JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1681 of 2158

30RH/32RH TRANSMISSION OVERHAUL

INDEX

page page

Adapter/Extension Housing Inspection and Park

Lock Component Overhaul................ 127

Front Clutch Overhaul..................... 134

Front Servo and Band Overhaul............. 146

Governor and Park Gear Overhaul........... 127

Oil Pump Overhaul....................... 131

Overhaul Service Information................ 125

Overrunning ClutchÐLow-Reverse DrumÐRear

Support Overhaul....................... 125

Planetary Gear Train Overhaul.............. 141Rear Clutch Overhaul..................... 138

Rear Servo and Band Overhaul.............. 146

Transmission Assembly and Adjustment Procedures. 155

Transmission Assembly Tips................ 155

Transmission Case Cleaning and Inspection.... 125

Transmission Disassembly.................. 119

Valve Body Assembly and Adjustment......... 153

Valve Body Disassembly and Inspection....... 147

TRANSMISSION DISASSEMBLY

(1) Clean transmission exterior with steam gun or

with solvent. Wear eye protection during cleaning

process.

(2) Remove throttle and shift levers from valve

body manual shaft and throttle lever shaft.

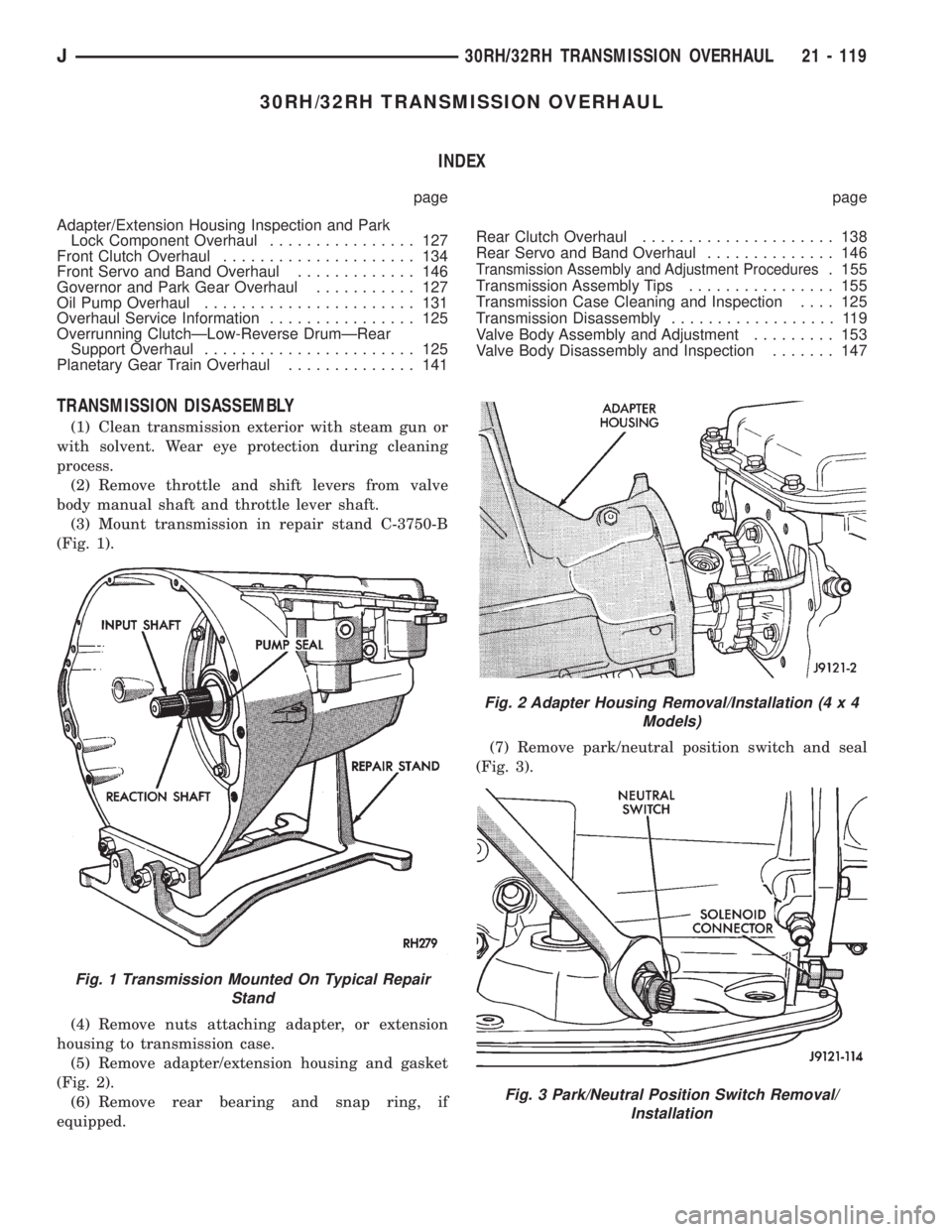

(3) Mount transmission in repair stand C-3750-B

(Fig. 1).

