JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1321 of 2158

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the connect-

ing rod and crankshaft journal flange. Refer to En-

gine Specifications for the proper clearance. Replace

the connecting rod if the side clearance is not within

specification.

PISTON FITTING

BORE GAUGE METHOD

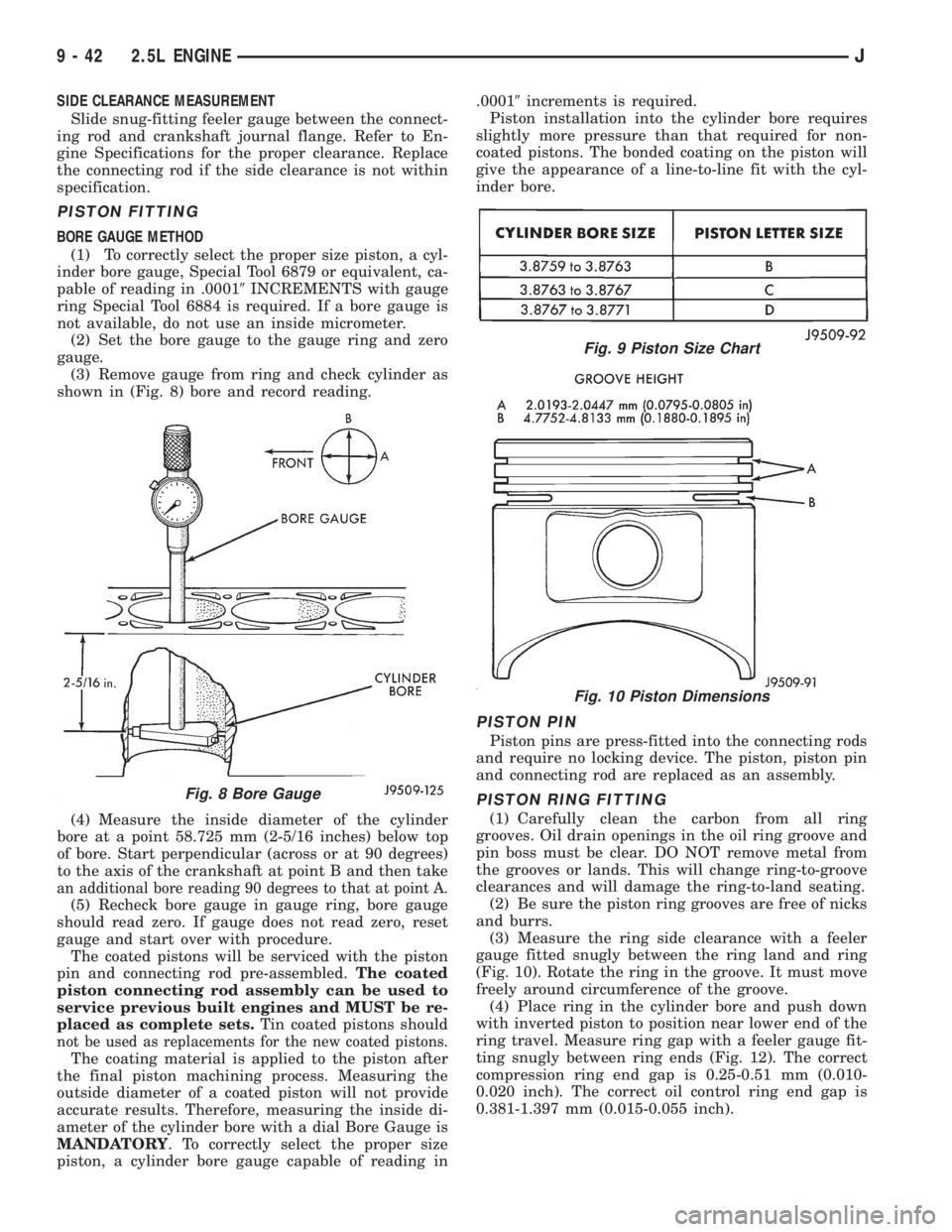

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, Special Tool 6879 or equivalent, ca-

pable of reading in .00019INCREMENTS with gauge

ring Special Tool 6884 is required. If a bore gauge is

not available, do not use an inside micrometer.

(2) Set the bore gauge to the gauge ring and zero

gauge.

(3) Remove gauge from ring and check cylinder as

shown in (Fig. 8) bore and record reading.

(4) Measure the inside diameter of the cylinder

bore at a point 58.725 mm (2-5/16 inches) below top

of bore. Start perpendicular (across or at 90 degrees)

to the axis of the crankshaft at point B and then take

an additional bore reading 90 degrees to that at point A.

(5) Recheck bore gauge in gauge ring, bore gauge

should read zero. If gauge does not read zero, reset

gauge and start over with procedure.

The coated pistons will be serviced with the piston

pin and connecting rod pre-assembled.The coated

piston connecting rod assembly can be used to

service previous built engines and MUST be re-

placed as complete sets.Tin coated pistons should

not be used as replacements for the new coated pistons.

The coating material is applied to the piston after

the final piston machining process. Measuring the

outside diameter of a coated piston will not provide

accurate results. Therefore, measuring the inside di-

ameter of the cylinder bore with a dial Bore Gauge is

MANDATORY. To correctly select the proper size

piston, a cylinder bore gauge capable of reading in.00019increments is required.

Piston installation into the cylinder bore requires

slightly more pressure than that required for non-

coated pistons. The bonded coating on the piston will

give the appearance of a line-to-line fit with the cyl-

inder bore.

PISTON PIN

Piston pins are press-fitted into the connecting rods

and require no locking device. The piston, piston pin

and connecting rod are replaced as an assembly.

PISTON RING FITTING

(1) Carefully clean the carbon from all ring

grooves. Oil drain openings in the oil ring groove and

pin boss must be clear. DO NOT remove metal from

the grooves or lands. This will change ring-to-groove

clearances and will damage the ring-to-land seating.

(2) Be sure the piston ring grooves are free of nicks

and burrs.

