JEEP YJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 121 of 2158

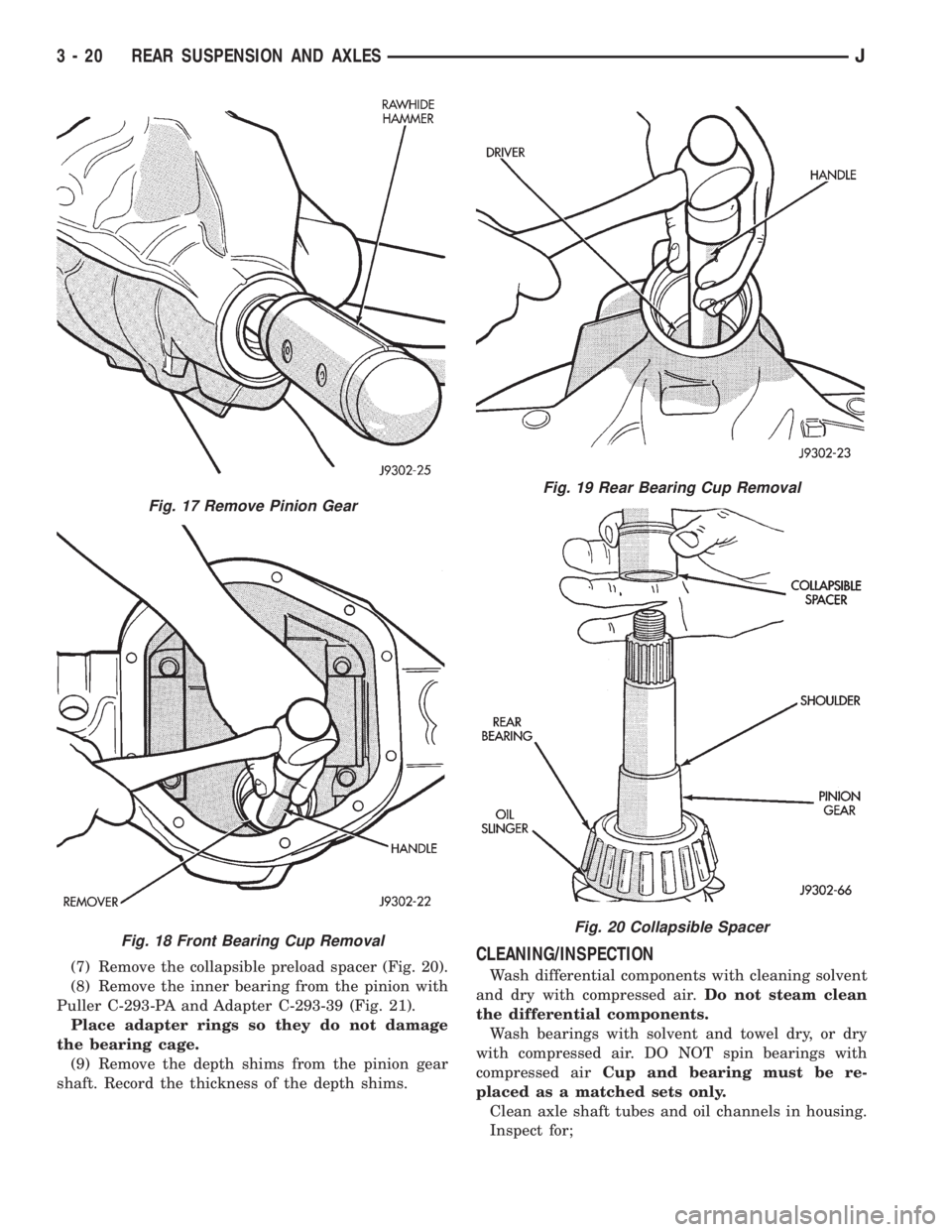

(7) Remove the collapsible preload spacer (Fig. 20).