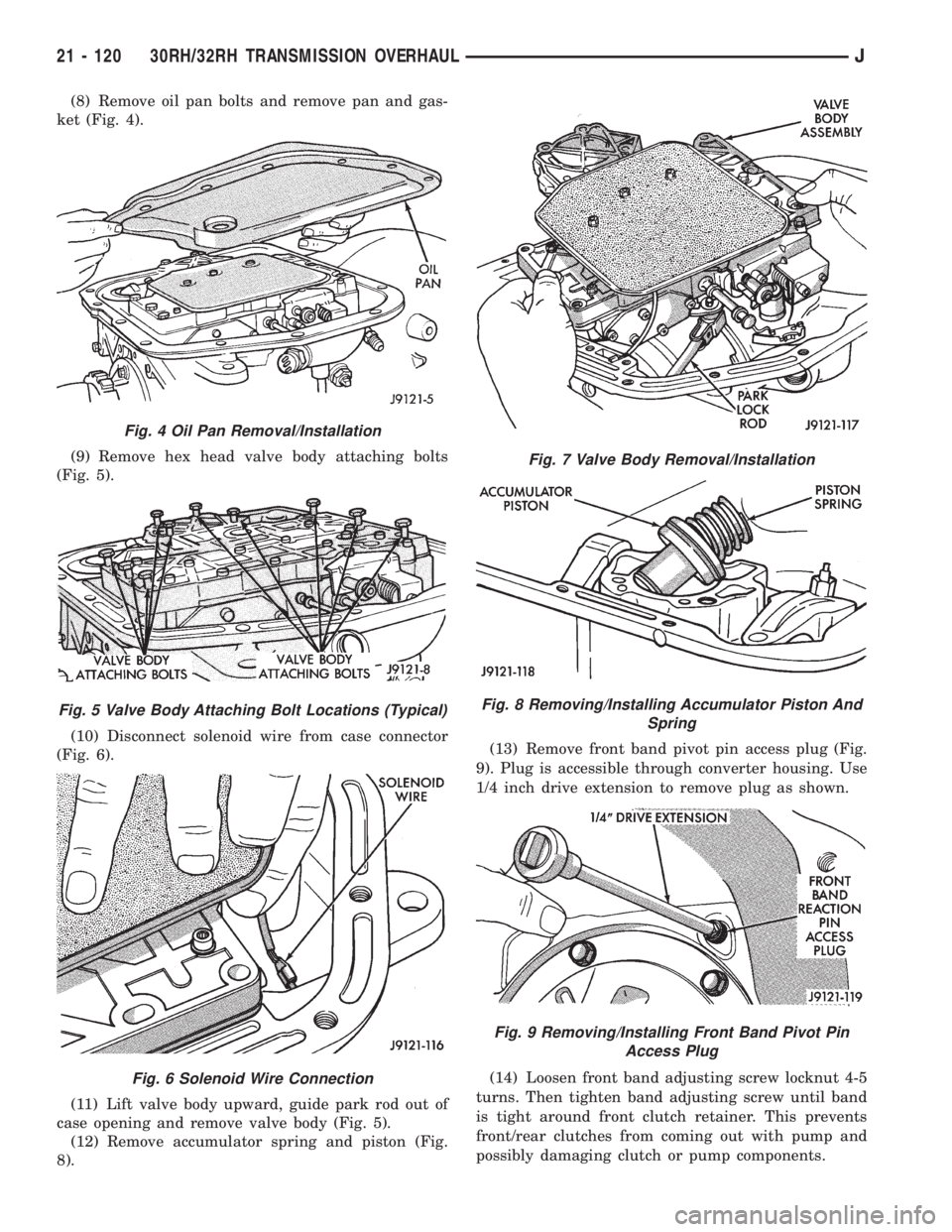

(4) Remove nuts attaching adapter, or extension

housing to transmission case.

(5) Remove adapter/extension housing and gasket

(Fig. 2).

(6) Remove rear bearing and snap ring, if

equipped.(7) Remove park/neutral position switch and seal

(Fig. 3).

Fig. 1 Transmission Mounted On Typical Repair

Stand

Fig. 2 Adapter Housing Removal/Installation (4 x 4

Models)

Fig. 3 Park/Neutral Position Switch Removal/

Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 119

Page 1682 of 2158

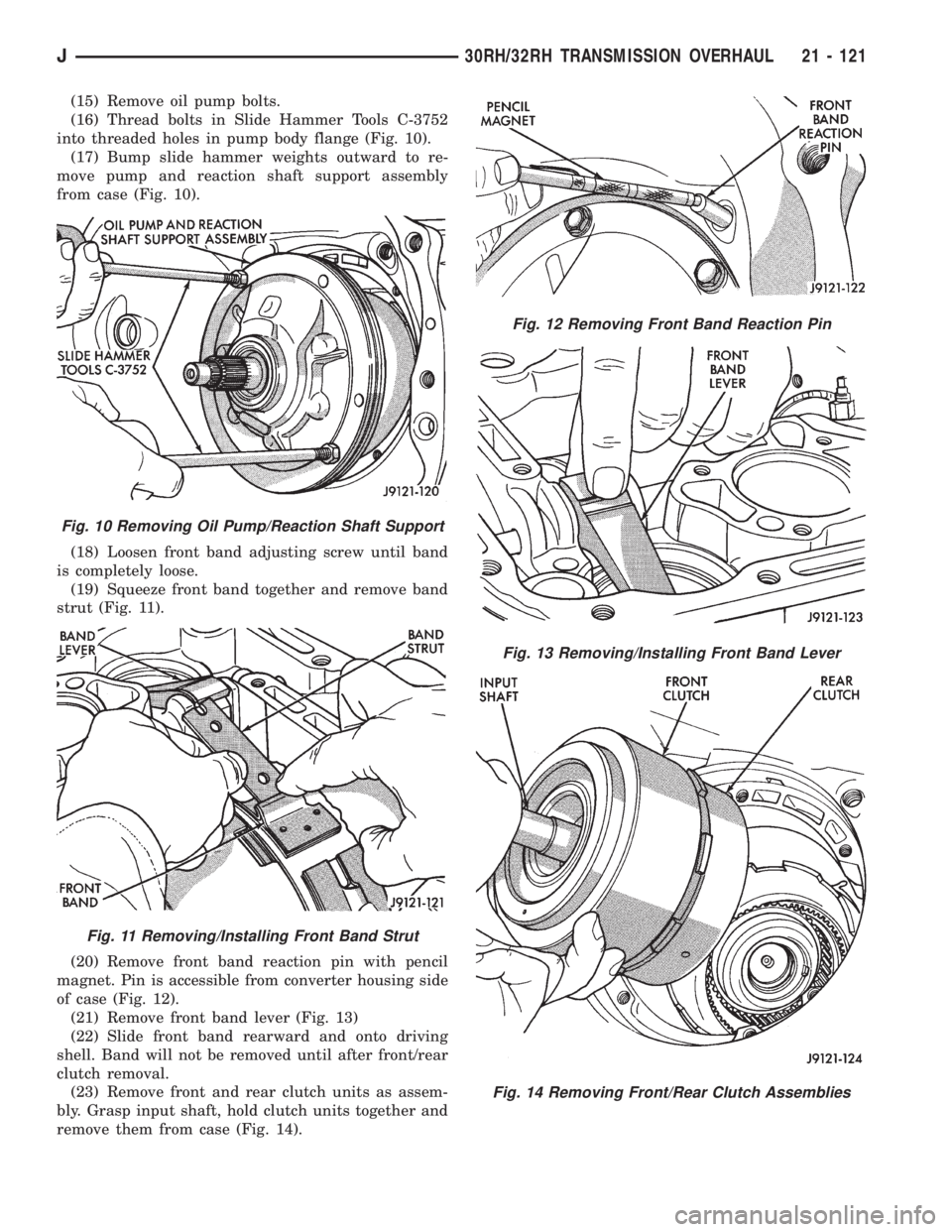

(8) Remove oil pan bolts and remove pan and gas-

ket (Fig. 4).

(9) Remove hex head valve body attaching bolts

(Fig. 5).

(10) Disconnect solenoid wire from case connector

(Fig. 6).

(11) Lift valve body upward, guide park rod out of

case opening and remove valve body (Fig. 5).