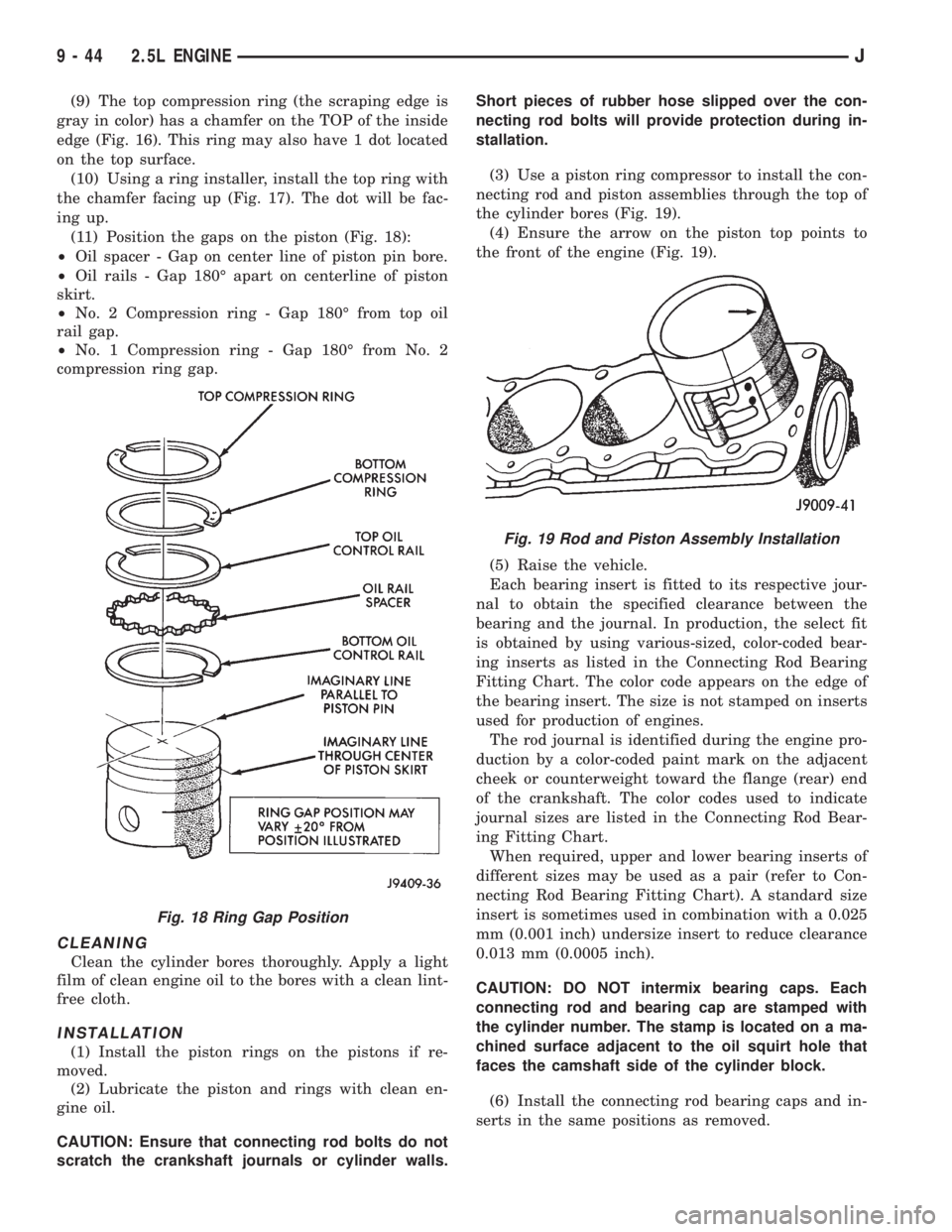

(3) Measure the ring side clearance with a feeler

gauge fitted snugly between the ring land and ring

(Fig. 10). Rotate the ring in the groove. It must move

freely around circumference of the groove.

(4) Place ring in the cylinder bore and push down

with inverted piston to position near lower end of the

ring travel. Measure ring gap with a feeler gauge fit-

ting snugly between ring ends (Fig. 12). The correct

compression ring end gap is 0.25-0.51 mm (0.010-

0.020 inch). The correct oil control ring end gap is

0.381-1.397 mm (0.015-0.055 inch).

Fig. 8 Bore Gauge

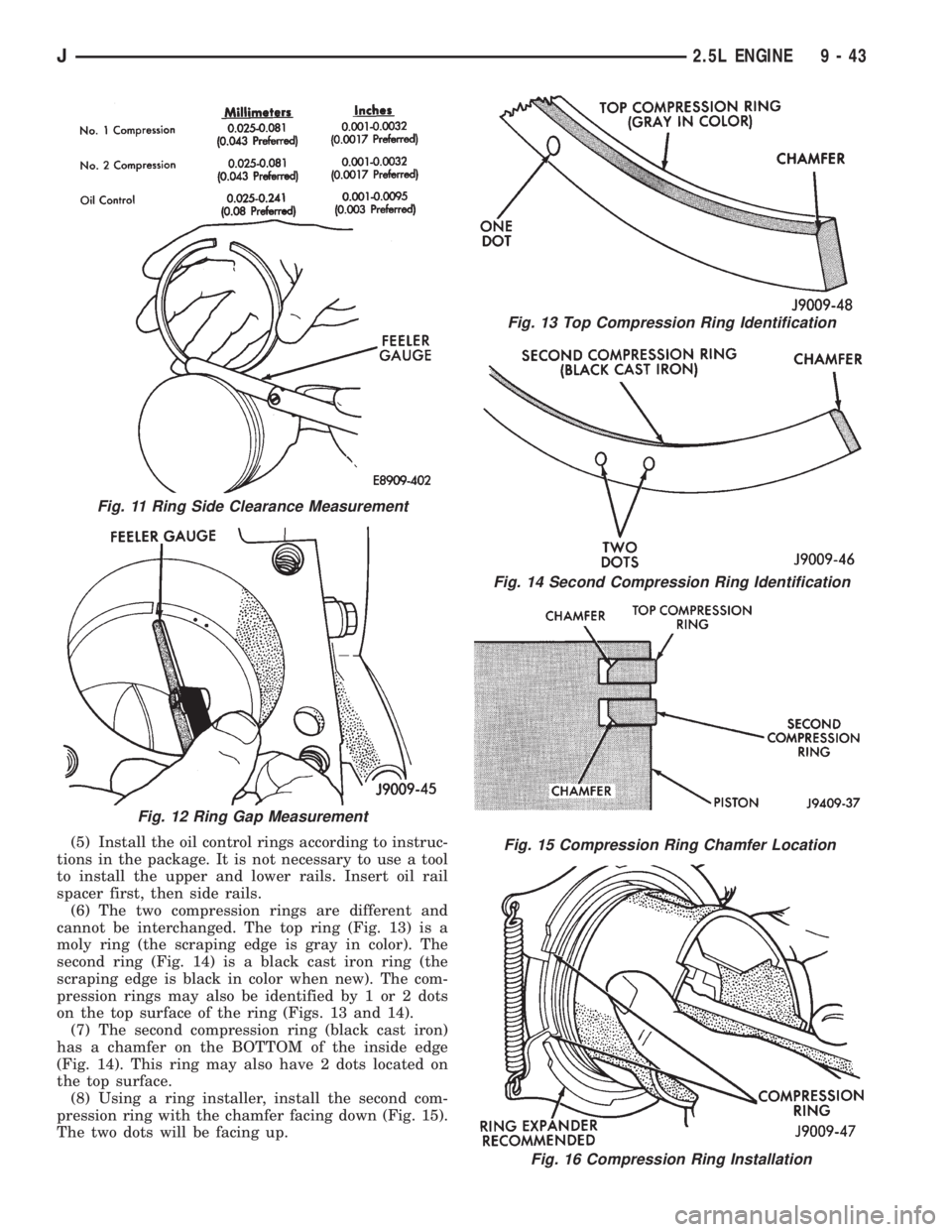

Fig. 9 Piston Size Chart

Fig. 10 Piston Dimensions

9 - 42 2.5L ENGINEJ

Page 1322 of 2158

(5) Install the oil control rings according to instruc-

tions in the package. It is not necessary to use a tool

to install the upper and lower rails. Insert oil rail

spacer first, then side rails.

(6) The two compression rings are different and

cannot be interchanged. The top ring (Fig. 13) is a

moly ring (the scraping edge is gray in color). The

second ring (Fig. 14) is a black cast iron ring (the

scraping edge is black in color when new). The com-

pression rings may also be identified by 1 or 2 dots

on the top surface of the ring (Figs. 13 and 14).

