JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1351 of 2158

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt and fan

shroud.

(3) Remove the vibration damper retaining bolt

and washer.

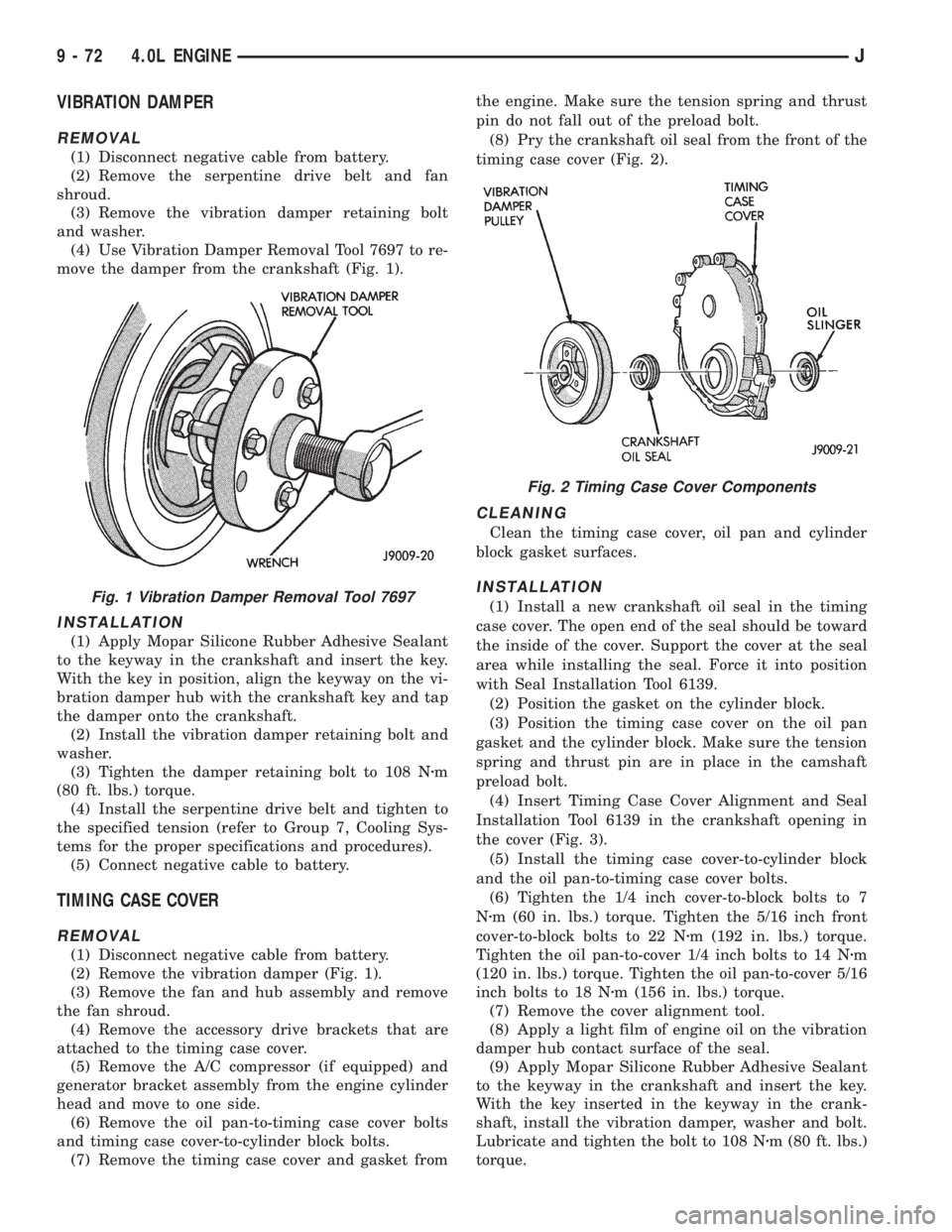

(4) Use Vibration Damper Removal Tool 7697 to re-

move the damper from the crankshaft (Fig. 1).

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in position, align the keyway on the vi-

bration damper hub with the crankshaft key and tap

the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 Nzm

(80 ft. lbs.) torque.

(4) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tems for the proper specifications and procedures).

(5) Connect negative cable to battery.

TIMING CASE COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the vibration damper (Fig. 1).

(3) Remove the fan and hub assembly and remove

the fan shroud.

(4) Remove the accessory drive brackets that are

attached to the timing case cover.

(5) Remove the A/C compressor (if equipped) and

generator bracket assembly from the engine cylinder

head and move to one side.

(6) Remove the oil pan-to-timing case cover bolts

and timing case cover-to-cylinder block bolts.

(7) Remove the timing case cover and gasket fromthe engine. Make sure the tension spring and thrust

pin do not fall out of the preload bolt.