(12) Remove accumulator spring and piston (Fig.

8).(13) Remove front band pivot pin access plug (Fig.

9). Plug is accessible through converter housing. Use

1/4 inch drive extension to remove plug as shown.

(14) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until band

is tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

Fig. 4 Oil Pan Removal/Installation

Fig. 5 Valve Body Attaching Bolt Locations (Typical)

Fig. 6 Solenoid Wire Connection

Fig. 7 Valve Body Removal/Installation

Fig. 8 Removing/Installing Accumulator Piston And

Spring

Fig. 9 Removing/Installing Front Band Pivot Pin

Access Plug

21 - 120 30RH/32RH TRANSMISSION OVERHAULJ

Page 1683 of 2158

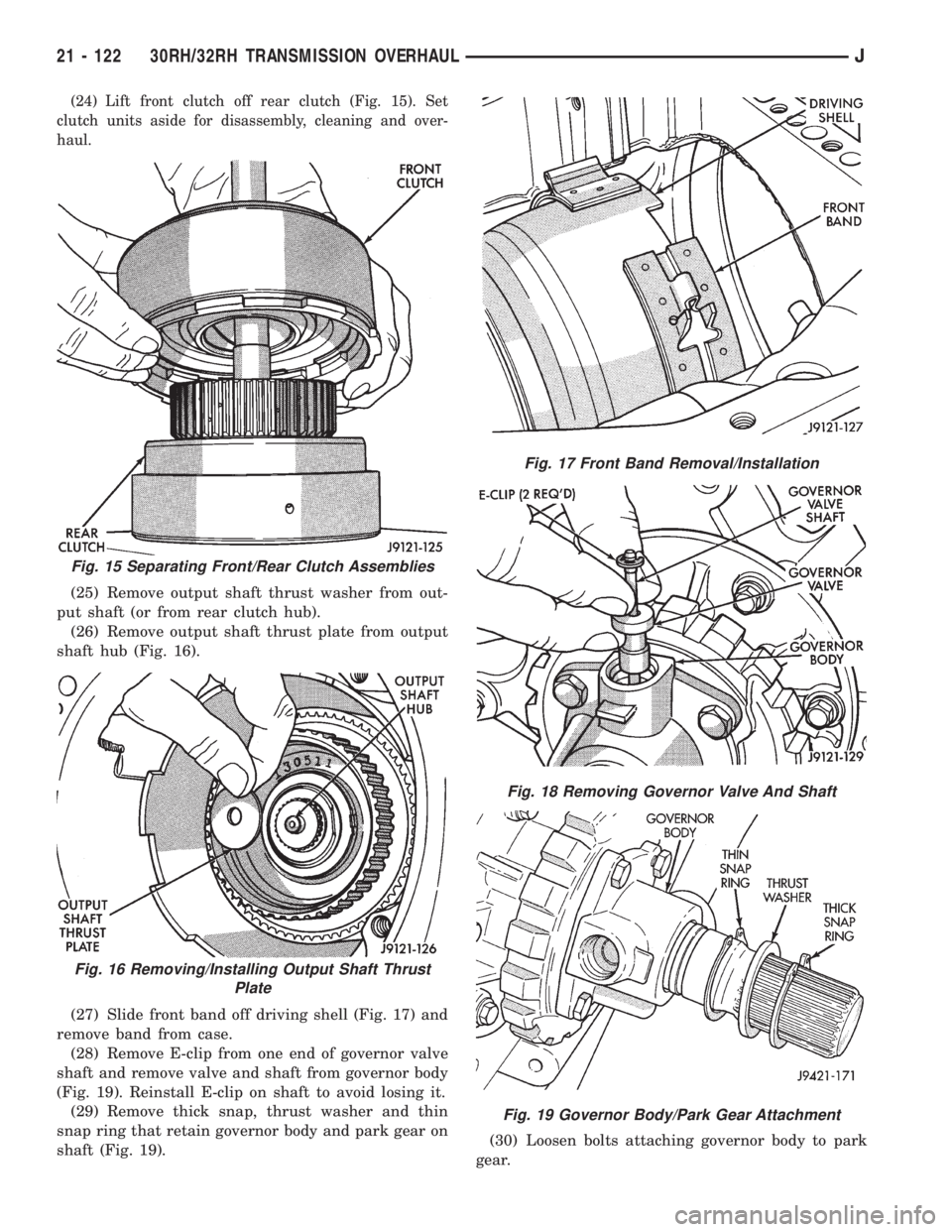

(15) Remove oil pump bolts.

(16) Thread bolts in Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 10).

(17) Bump slide hammer weights outward to re-

move pump and reaction shaft support assembly

from case (Fig. 10).

(18) Loosen front band adjusting screw until band

is completely loose.

(19) Squeeze front band together and remove band

strut (Fig. 11).

(20) Remove front band reaction pin with pencil

magnet. Pin is accessible from converter housing side

of case (Fig. 12).

(21) Remove front band lever (Fig. 13)

(22) Slide front band rearward and onto driving

shell. Band will not be removed until after front/rear

clutch removal.

(23) Remove front and rear clutch units as assem-

bly. Grasp input shaft, hold clutch units together and

remove them from case (Fig. 14).

Fig. 10 Removing Oil Pump/Reaction Shaft Support

Fig. 11 Removing/Installing Front Band Strut

Fig. 12 Removing Front Band Reaction Pin

Fig. 13 Removing/Installing Front Band Lever

Fig. 14 Removing Front/Rear Clutch Assemblies

J30RH/32RH TRANSMISSION OVERHAUL 21 - 121

Page 1684 of 2158

(24) Lift front clutch off rear clutch (Fig. 15). Set

clutch units aside for disassembly, cleaning and over-

haul.

(25) Remove output shaft thrust washer from out-

put shaft (or from rear clutch hub).

(26) Remove output shaft thrust plate from output

shaft hub (Fig. 16).

(27) Slide front band off driving shell (Fig. 17) and

remove band from case.

(28) Remove E-clip from one end of governor valve

shaft and remove valve and shaft from governor body

(Fig. 19). Reinstall E-clip on shaft to avoid losing it.

(29) Remove thick snap, thrust washer and thin

snap ring that retain governor body and park gear on

shaft (Fig. 19).(30) Loosen bolts attaching governor body to park

gear.

