JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 2071 of 2158

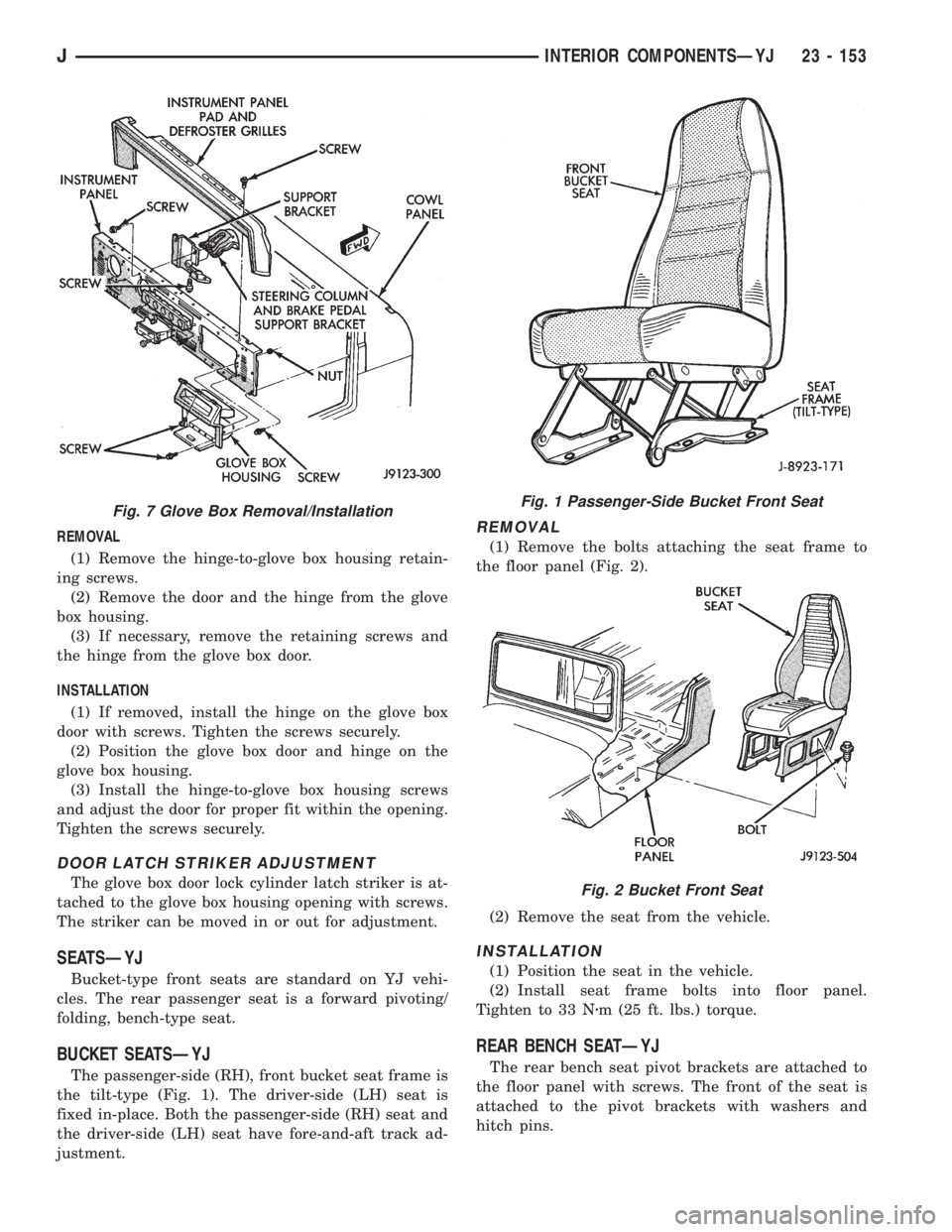

REMOVAL

(1) Remove the hinge-to-glove box housing retain-

ing screws.

(2) Remove the door and the hinge from the glove

box housing.

(3) If necessary, remove the retaining screws and

the hinge from the glove box door.

INSTALLATION

(1) If removed, install the hinge on the glove box

door with screws. Tighten the screws securely.

(2) Position the glove box door and hinge on the

glove box housing.

(3) Install the hinge-to-glove box housing screws

and adjust the door for proper fit within the opening.

Tighten the screws securely.

DOOR LATCH STRIKER ADJUSTMENT

The glove box door lock cylinder latch striker is at-

tached to the glove box housing opening with screws.

The striker can be moved in or out for adjustment.

SEATSÐYJ

Bucket-type front seats are standard on YJ vehi-

cles. The rear passenger seat is a forward pivoting/

folding, bench-type seat.