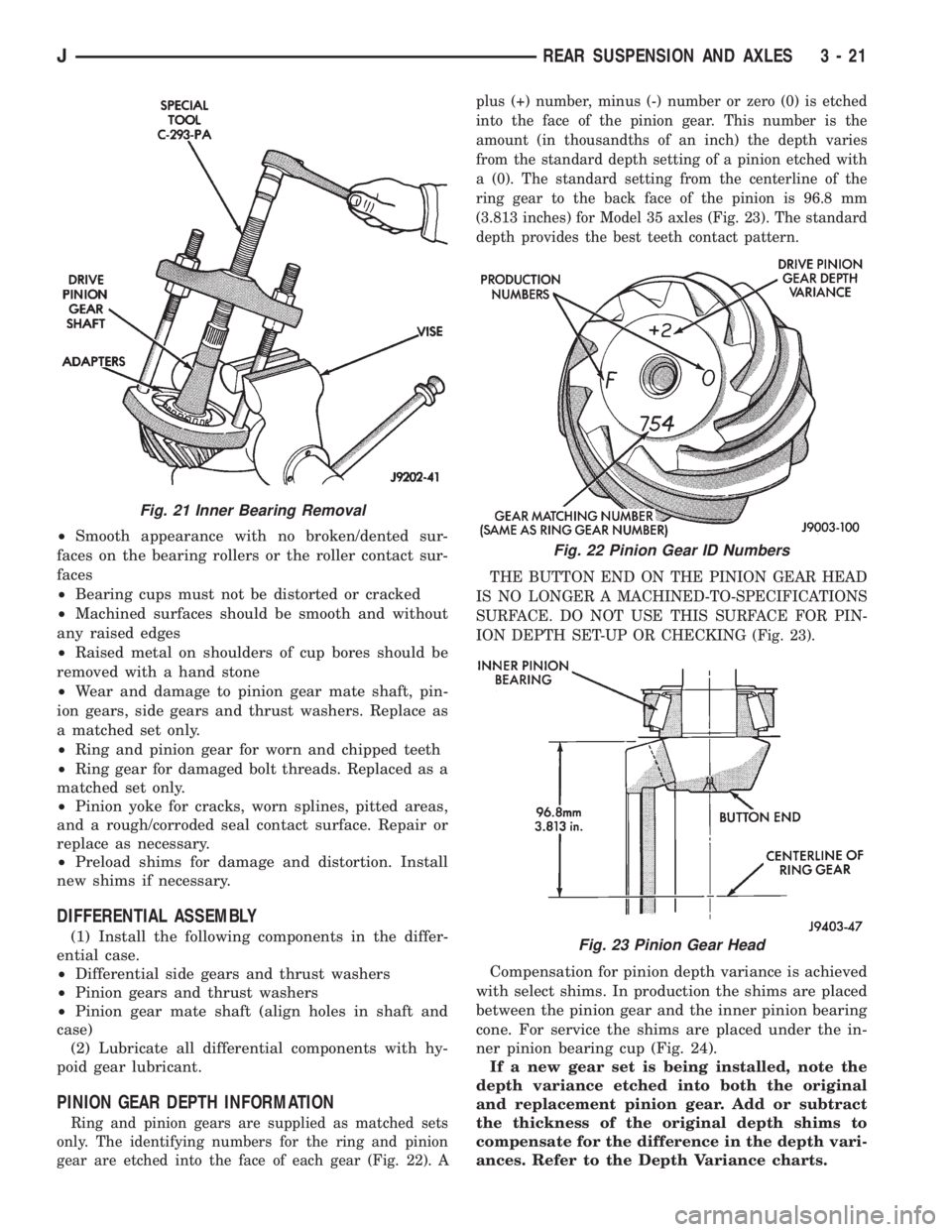

(8) Remove the inner bearing from the pinion with

Puller C-293-PA and Adapter C-293-39 (Fig. 21).

Place adapter rings so they do not damage

the bearing cage.

(9) Remove the depth shims from the pinion gear

shaft. Record the thickness of the depth shims.CLEANING/INSPECTION

Wash differential components with cleaning solvent

and dry with compressed air.Do not steam clean

the differential components.

Wash bearings with solvent and towel dry, or dry

with compressed air. DO NOT spin bearings with

compressed airCup and bearing must be re-

placed as a matched sets only.

Clean axle shaft tubes and oil channels in housing.

Inspect for;

Fig. 17 Remove Pinion Gear

Fig. 18 Front Bearing Cup Removal

Fig. 19 Rear Bearing Cup Removal

Fig. 20 Collapsible Spacer

3 - 20 REAR SUSPENSION AND AXLESJ

Page 122 of 2158

²Smooth appearance with no broken/dented sur-

faces on the bearing rollers or the roller contact sur-

faces

²Bearing cups must not be distorted or cracked

²Machined surfaces should be smooth and without

any raised edges

²Raised metal on shoulders of cup bores should be

removed with a hand stone

²Wear and damage to pinion gear mate shaft, pin-

ion gears, side gears and thrust washers. Replace as

a matched set only.

²Ring and pinion gear for worn and chipped teeth

²Ring gear for damaged bolt threads. Replaced as a

matched set only.

²Pinion yoke for cracks, worn splines, pitted areas,

and a rough/corroded seal contact surface. Repair or

replace as necessary.

²Preload shims for damage and distortion. Install

new shims if necessary.

DIFFERENTIAL ASSEMBLY

(1) Install the following components in the differ-

ential case.

²Differential side gears and thrust washers

²Pinion gears and thrust washers

²Pinion gear mate shaft (align holes in shaft and

case)

(2) Lubricate all differential components with hy-

poid gear lubricant.

PINION GEAR DEPTH INFORMATION

Ring and pinion gears are supplied as matched sets

only. The identifying numbers for the ring and pinion

gear are etched into the face of each gear (Fig. 22). Aplus (+) number, minus (-) number or zero (0) is etched

into the face of the pinion gear. This number is the

amount (in thousandths of an inch) the depth varies

from the standard depth setting of a pinion etched with

a (0). The standard setting from the centerline of the

ring gear to the back face of the pinion is 96.8 mm

(3.813 inches) for Model 35 axles (Fig. 23). The standard

depth provides the best teeth contact pattern.

THE BUTTON END ON THE PINION GEAR HEAD

IS NO LONGER A MACHINED-TO-SPECIFICATIONS

SURFACE. DO NOT USE THIS SURFACE FOR PIN-

ION DEPTH SET-UP OR CHECKING (Fig. 23).

Compensation for pinion depth variance is achieved

with select shims. In production the shims are placed

between the pinion gear and the inner pinion bearing

cone. For service the shims are placed under the in-

ner pinion bearing cup (Fig. 24).

If a new gear set is being installed, note the

depth variance etched into both the original

and replacement pinion gear. Add or subtract

the thickness of the original depth shims to

compensate for the difference in the depth vari-

ances. Refer to the Depth Variance charts.