Fig. 15 Separating Front/Rear Clutch Assemblies

Fig. 16 Removing/Installing Output Shaft Thrust

Plate

Fig. 17 Front Band Removal/Installation

Fig. 18 Removing Governor Valve And Shaft

Fig. 19 Governor Body/Park Gear Attachment

21 - 122 30RH/32RH TRANSMISSION OVERHAULJ

Page 1685 of 2158

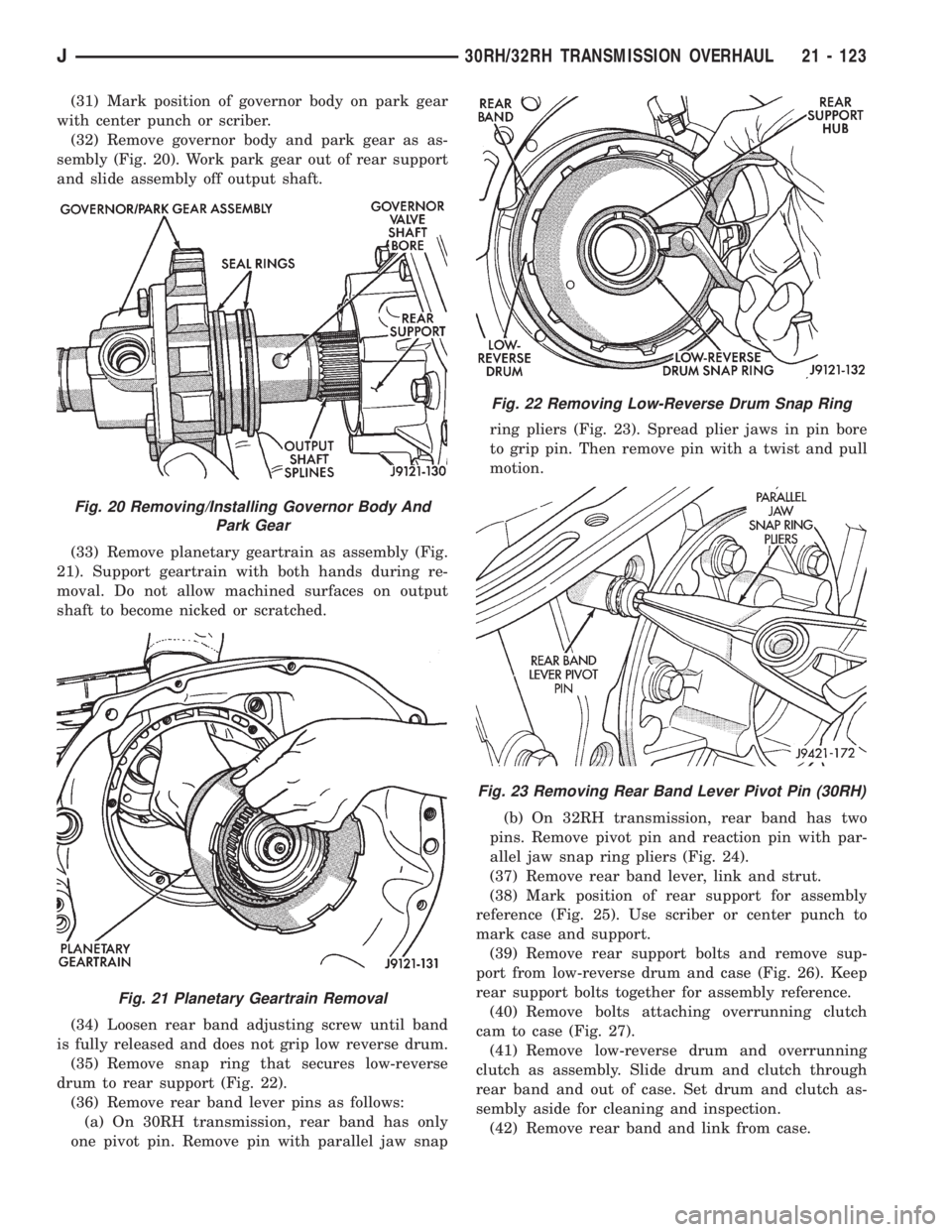

(31) Mark position of governor body on park gear

with center punch or scriber.

(32) Remove governor body and park gear as as-

sembly (Fig. 20). Work park gear out of rear support

and slide assembly off output shaft.

(33) Remove planetary geartrain as assembly (Fig.

21). Support geartrain with both hands during re-

moval. Do not allow machined surfaces on output

shaft to become nicked or scratched.