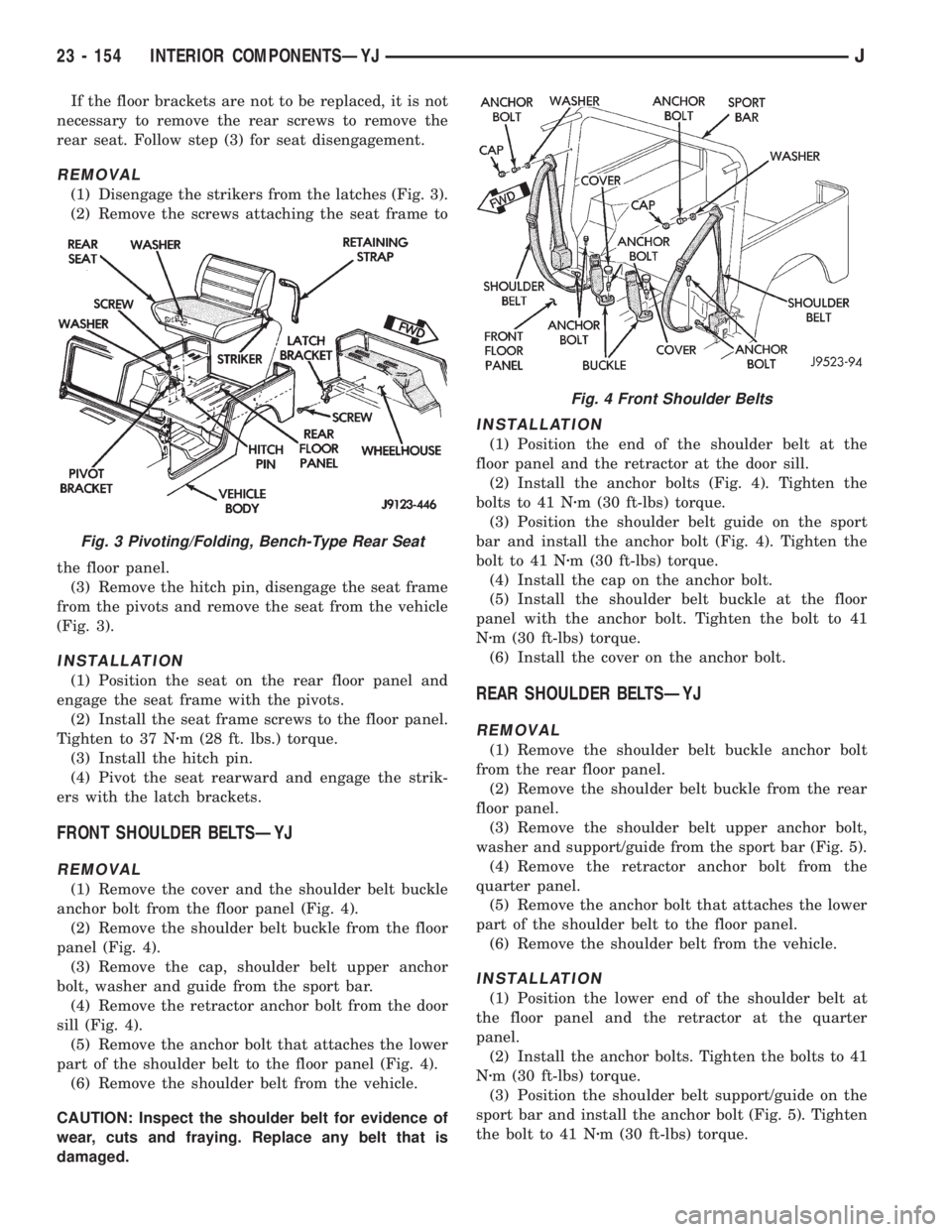

BUCKET SEATSÐYJ

The passenger-side (RH), front bucket seat frame is

the tilt-type (Fig. 1). The driver-side (LH) seat is

fixed in-place. Both the passenger-side (RH) seat and

the driver-side (LH) seat have fore-and-aft track ad-

justment.

REMOVAL

(1) Remove the bolts attaching the seat frame to

the floor panel (Fig. 2).

(2) Remove the seat from the vehicle.

INSTALLATION

(1) Position the seat in the vehicle.

(2) Install seat frame bolts into floor panel.

Tighten to 33 Nzm (25 ft. lbs.) torque.

REAR BENCH SEATÐYJ

The rear bench seat pivot brackets are attached to

the floor panel with screws. The front of the seat is

attached to the pivot brackets with washers and

hitch pins.

Fig. 7 Glove Box Removal/InstallationFig. 1 Passenger-Side Bucket Front Seat

Fig. 2 Bucket Front Seat

JINTERIOR COMPONENTSÐYJ 23 - 153

Page 2072 of 2158

If the floor brackets are not to be replaced, it is not

necessary to remove the rear screws to remove the

rear seat. Follow step (3) for seat disengagement.

REMOVAL

(1) Disengage the strikers from the latches (Fig. 3).

(2) Remove the screws attaching the seat frame to

the floor panel.

(3) Remove the hitch pin, disengage the seat frame

from the pivots and remove the seat from the vehicle

(Fig. 3).

INSTALLATION

(1) Position the seat on the rear floor panel and

engage the seat frame with the pivots.

(2) Install the seat frame screws to the floor panel.

Tighten to 37 Nzm (28 ft. lbs.) torque.

(3) Install the hitch pin.

(4) Pivot the seat rearward and engage the strik-

ers with the latch brackets.

