wiring diagram JEEP XJ 1995 Service And Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1450 of 2158

EXTENDED IDLE SWITCH TEST

OPTIONAL POLICE PACKAGE ONLY

OPERATION

The extended idle switch is used to raise the en-

gine idle speed to approximately 1000 rpm when the

shifter is in either the Park or Neutral position. A

rocker-type 2-wire switch (extended idle switch) is

mounted to the instrument panel.This switch is

available only with 4.0L engine when supplied

with the optional police package.

TESTING

The extended idle switch will control a ground cir-

cuit going to the powertrain control module (PCM).

When a ground signal (through this switch) has been

received at pin number 10 in the PCM, engine idle

speed will increase.

Bring the engine to normal operating temperature

and turn the extended idle switch to the ON position.

Engine speed should now increase to approximately

1000 rpm when the shifter is in either the Park or

Neutral position. If engine speed does not increase,

apply a good ground to pin number 10 at the PCM

using a small paper clip. Be careful not to damage

the wiring with the paper clip. If the engine speed

now increases, it can be assumed that the PCM is

functioning correctly. Check the instrument panel

mounted switch for a closed ground circuit when in

the ON position. If the engine speed will not increase

after applying a ground to pin number 10, replace

the PCM. Refer to Group 8W, Wiring Diagrams for

circuit and wiring information.

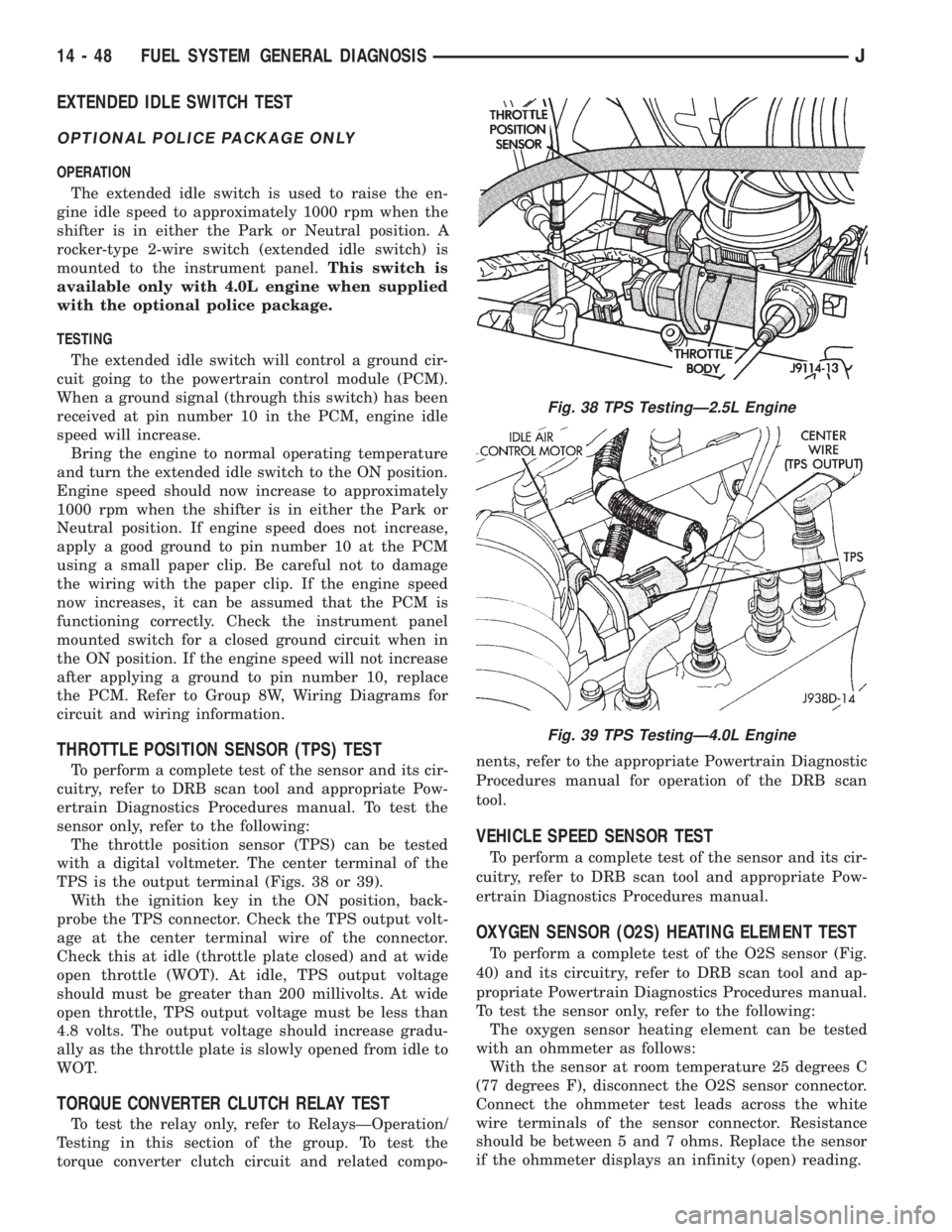

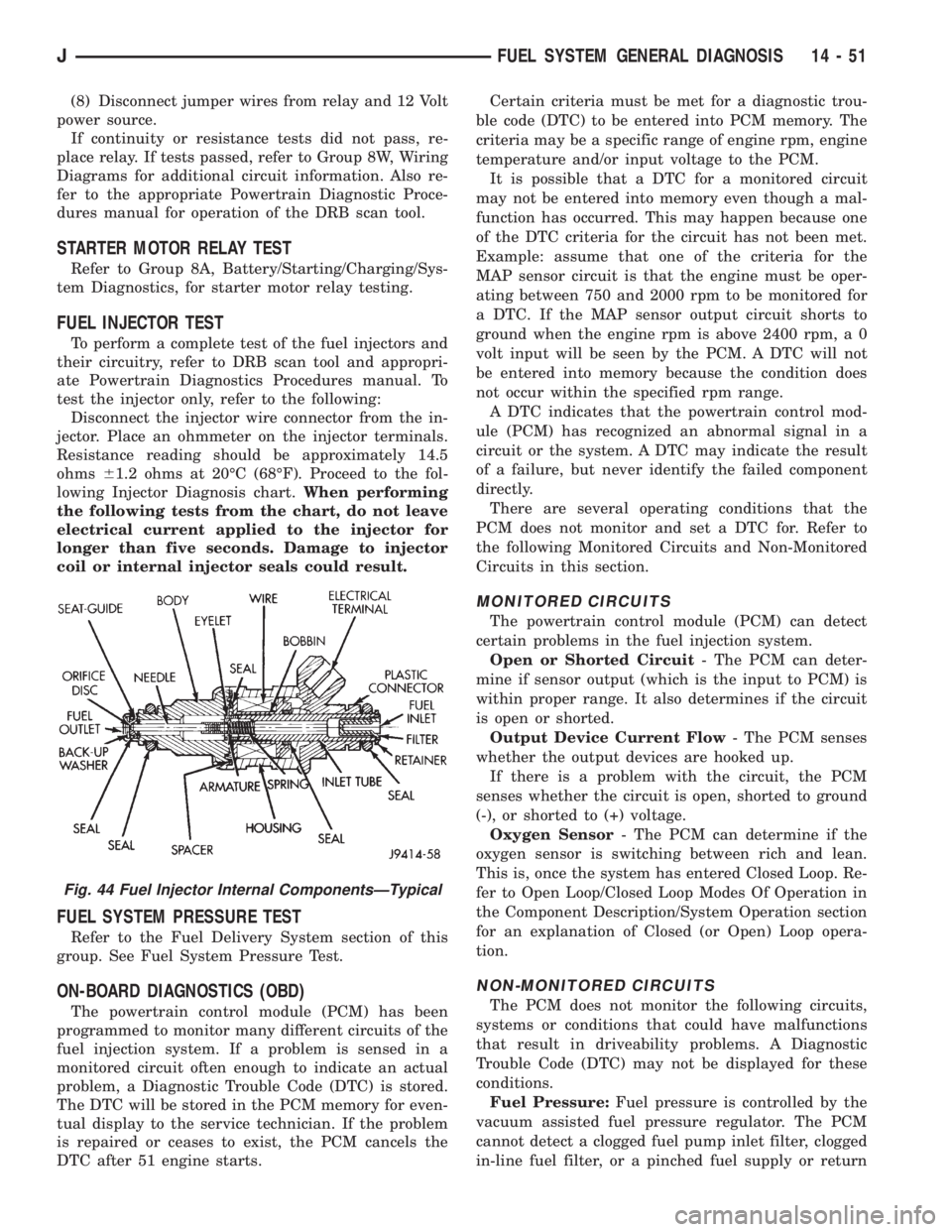

THROTTLE POSITION SENSOR (TPS) TEST

To perform a complete test of the sensor and its cir-

cuitry, refer to DRB scan tool and appropriate Pow-

ertrain Diagnostics Procedures manual. To test the

sensor only, refer to the following:

The throttle position sensor (TPS) can be tested

with a digital voltmeter. The center terminal of the

TPS is the output terminal (Figs. 38 or 39).

With the ignition key in the ON position, back-

probe the TPS connector. Check the TPS output volt-

age at the center terminal wire of the connector.

Check this at idle (throttle plate closed) and at wide

open throttle (WOT). At idle, TPS output voltage

should must be greater than 200 millivolts. At wide

open throttle, TPS output voltage must be less than

4.8 volts. The output voltage should increase gradu-

ally as the throttle plate is slowly opened from idle to

WOT.

TORQUE CONVERTER CLUTCH RELAY TEST

To test the relay only, refer to RelaysÐOperation/

Testing in this section of the group. To test the

torque converter clutch circuit and related compo-nents, refer to the appropriate Powertrain Diagnostic

Procedures manual for operation of the DRB scan

tool.

VEHICLE SPEED SENSOR TEST

To perform a complete test of the sensor and its cir-

cuitry, refer to DRB scan tool and appropriate Pow-

ertrain Diagnostics Procedures manual.

OXYGEN SENSOR (O2S) HEATING ELEMENT TEST

To perform a complete test of the O2S sensor (Fig.

40) and its circuitry, refer to DRB scan tool and ap-

propriate Powertrain Diagnostics Procedures manual.

To test the sensor only, refer to the following:

The oxygen sensor heating element can be tested

with an ohmmeter as follows:

With the sensor at room temperature 25 degrees C

(77 degrees F), disconnect the O2S sensor connector.

