tow JEEP XJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1820 of 2158

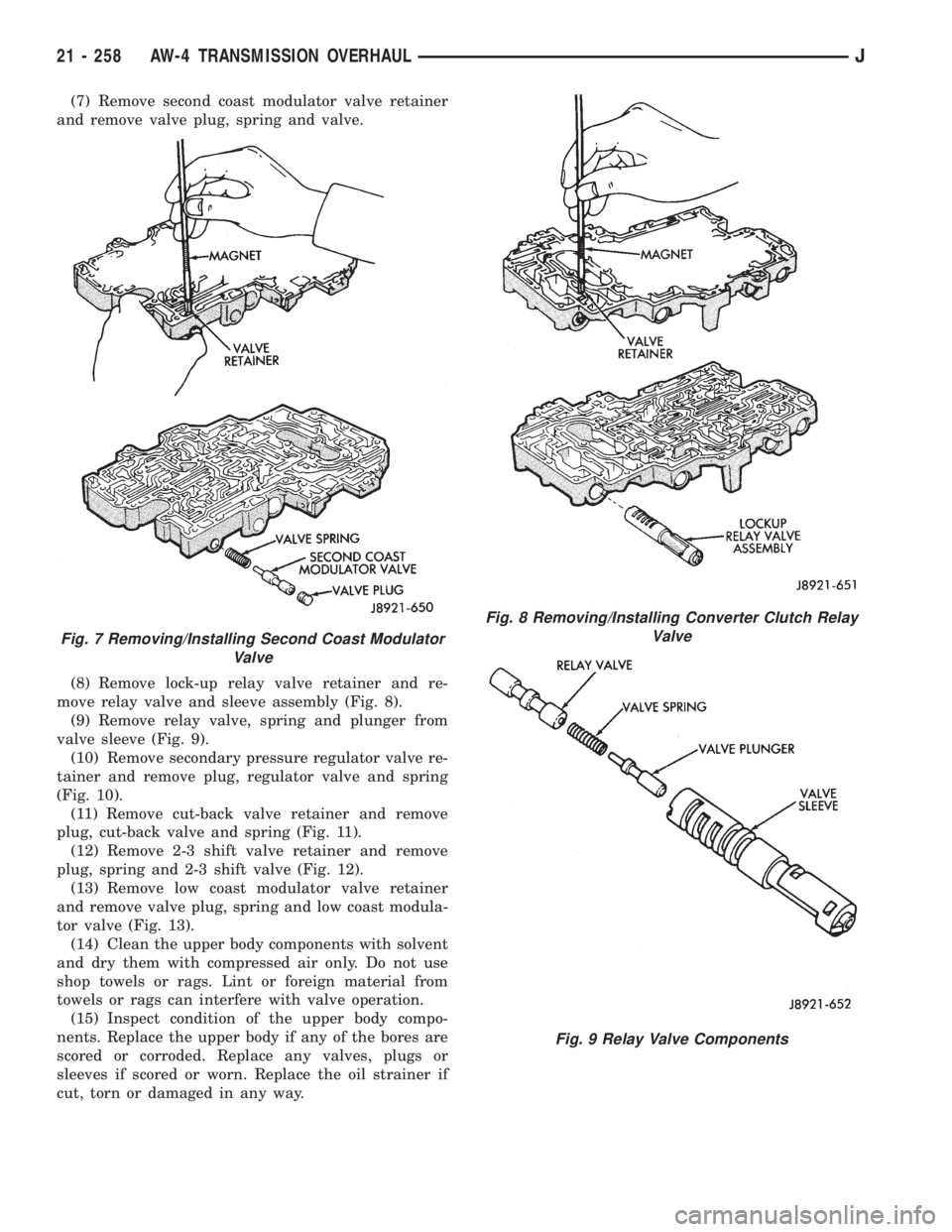

(7) Remove second coast modulator valve retainer

and remove valve plug, spring and valve.

(8) Remove lock-up relay valve retainer and re-

move relay valve and sleeve assembly (Fig. 8).

(9) Remove relay valve, spring and plunger from

valve sleeve (Fig. 9).

(10) Remove secondary pressure regulator valve re-

tainer and remove plug, regulator valve and spring

(Fig. 10).

(11) Remove cut-back valve retainer and remove

plug, cut-back valve and spring (Fig. 11).

(12) Remove 2-3 shift valve retainer and remove

plug, spring and 2-3 shift valve (Fig. 12).

(13) Remove low coast modulator valve retainer

and remove valve plug, spring and low coast modula-

tor valve (Fig. 13).

(14) Clean the upper body components with solvent

and dry them with compressed air only. Do not use

shop towels or rags. Lint or foreign material from

towels or rags can interfere with valve operation.

(15) Inspect condition of the upper body compo-

nents. Replace the upper body if any of the bores are

scored or corroded. Replace any valves, plugs or

sleeves if scored or worn. Replace the oil strainer if

cut, torn or damaged in any way.