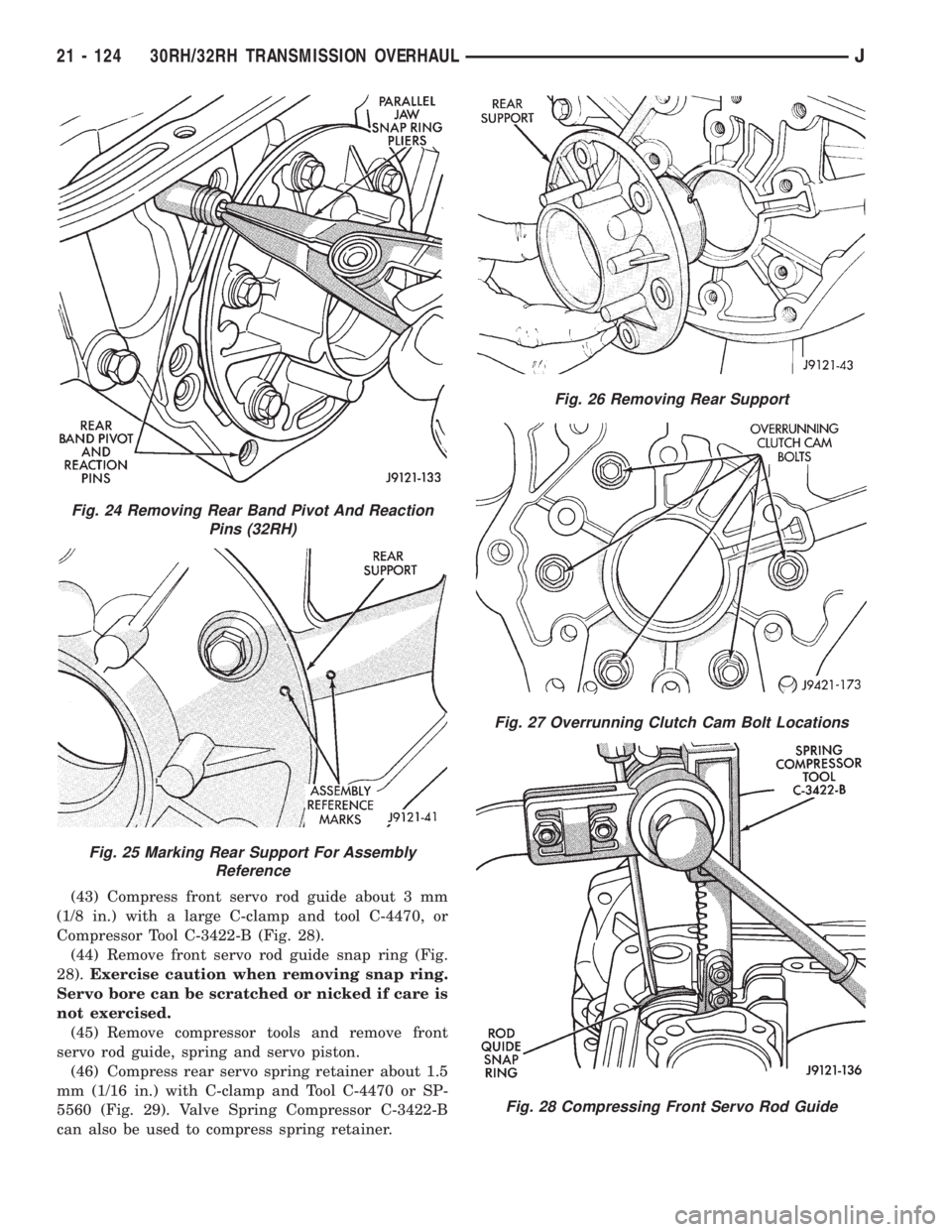

(34) Loosen rear band adjusting screw until band

is fully released and does not grip low reverse drum.

(35) Remove snap ring that secures low-reverse

drum to rear support (Fig. 22).

(36) Remove rear band lever pins as follows:

(a) On 30RH transmission, rear band has only

one pivot pin. Remove pin with parallel jaw snapring pliers (Fig. 23). Spread plier jaws in pin bore

to grip pin. Then remove pin with a twist and pull

motion.

(b) On 32RH transmission, rear band has two

pins. Remove pivot pin and reaction pin with par-

allel jaw snap ring pliers (Fig. 24).

(37) Remove rear band lever, link and strut.

(38) Mark position of rear support for assembly

reference (Fig. 25). Use scriber or center punch to

mark case and support.

(39) Remove rear support bolts and remove sup-

port from low-reverse drum and case (Fig. 26). Keep

rear support bolts together for assembly reference.

(40) Remove bolts attaching overrunning clutch

cam to case (Fig. 27).

(41) Remove low-reverse drum and overrunning

clutch as assembly. Slide drum and clutch through

rear band and out of case. Set drum and clutch as-

sembly aside for cleaning and inspection.

(42) Remove rear band and link from case.

Fig. 20 Removing/Installing Governor Body And

Park Gear

Fig. 21 Planetary Geartrain Removal

Fig. 22 Removing Low-Reverse Drum Snap Ring

Fig. 23 Removing Rear Band Lever Pivot Pin (30RH)

J30RH/32RH TRANSMISSION OVERHAUL 21 - 123

Page 1686 of 2158

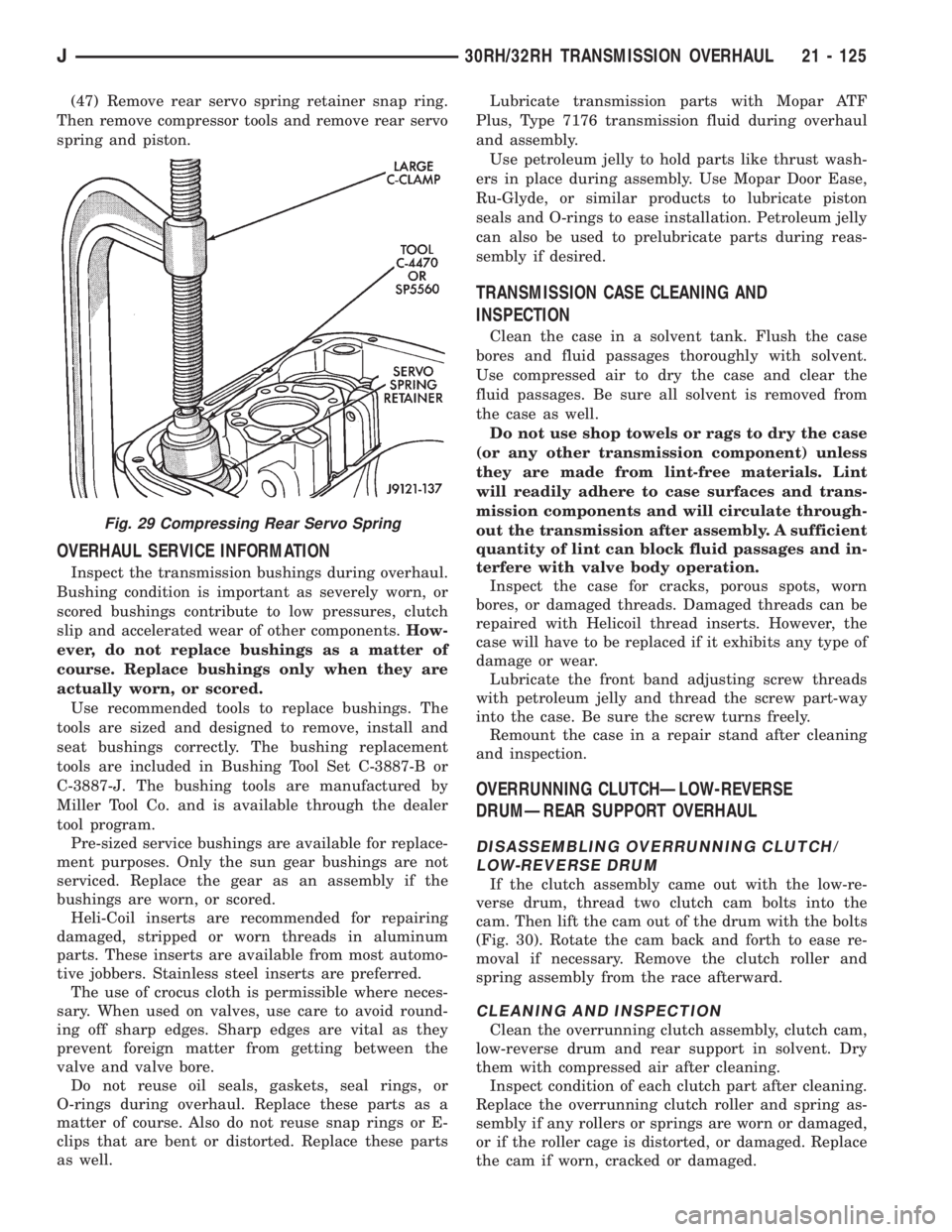

(43) Compress front servo rod guide about 3 mm

(1/8 in.) with a large C-clamp and tool C-4470, or

Compressor Tool C-3422-B (Fig. 28).

