length JEEP XJ 1995 Service And Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1939 of 2158

(4) If the original molding will be installed, also re-

move all adhesive from it.

INSTALLATION

(1) Install 3M 06379 double-sided tape on the

molding.

(2) For vertical alignment, use masking tape or a

string as reference.

(3) Remove the backing from the tape, align the

molding and position it on the body panel.

(4) Press the molding onto the body panel with a

roller or hand pressure.

BODY STRIPES/DECALSÐXJ

SERVICE INFORMATION

XJ body stripes and decals are weather resistant

tape with a adhesive backing.

REPAIR

Small nicks, scratches and other surface marks in

a body stripe/decal can be touched-up with paint.

To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin.

A heat gun can also be used to remove small wrin-

kles in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement requires that the

metal repair and paint refinish be completed first.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for removal and installation:

²Commercial tape stripe/decal removal solution.

²Commercial adhesive removal solution.

²Liquid dish detergent (for the wetting solution).

²Mixture of wetting solution.

²Commercial wax and silicone removal solution.

²Isopropyl (rubbing) alcohol.

²Small squeegee (plastic or hard rubber).

²Water bucket and sponge.

²Clean wiping rags or paper towels.

²Heat gun (or infra-red heat bulb).

²Wax pencil.

²

Sharp knife, single edge razor blade or X-acto knife.

²Pair of scissors.

²Needle or pin.

The use of a wetting solution aids the installation of a

tape stripe/decal on a painted panel. Prepare the wet-

ting solution by mixing two or three teaspoons of dish

detergent with 1 gallon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

(1) Clean the repaired surface, adjacent panels and

door the openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from panel.

WARNING: USE TAPE STRIPE/DECAL REMOVAL

SOLUTION IN A WELL-VENTILATED AREA ONLY.

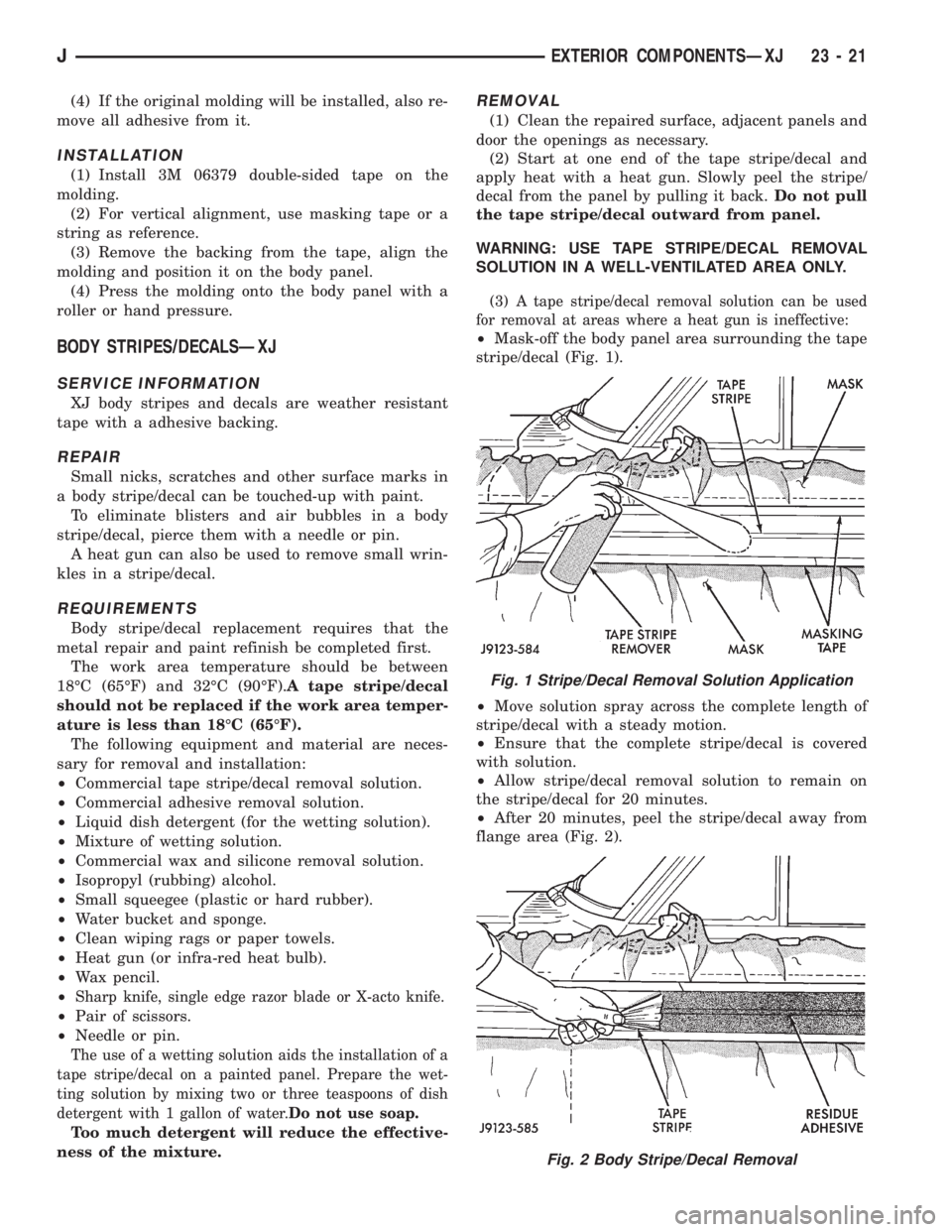

(3) A tape stripe/decal removal solution can be used

for removal at areas where a heat gun is ineffective:

²Mask-off the body panel area surrounding the tape

stripe/decal (Fig. 1).

²Move solution spray across the complete length of

stripe/decal with a steady motion.

²Ensure that the complete stripe/decal is covered

with solution.

²Allow stripe/decal removal solution to remain on

the stripe/decal for 20 minutes.