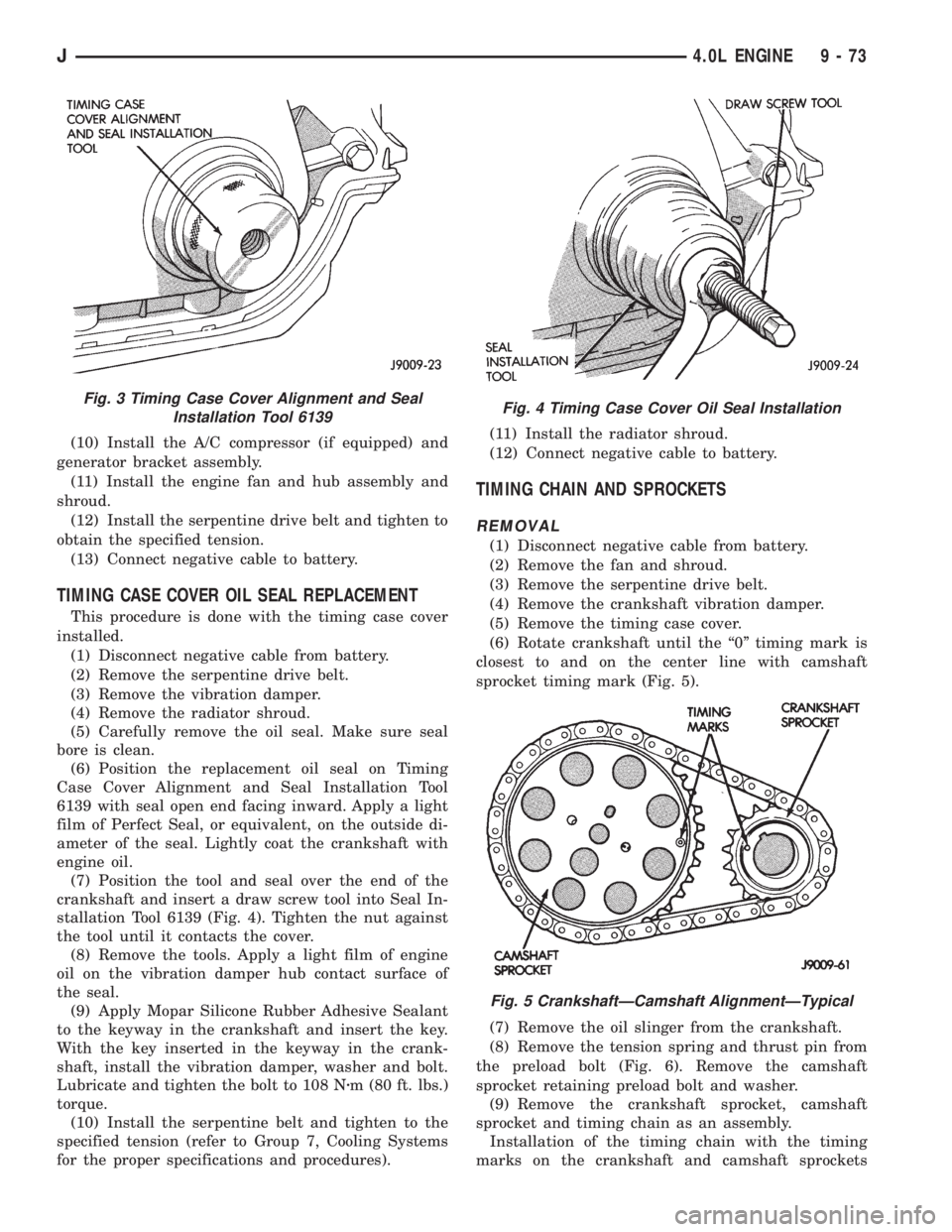

(8) Pry the crankshaft oil seal from the front of the

timing case cover (Fig. 2).

CLEANING

Clean the timing case cover, oil pan and cylinder

block gasket surfaces.

INSTALLATION

(1) Install a new crankshaft oil seal in the timing

case cover. The open end of the seal should be toward

the inside of the cover. Support the cover at the seal

area while installing the seal. Force it into position

with Seal Installation Tool 6139.

(2) Position the gasket on the cylinder block.

(3) Position the timing case cover on the oil pan

gasket and the cylinder block. Make sure the tension

spring and thrust pin are in place in the camshaft

preload bolt.

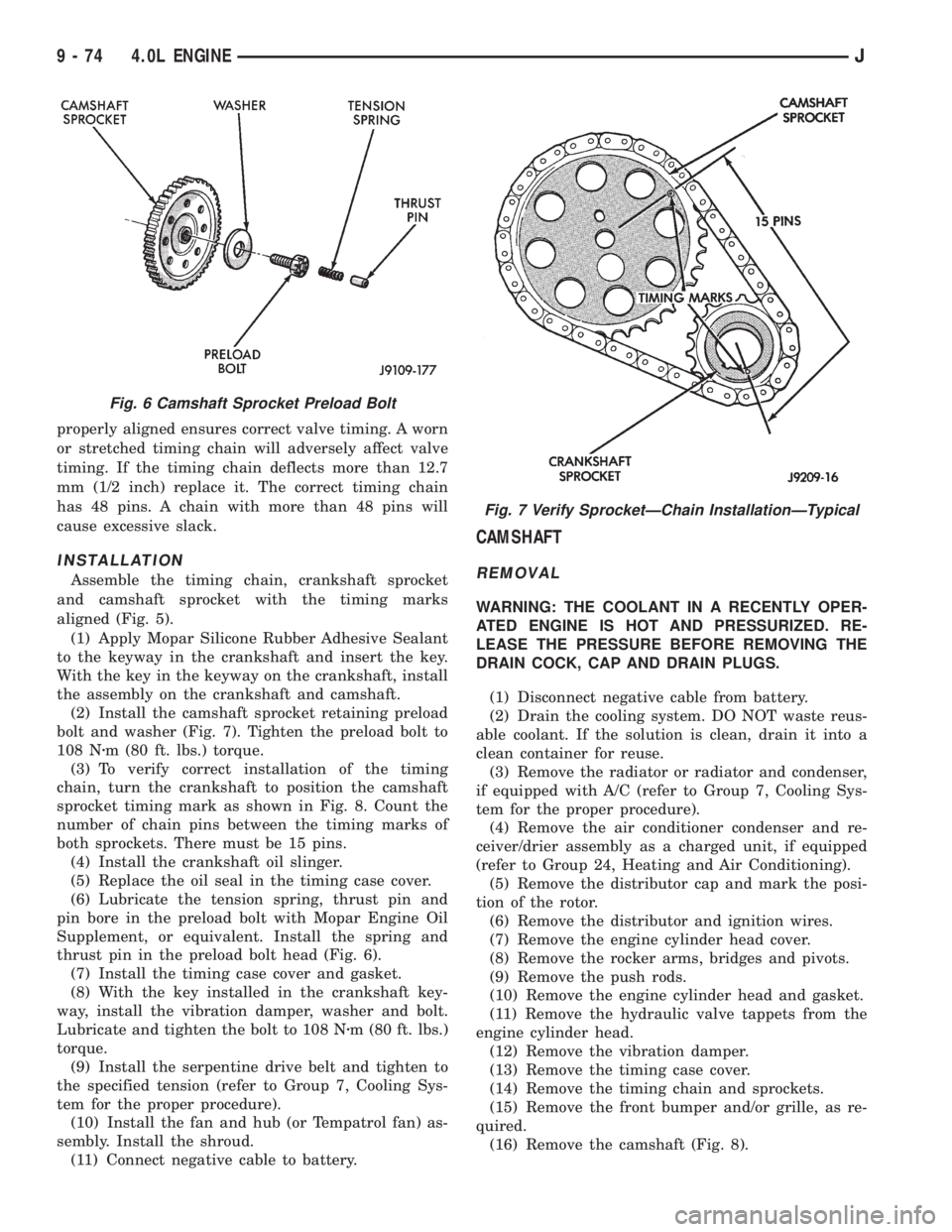

(4) Insert Timing Case Cover Alignment and Seal

Installation Tool 6139 in the crankshaft opening in

the cover (Fig. 3).

(5) Install the timing case cover-to-cylinder block

and the oil pan-to-timing case cover bolts.

(6) Tighten the 1/4 inch cover-to-block bolts to 7

Nzm (60 in. lbs.) torque. Tighten the 5/16 inch front

cover-to-block bolts to 22 Nzm (192 in. lbs.) torque.

Tighten the oil pan-to-cover 1/4 inch bolts to 14 Nzm

(120 in. lbs.) torque. Tighten the oil pan-to-cover 5/16

inch bolts to 18 Nzm (156 in. lbs.) torque.

(7) Remove the cover alignment tool.

(8) Apply a light film of engine oil on the vibration

damper hub contact surface of the seal.

(9) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key inserted in the keyway in the crank-

shaft, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.Fig. 1 Vibration Damper Removal Tool 7697

Fig. 2 Timing Case Cover Components

9 - 72 4.0L ENGINEJ

Page 1352 of 2158

(10) Install the A/C compressor (if equipped) and

generator bracket assembly.

(11) Install the engine fan and hub assembly and

shroud.

(12) Install the serpentine drive belt and tighten to

obtain the specified tension.

(13) Connect negative cable to battery.

TIMING CASE COVER OIL SEAL REPLACEMENT

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt.

(3) Remove the vibration damper.

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal. Make sure seal

bore is clean.

(6) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside di-

ameter of the seal. Lightly coat the crankshaft with

engine oil.

(7) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal In-

stallation Tool 6139 (Fig. 4). Tighten the nut against

the tool until it contacts the cover.

(8) Remove the tools. Apply a light film of engine

oil on the vibration damper hub contact surface of

the seal.

(9) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key inserted in the keyway in the crank-

shaft, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(10) Install the serpentine belt and tighten to the

specified tension (refer to Group 7, Cooling Systems

for the proper specifications and procedures).(11) Install the radiator shroud.