(44) Remove front servo rod guide snap ring (Fig.

28).Exercise caution when removing snap ring.

Servo bore can be scratched or nicked if care is

not exercised.

(45) Remove compressor tools and remove front

servo rod guide, spring and servo piston.

(46) Compress rear servo spring retainer about 1.5

mm (1/16 in.) with C-clamp and Tool C-4470 or SP-

5560 (Fig. 29). Valve Spring Compressor C-3422-B

can also be used to compress spring retainer.

Fig. 24 Removing Rear Band Pivot And Reaction

Pins (32RH)

Fig. 25 Marking Rear Support For Assembly

Reference

Fig. 26 Removing Rear Support

Fig. 27 Overrunning Clutch Cam Bolt Locations

Fig. 28 Compressing Front Servo Rod Guide

21 - 124 30RH/32RH TRANSMISSION OVERHAULJ

Page 1687 of 2158

(47) Remove rear servo spring retainer snap ring.

Then remove compressor tools and remove rear servo

spring and piston.

OVERHAUL SERVICE INFORMATION

Inspect the transmission bushings during overhaul.

Bushing condition is important as severely worn, or

scored bushings contribute to low pressures, clutch

slip and accelerated wear of other components.How-

ever, do not replace bushings as a matter of

course. Replace bushings only when they are

actually worn, or scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B or

C-3887-J. The bushing tools are manufactured by

Miller Tool Co. and is available through the dealer

tool program.

Pre-sized service bushings are available for replace-

ment purposes. Only the sun gear bushings are not

serviced. Replace the gear as an assembly if the

bushings are worn, or scored.

Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts. These inserts are available from most automo-

tive jobbers. Stainless steel inserts are preferred.

The use of crocus cloth is permissible where neces-

sary. When used on valves, use care to avoid round-

ing off sharp edges. Sharp edges are vital as they

prevent foreign matter from getting between the

valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or E-

clips that are bent or distorted. Replace these parts

as well.Lubricate transmission parts with Mopar ATF

Plus, Type 7176 transmission fluid during overhaul

and assembly.

Use petroleum jelly to hold parts like thrust wash-

ers in place during assembly. Use Mopar Door Ease,

Ru-Glyde, or similar products to lubricate piston

seals and O-rings to ease installation. Petroleum jelly

can also be used to prelubricate parts during reas-

sembly if desired.

TRANSMISSION CASE CLEANING AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Use compressed air to dry the case and clear the

fluid passages. Be sure all solvent is removed from

the case as well.

Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint

will readily adhere to case surfaces and trans-

mission components and will circulate through-

out the transmission after assembly. A sufficient

quantity of lint can block fluid passages and in-

terfere with valve body operation.

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Remount the case in a repair stand after cleaning

and inspection.

OVERRUNNING CLUTCHÐLOW-REVERSE

DRUMÐREAR SUPPORT OVERHAUL

DISASSEMBLING OVERRUNNING CLUTCH/

LOW-REVERSE DRUM

If the clutch assembly came out with the low-re-

verse drum, thread two clutch cam bolts into the

cam. Then lift the cam out of the drum with the bolts

(Fig. 30). Rotate the cam back and forth to ease re-

moval if necessary. Remove the clutch roller and

spring assembly from the race afterward.

CLEANING AND INSPECTION

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum and rear support in solvent. Dry

them with compressed air after cleaning.

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring as-

sembly if any rollers or springs are worn or damaged,

or if the roller cage is distorted, or damaged. Replace

the cam if worn, cracked or damaged.

Fig. 29 Compressing Rear Servo Spring

J30RH/32RH TRANSMISSION OVERHAUL 21 - 125

Page 1688 of 2158

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from

the low-reverse drum under any circumstances.

Replace the drum and race as an assembly if ei-

ther component is damaged.

Examine the rear support carefully for wear,

cracks, scoring or other damage. Be sure the support

hub is a snug fit in the case and drum. Replace the

support if worn or damaged.