(7) The second compression ring (black cast iron)

has a chamfer on the BOTTOM of the inside edge

(Fig. 14). This ring may also have 2 dots located on

the top surface.

(8) Using a ring installer, install the second com-

pression ring with the chamfer facing down (Fig. 15).

The two dots will be facing up.

Fig. 16 Compression Ring Installation

Fig. 13 Top Compression Ring Identification

Fig. 14 Second Compression Ring Identification

Fig. 15 Compression Ring Chamfer Location

Fig. 11 Ring Side Clearance Measurement

Fig. 12 Ring Gap Measurement

J2.5L ENGINE 9 - 43

Page 1323 of 2158

(9) The top compression ring (the scraping edge is

gray in color) has a chamfer on the TOP of the inside

edge (Fig. 16). This ring may also have 1 dot located

on the top surface.

(10) Using a ring installer, install the top ring with

the chamfer facing up (Fig. 17). The dot will be fac-

ing up.

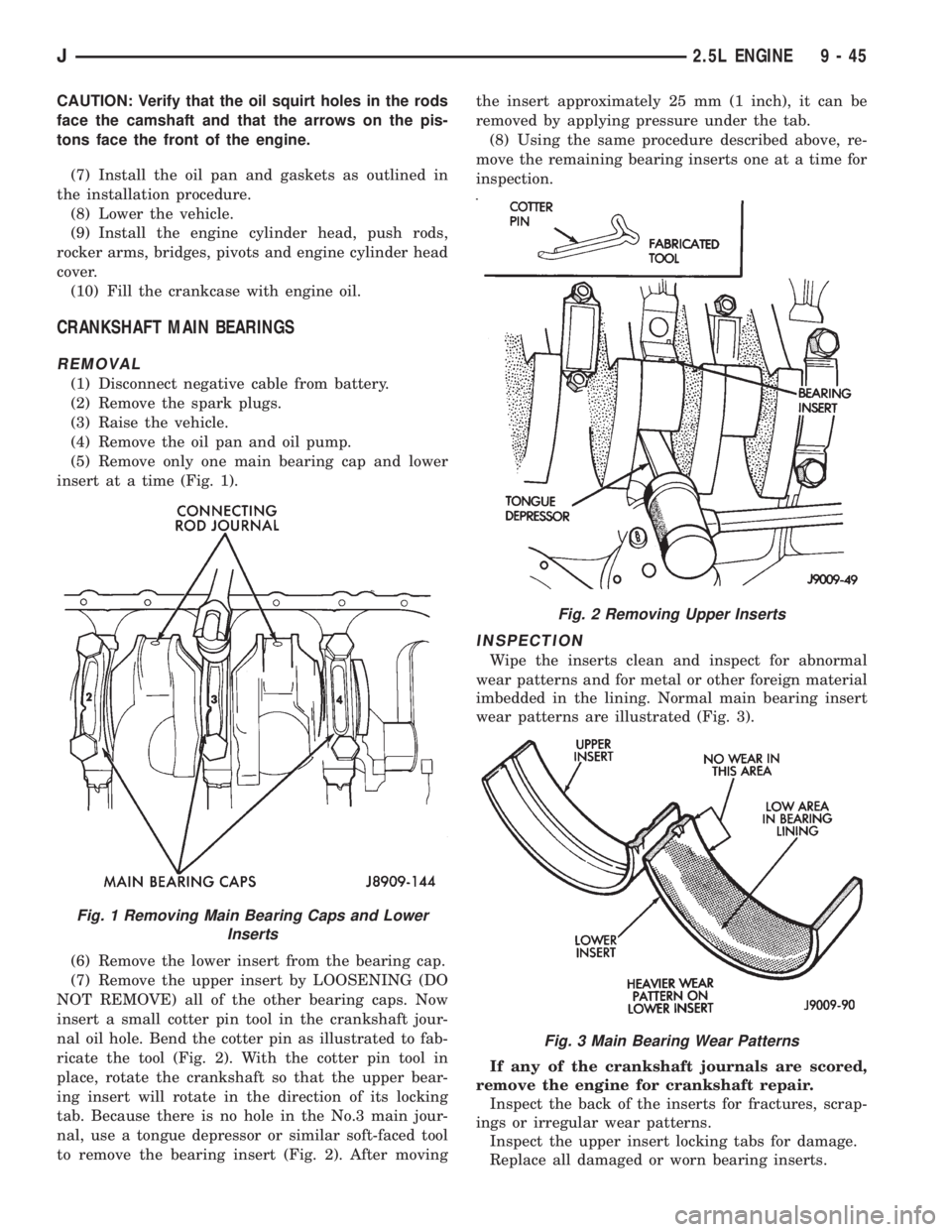

(11) Position the gaps on the piston (Fig. 18):

²Oil spacer - Gap on center line of piston pin bore.

²Oil rails - Gap 180É apart on centerline of piston

skirt.

²No. 2 Compression ring - Gap 180É from top oil

rail gap.

²No. 1 Compression ring - Gap 180É from No. 2

compression ring gap.

CLEANING

Clean the cylinder bores thoroughly. Apply a light

film of clean engine oil to the bores with a clean lint-

free cloth.

INSTALLATION

(1) Install the piston rings on the pistons if re-

moved.

(2) Lubricate the piston and rings with clean en-

gine oil.

CAUTION: Ensure that connecting rod bolts do not

scratch the crankshaft journals or cylinder walls.Short pieces of rubber hose slipped over the con-

necting rod bolts will provide protection during in-

stallation.

(3) Use a piston ring compressor to install the con-

necting rod and piston assemblies through the top of

the cylinder bores (Fig. 19).

(4) Ensure the arrow on the piston top points to

the front of the engine (Fig. 19).

(5) Raise the vehicle.

Each bearing insert is fitted to its respective jour-

nal to obtain the specified clearance between the

bearing and the journal. In production, the select fit

is obtained by using various-sized, color-coded bear-

ing inserts as listed in the Connecting Rod Bearing

Fitting Chart. The color code appears on the edge of

the bearing insert. The size is not stamped on inserts

used for production of engines.

The rod journal is identified during the engine pro-

duction by a color-coded paint mark on the adjacent

cheek or counterweight toward the flange (rear) end

of the crankshaft. The color codes used to indicate

journal sizes are listed in the Connecting Rod Bear-

ing Fitting Chart.

When required, upper and lower bearing inserts of

different sizes may be used as a pair (refer to Con-

necting Rod Bearing Fitting Chart). A standard size

insert is sometimes used in combination with a 0.025

mm (0.001 inch) undersize insert to reduce clearance

0.013 mm (0.0005 inch).

CAUTION: DO NOT intermix bearing caps. Each

connecting rod and bearing cap are stamped with

the cylinder number. The stamp is located on a ma-

chined surface adjacent to the oil squirt hole that

faces the camshaft side of the cylinder block.

(6) Install the connecting rod bearing caps and in-

serts in the same positions as removed.

Fig. 18 Ring Gap Position

Fig. 19 Rod and Piston Assembly Installation

9 - 44 2.5L ENGINEJ

Page 1324 of 2158

CAUTION: Verify that the oil squirt holes in the rods

face the camshaft and that the arrows on the pis-

tons face the front of the engine.