(12) Connect negative cable to battery.

TIMING CHAIN AND SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the fan and shroud.

(3) Remove the serpentine drive belt.

(4) Remove the crankshaft vibration damper.

(5) Remove the timing case cover.

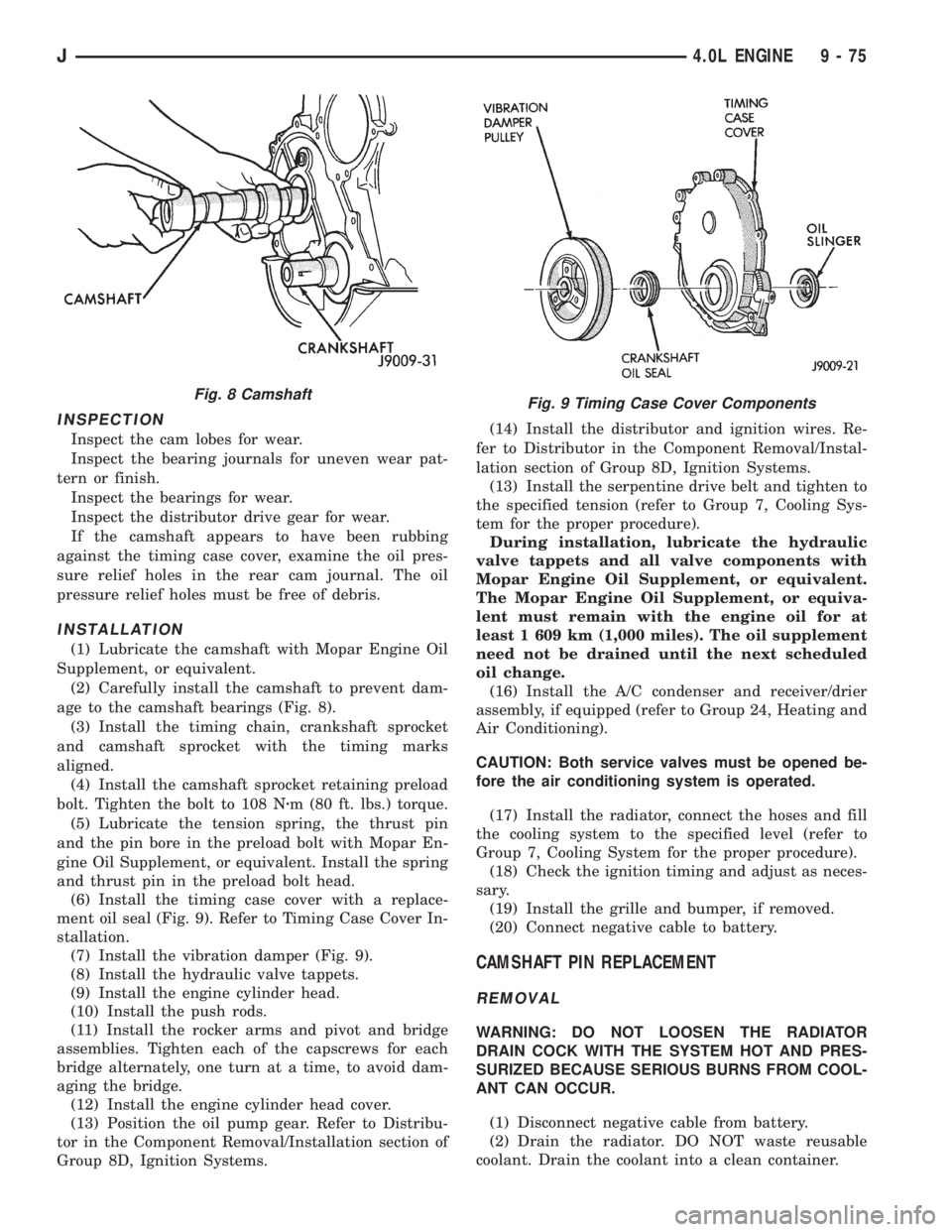

(6) Rotate crankshaft until the ``0'' timing mark is

closest to and on the center line with camshaft

sprocket timing mark (Fig. 5).

(7) Remove the oil slinger from the crankshaft.

(8) Remove the tension spring and thrust pin from

the preload bolt (Fig. 6). Remove the camshaft

sprocket retaining preload bolt and washer.

(9) Remove the crankshaft sprocket, camshaft

sprocket and timing chain as an assembly.

Installation of the timing chain with the timing

marks on the crankshaft and camshaft sprockets

Fig. 3 Timing Case Cover Alignment and Seal

Installation Tool 6139Fig. 4 Timing Case Cover Oil Seal Installation

Fig. 5 CrankshaftÐCamshaft AlignmentÐTypical

J4.0L ENGINE 9 - 73

Page 1353 of 2158

properly aligned ensures correct valve timing. A worn

or stretched timing chain will adversely affect valve

timing. If the timing chain deflects more than 12.7

mm (1/2 inch) replace it. The correct timing chain

has 48 pins. A chain with more than 48 pins will

cause excessive slack.

INSTALLATION

Assemble the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned (Fig. 5).

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in the keyway on the crankshaft, install

the assembly on the crankshaft and camshaft.

(2) Install the camshaft sprocket retaining preload

bolt and washer (Fig. 7). Tighten the preload bolt to

108 Nzm (80 ft. lbs.) torque.

(3) To verify correct installation of the timing

chain, turn the crankshaft to position the camshaft

sprocket timing mark as shown in Fig. 8. Count the

number of chain pins between the timing marks of

both sprockets. There must be 15 pins.

(4) Install the crankshaft oil slinger.

(5) Replace the oil seal in the timing case cover.

(6) Lubricate the tension spring, thrust pin and

pin bore in the preload bolt with Mopar Engine Oil

Supplement, or equivalent. Install the spring and

thrust pin in the preload bolt head (Fig. 6).

(7) Install the timing case cover and gasket.

(8) With the key installed in the crankshaft key-

way, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(9) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(10) Install the fan and hub (or Tempatrol fan) as-

sembly. Install the shroud.

(11) Connect negative cable to battery.

CAMSHAFT

REMOVAL

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. RE-

LEASE THE PRESSURE BEFORE REMOVING THE

DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

(2) Drain the cooling system. DO NOT waste reus-

able coolant. If the solution is clean, drain it into a

clean container for reuse.

(3) Remove the radiator or radiator and condenser,

if equipped with A/C (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(4) Remove the air conditioner condenser and re-

ceiver/drier assembly as a charged unit, if equipped

(refer to Group 24, Heating and Air Conditioning).

(5) Remove the distributor cap and mark the posi-

tion of the rotor.

(6) Remove the distributor and ignition wires.

(7) Remove the engine cylinder head cover.

(8) Remove the rocker arms, bridges and pivots.

(9) Remove the push rods.

(10) Remove the engine cylinder head and gasket.

(11) Remove the hydraulic valve tappets from the

engine cylinder head.

(12) Remove the vibration damper.

(13) Remove the timing case cover.

(14) Remove the timing chain and sprockets.

(15) Remove the front bumper and/or grille, as re-

quired.

(16) Remove the camshaft (Fig. 8).