Fig. 21 Inner Bearing Removal

Fig. 22 Pinion Gear ID Numbers

Fig. 23 Pinion Gear Head

JREAR SUSPENSION AND AXLES 3 - 21

Page 123 of 2158

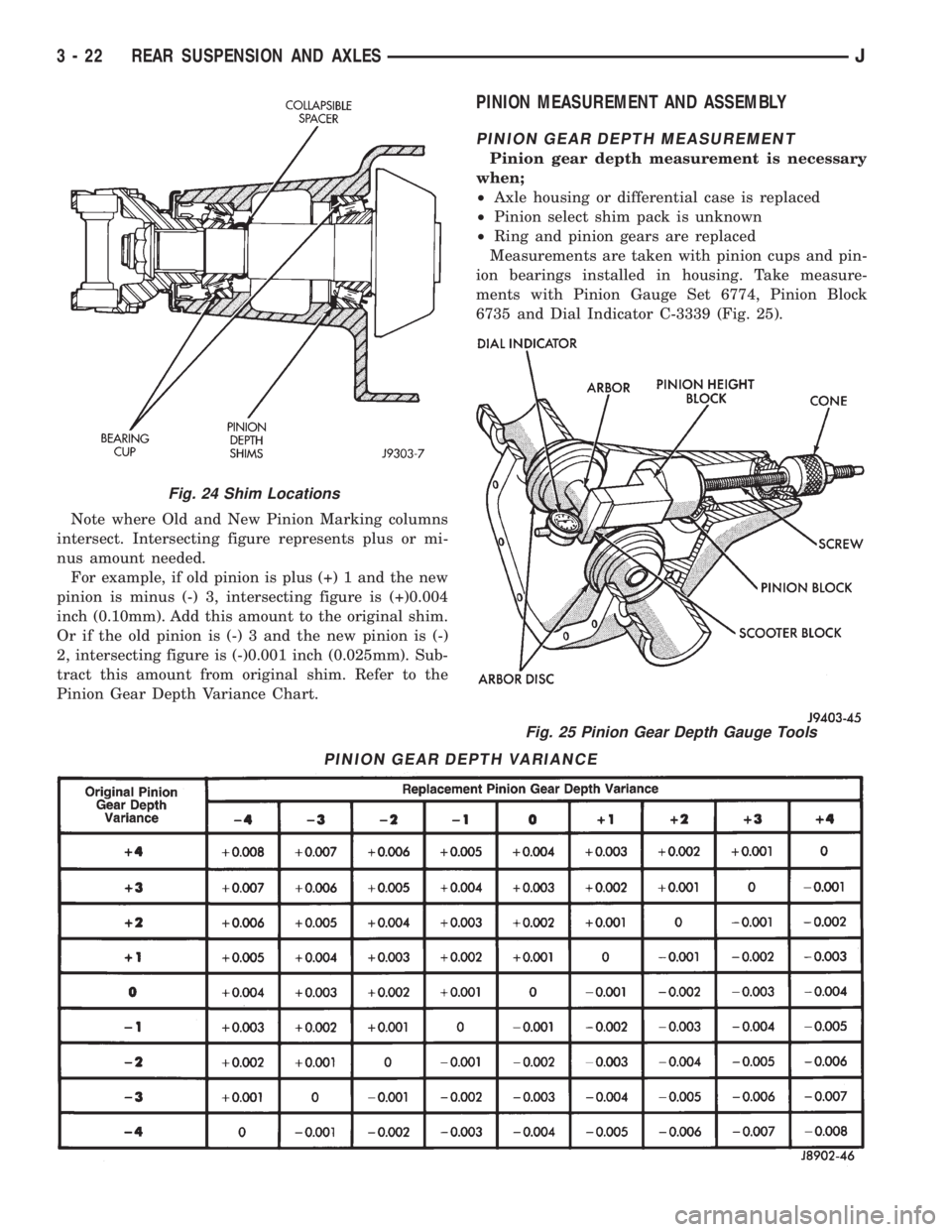

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or mi-

nus amount needed.

For example, if old pinion is plus (+) 1 and the new

pinion is minus (-) 3, intersecting figure is (+)0.004

inch (0.10mm). Add this amount to the original shim.

Or if the old pinion is (-) 3 and the new pinion is (-)

2, intersecting figure is (-)0.001 inch (0.025mm). Sub-

tract this amount from original shim. Refer to the

Pinion Gear Depth Variance Chart.

PINION MEASUREMENT AND ASSEMBLY

PINION GEAR DEPTH MEASUREMENT

Pinion gear depth measurement is necessary

when;

²Axle housing or differential case is replaced

²Pinion select shim pack is unknown

²Ring and pinion gears are replaced

Measurements are taken with pinion cups and pin-

ion bearings installed in housing. Take measure-

ments with Pinion Gauge Set 6774, Pinion Block

6735 and Dial Indicator C-3339 (Fig. 25).

Fig. 24 Shim Locations

PINION GEAR DEPTH VARIANCE

Fig. 25 Pinion Gear Depth Gauge Tools

3 - 22 REAR SUSPENSION AND AXLESJ

Page 124 of 2158

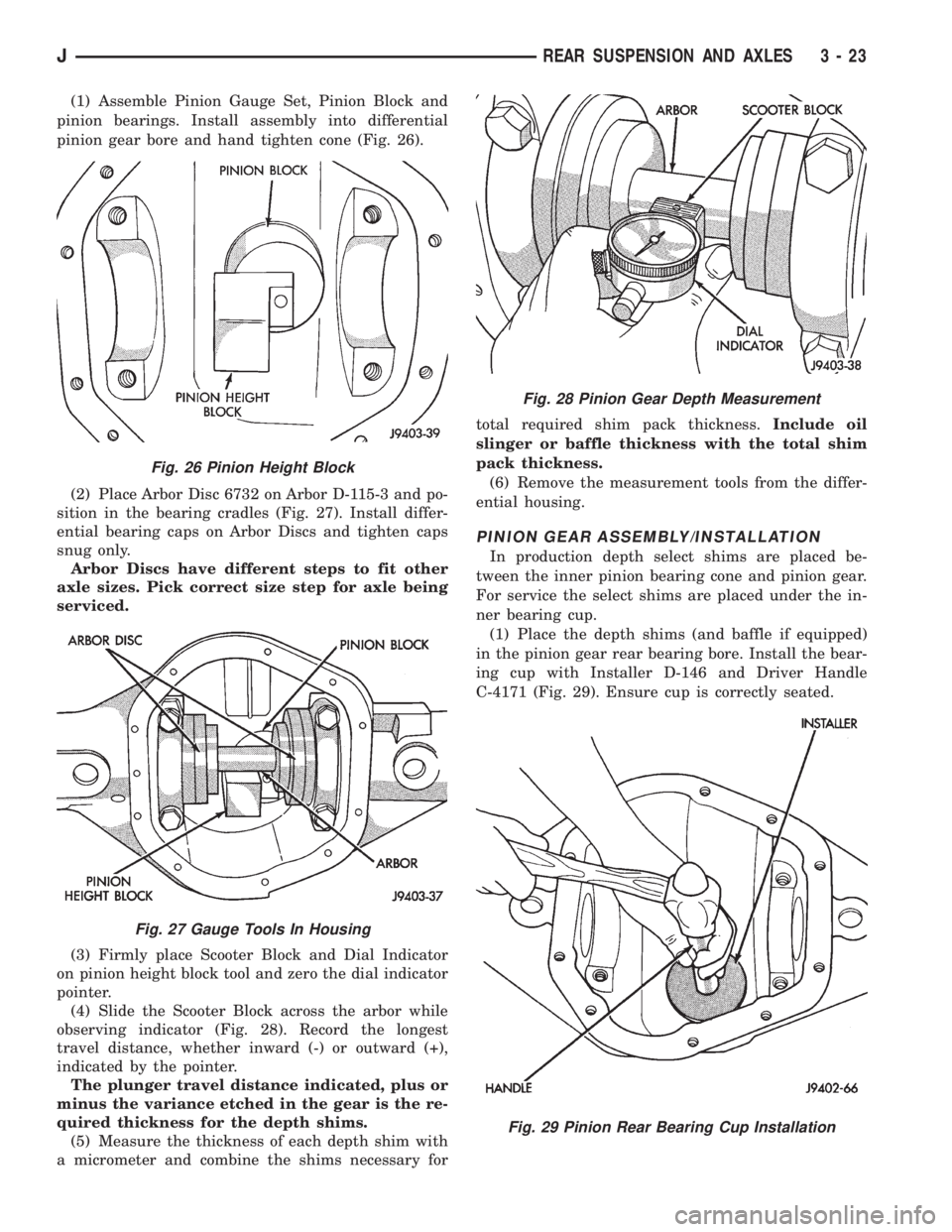

(1) Assemble Pinion Gauge Set, Pinion Block and

pinion bearings. Install assembly into differential

pinion gear bore and hand tighten cone (Fig. 26).