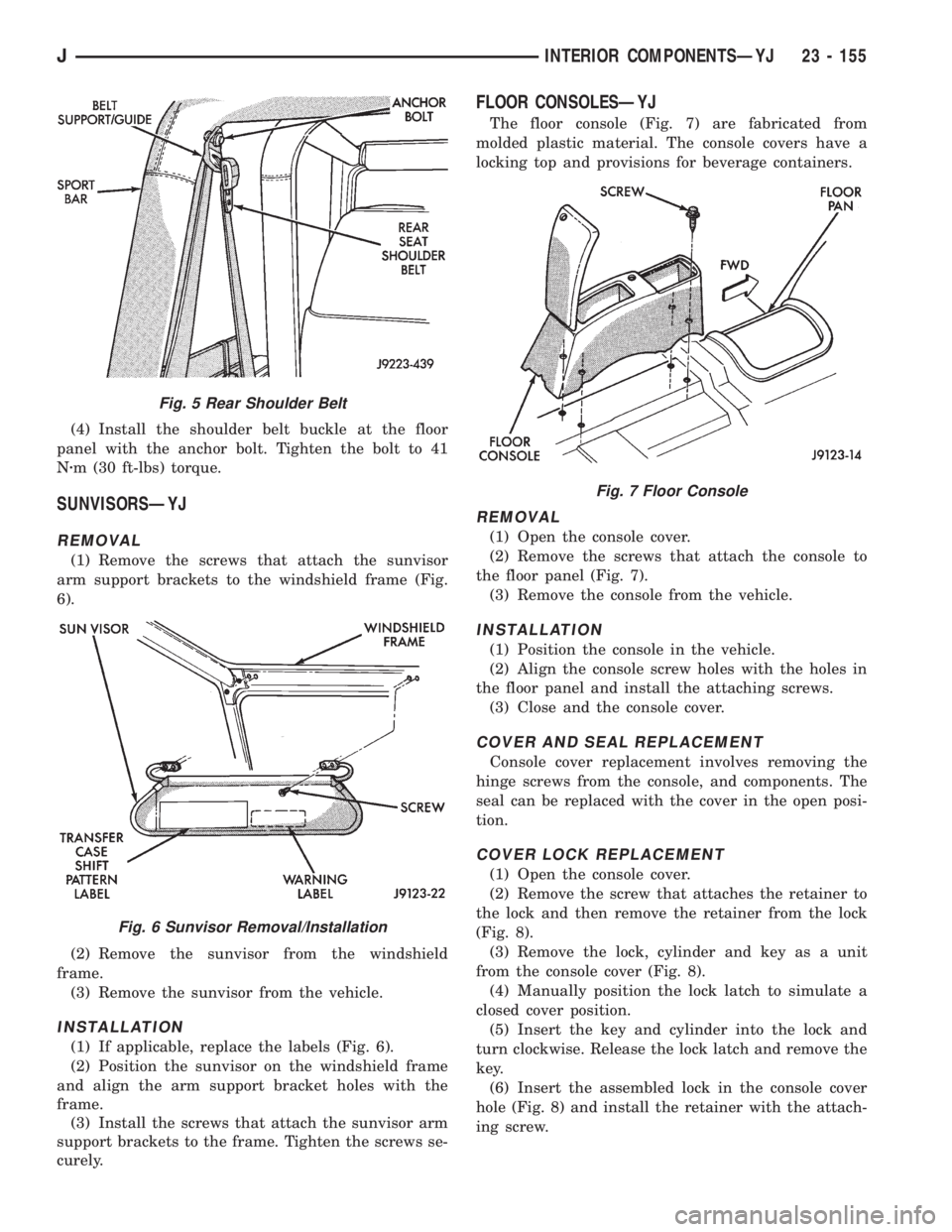

FRONT SHOULDER BELTSÐYJ

REMOVAL

(1) Remove the cover and the shoulder belt buckle

anchor bolt from the floor panel (Fig. 4).

(2) Remove the shoulder belt buckle from the floor

panel (Fig. 4).

(3) Remove the cap, shoulder belt upper anchor

bolt, washer and guide from the sport bar.

(4) Remove the retractor anchor bolt from the door

sill (Fig. 4).

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel (Fig. 4).

(6) Remove the shoulder belt from the vehicle.

CAUTION: Inspect the shoulder belt for evidence of

wear, cuts and fraying. Replace any belt that is

damaged.

INSTALLATION

(1) Position the end of the shoulder belt at the

floor panel and the retractor at the door sill.

(2) Install the anchor bolts (Fig. 4). Tighten the

bolts to 41 Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt guide on the sport

bar and install the anchor bolt (Fig. 4). Tighten the

bolt to 41 Nzm (30 ft-lbs) torque.

(4) Install the cap on the anchor bolt.

(5) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

(6) Install the cover on the anchor bolt.

REAR SHOULDER BELTSÐYJ

REMOVAL

(1) Remove the shoulder belt buckle anchor bolt

from the rear floor panel.

(2) Remove the shoulder belt buckle from the rear

floor panel.

(3) Remove the shoulder belt upper anchor bolt,

washer and support/guide from the sport bar (Fig. 5).

(4) Remove the retractor anchor bolt from the

quarter panel.

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel.

(6) Remove the shoulder belt from the vehicle.

INSTALLATION

(1) Position the lower end of the shoulder belt at

the floor panel and the retractor at the quarter

panel.

(2) Install the anchor bolts. Tighten the bolts to 41

Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt support/guide on the

sport bar and install the anchor bolt (Fig. 5). Tighten

the bolt to 41 Nzm (30 ft-lbs) torque.

Fig. 3 Pivoting/Folding, Bench-Type Rear Seat

Fig. 4 Front Shoulder Belts

23 - 154 INTERIOR COMPONENTSÐYJJ

Page 2073 of 2158

(4) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

SUNVISORSÐYJ

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support brackets to the windshield frame (Fig.

6).

(2) Remove the sunvisor from the windshield

frame.

(3) Remove the sunvisor from the vehicle.

INSTALLATION

(1) If applicable, replace the labels (Fig. 6).

(2) Position the sunvisor on the windshield frame

and align the arm support bracket holes with the

frame.

(3) Install the screws that attach the sunvisor arm

support brackets to the frame. Tighten the screws se-

curely.

FLOOR CONSOLESÐYJ

The floor console (Fig. 7) are fabricated from

molded plastic material. The console covers have a

locking top and provisions for beverage containers.

REMOVAL

(1) Open the console cover.

(2) Remove the screws that attach the console to

the floor panel (Fig. 7).

(3) Remove the console from the vehicle.

INSTALLATION

(1) Position the console in the vehicle.

(2) Align the console screw holes with the holes in

the floor panel and install the attaching screws.

(3) Close and the console cover.

COVER AND SEAL REPLACEMENT

Console cover replacement involves removing the

hinge screws from the console, and components. The

seal can be replaced with the cover in the open posi-

tion.

COVER LOCK REPLACEMENT

(1) Open the console cover.

(2) Remove the screw that attaches the retainer to

the lock and then remove the retainer from the lock

(Fig. 8).

(3) Remove the lock, cylinder and key as a unit

from the console cover (Fig. 8).

(4) Manually position the lock latch to simulate a

closed cover position.

(5) Insert the key and cylinder into the lock and

turn clockwise. Release the lock latch and remove the

key.

(6) Insert the assembled lock in the console cover

hole (Fig. 8) and install the retainer with the attach-

ing screw.