Connect the ohmmeter test leads across the white

wire terminals of the sensor connector. Resistance

should be between 5 and 7 ohms. Replace the sensor

if the ohmmeter displays an infinity (open) reading.

Fig. 38 TPS TestingÐ2.5L Engine

Fig. 39 TPS TestingÐ4.0L Engine

14 - 48 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1453 of 2158

(8) Disconnect jumper wires from relay and 12 Volt

power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wiring

Diagrams for additional circuit information. Also re-

fer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

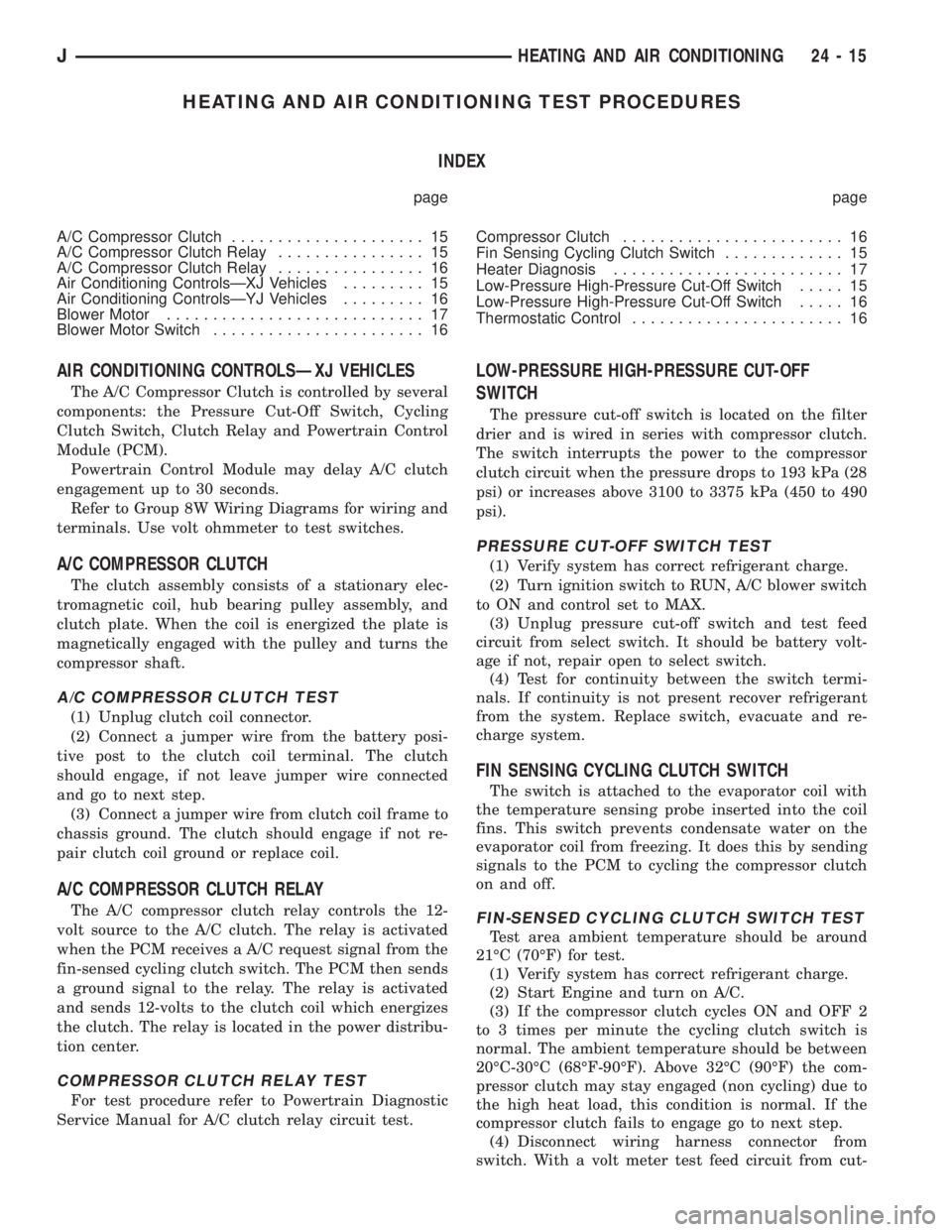

FUEL INJECTOR TEST

To perform a complete test of the fuel injectors and

their circuitry, refer to DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the injector only, refer to the following:

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to the fol-

lowing Injector Diagnosis chart.When performing

the following tests from the chart, do not leave

electrical current applied to the injector for

longer than five seconds. Damage to injector

coil or internal injector seals could result.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The powertrain control module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for even-

tual display to the service technician. If the problem

is repaired or ceases to exist, the PCM cancels the

DTC after 51 engine starts.Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, engine

temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.

There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure:Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

Fig. 44 Fuel Injector Internal ComponentsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 51

Page 2095 of 2158

HEATING AND AIR CONDITIONING TEST PROCEDURES

INDEX

page page

A/C Compressor Clutch..................... 15

A/C Compressor Clutch Relay................ 15

A/C Compressor Clutch Relay................ 16

Air Conditioning ControlsÐXJ Vehicles......... 15

Air Conditioning ControlsÐYJ Vehicles......... 16

Blower Motor............................ 17

Blower Motor Switch....................... 16Compressor Clutch........................ 16

Fin Sensing Cycling Clutch Switch............. 15

Heater Diagnosis......................... 17

Low-Pressure High-Pressure Cut-Off Switch..... 15

Low-Pressure High-Pressure Cut-Off Switch..... 16

Thermostatic Control....................... 16

AIR CONDITIONING CONTROLSÐXJ VEHICLES

The A/C Compressor Clutch is controlled by several

components: the Pressure Cut-Off Switch, Cycling

Clutch Switch, Clutch Relay and Powertrain Control

Module (PCM).

Powertrain Control Module may delay A/C clutch

engagement up to 30 seconds.

Refer to Group 8W Wiring Diagrams for wiring and

terminals. Use volt ohmmeter to test switches.

A/C COMPRESSOR CLUTCH

The clutch assembly consists of a stationary elec-

tromagnetic coil, hub bearing pulley assembly, and

clutch plate. When the coil is energized the plate is

magnetically engaged with the pulley and turns the

compressor shaft.

A/C COMPRESSOR CLUTCH TEST

(1) Unplug clutch coil connector.

(2) Connect a jumper wire from the battery posi-

tive post to the clutch coil terminal. The clutch

should engage, if not leave jumper wire connected

and go to next step.

(3) Connect a jumper wire from clutch coil frame to

chassis ground. The clutch should engage if not re-

pair clutch coil ground or replace coil.

A/C COMPRESSOR CLUTCH RELAY

The A/C compressor clutch relay controls the 12-

volt source to the A/C clutch. The relay is activated

when the PCM receives a A/C request signal from the

fin-sensed cycling clutch switch. The PCM then sends

a ground signal to the relay. The relay is activated

and sends 12-volts to the clutch coil which energizes

the clutch. The relay is located in the power distribu-

tion center.

COMPRESSOR CLUTCH RELAY TEST

For test procedure refer to Powertrain Diagnostic

Service Manual for A/C clutch relay circuit test.

LOW-PRESSURE HIGH-PRESSURE CUT-OFF

SWITCH

The pressure cut-off switch is located on the filter

drier and is wired in series with compressor clutch.

The switch interrupts the power to the compressor

clutch circuit when the pressure drops to 193 kPa (28

psi) or increases above 3100 to 3375 kPa (450 to 490

psi).

PRESSURE CUT-OFF SWITCH TEST

(1) Verify system has correct refrigerant charge.

(2) Turn ignition switch to RUN, A/C blower switch

to ON and control set to MAX.

(3) Unplug pressure cut-off switch and test feed

circuit from select switch. It should be battery volt-

age if not, repair open to select switch.

(4) Test for continuity between the switch termi-

nals. If continuity is not present recover refrigerant

from the system. Replace switch, evacuate and re-

charge system.

FIN SENSING CYCLING CLUTCH SWITCH

The switch is attached to the evaporator coil with

the temperature sensing probe inserted into the coil

fins. This switch prevents condensate water on the

evaporator coil from freezing. It does this by sending

signals to the PCM to cycling the compressor clutch

on and off.

FIN-SENSED CYCLING CLUTCH SWITCH TEST

Test area ambient temperature should be around

21ÉC (70ÉF) for test.

(1) Verify system has correct refrigerant charge.

(2) Start Engine and turn on A/C.

(3) If the compressor clutch cycles ON and OFF 2

to 3 times per minute the cycling clutch switch is

normal. The ambient temperature should be between

20ÉC-30ÉC (68ÉF-90ÉF). Above 32ÉC (90ÉF) the com-

pressor clutch may stay engaged (non cycling) due to

the high heat load, this condition is normal. If the

compressor clutch fails to engage go to next step.

(4) Disconnect wiring harness connector from

switch. With a volt meter test feed circuit from cut-

JHEATING AND AIR CONDITIONING 24 - 15

Page 2096 of 2158

off switch for battery voltage. If no voltage is present

test pressure cut-off switch. If voltage is present go

to next step.

(5) With ohmmeter test harness connector ground

circuit for continuity to ground. If circuit is open, (no

continuity) repair ground circuit. If circuit test OK

and clutch does not engage refer to Powertrain Diag-

nostic Service Manual for A/C clutch circuit test.

AIR CONDITIONING CONTROLSÐYJ VEHICLES

The air conditioning circuit consists of 3 segments;

battery supply, blower motor and compressor clutch.

The 3 segments have a common connection point at

the blower switch.

The power supply circuit extends from the HTR/

FAN fuse to the blower switch. From the blower

switch, battery feed is routed to the blower motor

and compressor clutch circuit.

Refer to Group 8W Wiring Diagrams for wiring

schematic and terminals. Use volt ohmmeter to test

switches.

COMPRESSOR CLUTCH

The clutch assembly consists of a stationary elec-

tromagnetic coil, hub bearing pulley assembly, and

clutch plate. When the coil is energized the plate is

magnetically engaged with the pulley and turns the

compressor shaft.

COMPRESSOR CLUTCH TEST

(1) Unplug clutch coil connector.

(2) Connect jumper wire from battery positive post

to clutch coil connector. The clutch should engage, if

not leave jumper wire connected and go to next step.