Fig. 6 Camshaft Sprocket Preload Bolt

Fig. 7 Verify SprocketÐChain InstallationÐTypical

9 - 74 4.0L ENGINEJ

Page 1354 of 2158

INSPECTION

Inspect the cam lobes for wear.

Inspect the bearing journals for uneven wear pat-

tern or finish.

Inspect the bearings for wear.

Inspect the distributor drive gear for wear.

If the camshaft appears to have been rubbing

against the timing case cover, examine the oil pres-

sure relief holes in the rear cam journal. The oil

pressure relief holes must be free of debris.

INSTALLATION

(1) Lubricate the camshaft with Mopar Engine Oil

Supplement, or equivalent.

(2) Carefully install the camshaft to prevent dam-

age to the camshaft bearings (Fig. 8).

(3) Install the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned.

(4) Install the camshaft sprocket retaining preload

bolt. Tighten the bolt to 108 Nzm (80 ft. lbs.) torque.

(5) Lubricate the tension spring, the thrust pin

and the pin bore in the preload bolt with Mopar En-

gine Oil Supplement, or equivalent. Install the spring

and thrust pin in the preload bolt head.

(6) Install the timing case cover with a replace-

ment oil seal (Fig. 9). Refer to Timing Case Cover In-

stallation.

(7) Install the vibration damper (Fig. 9).

(8) Install the hydraulic valve tappets.

(9) Install the engine cylinder head.

(10) Install the push rods.

(11) Install the rocker arms and pivot and bridge

assemblies. Tighten each of the capscrews for each

bridge alternately, one turn at a time, to avoid dam-

aging the bridge.

(12) Install the engine cylinder head cover.

(13) Position the oil pump gear. Refer to Distribu-

tor in the Component Removal/Installation section of

Group 8D, Ignition Systems.(14) Install the distributor and ignition wires. Re-

fer to Distributor in the Component Removal/Instal-

lation section of Group 8D, Ignition Systems.

(13) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

During installation, lubricate the hydraulic

valve tappets and all valve components with

Mopar Engine Oil Supplement, or equivalent.

The Mopar Engine Oil Supplement, or equiva-

lent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled

oil change.

(16) Install the A/C condenser and receiver/drier

assembly, if equipped (refer to Group 24, Heating and

Air Conditioning).

CAUTION: Both service valves must be opened be-

fore the air conditioning system is operated.

(17) Install the radiator, connect the hoses and fill

the cooling system to the specified level (refer to

Group 7, Cooling System for the proper procedure).

(18) Check the ignition timing and adjust as neces-

sary.

(19) Install the grille and bumper, if removed.

(20) Connect negative cable to battery.

CAMSHAFT PIN REPLACEMENT

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM COOL-

ANT CAN OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain the radiator. DO NOT waste reusable

coolant. Drain the coolant into a clean container.

Fig. 9 Timing Case Cover ComponentsFig. 8 Camshaft

J4.0L ENGINE 9 - 75

Page 1355 of 2158

(3) Remove the fan and shroud.

(4) Disconnect the radiator overflow tube, radiator

hoses, automatic transmission fluid cooler pipes (if

equipped).

(5) Remove the radiator.

(6) If equipped with air conditioning:

CAUTION: DO NOT loosen or disconnect any air

conditioner system fittings. Move the condenser

and receiver/drier aside as a complete assembly.

(a) Remove the A/C compressor serpentine drive

belt idler pulley.

(b) Disconnect and remove the generator.

(c) Remove the A/C condenser attaching bolts

and move the condenser and receiver/drier assem-

bly up and out of the way.

(7) Remove the serpentine drive belt.

(8) Remove the crankshaft vibration damper.

(9) Remove the timing case cover. Clean the gasket

material from the cover.

(10) Remove the thrust pin and tension spring

from the preload bolt head.

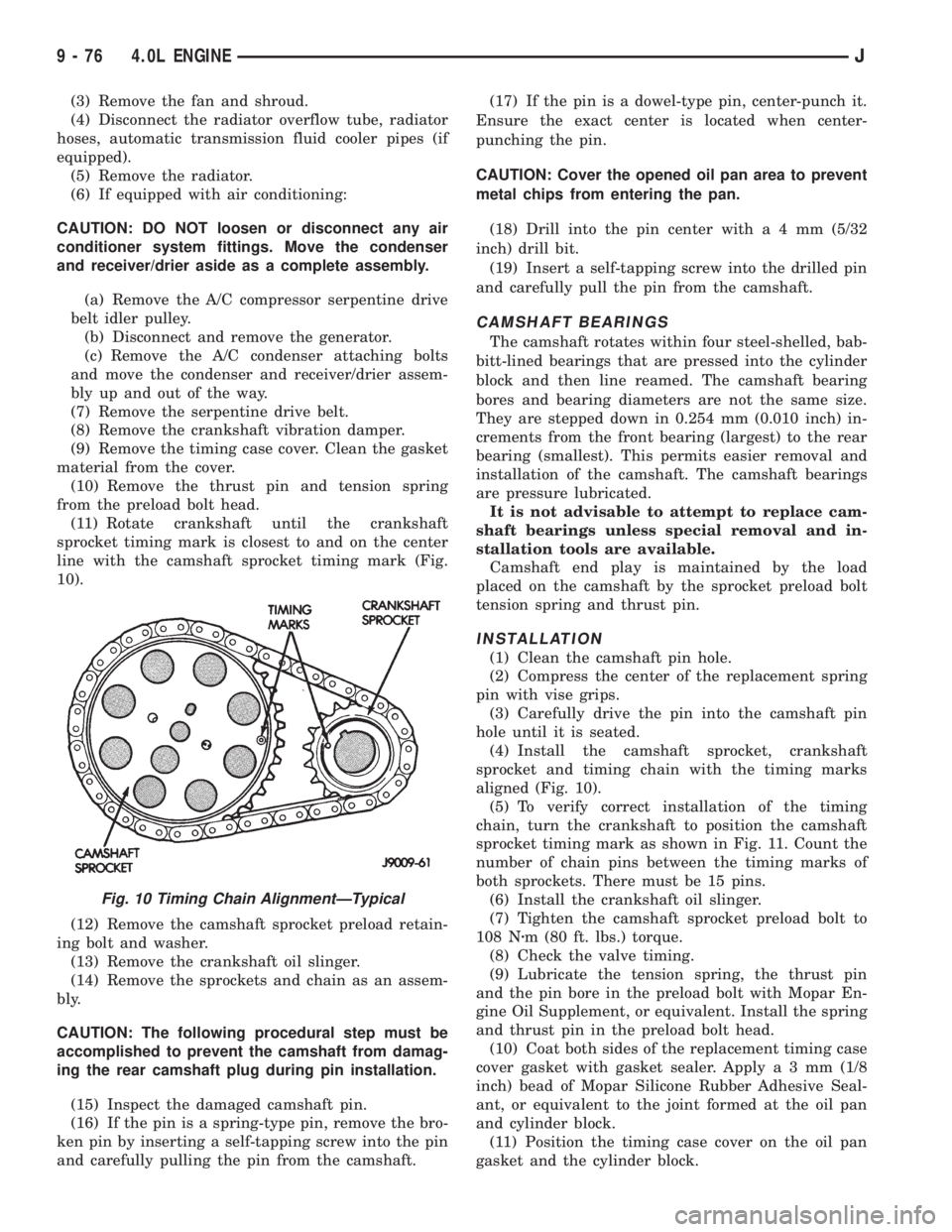

(11) Rotate crankshaft until the crankshaft

sprocket timing mark is closest to and on the center

line with the camshaft sprocket timing mark (Fig.