Fig. 5 Rear Shoulder Belt

Fig. 6 Sunvisor Removal/Installation

Fig. 7 Floor Console

JINTERIOR COMPONENTSÐYJ 23 - 155

Page 2074 of 2158

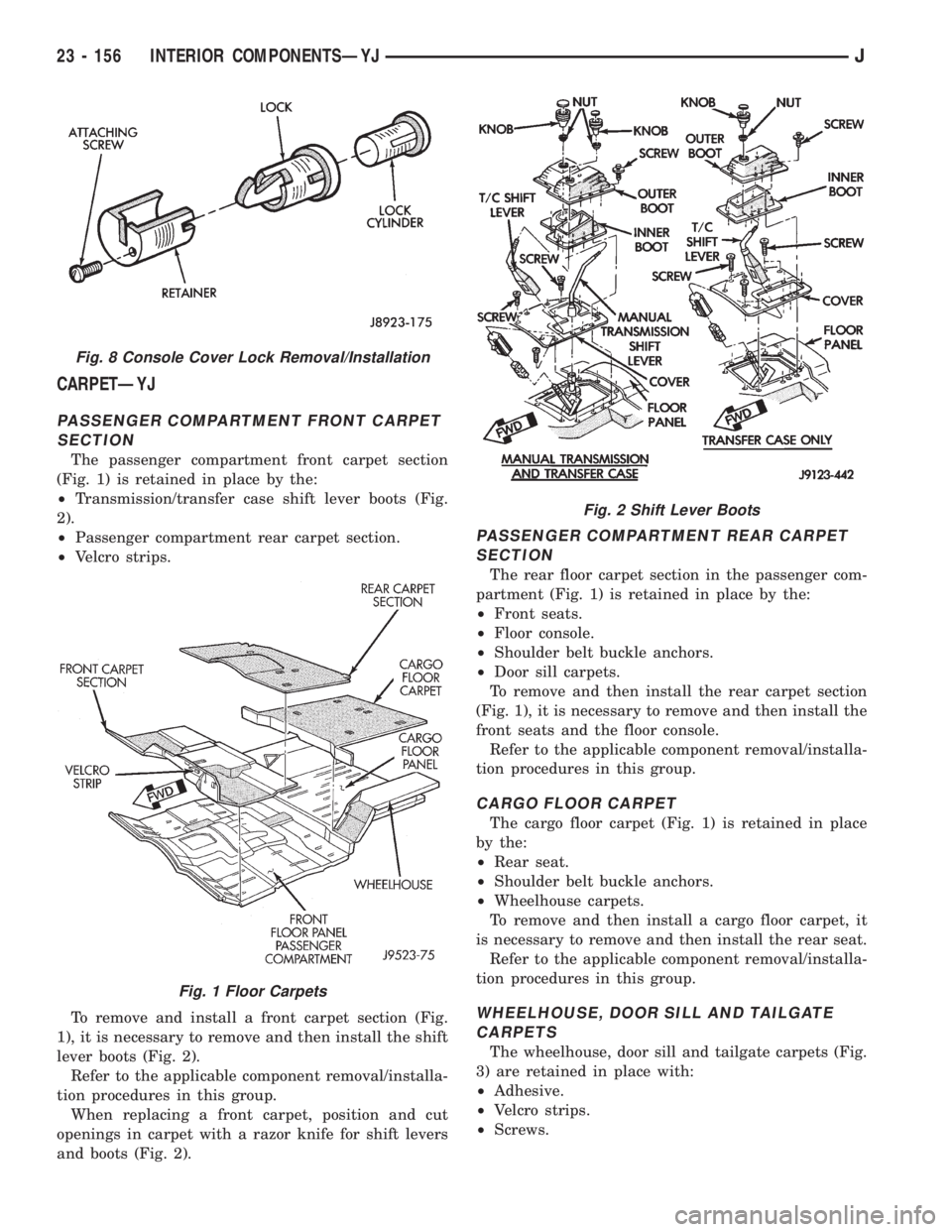

CARPETÐYJ

PASSENGER COMPARTMENT FRONT CARPET

SECTION

The passenger compartment front carpet section

(Fig. 1) is retained in place by the:

²Transmission/transfer case shift lever boots (Fig.

2).

²Passenger compartment rear carpet section.

²Velcro strips.

To remove and install a front carpet section (Fig.

1), it is necessary to remove and then install the shift

lever boots (Fig. 2).

Refer to the applicable component removal/installa-

tion procedures in this group.

When replacing a front carpet, position and cut

openings in carpet with a razor knife for shift levers

and boots (Fig. 2).

PASSENGER COMPARTMENT REAR CARPET

SECTION

The rear floor carpet section in the passenger com-

partment (Fig. 1) is retained in place by the:

²Front seats.

²Floor console.

²Shoulder belt buckle anchors.

²Door sill carpets.

To remove and then install the rear carpet section

(Fig. 1), it is necessary to remove and then install the

front seats and the floor console.

Refer to the applicable component removal/installa-

tion procedures in this group.

CARGO FLOOR CARPET

The cargo floor carpet (Fig. 1) is retained in place

by the:

²Rear seat.

²Shoulder belt buckle anchors.

²Wheelhouse carpets.

To remove and then install a cargo floor carpet, it

is necessary to remove and then install the rear seat.

Refer to the applicable component removal/installa-

tion procedures in this group.