ASSEMBLING OVERRUNNING CLUTCH/LOW-

REVERSE DRUM

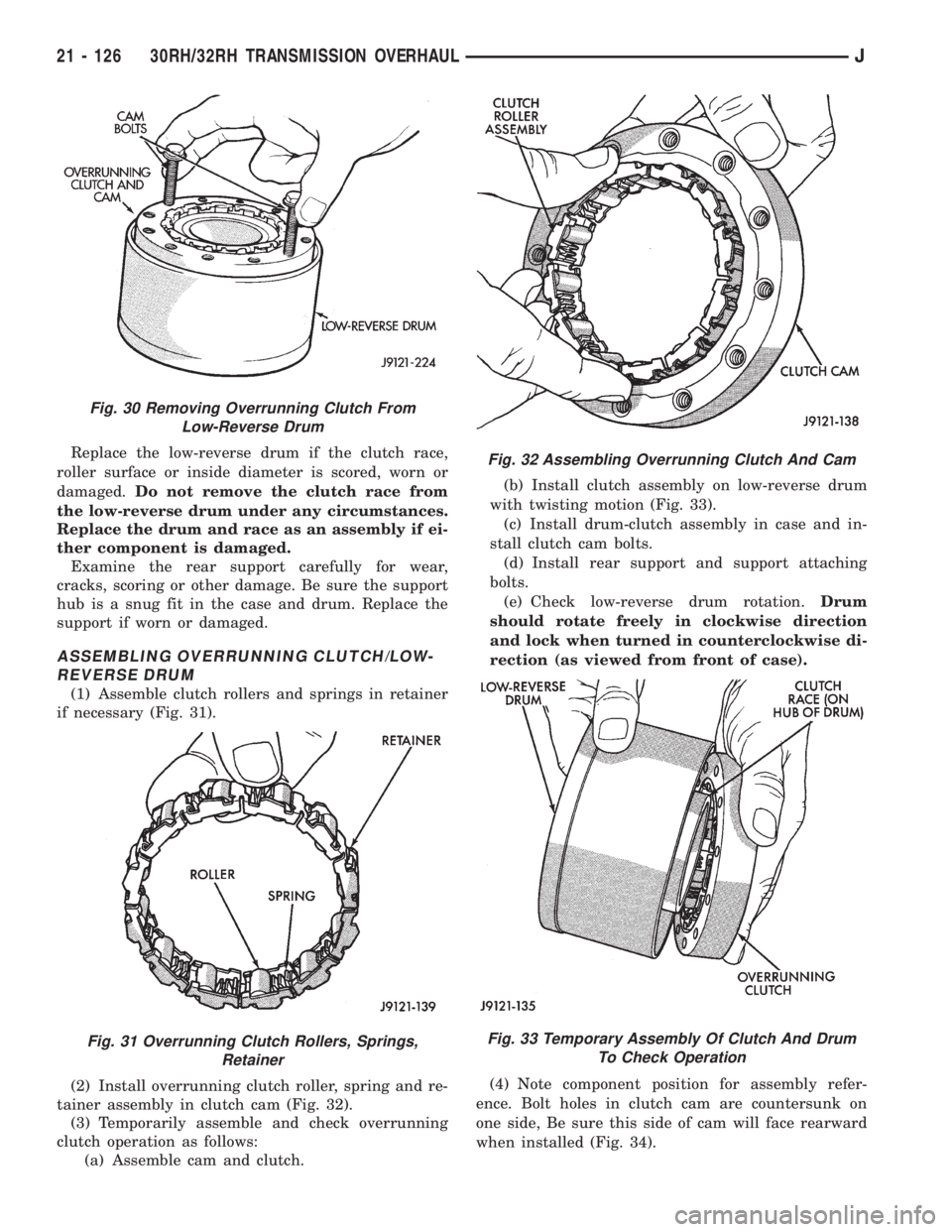

(1) Assemble clutch rollers and springs in retainer

if necessary (Fig. 31).

(2) Install overrunning clutch roller, spring and re-

tainer assembly in clutch cam (Fig. 32).

(3) Temporarily assemble and check overrunning

clutch operation as follows:

(a) Assemble cam and clutch.(b) Install clutch assembly on low-reverse drum

with twisting motion (Fig. 33).

(c) Install drum-clutch assembly in case and in-

stall clutch cam bolts.

(d) Install rear support and support attaching

bolts.

(e) Check low-reverse drum rotation.Drum

should rotate freely in clockwise direction

and lock when turned in counterclockwise di-

rection (as viewed from front of case).

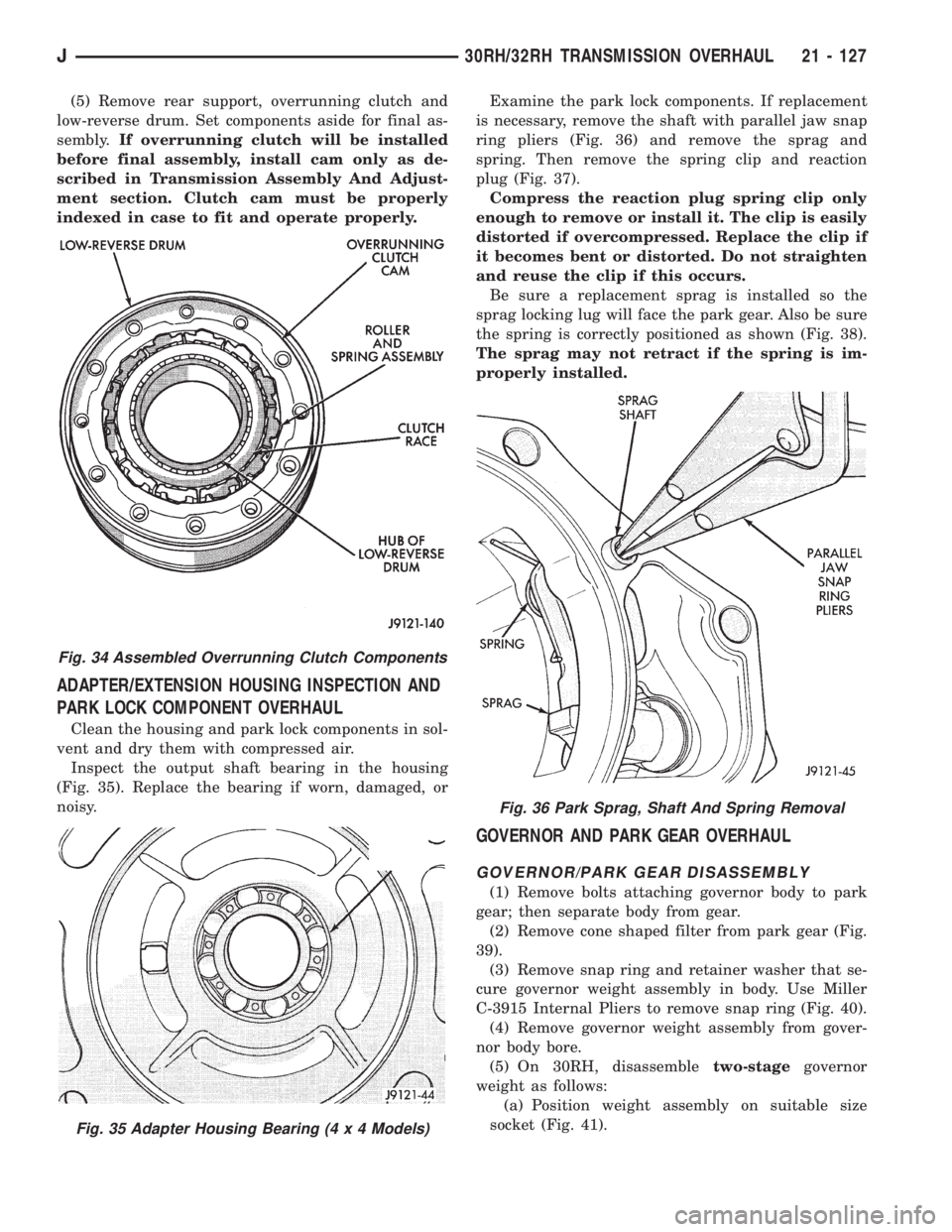

(4) Note component position for assembly refer-

ence. Bolt holes in clutch cam are countersunk on

one side, Be sure this side of cam will face rearward

when installed (Fig. 34).

Fig. 30 Removing Overrunning Clutch From

Low-Reverse Drum

Fig. 31 Overrunning Clutch Rollers, Springs,

Retainer

Fig. 32 Assembling Overrunning Clutch And Cam

Fig. 33 Temporary Assembly Of Clutch And Drum

To Check Operation

21 - 126 30RH/32RH TRANSMISSION OVERHAULJ

Page 1689 of 2158

(5) Remove rear support, overrunning clutch and

low-reverse drum. Set components aside for final as-

sembly.If overrunning clutch will be installed

before final assembly, install cam only as de-

scribed in Transmission Assembly And Adjust-

ment section. Clutch cam must be properly

indexed in case to fit and operate properly.

ADAPTER/EXTENSION HOUSING INSPECTION AND

PARK LOCK COMPONENT OVERHAUL

Clean the housing and park lock components in sol-

vent and dry them with compressed air.