Fig. 7 Removing/Installing Second Coast Modulator

Valve

Fig. 8 Removing/Installing Converter Clutch Relay

Valve

Fig. 9 Relay Valve Components

21 - 258 AW-4 TRANSMISSION OVERHAULJ

Page 1829 of 2158

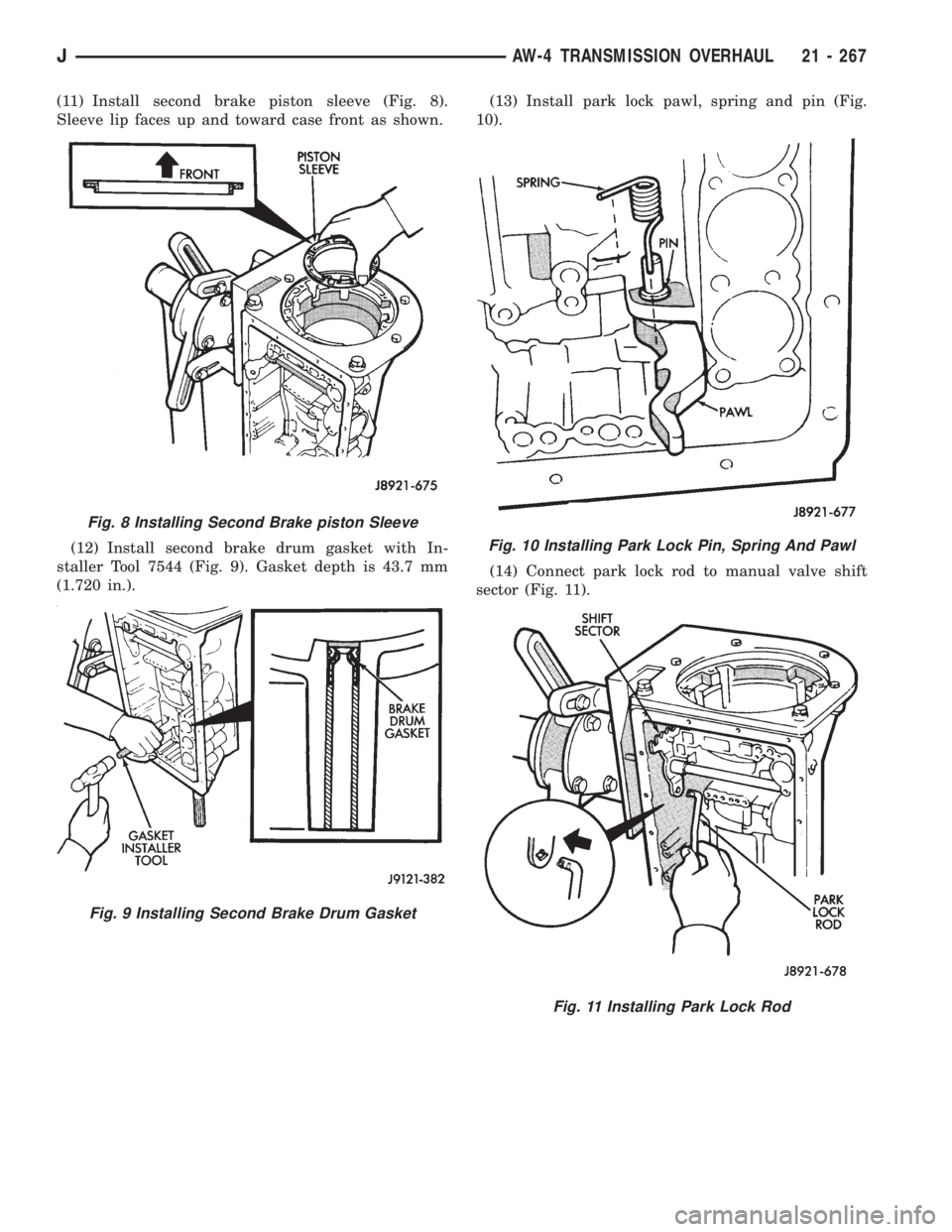

(11) Install second brake piston sleeve (Fig. 8).

Sleeve lip faces up and toward case front as shown.

(12) Install second brake drum gasket with In-

staller Tool 7544 (Fig. 9). Gasket depth is 43.7 mm

(1.720 in.).(13) Install park lock pawl, spring and pin (Fig.

10).

(14) Connect park lock rod to manual valve shift

sector (Fig. 11).

Fig. 8 Installing Second Brake piston Sleeve

Fig. 9 Installing Second Brake Drum Gasket

Fig. 10 Installing Park Lock Pin, Spring And Pawl

Fig. 11 Installing Park Lock Rod

JAW-4 TRANSMISSION OVERHAUL 21 - 267

Page 1830 of 2158

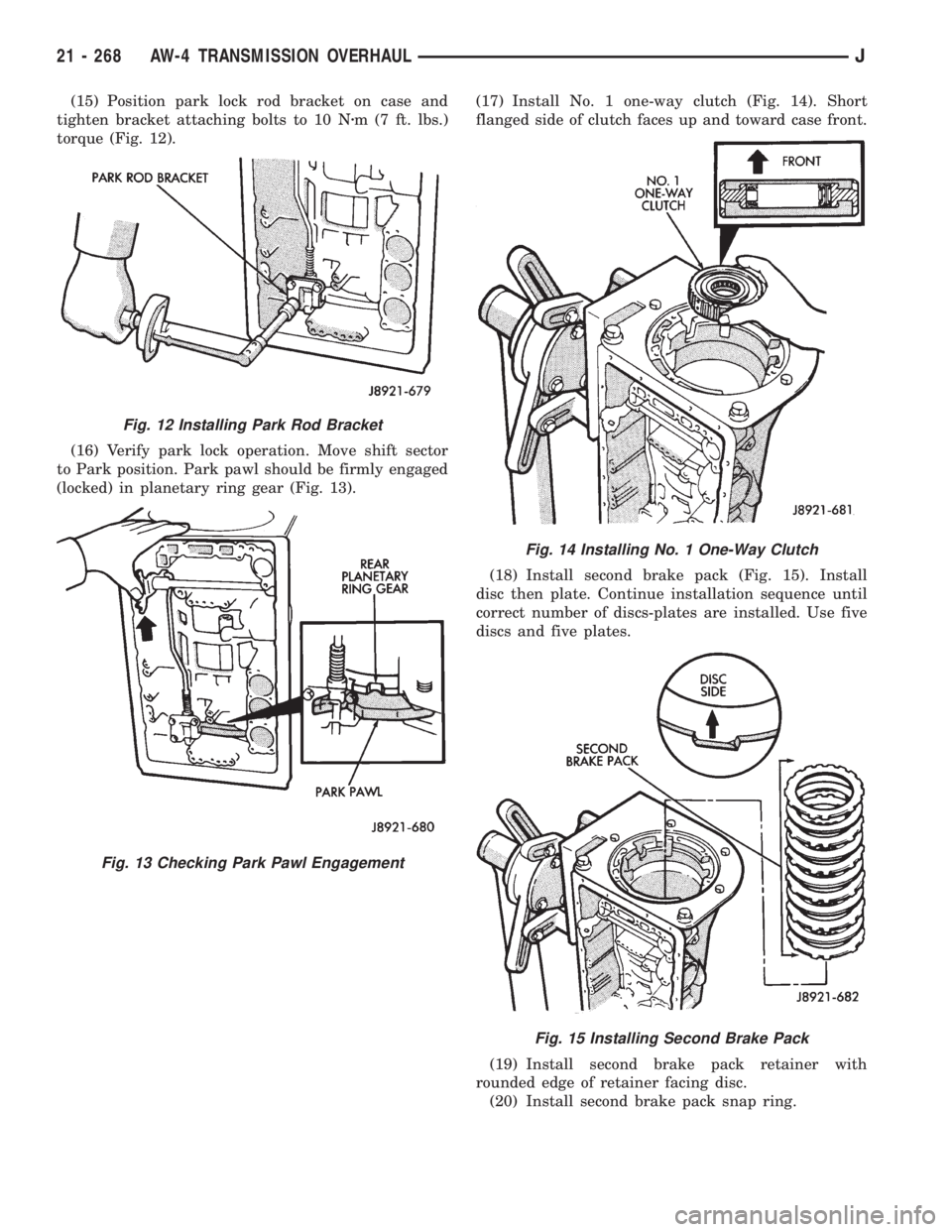

(15) Position park lock rod bracket on case and

tighten bracket attaching bolts to 10 Nzm (7 ft. lbs.)

torque (Fig. 12).