(3) Connect jumper wire from clutch coil frame to

chassis ground. The clutch should engage, if not re-

pair clutch coil ground or replace coil.

A/C COMPRESSOR CLUTCH RELAY

The A/C compressor clutch relay controls the 12-

volt source to the A/C clutch. The relay is activated

when the PCM receives a A/C request signal. The

PCM then sends a ground signal to the relay. The re-

lay is activated and sends 12-volts to the clutch coil

which energizes the clutch. The relay is located in

the power distribution center.

COMPRESSOR CLUTCH RELAY TEST

For test procedure refer to Powertrain Diagnostic

Service Manual for A/C clutch relay circuit test.

LOW-PRESSURE HIGH-PRESSURE CUT-OFF

SWITCH

The pressure cut-off switch is located on the filter

drier and is wired in series with compressor clutch.

The switch interrupts the power to the compressorclutch circuit when the pressure drops to 193 kPa (28

psi) or increases above 3100 to 3375 kPa (450 to 490

psi).

PRESSURE CUT-OFF SWITCH TEST

(1) Turn ignition switch to RUN, A/C blower switch

to ON and control set to MAX.

(2) Unplug pressure cut-off switch connector and

test feed circuit from the thermostatic, should be bat-

tery voltage. If not, proceed to thermostatic control

tests.

(3) Test for continuity between the switch termi-

nals. If continuity is not present recover refrigerant

system, replace switch, evacuate and recharge sys-

tem.

THERMOSTATIC CONTROL

Cycling of the compressor and therefore the tem-

perature of the outlet air is regulated by the thermo-

static control. A thermal sensor extends from the

control to the evaporator housing. When the temper-

ature of the evaporator drops below the set tempera-

ture, the thermostatic control opens the clutch

circuit. The circuit remains open until evaporator

temperature rises above the set temperature.

THERMOSTATIC CONTROL TEST

(1) Turn ignition switch to RUN, A/C blower switch

to ON and thermostatic control set to MAX cool.

(2) Test thermostatic control feed terminal from

blower switch, should be battery voltage. If not re-

pair open from blower switch.

(3) Test thermostatic control output terminal to

pressure cut-out switch, should be battery voltage. If

not, replace thermostatic control.

BLOWER MOTOR SWITCH

The blower switch controls blower motor speed.

The blower motor segment consists of the 3 wires

from the blower switch to the motor. Through the

switch, the 3 wires connect the motor brushes to bat-

tery supply. When connected to battery feed, the sep-

arate brushes provide the 3 blower speeds LO, MED,

and HIGH.

BLOWER MOTOR SWITCH TEST

(1) Turn ignition to RUN position.

(2) Test battery side of fuse for battery voltage. If

not, repair open from ignition switch.

(3) Test A/C blower switch feed circuit from fuse

box should be battery voltage. If not, repair open

from fuse panel.

(4) Test A/C blower switch LO terminal with

blower switch in LO, should be battery voltage. If

not, replace switch.

(5) Test A/C blower switch MED terminal with

blower switch in MED, should be battery voltage. If

not, replace switch.

24 - 16 HEATING AND AIR CONDITIONINGJ

Page 2097 of 2158

(6) Test A/C blower switch HIGH terminal with

blower switch in HIGH, should be battery voltage. If

not, replace switch.

BLOWER MOTOR

The A/C blower motor is attached to the evaporator

housing mounted under the instrument panel. The

motor has a ground wire and 3 wires connect to the

motor brushes. When voltage is applied to the sepa-

rate brushes it provides the 3 blower speeds LO,

MED, and HIGH.

BLOWER MOTOR TEST

Turn ignition switch to RUN for voltage tests and

turn ignition switch to OFF for resistance test.

(1) Test A/C blower motor ground terminal should

be 0 ohms. If not, repair ground circuit.

(2) Test A/C blower motor connector LO terminal

with blower switch in LO, should be battery voltage.

If not repair open from blower switch. If the blower

motor is still inoperative replace motor.

(3) Test A/C blower motor connector MED terminal

with blower switch in MED, should be battery volt-

age. If not repair open from blower switch. If the

blower motor is still inoperative replace motor.

(4) Test A/C blower motor connector HIGH termi-

nal with blower switch in HIGH, should be battery

voltage. If not, repair open from blower switch. If the

blower motor is still inoperative, replace motor.

HEATER DIAGNOSIS

On LHD XJ vehicles a water valve controls coolant

flow to the heater core. The valve is vacuum oper-

ated. When vacuum is applied, the valve opens and

coolant is directed through the heater core and back

to the engine. When the water valve is closed (no

vacuum applied) coolant flow bypasses the heater

core back to the engine.

The heating system receives its battery feed from

the fuse box. On YJ vehicles the feed circuit runs to

the HEATER/OFF switch and then to the BLOWER

switch. On XJ vehicles the feed circuit runs to the

HEAT/MODE switch and then to the BLOWER

switch.

The blower speed is controlled by the blower switch

and blower resistors. With the switch in LO, battery

voltage is supplied to the motor through all of the re-

sistors. The motor runs slowly. When the blower

switch is moved to a higher speed, battery voltage in-

creases to the blower motor which increase its speed.

This is accomplished by bypassing some of the blower

resistors. When the switch is in HI, blower resistors

are bypassed and battery voltage is applied directly

to the blower motor.

The following chart has been developed for quick

reference.

Refer to the Group 8W Wiring Diagrams for com-

plete wiring schematic.

JHEATING AND AIR CONDITIONING 24 - 17

Page 2128 of 2158

BUMPERÐXJ, LIFTGATE LICENSE PLATE

SCREW ANCHOR.....................23-65

BUMPERÐXJ, REAR SEATBACK LATCH

STRIKER...........................23-84

BUMPERS......................13-16,13-5

BUS, CCD; FUEL/IGNITION (XJ).......8W-30-5

BUSHING AND PISTON CLEARANCE,

AW-4 .............................21-339

BUSHING REPLACEMENT, AXLE......2-12,2-34

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-17

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-5,3-7

BUSHINGS, CLUTCH AND BRAKE PEDAL . . . 0-22

BUZZER, COMBINATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

BUZZER MODULE.................8U-1,8U-2

BUZZER MODULE SCHEMATIC - YJ.......8U-4

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-17,14-58

CABLE ADJUSTMENT, PARK INTERLOCK . 21-195

CABLE ADJUSTMENT, SHIFT...........21-195

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE.........................21-194

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-71

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK........................21-101

CABLE ADJUSTMENT (XJ), SHIFT.......21-100

CABLE ADJUSTMENT (XJ/YJ), THROTTLE

VALVE..............................21-101

CABLE REMOVE/INSTALL, SERVO.......8H-10

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-193

CABLE REPLACEMENT (XJ), PARKING

BRAKE REAR.........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-68

CABLE REPLACEMENTÐXJ, LATCH

RELEASE...........................23-11

CABLE RESISTANCE, SPARK PLUG......8D-14

CABLE, SERVO.......................8H-1

CABLE, SPEEDOMETER.................0-33

CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING BRAKE...............5-69

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-66

CABLE, THROTTLE...................14-17

CABLE/LINKAGE ADJUSTMENT,

GEARSHIFT.........................21-71

CABLES, DISTRIBUTOR CAP AND

ROTOR, IGNITION.....................0-20

CABLES, SPARK PLUG SECONDARY.....8D-14,

8D-24

CABLES, VENT DOOR CONTROL.........24-32

CALIBRATION, COMPASS...............8C-5

CALIPER ASSEMBLY...................5-50

CALIPER CLEANING AND INSPECTION.....5-50

CALIPER DISASSEMBLY................5-48

CALIPER INSTALLATION................5-51

CALIPER OPERATION AND WEAR

COMPENSATION......................5-45

CALIPER REMOVAL....................5-48

CAMSHAFT......................9-32,9-74

CAMSHAFT PIN REPLACEMENT......9-34,9-75

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-2

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-46

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS

...................8D-6

CAMSHAFT POSITION SENSORÐPCM

INPUT

.............................14-22

(CANADA ONLY)ÐXJ, DAYTIME

RUNNING LIGHTS

....................8L-15

(CANADA ONLY)ÐYJ, DAYTIME

RUNNING LIGHTS

....................8L-30

CANISTER, EVAP

..................25-4,25-7CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-20

CAP, DISTRIBUTOR....................8D-7

CAP, FUEL TANK FILLER TUBE;

EMISSION CONTROL SYSTEMS......25-4,25-7

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-13

CAP, RADIATOR PRESSURE.............7-25

CAPACITIES, COOLING SYSTEM..........7-45

CAPACITIES, FLUID.....................0-3

CAPACITIES, FUEL TANK..........14-13,14-67

CAPACITY TEST, FUEL PUMP............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN.........................19-23

CARDAN (CV), DOUBLE................16-11

CARDAN, SINGLE....................16-10

CARGO BARRIERÐXJ................23-101

CARGO LAMP AND DOME LAMP;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

CARGO LAMP, COURTESY LAMPS AND

DOME LAMP; INTERIOR LIGHTING (XJ) . 8W-44-1

CARGO LAMPÐXJ...................23-94

CARPET/MATÐXJ, FRONT.............23-99

CARPET/MATÐXJ, REAR.............23-100

CARPETÐYJ.......................23-156

CARPETS AND FLOOR MATSÐXJ.......23-99

CARRIERÐYJ, EXTERNAL SPARE/

WHEEL TIRE.......................23-133

CASE (4WD VEHICLES), TRANSFER........0-24

CASE ASSEMBLY, TRANSFER....21-294,21-319

CASE CHANGES, TRANSFER...........21-307

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-125

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-30,9-73

CASE COVER, TIMING..............9-31,9-72

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-289,21-310

CASE IDENTIFICATION, TRANSFER.....21-284,

21-307

CASE INSTALLATION, TRANSFER . 21-288,21-309

CASE LUBRICANT AND FILL LEVEL,

TRANSFER.........................21-284

CASE, NP231 TRANSFER.......21-283,21-305

CASE, NP242 TRANSFER.......21-307,21-331

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-247

CASE REMOVAL, TRANSFER.....21-287,21-309

CASE SKID PLATE, TRANSFER......13-15,13-3

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-333

CATALYTIC CONVERTER............11-1,11-4

CATALYTIC CONVERTOR................25-1

CAUTIONS, AND WARNINGS, NOTES;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