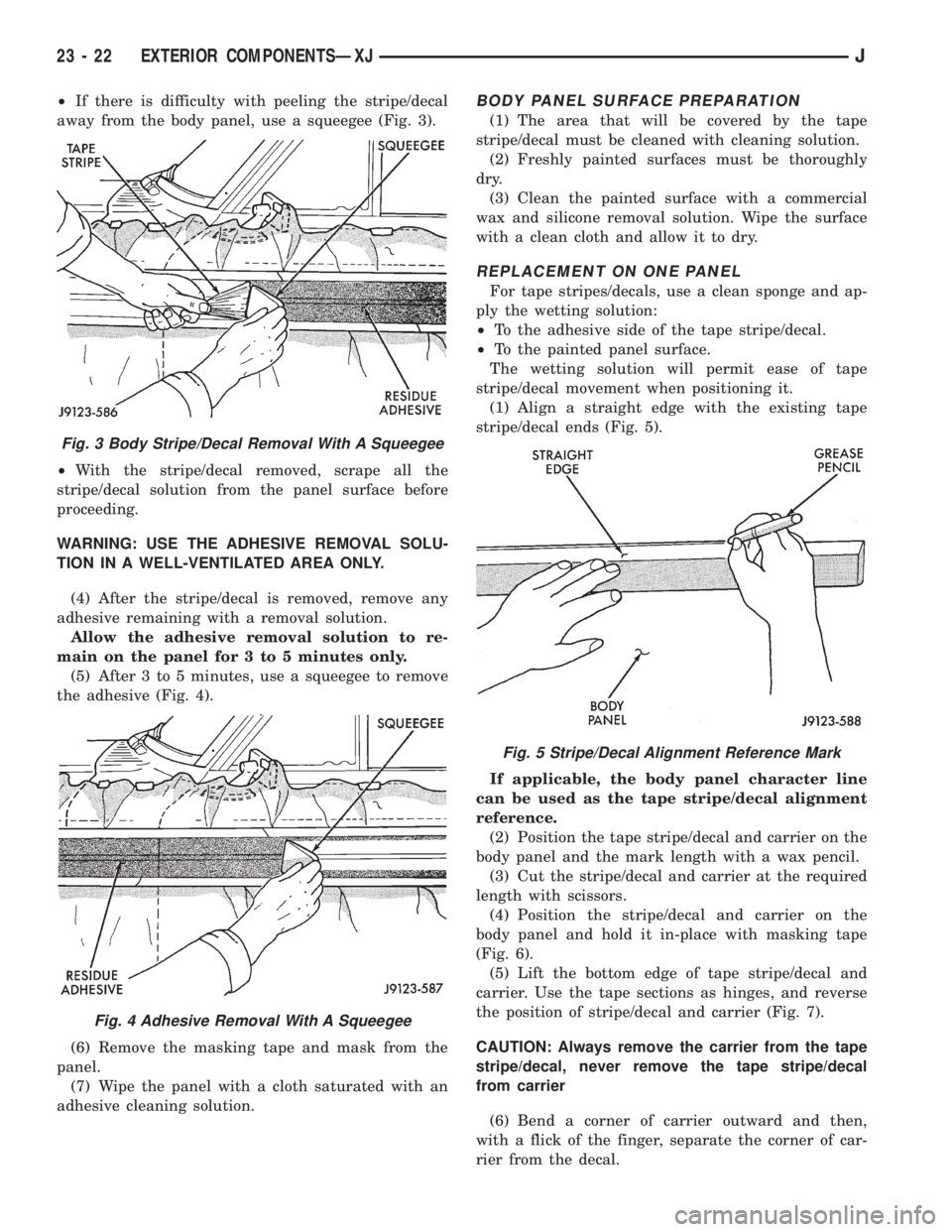

²After 20 minutes, peel the stripe/decal away from

flange area (Fig. 2).

Fig. 1 Stripe/Decal Removal Solution Application

Fig. 2 Body Stripe/Decal Removal

JEXTERIOR COMPONENTSÐXJ 23 - 21

Page 1940 of 2158

²If there is difficulty with peeling the stripe/decal

away from the body panel, use a squeegee (Fig. 3).

²With the stripe/decal removed, scrape all the

stripe/decal solution from the panel surface before

proceeding.

WARNING: USE THE ADHESIVE REMOVAL SOLU-

TION IN A WELL-VENTILATED AREA ONLY.

(4) After the stripe/decal is removed, remove any

adhesive remaining with a removal solution.

Allow the adhesive removal solution to re-

main on the panel for 3 to 5 minutes only.

(5) After 3 to 5 minutes, use a squeegee to remove

the adhesive (Fig. 4).

(6) Remove the masking tape and mask from the

panel.

(7) Wipe the panel with a cloth saturated with an

adhesive cleaning solution.BODY PANEL SURFACE PREPARATION

(1) The area that will be covered by the tape

stripe/decal must be cleaned with cleaning solution.

(2) Freshly painted surfaces must be thoroughly

dry.

(3) Clean the painted surface with a commercial

wax and silicone removal solution. Wipe the surface

with a clean cloth and allow it to dry.

REPLACEMENT ON ONE PANEL

For tape stripes/decals, use a clean sponge and ap-

ply the wetting solution:

²To the adhesive side of the tape stripe/decal.

²To the painted panel surface.

The wetting solution will permit ease of tape

stripe/decal movement when positioning it.

(1) Align a straight edge with the existing tape

stripe/decal ends (Fig. 5).

If applicable, the body panel character line

can be used as the tape stripe/decal alignment

reference.

(2) Position the tape stripe/decal and carrier on the

body panel and the mark length with a wax pencil.

(3) Cut the stripe/decal and carrier at the required

length with scissors.

(4) Position the stripe/decal and carrier on the

body panel and hold it in-place with masking tape

(Fig. 6).

(5) Lift the bottom edge of tape stripe/decal and

carrier. Use the tape sections as hinges, and reverse

the position of stripe/decal and carrier (Fig. 7).

CAUTION: Always remove the carrier from the tape

stripe/decal, never remove the tape stripe/decal

from carrier

(6) Bend a corner of carrier outward and then,

with a flick of the finger, separate the corner of car-

rier from the decal.

Fig. 3 Body Stripe/Decal Removal With A Squeegee

Fig. 4 Adhesive Removal With A Squeegee

Fig. 5 Stripe/Decal Alignment Reference Mark

23 - 22 EXTERIOR COMPONENTSÐXJJ

Page 1987 of 2158

(5) Start the hot knife blade (special tool C-4386)

between the glass and the urethane. Next, cut the

adhesive as close to the glass edge as possible (Fig.

1). Allow as much adhesive to remain on the pinch-

weld flange as possible.For best cutting results,

clean the knife blade frequently with steel wool

while the blade is hot.

(6) Remove the windshield glass from the body

opening.

(7) After the hot knife blade has cooled, clean the

blade with solvent and a clean cloth.