(16) Verify park lock operation. Move shift sector

to Park position. Park pawl should be firmly engaged

(locked) in planetary ring gear (Fig. 13).(17) Install No. 1 one-way clutch (Fig. 14). Short

flanged side of clutch faces up and toward case front.

(18) Install second brake pack (Fig. 15). Install

disc then plate. Continue installation sequence until

correct number of discs-plates are installed. Use five

discs and five plates.

(19) Install second brake pack retainer with

rounded edge of retainer facing disc.

(20) Install second brake pack snap ring.

Fig. 12 Installing Park Rod Bracket

Fig. 13 Checking Park Pawl Engagement

Fig. 14 Installing No. 1 One-Way Clutch

Fig. 15 Installing Second Brake Pack

21 - 268 AW-4 TRANSMISSION OVERHAULJ

Page 1832 of 2158

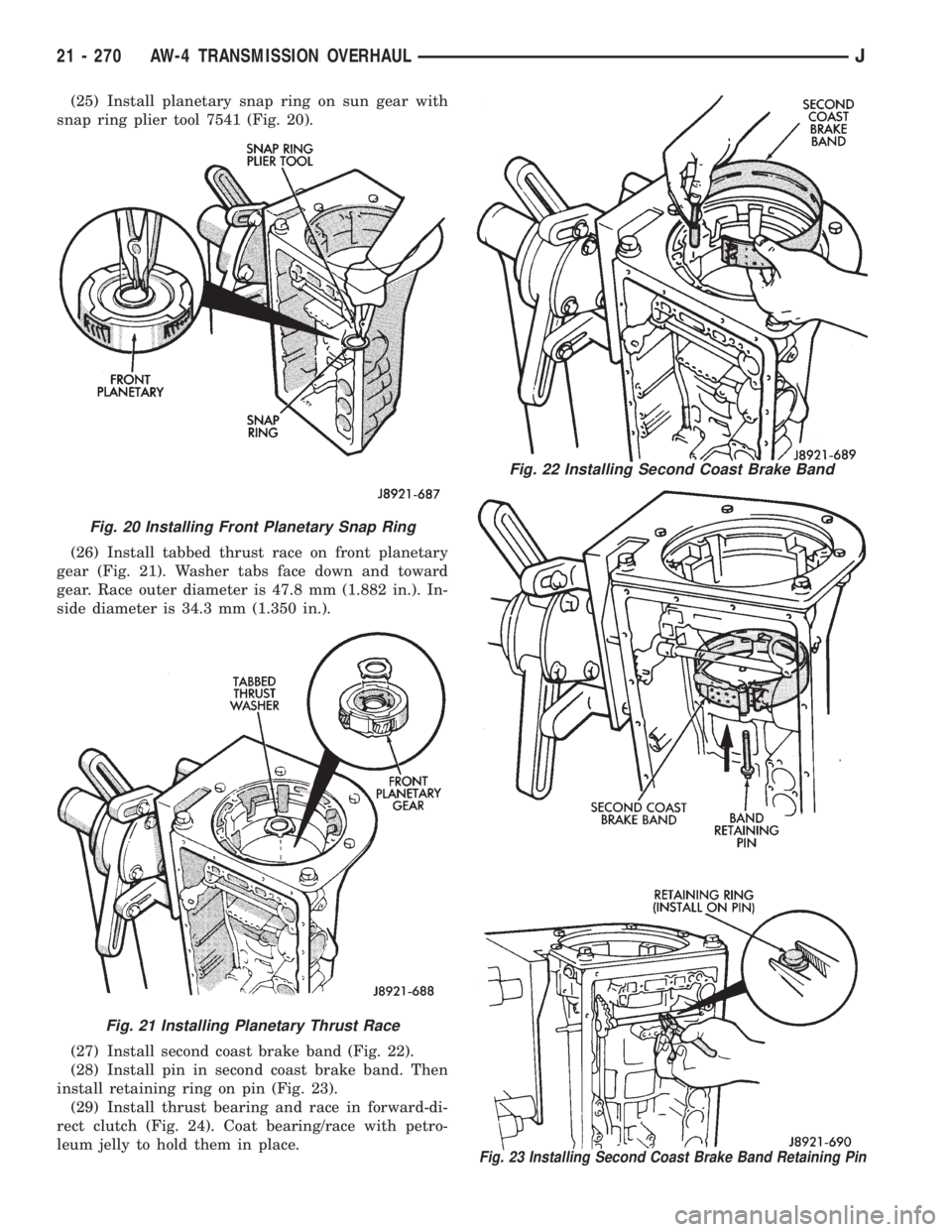

(25) Install planetary snap ring on sun gear with

snap ring plier tool 7541 (Fig. 20).

(26) Install tabbed thrust race on front planetary

gear (Fig. 21). Washer tabs face down and toward

gear. Race outer diameter is 47.8 mm (1.882 in.). In-

side diameter is 34.3 mm (1.350 in.).

(27) Install second coast brake band (Fig. 22).

(28) Install pin in second coast brake band. Then

install retaining ring on pin (Fig. 23).

(29) Install thrust bearing and race in forward-di-

rect clutch (Fig. 24). Coat bearing/race with petro-

leum jelly to hold them in place.