10).

(12) Remove the camshaft sprocket preload retain-

ing bolt and washer.

(13) Remove the crankshaft oil slinger.

(14) Remove the sprockets and chain as an assem-

bly.

CAUTION: The following procedural step must be

accomplished to prevent the camshaft from damag-

ing the rear camshaft plug during pin installation.

(15) Inspect the damaged camshaft pin.

(16) If the pin is a spring-type pin, remove the bro-

ken pin by inserting a self-tapping screw into the pin

and carefully pulling the pin from the camshaft.(17) If the pin is a dowel-type pin, center-punch it.

Ensure the exact center is located when center-

punching the pin.

CAUTION: Cover the opened oil pan area to prevent

metal chips from entering the pan.

(18) Drill into the pin center witha4mm(5/32

inch) drill bit.

(19) Insert a self-tapping screw into the drilled pin

and carefully pull the pin from the camshaft.

CAMSHAFT BEARINGS

The camshaft rotates within four steel-shelled, bab-

bitt-lined bearings that are pressed into the cylinder

block and then line reamed. The camshaft bearing

bores and bearing diameters are not the same size.

They are stepped down in 0.254 mm (0.010 inch) in-

crements from the front bearing (largest) to the rear

bearing (smallest). This permits easier removal and

installation of the camshaft. The camshaft bearings

are pressure lubricated.

It is not advisable to attempt to replace cam-

shaft bearings unless special removal and in-

stallation tools are available.

Camshaft end play is maintained by the load

placed on the camshaft by the sprocket preload bolt

tension spring and thrust pin.

INSTALLATION

(1) Clean the camshaft pin hole.

(2) Compress the center of the replacement spring

pin with vise grips.

(3) Carefully drive the pin into the camshaft pin

hole until it is seated.

(4) Install the camshaft sprocket, crankshaft

sprocket and timing chain with the timing marks

aligned (Fig. 10).

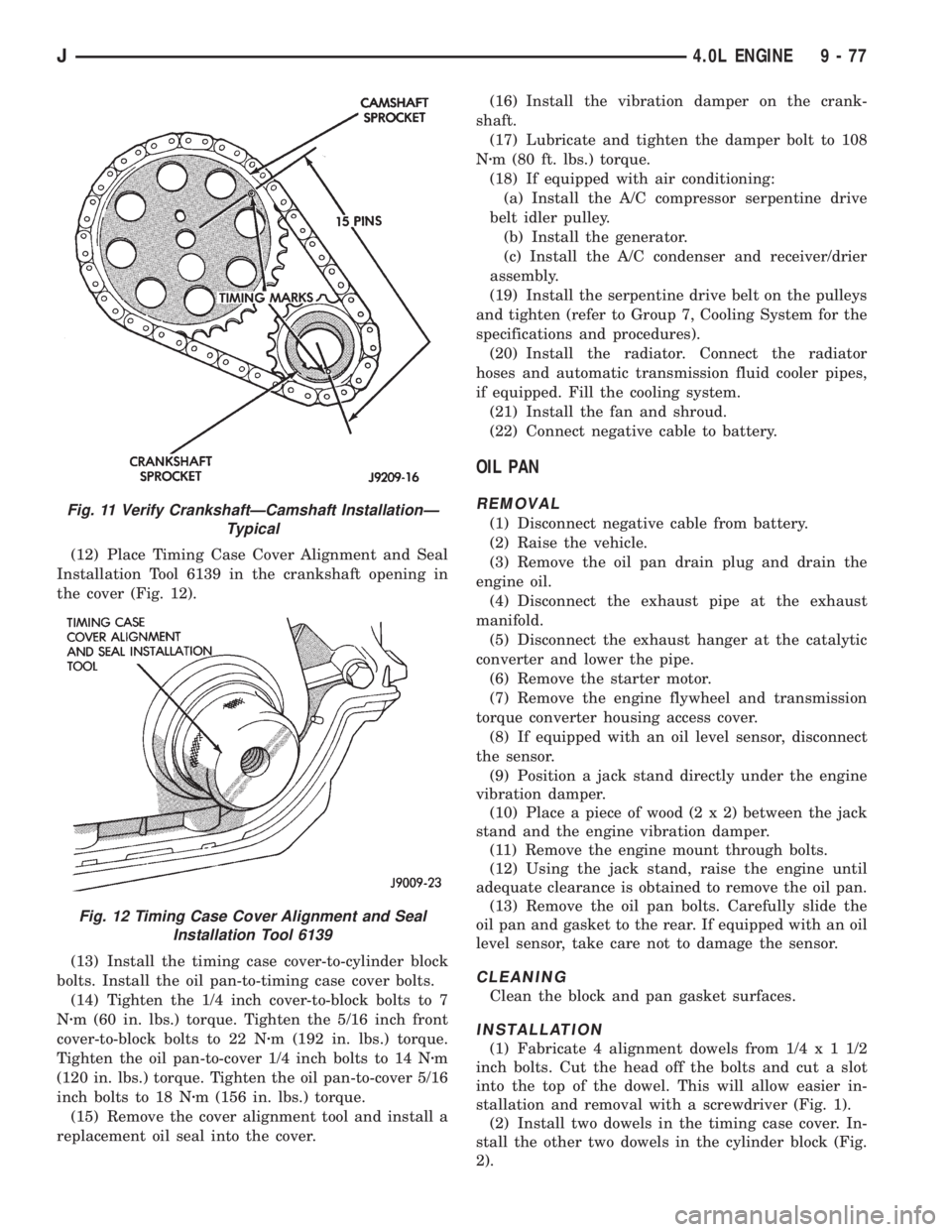

(5) To verify correct installation of the timing

chain, turn the crankshaft to position the camshaft

sprocket timing mark as shown in Fig. 11. Count the

number of chain pins between the timing marks of

both sprockets. There must be 15 pins.

(6) Install the crankshaft oil slinger.

(7) Tighten the camshaft sprocket preload bolt to

108 Nzm (80 ft. lbs.) torque.

(8) Check the valve timing.

(9) Lubricate the tension spring, the thrust pin

and the pin bore in the preload bolt with Mopar En-

gine Oil Supplement, or equivalent. Install the spring

and thrust pin in the preload bolt head.

(10) Coat both sides of the replacement timing case

cover gasket with gasket sealer. Applya3mm(1/8

inch) bead of Mopar Silicone Rubber Adhesive Seal-

ant, or equivalent to the joint formed at the oil pan

and cylinder block.

(11) Position the timing case cover on the oil pan

gasket and the cylinder block.