INSTALLATIONÐSHORT METHOD

Normally, after a replacement windshield glass is

installed, the rearview mirror bracket also requires

installation.Do not install the bracket until after

the windshield glass installation is completed.

(1) Inspect the windshield opening pinchweld

flanges. Prime any bare spots with urethane primer.

Allow a minimum of 18 minutes for dry time.

(2) Inspect urethane bead for high spots. Level

bead by shaving off high spots with a razor knife.

(3) Clean the outer edge of windshield glass with

naphtha or an equivalent product.

(4) Prime outer perimeter of interior side of glass 16

mm (5/8 inch) from edge. Use a wipe-off type urethane

primer and wipe glass dry after primer application.

NOTE: The reveal molding has an adhesive applied

to the windshield contact surface to help secure the

molding to the windshield during the installation

procedure.

(5) Apply the molding to the windshield:

²With the molding at room temperature, press the

molding onto the windshield corners.

²From corner to corner, work the molding to the

center of each side. (Some stretching of the mold-

ing may be required during this procedure.)(6) Place the glass on the pinchweld flanges and

inspect for gaps in the urethane. Gaps in excess of 3

mm (1/8 inch) must be filled with urethane.

(7) Adjust windshield glass position until it is

aligned with the flanges and adhesive. Next, make

alignment marks on the glass and body.

(8) Remove the windshield glass and position it on

a flat surface.

CAUTION: Avoid spilling or dripping primer on

painted surfaces. Clean spills or drips immediately.

The primer will damage the paint if it remains on

the surface for any length of time.

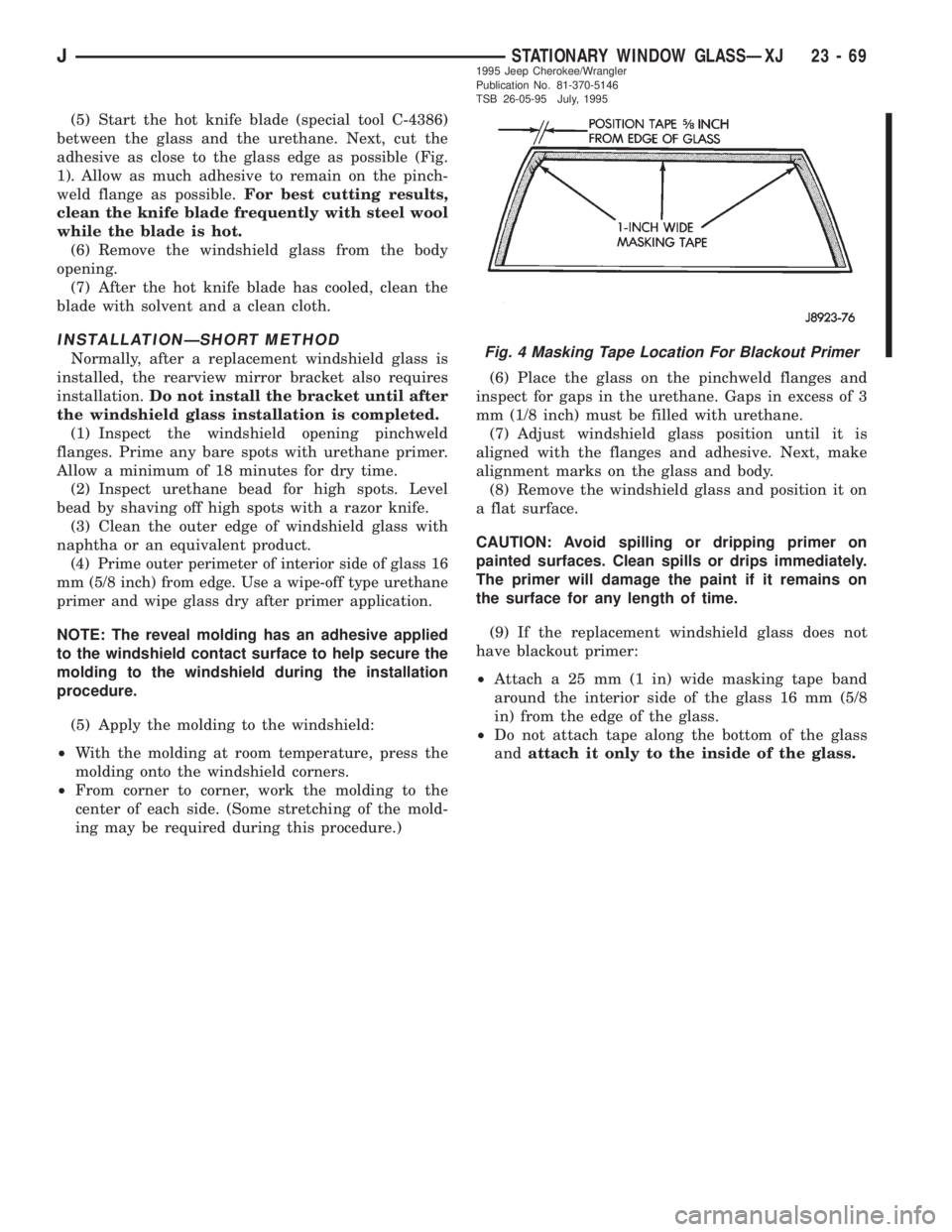

(9) If the replacement windshield glass does not

have blackout primer:

²Attach a 25 mm (1 in) wide masking tape band

around the interior side of the glass 16 mm (5/8

in) from the edge of the glass.

²Do not attach tape along the bottom of the glass

andattach it only to the inside of the glass.