Fig. 22 Installing Second Coast Brake Band

Fig. 23 Installing Second Coast Brake Band Retaining Pin

Fig. 20 Installing Front Planetary Snap Ring

Fig. 21 Installing Planetary Thrust Race

21 - 270 AW-4 TRANSMISSION OVERHAULJ

Page 1833 of 2158

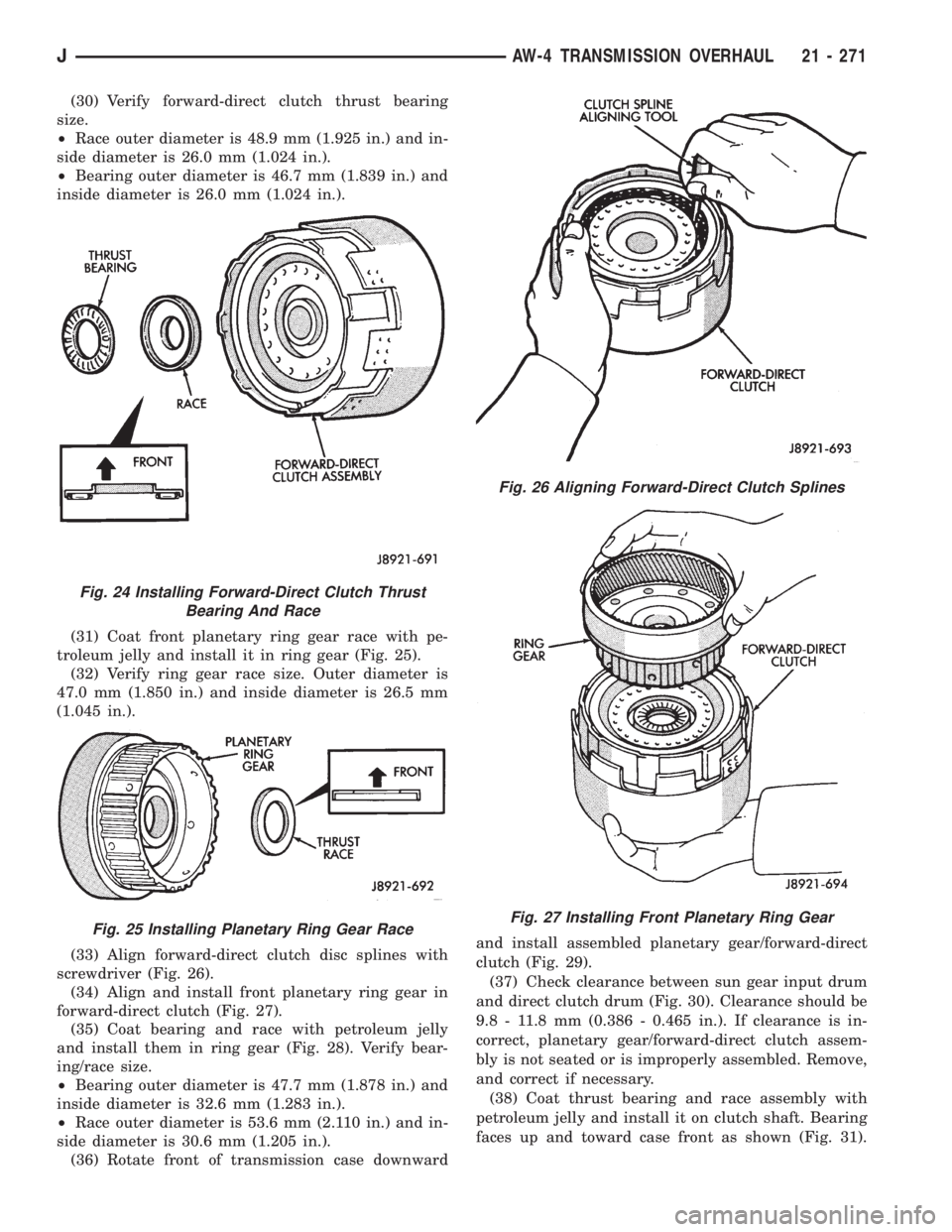

(30) Verify forward-direct clutch thrust bearing

size.

²Race outer diameter is 48.9 mm (1.925 in.) and in-

side diameter is 26.0 mm (1.024 in.).

²Bearing outer diameter is 46.7 mm (1.839 in.) and

inside diameter is 26.0 mm (1.024 in.).

(31) Coat front planetary ring gear race with pe-

troleum jelly and install it in ring gear (Fig. 25).

(32) Verify ring gear race size. Outer diameter is

47.0 mm (1.850 in.) and inside diameter is 26.5 mm

(1.045 in.).

(33) Align forward-direct clutch disc splines with

screwdriver (Fig. 26).

(34) Align and install front planetary ring gear in

forward-direct clutch (Fig. 27).

(35) Coat bearing and race with petroleum jelly

and install them in ring gear (Fig. 28). Verify bear-

ing/race size.

²Bearing outer diameter is 47.7 mm (1.878 in.) and

inside diameter is 32.6 mm (1.283 in.).

²Race outer diameter is 53.6 mm (2.110 in.) and in-

side diameter is 30.6 mm (1.205 in.).

(36) Rotate front of transmission case downwardand install assembled planetary gear/forward-direct

clutch (Fig. 29).

(37) Check clearance between sun gear input drum

and direct clutch drum (Fig. 30). Clearance should be

9.8 - 11.8 mm (0.386 - 0.465 in.). If clearance is in-

correct, planetary gear/forward-direct clutch assem-

bly is not seated or is improperly assembled. Remove,

and correct if necessary.

(38) Coat thrust bearing and race assembly with

petroleum jelly and install it on clutch shaft. Bearing

faces up and toward case front as shown (Fig. 31).