(7) Install the oil pan and gaskets as outlined in

the installation procedure.

(8) Lower the vehicle.

(9) Install the engine cylinder head, push rods,

rocker arms, bridges, pivots and engine cylinder head

cover.

(10) Fill the crankcase with engine oil.

CRANKSHAFT MAIN BEARINGS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the spark plugs.

(3) Raise the vehicle.

(4) Remove the oil pan and oil pump.

(5) Remove only one main bearing cap and lower

insert at a time (Fig. 1).

(6) Remove the lower insert from the bearing cap.

(7) Remove the upper insert by LOOSENING (DO

NOT REMOVE) all of the other bearing caps. Now

insert a small cotter pin tool in the crankshaft jour-

nal oil hole. Bend the cotter pin as illustrated to fab-

ricate the tool (Fig. 2). With the cotter pin tool in

place, rotate the crankshaft so that the upper bear-

ing insert will rotate in the direction of its locking

tab. Because there is no hole in the No.3 main jour-

nal, use a tongue depressor or similar soft-faced tool

to remove the bearing insert (Fig. 2). After movingthe insert approximately 25 mm (1 inch), it can be

removed by applying pressure under the tab.

(8) Using the same procedure described above, re-

move the remaining bearing inserts one at a time for

inspection.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 3).

If any of the crankshaft journals are scored,

remove the engine for crankshaft repair.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

Fig. 1 Removing Main Bearing Caps and Lower

Inserts

Fig. 2 Removing Upper Inserts

Fig. 3 Main Bearing Wear Patterns

J2.5L ENGINE 9 - 45

Page 1325 of 2158

FITTING (CRANKSHAFT INSTALLED)

The main bearing caps, numbered (front to rear)

from 1 through 5 have an arrow to indicate the for-

ward position. The upper main bearing inserts are

grooved to provide oil channels while the lower in-

serts are smooth.

Each bearing insert pair is selectively fitted to its

respective journal to obtain the specified operating

clearance. In production, the select fit is obtained by

using various-sized color-coded bearing insert pairs

as listed in the Main Bearing Fitting Chart. The

bearing color code appears on the edge of the insert.

The size is not stamped on bearing inserts used

for engine production.

The main bearing journal size (diameter) is identi-

fied by a color-coded paint mark on the adjacent

cheek. The rear main journal, is identified by a color-

coded paint mark on the crankshaft rear flange.

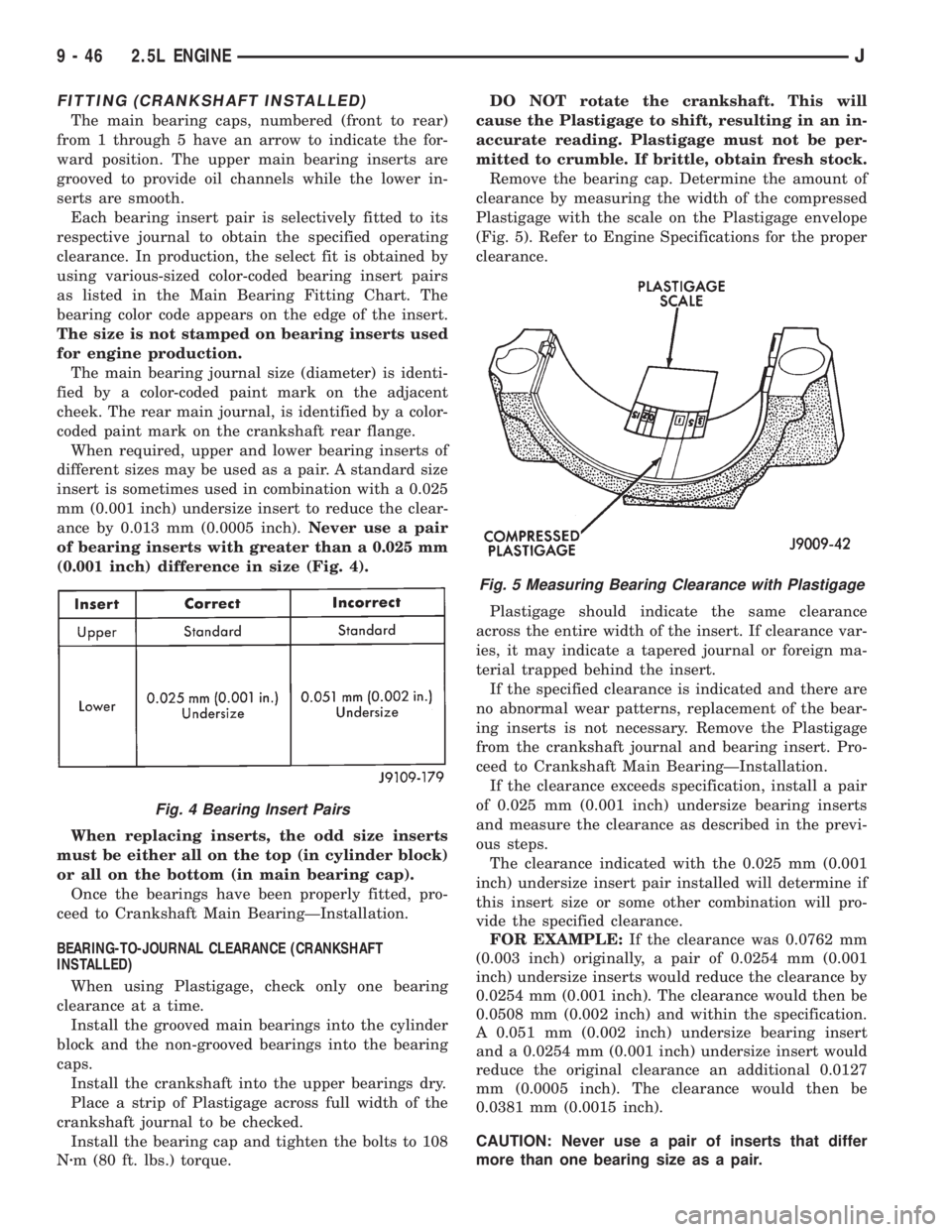

When required, upper and lower bearing inserts of

different sizes may be used as a pair. A standard size

insert is sometimes used in combination with a 0.025

mm (0.001 inch) undersize insert to reduce the clear-

ance by 0.013 mm (0.0005 inch).Never use a pair

of bearing inserts with greater than a 0.025 mm

(0.001 inch) difference in size (Fig. 4).

When replacing inserts, the odd size inserts

must be either all on the top (in cylinder block)

or all on the bottom (in main bearing cap).

Once the bearings have been properly fitted, pro-

ceed to Crankshaft Main BearingÐInstallation.