Fig. 4 Masking Tape Location For Blackout Primer

JSTATIONARY WINDOW GLASSÐXJ 23 - 691995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1992 of 2158

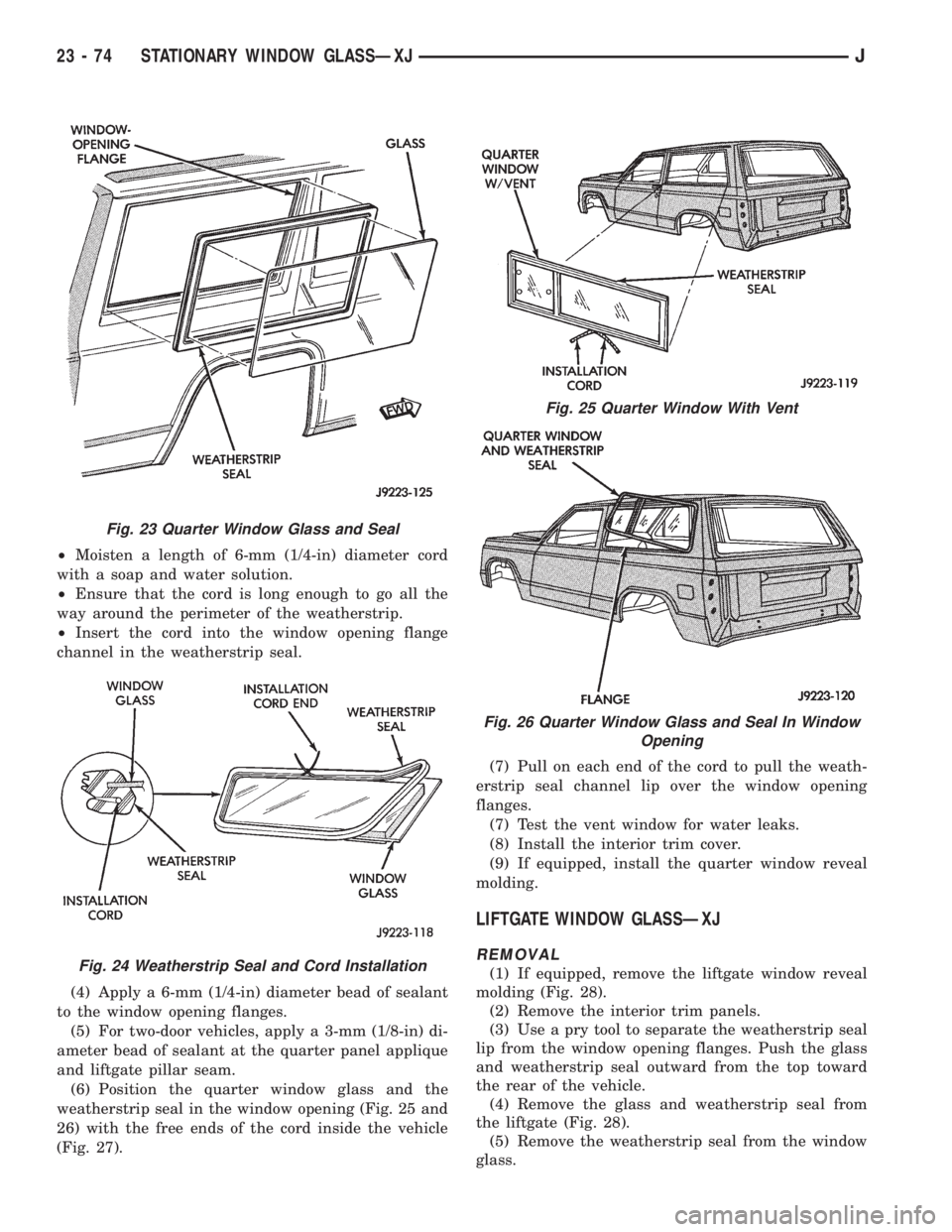

²Moisten a length of 6-mm (1/4-in) diameter cord

with a soap and water solution.

²Ensure that the cord is long enough to go all the

way around the perimeter of the weatherstrip.

²Insert the cord into the window opening flange

channel in the weatherstrip seal.

(4) Apply a 6-mm (1/4-in) diameter bead of sealant

to the window opening flanges.

(5) For two-door vehicles, apply a 3-mm (1/8-in) di-

ameter bead of sealant at the quarter panel applique

and liftgate pillar seam.

(6) Position the quarter window glass and the

weatherstrip seal in the window opening (Fig. 25 and

26) with the free ends of the cord inside the vehicle

(Fig. 27).(7) Pull on each end of the cord to pull the weath-

erstrip seal channel lip over the window opening

flanges.

(7) Test the vent window for water leaks.

(8) Install the interior trim cover.

(9) If equipped, install the quarter window reveal

molding.