CCD BUS; FUEL/IGNITION (XJ)........8W-30-5

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-12

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-28

CERTIFICATION LABEL, VEHICLE SAFETY . Intro.-4

CHAIN AND SPROCKETS, TIMING....9-31,9-73

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL

..........................0-16

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE

................2-23

CHANGE, LUBRICANT; REAR

SUSPENSION AND AXLES

...........3-13,3-31

CHANGE, REFILLING AFTER OVERHAUL

OR FLUID/FILTER

..............21-100,21-182

CHANGES AND PARTS

INTERCHANGEABILITY, TRANSMISSION

. . . 21-67

CHANGES, TRANSFER CASE

...........21-307

CHANNEL REPLACEMENTÐYJ, DOOR

FRAME GLASS

......................23-142

CHARGING, BATTERY

..................8A-7

CHARGING REFRIGERANT SYSTEM

......24-11

CHARGING SYSTEM; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS

.......................8A-17

CHARGING SYSTEM; CHARGING

SYSTEM (XJ)

.....................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (XJ-RHD)

.................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (YJ)

.....................8W-20-1CHARGING SYSTEM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-3

CHARGING SYSTEM SPECIFICATIONS....8A-23

CHARGING TIME TABLE, BATTERY........8A-8

CHART, MAIN BEARING FITTING......9-48,9-90

CHART, XJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHART, YJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP

RING.............................21-334

CHARTS, BRAKELINE..................5-12

CHARTS, DIAGNOSIS GUIDES...........21-77

CHARTS, GEARTRAIN OPERATION AND

APPLICATION.......................21-169

CHARTS, INSPECTION AND DIAGNOSIS.....6-4

CHASSIS AND BODY COMPONENTS.......0-28

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-28

CHECK VALVE TEST, POWER BOOSTER.....5-9

CHECKING FLUID LEVEL AND

CONDITION........................21-182

CHECKS, PRELIMINARY.................7-5

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ)....................8W-44-2

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ-RHD)................8W-44-2

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ)....................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ-RHD)................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (YJ)....................8W-51-1

(CHMSL)ÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-12

(CHMSL)ÐYJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-28

CIGAR LIGHTER; HORN/CIGAR LIGHTER . . . 8E-1

CIGAR LIGHTER; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

CIGAR LIGHTER; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

CIRCUIT IDENTIFICATION; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

CIRCUIT REMOVE/INSTALL, PRINTED....8E-19,

8E-40

CIRCUIT SENSEÐPCM INPUT, IGNITION . . 14-23

CIRCUIT VOLTAGE, OPEN...............8A-6

CLAMPS, FUEL TUBES/LINES/HOSES . 14-62,14-9

CLASSIFICATION OF LUBRICANTS.........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY...........................8A-23

CLEANER, AIR.......................14-29

CLEANER ELEMENT, AIR; EMISSION

CONTROL SYSTEMS...................25-7

CLEANER ELEMENT, AIR; FUEL SYSTEM . . 14-59

CLEANER ELEMENT, AIR; LUBRICATION

AND MAINTENANCE...................0-18

CLEANER HOUSING, AIR...............14-58

CLEANING AND INSPECTION, CALIPER....5-50

CLEANING AND INSPECTION, GEAR......19-42

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-125

CLEANING OF TIRES...................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE

................2-37

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES

...............3-20

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM

....................7-22

CLEARANCE AND RAMP ANGLE,

GROUND

............................0-11

CLEARANCE, AW-4 BUSHING AND

PISTON

...........................21-339

CLOCKSPRING

.......................19-51

CLUSTER AND GAUGE HOUSINGSÐYJ,

INSTRUMENT

......................23-151

CLUSTER ASSEMBLY REMOVE/INSTALL

. . 8E-17,

8E-35

CLUSTER BEZELÐXJ, INSTRUMENT

.....23-80

CLUSTER BEZELÐYJ, INSTRUMENT

....23-151

CLUSTER CONNECTORS (RHD)

.........8E-11

CLUSTER, GAUGE PACKAGE

.......8E-31,8E-43

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-3

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2129 of 2158

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-2

CLUSTER ILLUMINATION LAMPS . . 8E-16,8E-26,

8E-34,8E-4

CLUSTER, INSTRUMENT; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

CLUSTER, INSTRUMENT; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

CLUSTER, INSTRUMENT; INSTRUMENT

CLUSTER (YJ).....................8W-40-1

CLUSTER (LHD), HIGH-LINE GAUGE.......8E-9

CLUSTER (LHD), TELL-TALE............8E-10

CLUSTER, LOW-LINE GAUGE............8E-8

CLUSTER, MAIN.....................8E-30

CLUSTERS, INSTRUMENT..........8E-24,8E-1

CLUTCH, A/C COMPRESSOR............24-15

CLUTCH AND BRAKE PACK

REQUIREMENTS, AW-4...............21-341

CLUTCH AND BRAKE PEDAL BUSHINGS . . . 0-22

CLUTCH ASSEMBLY, COMPRESSOR......24-20

CLUTCH COMPONENT LUBRICATION......6-10

CLUTCH COMPONENTS..................6-1

CLUTCH, COMPRESSOR...............24-16

CLUTCH CONTAMINATION...............6-3

CLUTCH COVER AND DISC

INSTALLATION........................6-10

CLUTCH COVER AND DISC REMOVAL.....6-10

CLUTCH COVER AND DISC RUNOUT.......6-3

CLUTCH DIAGNOSIS.....................6-3

CLUTCH DISC AND PLATE THICKNESS,

AW-4 .............................21-338

CLUTCH FLUID LEVEL..................6-14

CLUTCH HOUSING MISALIGNMENT........6-4

CLUTCH HOUSING REPLACEMENT........6-13

CLUTCH HYDRAULIC LINKAGE

INSTALLATION........................6-14

CLUTCH HYDRAULIC LINKAGE REMOVAL . . 6-13

CLUTCH INSPECTION, TORQUE

CONVERTER STATOR................21-199

CLUTCH LINKAGE FLUID.................6-1

CLUTCH MASTER CYLINDER............0-22

CLUTCH MISALIGNMENT................6-3

CLUTCH OPERATION....................6-2

CLUTCH OVERHAUL, DIRECT..........21-228

CLUTCH OVERHAUL, OVERDRIVE

PLANETARY GEAR...................21-218

CLUTCH OVERHAUL, SUN GEAR AND

NO. 1 ONE-WAY....................21-238

CLUTCH PEDAL INSTALLATION..........6-15

CLUTCH PEDAL REMOVAL..............6-15

CLUTCH RELAY, A/C COMPRESSOR . 24-15,24-16

CLUTCH RELAY, AIR CONDITIONING

(A/C)..............................14-58

CLUTCH RELAY TEST, TORQUE

CONVERTER........................14-48

CLUTCH RELAY, TORQUE CONVERTER....14-65

CLUTCH RELAYÐPCM OUTPUT, AIR

CONDITIONING (A/C)..................14-26

CLUTCH RELAYÐPCM OUTPUT, TORQUE

CONVERTER........................14-29

CLUTCH SAFETY PRECAUTIONS..........6-10

CLUTCH SERVICE

.....................6-10

CLUTCH SWITCH, FIN SENSING

CYCLING

......................24-15,24-31

CLUTCH (TCC) SOLENOID AND RELAY,

TORQUE CONVERTER; FUEL/IGNITION

(XJ)

.............................8W-30-4

CLUTCH (TCC) SOLENOID AND RELAY,

TORQUE CONVERTER; TRANSMISSION

CONTROLS (YJ)

...................8W-31-1

CLUTCH (TCC) SOLENOID AND

RELAYÐ2.5L ENGINE ONLY, TORQUE

CONVERTER; TRANSMISSION

CONTROLS (XJ)

...................8W-31-1

CLUTCHÐLOW-REVERSE DRUMÐREAR

SUPPORT OVERHAUL, OVERRUNNING

. . . 21-125

CODE DECODING, VEHICLE

...........Intro.-5

CODE DESIGNATIONS, VEHICLE

........Intro.-1

CODE (DTC), DIAGNOSTIC TROUBLE

.....14-54

CODE, GENERATOR DIAGNOSTIC

TROUBLE

...........................8A-22

CODE IDENTIFICATION, WIRE; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)

...............................8W-1

CODE PLATE, VEHICLE

...............Intro.-4

CODE, SPEED CONTROL DIAGNOSTIC

TROUBLE

...........................8H-5CODES AND DIMENSIONS,

DESIGNATIONS, LABELS/PLATES.......Intro.-1

COIL, EVAPORATOR..................24-30

COIL, IGNITION; FUEL SYSTEM.........14-62

COIL, IGNITION; FUEL/IGNITION (XJ) . . . 8W-30-2

COIL, IGNITION; FUEL/IGNITION (YJ) . . . 8W-30-2

COIL, IGNITION; IGNITION SYSTEMS....8D-22,

8D-4,8D-9

COIL, IGNITION; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

COIL RESISTANCE, IGNITION............8D-9

COIL SPRING........................2-14

COILÐPCM OUTPUT, IGNITION.........14-28

COLD CRANKING SPECIFICATIONS, 2.5L

STARTING SYSTEM...................8A-23

COLD CRANKING SPECIFICATIONS, 4.0L

STARTING SYSTEM...................8A-23

COLUMN ASSEMBLY REPLACEMENT.....19-52

COLUMN COMPONENT SERVICE........19-54

COLUMN GENERAL SERVICEÐXJ,

STEERING..........................19-47

COLUMN, NON-TILT STEERING..........19-60

COLUMN REPLACEMENT..............19-58

COLUMN, TILT STEERING..............19-66

COLUMNÐXJ, STEERING..............19-78

COLUMNÐYJ, STEERING.........19-58,19-78

COMBINATION BUZZER; INTERIOR

LIGHTING (YJ)....................8W-44-1

COMBINATION FLASHER; TURN SIGNALS

(XJ).............................8W-52-1

COMBINATION VALVE..................5-34

COMBINATION VALVE INSTALLATION

(WITH ABS), MASTER CYLINDER.........5-20

COMBINATION VALVE REMOVAL (WITH

ABS), MASTER CYLINDER..............5-17

COMBINATION VALVE REPLACEMENT

(NON-ABS)..........................5-16

COMBUSTION PRESSURE LEAKAGE

TEST, CYLINDER.......................9-6

COMBUSTION PRESSURE LEAKAGE

TEST DIAGNOSIS, CYLINDER.............9-7

COMFORT SWITCH, TRANSMISSION;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