BEARING-TO-JOURNAL CLEARANCE (CRANKSHAFT

INSTALLED)

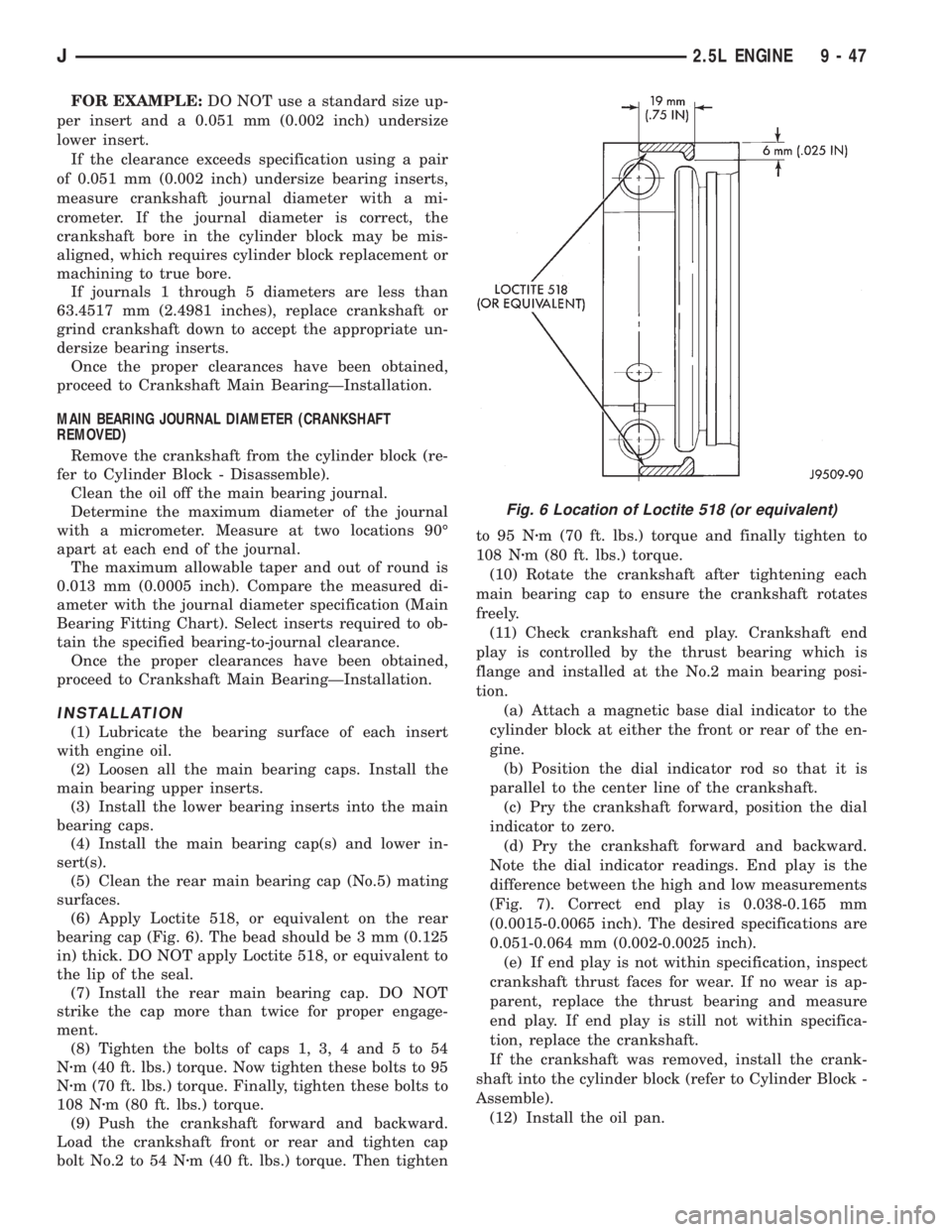

When using Plastigage, check only one bearing

clearance at a time.

Install the grooved main bearings into the cylinder

block and the non-grooved bearings into the bearing

caps.

Install the crankshaft into the upper bearings dry.

Place a strip of Plastigage across full width of the

crankshaft journal to be checked.

Install the bearing cap and tighten the bolts to 108

Nzm (80 ft. lbs.) torque.DO NOT rotate the crankshaft. This will

cause the Plastigage to shift, resulting in an in-

accurate reading. Plastigage must not be per-

mitted to crumble. If brittle, obtain fresh stock.

Remove the bearing cap. Determine the amount of

clearance by measuring the width of the compressed

Plastigage with the scale on the Plastigage envelope

(Fig. 5). Refer to Engine Specifications for the proper

clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If clearance var-

ies, it may indicate a tapered journal or foreign ma-

terial trapped behind the insert.

If the specified clearance is indicated and there are

no abnormal wear patterns, replacement of the bear-

ing inserts is not necessary. Remove the Plastigage

from the crankshaft journal and bearing insert. Pro-

ceed to Crankshaft Main BearingÐInstallation.

If the clearance exceeds specification, install a pair

of 0.025 mm (0.001 inch) undersize bearing inserts

and measure the clearance as described in the previ-

ous steps.

The clearance indicated with the 0.025 mm (0.001

inch) undersize insert pair installed will determine if

this insert size or some other combination will pro-

vide the specified clearance.

FOR EXAMPLE:If the clearance was 0.0762 mm

(0.003 inch) originally, a pair of 0.0254 mm (0.001

inch) undersize inserts would reduce the clearance by

0.0254 mm (0.001 inch). The clearance would then be

0.0508 mm (0.002 inch) and within the specification.

A 0.051 mm (0.002 inch) undersize bearing insert

and a 0.0254 mm (0.001 inch) undersize insert would

reduce the original clearance an additional 0.0127

mm (0.0005 inch). The clearance would then be

0.0381 mm (0.0015 inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

Fig. 4 Bearing Insert Pairs

Fig. 5 Measuring Bearing Clearance with Plastigage

9 - 46 2.5L ENGINEJ

Page 1326 of 2158

FOR EXAMPLE:DO NOT use a standard size up-

per insert and a 0.051 mm (0.002 inch) undersize

lower insert.

If the clearance exceeds specification using a pair

of 0.051 mm (0.002 inch) undersize bearing inserts,

measure crankshaft journal diameter with a mi-

crometer. If the journal diameter is correct, the

crankshaft bore in the cylinder block may be mis-

aligned, which requires cylinder block replacement or

machining to true bore.

If journals 1 through 5 diameters are less than

63.4517 mm (2.4981 inches), replace crankshaft or

grind crankshaft down to accept the appropriate un-

dersize bearing inserts.

Once the proper clearances have been obtained,

proceed to Crankshaft Main BearingÐInstallation.

MAIN BEARING JOURNAL DIAMETER (CRANKSHAFT

REMOVED)

Remove the crankshaft from the cylinder block (re-

fer to Cylinder Block - Disassemble).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper and out of round is

0.013 mm (0.0005 inch). Compare the measured di-

ameter with the journal diameter specification (Main

Bearing Fitting Chart). Select inserts required to ob-

tain the specified bearing-to-journal clearance.

Once the proper clearances have been obtained,

proceed to Crankshaft Main BearingÐInstallation.

INSTALLATION

(1) Lubricate the bearing surface of each insert

with engine oil.

(2) Loosen all the main bearing caps. Install the

main bearing upper inserts.

(3) Install the lower bearing inserts into the main

bearing caps.

(4) Install the main bearing cap(s) and lower in-

sert(s).

(5) Clean the rear main bearing cap (No.5) mating

surfaces.