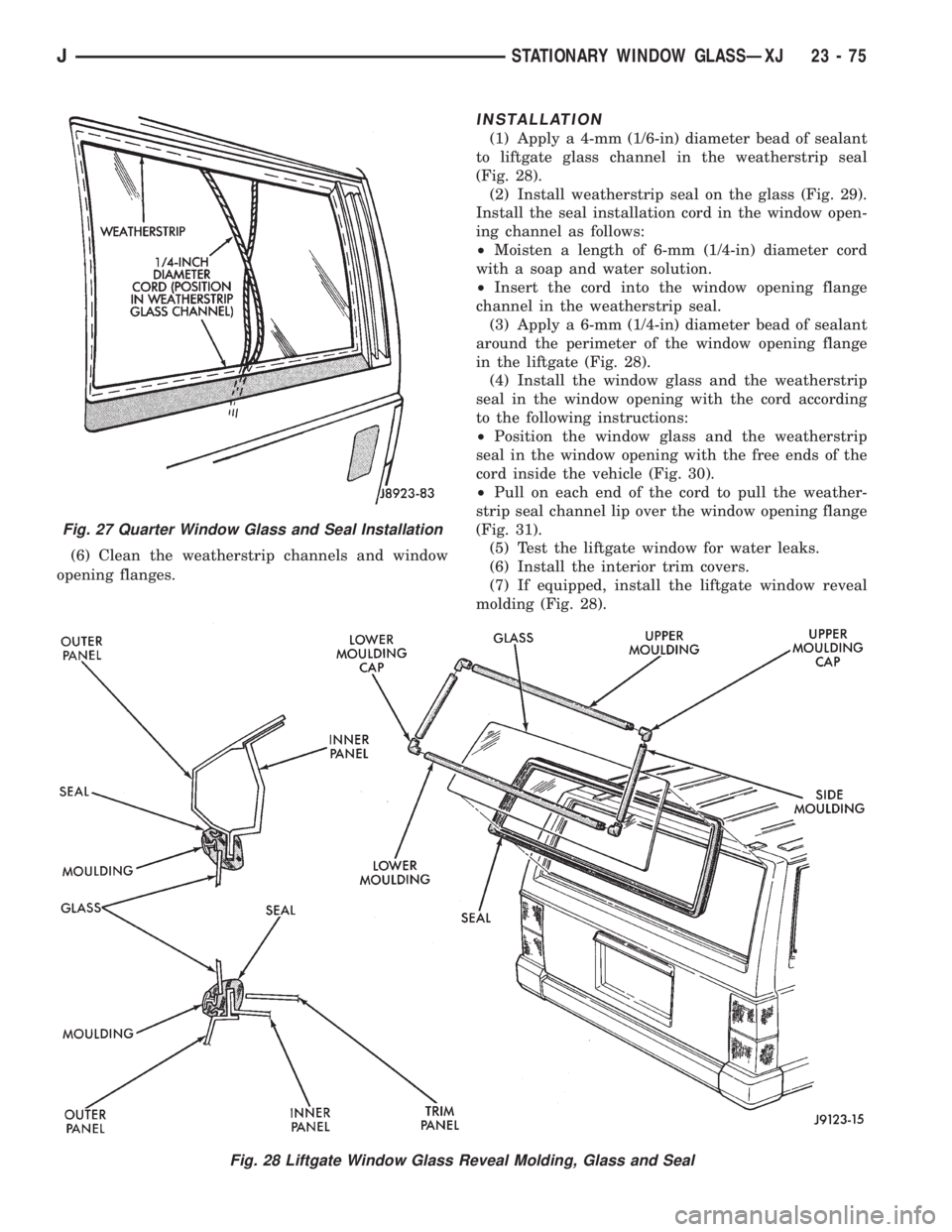

LIFTGATE WINDOW GLASSÐXJ

REMOVAL

(1) If equipped, remove the liftgate window reveal

molding (Fig. 28).

(2) Remove the interior trim panels.

(3) Use a pry tool to separate the weatherstrip seal

lip from the window opening flanges. Push the glass

and weatherstrip seal outward from the top toward

the rear of the vehicle.

(4) Remove the glass and weatherstrip seal from

the liftgate (Fig. 28).

(5) Remove the weatherstrip seal from the window

glass.

Fig. 23 Quarter Window Glass and Seal

Fig. 24 Weatherstrip Seal and Cord Installation

Fig. 25 Quarter Window With Vent

Fig. 26 Quarter Window Glass and Seal In Window

Opening

23 - 74 STATIONARY WINDOW GLASSÐXJJ

Page 1993 of 2158

(6) Clean the weatherstrip channels and window

opening flanges.

INSTALLATION

(1) Apply a 4-mm (1/6-in) diameter bead of sealant

to liftgate glass channel in the weatherstrip seal

(Fig. 28).

(2) Install weatherstrip seal on the glass (Fig. 29).

Install the seal installation cord in the window open-

ing channel as follows:

²Moisten a length of 6-mm (1/4-in) diameter cord

with a soap and water solution.

²Insert the cord into the window opening flange

channel in the weatherstrip seal.

(3) Apply a 6-mm (1/4-in) diameter bead of sealant

around the perimeter of the window opening flange

in the liftgate (Fig. 28).

(4) Install the window glass and the weatherstrip

seal in the window opening with the cord according

to the following instructions:

²Position the window glass and the weatherstrip

seal in the window opening with the free ends of the

cord inside the vehicle (Fig. 30).

²Pull on each end of the cord to pull the weather-

strip seal channel lip over the window opening flange

(Fig. 31).

(5) Test the liftgate window for water leaks.

(6) Install the interior trim covers.

(7) If equipped, install the liftgate window reveal

molding (Fig. 28).

Fig. 28 Liftgate Window Glass Reveal Molding, Glass and Seal

Fig. 27 Quarter Window Glass and Seal Installation

JSTATIONARY WINDOW GLASSÐXJ 23 - 75

Page 2016 of 2158

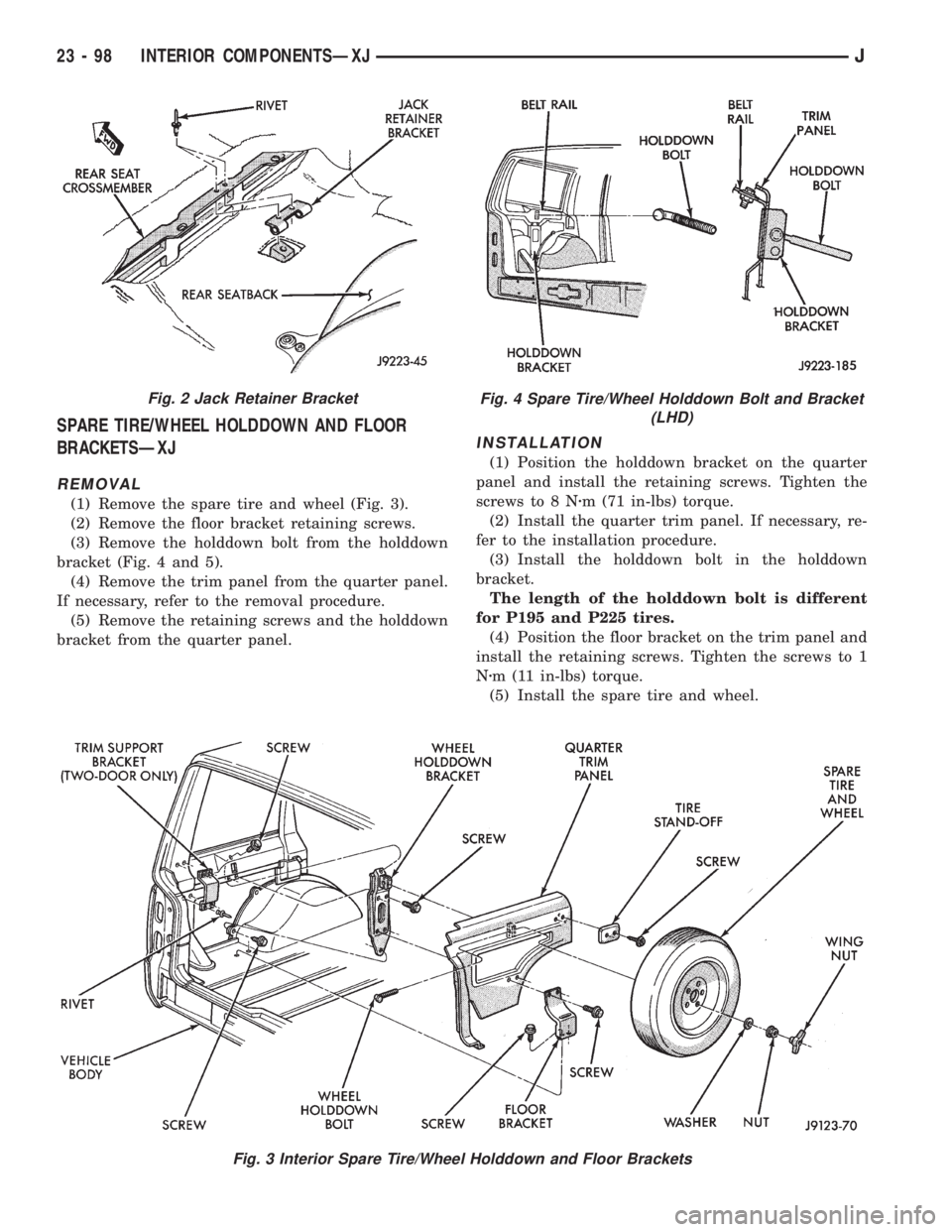

SPARE TIRE/WHEEL HOLDDOWN AND FLOOR

BRACKETSÐXJ

REMOVAL

(1) Remove the spare tire and wheel (Fig. 3).