Fig. 24 Installing Forward-Direct Clutch Thrust

Bearing And Race

Fig. 25 Installing Planetary Ring Gear Race

Fig. 26 Aligning Forward-Direct Clutch Splines

Fig. 27 Installing Front Planetary Ring Gear

JAW-4 TRANSMISSION OVERHAUL 21 - 271

Page 1836 of 2158

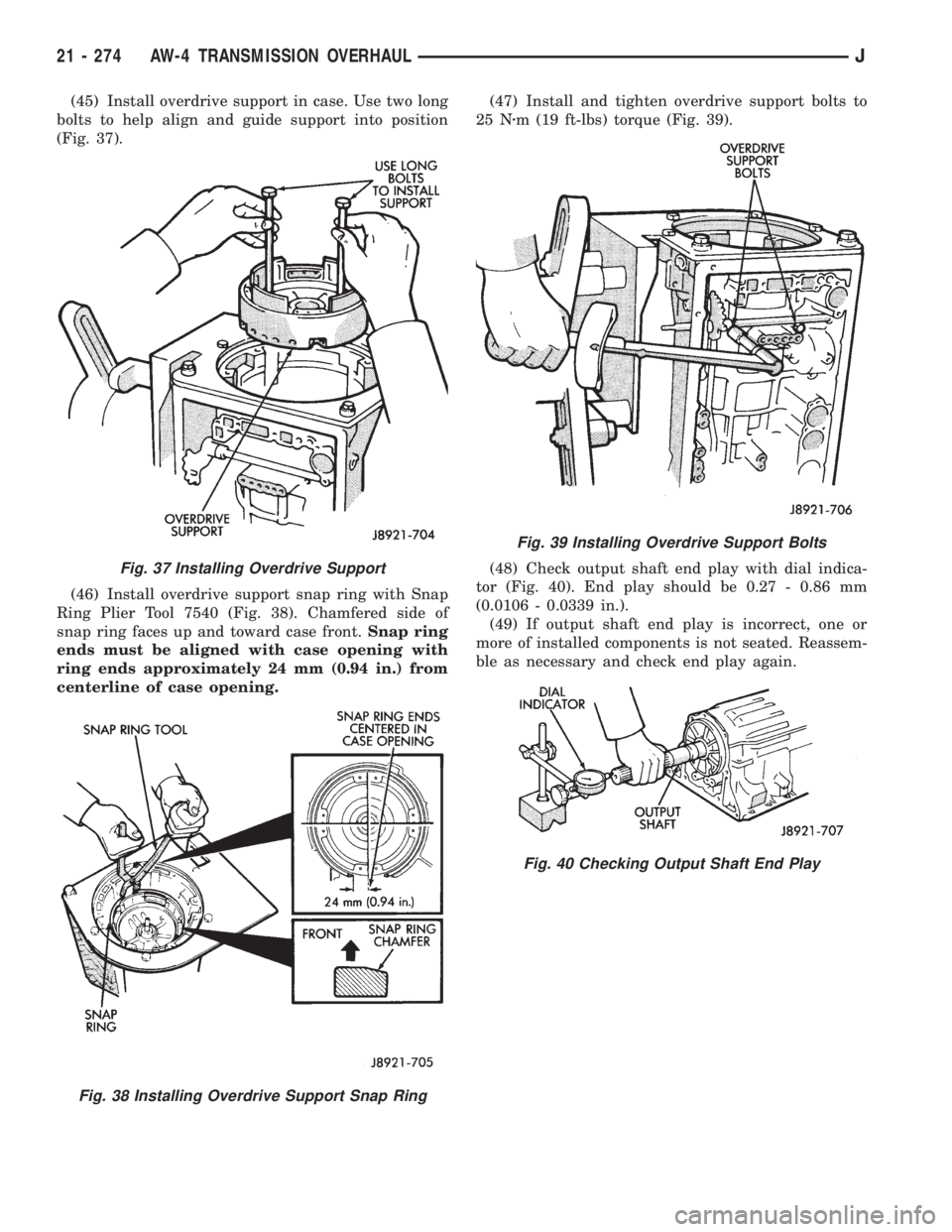

(45) Install overdrive support in case. Use two long

bolts to help align and guide support into position

(Fig. 37).

(46) Install overdrive support snap ring with Snap

Ring Plier Tool 7540 (Fig. 38). Chamfered side of

snap ring faces up and toward case front.Snap ring

ends must be aligned with case opening with

ring ends approximately 24 mm (0.94 in.) from

centerline of case opening.(47) Install and tighten overdrive support bolts to

25 Nzm (19 ft-lbs) torque (Fig. 39).

(48) Check output shaft end play with dial indica-

tor (Fig. 40). End play should be 0.27 - 0.86 mm

(0.0106 - 0.0339 in.).

(49) If output shaft end play is incorrect, one or

more of installed components is not seated. Reassem-

ble as necessary and check end play again.

Fig. 37 Installing Overdrive Support

Fig. 38 Installing Overdrive Support Snap Ring

Fig. 39 Installing Overdrive Support Bolts

Fig. 40 Checking Output Shaft End Play

21 - 274 AW-4 TRANSMISSION OVERHAULJ

Page 1863 of 2158

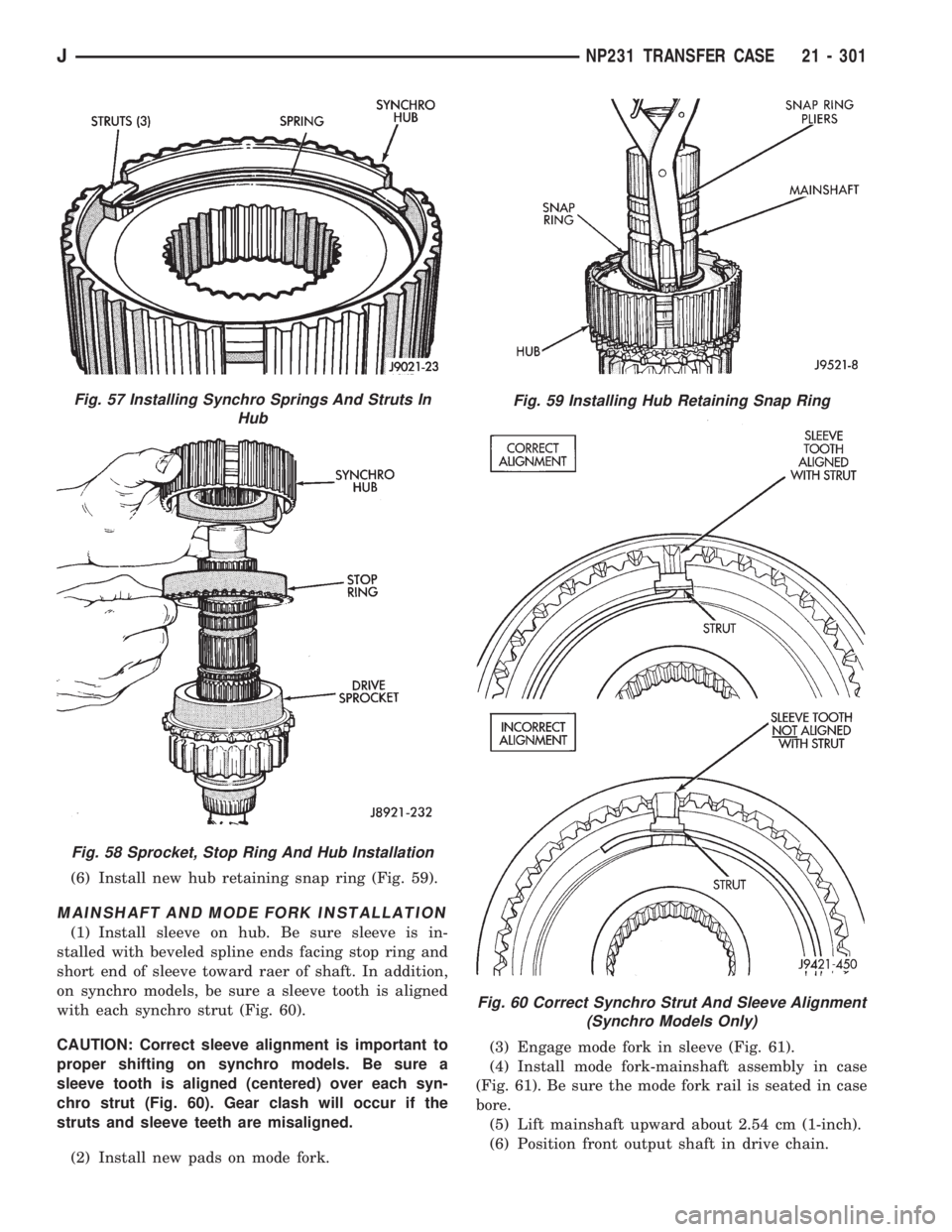

(6) Install new hub retaining snap ring (Fig. 59).