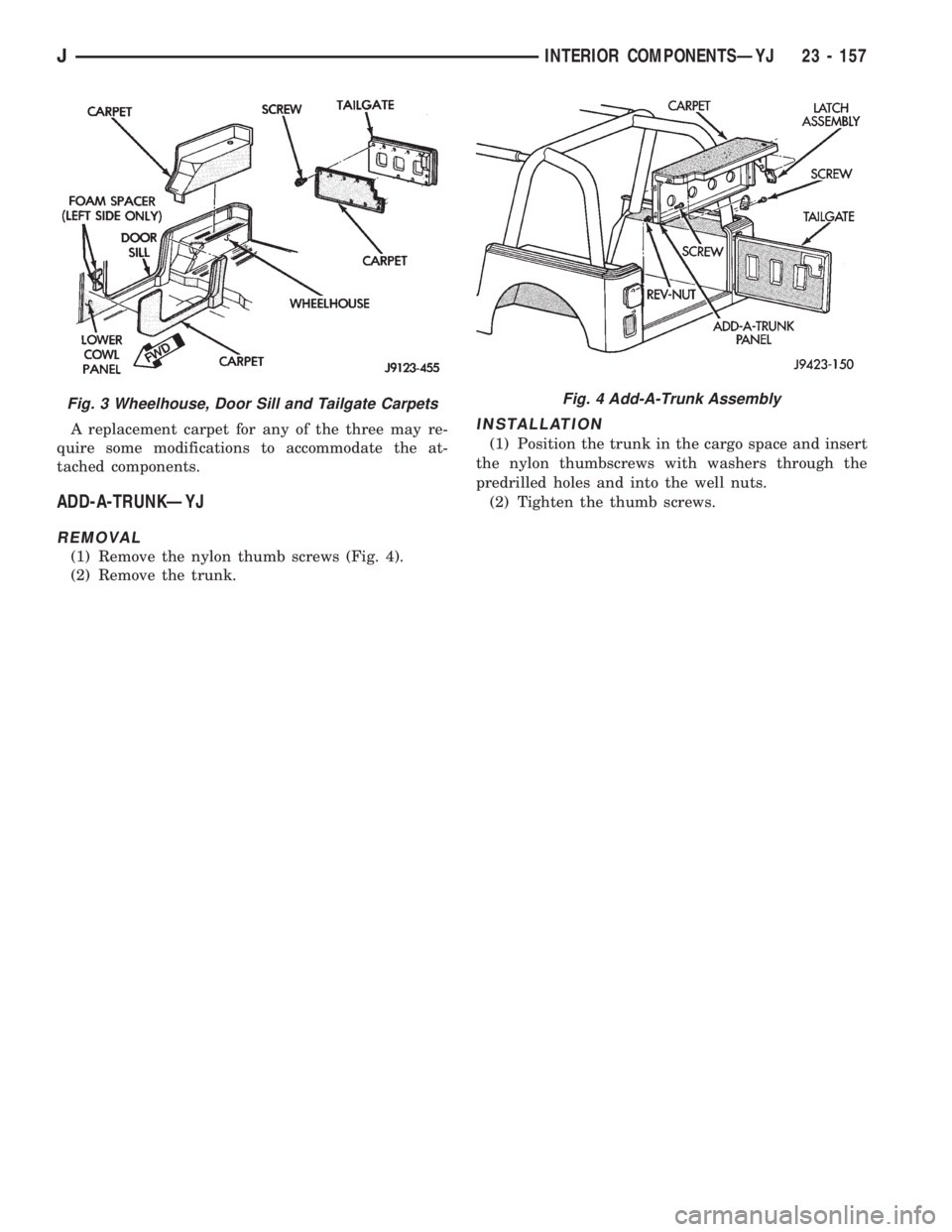

WHEELHOUSE, DOOR SILL AND TAILGATE

CARPETS

The wheelhouse, door sill and tailgate carpets (Fig.

3) are retained in place with:

²Adhesive.

²Velcro strips.

²Screws.

Fig. 8 Console Cover Lock Removal/Installation

Fig. 1 Floor Carpets

Fig. 2 Shift Lever Boots

23 - 156 INTERIOR COMPONENTSÐYJJ

Page 2075 of 2158

A replacement carpet for any of the three may re-

quire some modifications to accommodate the at-

tached components.

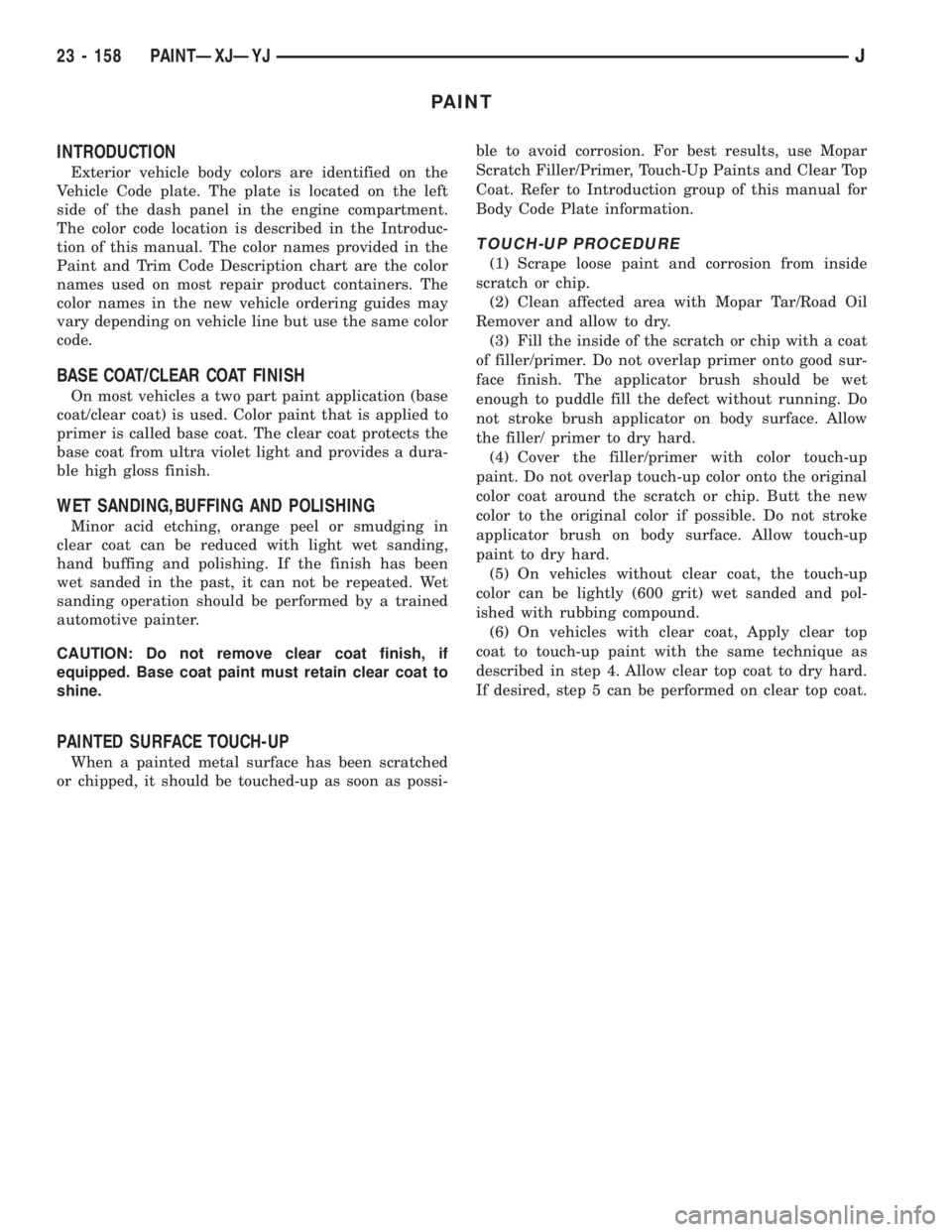

ADD-A-TRUNKÐYJ

REMOVAL

(1) Remove the nylon thumb screws (Fig. 4).