COMPASS...........................8C-1

COMPASS/DISPLAY SELF-DIAGNOSTIC

TEST...............................8C-2

COMPASS/THERMOMETER DIAGNOSIS....8C-4

COMPENSATION, CALIPER OPERATION

AND WEAR..........................5-45

COMPONENTSÐYJ, EVAPORATIVE

HOUSING............................24-6

COMPONENTSÐYJ, INSTRUMENT

PANEL............................23-152

COMPONENTSÐYJ VEHICLES, BODY....23-102

COMPRESSION PRESSURE TEST,

CYLINDER............................9-5

COMPRESSOR.......................24-19

COMPRESSOR, A/C; AIR CONDITIONING/

HEATER (YJ)......................8W-42-2

COMPRESSOR, AIR-CONDITIONER........0-21

COMPRESSOR CLUTCH...............24-16

COMPRESSOR CLUTCH, A/C............24-15

COMPRESSOR CLUTCH ASSEMBLY......24-20

COMPRESSOR CLUTCH RELAY, A/C . 24-15,24-16

COMPRESSOR SERVICE...............24-19

CONDENSER, A/C

....................24-34

CONDENSER FILTER DRIERÐ2.5L

ENGINES

...........................24-27

CONDENSERÐ4.0L ENGINES

...........24-28

CONDITION, CHECKING FLUID LEVEL

....21-182

CONDITIONING (A/C) CLUTCH RELAY,

AIR

...............................14-58

CONDITIONING (A/C) CLUTCH

RELAYÐPCM OUTPUT, AIR

............14-26

CONDITIONING (A/C) CONTROLSÐPCM

INPUT, AIR

.........................14-21

CONDITIONING, AIR

..................24-37

CONDITIONING CONTROLSÐXJ

VEHICLES, AIR

......................24-15

CONDITIONING CONTROLSÐYJ

VEHICLES, AIR

......................24-16

CONDITIONING, HEATER AND AIR; AIR

CONDITIONING/HEATER (YJ)

.........8W-42-2

CONDITIONING OPERATION, AIR; AIR

CONDITIONING/HEATER (XJ)

.........8W-42-2

CONDITIONING OPERATION, AIR; AIR

CONDITIONING/HEATER (XJ-RHD)

.....8W-42-2CONDITIONING PERFORMANCE TESTS,

AIR ...............................24-12

CONDITIONING SCHEMATICÐXJ, AIR.....24-5

CONDITIONING TEST PROCEDURES,

HEATING AND AIR....................24-15

CONDITIONS, NORMAL OPERATING........5-3

CONNECTING ROD BEARING FITTING

CHART..........................9-41,9-83

CONNECTING RODS, PISTONS.......9-39,9-81

CONNECTIONS, INTERMITTENT AND

POOR; WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-4

CONNECTIONS, RADIO ILLUMINATION

RELAY..............................8F-4

CONNECTIONS, STARTER RELAY........8A-15

CONNECTOR, ABS DIAGNOSTIC.......5-35,5-3

CONNECTOR AND TERMINAL

REPLACEMENT; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-7

CONNECTOR, DATA LINK; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

CONNECTOR, DATA LINK; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

CONNECTOR, DATA LINK; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

CONNECTOR, DATA LINK; FUEL/IGNITION

(XJ).............................8W-30-5

CONNECTOR, DATA LINK; FUEL/IGNITION

(YJ).............................8W-30-5

CONNECTOR, DATA LINK;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

CONNECTOR, DATA LINK; FUEL/IGNITION

(XJ-RHD)..........................8W-30-4

CONNECTOR LOCATIONS; CONNECTOR

LOCATIONS (XJ)...................8W-90-1

CONNECTOR LOCATIONS; CONNECTOR

LOCATIONS (XJ-RHD)...............8W-90-1

CONNECTOR LOCATIONS; CONNECTOR

LOCATIONS (YJ)...................8W-90-1

CONNECTOR LOCATIONS; CONNECTOR

PIN OUTS (XJ)....................8W-80-1

CONNECTOR LOCATIONS; CONNECTOR

PIN OUTS (XJ-RHD)................8W-80-1

CONNECTOR LOCATIONS; CONNECTOR

PIN OUTS (YJ)....................8W-80-1

CONNECTOR LOCATIONS; WIRING

DIAGRAMS (XJ)......................8W-1

CONNECTOR LOCATIONS; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

CONNECTOR LOCATIONS; WIRING

DIAGRAMS (YJ)......................8W-1

CONNECTOR, POWERTRAIN CONTROL

MODULE (PCM) 60-WAY...............14-40

CONNECTOR REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-6

CONNECTORÐPCM INPUT, DATA LINK . . . 14-22

CONNECTORÐPCM OUTPUT, DATA LINK . . 14-27

CONNECTORS; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-2

CONNECTORS (RHD), CLUSTER.........8E-11

CONNECTORS, TERMINAL/CONNECTOR

REPAIRÐMOLEX; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-6

CONSOLE, OVERHEAD; OVERHEAD

CONSOLE (XJ)....................8W-49-1

CONSOLE, OVERHEAD; OVERHEAD

CONSOLE (XJ-RHD)................8W-49-1

CONSOLE REMOVE/INSTALL, OVERHEAD . . . 8C-6

CONSOLE SHIFT, DISASSEMBLYÐ

COLUMN OR........................19-60

CONSOLEÐXJ, FULL FLOOR...........23-95

CONSOLEÐXJ, MINI-FLOOR............23-94

CONSOLEÐXJ, OVERHEAD; BODY

COMPONENTSÐXJ VEHICLES..........23-93

CONSOLEÐXJ, OVERHEAD; LAMPS......8L-17

CONSOLESÐYJ, FLOOR..............23-155

CONTACT PATTERN ANALYSIS,

BACKLASH; FRONT SUSPENSION AND

AXLE...............................2-45

CONTACT PATTERN ANALYSIS,

BACKLASH; REAR SUSPENSION AND

AXLES

..............................3-27

CONTACT/CLOCKSPRING, HORN

.........8G-4

CONTAMINATED BRAKELINING

............5-7

CONTAMINATION, BRAKE FLUID

.......5-10,5-7

CONTAMINATION, CLUTCH

...............6-3

JINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2131 of 2158

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST DIAGNOSIS..............9-7

CYLINDER COMPRESSION PRESSURE

TEST................................9-5

CYLINDER DISPOSALÐXJ, LIFTGATE

SUPPORT ROD......................23-63

CYLINDER ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4...................25-3

CYLINDER ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6...................25-3

CYLINDER HEAD COVER, ENGINE....9-22,9-64

CYLINDER HEAD, ENGINE...........9-25,9-67

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS, ENGINE....................9-5

CYLINDER INSTALLATION (NON-ABS),

MASTER............................5-16

CYLINDER INSTALLATION, WHEEL........5-58

CYLINDER OVERHAUL (4-CYLINDER

MODELS), MASTER....................5-16

CYLINDER OVERHAUL, WHEEL...........5-57

CYLINDER REMOVAL (NON-ABS),

MASTER............................5-15

CYLINDER REMOVAL, WHEEL...........5-57

CYLINDER SERVICE, IGNITION SWITCH

AND KEY...........................8D-26

CYLINDERÐCOMBINATION VALVE,

MASTER............................5-15

CYLINDERÐXJ, DOOR KEY LOCK.......23-47

CYLINDERÐXJ, LIFTGATE SUPPORT

ROD...............................23-62

CYLINDERÐYJ, FULL-METAL DOOR KEY

LOCK..............................23-139

CYLINDERÐYJ, TAILGATE LOCK.......23-122

CYLINDER/POWER BOOSTER TEST,

MASTER.............................5-8

CYLINDER/POWER BRAKE BOOSTER,

MASTER............................5-34

CYLINDER/STRIKERÐXJ, LIFTGATE

LATCH/KEY LOCK....................23-61

DAMAGED OR WORN THREADS, REPAIR....9-4

DAMPER, ENGINE.....................9-17

DAMPER, STEERING.............19-17,19-20

DAMPER, VIBRATION..............9-30,9-72

DASH PANEL INSULATOR PANELÐXJ....23-12

DATA LINK CONNECTOR; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

DATA LINK CONNECTOR; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

DATA LINK CONNECTOR; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

DATA LINK CONNECTOR; FUEL/IGNITION

(XJ).............................8W-30-5

DATA LINK CONNECTOR; FUEL/IGNITION

(YJ).............................8W-30-5

DATA LINK CONNECTOR;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

DATA LINK CONNECTOR; FUEL/IGNITION

(XJ-RHD).........................8W-30-4

DATA LINK CONNECTORÐPCM INPUT....14-22

DATA LINK CONNECTORÐPCM OUTPUT . . 14-27

DATA, VEHICLE DIMENSION.....Intro.-5,Intro.-6

DATA, VEHICLE LOAD................Intro.-5

DATAÐXJ, VEHICLE LOAD............Intro.-7

DATAÐYJ, VEHICLE LOAD............Intro.-8

DAYTIME RUNNING LAMP (DRL)

MODULE; FRONT LIGHTING (XJ)......8W-50-2

DAYTIME RUNNING LAMP (DRL)

MODULEÐCANADIAN VEHICLES ONLY;

FRONT LIGHTING (YJ)

..............8W-50-2

DAYTIME RUNNING LIGHTS (CANADA

ONLY)ÐXJ

.........................8L-15

DAYTIME RUNNING LIGHTS (CANADA

ONLY)ÐYJ

.........................8L-30

DECODING, VEHICLE CODE

...........Intro.-5

DECODING, VEHICLE IDENTIFICATION

NUMBER (VIN)

.....................Intro.-4

DEFLECTORÐXJ, COWL WEATHERSTRIP

SEAL/CROSSMEMBER AIR

.............23-11

DEFOGGER RELAY

....................8N-3

DEFOGGER RELAY/TIMER

...............8N-1

DEFOGGER RELAY/TIMER REMOVE/

INSTALL

............................8N-4

DEFOGGER SWITCH

...............8N-1,8N-3

DEFOGGER SWITCH REMOVE/INSTALL

....8N-4

DEFROSTER NOZZLE AND DUCT

........24-33

DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ, HEADLAMP

...........8L-14DELAY MODULE, HEADLAMP; FRONT

LIGHTING (XJ)....................8W-50-2

DELAY MODULE, HEADLAMP; FRONT

LIGHTING (XJ-RHD)................8W-50-1

DELAY MODULE REPLACEMENTÐXJ,

HEADLAMP.........................8L-14

DELAY MODULEÐXJ, SENTINEL

HEADLAMP.........................8L-14

DELIVERY SYSTEM, FUEL...............14-3

DEMAGNETIZING, COMPASS............8C-5

DEPTH INFORMATION, PINION GEAR;