MAINSHAFT AND MODE FORK INSTALLATION

(1) Install sleeve on hub. Be sure sleeve is in-

stalled with beveled spline ends facing stop ring and

short end of sleeve toward raer of shaft. In addition,

on synchro models, be sure a sleeve tooth is aligned

with each synchro strut (Fig. 60).

CAUTION: Correct sleeve alignment is important to

proper shifting on synchro models. Be sure a

sleeve tooth is aligned (centered) over each syn-

chro strut (Fig. 60). Gear clash will occur if the

struts and sleeve teeth are misaligned.

(2) Install new pads on mode fork.(3) Engage mode fork in sleeve (Fig. 61).

(4) Install mode fork-mainshaft assembly in case

(Fig. 61). Be sure the mode fork rail is seated in case

bore.

(5) Lift mainshaft upward about 2.54 cm (1-inch).

(6) Position front output shaft in drive chain.

Fig. 57 Installing Synchro Springs And Struts In

Hub

Fig. 58 Sprocket, Stop Ring And Hub Installation

Fig. 59 Installing Hub Retaining Snap Ring

Fig. 60 Correct Synchro Strut And Sleeve Alignment

(Synchro Models Only)

JNP231 TRANSFER CASE 21 - 301

Page 1939 of 2158

(4) If the original molding will be installed, also re-

move all adhesive from it.

INSTALLATION

(1) Install 3M 06379 double-sided tape on the

molding.

(2) For vertical alignment, use masking tape or a

string as reference.

(3) Remove the backing from the tape, align the

molding and position it on the body panel.

(4) Press the molding onto the body panel with a

roller or hand pressure.

BODY STRIPES/DECALSÐXJ

SERVICE INFORMATION

XJ body stripes and decals are weather resistant

tape with a adhesive backing.

REPAIR

Small nicks, scratches and other surface marks in

a body stripe/decal can be touched-up with paint.

To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin.

A heat gun can also be used to remove small wrin-

kles in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement requires that the

metal repair and paint refinish be completed first.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for removal and installation:

²Commercial tape stripe/decal removal solution.

²Commercial adhesive removal solution.

²Liquid dish detergent (for the wetting solution).

²Mixture of wetting solution.

²Commercial wax and silicone removal solution.

²Isopropyl (rubbing) alcohol.

²Small squeegee (plastic or hard rubber).

²Water bucket and sponge.

²Clean wiping rags or paper towels.

²Heat gun (or infra-red heat bulb).

²Wax pencil.

²

Sharp knife, single edge razor blade or X-acto knife.

²Pair of scissors.

²Needle or pin.

The use of a wetting solution aids the installation of a

tape stripe/decal on a painted panel. Prepare the wet-

ting solution by mixing two or three teaspoons of dish

detergent with 1 gallon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

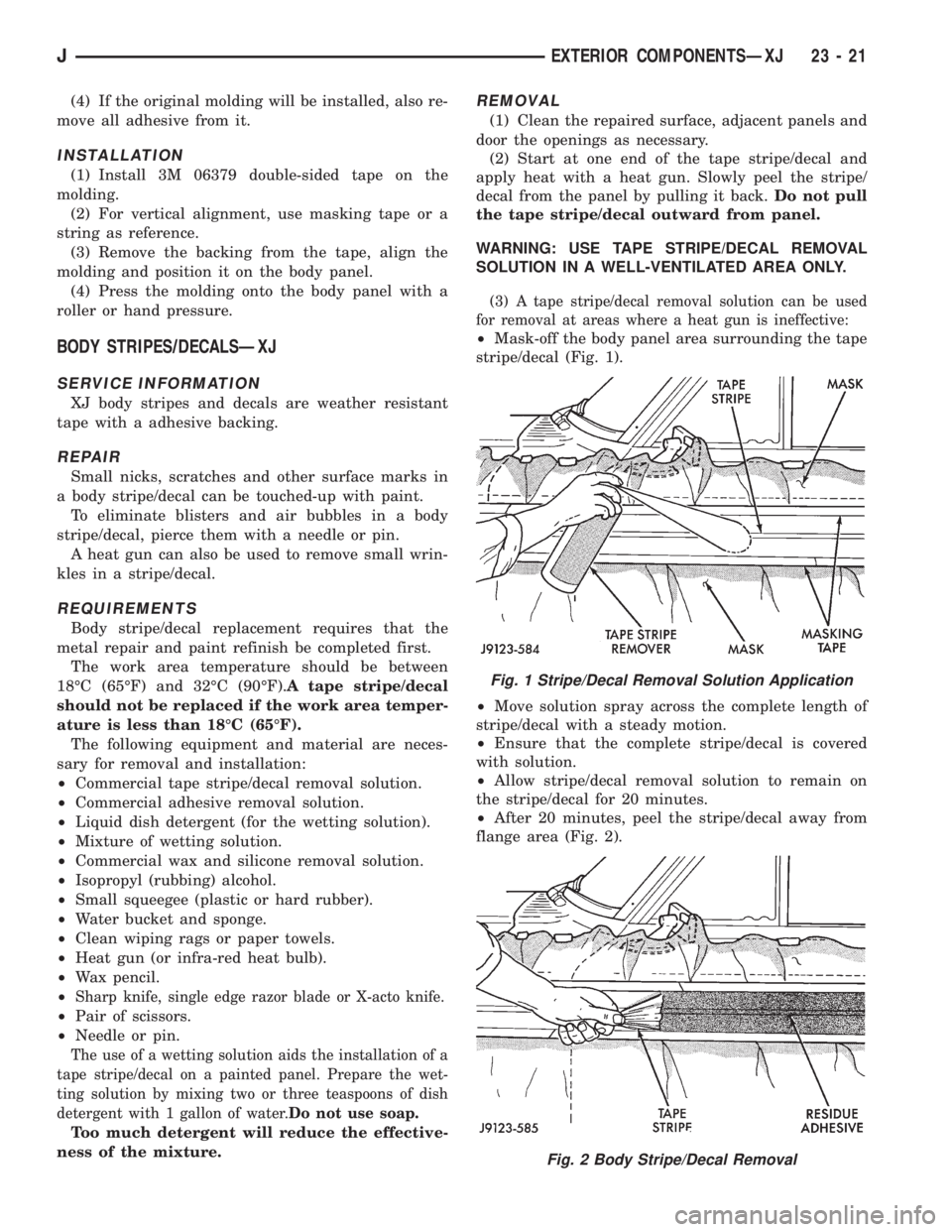

REMOVAL

(1) Clean the repaired surface, adjacent panels and

door the openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from panel.