(2) Remove the trunk.

INSTALLATION

(1) Position the trunk in the cargo space and insert

the nylon thumbscrews with washers through the

predrilled holes and into the well nuts.

(2) Tighten the thumb screws.

Fig. 3 Wheelhouse, Door Sill and Tailgate CarpetsFig. 4 Add-A-Trunk Assembly

JINTERIOR COMPONENTSÐYJ 23 - 157

Page 2076 of 2158

PAINT

INTRODUCTION

Exterior vehicle body colors are identified on the

Vehicle Code plate. The plate is located on the left

side of the dash panel in the engine compartment.

The color code location is described in the Introduc-

tion of this manual. The color names provided in the

Paint and Trim Code Description chart are the color

names used on most repair product containers. The

color names in the new vehicle ordering guides may

vary depending on vehicle line but use the same color

code.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultra violet light and provides a dura-

ble high gloss finish.

WET SANDING,BUFFING AND POLISHING

Minor acid etching, orange peel or smudging in

clear coat can be reduced with light wet sanding,

hand buffing and polishing. If the finish has been

wet sanded in the past, it can not be repeated. Wet

sanding operation should be performed by a trained

automotive painter.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat to

shine.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-ble to avoid corrosion. For best results, use Mopar

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with Mopar Tar/Road Oil

Remover and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/ primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly (600 grit) wet sanded and pol-

ished with rubbing compound.

(6) On vehicles with clear coat, Apply clear top

coat to touch-up paint with the same technique as

described in step 4. Allow clear top coat to dry hard.

If desired, step 5 can be performed on clear top coat.