(2) Place Arbor Disc 6732 on Arbor D-115-3 and po-

sition in the bearing cradles (Fig. 27). Install differ-

ential bearing caps on Arbor Discs and tighten caps

snug only.

Arbor Discs have different steps to fit other

axle sizes. Pick correct size step for axle being

serviced.

(3) Firmly place Scooter Block and Dial Indicator

on pinion height block tool and zero the dial indicator

pointer.

(4) Slide the Scooter Block across the arbor while

observing indicator (Fig. 28). Record the longest

travel distance, whether inward (-) or outward (+),

indicated by the pointer.

The plunger travel distance indicated, plus or

minus the variance etched in the gear is the re-

quired thickness for the depth shims.

(5) Measure the thickness of each depth shim with

a micrometer and combine the shims necessary fortotal required shim pack thickness.Include oil

slinger or baffle thickness with the total shim

pack thickness.

(6) Remove the measurement tools from the differ-

ential housing.

PINION GEAR ASSEMBLY/INSTALLATION

In production depth select shims are placed be-

tween the inner pinion bearing cone and pinion gear.

For service the select shims are placed under the in-

ner bearing cup.

(1) Place the depth shims (and baffle if equipped)

in the pinion gear rear bearing bore. Install the bear-

ing cup with Installer D-146 and Driver Handle

C-4171 (Fig. 29). Ensure cup is correctly seated.

Fig. 26 Pinion Height Block

Fig. 27 Gauge Tools In Housing

Fig. 28 Pinion Gear Depth Measurement

Fig. 29 Pinion Rear Bearing Cup Installation

JREAR SUSPENSION AND AXLES 3 - 23

Page 125 of 2158

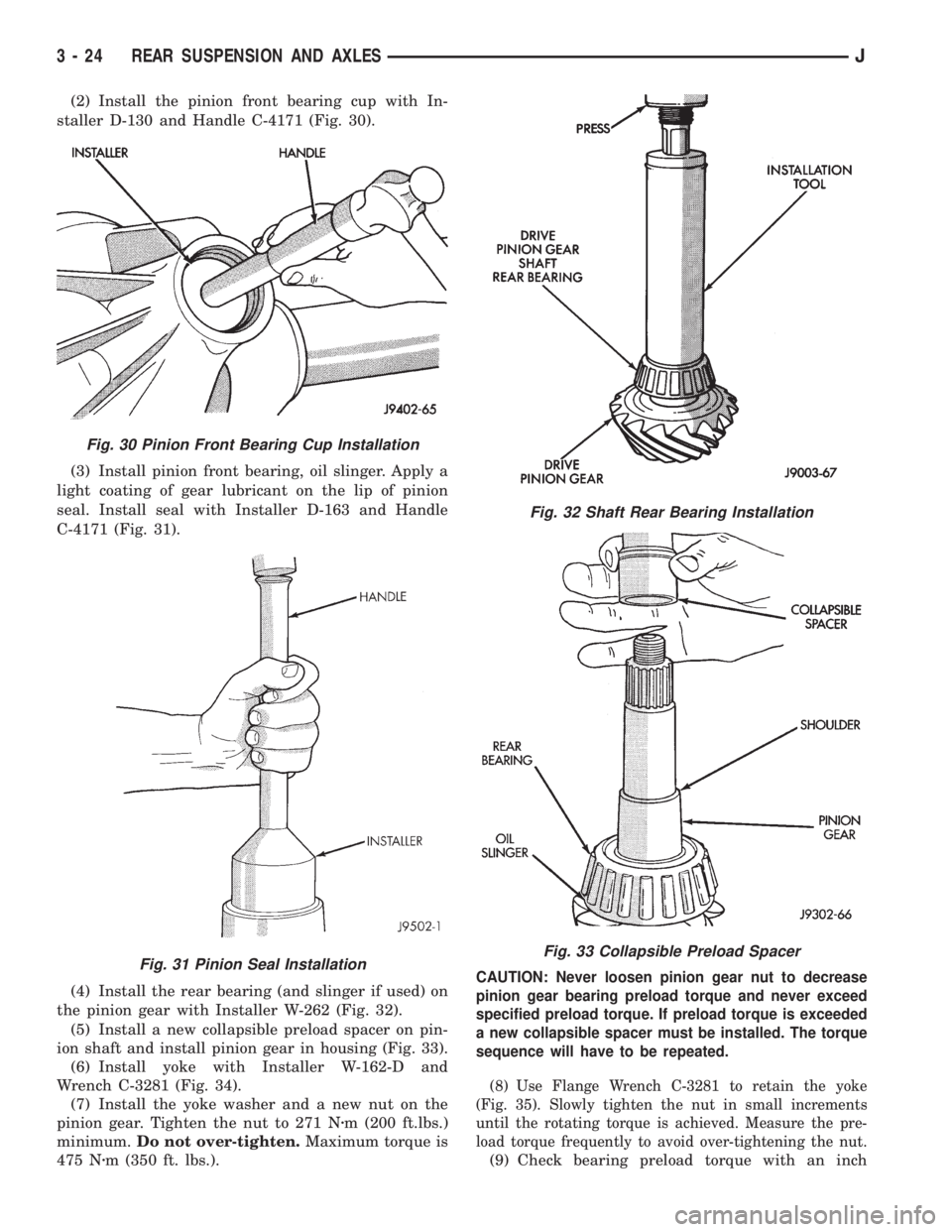

(2) Install the pinion front bearing cup with In-

staller D-130 and Handle C-4171 (Fig. 30).

(3) Install pinion front bearing, oil slinger. Apply a

light coating of gear lubricant on the lip of pinion

seal. Install seal with Installer D-163 and Handle

C-4171 (Fig. 31).