(2) Remove the floor bracket retaining screws.

(3) Remove the holddown bolt from the holddown

bracket (Fig. 4 and 5).

(4) Remove the trim panel from the quarter panel.

If necessary, refer to the removal procedure.

(5) Remove the retaining screws and the holddown

bracket from the quarter panel.

INSTALLATION

(1) Position the holddown bracket on the quarter

panel and install the retaining screws. Tighten the

screws to 8 Nzm (71 in-lbs) torque.

(2) Install the quarter trim panel. If necessary, re-

fer to the installation procedure.

(3) Install the holddown bolt in the holddown

bracket.

The length of the holddown bolt is different

for P195 and P225 tires.

(4) Position the floor bracket on the trim panel and

install the retaining screws. Tighten the screws to 1

Nzm (11 in-lbs) torque.

(5) Install the spare tire and wheel.

Fig. 3 Interior Spare Tire/Wheel Holddown and Floor Brackets

Fig. 2 Jack Retainer BracketFig. 4 Spare Tire/Wheel Holddown Bolt and Bracket

(LHD)

23 - 98 INTERIOR COMPONENTSÐXJJ

Page 2035 of 2158

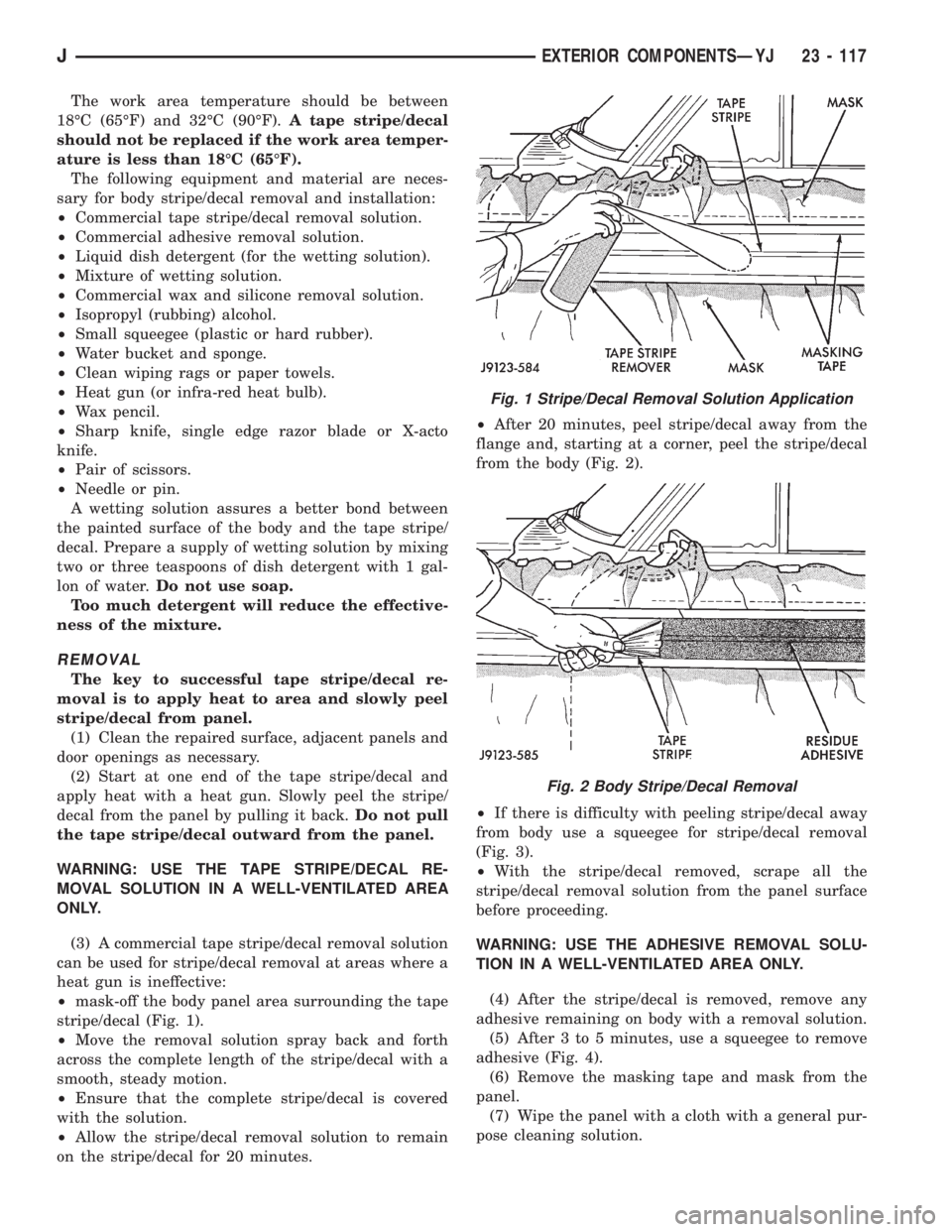

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for body stripe/decal removal and installation:

²Commercial tape stripe/decal removal solution.

²Commercial adhesive removal solution.

²Liquid dish detergent (for the wetting solution).

²Mixture of wetting solution.

²Commercial wax and silicone removal solution.

²Isopropyl (rubbing) alcohol.

²Small squeegee (plastic or hard rubber).

²Water bucket and sponge.

²Clean wiping rags or paper towels.

²Heat gun (or infra-red heat bulb).

²Wax pencil.

²Sharp knife, single edge razor blade or X-acto

knife.

²Pair of scissors.

²Needle or pin.