23 - 158 PAINTÐXJÐYJJ

Page 2077 of 2158

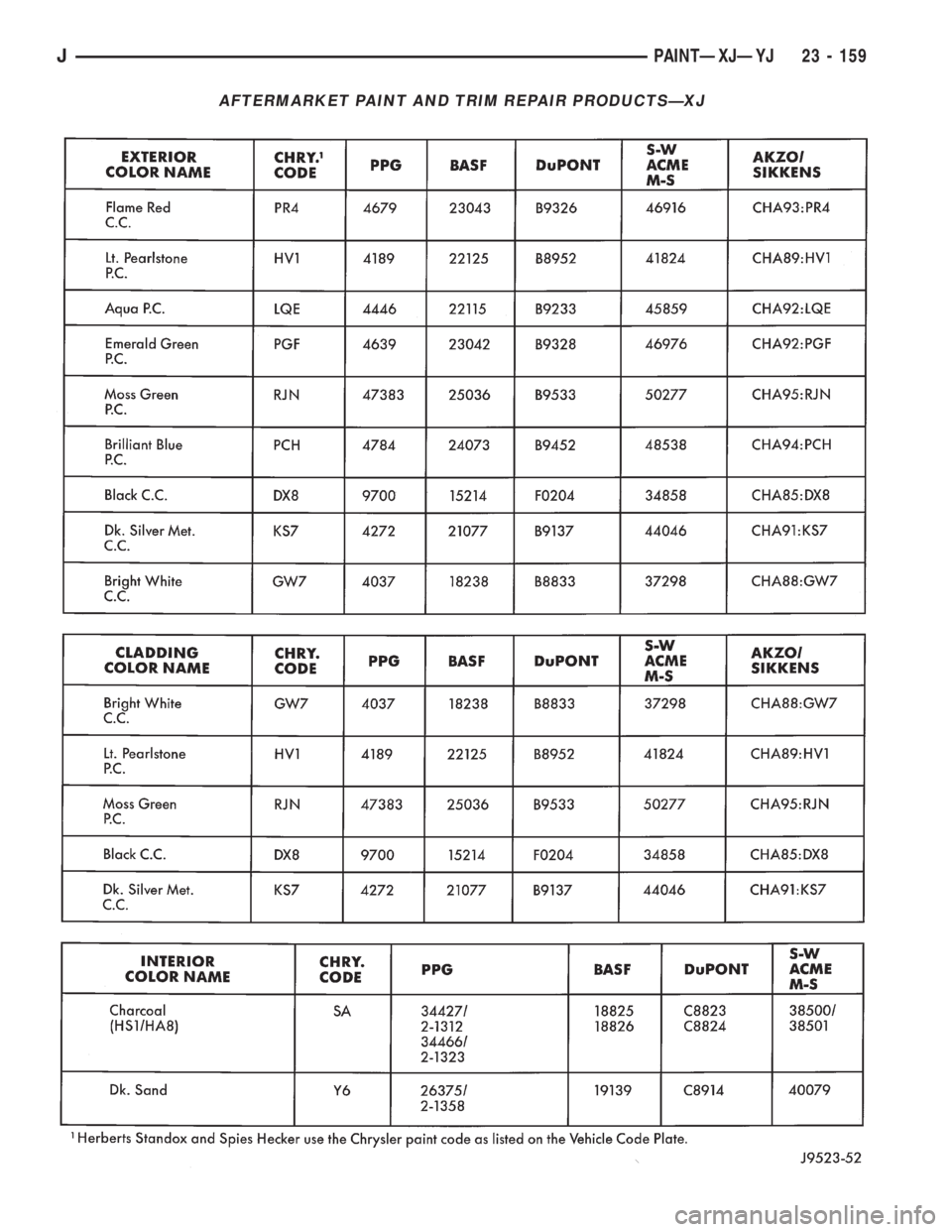

AFTERMARKET PAINT AND TRIM REPAIR PRODUCTSÐXJ

JPAINTÐXJÐYJ 23 - 159

Page 2078 of 2158

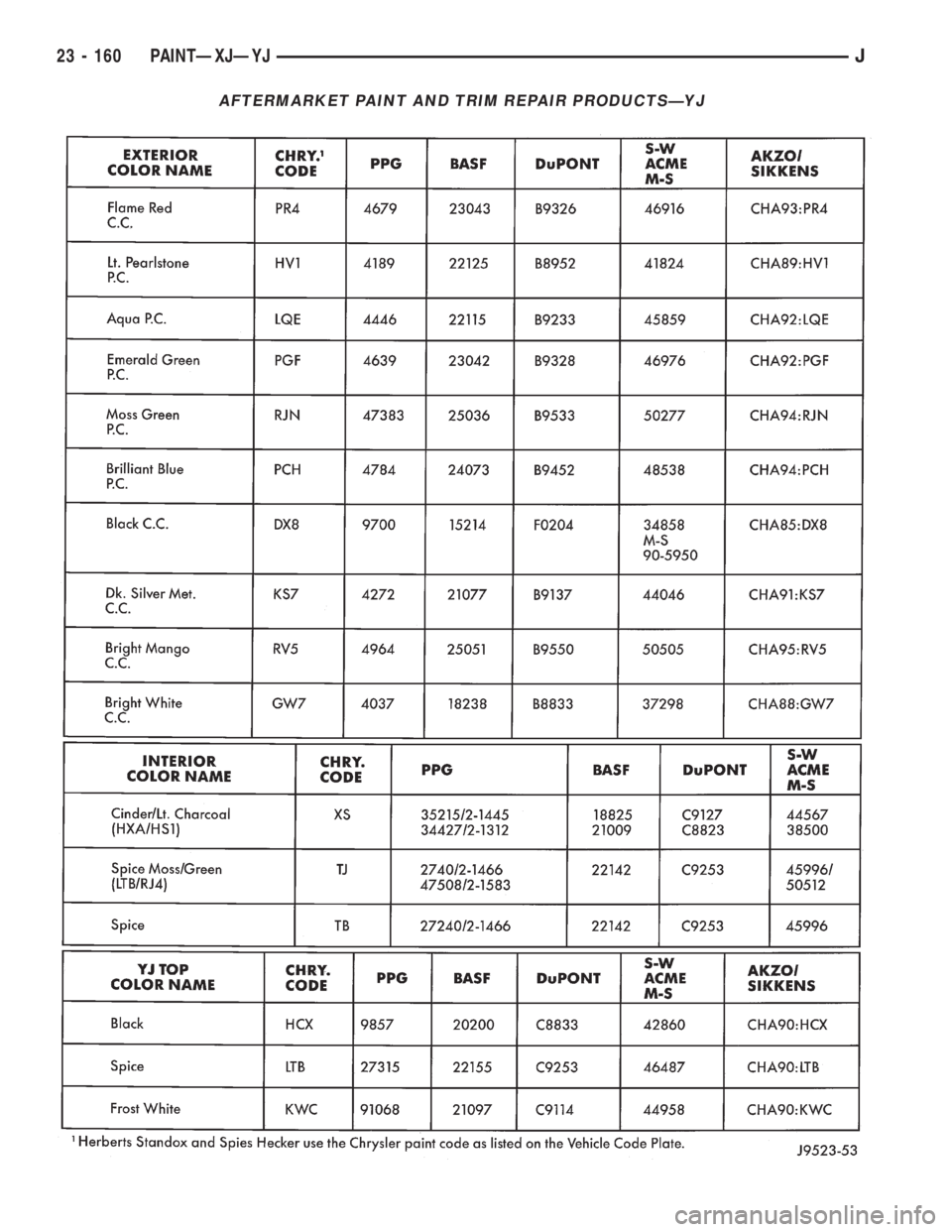

AFTERMARKET PAINT AND TRIM REPAIR PRODUCTSÐYJ