Fig. 10 Timing Chain AlignmentÐTypical

9 - 76 4.0L ENGINEJ

Page 1356 of 2158

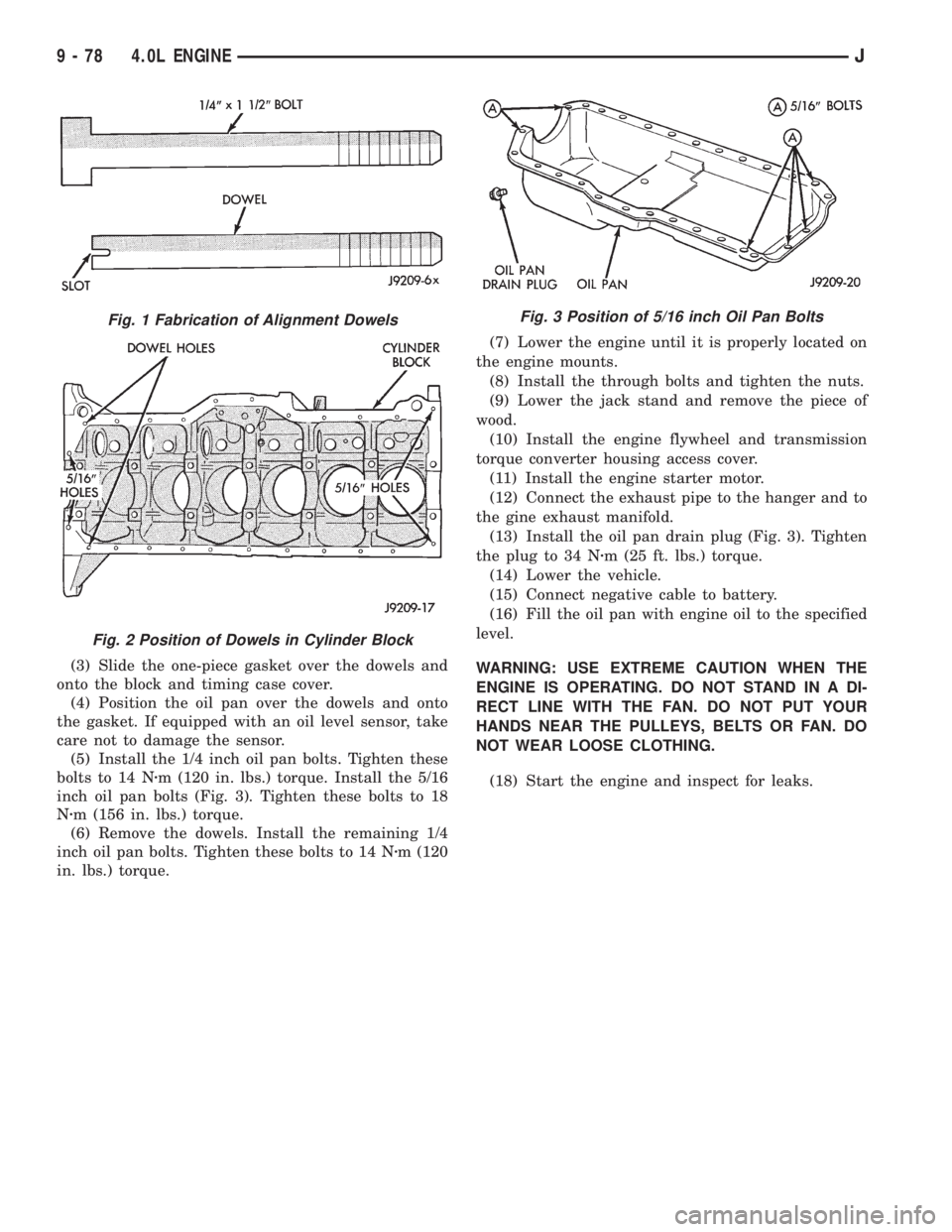

(12) Place Timing Case Cover Alignment and Seal

Installation Tool 6139 in the crankshaft opening in

the cover (Fig. 12).

(13) Install the timing case cover-to-cylinder block

bolts. Install the oil pan-to-timing case cover bolts.

(14) Tighten the 1/4 inch cover-to-block bolts to 7

Nzm (60 in. lbs.) torque. Tighten the 5/16 inch front

cover-to-block bolts to 22 Nzm (192 in. lbs.) torque.

Tighten the oil pan-to-cover 1/4 inch bolts to 14 Nzm

(120 in. lbs.) torque. Tighten the oil pan-to-cover 5/16

inch bolts to 18 Nzm (156 in. lbs.) torque.

(15) Remove the cover alignment tool and install a

replacement oil seal into the cover.(16) Install the vibration damper on the crank-

shaft.

(17) Lubricate and tighten the damper bolt to 108

Nzm (80 ft. lbs.) torque.

(18) If equipped with air conditioning:

(a) Install the A/C compressor serpentine drive

belt idler pulley.

(b) Install the generator.

(c) Install the A/C condenser and receiver/drier

assembly.

(19) Install the serpentine drive belt on the pulleys

and tighten (refer to Group 7, Cooling System for the

specifications and procedures).

(20) Install the radiator. Connect the radiator

hoses and automatic transmission fluid cooler pipes,

if equipped. Fill the cooling system.

(21) Install the fan and shroud.

(22) Connect negative cable to battery.

OIL PAN

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Remove the oil pan drain plug and drain the

engine oil.

(4) Disconnect the exhaust pipe at the exhaust

manifold.

(5) Disconnect the exhaust hanger at the catalytic

converter and lower the pipe.

(6) Remove the starter motor.

(7) Remove the engine flywheel and transmission

torque converter housing access cover.

(8) If equipped with an oil level sensor, disconnect

the sensor.

(9) Position a jack stand directly under the engine

vibration damper.

(10) Place a piece of wood (2 x 2) between the jack

stand and the engine vibration damper.

(11) Remove the engine mount through bolts.

(12) Using the jack stand, raise the engine until

adequate clearance is obtained to remove the oil pan.

(13) Remove the oil pan bolts. Carefully slide the

oil pan and gasket to the rear. If equipped with an oil

level sensor, take care not to damage the sensor.

CLEANING

Clean the block and pan gasket surfaces.