A wetting solution assures a better bond between

the painted surface of the body and the tape stripe/

decal. Prepare a supply of wetting solution by mixing

two or three teaspoons of dish detergent with 1 gal-

lon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

The key to successful tape stripe/decal re-

moval is to apply heat to area and slowly peel

stripe/decal from panel.

(1) Clean the repaired surface, adjacent panels and

door openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from the panel.

WARNING: USE THE TAPE STRIPE/DECAL RE-

MOVAL SOLUTION IN A WELL-VENTILATED AREA

ONLY.

(3) A commercial tape stripe/decal removal solution

can be used for stripe/decal removal at areas where a

heat gun is ineffective:

²mask-off the body panel area surrounding the tape

stripe/decal (Fig. 1).

²Move the removal solution spray back and forth

across the complete length of the stripe/decal with a

smooth, steady motion.

²Ensure that the complete stripe/decal is covered

with the solution.

²Allow the stripe/decal removal solution to remain

on the stripe/decal for 20 minutes.²After 20 minutes, peel stripe/decal away from the

flange and, starting at a corner, peel the stripe/decal

from the body (Fig. 2).

²If there is difficulty with peeling stripe/decal away

from body use a squeegee for stripe/decal removal

(Fig. 3).

²With the stripe/decal removed, scrape all the

stripe/decal removal solution from the panel surface

before proceeding.

WARNING: USE THE ADHESIVE REMOVAL SOLU-

TION IN A WELL-VENTILATED AREA ONLY.

(4) After the stripe/decal is removed, remove any

adhesive remaining on body with a removal solution.

(5) After 3 to 5 minutes, use a squeegee to remove

adhesive (Fig. 4).

(6) Remove the masking tape and mask from the

panel.

(7) Wipe the panel with a cloth with a general pur-

pose cleaning solution.

Fig. 1 Stripe/Decal Removal Solution Application

Fig. 2 Body Stripe/Decal Removal

JEXTERIOR COMPONENTSÐYJ 23 - 117

Page 2036 of 2158

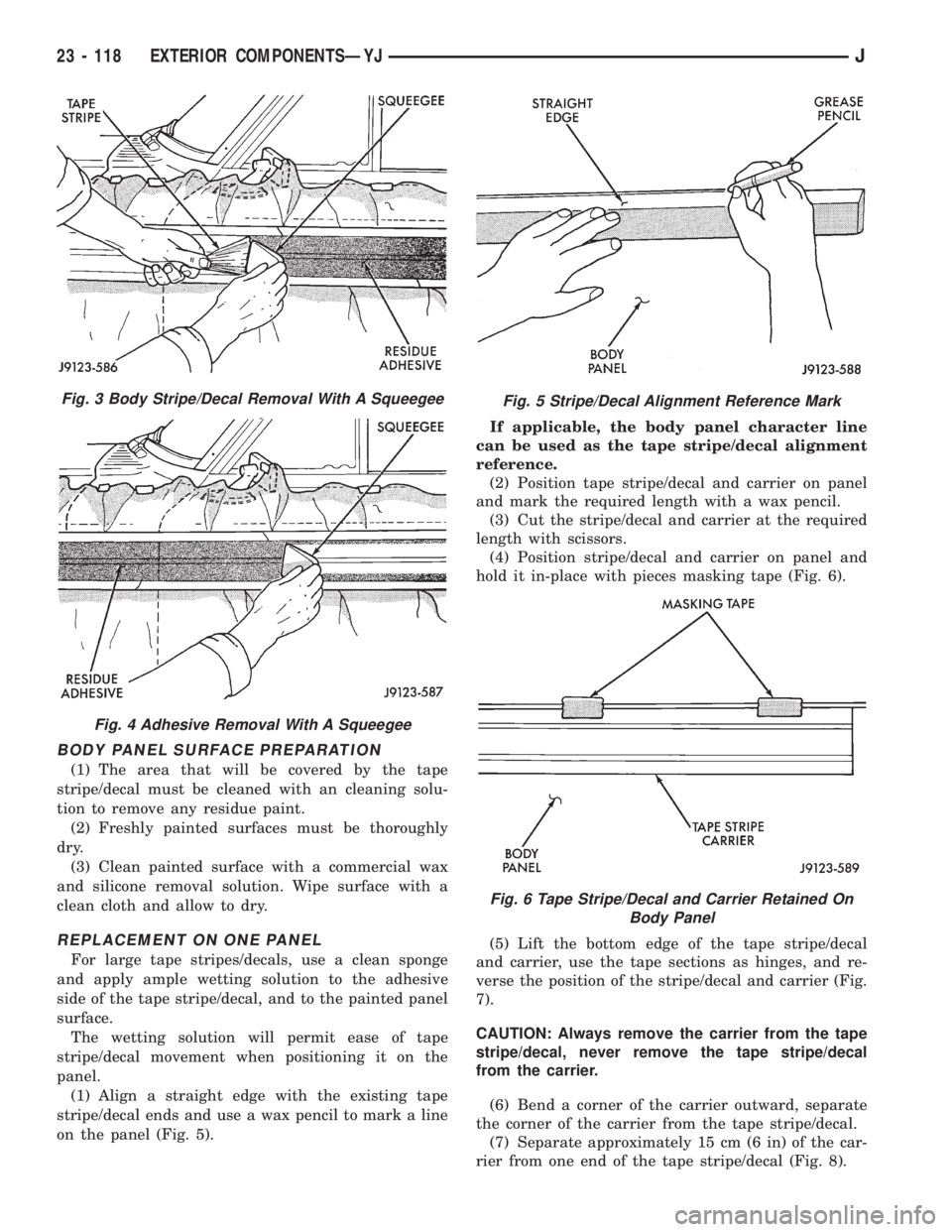

BODY PANEL SURFACE PREPARATION

(1) The area that will be covered by the tape

stripe/decal must be cleaned with an cleaning solu-

tion to remove any residue paint.

(2) Freshly painted surfaces must be thoroughly

dry.

(3) Clean painted surface with a commercial wax

and silicone removal solution. Wipe surface with a

clean cloth and allow to dry.

REPLACEMENT ON ONE PANEL

For large tape stripes/decals, use a clean sponge

and apply ample wetting solution to the adhesive

side of the tape stripe/decal, and to the painted panel

surface.

The wetting solution will permit ease of tape

stripe/decal movement when positioning it on the

panel.

(1) Align a straight edge with the existing tape

stripe/decal ends and use a wax pencil to mark a line

on the panel (Fig. 5).If applicable, the body panel character line

can be used as the tape stripe/decal alignment

reference.