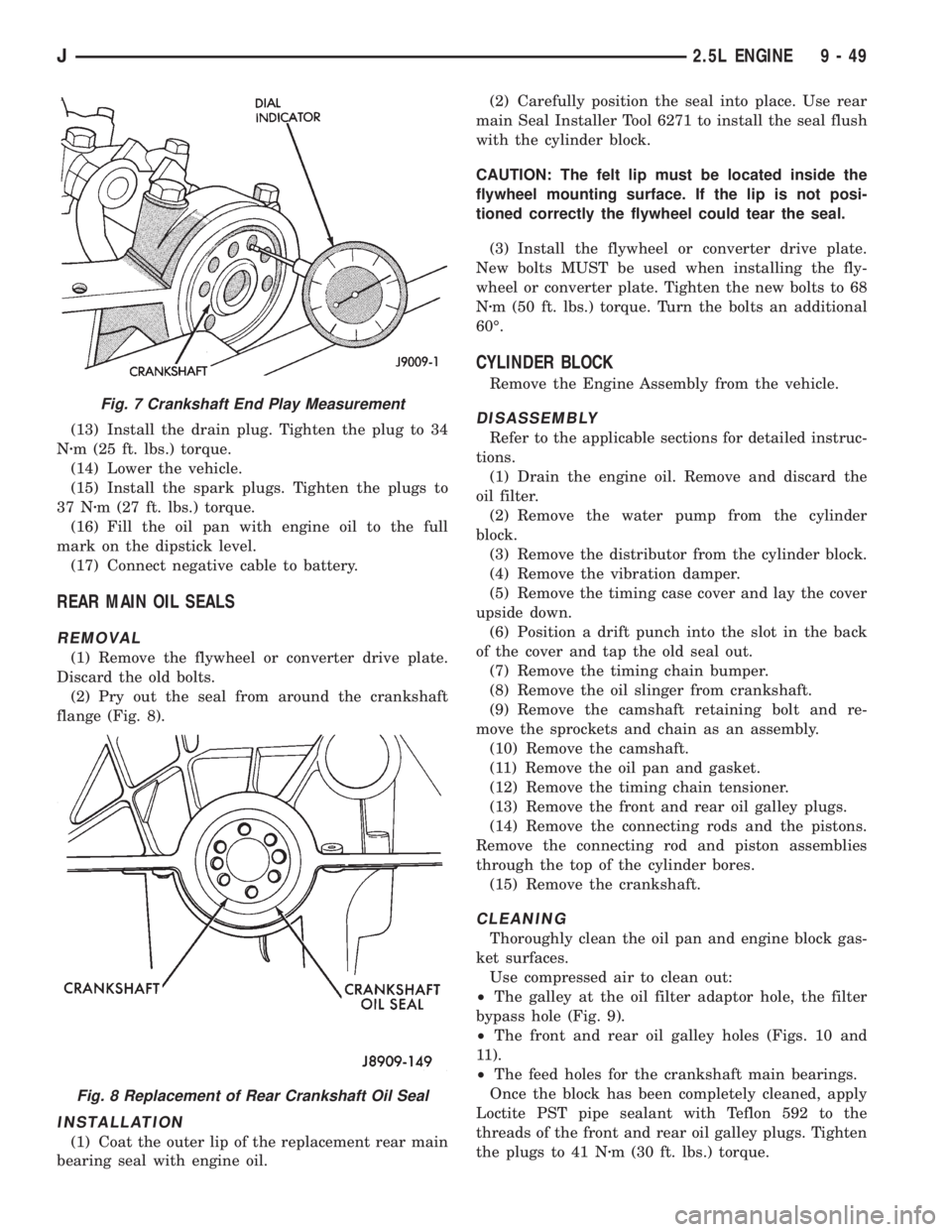

(6) Apply Loctite 518, or equivalent on the rear

bearing cap (Fig. 6). The bead should be 3 mm (0.125

in) thick. DO NOT apply Loctite 518, or equivalent to

the lip of the seal.

(7) Install the rear main bearing cap. DO NOT

strike the cap more than twice for proper engage-

ment.

(8) Tighten the bolts of caps 1, 3, 4 and 5 to 54

Nzm (40 ft. lbs.) torque. Now tighten these bolts to 95

Nzm (70 ft. lbs.) torque. Finally, tighten these bolts to

108 Nzm (80 ft. lbs.) torque.

(9) Push the crankshaft forward and backward.

Load the crankshaft front or rear and tighten cap

bolt No.2 to 54 Nzm (40 ft. lbs.) torque. Then tightento 95 Nzm (70 ft. lbs.) torque and finally tighten to

108 Nzm (80 ft. lbs.) torque.

(10) Rotate the crankshaft after tightening each

main bearing cap to ensure the crankshaft rotates

freely.

(11) Check crankshaft end play. Crankshaft end

play is controlled by the thrust bearing which is

flange and installed at the No.2 main bearing posi-

tion.

(a) Attach a magnetic base dial indicator to the

cylinder block at either the front or rear of the en-

gine.

(b) Position the dial indicator rod so that it is

parallel to the center line of the crankshaft.

(c) Pry the crankshaft forward, position the dial

indicator to zero.

(d) Pry the crankshaft forward and backward.

Note the dial indicator readings. End play is the

difference between the high and low measurements

(Fig. 7). Correct end play is 0.038-0.165 mm

(0.0015-0.0065 inch). The desired specifications are

0.051-0.064 mm (0.002-0.0025 inch).

(e) If end play is not within specification, inspect

crankshaft thrust faces for wear. If no wear is ap-

parent, replace the thrust bearing and measure

end play. If end play is still not within specifica-

tion, replace the crankshaft.

If the crankshaft was removed, install the crank-

shaft into the cylinder block (refer to Cylinder Block -

Assemble).

(12) Install the oil pan.

Fig. 6 Location of Loctite 518 (or equivalent)