INSTALLATION

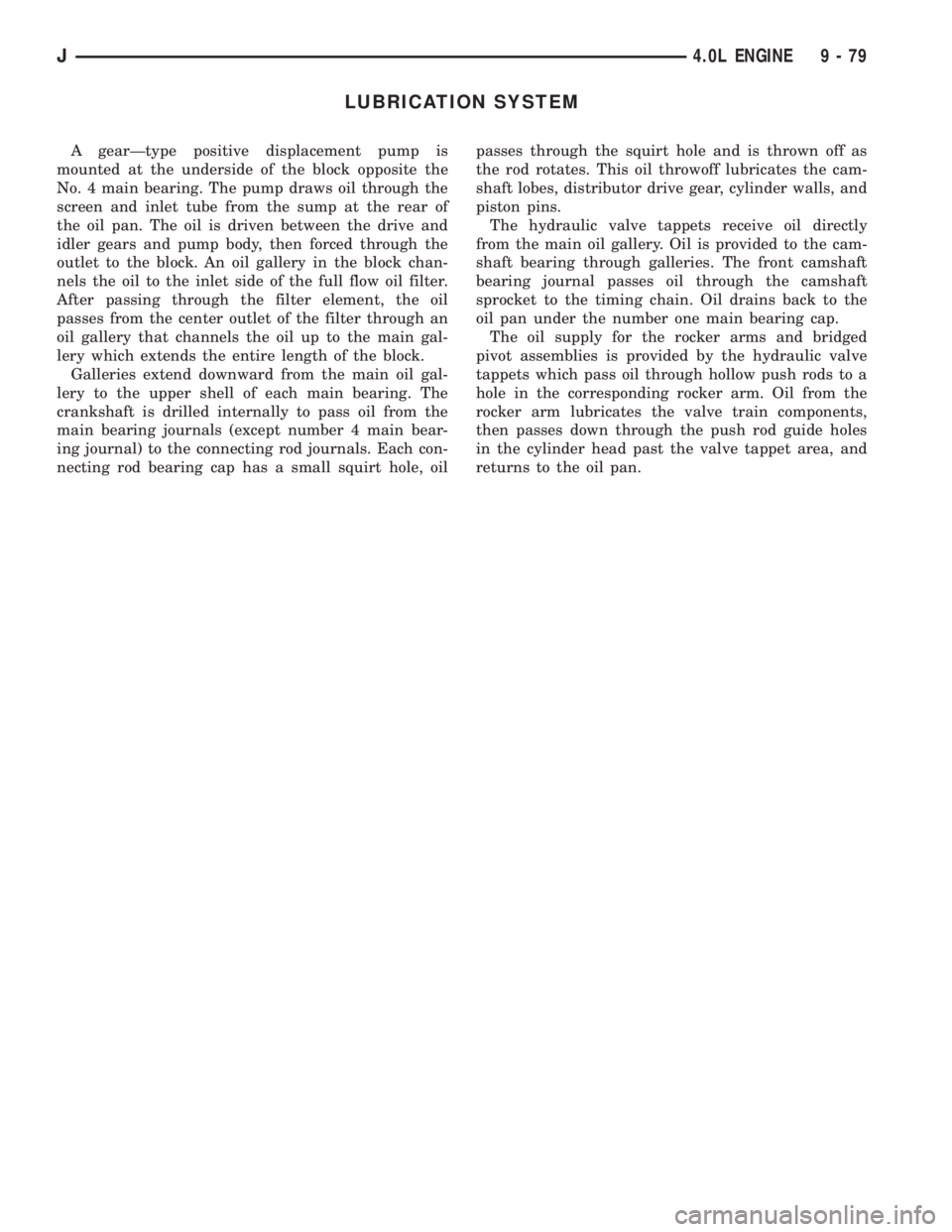

(1) Fabricate 4 alignment dowels from 1/4 x 1 1/2

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier in-

stallation and removal with a screwdriver (Fig. 1).

(2) Install two dowels in the timing case cover. In-

stall the other two dowels in the cylinder block (Fig.

2).

Fig. 11 Verify CrankshaftÐCamshaft InstallationÐ

Typical

Fig. 12 Timing Case Cover Alignment and Seal

Installation Tool 6139

J4.0L ENGINE 9 - 77

Page 1357 of 2158

(3) Slide the one-piece gasket over the dowels and

onto the block and timing case cover.

(4) Position the oil pan over the dowels and onto

the gasket. If equipped with an oil level sensor, take

care not to damage the sensor.

(5) Install the 1/4 inch oil pan bolts. Tighten these

bolts to 14 Nzm (120 in. lbs.) torque. Install the 5/16

inch oil pan bolts (Fig. 3). Tighten these bolts to 18

Nzm (156 in. lbs.) torque.

(6) Remove the dowels. Install the remaining 1/4

inch oil pan bolts. Tighten these bolts to 14 Nzm (120

in. lbs.) torque.(7) Lower the engine until it is properly located on

the engine mounts.

(8) Install the through bolts and tighten the nuts.

(9) Lower the jack stand and remove the piece of

wood.

(10) Install the engine flywheel and transmission

torque converter housing access cover.

(11) Install the engine starter motor.

(12) Connect the exhaust pipe to the hanger and to

the gine exhaust manifold.

(13) Install the oil pan drain plug (Fig. 3). Tighten

the plug to 34 Nzm (25 ft. lbs.) torque.

(14) Lower the vehicle.

(15) Connect negative cable to battery.

(16) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(18) Start the engine and inspect for leaks.

Fig. 1 Fabrication of Alignment Dowels

Fig. 2 Position of Dowels in Cylinder Block

Fig. 3 Position of 5/16 inch Oil Pan Bolts

9 - 78 4.0L ENGINEJ

Page 1358 of 2158

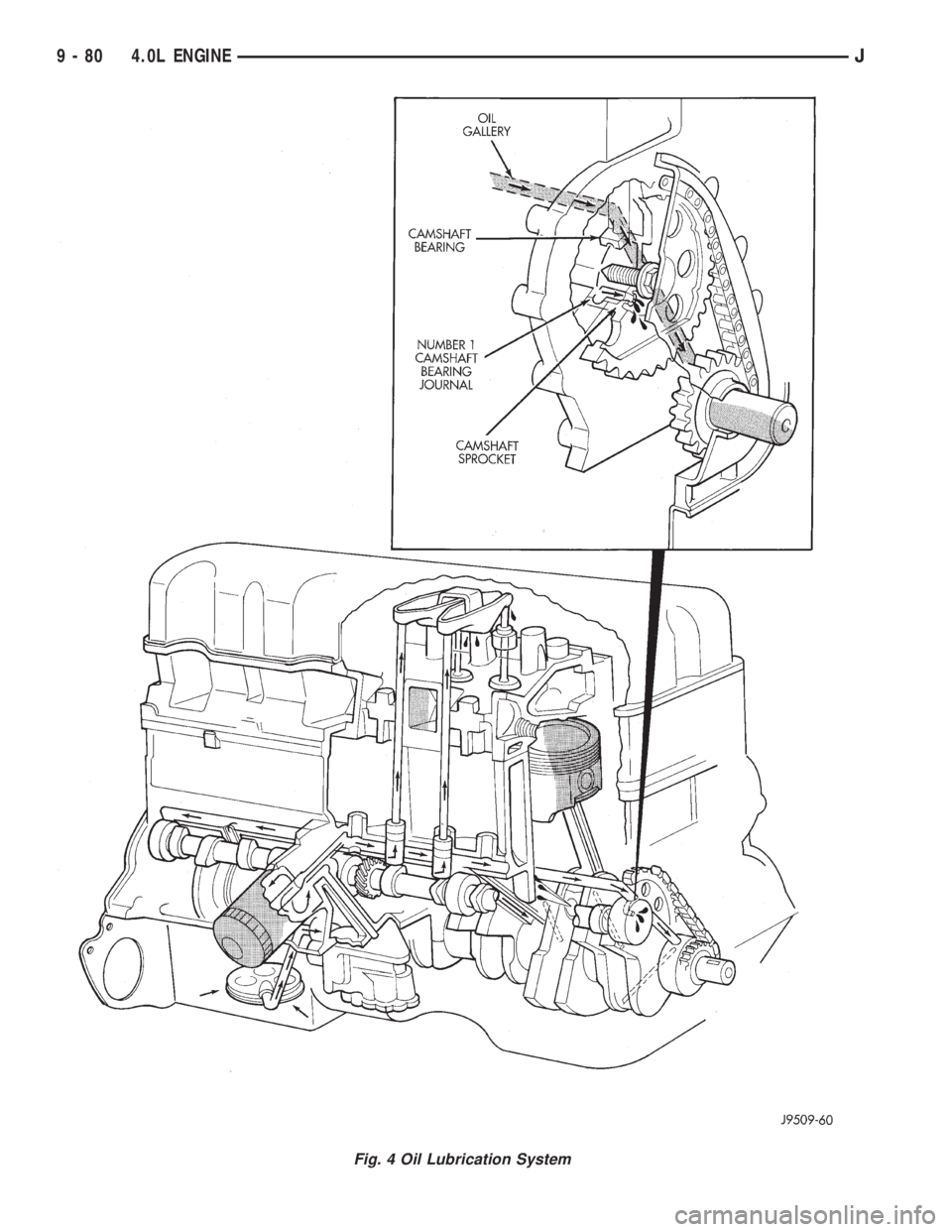

LUBRICATION SYSTEM

A gearÐtype positive displacement pump is

mounted at the underside of the block opposite the

No. 4 main bearing. The pump draws oil through the

screen and inlet tube from the sump at the rear of

the oil pan. The oil is driven between the drive and

idler gears and pump body, then forced through the

outlet to the block. An oil gallery in the block chan-

nels the oil to the inlet side of the full flow oil filter.