WARNING: USE TAPE STRIPE/DECAL REMOVAL

SOLUTION IN A WELL-VENTILATED AREA ONLY.

(3) A tape stripe/decal removal solution can be used

for removal at areas where a heat gun is ineffective:

²Mask-off the body panel area surrounding the tape

stripe/decal (Fig. 1).

²Move solution spray across the complete length of

stripe/decal with a steady motion.

²Ensure that the complete stripe/decal is covered

with solution.

²Allow stripe/decal removal solution to remain on

the stripe/decal for 20 minutes.

²After 20 minutes, peel the stripe/decal away from

flange area (Fig. 2).

Fig. 1 Stripe/Decal Removal Solution Application

Fig. 2 Body Stripe/Decal Removal

JEXTERIOR COMPONENTSÐXJ 23 - 21

Page 1981 of 2158

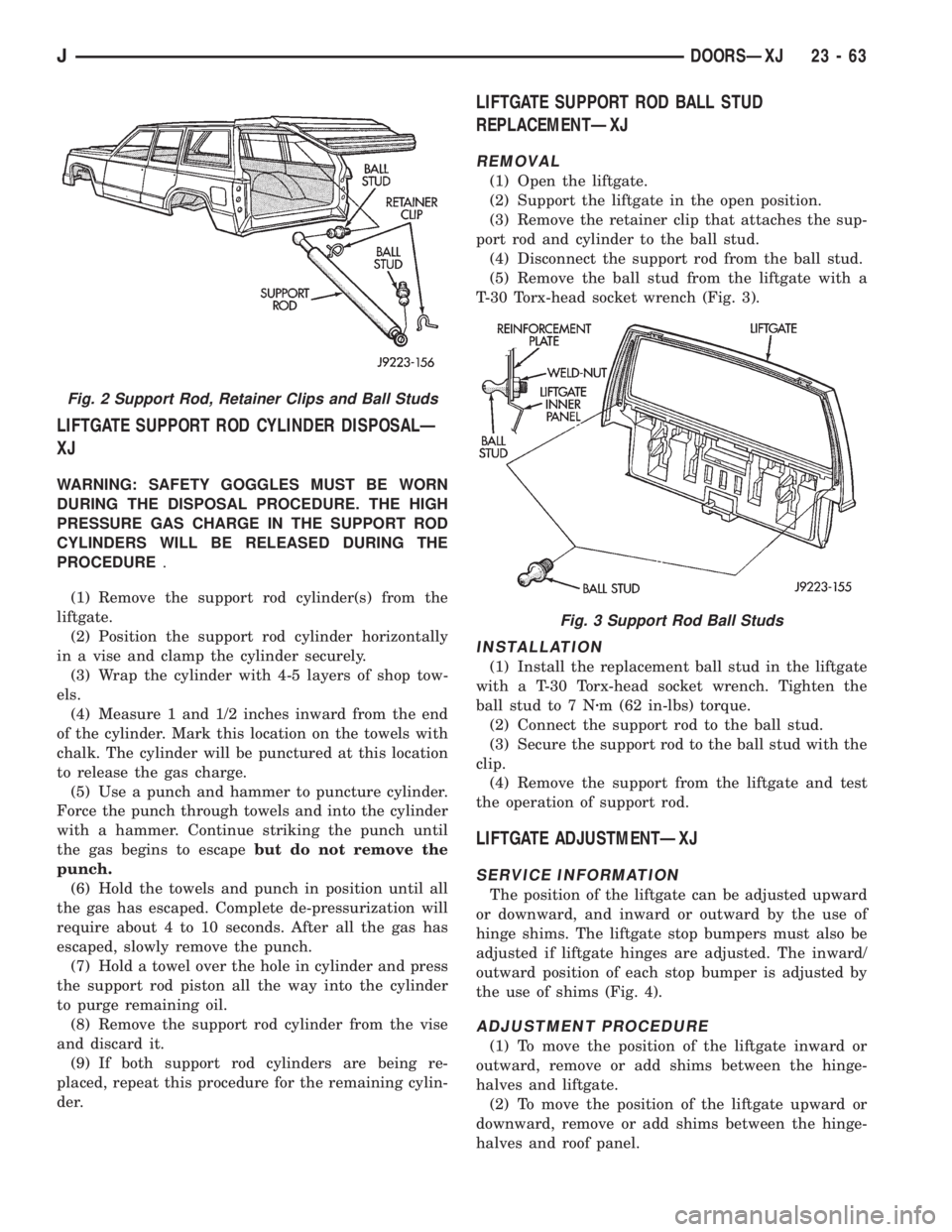

LIFTGATE SUPPORT ROD CYLINDER DISPOSALÐ

XJ

WARNING: SAFETY GOGGLES MUST BE WORN

DURING THE DISPOSAL PROCEDURE. THE HIGH

PRESSURE GAS CHARGE IN THE SUPPORT ROD

CYLINDERS WILL BE RELEASED DURING THE

PROCEDURE.

(1) Remove the support rod cylinder(s) from the

liftgate.

(2) Position the support rod cylinder horizontally

in a vise and clamp the cylinder securely.

(3) Wrap the cylinder with 4-5 layers of shop tow-

els.

(4) Measure 1 and 1/2 inches inward from the end

of the cylinder. Mark this location on the towels with

chalk. The cylinder will be punctured at this location

to release the gas charge.

(5) Use a punch and hammer to puncture cylinder.

Force the punch through towels and into the cylinder

with a hammer. Continue striking the punch until

the gas begins to escapebut do not remove the

punch.

(6) Hold the towels and punch in position until all

the gas has escaped. Complete de-pressurization will

require about 4 to 10 seconds. After all the gas has

escaped, slowly remove the punch.

(7) Hold a towel over the hole in cylinder and press

the support rod piston all the way into the cylinder

to purge remaining oil.

(8) Remove the support rod cylinder from the vise

and discard it.

(9) If both support rod cylinders are being re-

placed, repeat this procedure for the remaining cylin-

der.

LIFTGATE SUPPORT ROD BALL STUD

REPLACEMENTÐXJ

REMOVAL

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the retainer clip that attaches the sup-

port rod and cylinder to the ball stud.

(4) Disconnect the support rod from the ball stud.

(5) Remove the ball stud from the liftgate with a

T-30 Torx-head socket wrench (Fig. 3).

INSTALLATION

(1) Install the replacement ball stud in the liftgate

with a T-30 Torx-head socket wrench. Tighten the

ball stud to 7 Nzm (62 in-lbs) torque.