J2.5L ENGINE 9 - 47

Page 1327 of 2158

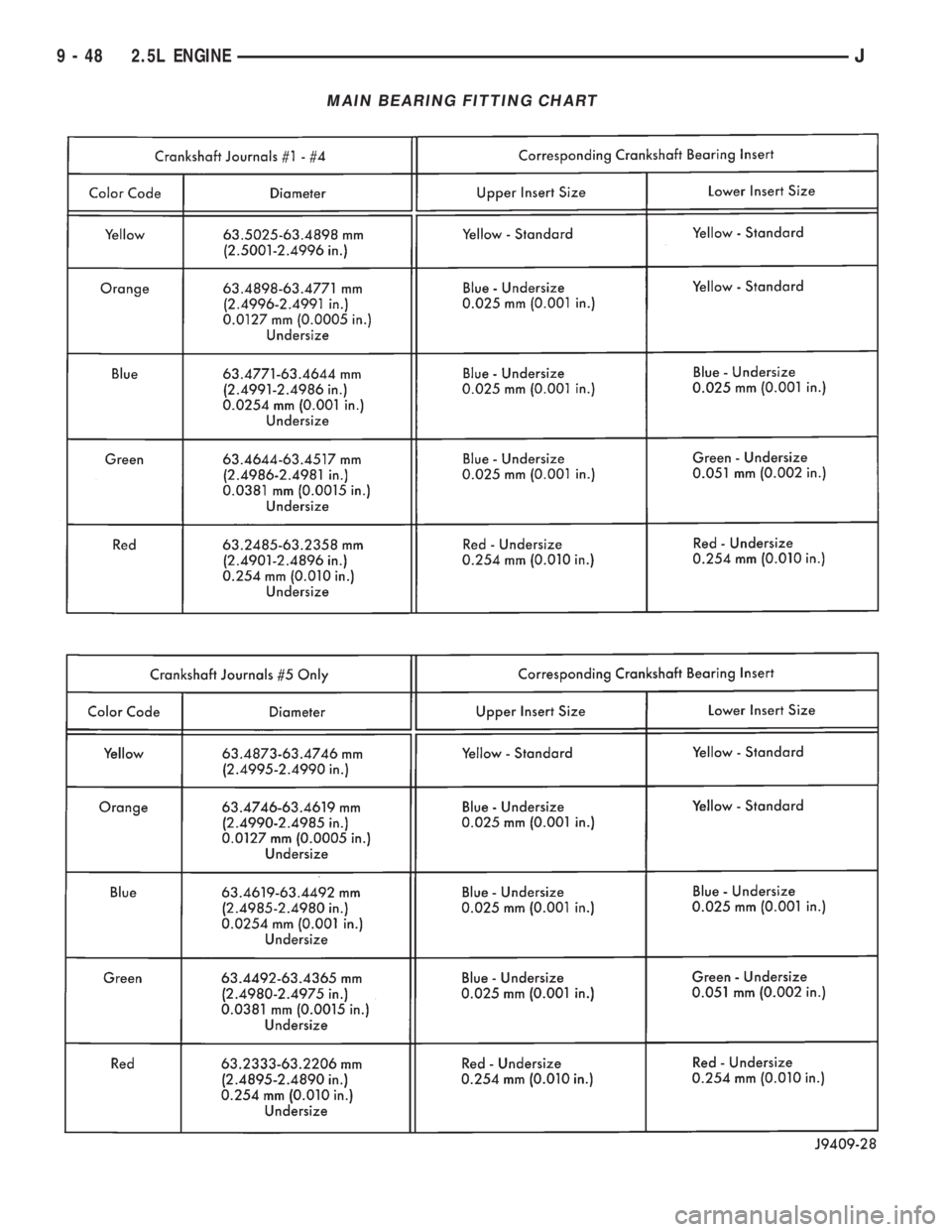

MAIN BEARING FITTING CHART

9 - 48 2.5L ENGINEJ

Page 1328 of 2158

(13) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(14) Lower the vehicle.

(15) Install the spark plugs. Tighten the plugs to

37 Nzm (27 ft. lbs.) torque.

(16) Fill the oil pan with engine oil to the full

mark on the dipstick level.

(17) Connect negative cable to battery.

REAR MAIN OIL SEALS

REMOVAL

(1) Remove the flywheel or converter drive plate.

Discard the old bolts.

(2) Pry out the seal from around the crankshaft

flange (Fig. 8).

INSTALLATION

(1) Coat the outer lip of the replacement rear main

bearing seal with engine oil.(2) Carefully position the seal into place. Use rear

main Seal Installer Tool 6271 to install the seal flush

with the cylinder block.

CAUTION: The felt lip must be located inside the

flywheel mounting surface. If the lip is not posi-

tioned correctly the flywheel could tear the seal.

(3) Install the flywheel or converter drive plate.

New bolts MUST be used when installing the fly-

wheel or converter plate. Tighten the new bolts to 68

Nzm (50 ft. lbs.) torque. Turn the bolts an additional

60É.

CYLINDER BLOCK

Remove the Engine Assembly from the vehicle.

DISASSEMBLY

Refer to the applicable sections for detailed instruc-

tions.

(1) Drain the engine oil. Remove and discard the

oil filter.

(2) Remove the water pump from the cylinder

block.

(3) Remove the distributor from the cylinder block.

(4) Remove the vibration damper.

(5) Remove the timing case cover and lay the cover

upside down.

(6) Position a drift punch into the slot in the back

of the cover and tap the old seal out.

(7) Remove the timing chain bumper.

(8) Remove the oil slinger from crankshaft.

(9) Remove the camshaft retaining bolt and re-

move the sprockets and chain as an assembly.

(10) Remove the camshaft.

(11) Remove the oil pan and gasket.

(12) Remove the timing chain tensioner.

(13) Remove the front and rear oil galley plugs.

(14) Remove the connecting rods and the pistons.

Remove the connecting rod and piston assemblies

through the top of the cylinder bores.

(15) Remove the crankshaft.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

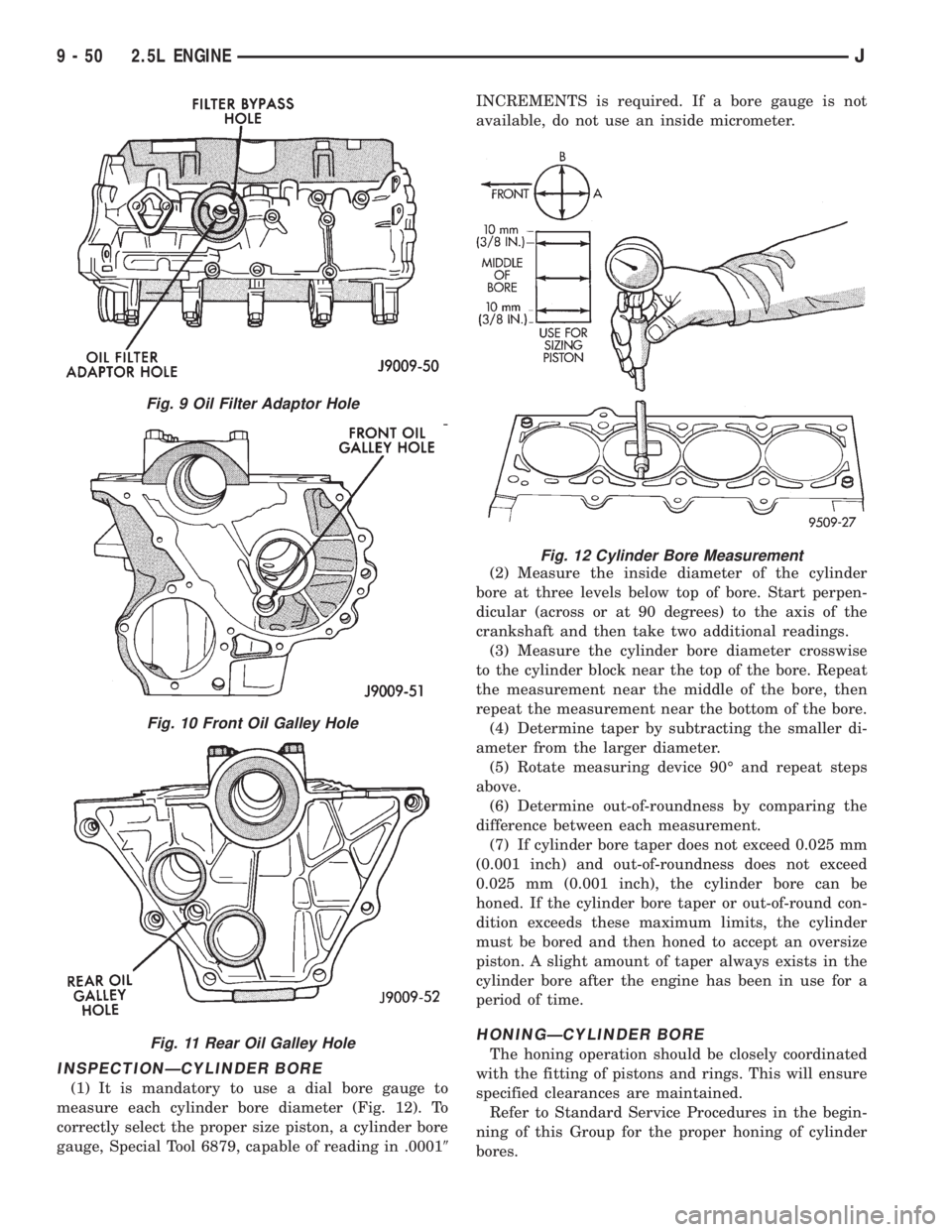

Use compressed air to clean out:

²The galley at the oil filter adaptor hole, the filter

bypass hole (Fig. 9).