(2) Position tape stripe/decal and carrier on panel

and mark the required length with a wax pencil.

(3) Cut the stripe/decal and carrier at the required

length with scissors.

(4) Position stripe/decal and carrier on panel and

hold it in-place with pieces masking tape (Fig. 6).

(5) Lift the bottom edge of the tape stripe/decal

and carrier, use the tape sections as hinges, and re-

verse the position of the stripe/decal and carrier (Fig.

7).

CAUTION: Always remove the carrier from the tape

stripe/decal, never remove the tape stripe/decal

from the carrier.

(6) Bend a corner of the carrier outward, separate

the corner of the carrier from the tape stripe/decal.

(7) Separate approximately 15 cm (6 in) of the car-

rier from one end of the tape stripe/decal (Fig. 8).

Fig. 3 Body Stripe/Decal Removal With A Squeegee

Fig. 4 Adhesive Removal With A Squeegee

Fig. 5 Stripe/Decal Alignment Reference Mark

Fig. 6 Tape Stripe/Decal and Carrier Retained On

Body Panel

23 - 118 EXTERIOR COMPONENTSÐYJJ

Page 2061 of 2158

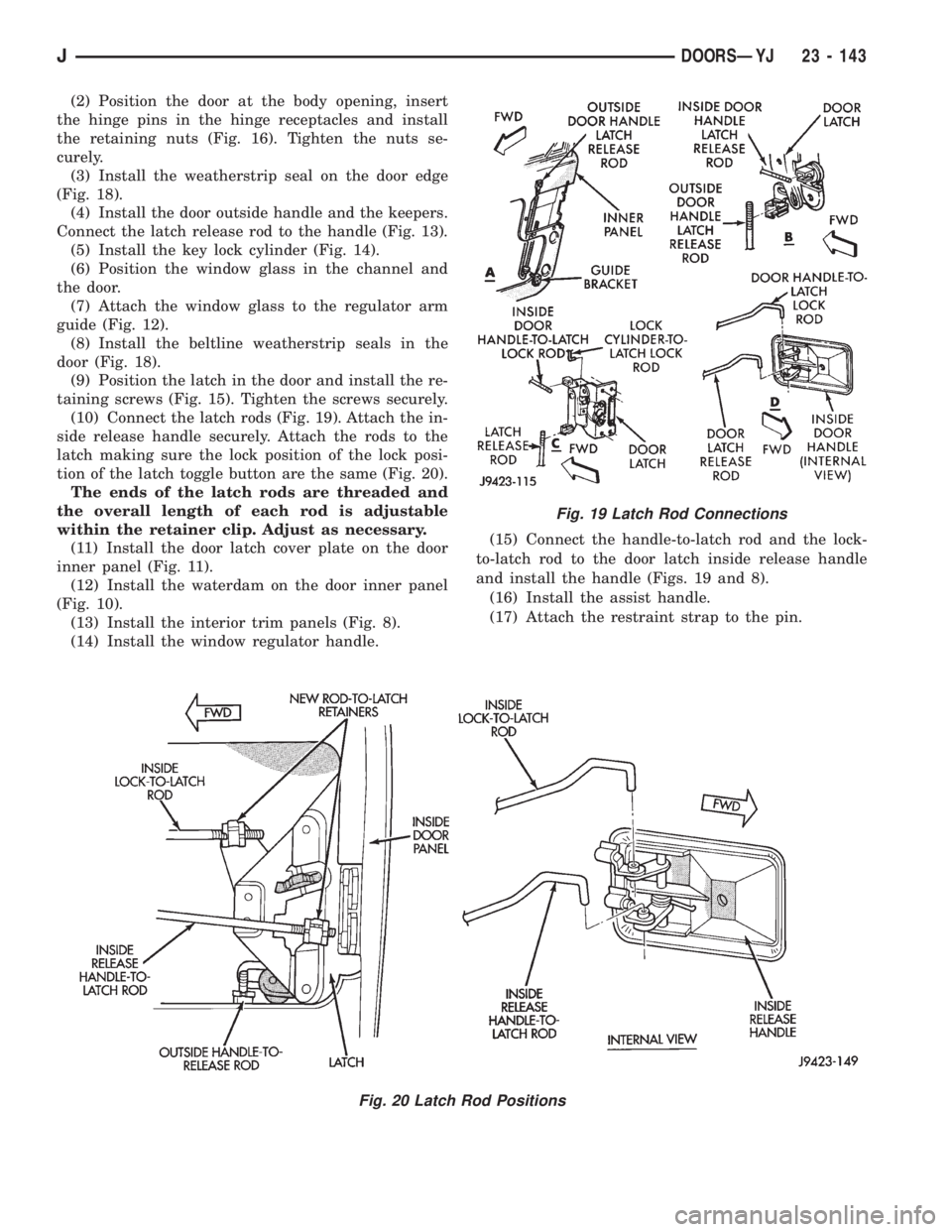

(2) Position the door at the body opening, insert

the hinge pins in the hinge receptacles and install

the retaining nuts (Fig. 16). Tighten the nuts se-

curely.

(3) Install the weatherstrip seal on the door edge

(Fig. 18).

(4) Install the door outside handle and the keepers.

Connect the latch release rod to the handle (Fig. 13).

(5) Install the key lock cylinder (Fig. 14).

(6) Position the window glass in the channel and

the door.

(7) Attach the window glass to the regulator arm

guide (Fig. 12).

(8) Install the beltline weatherstrip seals in the

door (Fig. 18).

(9) Position the latch in the door and install the re-

taining screws (Fig. 15). Tighten the screws securely.

(10) Connect the latch rods (Fig. 19). Attach the in-

side release handle securely. Attach the rods to the

latch making sure the lock position of the lock posi-

tion of the latch toggle button are the same (Fig. 20).

The ends of the latch rods are threaded and

the overall length of each rod is adjustable

within the retainer clip. Adjust as necessary.

(11) Install the door latch cover plate on the door

inner panel (Fig. 11).

(12) Install the waterdam on the door inner panel

(Fig. 10).

(13) Install the interior trim panels (Fig. 8).

(14) Install the window regulator handle.(15) Connect the handle-to-latch rod and the lock-

to-latch rod to the door latch inside release handle

and install the handle (Figs. 19 and 8).

(16) Install the assist handle.

(17) Attach the restraint strap to the pin.

Fig. 19 Latch Rod Connections

Fig. 20 Latch Rod Positions

JDOORSÐYJ 23 - 143