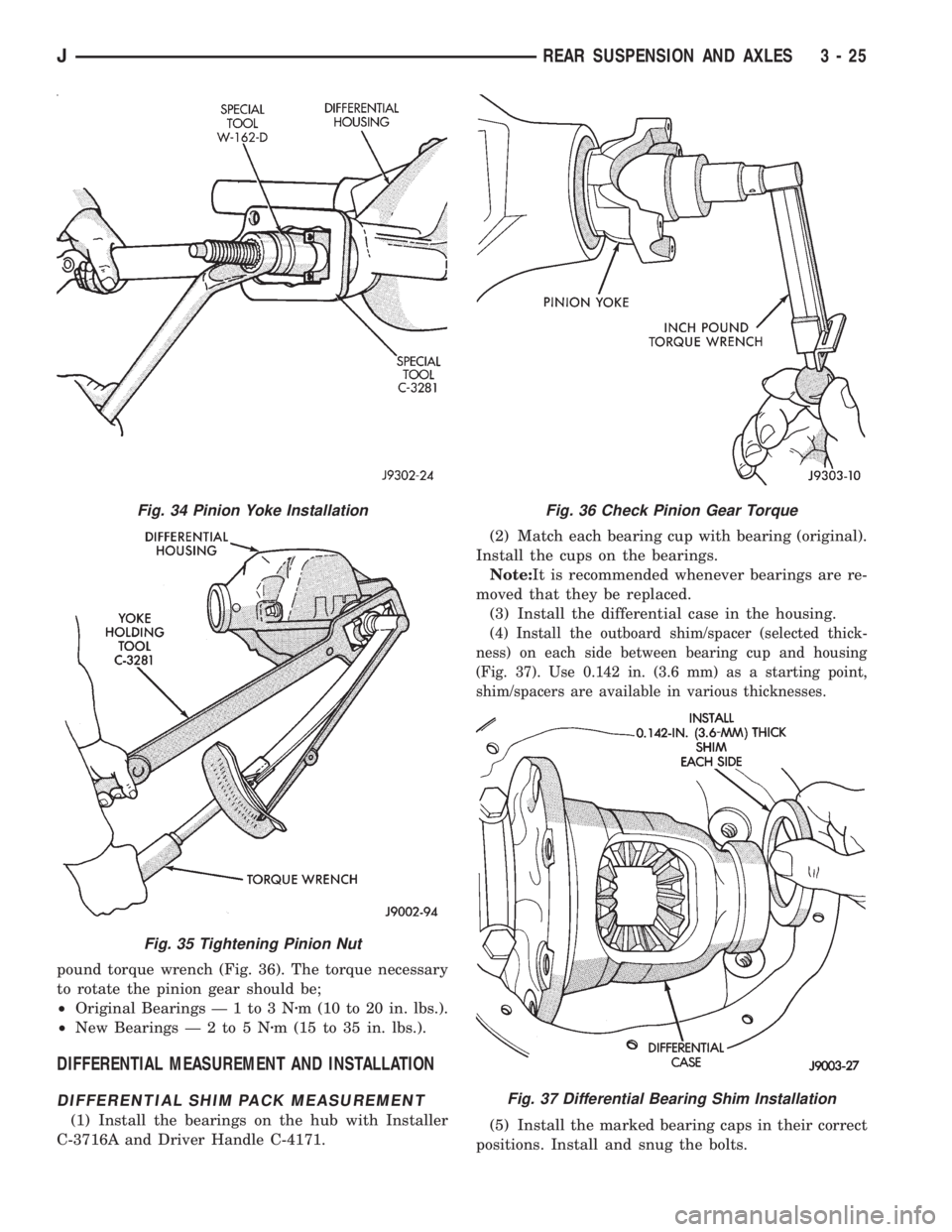

(4) Install the rear bearing (and slinger if used) on

the pinion gear with Installer W-262 (Fig. 32).

(5) Install a new collapsible preload spacer on pin-

ion shaft and install pinion gear in housing (Fig. 33).

