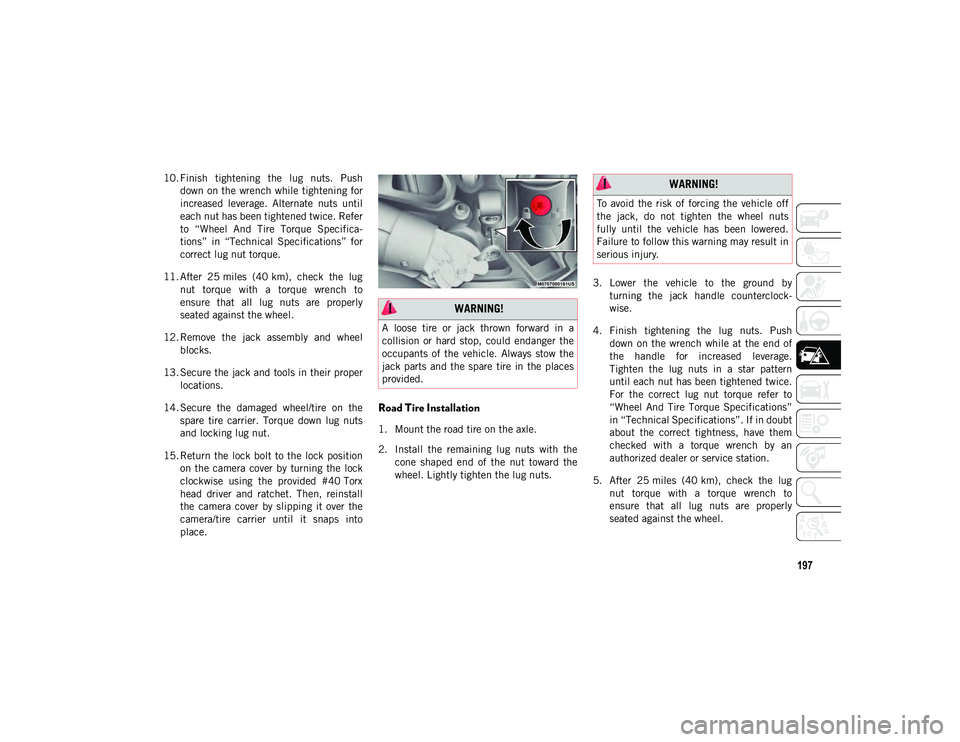

10. Finish tightening the lug nuts. Pushdown on the wrench while tightening for

increased leverage. Alternate nuts until

each nut has been tightened twice. Refer

to “Wheel And Tire Torque Specifica -

tions” in “Technical Specifications” for

correct lug nut torque.

11. After 25 miles (40 km), check the lug nut torque with a torque wrench to

ensure that all lug nuts are properly

seated against the wheel.

12. Remove the jack assembly and wheel blocks.

13. Secure the jack and tools in their proper locations.

14. Secure the damaged wheel/tire on the spare tire carrier. Torque down lug nuts

and locking lug nut.

15. Return the lock bolt to the lock position on the camera cover by turning the lock

clockwise using the provided #40 Torx

head driver and ratchet. Then, reinstall

the camera cover by slipping it over the

camera/tire carrier until it snaps into

place.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with thecone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts. 3. Lower the vehicle to the ground by

turning the jack handle counterclock -

wise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of

the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened twice.

For the correct lug nut torque refer to

“Wheel And Tire Torque Specifications”

in “Technical Specifications”. If in doubt

about the correct tightness, have them

checked with a torque wrench by an

authorized dealer or service station.

5. After 25 miles (40 km), check the lug nut torque with a torque wrench to

ensure that all lug nuts are properly

seated against the wheel.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 197

Page 200 of 330

IN CASE OF EMERGENCY

198

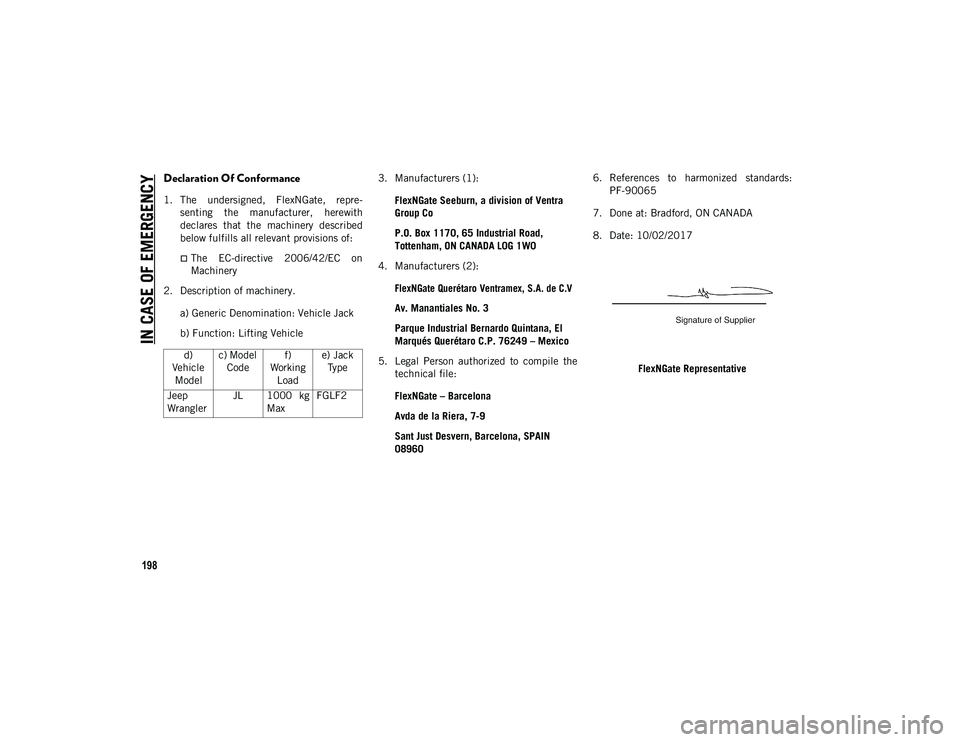

Declaration Of Conformance

1. The undersigned, FlexNGate, repre-

senting the manufacturer, herewith

declares that the machinery described

below fulfills all relevant provisions of:

The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle 3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road,

Tottenham, ON CANADA L0G 1W0

4. Manufacturers (2):

FlexNGate Querétaro Ventramex, S.A. de C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico

5. Legal Person authorized to compile the technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN

08960 6. References to harmonized standards:

PF-90065

7. Done at: Bradford, ON CANADA

8. Date: 10/02/2017

FlexNGate Representative

d)

Vehicle Model c) Model

Code f)

Working Load e) Jack

Type

Jeep

Wrangler JL 1000 kg

Max FGLF2

2020_JEEP_JL_WRANGLER_UG_RHD_UK.book Page 198