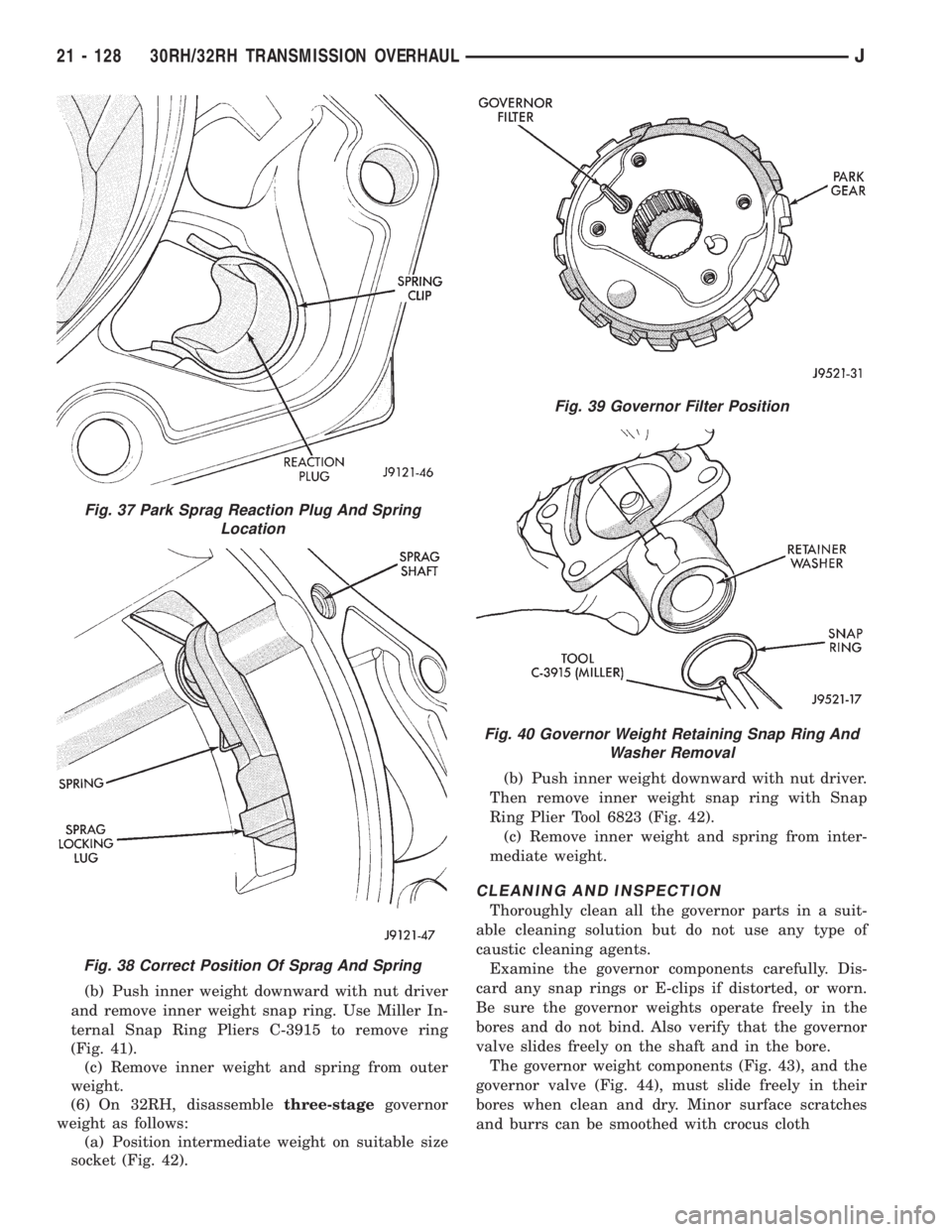

Inspect the output shaft bearing in the housing

(Fig. 35). Replace the bearing if worn, damaged, or

noisy.Examine the park lock components. If replacement

is necessary, remove the shaft with parallel jaw snap

ring pliers (Fig. 36) and remove the sprag and

spring. Then remove the spring clip and reaction

plug (Fig. 37).

Compress the reaction plug spring clip only

enough to remove or install it. The clip is easily

distorted if overcompressed. Replace the clip if

it becomes bent or distorted. Do not straighten

and reuse the clip if this occurs.

Be sure a replacement sprag is installed so the

sprag locking lug will face the park gear. Also be sure

the spring is correctly positioned as shown (Fig. 38).

The sprag may not retract if the spring is im-

properly installed.

GOVERNOR AND PARK GEAR OVERHAUL

GOVERNOR/PARK GEAR DISASSEMBLY

(1) Remove bolts attaching governor body to park

gear; then separate body from gear.

(2) Remove cone shaped filter from park gear (Fig.

39).

(3) Remove snap ring and retainer washer that se-

cure governor weight assembly in body. Use Miller

C-3915 Internal Pliers to remove snap ring (Fig. 40).

(4) Remove governor weight assembly from gover-

nor body bore.

(5) On 30RH, disassembletwo-stagegovernor

weight as follows:

(a) Position weight assembly on suitable size

socket (Fig. 41).

Fig. 34 Assembled Overrunning Clutch Components

Fig. 35 Adapter Housing Bearing (4 x 4 Models)

Fig. 36 Park Sprag, Shaft And Spring Removal

J30RH/32RH TRANSMISSION OVERHAUL 21 - 127

Page 1690 of 2158

(b) Push inner weight downward with nut driver

and remove inner weight snap ring. Use Miller In-

ternal Snap Ring Pliers C-3915 to remove ring

(Fig. 41).

(c) Remove inner weight and spring from outer

weight.

(6) On 32RH, disassemblethree-stagegovernor

weight as follows:

(a) Position intermediate weight on suitable size

socket (Fig. 42).(b) Push inner weight downward with nut driver.

Then remove inner weight snap ring with Snap

Ring Plier Tool 6823 (Fig. 42).

(c) Remove inner weight and spring from inter-

mediate weight.

CLEANING AND INSPECTION

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

Examine the governor components carefully. Dis-

card any snap rings or E-clips if distorted, or worn.

Be sure the governor weights operate freely in the

bores and do not bind. Also verify that the governor

valve slides freely on the shaft and in the bore.

The governor weight components (Fig. 43), and the

governor valve (Fig. 44), must slide freely in their

bores when clean and dry. Minor surface scratches

and burrs can be smoothed with crocus cloth

Fig. 37 Park Sprag Reaction Plug And Spring

Location

Fig. 38 Correct Position Of Sprag And Spring

Fig. 39 Governor Filter Position

Fig. 40 Governor Weight Retaining Snap Ring And

Washer Removal

21 - 128 30RH/32RH TRANSMISSION OVERHAULJ