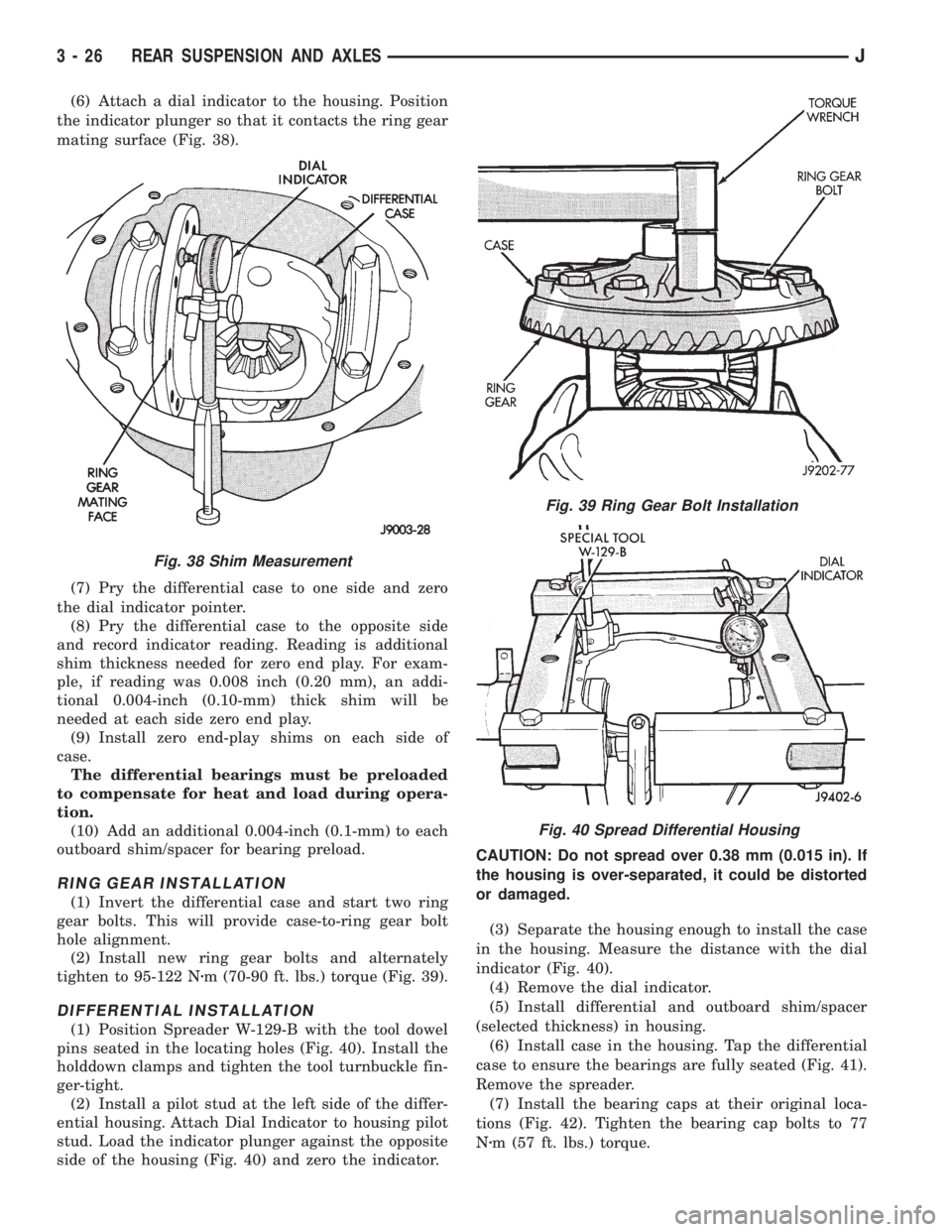

(6) Install yoke with Installer W-162-D and

Wrench C-3281 (Fig. 34).

(7) Install the yoke washer and a new nut on the

pinion gear. Tighten the nut to 271 Nzm (200 ft.lbs.)

minimum.Do not over-tighten.Maximum torque is

475 Nzm (350 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion gear bearing preload torque and never exceed

specified preload torque. If preload torque is exceeded

a new collapsible spacer must be installed. The torque

sequence will have to be repeated.

(8) Use Flange Wrench C-3281 to retain the yoke

(Fig. 35). Slowly tighten the nut in small increments

until the rotating torque is achieved. Measure the pre-

load torque frequently to avoid over-tightening the nut.

(9) Check bearing preload torque with an inch

Fig. 30 Pinion Front Bearing Cup Installation

Fig. 31 Pinion Seal Installation

Fig. 32 Shaft Rear Bearing Installation

Fig. 33 Collapsible Preload Spacer

3 - 24 REAR SUSPENSION AND AXLESJ

Page 126 of 2158

pound torque wrench (Fig. 36). The torque necessary

to rotate the pinion gear should be;

²Original Bearings Ð 1 to 3 Nzm (10 to 20 in. lbs.).

²New BearingsÐ2to5Nzm (15 to 35 in. lbs.).

DIFFERENTIAL MEASUREMENT AND INSTALLATION

DIFFERENTIAL SHIM PACK MEASUREMENT

(1) Install the bearings on the hub with Installer

C-3716A and Driver Handle C-4171.(2) Match each bearing cup with bearing (original).

Install the cups on the bearings.

Note:It is recommended whenever bearings are re-

moved that they be replaced.

(3) Install the differential case in the housing.

(4) Install the outboard shim/spacer (selected thick-

ness) on each side between bearing cup and housing

(Fig. 37). Use 0.142 in. (3.6 mm) as a starting point,

shim/spacers are available in various thicknesses.

(5) Install the marked bearing caps in their correct

positions. Install and snug the bolts.

Fig. 34 Pinion Yoke Installation

Fig. 35 Tightening Pinion Nut

Fig. 36 Check Pinion Gear Torque

Fig. 37 Differential Bearing Shim Installation

JREAR SUSPENSION AND AXLES 3 - 25

Page 127 of 2158

(6) Attach a dial indicator to the housing. Position

the indicator plunger so that it contacts the ring gear

mating surface (Fig. 38).

(7) Pry the differential case to one side and zero

the dial indicator pointer.

(8) Pry the differential case to the opposite side

and record indicator reading. Reading is additional

shim thickness needed for zero end play. For exam-

ple, if reading was 0.008 inch (0.20 mm), an addi-

tional 0.004-inch (0.10-mm) thick shim will be

needed at each side zero end play.

(9) Install zero end-play shims on each side of

case.

The differential bearings must be preloaded

to compensate for heat and load during opera-

tion.

(10) Add an additional 0.004-inch (0.1-mm) to each

outboard shim/spacer for bearing preload.

RING GEAR INSTALLATION

(1) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(2) Install new ring gear bolts and alternately

tighten to 95-122 Nzm (70-90 ft. lbs.) torque (Fig. 39).

DIFFERENTIAL INSTALLATION

(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 40). Install the

holddown clamps and tighten the tool turnbuckle fin-

ger-tight.

(2) Install a pilot stud at the left side of the differ-

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 40) and zero the indicator.CAUTION: Do not spread over 0.38 mm (0.015 in). If

the housing is over-separated, it could be distorted

or damaged.

(3) Separate the housing enough to install the case

in the housing. Measure the distance with the dial

indicator (Fig. 40).

(4) Remove the dial indicator.

(5) Install differential and outboard shim/spacer

(selected thickness) in housing.

(6) Install case in the housing. Tap the differential

case to ensure the bearings are fully seated (Fig. 41).

Remove the spreader.

(7) Install the bearing caps at their original loca-

tions (Fig. 42). Tighten the bearing cap bolts to 77

Nzm (57 ft. lbs.) torque.