23 - 160 PAINTÐXJÐYJJ

Page 2079 of 2158

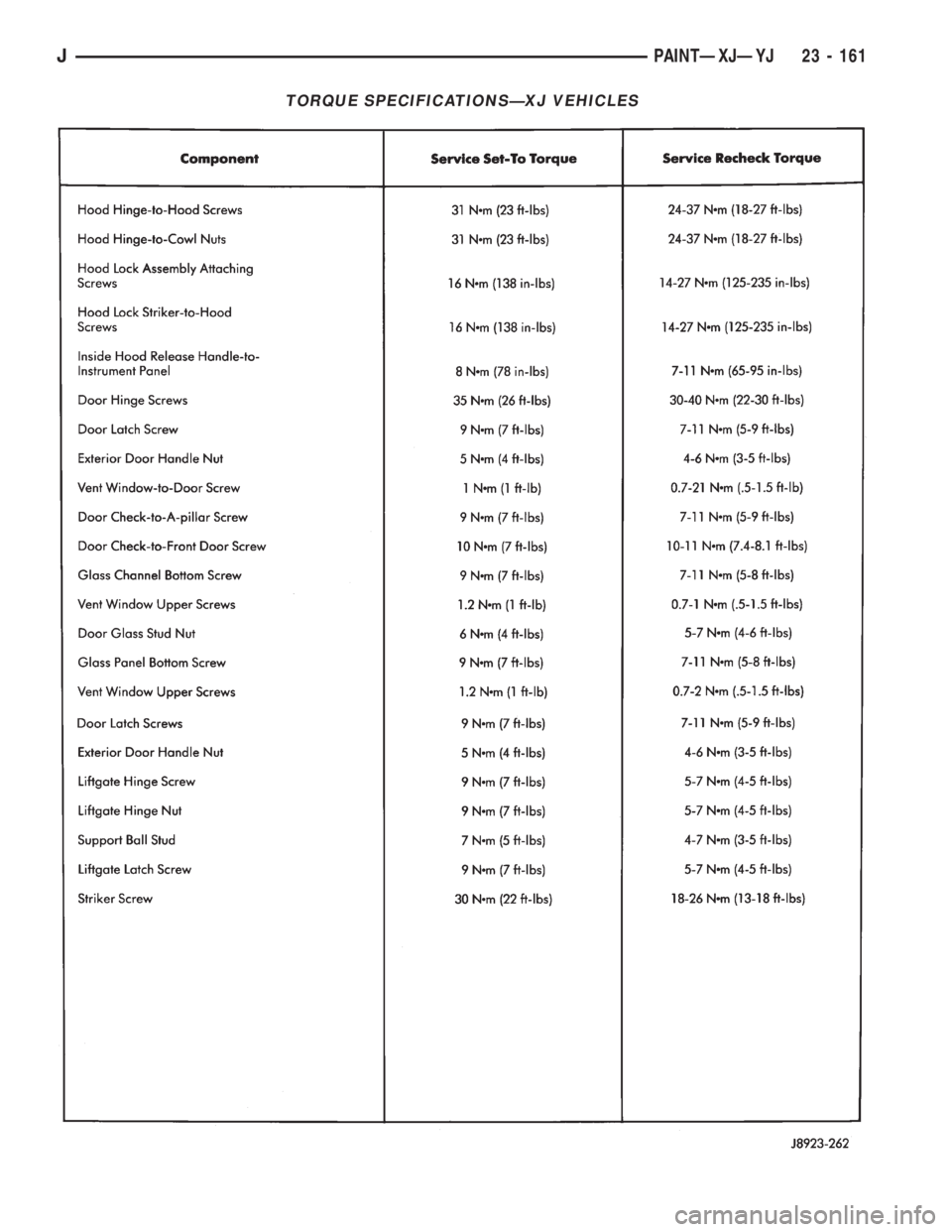

TORQUE SPECIFICATIONSÐXJ VEHICLES

JPAINTÐXJÐYJ 23 - 161

Page 2080 of 2158

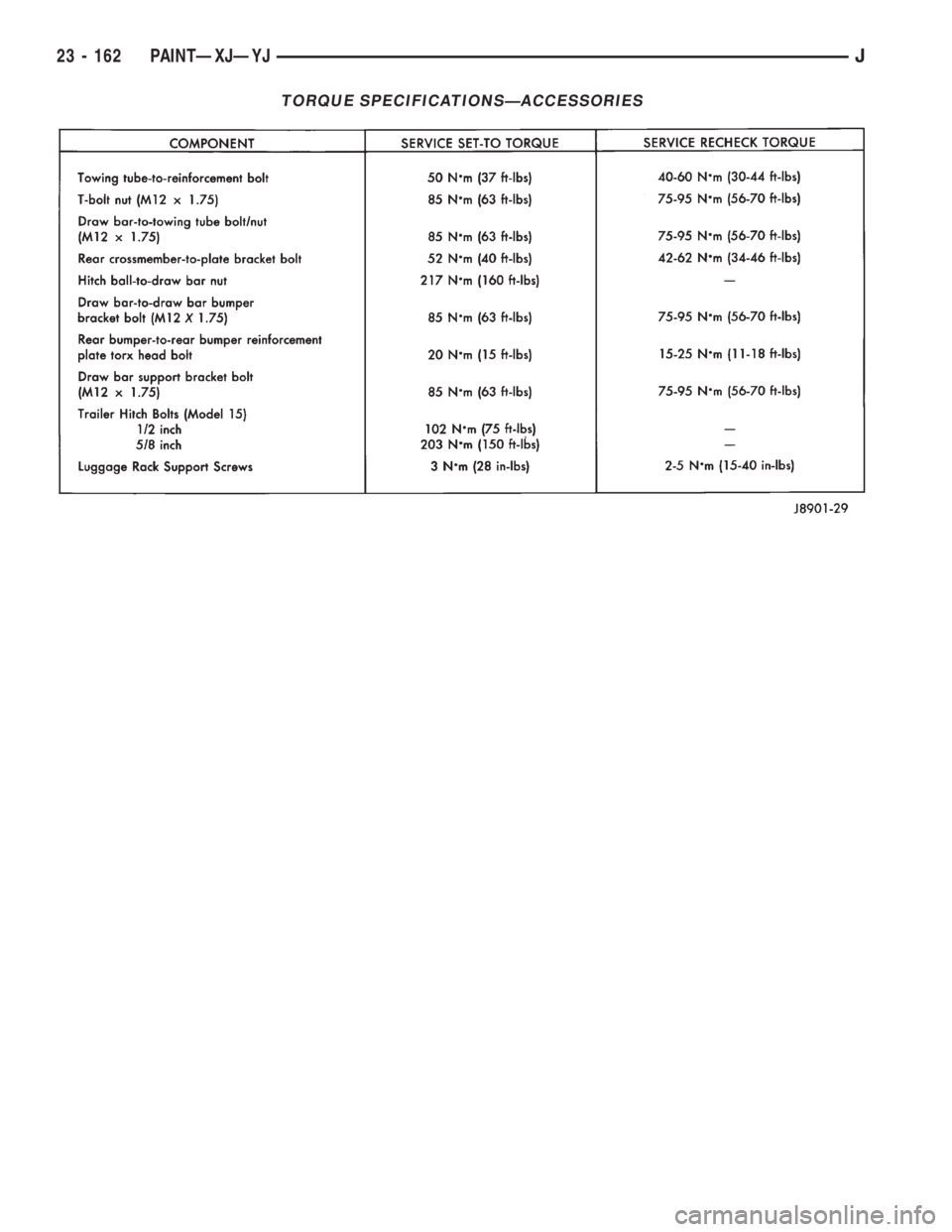

TORQUE SPECIFICATIONSÐACCESSORIES

23 - 162 PAINTÐXJÐYJJ