After passing through the filter element, the oil

passes from the center outlet of the filter through an

oil gallery that channels the oil up to the main gal-

lery which extends the entire length of the block.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals (except number 4 main bear-

ing journal) to the connecting rod journals. Each con-

necting rod bearing cap has a small squirt hole, oilpasses through the squirt hole and is thrown off as

the rod rotates. This oil throwoff lubricates the cam-

shaft lobes, distributor drive gear, cylinder walls, and

piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. Oil is provided to the cam-

shaft bearing through galleries. The front camshaft

bearing journal passes oil through the camshaft

sprocket to the timing chain. Oil drains back to the

oil pan under the number one main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components,

then passes down through the push rod guide holes

in the cylinder head past the valve tappet area, and

returns to the oil pan.

J4.0L ENGINE 9 - 79

Page 1359 of 2158

Fig. 4 Oil Lubrication System

9 - 80 4.0L ENGINEJ

Page 1360 of 2158

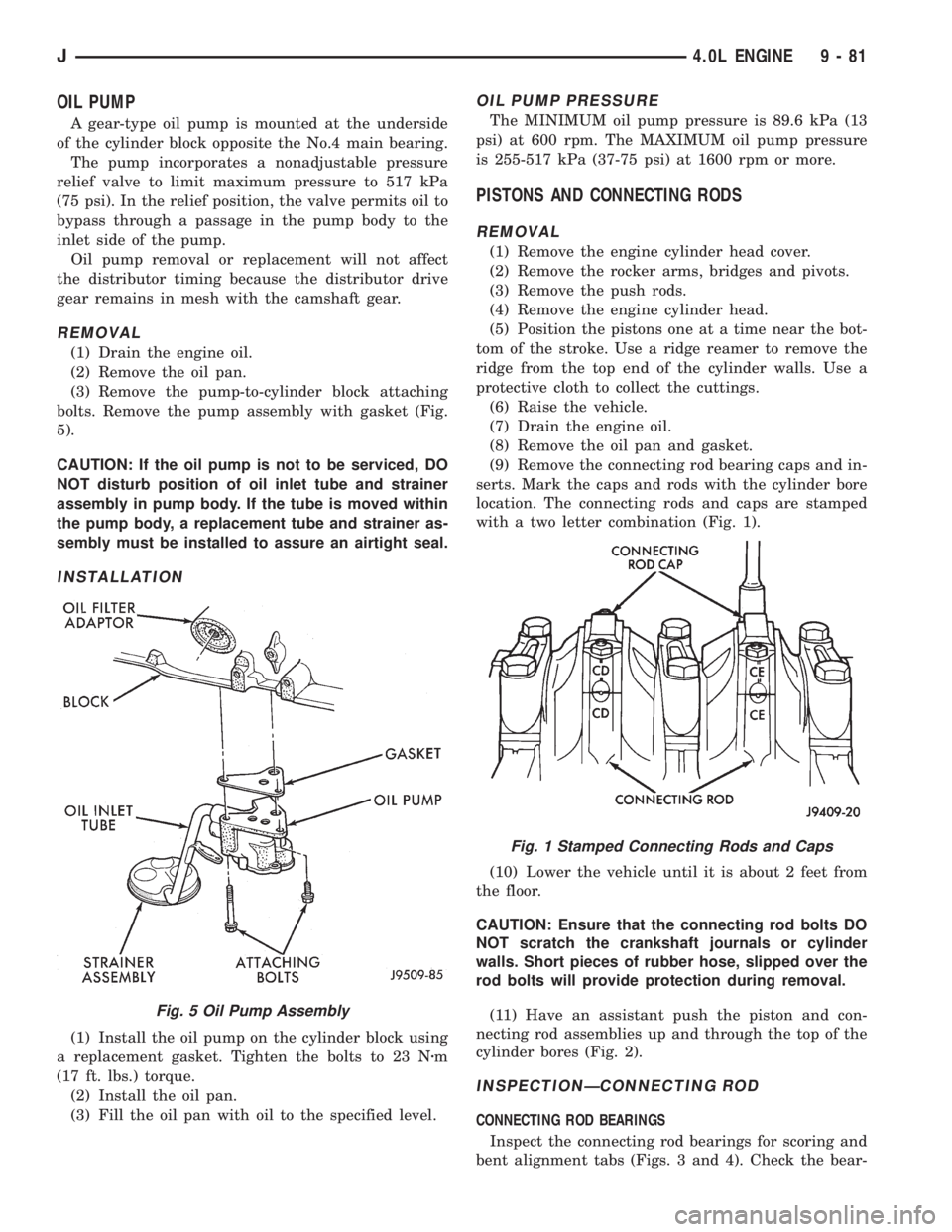

OIL PUMP

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

The pump incorporates a nonadjustable pressure

relief valve to limit maximum pressure to 517 kPa

(75 psi). In the relief position, the valve permits oil to

bypass through a passage in the pump body to the

inlet side of the pump.

Oil pump removal or replacement will not affect

the distributor timing because the distributor drive

gear remains in mesh with the camshaft gear.

REMOVAL

(1) Drain the engine oil.

(2) Remove the oil pan.

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

5).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer as-

sembly must be installed to assure an airtight seal.

INSTALLATION

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the bolts to 23 Nzm

(17 ft. lbs.) torque.

(2) Install the oil pan.

(3) Fill the oil pan with oil to the specified level.

OIL PUMP PRESSURE

The MINIMUM oil pump pressure is 89.6 kPa (13

psi) at 600 rpm. The MAXIMUM oil pump pressure

is 255-517 kPa (37-75 psi) at 1600 rpm or more.

PISTONS AND CONNECTING RODS

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the rocker arms, bridges and pivots.

(3) Remove the push rods.

(4) Remove the engine cylinder head.

(5) Position the pistons one at a time near the bot-

tom of the stroke. Use a ridge reamer to remove the

ridge from the top end of the cylinder walls. Use a

protective cloth to collect the cuttings.

(6) Raise the vehicle.

(7) Drain the engine oil.

(8) Remove the oil pan and gasket.

(9) Remove the connecting rod bearing caps and in-

serts. Mark the caps and rods with the cylinder bore

location. The connecting rods and caps are stamped

with a two letter combination (Fig. 1).

(10) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(11) Have an assistant push the piston and con-

necting rod assemblies up and through the top of the

cylinder bores (Fig. 2).

INSPECTIONÐCONNECTING ROD

CONNECTING ROD BEARINGS

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Figs. 3 and 4). Check the bear-

Fig. 5 Oil Pump Assembly

Fig. 1 Stamped Connecting Rods and Caps

J4.0L ENGINE 9 - 81