Fig. 38 Shim Measurement

Fig. 39 Ring Gear Bolt Installation

Fig. 40 Spread Differential Housing

3 - 26 REAR SUSPENSION AND AXLESJ

Page 128 of 2158

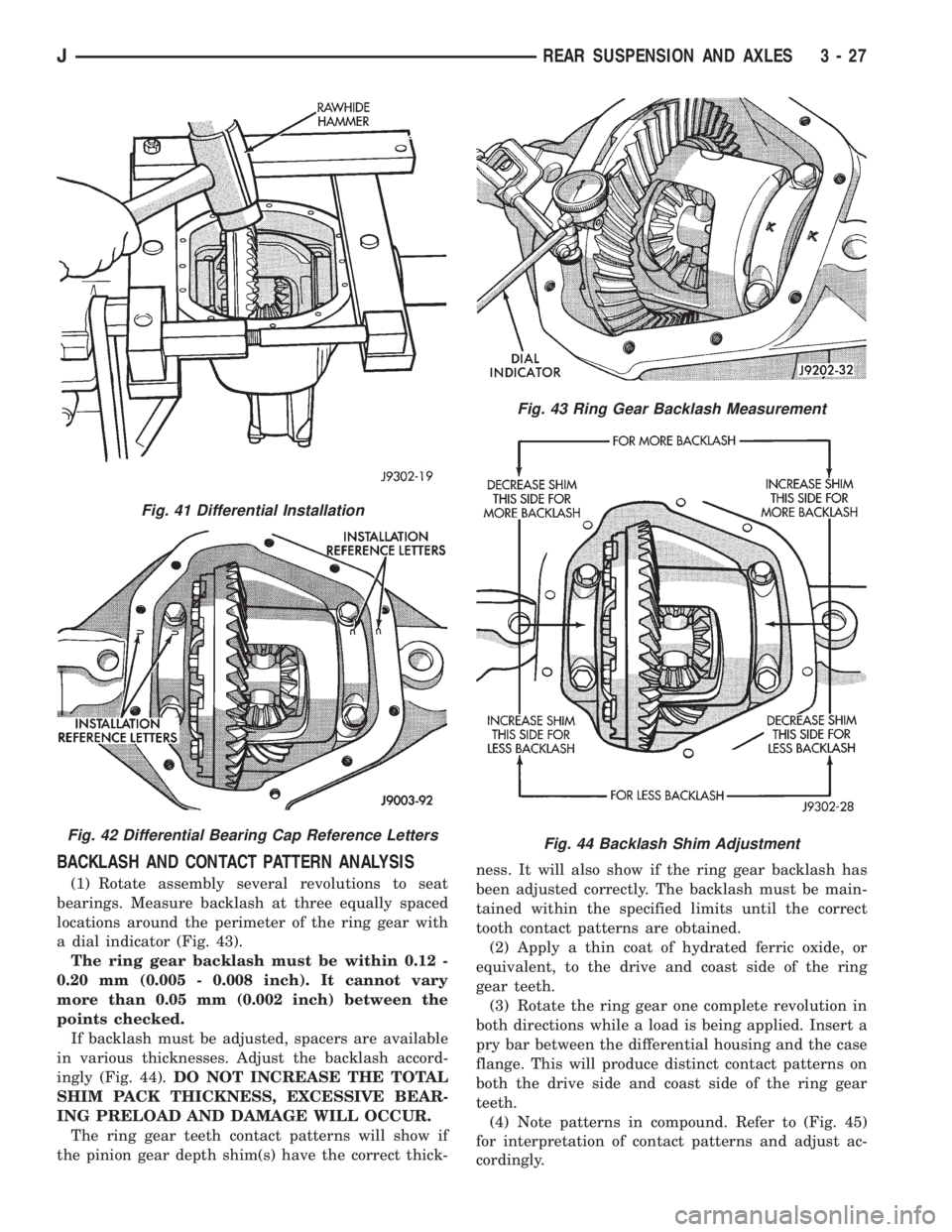

BACKLASH AND CONTACT PATTERN ANALYSIS

(1) Rotate assembly several revolutions to seat

bearings. Measure backlash at three equally spaced

locations around the perimeter of the ring gear with

a dial indicator (Fig. 43).

The ring gear backlash must be within 0.12 -

0.20 mm (0.005 - 0.008 inch). It cannot vary

more than 0.05 mm (0.002 inch) between the

points checked.

If backlash must be adjusted, spacers are available

in various thicknesses. Adjust the backlash accord-

ingly (Fig. 44).DO NOT INCREASE THE TOTAL

SHIM PACK THICKNESS, EXCESSIVE BEAR-

ING PRELOAD AND DAMAGE WILL OCCUR.

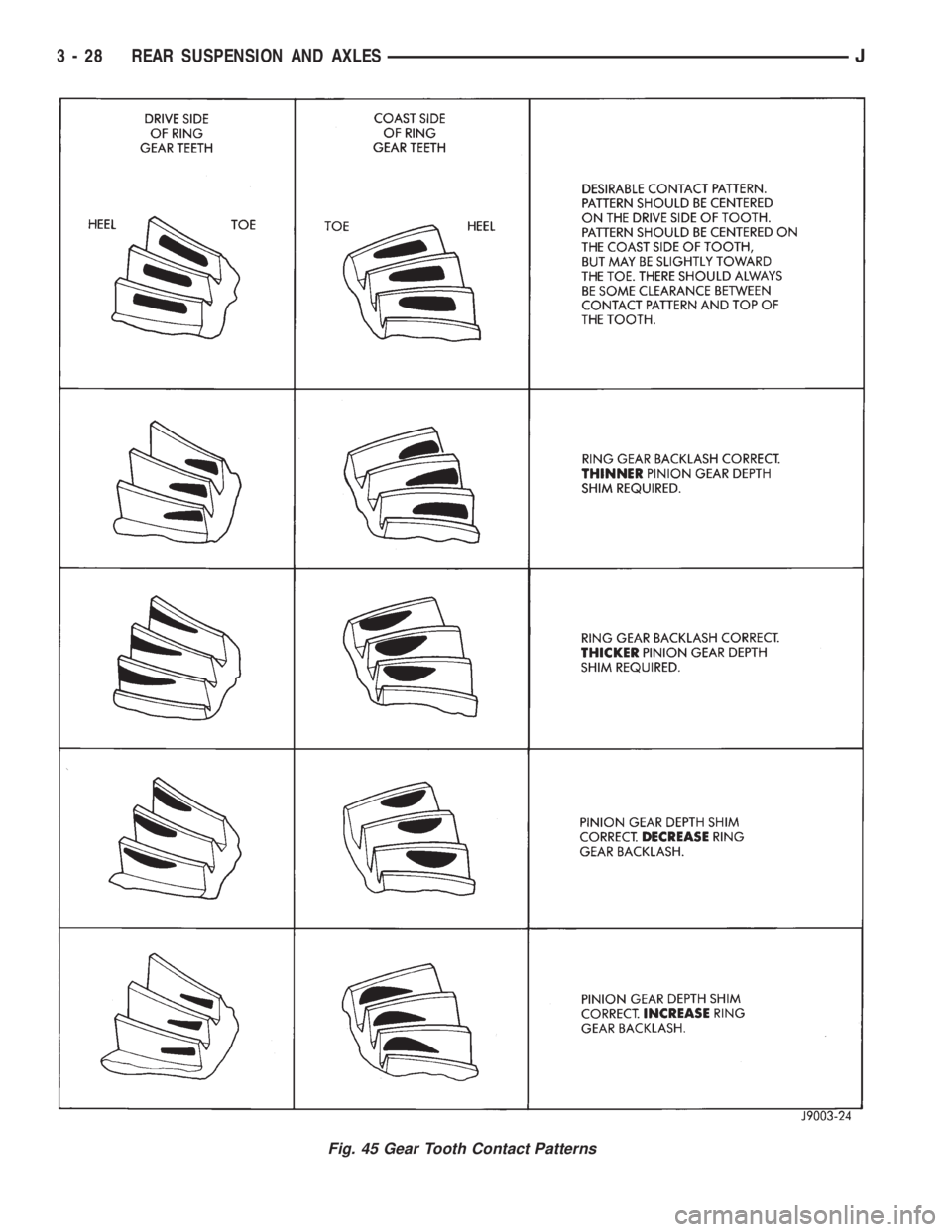

The ring gear teeth contact patterns will show if

the pinion gear depth shim(s) have the correct thick-ness. It will also show if the ring gear backlash has

been adjusted correctly. The backlash must be main-

tained within the specified limits until the correct

tooth contact patterns are obtained.