(2) Connect the support rod to the ball stud.

(3) Secure the support rod to the ball stud with the

clip.

(4) Remove the support from the liftgate and test

the operation of support rod.

LIFTGATE ADJUSTMENTÐXJ

SERVICE INFORMATION

The position of the liftgate can be adjusted upward

or downward, and inward or outward by the use of

hinge shims. The liftgate stop bumpers must also be

adjusted if liftgate hinges are adjusted. The inward/

outward position of each stop bumper is adjusted by

the use of shims (Fig. 4).

ADJUSTMENT PROCEDURE

(1) To move the position of the liftgate inward or

outward, remove or add shims between the hinge-

halves and liftgate.

(2) To move the position of the liftgate upward or

downward, remove or add shims between the hinge-

halves and roof panel.

Fig. 2 Support Rod, Retainer Clips and Ball Studs

Fig. 3 Support Rod Ball Studs

JDOORSÐXJ 23 - 63

Page 1984 of 2158

STATIONARY WINDOW GLASS

INDEX

page page

Interior Rearview MirrorÐXJ Removal and

Installation............................. 66

Interior Rearview Mirror Support Bracket

ReplacementÐXJ Preparation and Installation . . . 66

Description and Operation.......... ..........67

InstallationÐShort Method.......... ..........69

InstallationÐExtended Method........ ........71Rear Door Stationary Window Glass...... ......72

Rear Quarter Vent Window GlassÐXJ Removal

and Installation............. .............73

Rear Quarter Window Glass/Rear Quarter Plastic

InsertÐXJ Removal and Installation..... .....73

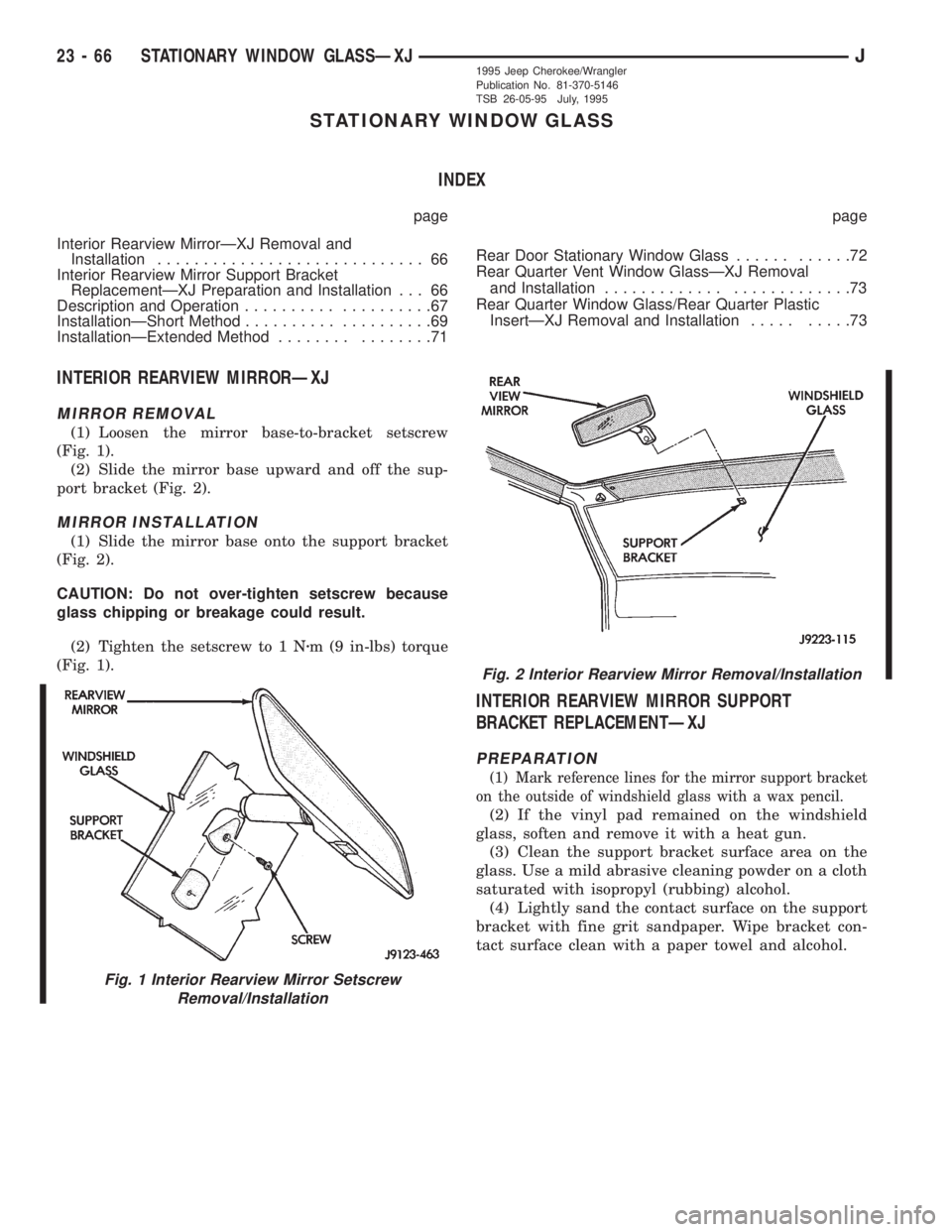

INTERIOR REARVIEW MIRRORÐXJ

MIRROR REMOVAL

(1) Loosen the mirror base-to-bracket setscrew

(Fig. 1).

(2) Slide the mirror base upward and off the sup-

port bracket (Fig. 2).

MIRROR INSTALLATION

(1) Slide the mirror base onto the support bracket

(Fig. 2).

CAUTION: Do not over-tighten setscrew because

glass chipping or breakage could result.

(2) Tighten the setscrew to 1 Nzm (9 in-lbs) torque

(Fig. 1).

INTERIOR REARVIEW MIRROR SUPPORT

BRACKET REPLACEMENTÐXJ

PREPARATION

(1) Mark reference lines for the mirror support bracket

on the outside of windshield glass with a wax pencil.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun.

(3) Clean the support bracket surface area on the

glass. Use a mild abrasive cleaning powder on a cloth

saturated with isopropyl (rubbing) alcohol.

(4) Lightly sand the contact surface on the support

bracket with fine grit sandpaper. Wipe bracket con-

tact surface clean with a paper towel and alcohol.

Fig. 1 Interior Rearview Mirror Setscrew

Removal/Installation

Fig. 2 Interior Rearview Mirror Removal/Installation

23 - 66 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995