FRONT SUSPENSION AND AXLE..........2-39

DEPTH INFORMATION, PINION GEAR;

REAR SUSPENSION AND AXLES..........3-21

DEPTH VARIANCE, PINION GEAR; FRONT

SUSPENSION AND AXLE................2-40

DEPTH VARIANCE, PINION GEAR; REAR

SUSPENSION AND AXLES...........3-22,3-39

DESCRIPTION; HEATING AND AIR

CONDITIONING............24-19,24-23,24-32

DESCRIPTION; TRANSMISSION AND

TRANSFER CASE....................21-165

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT FUEL INJECTION

(MFI)ÐCOMPONENT..................14-19

DESIGNATIONS, LABELS/PLATES, CODES

AND DIMENSIONS..................Intro.-1

DESIGNATIONS, VEHICLE.............Intro.-1

DESIGNATIONS, VEHICLE CODE........Intro.-1

DETECTION AND REPAIRÐXJ,

STATIONARY GLASS WATER LEAK.......23-76

DETECTION AND REPAIRÐYJ,

STATIONARY GLASS WATER LEAK.......23-150

DEVICES, ELECTROSTATIC DISCHARGE

(ESD) SENSITIVE; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

DIAGNOSING PARKING BRAKE

MALFUNCTIONS.......................5-8

DIAGNOSIS; AUDIO SYSTEMS...........8F-2

DIAGNOSIS; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS.....8A-10,

8A-11,8A-17,8A-3

DIAGNOSIS; CHIME/BUZZER WARNING

SYSTEMS...........................8U-2

DIAGNOSIS; COOLING SYSTEM...........7-4

DIAGNOSIS; HORNS...................8G-2

DIAGNOSIS; INSTRUMENT PANEL AND

GAUGESÐXJ....................8E-27,8E-5

DIAGNOSIS; OVERHEAD CONSOLE........8C-2

DIAGNOSIS; POWER LOCKS.............8P-2

DIAGNOSIS; POWER MIRRORS..........8T-1

DIAGNOSIS; POWER SEATS.............8R-2

DIAGNOSIS; POWER WINDOWS..........8S-1

DIAGNOSIS; REAR WINDOW DEFOGGER . . . 8N-1

DIAGNOSIS; RESTRAINT SYSTEMS.......8M-2

DIAGNOSIS; STEERING................19-37

DIAGNOSIS; TURN SIGNAL AND HAZARD

WARNING SYSTEMS...................8J-3

DIAGNOSIS; VEHICLE SPEED CONTROL

SYSTEM............................8H-2

DIAGNOSIS, 2.5L STARTER NOISE.......8A-16

DIAGNOSIS, 30RH/32RH TRANSMISSION . 21-70

DIAGNOSIS, ABS BRAKE.................5-3

DIAGNOSIS, ANTILOCK ECU AND HCU......5-3

DIAGNOSIS, AW-4 TRANSMISSION.....21-176

DIAGNOSIS, AXLE NOISE/VIBRATION;

FRONT SUSPENSION AND AXLE..........2-18

DIAGNOSIS, AXLE NOISE/VIBRATION;

REAR SUSPENSION AND AXLES..........3-9

DIAGNOSIS, BATTERY..................8A-4

DIAGNOSIS, BELT.....................7-38

DIAGNOSIS, CHARGING SYSTEM........8A-19

DIAGNOSIS, CLUTCH...................6-3

DIAGNOSIS, COMPASS/THERMOMETER....8C-4

DIAGNOSIS (CONT.), COOLING SYSTEM . . . 7-10,

7-11,7-12,7-7,7-8,7-9

DIAGNOSIS (CONT.), SERPENTINE DRIVE

BELT ...............................7-40

DIAGNOSIS (CONT'D), DISCONNECT

AXLE/SHIFT MOTOR

...................2-30

DIAGNOSIS (CONT'D), SERVICE; FRONT

SUSPENSION AND AXLE

................2-21

DIAGNOSIS (CONT'D), SERVICE; REAR

SUSPENSION AND AXLES

...............3-12

DIAGNOSIS, CONVERTER HOUSING

LEAK

..............................21-75

DIAGNOSIS, COOLING SYSTEM

...........7-6DIAGNOSIS, CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST...............9-7

DIAGNOSIS, DISCONNECT AXLE/SHIFT

MOTOR.............................2-29

DIAGNOSIS, ENGINE....................9-5

DIAGNOSIS, ENGINE CYLINDER HEAD

GASKET FAILURE......................9-5

DIAGNOSIS, EXHAUST SYSTEM..........11-2

DIAGNOSIS, FOG LAMP...........8L-21,8L-3

DIAGNOSIS, GEAR LEAKAGE............19-10

DIAGNOSIS, HEADLAMP...........8L-20,8L-2

DIAGNOSIS, HEATER..................24-17

DIAGNOSIS, HEATING SYSTEM..........24-18

DIAGNOSIS, IGNITION SECONDARY

CIRCUIT...........................8D-10

DIAGNOSIS INFORMATION, GENERAL;

CLUTCH..............................6-3

DIAGNOSIS INFORMATION, GENERAL;

TRANSMISSION AND TRANSFER CASE . . 21-176

DIAGNOSIS, INTAKE MANIFOLD

LEAKAGE.............................9-5

DIAGNOSIS, MANUAL STEERING

SYSTEM............................19-38

DIAGNOSIS, MULTI-PORT FUEL

INJECTION (MFI)ÐGENERAL...........14-35

DIAGNOSIS, NP231 SERVICE..........21-285

DIAGNOSIS, NP242 SERVICE..........21-308

DIAGNOSIS, PERFORMANCE............24-14

DIAGNOSIS, POWER STEERING SYSTEM . . 19-3,

19-4,19-5,19-6,19-7,19-8,19-9

DIAGNOSIS, PUMP LEAKAGE...........19-10

DIAGNOSIS, RADIO....................8F-3

DIAGNOSIS, SERPENTINE DRIVE BELT.....7-39

DIAGNOSIS, SERVICE; FRONT

SUSPENSION AND AXLE................2-20

DIAGNOSIS, SERVICE; PROPELLER

SHAFTS.............................16-3

DIAGNOSIS, SERVICE; REAR

SUSPENSION AND AXLES...............3-11

DIAGNOSIS, SERVICE; TRANSMISSION

AND TRANSFER CASE . 21-180,21-181,21-34,21-2

DIAGNOSIS, SERVICE BRAKE.............5-4

DIAGNOSIS, SPRING AND SHOCK;

FRONT SUSPENSION AND AXLE......2-13,2-15

DIAGNOSIS, SPRING AND SHOCK; REAR

SUSPENSION AND AXLES.............3-3,3-6

DIAGNOSIS, SPRING AND SHOCK

ABSORBER........................3-3,3-6

DIAGNOSIS, STARTER NOISE...........8A-16

DIAGNOSIS, STARTING SYSTEM........8A-12

DIAGNOSIS, SUSPENSION AND

STEERING SYSTEM.....................2-7

DIAGNOSIS, THERMOMETER............8C-2

DIAGNOSIS, TORQUE CONVERTER . 21-86,21-87,

21-88

DIAGNOSIS, TRANSMISSION . 21-78,21-79,21-80,

21-81,21-82,21-83,21-84,21-85

DIAGNOSIS, VIBRATION..........22-10,22-11

DIAGNOSISÐLUBRICATION SERVICE......9-12

DIAGNOSISÐXJ, DOME/COURTESY

LAMP TROUBLE.....................8L-16

DIAGNOSISÐXJ, HEADLAMP DELAY

FUNCTION TROUBLE..................8L-14

DIAGNOSISÐXJ, LIGHTED VANITY

MIRROR TROUBLE...................8L-16

DIAGNOSISÐYJ, DOME/COURTESY

LAMP TROUBLE.....................8L-31

DIAGNOSTIC CONNECTOR, ABS.......5-35,5-3

DIAGNOSTIC PROCEDURESÐXJ.........8L-1

DIAGNOSTIC PROCEDURESÐYJ........8L-19

DIAGNOSTIC SYSTEM, USING

ON-BOARD; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS.....8A-22

DIAGNOSTIC SYSTEM, USING

ON-BOARD; VEHICLE SPEED CONTROL

SYSTEM............................8H-5

DIAGNOSTIC TROUBLE CODE (DTC)......14-54

DIAGNOSTIC TROUBLE CODE,

GENERATOR........................8A-22

DIAGNOSTIC TROUBLE CODE, SPEED

CONTROL

...........................8H-5

DIAGNOSTICS (OBD), ON-BOARD;

COOLING SYSTEM

.....................7-4

DIAGNOSTICS (OBD), ON-BOARD; FUEL

SYSTEM

............................14-51

DIAGNOSTICS, ON-BOARD

.............8D-15

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (XJ)

......................8W-42-2

JINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 2132 of 2158

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-2

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (YJ)...............8W-42-1,8W-42-2

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ).............................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ-RHD).........................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(YJ).............................8W-32-2

DIAGRAM INDEX; CHARGING SYSTEM

(XJ).............................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(XJ-RHD).........................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(YJ).............................8W-20-1

DIAGRAM INDEX; FRONT LIGHTING (XJ) . 8W-50-2

DIAGRAM INDEX; FRONT LIGHTING

(XJ-RHD).........................8W-50-3

DIAGRAM INDEX; FRONT LIGHTING (YJ) . 8W-50-2

DIAGRAM INDEX; FUEL/IGNITION (YJ) . . 8W-30-5

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ).............................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ-RHD).........................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(YJ).............................8W-10-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ)................8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (YJ)..................8W-15-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ).....................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ-RHD).................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (YJ).....................8W-48-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER . . . 8E-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ).............8W-40-1,8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (YJ).....................8W-40-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ).............................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(YJ).............................8W-44-2

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ).............................8W-49-1

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ-RHD).........................8W-49-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ).............................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ-RHD).........................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(YJ).............................8W-11-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ)

.............................8W-61-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ-RHD)