(2) Apply a thin coat of hydrated ferric oxide, or

equivalent, to the drive and coast side of the ring

gear teeth.

(3) Rotate the ring gear one complete revolution in

both directions while a load is being applied. Insert a

pry bar between the differential housing and the case

flange. This will produce distinct contact patterns on

both the drive side and coast side of the ring gear

teeth.

(4) Note patterns in compound. Refer to (Fig. 45)

for interpretation of contact patterns and adjust ac-

cordingly.

Fig. 41 Differential Installation

Fig. 42 Differential Bearing Cap Reference Letters

Fig. 43 Ring Gear Backlash Measurement

Fig. 44 Backlash Shim Adjustment

JREAR SUSPENSION AND AXLES 3 - 27

Page 129 of 2158

Fig. 45 Gear Tooth Contact Patterns

3 - 28 REAR SUSPENSION AND AXLESJ

Page 130 of 2158

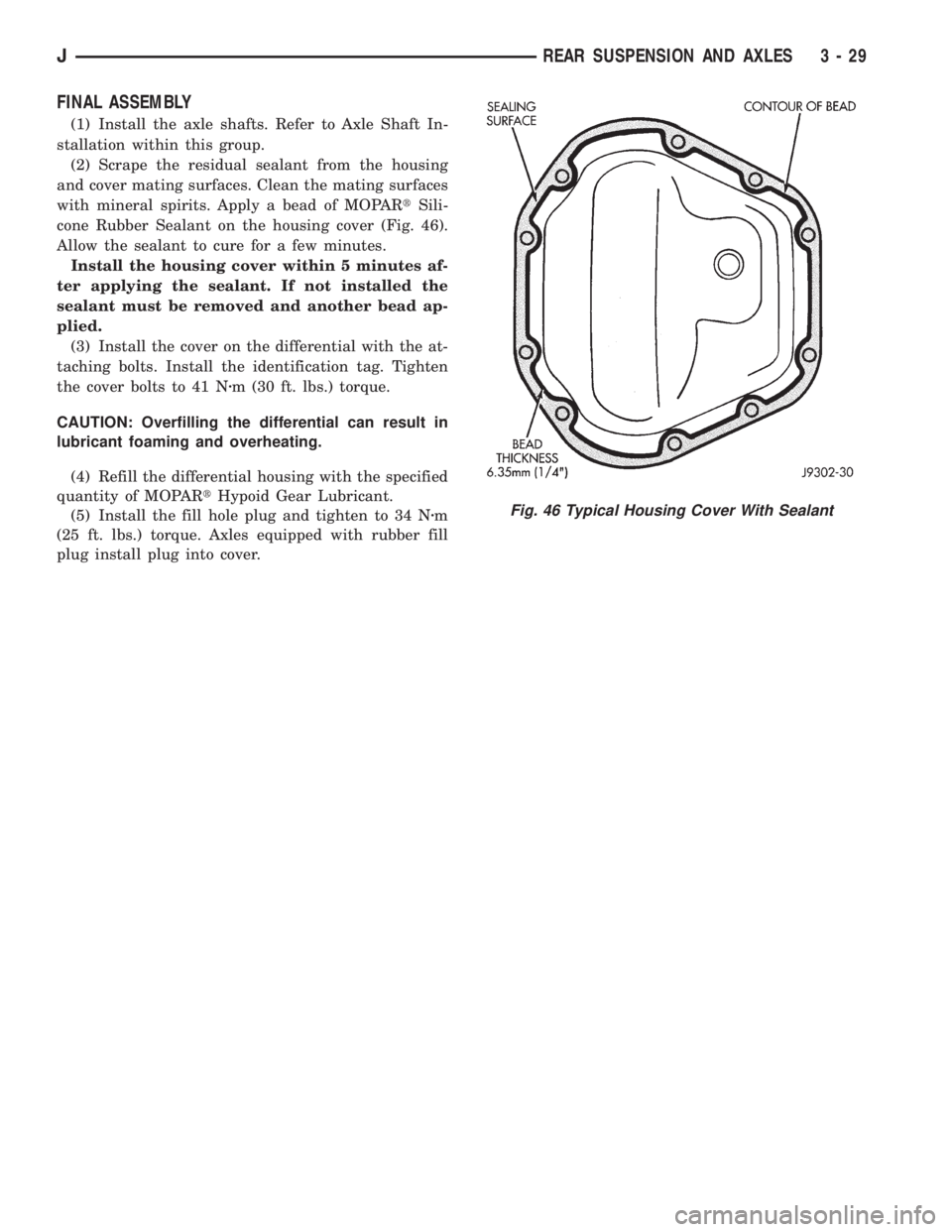

FINAL ASSEMBLY

(1) Install the axle shafts. Refer to Axle Shaft In-

stallation within this group.

(2) Scrape the residual sealant from the housing

and cover mating surfaces. Clean the mating surfaces

with mineral spirits. Apply a bead of MOPARtSili-

cone Rubber Sealant on the housing cover (Fig. 46).

Allow the sealant to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the

sealant must be removed and another bead ap-

plied.

(3) Install the cover on the differential with the at-

taching bolts. Install the identification tag. Tighten

the cover bolts to 41 Nzm (30 ft. lbs.) torque.

CAUTION: Overfilling the differential can result in

lubricant foaming and overheating.

(4) Refill the differential housing with the specified

quantity of MOPARtHypoid Gear Lubricant.

(5) Install the fill hole plug and tighten to 34 Nzm

(25 ft. lbs.) torque. Axles equipped with rubber fill

plug install plug into cover.

Fig. 46 Typical Housing Cover With Sealant

JREAR SUSPENSION AND AXLES 3 - 29