²The front and rear oil galley holes (Figs. 10 and

11).

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 41 Nzm (30 ft. lbs.) torque.

Fig. 7 Crankshaft End Play Measurement

Fig. 8 Replacement of Rear Crankshaft Oil Seal

J2.5L ENGINE 9 - 49

Page 1329 of 2158

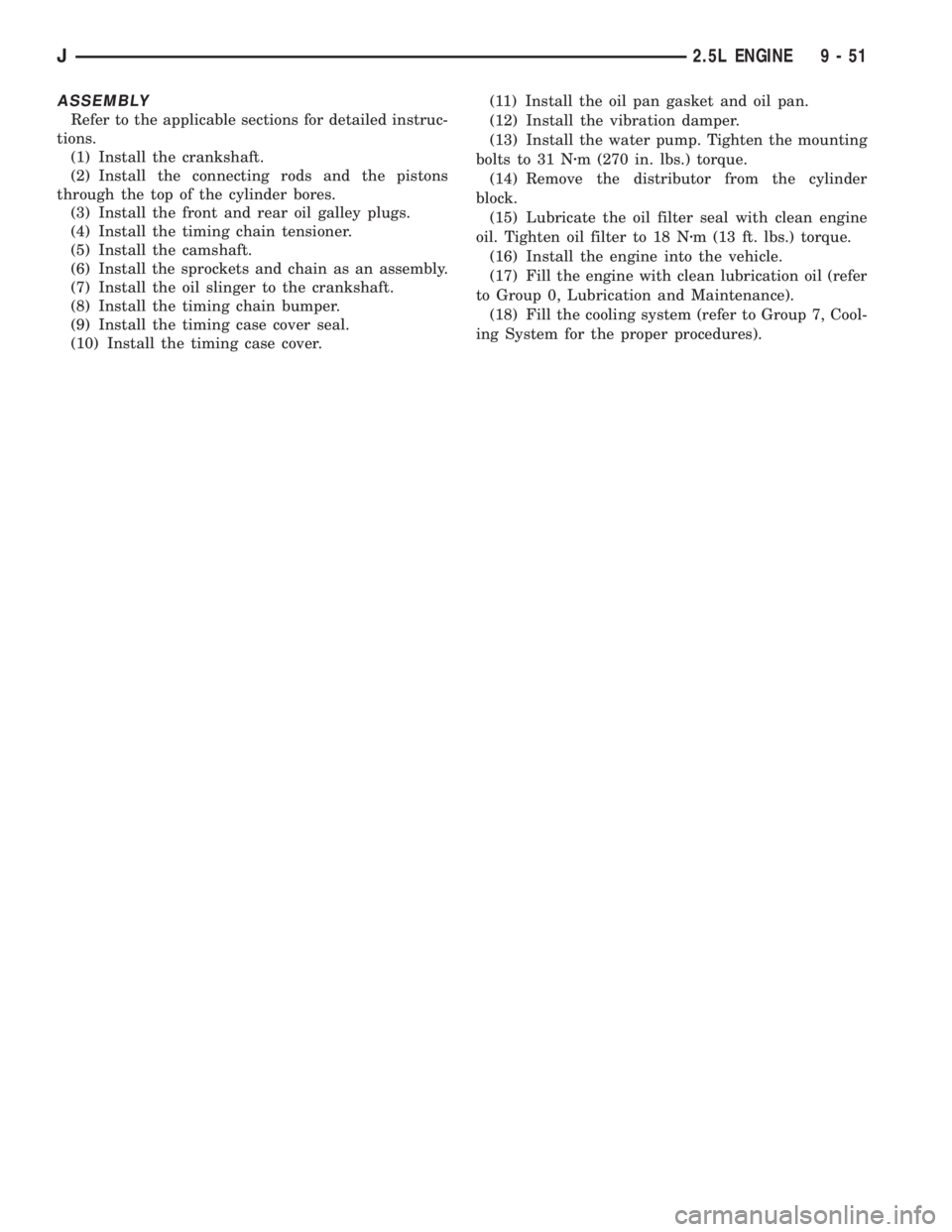

INSPECTIONÐCYLINDER BORE

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter (Fig. 12). To

correctly select the proper size piston, a cylinder bore

gauge, Special Tool 6879, capable of reading in .00019INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional readings.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller di-

ameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025 mm

(0.001 inch) and out-of-roundness does not exceed

0.025 mm (0.001 inch), the cylinder bore can be

honed. If the cylinder bore taper or out-of-round con-

dition exceeds these maximum limits, the cylinder

must be bored and then honed to accept an oversize

piston. A slight amount of taper always exists in the

cylinder bore after the engine has been in use for a

period of time.

HONINGÐCYLINDER BORE

The honing operation should be closely coordinated

with the fitting of pistons and rings. This will ensure

specified clearances are maintained.

Refer to Standard Service Procedures in the begin-

ning of this Group for the proper honing of cylinder

bores.

Fig. 9 Oil Filter Adaptor Hole

Fig. 10 Front Oil Galley Hole

Fig. 11 Rear Oil Galley Hole

Fig. 12 Cylinder Bore Measurement

9 - 50 2.5L ENGINEJ

Page 1330 of 2158

ASSEMBLY

Refer to the applicable sections for detailed instruc-

tions.

(1) Install the crankshaft.

(2) Install the connecting rods and the pistons

through the top of the cylinder bores.

(3) Install the front and rear oil galley plugs.

(4) Install the timing chain tensioner.

(5) Install the camshaft.

(6) Install the sprockets and chain as an assembly.

(7) Install the oil slinger to the crankshaft.

(8) Install the timing chain bumper.

(9) Install the timing case cover seal.

(10) Install the timing case cover.(11) Install the oil pan gasket and oil pan.

(12) Install the vibration damper.

(13) Install the water pump. Tighten the mounting

bolts to 31 Nzm (270 in. lbs.) torque.

(14) Remove the distributor from the cylinder

block.

(15) Lubricate the oil filter seal with clean engine

oil. Tighten oil filter to 18 Nzm (13 ft. lbs.) torque.

(16) Install the engine into the vehicle.

(17) Fill the engine with clean lubrication oil (refer

to Group 0, Lubrication and Maintenance).

(18) Fill the cooling system (refer to Group 7, Cool-

ing System for the proper procedures).

J2.5L ENGINE 9 - 51