.........................8W-61-1

DIAGRAM INDEX; POWER MIRRORS

(XJ)

.............................8W-62-1

DIAGRAM INDEX; POWER MIRRORS

(XJ-RHD)

.........................8W-62-1

DIAGRAM INDEX; POWER SEAT (XJ)

. . . 8W-63-1

DIAGRAM INDEX; POWER SEAT

(XJ-RHD)

.........................8W-63-1

DIAGRAM INDEX; POWER WINDOWS

(XJ)

.............................8W-60-2

DIAGRAM INDEX; POWER WINDOWS

(XJ-RHD)

.........................8W-60-2

DIAGRAM INDEX; REAR LIGHTING (XJ)

. 8W-51-1

DIAGRAM INDEX; REAR LIGHTING

(XJ-RHD)

.........................8W-51-1

DIAGRAM INDEX; REAR LIGHTING (YJ)

. 8W-51-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ)

.............................8W-21-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ-RHD)

.........................8W-21-1DIAGRAM INDEX; STARTING SYSTEM

(YJ).............................8W-21-1

DIAGRAM INDEX; TRAILER TOW (XJ) . . 8W-54-1

DIAGRAM INDEX; TRAILER TOW

(XJ-RHD).........................8W-54-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ-RHD)...............8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (YJ)...................8W-31-1

DIAGRAM INDEX; TURN SIGNALS (XJ) . 8W-52-1

DIAGRAM INDEX; TURN SIGNALS

(XJ-RHD).........................8W-52-1

DIAGRAM INDEX; TURN SIGNALS (YJ) . 8W-52-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ)....................8W-33-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ-RHD)................8W-33-1

DIAGRAM INDEX; WIPERS (XJ).......8W-53-2

DIAGRAM INDEX; WIPERS (XJ-RHD) . . . 8W-53-2

DIAGRAM INDEX; WIPERS (YJ).......8W-53-2

DIAGRAM INDEX; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

DIAGRAM INDEXÐ2.5L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIAGRAM INDEXÐ4.0L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIFFERENTIAL AND PINION

MEASUREMENT.......................2-40

DIFFERENTIAL ASSEMBLY; FRONT

SUSPENSION AND AXLE.................2-38

DIFFERENTIAL ASSEMBLY; REAR

SUSPENSION AND AXLES...............3-21

DIFFERENTIAL DISASSEMBLY; FRONT

SUSPENSION AND AXLE................2-35

DIFFERENTIAL DISASSEMBLY; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL INSTALLATION............2-44

DIFFERENTIAL, LIMITED SLIP............3-10

DIFFERENTIAL MEASUREMENT AND

INSTALLATION........................3-25

DIFFERENTIAL OVERHAUL..............3-46

DIFFERENTIAL REMOVAL; FRONT

SUSPENSION AND AXLE................2-34

DIFFERENTIAL REMOVAL; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL SERVICE................3-34

DIFFERENTIAL SHIM PACK

MEASUREMENT AND ADJUSTMENT.......2-43

DIFFERENTIAL, TRAC-LOK..............3-45

DIMENSION DATA, VEHICLE.....Intro.-5,Intro.-6

DIMENSIONS, AW-4 VALVE BODY CHECK

BALL.............................21-341

DIMENSIONS, DESIGNATIONS,

LABELS/PLATES, CODES..............Intro.-1

DIMENSIONS, FRAME.............13-13,13-1

DIMMER SWITCH REMOVE/INSTALL,

HEADLAMP OR PANEL................8E-42

DIMMER SWITCH REPLACEMENTÐYJ,

HEADLAMP.........................8L-26

DIMMING MODULE; FRONT LIGHTING

(XJ-RHD).........................8W-50-1

DIODE REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-8

DIRECT CLUTCH OVERHAUL...........21-228

DISASSEMBLY AND INSPECTION, VALVE

BODY.............................21-147

DISASSEMBLY AND OVERHAUL,

TRANSFER CASE..............21-289,21-310

DISASSEMBLY AND OVERHAUL,

TRANSMISSION.................21-37,21-5

DISASSEMBLY, CALIPER................5-48

DISASSEMBLY, DIFFERENTIAL; FRONT

SUSPENSION AND AXLE................2-35

DISASSEMBLY, DIFFERENTIAL; REAR

SUSPENSION AND AXLES...............3-18

DISASSEMBLY, TRANSMISSION . . 21-119,21-201

DISASSEMBLYÐCOLUMN OR CONSOLE

SHIFT..............................19-60

DISC AND PLATE THICKNESS, AW-4

CLUTCH...........................21-338

DISC BRAKE ROTOR REFINISHING

........5-53

DISC BRAKE ROTOR RUNOUT

...........5-52

DISC BRAKE ROTOR THICKNESS

.........5-52

DISC BRAKES

........................5-45

DISC BRAKESHOE INSTALLATION

.........5-47DISC BRAKESHOE REMOVAL............5-46

DISC INSTALLATION, CLUTCH COVER.....6-10

DISC REMOVAL, CLUTCH COVER.........6-10

DISC RUNOUT, CLUTCH COVER...........6-3

DISCHARGE (ESD) SENSITIVE DEVICES,

ELECTROSTATIC; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

DISCONNECT AXLEÐYJ VEHICLES,

VACUUM............................2-27

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS..........................2-29

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS (CONT'D)..................2-30

DISPLAY, ABS WARNING LIGHT...........5-3

DISPLAY SYMBOLS, INTERNATIONAL

VEHICLE CONTROL..................Intro.-5

DISPLAY SYMBOLS, VEHICLE CONTROL . Intro.-10

DISPOSALÐXJ, LIFTGATE SUPPORT

ROD CYLINDER......................23-63

DISTRIBUTOR.......................8D-19

DISTRIBUTOR CAP....................8D-7

DISTRIBUTOR CAP AND ROTOR,

IGNITION CABLES.....................0-20

DISTRIBUTOR ROTOR.................8D-8

DISTRIBUTORS.......................8D-4

DOME LAMP, CARGO LAMP; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

DOME LAMP, CARGO LAMP, COURTESY

LAMPS; INTERIOR LIGHTING (XJ).....8W-44-1

DOME LAMP REPLACEMENTÐXJ.........8L-17

DOME LAMPÐXJ....................23-93

DOME LAMPS, COURTESY LAMPS;

INTERIOR LIGHTING (YJ)............8W-44-1

DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES,

HARDTOP..........................8L-31

DOME/COURTESY LAMP SERVICE

INFORMATIONÐXJ...................8L-16

DOME/COURTESY LAMP SERVICE

INFORMATIONÐYJ...................8L-31

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐXJ.....................8L-16

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐYJ.....................8L-31

DOOR ALIGNMENT ADJUSTMENTÐ

MAJOR............................23-41

DOOR ALIGNMENT ADJUSTMENTÐ

MINOR.............................23-37

DOOR ASSIST HANDLEÐYJ, FULL-

METAL............................23-136

DOOR BUMPERSÐXJ, FUEL FILLER.....23-27

DOOR CONTROL CABLES, VENT.........24-32

DOOR EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ.........................23-54

DOOR EXTERNAL HANDLEÐXJ.........23-48

DOOR FRAME GLASS CHANNEL

REPLACEMENTÐYJ.................23-142

DOOR HINGE/HINGE PIN

REPLACEMENTÐXJ..................23-52

DOOR HINGESÐYJ, FULL-METAL.......23-140

DOOR INSIDE LATCH RELEASE AND

LOCK RODSÐXJ.....................23-50

DOOR JAMB SWITCH, DRIVER'S.....8U-1,8U-2

DOOR KEY LOCK CYLINDERÐXJ........23-47

DOOR KEY LOCK CYLINDERÐYJ,

FULL-METAL.......................23-139

DOOR LATCH ADJUSTMENTÐXJ........23-48

DOOR LATCH EXTERNAL RELEASE

HANDLEÐYJ, FULL-METAL............23-140

DOOR LATCH INSIDE RELEASE AND

LOCK HANDLEÐYJ, FULL-METAL.......23-137

DOOR LATCH STRIKERÐYJ, HALF-

METAL............................23-135

DOOR LATCHÐXJ....................23-49

DOOR LATCHÐYJ, FULL-METAL........23-140

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ).......................8W-61-1

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ-RHD)

..................8W-61-1

DOOR MIRROR (EXTERNAL)ÐYJ, HALF

METAL

............................23-121

DOOR MOTOR SWITCH REPLACEMENT,

BLOWER MOTOR/AIR

.................24-32

DOOR OPENER STORAGE, REMOTE

GARAGE

............................8C-1

DOOR OPENING WEATHERSTRIP

SEALSÐXJ, DOOR WINDOW GLASS

.....23-55

8 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2133 of 2158

DOOR REMOVAL/INSTALLATIONÐXJ.....23-35

DOOR RESTRAINT REPLACEMENTÐXJ . . . 23-41

DOOR SERVICEÐYJ, FULL-METAL......23-142

DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES, FRONT....................23-53

DOOR STATIONARY WINDOW

GLASSÐXJ, REAR...................23-46

DOOR TRIM PANELÐXJ...............23-31

DOOR TRIM PANELÐYJ, FULL-METAL . . . 23-137

DOOR VACUUM MOTOR, FRESH AIR.....24-34

DOOR VACUUM MOTOR REPLACEMENT,

A/C RECIRCULATING..................24-27

DOOR VENT WINDOW GLASSÐYJ,

FULL-METAL.......................23-137

DOOR WATERDAMÐYJ, FULL-METAL . . . 23-137

DOOR WEATHERSTRIP SEAL

REPLACEMENTÐYJ.................23-142

DOOR WEATHERSTRIP SEALSÐYJ,

FULL-METAL.......................23-141

DOOR WINDOW EXTERIOR

MOLDINGSÐXJ.....................23-54

DOOR WINDOW GLASS AND DOOR

OPENING WEATHERSTRIP SEALSÐXJ....23-55

DOOR WINDOW GLASS REGULATOR

HANDLEÐYJ, FULL-METAL............23-136

DOOR WINDOW GLASS REGULATORÐ

XJ, FRONT..........................23-42

DOOR WINDOW GLASS REGULATORÐ

XJ, REAR...........................23-44

DOOR WINDOW GLASS REGULATORÐ

YJ, FULL-METAL....................23-138

DOOR WINDOW GLASSÐXJ, FRONT.....23-43

DOOR WINDOW GLASSÐXJ, REAR......23-45

DOOR WINDOW GLASSÐYJ, FULL-

METAL............................23-139

DOORÐYJ, HALF-METAL SOFT TOP.....23-134

DOUBLE CARDAN (CV)................16-11

DRAG LINK....................19-16,19-20

DRAINING COOLING SYSTEM............7-21

DRAW FUSE, IGNITION-OFF.............8F-1

DRAW, IGNITION-OFF.................8A-10

DRB SCAN TOOL; BRAKES...............5-3

DRB SCAN TOOL; COOLING SYSTEM.......7-5

DRB SCAN TOOL; EMISSION CONTROL

SYSTEMS...........................25-2

DRB SCAN TOOL; FUEL SYSTEM........14-54

DRB SCAN TOOL; IGNITION SYSTEMS....8D-8

DRIERÐ2.5L ENGINES, CONDENSER

FILTER.............................24-27

DRIERÐ4.0L ENGINES, FILTER.........24-28

DRIP RAIL MOLDINGÐXJ.............23-25

DRIVE (4WD) SWITCH, FOUR-WHEEL;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

DRIVE (4WD) SWITCH, FOUR-WHEEL;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

DRIVE, AUTOMATIC BELT TENSIONERÐ

XJ MODELS WITH RIGHT HAND..........7-42

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-23

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; REAR

SUSPENSION AND AXLES...........3-14,3-31

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-24

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; REAR

SUSPENSION AND AXLES

...............3-14

DRIVE AXLE, FRONT

....................2-3

DRIVE BELT, ACCESSORY

...............0-21

DRIVE BELT DIAGNOSIS (CONT.),

SERPENTINE

.........................7-40

DRIVE BELT DIAGNOSIS, SERPENTINE

.....7-39

DRIVE, BELT SERVICEÐEXCEPT RIGHT

HAND

...............................7-40

DRIVE, BELT SERVICEÐXJ MODELS

WITH RIGHT HAND

....................7-42

DRIVE BELT TENSION

..................7-45

DRIVE BELTS, ENGINE ACCESSORY

.......7-38

DRIVE GEAR, SPEED SENSOR

ROTORÐSPEEDOMETER

.............21-193

DRIVE, GENERATOR REMOVE/INSTALLÐ

LEFT-HAND

..........................8B-6

DRIVE, GENERATOR REMOVE/INSTALLÐ

RIGHT-HAND

.........................8B-7

DRIVE PULLEY REPLACEMENT

..........19-13DRIVE (RHD), BELT TENSIONÐEXCEPT

RIGHT HAND.........................7-38

DRIVE (RHD), BELT TENSIONÐRIGHT

HAND...............................7-38

DRIVE (RHD) MODELS, BELT TENSIONÐ

EXCEPT RIGHT HAND..................7-45

DRIVE SHAFTS.......................0-26

DRIVE VEHICLES, RIGHT HAND..........23-1

DRIVE, VISCOUS FAN..................7-34

DRIVELINE SNAP; FRONT SUSPENSION

AND AXLE...........................2-19

DRIVELINE SNAP; REAR SUSPENSION

AND AXLES..........................3-10

DRIVELINE VIBRATION.................16-3

DRIVER'S DOOR JAMB SWITCH.....8U-1,8U-2

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (LHD).........................8P-3

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (RHD).........................8P-4

DRIVER'S POWER LOCK SWITCHÐ4-

DOOR..............................8P-5

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (LHD).......................8S-4

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (RHD).......................8S-5

DRIVER'S POWER WINDOW SWITCHÐ

4-DOOR.............................8S-3

DRIVER'S SEAT BELT SWITCH.......8U-1,8U-3

DRIVETRAIN.........................0-22

DRL MODULE REPLACEMENTÐXJ.......8L-15

DRL MODULE REPLACEMENTÐYJ........8L-30

DRUM BRAKE ADJUSTMENT............5-57

DRUM BRAKES.......................5-55

DRUM BRAKESHOE INSTALLATION.......5-55

DRUM BRAKESHOE REMOVAL...........5-55

DRUM REFINISHING, BRAKE............5-58

DRUMÐREAR SUPPORT OVERHAUL,

OVERRUNNING CLUTCHÐLOW-

REVERSE..........................21-125

DUCT, DEFROSTER NOZZLE............24-33

DUCT, FRESH AIR INTAKE..............24-34

ECU AND HCU DIAGNOSIS, ANTILOCK......5-3

ECU INSTALLATION (XJ MODELS)........5-40

ECU OPERATION......................5-37

ECU REMOVAL (XJ MODELS)............5-40

ECU REMOVAL/INSTALLATION (YJ

MODELS)............................5-41

EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ, DOOR....................23-54

EFFECTS OF INCORRECT FLUID LEVEL....21-71

EFFORT, HARD PEDAL OR HIGH PEDAL.....5-6

ELECTRIC COOLING FANÐXJ MODELS

WITH 4.0L 6-CYLINDER ENGINE,

AUXILIARY..........................7-35

ELECTRICAL CONTROL, FUEL PUMP......14-5

ELECTRONIC CONTROL UNIT (ECU).......5-34

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

ELEMENT, AIR CLEANER; EMISSION

CONTROL SYSTEMS...................25-7

ELEMENT, AIR CLEANER; FUEL SYSTEM . . 14-59

ELEMENT, AIR CLEANER; LUBRICATION

AND MAINTENANCE...................0-18

ELEMENT TEST, OXYGEN SENSOR (O2S)

HEATING...........................14-48

ELEMENTS, HEATER; POWER MIRRORS

(XJ-RHD).........................8W-62-1

EMISSION CONTROL INFORMATION

(VECI) LABEL, VEHICLE.................25-1

EMISSION CONTROL SYSTEM...........0-20

EMISSION CONTROL SYSTEM

MAINTENANCE........................0-4

EMISSION CONTROLS..................25-4

EMR LAMPÐPCM OUTPUT............14-27

ENGINE ACCESSORY DRIVE BELTS.......7-38

ENGINE AND TRANSMISSION/TRANSFER

CASE IDENTIFICATION...............Intro.-5

ENGINE ASSEMBLY (SHORT BLOCK),

SERVICE.............................9-4

ENGINE ASSEMBLYÐXJ VEHICLES

. . . 9-18,9-59

ENGINE ASSEMBLYÐYJ VEHICLES

. . . 9-20,9-62

ENGINE, AUXILIARY ELECTRIC COOLING

FANÐXJ MODELS WITH 4.0L

6-CYLINDER

.........................7-35

ENGINE BLOCK HEATER

................7-44

ENGINE BREAK-IN

.....................0-15ENGINE COOLANT TEMPERATURE

GAUGE; INSTRUMENT CLUSTER (XJ) . . 8W-40-1

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL SYSTEM...............14-60

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (YJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; IGNITION SYSTEMS......8D-19,8D-5

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ-RHD)....8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR TEST; FUEL SYSTEM..........14-46

ENGINE COOLANT TEMPERATURE

SENSOR TEST; IGNITION SYSTEMS.......8D-9

ENGINE COOLANT TEMPERATURE

SENSORÐPCM INPUT................14-23

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

ENGINE COOLING SYSTEM..............0-18

ENGINE CYLINDER HEAD...........9-25,9-67

ENGINE CYLINDER HEAD COVER.....9-22,9-64

ENGINE CYLINDER HEAD GASKET

FAILURE DIAGNOSIS....................9-5

ENGINE DAMPER.....................9-17

ENGINE DIAGNOSIS....................9-5

ENGINE, DIAGRAM INDEXÐ2.5L;

FUEL/IGNITION (XJ)..................8W-30-6

ENGINE, DIAGRAM INDEXÐ4.0L;

FUEL/IGNITION (XJ)................8W-30-6

ENGINE, ENGINE EXHAUST MANIFOLDÐ

2.5L................................11-7

ENGINE, ENGINE EXHAUST MANIFOLDÐ

4.0L................................11-7

ENGINE, ENGINE FIRING ORDERÐ2.5L

4-CYLINDER........................8D-32

ENGINE, ENGINE FIRING ORDERÐ4.0L

6-CYLINDER........................8D-32

ENGINE EXHAUST MANIFOLDÐ2.5L

ENGINE.............................11-7

ENGINE EXHAUST MANIFOLDÐ4.0L

ENGINE.............................11-7

ENGINE FIRING ORDERÐ2.5L

4-CYLINDER ENGINE.................8D-32

ENGINE FIRING ORDERÐ4.0L

6-CYLINDER ENGINE.................8D-32

ENGINE, INTAKE MANIFOLDÐ2.5L........11-7

ENGINE, INTAKE MANIFOLDÐ4.0L........11-8

ENGINE MAINTENANCE.................0-15

ENGINE MOUNTÐREAR............9-16,9-57

ENGINE MOUNTSÐFRONT..........9-14,9-56

ENGINE OIL..........................0-15

ENGINE OIL CHANGE AND FILTER

REPLACEMENT.......................0-16

ENGINE OIL FILTER....................0-17

ENGINE OIL PRESSURE.................9-7

ENGINE ONLY, POWER STEERING

PRESSURE SWITCHÐ2.5L.............14-63

ENGINE ONLY, TORQUE CONVERTER

CLUTCH (TCC) SOLENOID AND

RELAYÐ2.5L; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

ENGINE ONLY, TRANSMISSION

CONTROL MODULEÐ4.0L;

TRANSMISSION CONTROLS (XJ)......8W-31-1

ENGINE PERFORMANCE.................9-2

ENGINE SERVICE PROCEDURES, 2.5L.....9-13

ENGINE SERVICE PROCEDURES, 4.0L.....9-55

ENGINE SPECIFICATIONS...........9-52,9-93

ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4 CYLINDER..........25-3

ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6 CYLINDER..........25-3

ENGINES, CONDENSER FILTER

DRIERÐ2.5L........................24-27

ENGINES, CONDENSERÐ4.0L..........24-28

ENGINES, FILTER DRIERÐ4.0L

.........24-28

ENGINES, FUEL USAGE STATEMENTÐ

GAS

................................0-19

ENGLISH/SAE CONVERSION, METRIC

. . Intro.-11

ENTRY MODULE, KEYLESS

.........8P-1,8P-7

ENTRY MODULE, REMOTE KEYLESS;

POWER DOOR LOCKS (XJ)

...........8W-61-1

JINDEX 9

Description Group-Page Description Group-Page Description Group-Page